ECU DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 522 of 548

REFRIGERANT

LINES

Air

Conditioning

@

I

J

L

S

r

Z

S

t

@

See

Fig

AC

29

When

replacing

flexible

hose

and

tube

observe

the

following

1

Before

starting

work

be

sure

to

discharge

system

2

When

disconnecting

tubes

be

sure

to

use

two

wrenches

on

both

tubes

3

After

discon

ecting

tubes

plug

all

openings

immediately

to

prevent

entrance

of

dirt

and

moisture

4

Compressed

air

must

never

be

used

to

clean

dirty

line

Clean

with

refrigerant

gas

5

In

connecting

tubes

be

sure

to

apply

compressor

oil

to

seating

surface

and

then

tighten

tubes

to

specified

tightening

torque

See

Fig

AC

30

Be

sure

to

use

two

wrenches

when

tightening

a

flare

nut

of

tube

Coat

seat

surfaces

with

com

pressor

oil

and

then

tighten

AC263

Fig

AC

30

Line

Connection

CD

6

Make

sure

refrigerant

line

is

clamped

securely

Start

engine

and

raise

engine

speed

to

inspect

if

there

is

vibration

or

unusual

noise

7

Conduct

leak

t

st

and

make

su

e

that

there

is

no

leak

from

connections

8

Refer

to

General

Service

for

evacuating

and

charging

system

COOLING

UNIT

REMOVAL

I

Disconnect

battery

ground

cable

2

Discharge

refrigerant

from

sys

tern

Refer

to

General

Service

3

Loosen

flare

nuts

at

each

con

nection

of

inlet

and

outlet

pipes

of

evaporator

AC

21

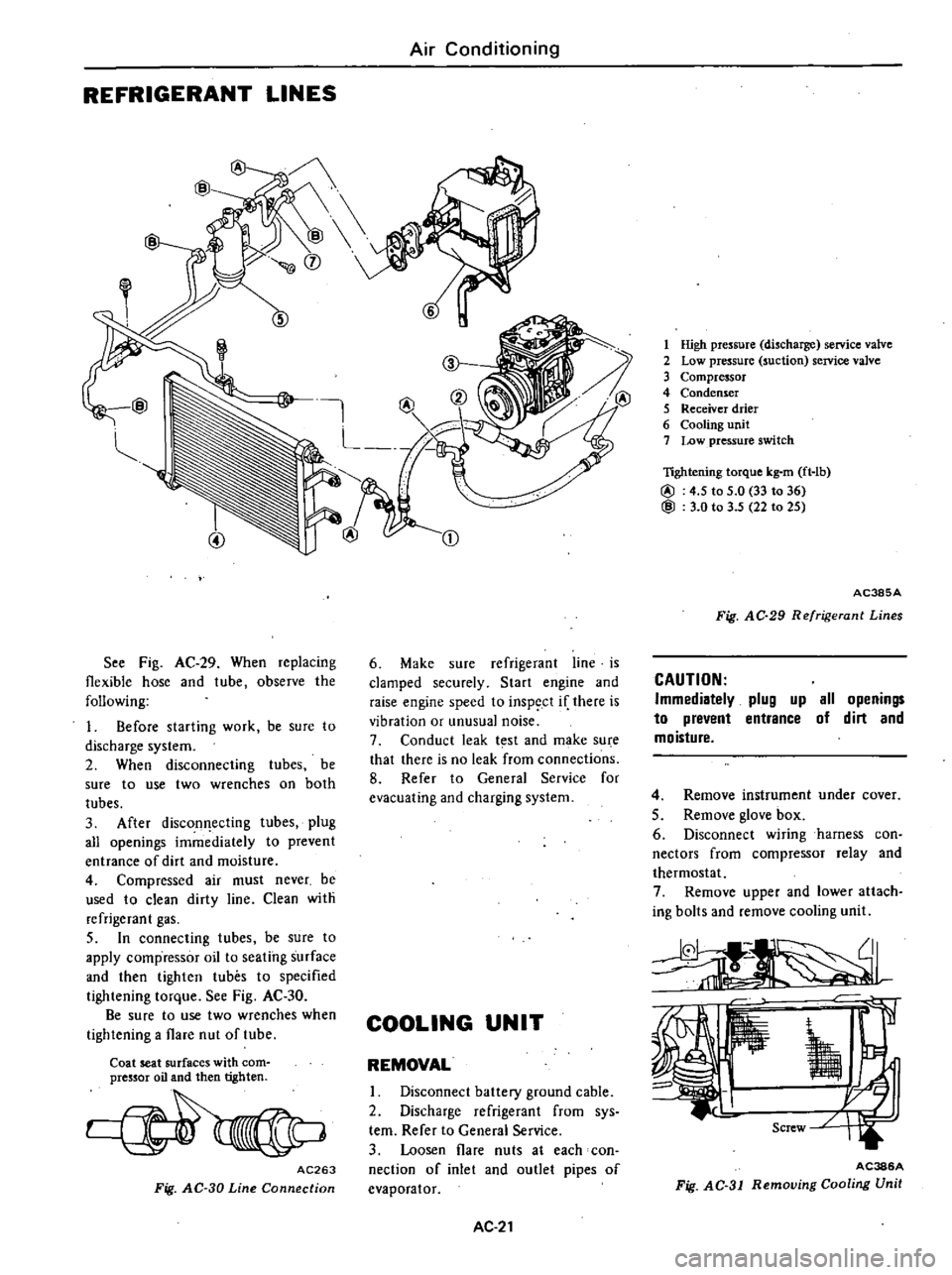

1

High

pressure

discharge

service

valve

2

Low

pressure

suction

service

valve

3

Compressor

4

Condenser

5

Receiver

drier

6

Cooling

unit

7

Low

pressure

switch

lightening

torque

kg

m

ft

lb

@

4

5

to

5

0

33

to

36

@

3

0

to

3

5

22

to

25

AC385A

Fig

AC

29

Refrigerant

Lines

CAUTION

Immediatelv

plug

up

all

openings

to

prevent

entrance

of

dirt

and

moisture

4

Remove

instrument

under

cover

5

Remove

glove

box

6

Disconnect

wiring

harness

con

nectors

from

compressor

relay

and

thermostat

7

Remove

upper

and

lower

attach

ing

bolts

and

remove

cooling

unit

AC386A

Fig

AC

31

Removing

Cooling

Unit

Page 525 of 548

LOW

PRESSURE

SWITCH

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Discharge

refrigerant

from

sys

tem

Refer

to

General

Service

3

Disconnect

connector

to

low

pressure

switch

4

Remove

low

pressure

switch

by

turning

the

switch

5

Installation

is

in

the

reverse

order

of

removal

INSPECTION

Using

a

circuit

tester

make

sure

that

low

pressure

switch

exhibits

con

tinuity

when

gas

pressure

of

refriger

ant

in

system

is

normal

and

that

low

pressure

switch

does

not

exhibit

con

tinuity

when

gas

pressure

drops

below

2

2

kg

cm2

31

p

i

MAGNET

VALVE

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Disconnect

magnet

valve

lead

wires

and

vacuum

hoses

3

Remove

magnet

valve

securing

screws

and

then

remove

magnet

valve

i

i

WrE

AC389A

Fig

AC

36

Removjng

Magnet

Valve

4

Installation

is

in

the

reverse

order

of

removal

INSPECTION

I

rest

continuity

with

ohmmeter

2

Apply

D

C

12

volts

across

termi

Air

Conditioning

031

under

this

state

orally

blow

through

one

vacuum

port

to

ensure

that

there

is

air

flow

at

the

other

FUSE

REPLACEMENT

REPLACEMENT

A

20

ampere

in

line

fuse

is

part

of

air

conditioner

harness

located

behind

glove

box

J

Disconnect

batiery

ground

cable

2

Remove

instrument

under

cover

3

Remove

glove

box

4

Take

out

fuse

holder

from

air

conditioner

harness

and

replace

fuse

with

a

new

one

CAUTION

If

fuse

is

blown

be

sure

to

climi

nate

the

cause

befure

installing

new

fuse

in

position

r

AC276A

Fig

AC

37

Fu

e

Replacement

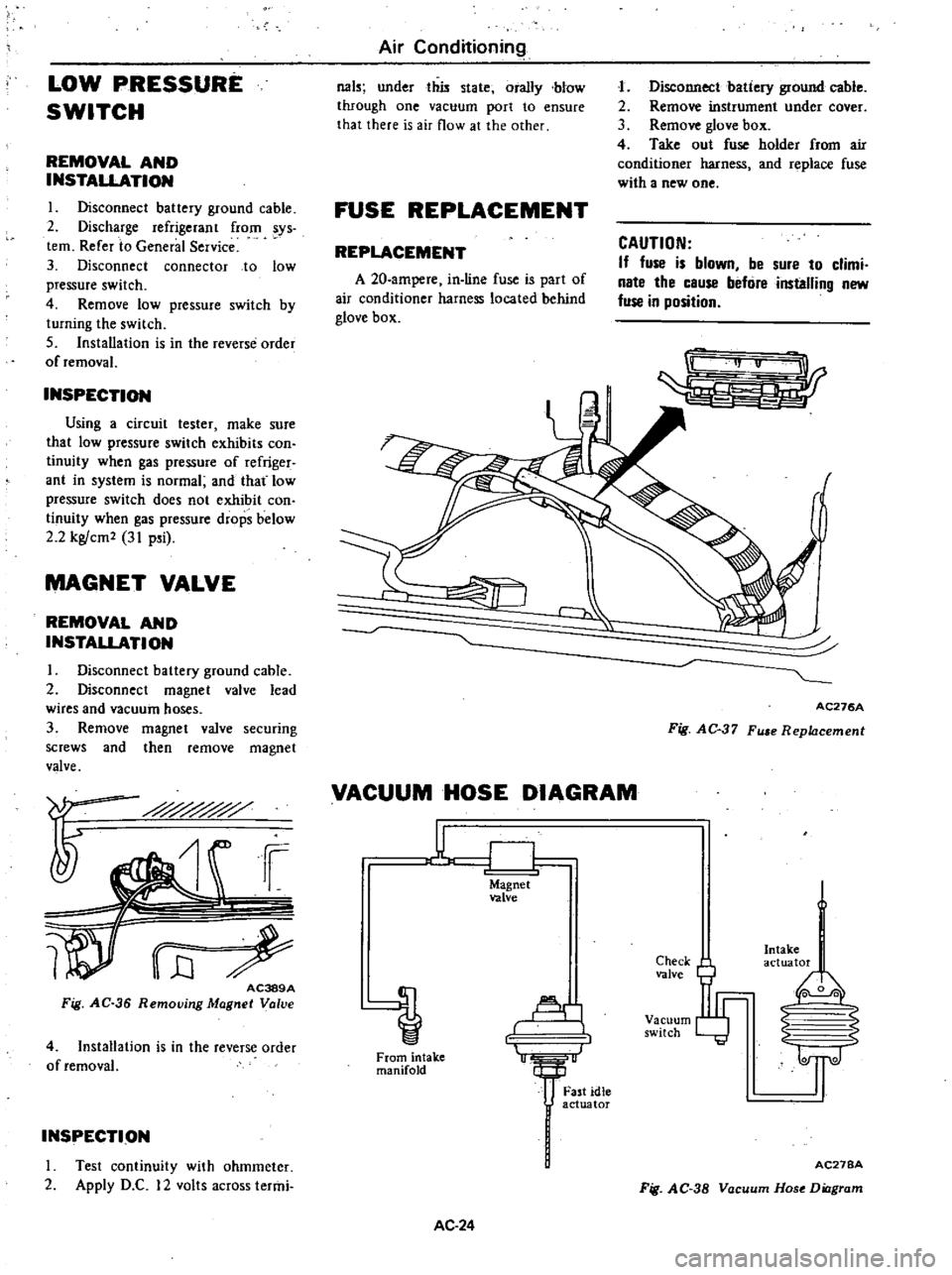

VACUUM

HOSE

DIAGRAM

u

CJ

Magnet

valve

Al

1

From

intake

manifold

AC

24

Fast

idle

actuator

Check

valve

Vacuum

switch

Intake

actuator

I

0

0

2

S

1l

AC27BA

Fig

AC

38

Vacuum

Hose

Diagram

Page 528 of 548

PRELIMINARY

CLEANING

Before

starting

work

remove

dirt

from

outside

the

detached

compressor

Clean

the

workbench

tool

and

your

hands

COMPRESSOR

CLUTCH

The

most

likely

source

of

problem

is

clutch

slippage

Factors

are

listed

here

Exercise

ample

care

1

Clearance

between

clutch

hub

and

pulley

should

be

0

4

to

0

6

mm

0

016

to

0

024

in

at

aU

peripheral

points

2

Make

sure

that

there

is

no

oil

or

dirt

on

friction

surfaces

of

clutch

disc

clutch

hub

and

pulley

Remove

oil

or

dirt

with

clean

lint

free

cloth

3

Make

sure

that

terminal

voltage

at

magnetic

coil

is

above

10

5V

REMOVAL

I

Using

Clutch

Spanner

Wrench

hold

clutch

hub

With

suitable

socket

wrench

remove

bolt

retaining

clutch

hub

to

crankshaft

AC391A

Fig

AC

41

Removing

Bolt

2

Then

using

Clutch

Removing

Bolt

remove

clutch

assembly

from

crankshaft

CAUTION

Be

careful

not

to

demage

key

on

compressor

crankshaft

Air

Conditioning

AC392A

Fig

AC

42

Removing

Clutch

Assembly

3

Loosen

four

electromagnetic

coil

mounting

screws

Coil

assembly

can

then

be

taken

out

easily

AC869

Fig

AC

43

R

mouing

Magnetic

Clutch

INSTALLATION

Locate

the

electromagnetic

coil

at

the

correct

position

on

compressor

housing

Then

secure

four

electro

magnetic

coil

mounting

screws

@

Tightening

torque

Electromagnetic

coil

mounting

screws

0

7

kltm

5

1

ft

Ibl

2

InstaU

the

clutch

assembly

on

the

crankshaft

Note

Key

should

be

set

on

crank

shaft

before

installing

clutch

assem

bly

3

Using

Clutch

Spanner

Wrench

hold

clutch

hub

With

socket

wrench

secure

clutch

hub

securing

bolt

iJJ

Tightening

torque

Clutch

hub

securing

bolt

1

5

kg

m

11

ft

Ib

AC

27

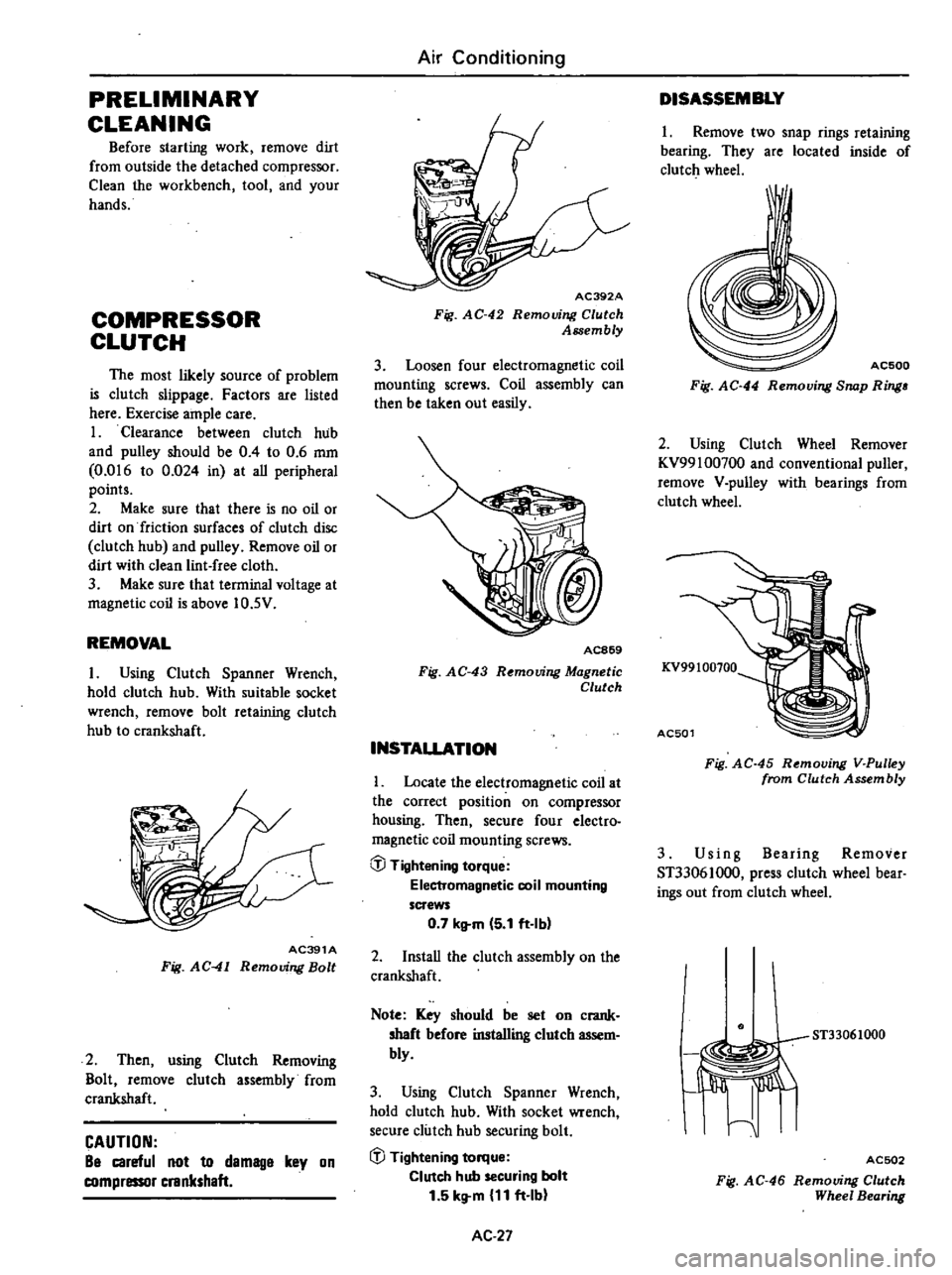

DISASSEMBLY

1

Remove

two

snap

rings

retaining

bearing

They

are

located

inside

of

clutch

wheel

I

AC500

Fig

AC

44

Removing

Snap

Ring

2

Using

Clutch

Wheel

Remover

KV99100700

and

conventional

puller

remove

V

pulley

with

bearings

from

clutch

wheel

KV99100100

AC501

Fig

AC

45

Removing

V

Pulley

from

Clutch

Assembly

3

Us

i

n

g

Bearing

Remover

ST33061000

press

clutch

wheel

bear

ings

out

from

clutch

wheel

ST33061000

I

Jiffi

I

ACSD2

Fig

AC

46

Removing

Clutch

Wheel

Bearing

Page 530 of 548

AC867

Fig

AC

53

Removing

Shaft

Seal

INSTALLATION

1

Clean

shaft

and

seal

cavity

with

clean

lint

free

cloth

2

Dip

seal

gland

in

clean

refrigerant

oil

3

Push

seal

assembly

except

carbon

ring

over

end

of

shaft

with

carbon

ring

retainer

facing

out

4

Move

seal

assembly

into

position

on

shaft

ACB68

Fig

AC

54

1merting

Shaft

Seal

Assembly

5

Place

carbon

ring

in

ring

reta

iner

so

lapped

surface

is

facing

outward

Note

The

indentions

in

outside

edge

of

carbon

ring

must

engage

driving

lugs

and

be

rmnly

seated

in

re

tainer

6

Install

new

Q

ring

in

groove

of

seal

plate

Note

Use

refrigeration

oil

to

make

it

adhere

to

surface

Air

Conditioning

7

Space

seal

plate

with

equal

clear

ance

around

shaft

and

insert

cap

screws

Tighten

these

screws

evenly

IiJ

Tightening

torque

Seal

plate

securing

cap

screws

0

7

to

1

0

kg

m

5

1

to

7

2

ft

Ibl

AC869

Fig

AC

55

Spacing

Seal

Plate

and

Tightening

Cap

Screws

8

Install

clutch

Refer

to

Compres

sor

Clutch

for

installation

9

Charge

lubricant

To

Low

pressure

service

valve

10

Install

oil

filler

plug

together

with

O

ring

CAUTION

Use

new

O

ring

when

installing

oil

filler

plug

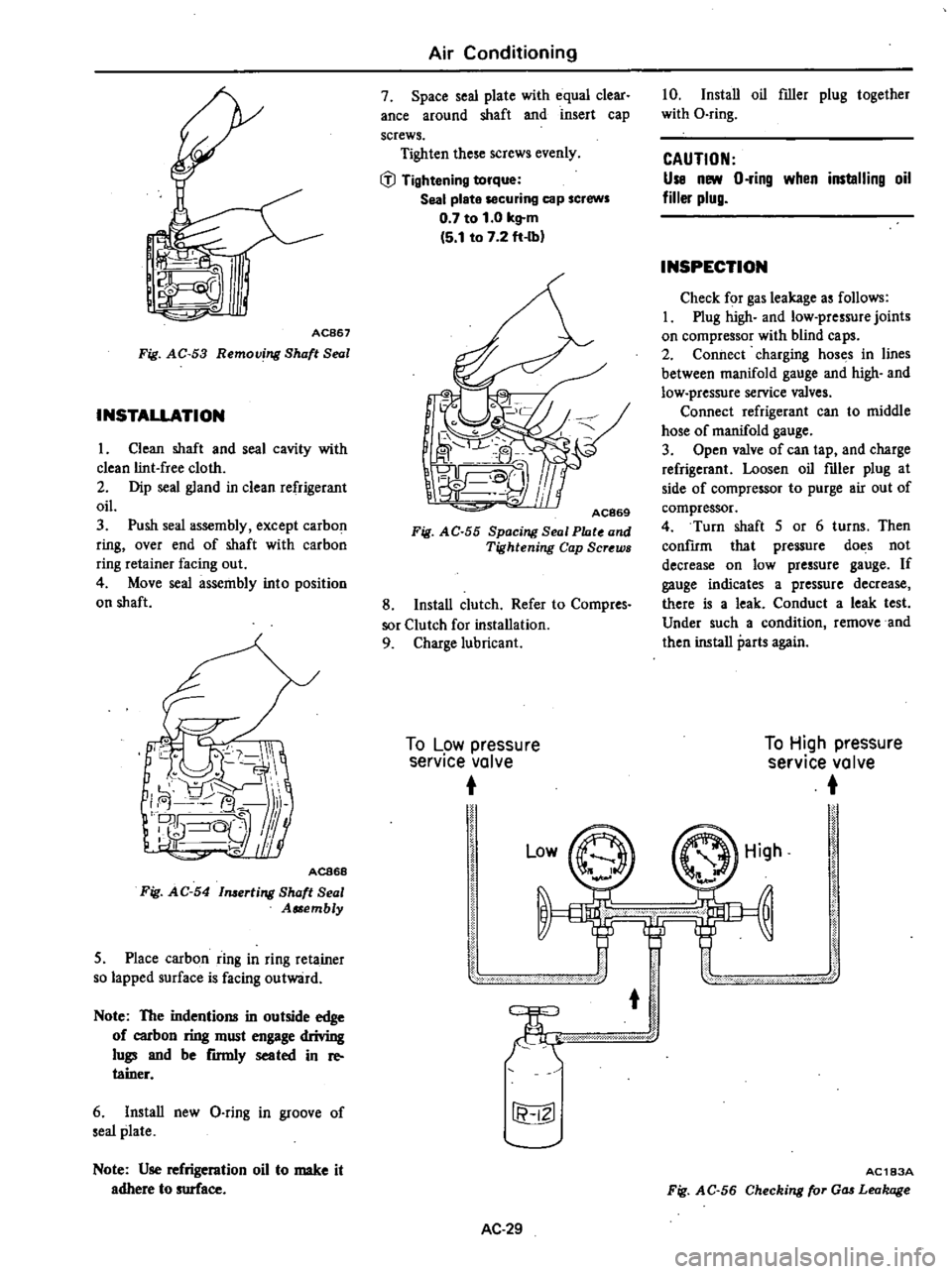

INSPECTION

Check

for

gas

leakage

as

follows

I

Plug

high

and

low

pressure

joints

on

compressor

with

blind

caps

2

Connect

charging

hoses

in

lines

between

manifold

gauge

and

high

and

low

pressure

service

valves

Connect

refrigerant

can

to

middle

hose

of

manifold

gauge

3

Open

valve

of

can

tap

and

charge

refrigerant

Loosen

oil

filler

plug

at

side

of

compressor

to

purge

air

out

of

compressor

4

Turn

shaft

5

or

6

turns

Then

confIrm

that

pressure

does

not

decrease

on

low

pressure

gauge

If

gauge

indicates

a

pressure

decrease

there

is

a

leak

Conduct

a

leak

test

Under

such

a

condition

remove

and

then

install

parts

again

To

High

pressure

service

valve

Low

r

fi

IZl

AC

29

High

AC183A

Fig

AC

56

Checking

for

Gas

Leakage

Page 531 of 548

r

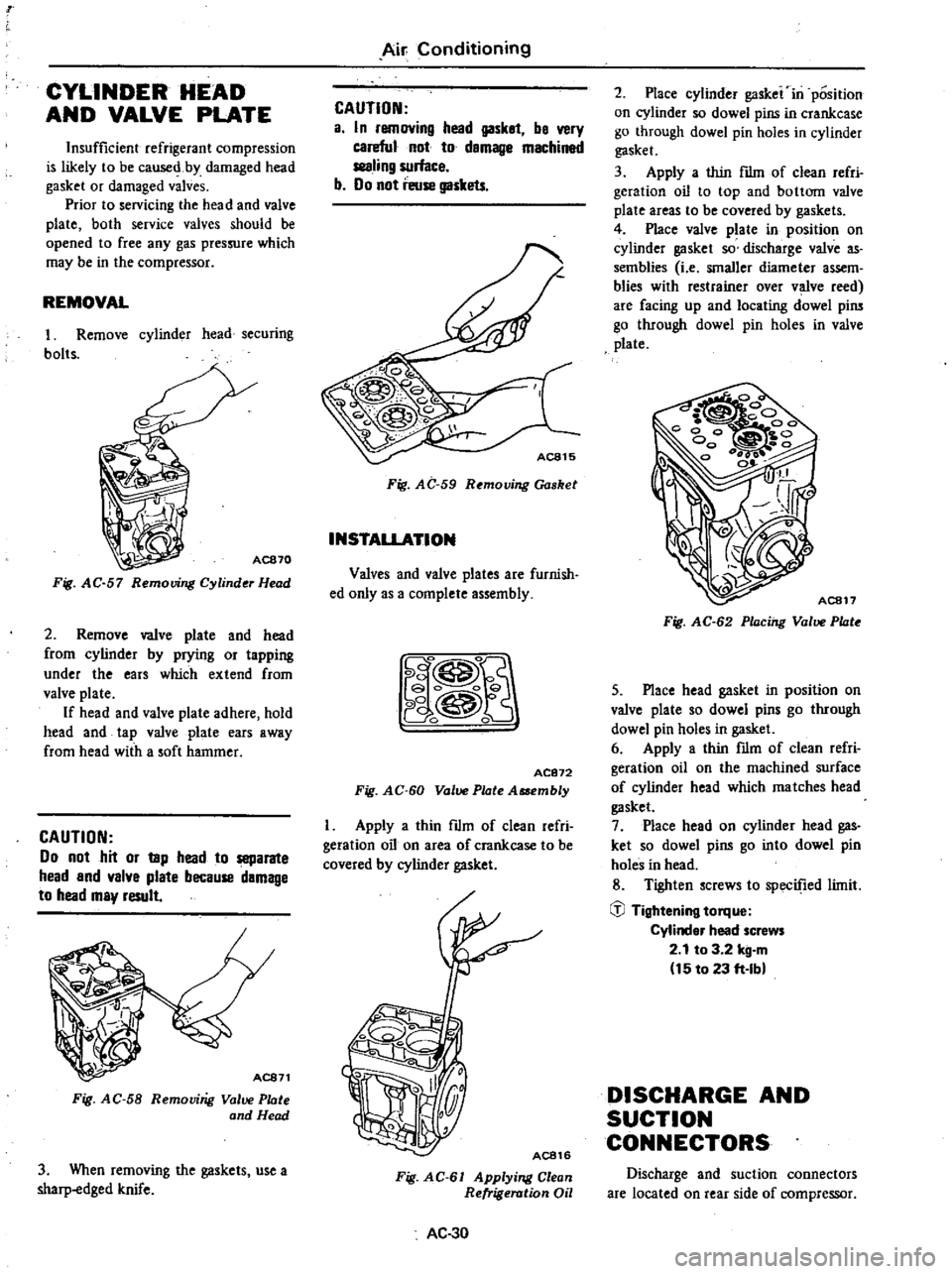

CYLINDER

HEAD

AND

VALVE

PLATE

Insufficient

refrigerant

v

p

sion

is

likely

to

be

caused

by

damaged

head

gasket

or

damaged

valves

Prior

to

servicing

the

head

and

valve

plate

both

service

valves

should

be

opened

to

free

any

gas

pressure

which

may

be

in

the

compressor

REMOVAL

I

Remove

cylinder

head

securing

bolts

Fig

AC

57

Removing

Cylinder

Head

2

Remove

valve

plate

and

head

from

cylinder

by

prying

or

tapping

under

the

ears

which

extend

from

valve

plate

If

head

and

valve

plate

adhere

hold

head

and

tap

valve

plate

ears

away

from

head

with

a

soft

hammer

CAUTION

00

not

hit

or

llIp

head

to

separate

head

and

valve

plate

because

damage

to

head

may

result

AC871

Fig

AC

58

Removing

Volve

Plate

and

Head

3

When

removing

the

gaskets

use

a

sharp

edged

knife

Air

Conditioning

CAUTION

a

In

removing

head

gasket

be

very

careful

not

to

damage

machined

sealing

surface

b

00

not

reuse

gaskets

AC815

Fig

AC

59

Removing

Gasket

INSTALLATION

Valves

and

valve

plates

are

furnish

ed

only

as

a

complete

assembly

8

AC872

Fig

AC

60

Valve

Plate

Assembly

I

Apply

a

thin

mm

of

clean

refri

geration

oil

on

area

of

crankcase

to

be

covered

by

cylinder

gasket

Fig

AC

61

Applying

Clean

Refrigeration

Oil

AC

30

2

Place

cylinder

gasket

in

position

on

cylinder

so

dowel

pins

in

crankcase

go

through

dowel

pin

holes

in

cylinder

gasket

3

Apply

a

thin

flim

of

clean

refri

geralion

oil

to

top

and

bottom

valve

plate

areas

to

be

covered

by

gaskets

4

Place

valve

plate

in

position

on

cylinder

gasket

so

discharge

valve

as

semblies

I

e

smaller

diameter

assem

blies

with

restrainer

over

valve

reed

are

facing

up

and

locating

dowel

pins

go

through

dowel

pin

holes

in

valve

plate

AC817

Fig

AC

62

Placing

Valve

Plate

5

Place

head

gasket

in

position

on

valve

plate

so

dowel

pins

go

through

dowel

pin

holes

in

gasket

6

Apply

a

thin

mm

of

clean

refri

geration

oil

on

the

machined

surface

of

cylinder

head

which

matches

head

gasket

7

Place

head

on

cylinder

head

gas

ket

so

dowel

pins

go

into

dowel

pin

holes

in

head

8

Tighten

screws

to

specified

limit

iil

Tightening

torque

Cvlinder

head

screws

2

1

to

3

2

kg

m

15

to

23

ft

Ibl

DISCHARGE

AND

SUCTION

CONNECTORS

Discharge

and

suction

connectors

are

located

on

rear

side

of

compressor

Page 532 of 548

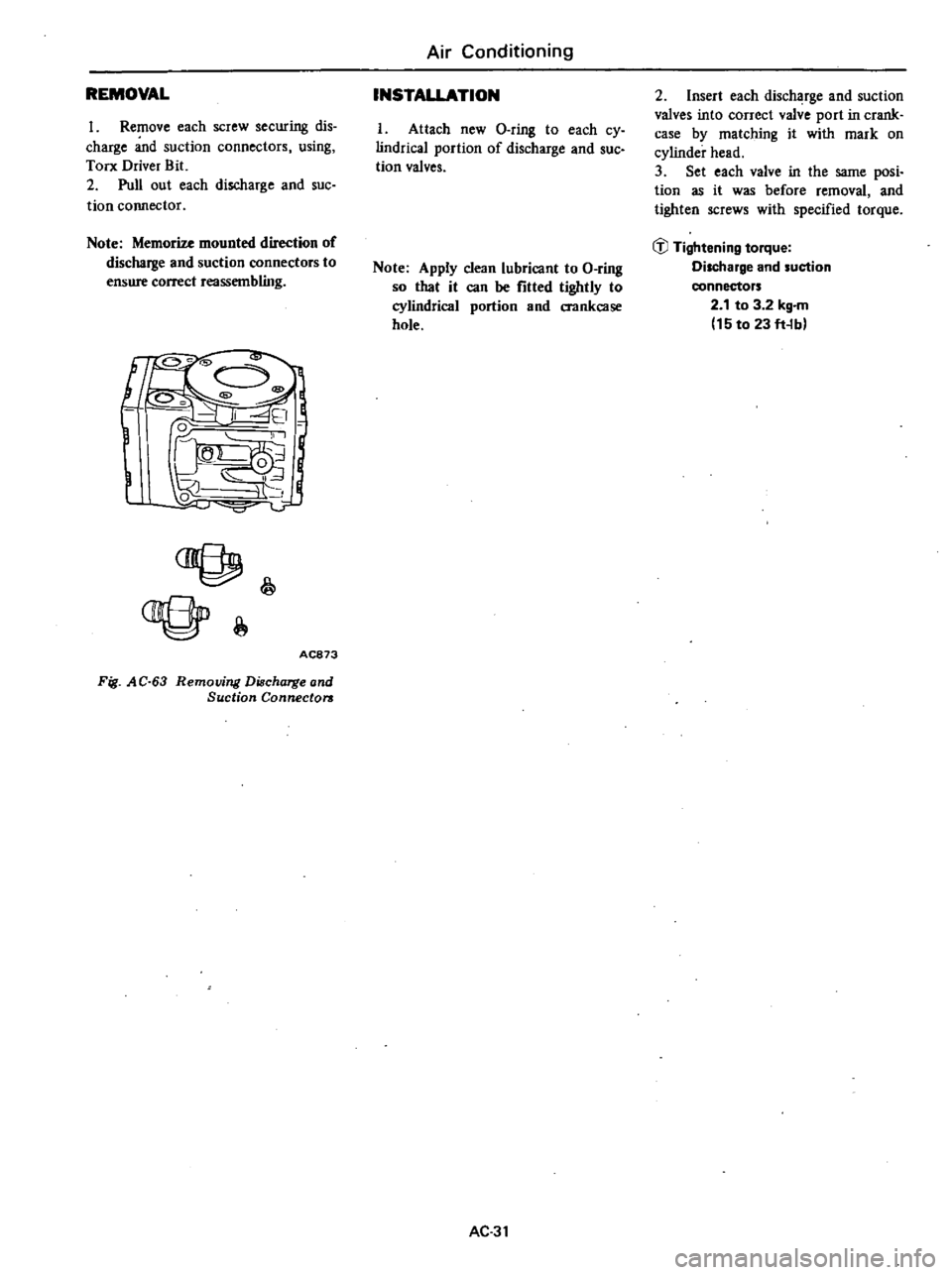

REMOVAL

1

Remove

each

screw

securing

dis

charge

and

suction

connectors

using

TOD

Driver

Bit

2

Pull

out

each

discharge

and

suc

tion

connector

Note

Memorize

mounted

direction

of

discharge

and

suction

connectors

to

ensure

correct

reassembling

a@

AC873

Fig

AC

63

Removing

Discharge

and

Suction

Connectors

Air

Conditioning

INSTALLATION

I

Attach

new

O

ring

to

each

cy

lindrical

portion

of

discharge

and

suc

tion

valves

Note

Apply

clean

lubricant

to

O

ring

so

that

it

can

be

fitted

tightly

to

cylindrical

portion

and

crankcase

hole

AC

31

2

Insert

each

discharge

and

suction

valves

into

correct

valve

port

in

crank

case

by

matching

it

with

mark

on

cylinder

head

3

Set

each

valve

in

the

same

posi

tion

as

it

was

before

removal

and

tighten

screws

with

specified

torque

cD

Tightening

torque

Discharge

and

suction

connectors

2

1

to

3

2

kg

m

15

to

23

ft

b

Page 544 of 548

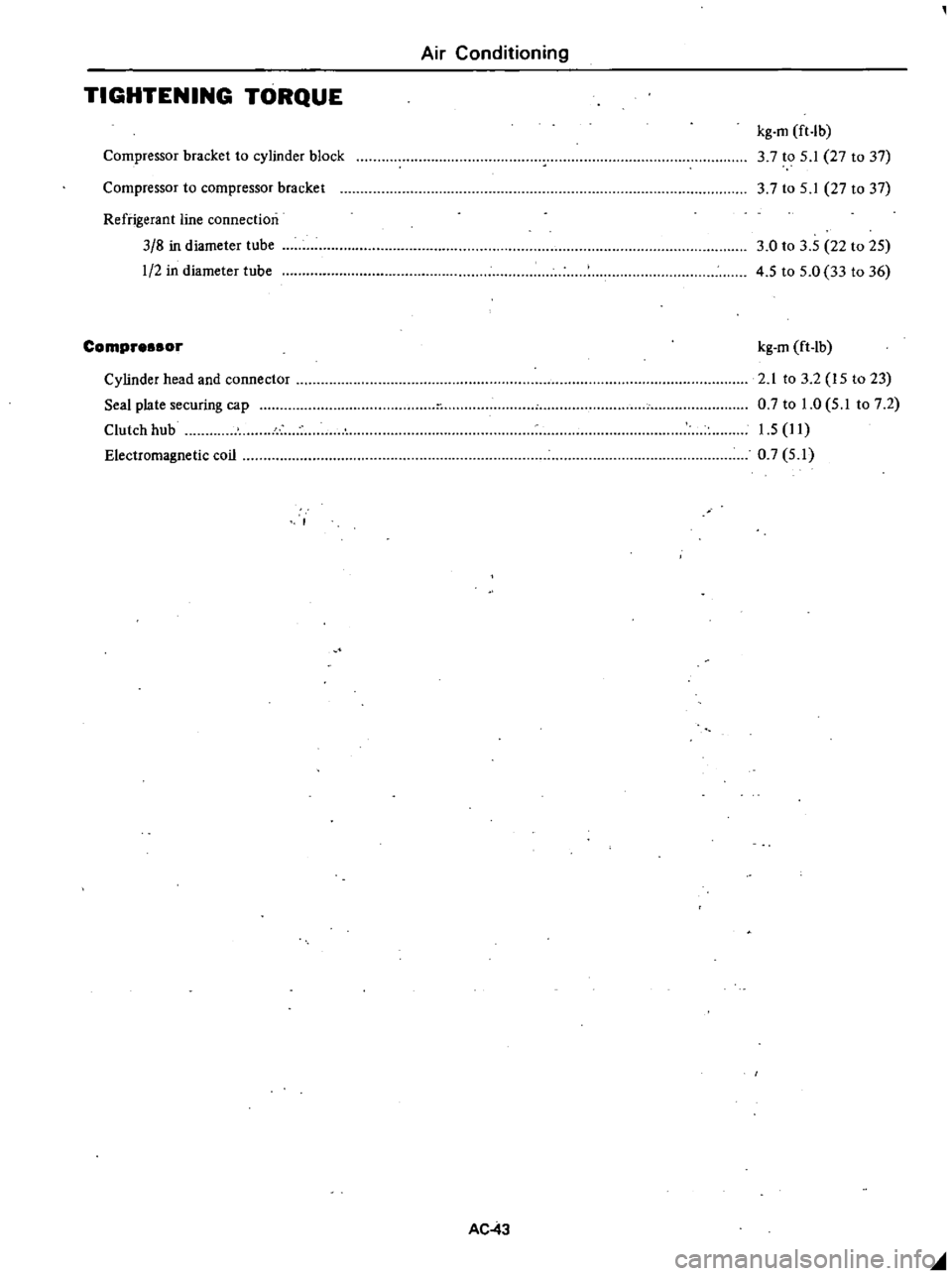

Air

Conditioning

TIGHTENING

TORQUE

Compressor

bracket

to

cylinder

block

kg

m

ft

lb

3

7

to

5

1

27

to

37

37

to

5

1

27

to

37

Compressor

to

compressor

bracket

Refrigerant

line

connection

3

8

in

diameter

tube

1

2

in

diameter

tube

3

0

to

3

5

22

to

25

4

5

to

5

0

33

to

36

Compre

or

Electromagnetic

coil

kg

m

ft

lb

2

1

to

3

2

15

to

23

0

7

to

1

0

5

1

to

7

2

1

5

11

0

7

5

1

Cylinder

head

and

connector

Seal

plate

securing

cap

Clutch

hub

AC

43

olIIl