ECU DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 422 of 548

HOOD

ADJUSTMENT

Hood

can

be

adjusted

with

bolts

attaching

hood

to

hood

hinges

hood

lock

mechanism

and

hood

bumpers

Adjust

hood

for

an

even

fit

between

front

fenders

Adjust

hood

according

to

the

following

procedures

I

Adjust

hood

fore

and

aft

by

loosening

bolts

attaching

hood

to

hinge

and

repositioning

hood

2

Loosen

hood

bumper

lock

nuts

and

lower

bumpers

until

they

do

not

contact

front

of

hood

when

hood

is

closed

3

Set

striker

at

center

of

hood

lock

and

tighten

hood

lock

securing

bolts

temporarily

4

Raise

two

hood

bumpers

until

hood

is

flush

with

fenders

5

Tighten

hood

lock

securing

bolts

after

the

proper

adjustment

has

been

obtained

REMOVAL

AND

INSTALLATION

I

Open

hood

and

protect

body

with

covers

to

prevent

scratching

painted

surface

2

Mark

hood

hinge

locations

on

hood

for

proper

reinstallation

3

Holding

both

sides

of

hood

unscrew

bolts

securing

hinge

to

hood

and

remove

hood

This

operation

re

quires

two

men

4

Installation

is

in

the

reverse

order

of

removal

HOOD

LOCK

CONTROL

REMOVAL

AND

INSTALLATION

1

Disconnect

control

cable

from

hood

lock

2

Remove

hood

lock

3

Remove

control

cable

retaining

clamp

from

engine

compartment

4

Remove

hood

lock

release

handle

attaching

bolts

and

remove

hood

lock

release

handle

and

control

cable

from

dash

side

panel

5

Installation

is

in

the

reverse

order

of

removal

referring

to

Hood

Adjust

Body

@

C

ZiIfii

1

Striker

2

Hinge

3

Hood

bumper

4

Hood

lock

BF526B

Fig

BF

16

Adju

ting

Hood

1

Cable

bracket

2

Cable

clip

3

Hood

lock

4

Safety

catth

lever

5

Striker

3

II

5

1

LeS5

than

rJ

3

5

mm

O

l

BF746B

Fig

BF

17

Hood

Lock

Control

ment

6

Open

and

close

hood

several

times

to

check

operation

7

Make

sure

safety

catch

lever

re

tains

hood

properly

when

hood

lock

is

disengaged

Note

a

Lubricate

pivot

safety

catch

lever

and

return

spring

b

Inspect

safety

catch

lever

and

re

turn

spring

for

defonnation

fatigue

or

rusting

BF

ll

Page 428 of 548

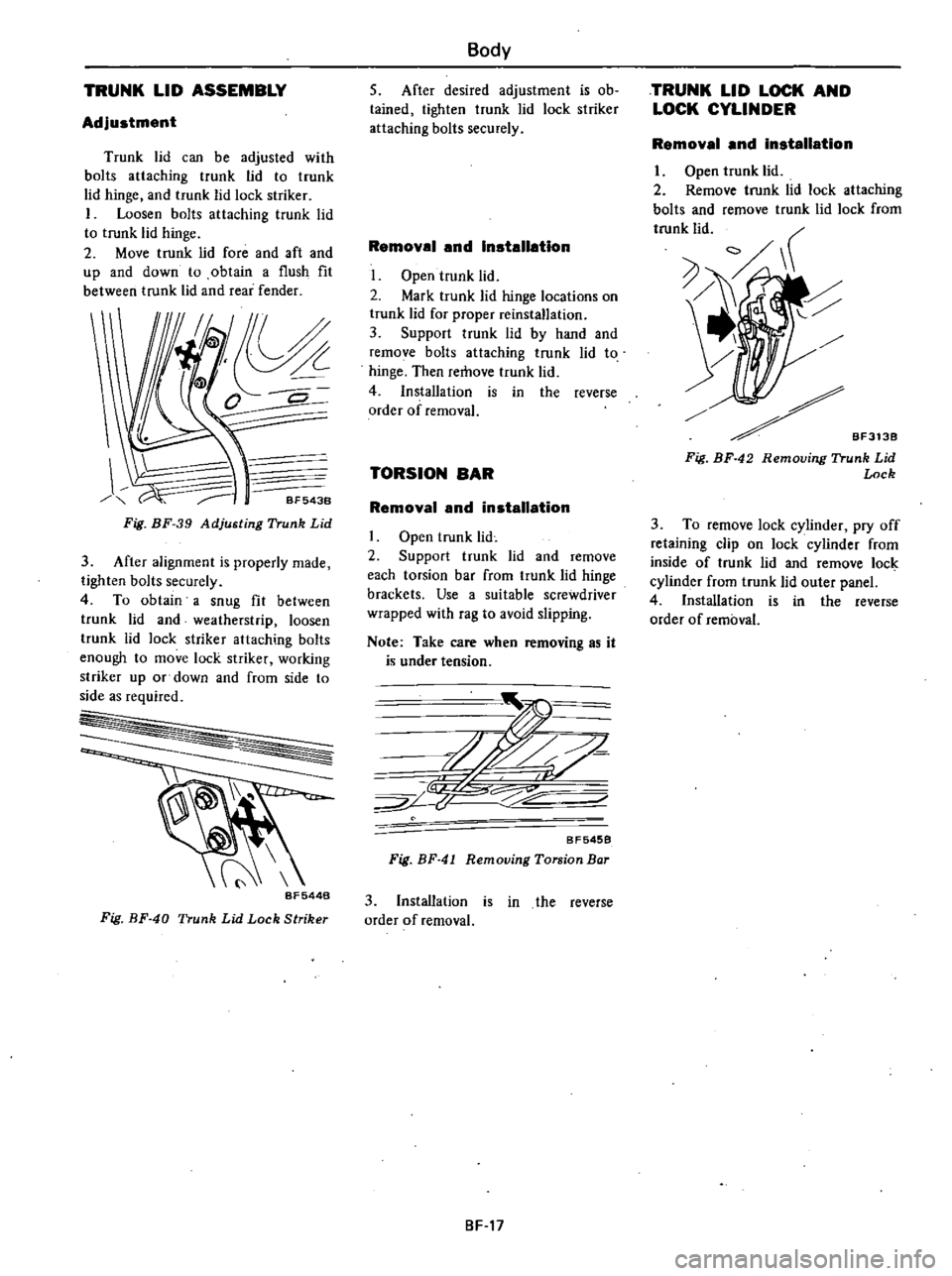

Adjustment

TRUNK

LID

ASSEMBLY

Trunk

lid

can

be

adjusted

with

bolts

attaching

trunk

lid

to

trunk

lid

hinge

and

trunk

lid

lock

striker

I

Loosen

bolts

attaching

trunk

lid

to

trunk

lid

hinge

2

Move

trunk

lid

fore

and

aft

and

up

and

down

to

obtain

a

flush

fit

between

trunk

lid

and

rear

fender

L

BF543B

Fig

BF

39

Adjusting

Trunk

Lid

3

After

alignment

is

properly

made

tighten

bolts

securely

4

To

obtain

a

snug

fit

between

trunk

lid

and

weatherstrip

loosen

trunk

lid

lock

striker

attaching

bolts

enough

to

move

lock

striker

working

striker

up

or

down

and

from

side

to

side

as

required

I

Fig

BF

40

Trunk

Lid

Lock

Striker

Body

5

After

desired

adjustment

is

ob

tained

tighten

trunk

lid

lock

striker

attaching

bolts

securely

Removal

and

Inatallatlon

Open

trunk

lid

2

Mark

trunk

lid

hinge

locations

on

trunk

lid

for

proper

reinstallation

3

Support

trunk

lid

by

hand

and

remove

bolts

attaching

trunk

lid

to

hinge

Then

remove

trunk

lid

4

Installation

is

in

the

reverse

order

of

removal

TORSION

BAR

Removal

and

installation

Open

trunk

lid

2

Support

trunk

lid

and

remove

each

torsion

bar

from

trunk

lid

hinge

brackets

Use

a

suitable

screwdriver

wrapped

with

rag

to

avoid

slipping

Note

Take

care

when

removing

as

it

is

under

tension

n

J

7

YZ

BF545B

Fig

BF

41

Removing

Torsion

Bar

3

Installation

is

in

the

reverse

order

of

removal

BF

17

TRUNK

LID

LOCK

AND

LOCK

CYLINDER

Removal

and

installation

Open

trunk

lid

2

Remove

trunk

lid

lock

attaching

bolts

and

remove

trunk

lid

lock

from

trunk

lid

8F3138

Fig

BF

42

Removing

Trunk

Lid

Lock

3

To

remove

lock

cylinder

pry

off

retaining

clip

on

lock

cylinder

from

inside

of

trunk

lid

and

remove

lock

cylinder

from

trunk

lid

outer

panel

4

Installation

is

in

the

reverse

order

of

removal

Page 429 of 548

CV

j

r

J

j

J

BACK

DOOR

Hatchback

BACK

DOOR

ASSEMBLY

Adjustment

Back

door

can

be

adjusted

with

bolts

attaching

back

door

to

back

door

hinge

and

back

door

lock

I

Loosen

bolts

attaching

back

door

to

back

door

hinge

2

To

make

side

to

ide

adjustment

move

back

door

to

left

or

right

as

required

to

obtain

an

equal

clearance

between

back

door

and

rear

fender

on

both

sides

3

To

make

fore

and

aft

adjustment

move

back

door

in

fore

and

aft

direc

lion

as

required

to

obtain

an

equal

clearance

between

back

door

and

roof

Body

@

1

Back

door

hinge

2

Side

stopper

striker

3

Back

door

4

Striker

S

Back

door

stay

6

Side

stopper

7

Lock

cylinder

8

Back

door

lock

6

BF547B

Fig

BF

43

Back

Door

5

To

obtain

a

snug

fit

between

back

door

and

weatherstrip

loosen

back

door

striker

attaching

bolts

enough

to

move

striker

working

it

up

or

down

and

from

side

to

side

as

required

Af

0

l

SF

596B

g@VJ

Fig

BF

44

Adjusting

Back

Door

4

After

alignment

is

properly

made

tighten

bolts

securely

BF548B

Fig

BF

45

Adjusting

Back

Door

Striker

BF

18

Page 430 of 548

6

After

desired

adjustment

is

ob

tained

tighten

back

door

lock

attach

ing

bolts

securely

Removal

and

installation

I

Open

back

door

2

Mark

back

door

hinge

location

on

back

door

for

proper

reinstallation

3

Disconnect

rear

defogger

harness

connector

4

Support

back

door

and

remove

back

door

to

back

door

stay

bolts

and

back

door

to

back

door

hinge

attaching

bolts

Then

remove

back

door

This

operation

requires

two

men

CAUTION

Place

rags

between

roof

and

upper

end

of

back

door

to

avoid

damaging

paint

ed

surfaces

BF549B

Fig

BF

46

Removing

Bac

Door

Body

5

Installation

is

in

the

reverse

order

of

removal

Note

Before

securing

back

door

stay

to

car

body

with

bolts

make

sure

component

parts

are

properly

as

sembled

CAUTION

Be

careful

not

to

scratch

back

door

stay

when

installing

A

scratched

stay

may

cause

gas

leakage

BACK

DOOR

LOCK

AND

LOCK

CYLINDER

Removal

and

Installation

I

Open

back

door

and

keep

it

in

the

open

position

2

Remove

back

door

finisher

3

Loosen

bolts

attaching

back

door

lock

to

back

door

and

remove

lock

assembly

I

I

d

1

o

BF161A

Fig

BF

47

Removing

Back

Door

Lock

BF

19

4

To

remove

lock

cylinder

pry

off

lock

plate

between

lock

cylinder

and

back

door

panel

and

take

out

lock

cylinder

O

J6

J

II

Fig

BF

4

Removing

Lock

Cylinder

BF550B

5

Installation

is

in

the

reverse

order

of

removal

Adjust

back

door

lock

referring

to

Back

Door

Adjustment

Page 431 of 548

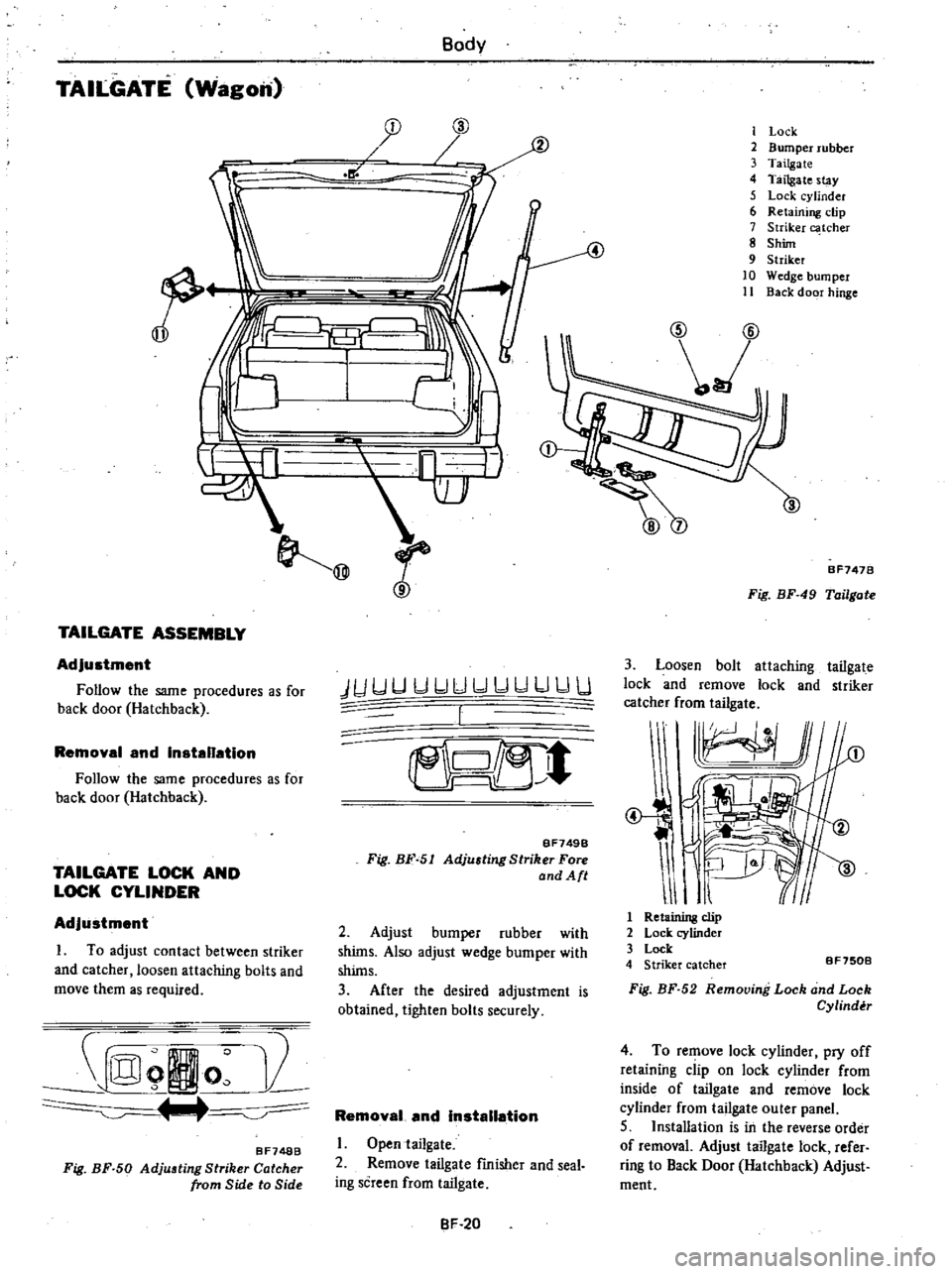

TAILGATE

Wagon

Body

J

L

il

@

2

TAILGATE

ASSEMBLY

Adjustment

Follow

the

same

procedures

as

for

back

door

Hatchback

Removal

and

Installation

Follow

the

same

procedures

as

for

back

door

Hatchback

TAILGATE

LOCK

AND

LOCK

CYLINDER

Adjustment

1

To

adjust

contact

between

striker

and

catcher

loosen

attaching

bolts

and

move

them

as

required

Io

iL

BF748B

Fig

BF

50

Adjusting

Striker

Catcher

rom

Side

to

Side

4

1

Lock

2

Bumper

rubber

3

Tailgate

4

Tailgate

stay

5

Lock

cylinder

6

Retaining

clip

7

Striker

C

tcher

8

Shim

9

Striker

10

Wedge

bumper

11

Back

door

hinge

JUUUbJUlIbJUULJUU

I

t

BF749B

Fig

BF

51

Adjusting

Striker

Fore

and

Aft

2

Adjust

bumper

rubber

with

shilns

Also

adjust

wedge

bumper

with

shilns

3

After

the

desired

adjustment

is

obtained

tighten

bolts

securely

Removal

and

Installation

Open

tailgate

2

Remove

tailgate

fmisher

and

seal

ing

screen

from

tailgate

BF

20

BF1478

Fig

BF

49

Tai

gote

3

Loosen

bolt

attaching

tailgate

lock

and

remove

lock

and

striker

catcher

from

tailgate

III

J

1l

d

l

I

1

p

1

RetBinin8

clip

2

Lock

cylinder

3

Lock

4

Striker

catcher

BF750B

Fig

BF

52

Removing

Lock

and

Lock

Cylindir

4

To

remove

lock

cylinder

pry

off

retaining

clip

on

lock

cylinder

from

inside

of

tailgate

and

remove

lock

cylinder

from

tailgate

outer

panel

5

Installation

is

in

the

reverse

order

of

removal

Adjust

tailgate

lock

refer

ring

to

Back

Door

Hatchback

Adjust

ment

Page 435 of 548

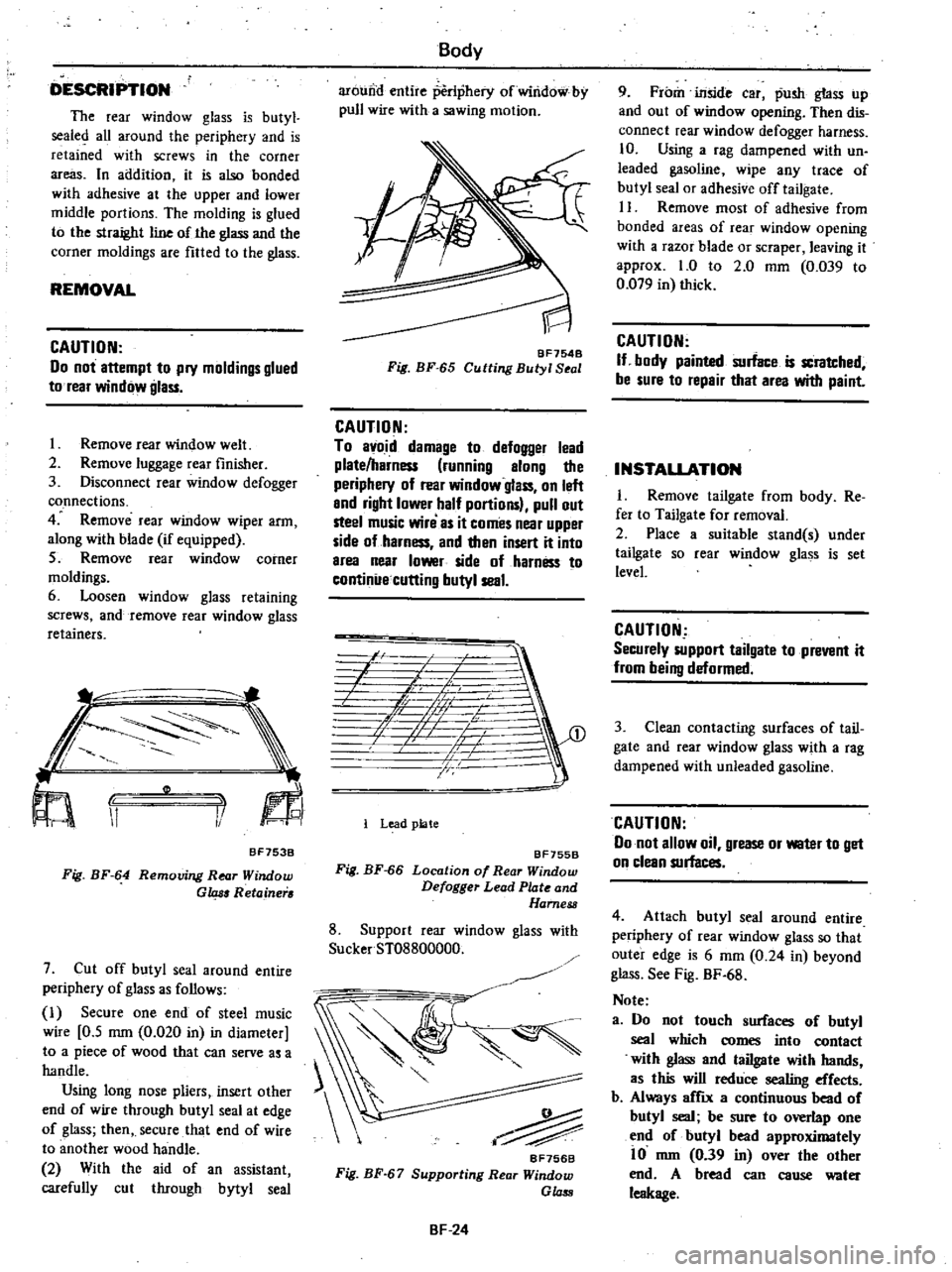

DESCRIPTION

The

rear

window

glass

is

butyl

sealed

aU

around

the

periphery

and

is

retained

with

screws

in

the

corner

areas

In

addition

it

is

also

bonded

with

adhesive

at

the

upper

and

lower

middle

portions

The

molding

is

glued

to

the

straight

line

of

the

glass

and

the

corner

moldings

are

fitted

to

the

glass

REMOVAL

CAUTION

00

not

attempt

to

pry

moldings

glued

to

rear

window

glass

1

Remove

rear

window

welt

2

Remove

luggage

rear

finisher

3

Disconnect

rear

window

defogger

connections

4

Remove

rear

window

wiper

arm

along

with

blade

if

equipped

5

Remove

rear

window

comer

moldings

6

Loosen

window

glass

retaining

screws

and

remove

rear

window

glass

retainers

II

1

BF753B

Fig

BF

64

Removing

RNr

Window

G

Retainer

7

Cut

off

butyl

seal

around

entire

periphery

of

glass

as

follows

I

Secure

one

end

of

steel

music

wire

0

5

mm

0

020

in

in

diameter

to

a

piece

of

wood

that

can

serve

as

a

handle

Using

long

nose

pliers

insert

other

end

of

wire

through

butyl

seal

at

edge

of

glass

then

secure

that

end

of

wire

to

another

wood

handle

2

With

the

aid

of

an

assistant

carefully

cut

through

bytyl

seal

Body

arDUna

entire

periphery

ofwirid6

by

pull

wire

with

a

sawing

motion

BF754B

Fig

BF

65

Cutting

Butyl

S

I

CAUTION

To

avoid

damage

to

defogger

lead

plate

harness

running

along

the

periphery

of

rear

window

glass

on

left

and

right

lower

half

portions

pull

out

steel

music

willi

as

it

comes

near

upper

side

of

harness

and

then

insert

it

into

area

near

lower

side

of

harness

to

continue

cutting

butyl

seal

71

A

L

0

fr

f

1

Lead

plate

BF755B

Fig

BF

66

Location

of

Rear

Window

Defogger

Lead

Plate

and

Harness

8

Support

rear

window

glass

with

SuckerST08800000

BF756B

Fig

BF

67

Supporting

Rear

Window

GLus

BF

24

9

From

inside

car

push

glass

up

and

out

of

window

opening

Then

dis

connect

rear

window

defogger

harness

10

Using

a

rag

dampened

with

un

leaded

gasoline

wipe

any

trace

of

butyl

seal

or

adhesive

off

tailgate

II

Remove

most

of

adhesive

from

bonded

areas

of

rear

window

opening

with

a

razor

blade

or

scraper

leaving

it

approx

1

0

to

2

0

mm

0

039

to

0

079

in

thick

CAUTION

If

body

painted

surtin

e

is

scratched

be

sure

to

repair

that

area

with

paint

INSTALLATION

I

Remove

tailgate

from

body

Re

fer

to

Tailgate

for

removal

2

Place

a

suitable

stand

s

under

tailgate

so

rear

window

gla

s

is

set

level

CAUTION

Securely

support

tailgate

to

prevent

it

from

being

deformed

3

Clean

contacting

surfaces

of

tail

gate

and

rear

window

glass

with

a

rag

dampened

with

unleaded

gasoline

CAUTION

00

not

allow

oil

grease

or

water

to

get

on

clean

surfaces

4

Attach

butyl

seal

around

entire

periphery

of

rear

window

glass

so

that

outer

edge

is

6

mm

0

24

in

beyond

glass

See

Fig

BF

68

Note

a

Do

not

touch

surfaces

of

butyl

seal

which

comes

into

contact

with

glass

and

tailgate

with

hands

as

this

will

reduce

sealing

effects

b

Always

amx

a

continuous

bead

of

butyl

seal

be

sure

to

overlap

one

end

of

butyl

bead

approximately

i

0

mm

0

39

in

over

the

other

end

A

bread

can

cause

water

leakage

Page 438 of 548

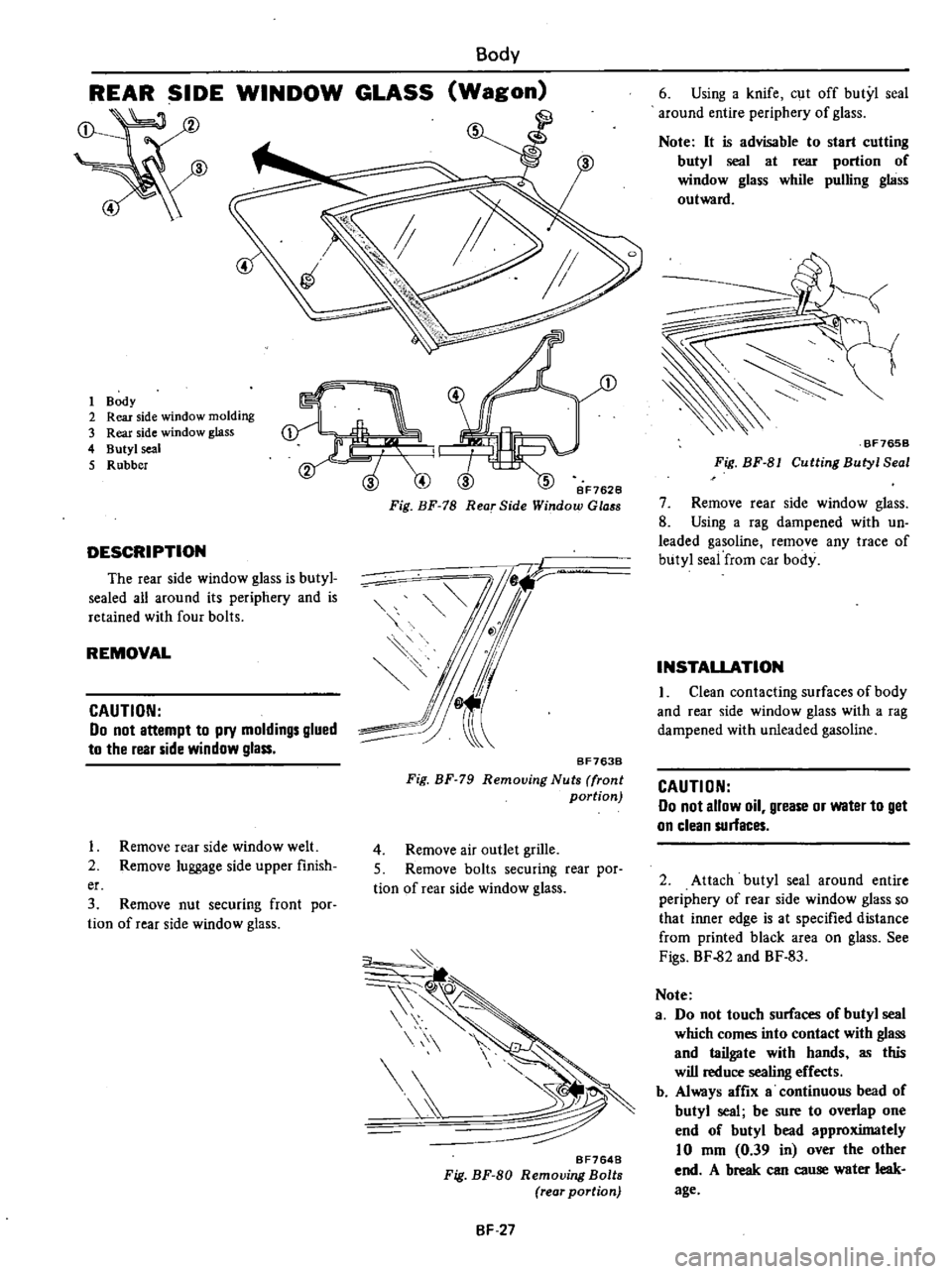

Body

REAR

SIDE

WINDOW

GLASS

Wagon

4

1

Body

2

Rear

side

window

molding

3

Rear

side

window

glass

4

Butyl

seal

5

Rubber

Bf7628

Fig

BF

78

Rear

Side

Window

Glo

8

DESCRIPTION

The

rear

side

window

glass

is

butyl

sealed

all

around

its

periphery

and

is

retained

with

four

bolts

REMOVAL

CAUTION

Do

not

attempt

to

pry

moldings

glued

to

the

rear

side

window

glass

BF763B

Fig

BF

79

Removing

Nuts

front

portion

1

Remove

rear

side

window

welt

2

Remove

luggage

side

upper

finish

4

Remove

air

outlet

grille

S

Remove

bolts

securing

rear

por

tion

of

rear

side

window

glass

er

3

Remove

nut

securing

front

por

tion

of

rear

side

window

glass

lt

BF7648

Fig

BF

80

Removing

Bolts

rear

portion

BF

27

6

Using

a

knife

cut

off

butyl

seal

around

entire

periphery

of

glass

Note

It

is

advisable

to

start

cutting

butyl

seal

at

rear

portion

of

window

glass

while

pulling

glass

outward

BF765B

Fig

BF

81

Cutting

Butyl

Seal

7

Remove

rear

side

window

glass

8

Using

a

rag

dampened

with

un

leaded

gasoline

remove

any

trace

of

butyl

seai

from

car

body

INSTALLATION

I

Clean

contacting

surfaces

of

body

and

rear

side

window

glass

with

a

rag

dampened

with

unleaded

gasoline

CAUTION

Do

not

allow

oil

grease

or

water

to

get

on

clean

surfaces

2

Attach

butyl

seal

around

entire

periphery

of

rear

side

window

glass

so

that

inner

edge

is

at

specified

distance

from

printed

black

area

on

glass

See

Figs

BF

82

and

BF

83

Note

a

Do

not

touch

surfaces

of

butyl

seal

which

comes

into

contact

with

glass

and

tailgate

with

hands

as

this

will

reduce

sealing

effects

b

Always

affix

a

continuous

bead

of

butyl

seal

be

sure

to

overlap

one

end

of

butyl

bead

approximately

10

mm

0

39

in

over

the

other

end

A

break

can

cause

water

leak

age

Page 439 of 548

More

than

5

0

20

More

than

5

0

20

j

0

31

I

I

I

Oi6

I

Glass

yi

Yl

Prin

ed

portion

Unit

mm

in

Sectional

view

or

butyl

seal

BF766B

Fig

BF

82

Attaching

Butyl

Seal

3

Position

rear

side

window

glass

in

opening

flange

of

rear

side

window

Body

More

than

5

0

20

Note

Make

sure

that

clearances

be

tween

rear

side

window

molding

BF

28

and

CaibOdy

molding

are

ilithe

specified

value

5

0

20

I

1

O

I

I

ri

04

Unit

rom

in

BF767B

Fig

BF

83

Clearance

between

Rear

Side

Window

and

Car

Body

4

Using

a

heat

gun

heat

butyl

seal

on

inner

side

of

rear

side

window

to

approxilnately

800C

1760F

and

apply

hand

pressure

to

glass

5

Tighten

bolts

and

nuts

securing

rear

side

window

glass

6

Install

all

previously

removed

parts

in

the

reverse

order

of

removal

Page 441 of 548

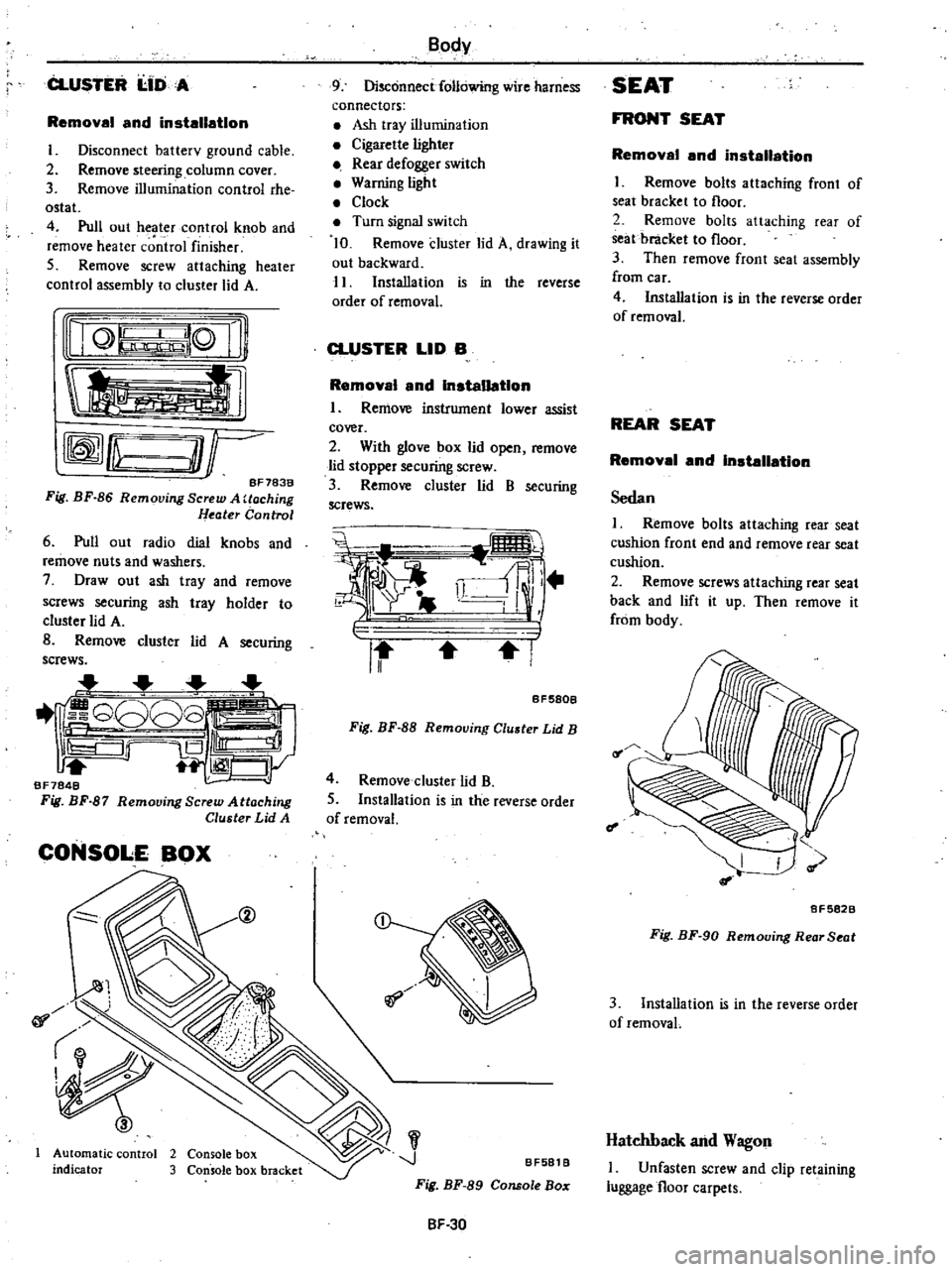

CLUSTER

I

IDA

Removal

and

installation

I

Disconnect

batterv

ground

cable

2

Remove

steering

column

cover

3

Remove

illumination

control

rhe

ostat

4

Pull

out

heater

control

knob

and

remove

heater

c

ntrol

finisher

5

Remove

screw

attaching

heater

control

assembly

to

cluster

lid

A

nQ

lQ

Ii

tl

rffmfLu

O

r

BF783B

Fig

BF

86

Removing

Screw

A

Uoching

Heater

Control

6

Pull

out

radio

dial

knobs

and

remove

nuts

and

washers

7

Draw

out

ash

tray

and

remove

screws

securing

ash

tray

holder

to

cluster

lid

A

B

Remove

cluster

lid

A

securing

screws

1

G808

iS

Ill

1

CJy

BF7848

Fig

BF

87

Remooing

Screw

Attaching

Cluster

Lid

A

CONSOLE

BOX

@

01

Automatic

control

2

Console

box

indicator

3

Console

box

bracket

Body

9

Disconnect

following

wire

harness

connectors

Ash

tray

illumination

Cigarette

lighter

Rear

defogger

switch

Warning

light

Clock

Turn

signal

switch

10

Remove

cluster

lid

A

drawing

it

out

backward

11

Installation

is

in

the

reverse

order

of

removal

CLUSTER

LID

B

Removal

and

Installation

I

Remove

instrument

lower

assist

cover

2

With

glove

box

lid

open

remove

lid

stopper

securing

screw

3

Remove

cluster

lid

B

securing

screws

i

i

ll

r

II

I

BF580B

Fig

BF

88

Removing

Cluster

Lid

B

4

Remove

cluster

lid

B

5

Installation

is

in

the

reverse

order

of

removal

J

BF581

B

Fig

BF

89

Console

Bo

SF

30

SEAT

FRONT

SEAT

Removal

and

installation

I

Remove

bolts

attaching

front

of

seat

bracket

to

floor

2

Remove

bolts

attaching

rear

of

seat

bracket

to

floor

3

Then

remove

front

seat

assembly

from

car

4

Installation

is

in

the

reverse

order

of

removal

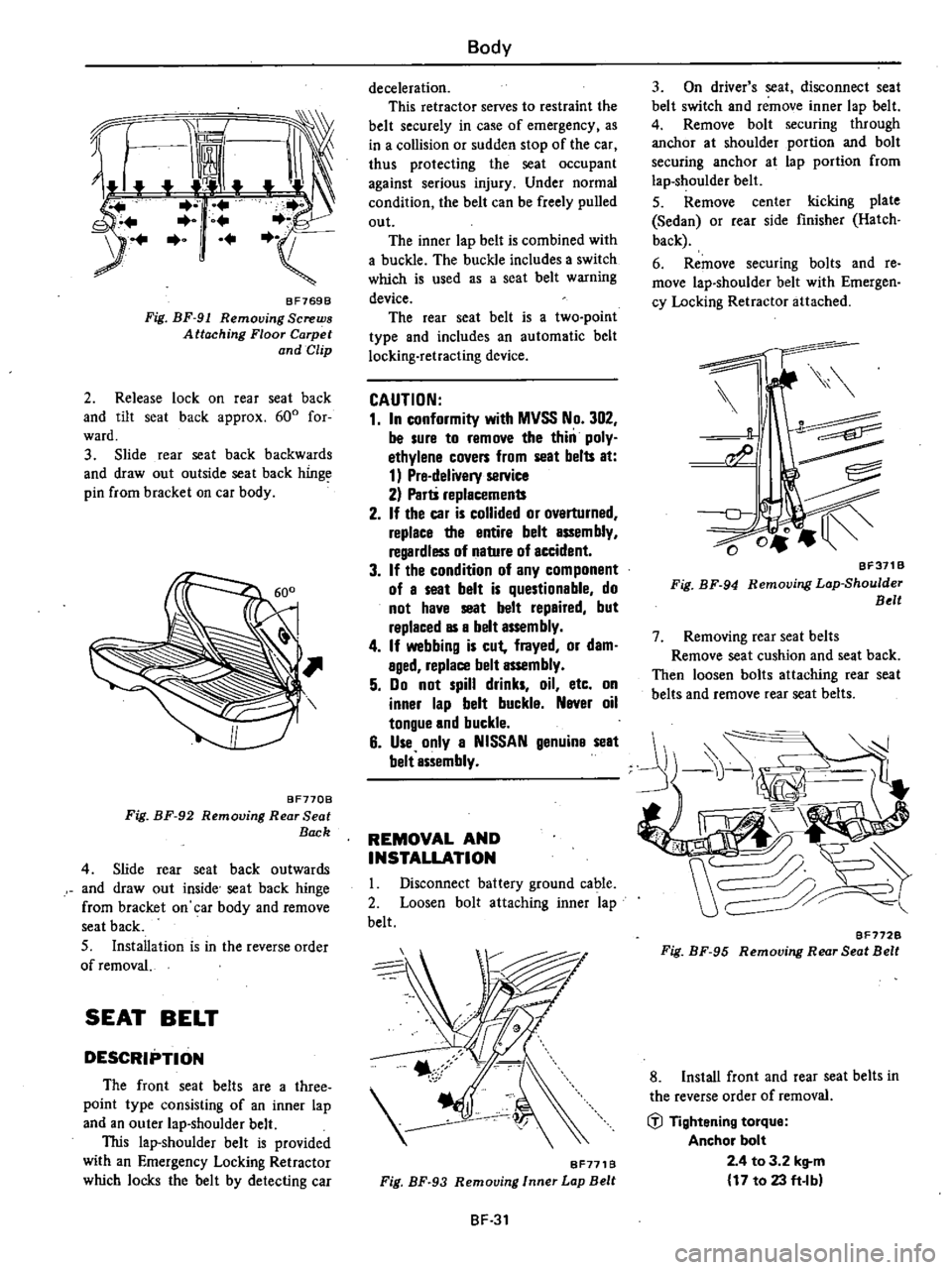

REAR

SEAT

Removal

and

Installation

Sedan

I

Remove

bolts

attaching

rear

seat

cushion

front

end

and

remove

rear

seat

cushion

2

Remove

screws

attaching

rear

seat

back

and

lift

it

up

Then

remove

it

from

body

f

I

8F5828

Fig

BF

90

Removing

Rear

Seat

3

Installation

is

in

the

reverse

order

of

removaL

Hatchback

and

Wagon

I

Unfasten

screw

and

clip

retaining

luggage

floor

carpets

Page 442 of 548

Z

jJ

BF769B

Fig

BF

91

Removing

Screws

Attaching

Floor

Carpet

and

Clip

2

Release

lock

on

rear

seat

back

and

tilt

seat

back

approx

600

for

ward

3

Slide

rear

seat

back

backwards

and

draw

out

outside

seat

back

hinge

pin

from

bracket

on

car

body

BF770B

Fig

BF

92

Removing

Rear

Seat

Back

4

Slide

rear

seat

back

outwards

and

draw

out

inside

seat

back

hinge

from

bracket

on

car

body

and

remove

seat

back

S

Installation

is

in

the

reverse

order

of

removal

SEAT

BELT

DESCRIPTION

The

front

seat

belts

are

a

three

point

type

consisting

of

an

inner

lap

and

an

outer

lap

shoulder

belt

This

lap

shoulder

belt

is

provided

with

an

Emergency

Locking

Retractor

which

locks

the

belt

by

detecting

car

Body

deceleration

This

retractor

serves

to

restraint

the

belt

securely

in

case

of

emergency

as

in

a

collision

or

sudden

stop

of

the

car

thus

protecting

the

seat

occupant

against

serious

injury

Under

normal

condition

the

belt

can

be

freely

pulled

out

The

inner

lap

belt

is

combined

with

a

buckle

The

buckle

includes

a

switch

which

is

used

as

a

seat

belt

warning

device

The

rear

seat

belt

is

a

two

point

type

and

includes

an

automatic

belt

locking

retracting

device

CAUTION

1

In

conformity

with

MVSS

No

302

be

sure

to

remove

the

thin

poly

ethylene

covers

from

seat

belts

at

1

Pre

delivery

service

2

Parti

replacements

2

If

the

car

is

collided

or

ovarturned

replace

the

entire

belt

assembly

regardless

of

nature

of

accident

3

If

the

condition

of

any

component

of

a

seat

belt

is

questionable

do

not

have

seat

belt

repaired

but

raplaced

as

a

belt

assembly

4

If

webbing

is

cut

frayed

or

dam

aged

replace

belt

assembly

5

Do

not

spill

drinks

oil

etc

on

inner

lap

belt

buckla

Naver

oil

tongue

and

buckle

6

Use

only

a

NISSAN

genuina

seat

belt

assembly

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Loosen

bolt

attaching

inner

lap

belt

BF771B

Fig

BF

93

Removing

Inner

Lap

Belt

BF

31

3

On

driver

s

seat

disconnect

seat

belt

switch

and

remove

inner

lap

belt

4

Remove

bolt

securing

through

anchor

at

shoulder

portion

and

bolt

securing

anchor

at

lap

portion

from

lap

shoulder

belt

5

Remove

center

kicking

plate

Sedan

or

rear

side

finisher

Hatch

back

6

Remove

securing

bolts

and

re

move

lap

shoulder

belt

with

Emergen

cy

Locking

Retractor

attached

BF311B

Fig

BF

94

Removing

Lop

Shoulder

Belt

7

Removing

rear

seat

belts

Remove

seat

cushion

and

seat

back

Then

loosen

bolts

attaching

rear

seat

belts

and

remove

rear

seat

belts

BF772B

Fig

BF

95

Removing

Rear

Seat

Belt

8

Install

front

and

rear

seat

belts

in

the

reverse

order

of

removal

iil

Tightening

torque

Anchor

bolt

2

4

to

3

2

kg

m

17

to

23

ft

Ibl