check oil DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 361 of 548

BR563

Fig

BR

10

Removing

Pad

Inspection

Clean

pads

with

cleaning

solvent

CAUTION

Use

brake

fluid

to

clean

Never

use

mineral

oil

2

When

pads

are

heavily

fouled

with

oil

or

grease

or

when

pad

is

deteriorated

or

deformed

replace

it

3

If

pad

is

worn

to

less

than

the

specified

value

replace

Pad

wear

limit

Minimum

thickness

t

6

mm

0

063

in

Note

Always

replace

pads

in

pad

kit

four

pads

two

clips

four

pad

pins

and

four

pad

springs

4

Check

rotor

referring

to

Rotor

for

inspection

Installetlon

I

Clean

and

apply

P

RC

grease

on

yoke

guide

groove

of

cylinder

body

sliding

contact

portions

of

yoke

and

end

surface

of

piston

Note

a

Do

not

use

common

brake

grease

b

Be

careful

not

to

get

brake

grease

on

rotor

and

pads

2

Loosen

air

bleeder

and

push

pis

ton

B

outer

piston

in

cylinder

until

end

surface

of

piston

B

coincides

with

end

surface

of

retaining

ring

on

boot

Then

inner

pad

can

be

installed

Brake

System

BR564

Fig

BR

11

Pushing

Piston

CAUTION

Piston

can

be

easily

pushed

in

by

hand

but

if

pushed

too

far

groove

of

piston

will

go

inside

of

piston

seal

as

shown

in

Fig

BR

12

At

this

point

if

piston

is

pressured

or

moved

piston

seal

will

be

damaged

If

piston

has

been

pushed

in

too

far

remove

brake

assembly

and

disassemble

it

Then

push

piston

out

in

the

direction

shown

by

arrow

Assemble

it

again

referring

to

follow

ing

section

00

I

Normal

I

position

L

BR409

Fig

BR

12

Position

for

Pushing

Piston

3

Push

piston

A

inner

piston

in

cylinder

by

pulling

yoke

as

shown

The

outer

pad

can

then

be

installed

BRS6S

Fig

BR

13

Pulling

in

Piston

A

BR

7

4

After

installing

pads

depress

brake

pedal

several

times

and

pads

will

settle

into

proper

position

Note

When

worn

out

pads

are

re

placed

with

new

ones

brake

fluid

may

overflow

reservoir

While

re

placing

pads

keep

loosening

bleeder

to

release

brake

fluid

5

Install

wheels

and

lower

car

to

ground

REMOVAL

I

Remove

pads

Refer

to

Pad

Re

placement

2

Remove

brake

tube

from

caliper

assembly

CAUTION

When

removing

brake

tube

use

suit

able

tube

wrench

Never

use

open

end

or

adjustable

wrench

Note

Plug

up

hole

in

caliper

so

that

brake

fluid

does

not

flow

out

from

cylinder

body

3

Loosen

bolts

securing

cylinder

body

to

knuckle

spindle

and

remove

caliper

assembly

from

strut

DISASSEMBLY

I

Drain

brake

fluid

from

top

hole

of

cylinder

body

2

Push

both

pistons

A

and

B

into

cylinder

Refer

to

Pad

Replacement

3

Tap

cylinder

body

lightly

with

a

plastic

hammer

Cylinder

will

then

separate

from

yoke

BR115A

Fig

BR

14

Tapping

Cylinder

Block

Page 362 of 548

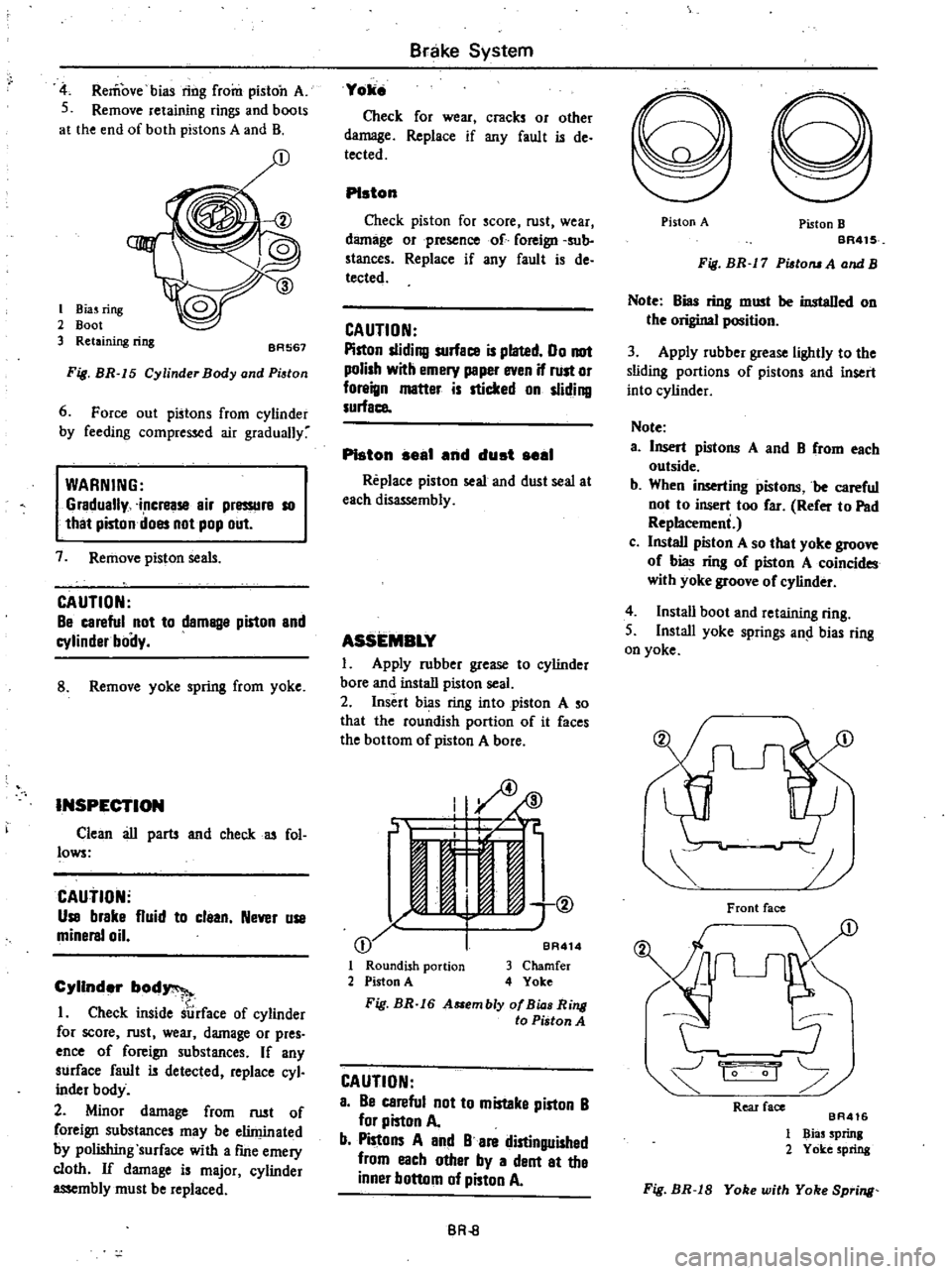

Remove

bias

ring

from

piston

A

S

Remove

retaining

rings

and

boots

at

the

end

of

both

pistons

A

and

B

I

Biuring

2

Boot

3

Retaining

ring

BA567

Fig

BR

15

Cylinder

Body

and

Pi

tan

6

Force

out

pistons

from

cylinder

by

feeding

compressed

air

gradually

WARNING

Gradually

increase

air

pressurs

10

that

piston

does

not

pop

out

7

Remove

piston

seals

CAUTION

Be

careful

not

to

damBlle

piston

and

cylinder

boily

8

Remove

yoke

spring

from

yoke

INSPECTION

Clean

au

parts

and

check

u

fol

lows

CAutiON

Use

brake

fluid

to

claan

Never

use

minersl

oil

Cylinder

bod

1

Check

inside

surface

of

cylinder

for

score

rust

wear

damage

or

pres

ence

of

foreign

substances

If

any

surface

fault

is

detected

replace

cyl

inder

body

2

Minor

damage

from

rust

of

foreign

substances

may

be

eliminated

by

polishing

surface

with

a

fme

emery

cloth

If

damage

is

major

cylinder

assembly

must

be

replaced

Brake

System

Yoke

Check

for

wear

cracks

or

other

damage

Replace

if

any

fault

is

de

tected

PIston

Check

piston

for

score

rust

wear

damage

orpresenco

of

foreign

sub

stances

Replace

if

any

fault

is

de

tected

CAUTION

Piston

sliding

surface

is

plated

00

not

polish

with

emery

peper

even

if

rust

or

foreign

matter

is

sticked

on

sliding

surface

PIston

seal

end

dust

seel

Replace

piston

seal

and

dust

seal

at

each

dis

mbly

ASSEMBLY

1

Apply

rubber

grease

to

cylinder

bore

and

install

piston

seal

2

Insert

bias

ring

into

piston

A

so

that

the

roundish

portion

of

it

faces

the

bottom

of

piston

A

bore

I

ID

J

if

C

jt

11

e

1

@

I

j

BA

I

Roundish

portion

3

Chamfer

2

Piston

A

4

Yoke

Fig

BR

16

A

embly

af

Bia

Ring

to

Piston

A

CAUTION

a

Be

careful

not

to

mistaka

piston

B

for

piston

A

b

Pistons

A

and

B

are

distinguished

from

each

other

by

a

dent

at

the

inner

bottom

of

piston

A

BR

8

Piston

A

Piston

B

BR41S

Fig

BR

17

Pisto

A

and

B

Note

Bias

ring

must

be

instaDed

on

the

original

position

3

Apply

rubber

grease

lightly

to

the

sliding

portions

of

pistons

and

insert

into

cylinder

Note

a

Insert

pistons

A

and

B

from

each

outside

b

When

inserting

pistons

be

careful

not

to

insert

too

far

Refer

to

Pad

Replacemeni

c

Install

piston

A

so

that

yoke

groove

of

bias

ring

of

piston

A

coincides

with

yoke

groove

of

cylinder

4

Instau

boot

and

retaining

ring

S

Install

yoke

springs

an

bias

ring

on

yoke

Front

face

1

1

0

Rear

face

BA416

1

Bias

Sprinl

2

Yoke

spring

Fig

BR

18

Yoke

with

Yoke

Spring

Page 365 of 548

INSPECTION

Brake

drum

I

Check

inner

diameter

of

brake

drum

to

make

sure

it

is

properly

round

and

tapered

If

it

is

not

repair

or

replace

brake

drum

Inner

diameter

Standard

diametel

203

2

mm

8

in

Maximum

diameter

204

5

mm

8

05

in

Out

of

loundness

ellipticity

less

than

0

02

mm

0

0008

in

Radial

runout

less

than

0

1

mm

0

004

in

Total

indicator

reading

Taper

less

than

0

02

mm

0

0008

in

Measured

at

a

point

40

mm

1

57

in

flam

inlet

2

Contact

surface

with

which

lin

ings

come

into

contact

should

be

fine

finished

with

No

120

to

150

sandpaper

3

Using

a

drum

racer

finish

brake

drum

by

machining

if

it

shows

any

sign

of

score

marks

partial

wear

or

stepped

wear

on

its

contact

surface

Note

After

brake

drum

has

been

completely

re

conditioned

or

re

placed

check

drum

and

shoes

for

proper

contact

pattern

Brake

e

embly

1

Replace

any

linings

which

are

cracked

worn

or

oil

stained

2

If

lining

is

worn

to

less

than

the

specified

value

replace

Lining

wear

limit

Minimum

thickness

1

5

mm

0

059

in

3

Replace

any

shoe

return

springs

which

are

broken

or

fatigued

4

Replace

fatigued

anti

rattle

spring

damaged

pin

and

or

retainer

Wheel

cylinder

I

Replace

any

cylinder

or

piston

which

is

scratched

scored

or

worn

on

its

sliding

contact

surface

Brake

System

2

Replace

worn

parts

if

piston

to

cylinder

clearance

is

beyond

limit

Piston

ta

cylinder

clearance

less

than

0

15

mm

0

0059

in

3

Replace

any

piston

cup

which

is

worn

or

otherwise

damaged

4

Replace

if

contacting

face

of

cyl

inder

and

shoe

is

worn

locally

or

in

step

5

Replace

any

damaged

dust

cover

fatigued

piston

spring

or

faulty

thread

ed

parts

6

Replace

any

tube

connector

which

is

worn

on

its

threaded

portion

INSTALLATION

Install

rear

brake

in

reverse

order

of

removal

closely

observing

the

follow

ing

1

Tighten

following

parts

to

speci

fied

torque

CAUTION

When

installing

brake

tube

use

Flare

Nut

Torque

Wrench

6694310000

ifl

Tightening

torque

Flared

nut

1

5

to

1

8

kg

m

11

to

13

fHb

Ail

bleedel

0

7

to

0

9

kg

m

15

1

to

6

5

ft

Ib

Wheel

cylinder

mounting

bolt

0

6

to

0

8

kg

m

4

3

to

5

8

ft

b

2

There

are

two

types

of

adjusters

which

have

right

thread

or

left

thread

R

H

brake

Right

thread

adjuster

L

H

brake

Left

thread

adjuster

3

Sparingly

apply

a

coat

of

brake

grease

to

the

following

points

Lubricating

points

e

Adjuster

nut

and

rod

threads

Mating

surfaces

between

adjuster

and

toggle

lever

and

pin

and

roller

BR

ll

0

J

o

BR

117

A

Fig

BR

24

Lubricating

Points

of

Adju

ter

4

Referring

to

Fig

BR

25

for

locations

of

lubricating

points

apply

a

coat

of

brake

grease

to

these

points

Exercise

care

not

to

allow

grease

to

come

into

contact

with

lining

or

ad

juster

screws

Lubricating

points

e

Contact

areas

between

wheel

cyl

inder

anchor

block

and

brake

shoe

e

Mating

surfaces

between

brake

shoe

and

brake

disc

Contact

areas

between

hand

brake

adjuster

and

brake

shoe

Contact

areas

between

brake

disc

brake

shoe

and

toggle

lever

Contact

areas

between

anti

rattle

pin

spring

retainer

and

brake

shoe

Fig

BR

25

Lubricating

Points

5

To

prevent

water

from

entering

brake

drum

apply

dry

sealant

to

brake

disc

mounting

surfaces

of

the

follow

ing

parts

Wheel

cylinder

Anti

rattle

spring

6

Make

sure

that

entire

brake

shoe

fits

in

place

7

Make

sure

that

adjuster

operates

properly

8

After

installation

is

completed

check

and

adjust

shoe

to

drum

clear

ance

by

operating

hand

brake

several

times

9

Bleed

brake

system

Page 366 of 548

BRAKE

BOOSTE

R

INSPECTION

OF

OPERATION

Checking

vecuum

pressure

I

Connect

a

vacuum

gauge

in

the

tine

between

check

velve

and

brake

booster

1

Check

valVe

2

Vacuum

gauge

BA942

Fig

BR

26

Air

Tighte

Te

Set

Up

Probable

cause

Air

leakage

at

check

valve

2

Air

leakage

at

push

rod

seal

3

Air

leakage

between

valve

body

and

seal

4

Air

leakage

at

valve

plunger

seat

5

Damaged

piping

or

joints

Air

tight

test

Under

loed

Fifteen

seconds

after

engine

is

stopped

and

brake

fully

applied

ob

serve

the

rate

of

drop

in

air

pressure

registered

by

vacuum

gauge

If

vacuum

Probable

cause

Air

leakage

at

check

valve

2

Damaged

diaphragm

3

Reaction

disc

dropped

off

4

Air

leakage

at

poppet

assembly

seat

and

valve

body

Inspec

tinK

chec

k

valve

Remove

clip

and

disconnect

hoses

Brake

System

2

Start

engine

end

merease

engine

speed

Stop

engine

when

vacuum

gauge

indicates

500

mmHg

l9

69

inHg

Air

tiKht

test

No

load

Fifteen

seconds

after

engine

is

stopped

observe

the

rate

of

drop

in

air

pressure

registered

by

vacuum

gauge

If

vacuum

pressure

drop

below

the

specified

value

refer

to

the

following

chart

to

determine

the

cause

of

failure

Maximum

vacuum

leakage

25

mmHg

0

98

inHgl

Corrective

action

Replace

check

valve

Replace

brake

booster

as

an

assembly

Repair

or

replace

pressure

drops

below

the

specified

value

refer

to

the

following

chart

to

determine

the

cause

of

failure

Maximum

vacuum

leakage

25

mmHg

0

98

inHgl

Corrective

action

Replace

check

valve

Replace

brake

booster

as

an

assembly

at

connections

The

check

valve

can

now

be

removed

BR

12

JQeL

i

l

f

BR119A

Fis

BR

27

Location

of

Check

Valllt

2

Using

a

brake

booster

testel

apply

a

vacuum

pressure

of

500

mmHg

19

69

inHg

to

the

port

of

check

valve

on

the

brake

booster

side

If

vacuum

pressure

drops

below

the

specified

value

in

15

seconds

replace

check

valve

with

a

new

one

Maximum

vacuum

leakage

01

eheck

valn

10

mmHg

0

39

inHgl

3

When

pressure

is

applied

to

the

b

rake

booster

side

of

check

valve

and

valve

does

not

open

replace

check

valve

with

a

new

one

I

0

tLLiJ

Manifold

side

Brake

booster

side

1

Spring

2

Valve

BR963

Fig

BR

28

Check

Value

4

When

installing

check

valve

be

careful

to

avoid

incorrect

connectiolU

See

Fig

DR

28

Operetlns

test

1

Connect

an

oil

pressure

gauge

to

brake

ine

at

connection

on

master

cylinder

2

Install

a

pedal

force

gauge

on

brake

pedal

3

Start

engine

end

increase

engine

speed

until

a

vacuum

pressure

of

500

mmHg

19

69

inHg

is

registered

on

vacuum

pressure

gauge

With

a

steady

vacuum

pressure

of

500

mmHg

19

69

inHg

measure

oil

pressure

with

res

pect

to

each

pedal

operating

force

Page 367 of 548

Relationship

between

oil

pressure

and

pedal

operating

force

is

illustrated

in

Fig

BR

29

If

test

results

are

not

as

specified

in

Fig

BR

29

check

brake

booster

for

condition

in

manner

des

cribed

under

Inspection

before

re

moval

of

this

unit

REMOVAL

M60

120

1

710

AA

I

1

1

110

1

560

1

v

e

100

1

420

I

90

1

280

I

1

1

80

1

140

I

Z

I

t

70

1

000

i

60

850

I

o

50

710

d

40

570

g

i

gl

j

ll

10

140

J

0

1

0

2

0

221

441

Rod

operating

force

kg

lb

Brake

System

Also

check

brake

line

for

evidence

of

fluid

leakage

Note

Detennine

whether

source

of

problem

is

in

brake

booster

or

check

valve

Before

you

reach

a

fmal

conclusion

always

inspect

check

valve

first

o

10

20

30

40

50

22

44

66

88

110

Pedal

operating

force

kg

lb

BA121A

Fig

BR

29

Performance

Diagram

of

Brake

Booster

Remo

parts

in

numerical

order

enumerated

BR593

ti

J

Fig

BR

30

Procedures

for

Removing

Brake

Booster

ADJUSTMENT

I

Adjust

the

length

of

push

rod

to

the

value

indicated

below

Length

ad

justment

of

push

rod

is

made

at

the

tip

of

push

rod

Length

A

9

75

to

10

00

mm

0

3839

to

0

3937

in

j

f

Irl

I

l

if

L

J

BA290

Fig

BR

31

Length

A

BR

13

BR288

Fig

BR

32

Adjusting

Push

Rod

Length

2

Install

clevis

Adjust

length

of

operating

rod

to

specified

value

length

B

135

mm

5

31

in

c

f

lIJ

t

t

B

BR947

Fig

BR

33

Length

B

INSTALLATION

Install

in

the

reverse

sequence

of

removaJ

IiJ

Tightening

torque

Master

cylinder

to

brake

booster

0

8

to

1

1

kg

m

5

8

to

8

0

ft

Ib

Brake

booster

to

body

0

8

to

1

1

kg

m

5

8

to

8

0

ft

lbl

Note

After

brake

boOster

is

properly

installed

in

car

conduct

an

air

tight

and

op

rational

tests

as

previously

described

Page 373 of 548

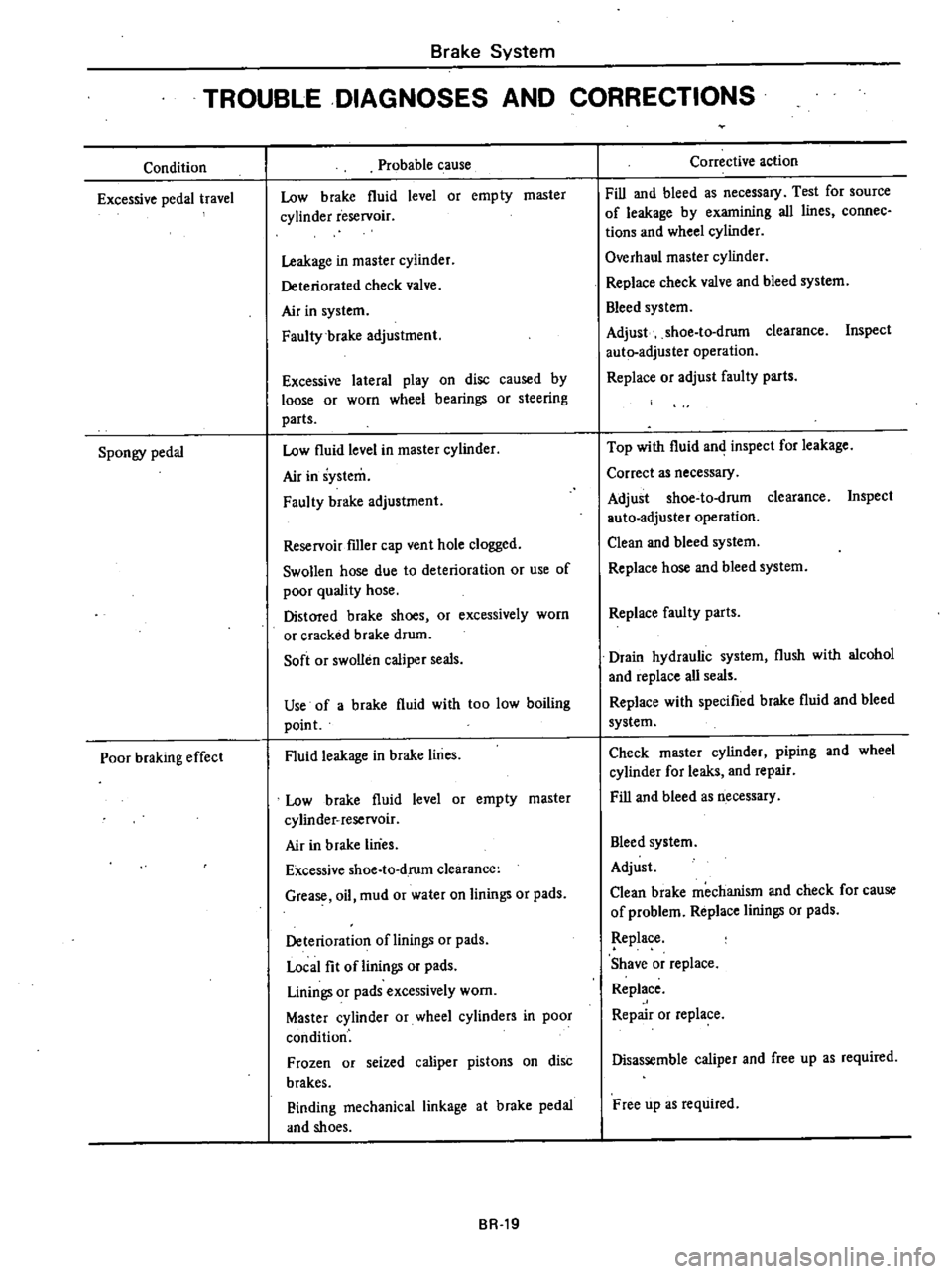

Brake

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Excessive

pedal

travel

Spongy

pedal

Poor

braking

effect

Probable

cause

Low

brake

fluid

level

or

empty

master

cyUnder

reservoir

Leakage

in

master

cylinder

Deteriorated

check

valve

Air

in

system

Faulty

brake

adjustment

Excessive

lateral

play

on

disc

caused

by

loose

or

worn

wheel

bearings

or

steering

parts

Low

fluid

level

in

master

cylinder

Air

in

system

Faulty

brake

adjustment

Reservoir

fIller

cap

vent

hole

clogged

Swollen

hose

due

to

deterioration

or

use

of

poor

quality

hose

Distored

brake

shoes

or

excessively

worn

or

cracked

brake

drum

Soft

or

swollen

caliper

seals

Use

of

a

brake

fluid

with

too

low

boiling

point

Fluid

leakage

in

brake

lines

Low

brake

fluid

level

or

empty

master

cylinder

reservoir

Air

in

brake

lines

Excessive

shoe

to

d

rum

clearance

Grease

oil

mud

or

water

on

linings

or

pads

Deterioration

of

linings

or

pads

Local

fit

of

linings

or

pads

Linings

or

pads

excessively

worn

Master

cylinder

or

wheel

cylinders

in

poor

condition

Frozen

or

seized

caliper

pistons

on

disc

brakes

Finding

mechanical

linkage

at

brake

pedal

and

shoes

BR

19

Corrective

action

Fill

and

bleed

as

necessary

Test

for

source

of

leakage

by

examining

all

lines

connec

tions

and

wheel

cylinder

Overhaul

master

cylinder

Replace

check

valve

and

bleed

system

Bleed

system

Adjust

shoe

to

drum

clearance

Inspect

auto

adjuster

operation

Replace

or

adjust

faulty

parts

Top

with

fluid

and

inspect

for

leakage

Correct

as

necessary

Adjust

shoe

to

drum

clearance

Inspect

auto

adjuster

operation

Clean

and

bleed

system

Replace

hose

and

bleed

system

Replace

faul

ty

parts

Drain

hydraulic

system

flush

with

alcohol

and

replace

all

seals

Replace

with

specified

brake

fluid

and

bleed

system

Check

master

cylinder

p

pmg

and

wheel

cylinder

for

leaks

and

repair

Fill

and

bleed

as

necessary

Bleed

system

Adjust

Clean

brake

mechanism

and

check

for

cause

of

problem

Replace

linings

or

pads

Replace

Shave

or

replace

Replace

Repair

or

replace

Disassemble

caliper

and

free

up

as

required

Free

up

as

required

Page 374 of 548

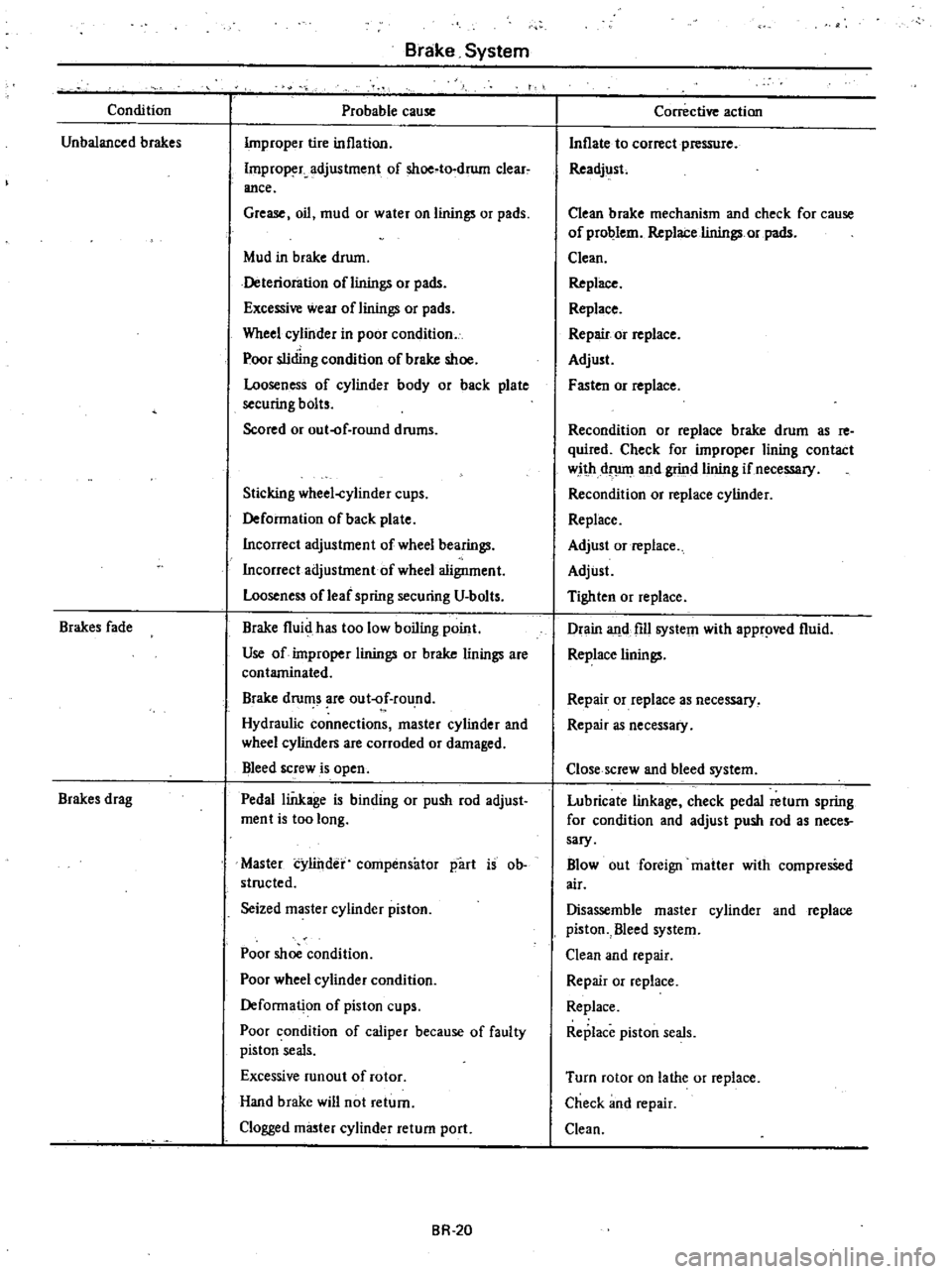

Condition

Unbalanced

brakes

Brakes

fade

Brakes

drag

Brake

System

Probable

cause

Improper

tire

inflation

Improp

r

adjustment

of

shoe

to

drum

clear

ance

Grease

oil

mud

or

water

on

linings

or

pads

Mud

in

brake

drum

Deterioration

oflinings

or

pads

Excessi

wear

of

linings

or

pads

Wheel

cylinder

in

poor

condition

Poor

sliding

condition

of

brake

shoe

Looseness

of

cylinder

body

or

back

plate

securing

bolts

Scored

or

out

f

round

drums

Sticking

wheel

cylinder

cups

Deformation

of

back

plate

Incorrect

adjustment

of

wheel

bearings

Incorrect

adjustment

of

wheel

aligoment

Looseness

of

leaf

spring

securing

U

bolts

Brake

fluid

has

too

low

boiling

point

Use

of

improper

linings

or

brake

linings

are

contaminated

Brake

drums

are

out

f

round

Hydraulic

connections

master

cylinder

and

wheel

cylinders

are

corroded

or

damaged

Bleed

screw

is

open

Pedal

linkage

is

binding

or

push

rod

adjust

ment

is

too

long

Master

cylinder

compensator

part

is

ob

structed

Seized

master

cylinder

piston

Poor

shoe

condition

Poor

wheel

cylinder

condition

Deformation

of

piston

cups

Poor

condition

of

caliper

because

of

faulty

piston

seals

Excessive

runaut

of

rotor

Hand

brake

will

not

return

Clogged

m

ter

cylinder

return

port

BR

20

Corrective

action

Inflate

to

correct

pressure

Readjust

Clean

brake

mechanism

and

check

for

cause

of

problem

Replace

linings

or

pads

Clean

Replace

Replace

Repair

or

replace

Adjust

F

ten

or

replace

Recondition

or

replace

brake

drum

as

re

quired

Check

for

improper

lining

contact

with

dflllll

and

grind

lining

if

necessary

Recondition

or

replace

cylinder

Replace

Adjust

or

replace

Adjust

Tighten

or

replace

Drain

and

fill

system

with

appr

d

fluid

Replace

linings

Repair

or

replace

as

necessary

Repair

as

necessary

Close

screw

and

bleed

system

Lubricate

linkage

check

pedal

return

spring

for

condition

and

adjust

push

rod

as

neces

sary

Blowout

foreign

matter

with

compresSed

air

Disassemble

master

cylinder

and

replace

piston

Bleed

system

Clean

and

repair

Repair

or

replace

Replace

Replace

piston

seals

Turn

rotor

on

lathe

or

replace

Check

and

repair

Clean

Page 375 of 548

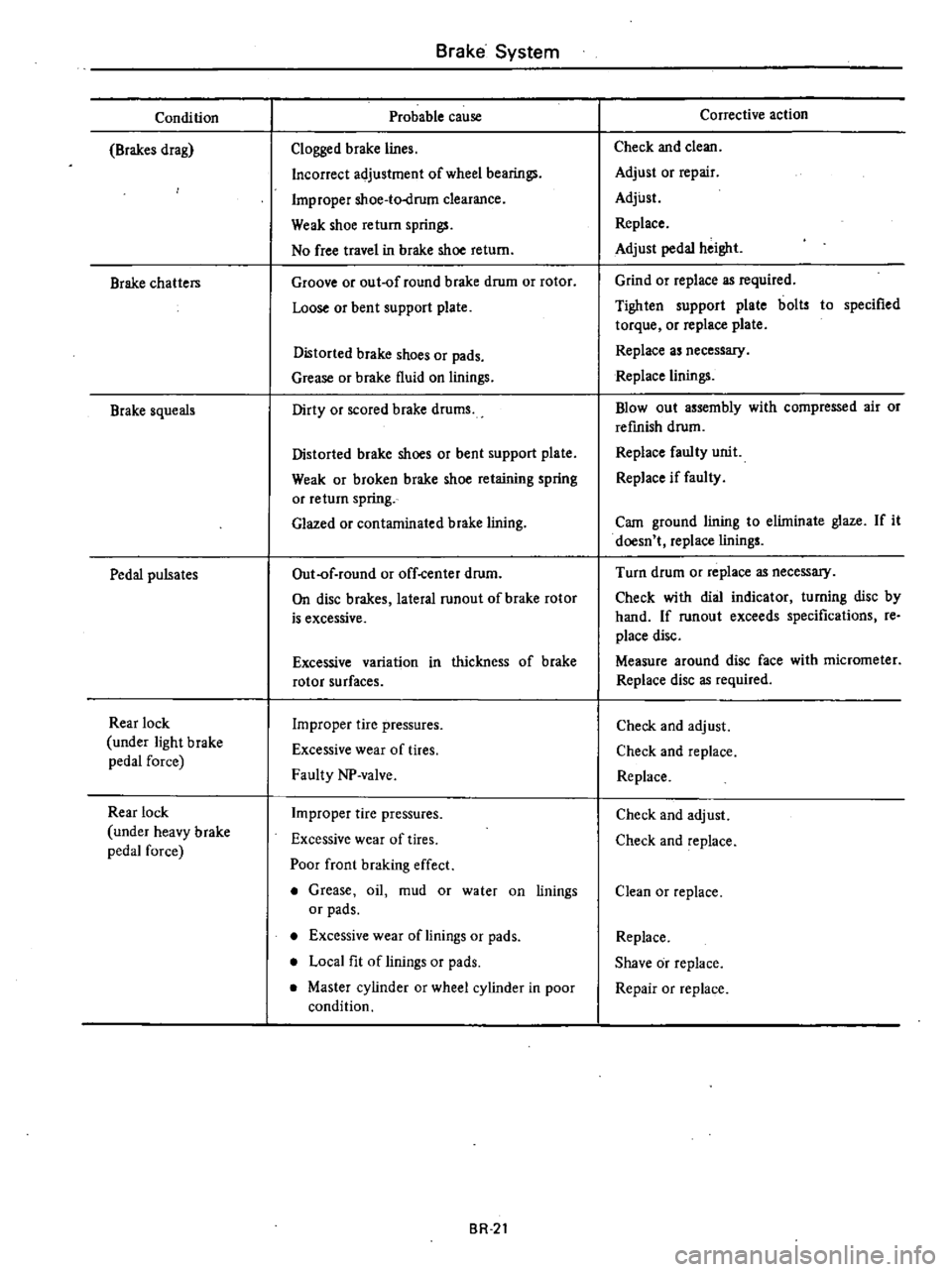

Condition

Brakes

drag

Brake

chatters

Brake

squeals

Pedal

pulsates

Rear

lock

under

light

brake

pedal

force

Rear

lock

under

heavy

brake

pedal

force

Brake

System

Probable

cause

Clogged

brake

lines

Incorrect

adjustment

of

wheel

bearings

Improper

shoe

to

drum

clearance

Weak

shoe

return

springs

No

free

travel

in

brake

shoe

return

Groove

or

out

of

round

brake

drum

or

rotor

Loose

or

bent

support

plate

Distorted

brake

shoes

or

pads

Grease

or

brake

fluid

on

linings

Dirty

or

scored

brake

drums

Distorted

brake

shoes

or

bent

support

plate

Weak

or

broken

brake

shoe

retaining

spring

or

return

spring

Glazed

or

contaminated

brake

lining

Out

of

round

or

off

center

drum

On

disc

brakes

lateral

runout

of

brake

rotor

is

excessive

Excessive

variation

in

thickness

of

brake

rotor

surfaces

Improper

tire

pressures

Excessive

wear

of

tires

Faulty

NP

valve

Improper

tire

pressures

Excessive

wear

of

tires

Poor

front

braking

effect

Grease

oil

mud

or

water

on

linings

or

pads

Excessive

wear

of

linings

or

pads

Local

fit

of

linings

or

pads

Master

cylinder

or

wheel

cylinder

in

poor

condition

BR

2t

Corrective

action

Check

and

clean

Adjust

or

repair

Adjust

Replace

Adjust

pedal

height

Grind

or

replace

as

required

Tighten

support

plate

bolts

to

specified

torque

or

replace

plate

Replace

as

necessary

Replace

linings

Blowout

assembly

with

compressed

air

or

refinish

drum

Replace

faulty

unit

Replace

if

faulty

Cam

ground

lining

to

elilninate

glaze

If

it

doesn

t

replace

linings

Turn

drum

or

replace

as

necessary

Check

with

dial

indicator

turning

disc

by

hand

If

runout

exceeds

specifications

re

place

disc

Measure

around

disc

face

with

micrometer

Replace

disc

as

required

Check

and

adjust

Check

and

replace

Replace

Check

and

adjust

Check

and

replace

Clean

or

replace

Replace

Shave

or

replace

Repair

or

replace

Page 390 of 548

CAUTION

a

Be

careful

not

to

allow

ball

nut

to

run

down

to

either

end

of

worm

The

ends

of

ball

guides

will

be

damaged

if

nut

is

rotated

until

it

stops

at

the

end

of

worm

b

00

not

detach

ball

nut

from

worm

shaft

assembly

If

necessary

replace

assembly

c

Do

not

remove

sector

shaft

bush

ings

from

steering

gear

housing

If

necessary

replace

gear

housing

assembly

d

Be

careful

not

to

allow

penetration

of

any

other

element

like

dust

or

dirt

Inspection

Wash

clean

all

the

disassembled

parts

in

cleaning

solvent

and

check

for

condition

Sector

shaft

I

Check

gear

tooth

surface

for

pitting

burrs

cracks

or

any

other

damage

and

replace

if

damaged

2

Check

sector

shaft

for

distortion

of

its

serration

and

if

necessary

re

place

In

this

case

be

8ure

to

check

gear

housing

and

steering

worm

as

sembly

for

deformation

Steering

worm

assembly

I

Inspect

ball

nut

gear

tooth

sur

face

and

replace

if

pitting

burrs

wear

or

any

other

damage

is

found

2

Ball

nut

must

rotate

smoothly

on

worm

gear

If

found

too

tight

as

sembly

should

be

replaced

Check

as

follows

I

Move

ball

nut

to

either

end

of

worm

gear

and

gradually

stand

worm

shaft

and

ball

nut

assembly

until

ball

nut

moves

downward

on

worm

gear

under

its

own

weight

2

In

the

above

test

if

ball

nut

does

not

move

freely

over

entire

stroke

assembly

may

be

damaged

Replace

with

a

new

one

Note

In

this

inspection

be

careful

not

to

damage

ball

nut

guide

tube

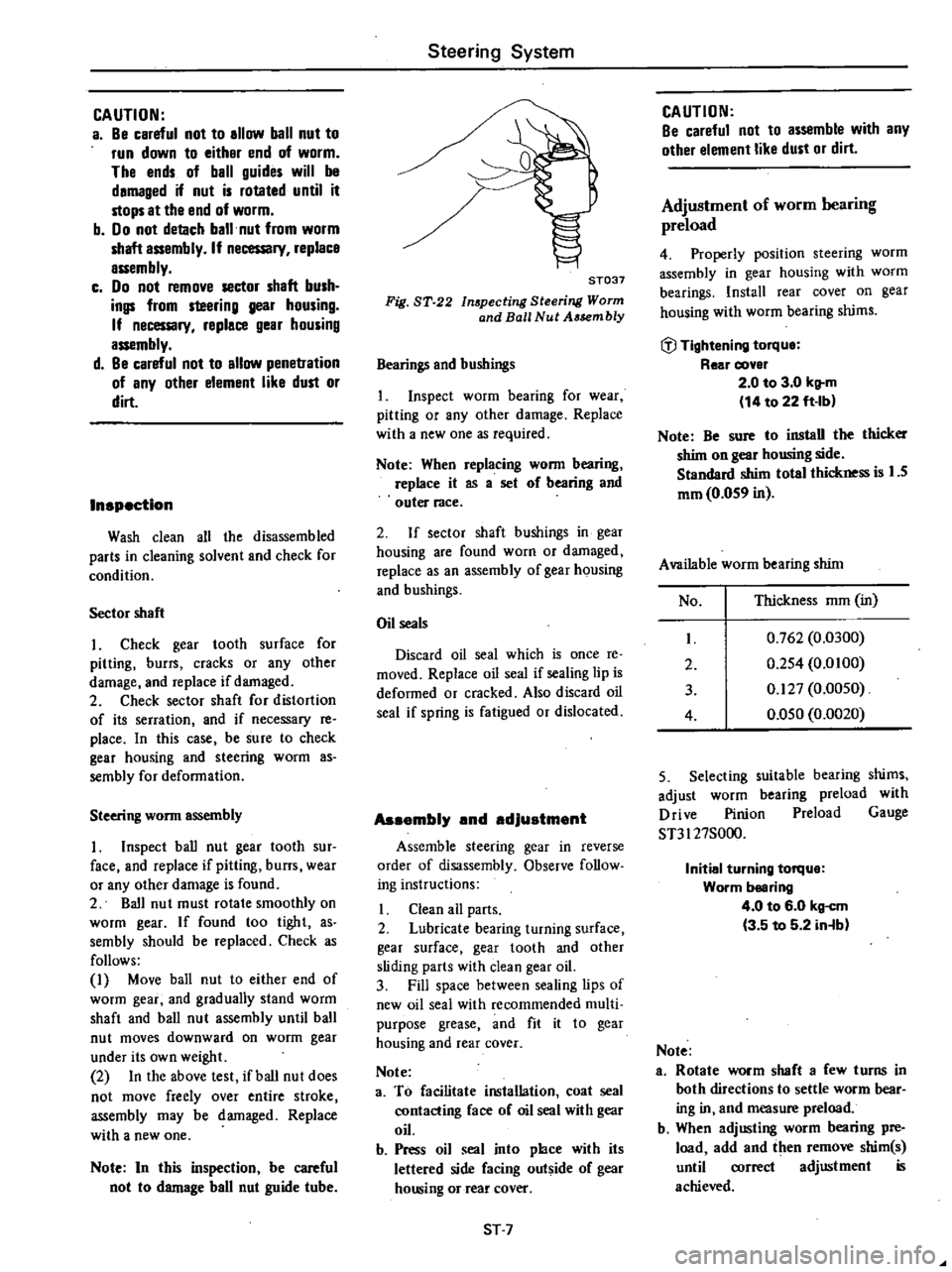

Steering

System

ST037

Fig

ST

22

In

pecting

Steering

Worm

and

Ball

Nut

A8sembly

Bearings

and

bushings

I

Inspect

worm

bearing

for

wear

pitting

or

any

other

damage

Replace

with

a

new

one

as

required

Note

When

replacing

worm

bearing

replace

it

as

a

set

of

bearing

and

outer

race

2

If

sector

shaft

bushings

in

gear

housing

are

found

worn

or

damaged

replace

as

an

assembly

of

gear

housing

and

bushings

Oil

seals

Discard

oil

seal

which

is

once

re

moved

Replace

oil

seal

if

sealing

lip

is

deformed

or

cracked

Also

discard

oil

seal

if

spring

is

fatigued

or

dislocated

Assembly

snd

adjustment

Assemble

steering

gear

in

reverse

order

of

disassembly

Observe

follow

ing

instructions

Clean

all

parts

2

Lubricate

bearing

turning

surface

gear

surface

gear

tooth

and

other

sliding

parts

with

clean

gear

oil

3

Fill

space

between

sealing

lips

of

new

oil

seal

with

recommended

multi

purpose

grease

and

fit

it

to

gear

housing

and

rear

cover

Note

a

To

facilitate

installation

coat

seal

contacting

face

of

oil

seal

with

gear

oil

b

Press

oil

seal

into

place

with

its

lettered

side

facing

outside

of

gear

housing

or

rear

cover

5T

7

CAUTION

Be

careful

not

to

assemble

with

any

other

element

like

dust

or

dirt

Adjustment

of

worm

bearing

preload

4

Properly

position

steering

worm

assembly

in

gear

housing

with

worm

bearings

Install

rear

cover

on

gear

housing

with

worm

bearing

shims

fJ

Tightening

torqu

Rear

coyer

2

0

to

3

0

kltm

14

to

22

ft

Ibl

Note

Be

sure

to

install

the

thicker

shUn

on

gear

housing

side

Standard

shim

total

thickness

is

1

5

mm

0

059

in

Available

worm

bearing

shUn

No

Thickness

mm

in

I

0

762

0

0300

2

0

254

0

0100

3

0

127

0

0050

4

0

050

0

0020

5

Selecting

suitable

bearing

shims

adjust

worm

bearing

preload

with

Drive

Pinion

Preload

Gauge

ST3I

27S000

Initial

turning

torque

Worm

bearing

4

0

to

6

0

kg

m

3

5

to

5

2

in

bl

Note

a

Rotate

worm

shaft

a

few

turns

in

both

directions

to

settle

worm

bear

ing

in

and

measure

preload

b

When

adjusting

worm

bearing

pre

load

add

and

then

remove

shim

s

until

correct

adjustment

is

achieved

Page 393 of 548

REMOVAL

I

Jack

up

the

front

of

car

and

support

it

on

the

safety

stands

2

Remove

cotter

pins

and

nuts

fastening

side

rod

ball

studs

to

knuckle

arms

3

To

detach

side

rod

ball

studs

from

knuckle

arms

iJuert

Steering

BaII

Joint

Remover

HT72520000

between

them

and

separate

them

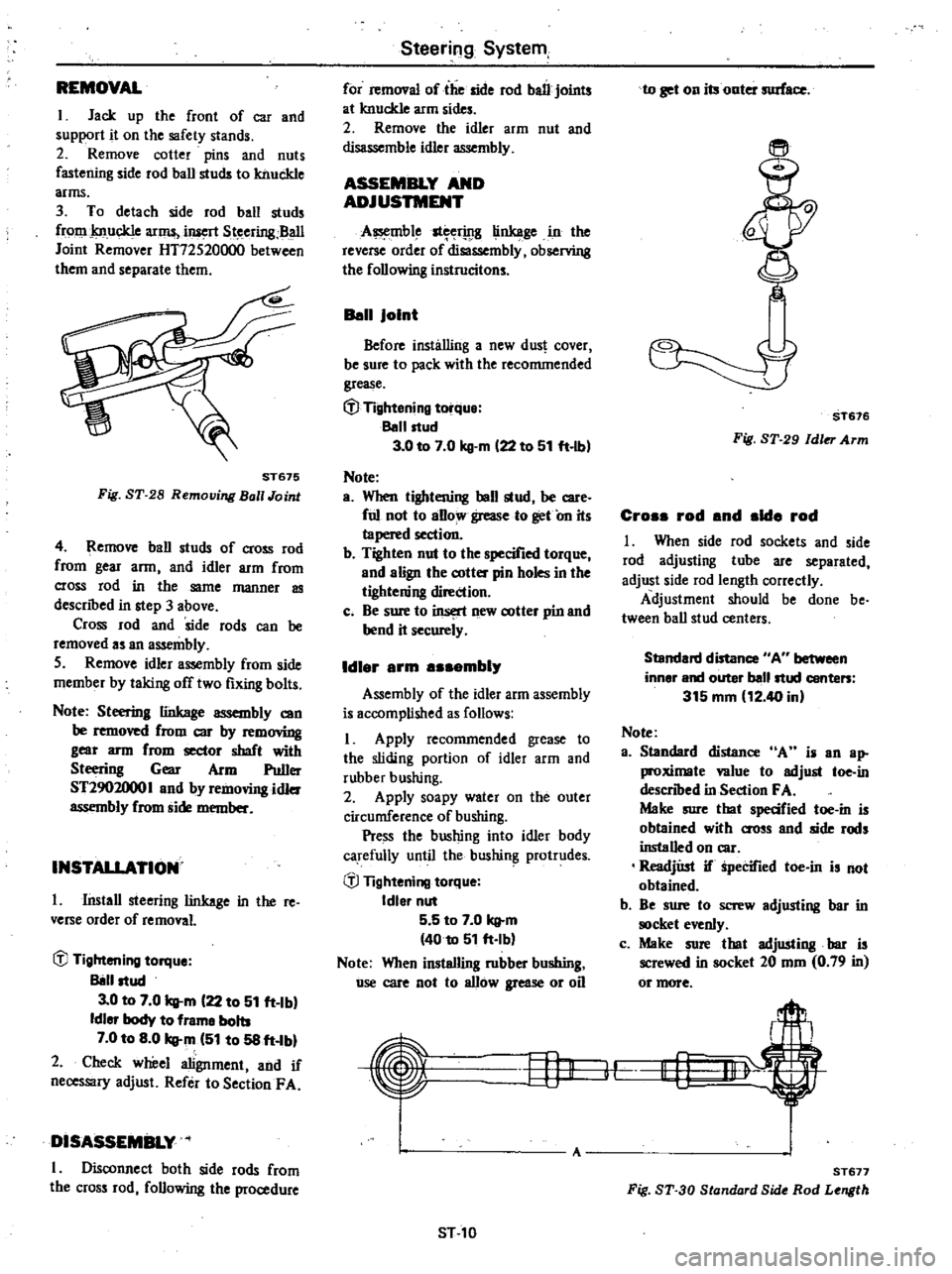

ST675

Fig

ST

28

Remouing

Ball

Joint

4

Remove

ball

studs

of

cross

rod

from

gear

arm

and

idler

arm

from

cross

rod

in

the

same

manner

as

descnbed

in

step

3

above

Cross

rod

and

side

rods

can

be

removed

as

an

assembly

5

Remove

idler

assembly

from

side

member

by

taking

off

two

fixing

bolts

Note

Steering

linkage

assembly

can

be

removed

from

CIC

by

rem

mng

gear

arm

from

sector

shaft

with

Steering

Gear

Arm

Puller

ST2902000

I

and

by

removing

idler

assembly

from

side

member

INSTAllATION

I

Install

steering

linkage

in

the

re

verse

order

of

removal

iJJ

Tightening

torque

Il8l1ltud

3

0

to

7

0

q

m

122

to

51

ft

Ibl

Idler

body

to

frame

bolts

7

0

to

8

0

q

m

151

to

58

ft

Ibl

2

Check

wheel

alignment

and

if

necessary

adjust

Refer

to

SectionF

A

DISASSEMBLY

I

Disconnect

both

side

rods

from

the

cross

rod

following

the

procedure

Steering

System

for

removal

of

the

side

rod

ball

joints

at

knuckle

arm

sides

2

Remove

the

idler

arm

nut

and

disassemble

idler

assembly

ASSEMBLY

AND

ADJUSTMENT

A

mble

st

rwg

linkage

in

the

reverse

order

of

disassembly

observing

the

following

instrucitons

Ban

Joint

Before

installing

a

new

dus

cover

be

sure

to

pack

with

the

recommended

grease

t

J

Tightening

torque

Ballltud

3

0

to

7

0

kg

m

122

to

51

ft

lbl

Note

a

When

tightening

ball

stud

be

care

ful

not

to

aBow

grease

to

get

On

its

tapered

section

b

Tighten

nut

to

the

specified

torque

and

align

the

cotter

pin

holes

in

the

tightening

direction

c

Be

sure

to

insert

new

cotter

pin

and

bend

it

securely

Idl

r

rm

mbl

Assembly

of

the

idler

arm

assembly

is

accomplished

as

follows

I

Apply

recommended

grease

to

the

sliding

portion

of

idler

arm

and

rubber

bushing

2

Apply

soapy

water

on

the

outer

circumference

of

bushing

Pre

ss

the

bushing

into

idler

body

carefully

until

the

bushin

protrudes

iJJ

Tightening

torque

Idler

nut

5

5

to

7

0

q

m

4010

51

ft

Ib

Note

When

installing

rubber

bushing

use

care

not

to

allow

grease

or

oil

Hj1

ST

10

to

get

on

its

onter

surface

ST676

Fig

ST

29

Idler

Arm

Cro

rod

nd

Id

rod

I

When

side

rod

sockets

and

side

rod

adjusting

tube

are

separated

adjust

side

rod

length

correctly

Adjustment

should

be

done

be

tween

ball

stud

centers

Standard

distance

AU

between

inner

and

outer

ballltud

conte

315

mm

12

40

in

Note

a

Standard

distance

A

i

an

ap

proximale

value

to

adjust

toe

in

descnbed

in

Section

FA

Maire

sure

tbat

specified

toe

in

is

obtained

with

O

OSs

and

side

rods

installed

on

car

ReadjUst

if

Specified

toe

in

is

not

obtained

b

Be

sure

to

screw

adjusting

bar

in

clret

evenly

c

Make

sure

that

adjusting

bar

is

screwed

in

socket

20

mm

0

79

in

or

more

I

lf

A

ST

77

Fig

ST

30

Standard

Side

Rod

Length