check oil DATSUN 210 1979 Manual Online

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 292 of 548

Place

the

vehicle

in

a

pit

and

by

sampling

the

lealeed

oil

deiermine

if

it

is

the

torque

converter

oil

The

torque

converter

oil

has

a

color

like

red

wine

so

it

is

easily

distinguished

from

engine

oil

or

gear

oil

Wipe

off

the

lealeing

oil

and

dust

and

detect

the

spot

of

ill

lell8e

nonflammable

organic

solvent

such

as

carbon

tetrachloride

for

wiping

Raise

the

oil

tcmperature

by

op

erating

the

engine

and

shift

the

lever

to

D

to

increase

the

oil

pressure

The

sp

Q

of

o

1

1I8

u

J1en

be

found

more

easily

Note

As

oil

leakage

from

the

breath

er

does

not

talee

place

except

when

running

at

high

peed

it

iSimpos

sible

to

ate

this

lealcage

with

vehicle

stationary

CHECKING

ENGINE

IDLING

REVOLunON

The

engine

idling

revolution

should

be

properly

adjusted

If

the

engine

revolution

is

too

low

the

e

gine

does

not

operate

smoothly

and

if

too

high

a

strong

shocle

or

creep

develops

when

changing

over

from

ON

to

Dn

or

R

CHECKING

AND

ADJUSTING

KICK

WN

SWITCH

AND

DOWNSH

FT

SOLENOID

When

the

Ieickdown

operation

is

not

made

properly

or

the

speed

chang

ingpoint

is

too

high

check

the

kick

down

switch

downshift

solenoid

and

wiring

between

them

When

the

igni

tion

Ieey

is

po

iti

ned

at

the

1st

stage

and

the

accelerator

pedal

is

depressed

deeply

the

switch

contact

hould

be

closed

and

the

solenoid

should

clicle

If

it

does

not

click

it

indicates

a

defect

Then

check

each

part

with

the

testing

inatrumen15

Auto

lT1atic

Transmissiqn

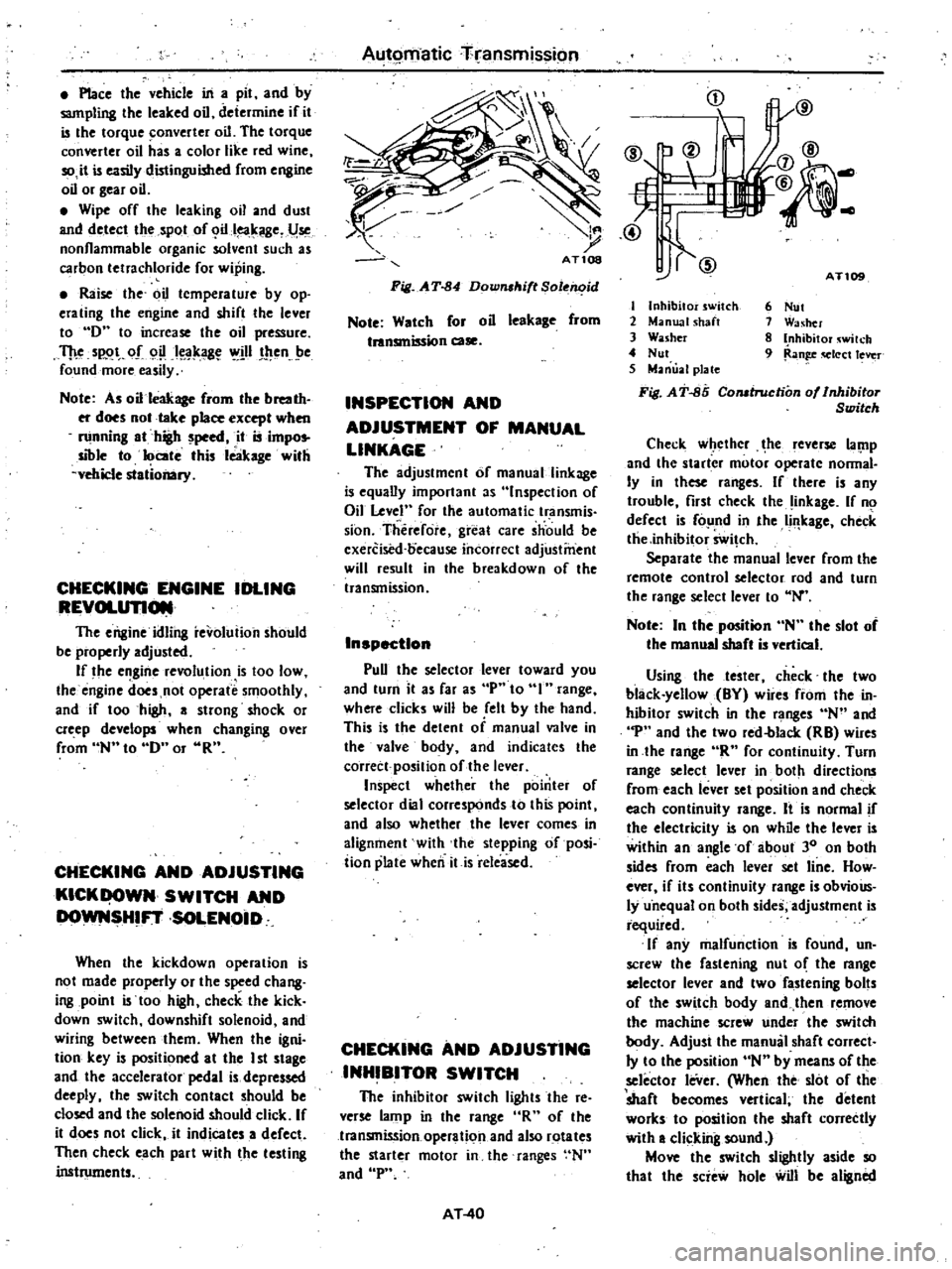

Fi

J

A

T

84

Down

ltift

Sole

id

Note

Watch

for

oil

leekage

from

tnnsmission

case

INSPECTION

AND

ADJUSTMENT

OF

MANUAL

LINKAGE

The

adjustmcnt

of

manual

linkage

i

equany

important

as

Inspection

of

Oil

Level

for

the

automatic

transmis

sion

Therefore

great

care

should

be

cxercised

oecause

incorrect

adjustment

will

result

in

the

breakdown

of

the

transmission

Inspection

pun

the

selector

lever

toward

you

and

turn

it

as

far

as

p

to

range

where

clicks

will

be

ell

by

the

hand

This

is

the

detent

of

manual

valve

in

the

valve

body

and

indicates

the

corrett

position

of

the

lever

Inspect

whether

the

pointer

of

selector

dial

corresponds

to

this

point

and

also

whether

the

lever

comes

in

alignment

with

the

stepping

of

posi

iion

plate

when

itis

released

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

The

inhibitor

switch

lights

the

re

verse

lamp

in

the

range

R

of

the

transmission

operation

and

also

rotates

the

starter

motor

in

the

ranges

N

and

P

AT

40

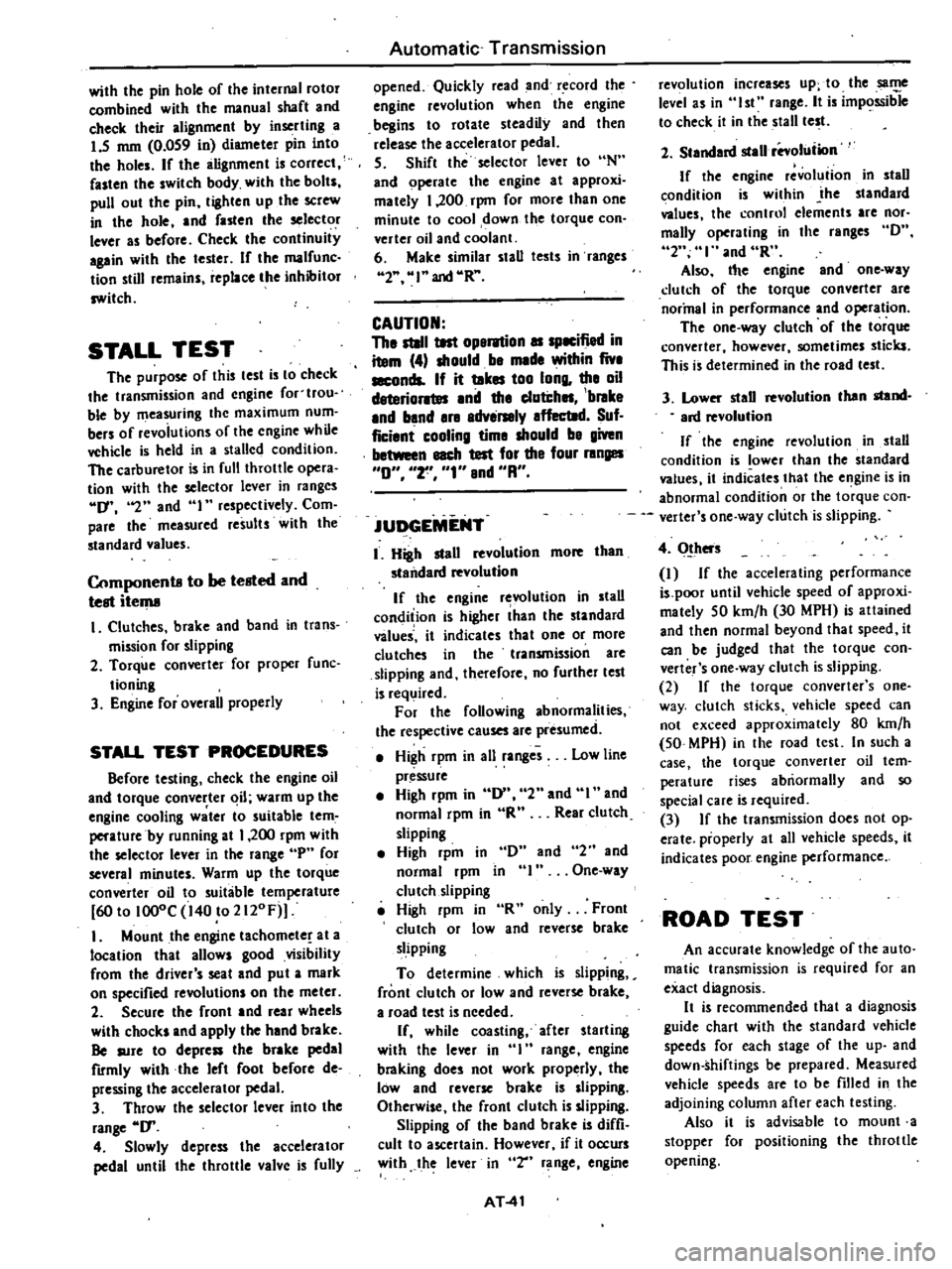

i

j

tI

IlV

@

@

AT

I

Inhibitor

switch

2

Manual

shaft

3

Washer

4

Nut

5

Manual

plate

Fi

J

AT

85

Comtruction

of

Inhibitor

Switch

6

Nut

1

Washer

8

Inhibitor

wilch

9

Ran

q

Iect

lever

Check

w

ethcr

he

leverse

lal

1p

and

the

starter

motor

operate

nonnal

Iy

in

these

ranges

If

there

is

any

trouble

first

check

the

inkage

If

no

defect

is

fo

nd

in

the

Ii

leage

check

tlie

inhibitor

Swi

ch

Separate

the

manual

lever

from

the

remote

control

selector

rod

and

turn

the

range

select

lever

to

N

Note

In

the

position

N

the

slot

of

the

manual

shaft

is

vertical

Using

the

tester

check

the

two

black

yellow

BY

wire

from

the

in

hibitor

switch

in

the

ranges

N

and

p

and

the

two

red

blacle

RB

wires

in

the

lange

R

for

continuity

Turn

range

select

lever

in

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

30

on

both

sides

from

each

lever

set

line

How

ever

if

its

continuity

range

is

obvioUs

ly

u

nequal

on

both

sides

adjustment

is

required

If

any

malfunction

is

found

un

screw

the

fastening

nut

o

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

Iy

to

the

position

N

by

means

of

the

selector

leVer

When

the

slot

of

the

shaft

becomes

vertical

the

detent

worles

to

position

the

shaft

correctly

with

a

clicking

sound

Move

the

switch

slightly

aside

so

that

the

scie

hole

will

be

aligned

Page 293 of 548

with

the

pin

hole

of

the

internal

rotor

combined

with

the

manual

shaft

and

check

their

alignment

by

inserting

a

1

5

mm

0

059

in

diameter

pin

into

the

holes

If

the

alignment

is

correct

fasten

the

switch

body

with

the

bolts

pull

out

the

pin

tighten

up

the

screw

in

the

hole

and

fasten

the

selector

lever

as

before

Check

the

continuity

pin

with

the

lesler

If

Ihe

malfunc

tion

still

remains

replace

the

inhibitor

switch

STALL

TEST

The

purpose

of

this

test

is

to

check

the

transmission

and

engine

for

trou

ble

by

measuring

the

maximum

num

bers

of

revoiutions

o

the

cngine

while

vehicle

is

held

in

a

stalled

condition

The

carburetor

is

in

fullthrollle

opera

tion

with

the

selector

lever

in

ranges

1

2

and

I

respectively

Com

pale

the

measured

results

with

the

standard

values

Components

to

be

tested

and

test

itelJUl

I

Clutches

brake

and

band

in

trans

mission

for

slipping

2

Torque

converter

for

proper

func

tioning

3

Engine

for

overall

properly

STAU

TEST

PROCEDURES

Before

testing

check

the

engine

oil

and

torque

converter

oil

warm

up

the

engine

cooling

w

ter

to

suitable

tem

perature

by

running

at

1

200

rpm

with

the

selector

lever

in

the

range

P

for

sevcral

minutes

Warm

up

the

torque

converter

oil

to

suitable

temperature

60

to

lOOoC

140

to

2120F

I

Mount

the

engine

tachometer

at

a

location

that

allows

good

visibility

from

the

driver

s

seat

and

put

a

mark

on

specified

revolutions

on

the

meter

2

Secure

the

front

and

rear

wheels

with

chocks

and

apply

the

hand

brake

Be

SIIre

to

depress

the

brake

pedal

firmly

with

the

left

foot

before

de

pressing

the

accelerator

pedal

3

Throw

the

selector

lever

into

the

range

11

4

Slowly

depress

the

accelerator

pedal

until

the

throttle

valvc

is

fully

Automatic

Transmission

opened

Quickly

read

and

record

the

engine

revolution

when

the

engine

begins

to

rotate

steadily

and

then

release

the

accelerator

pedal

5

Shift

the

selector

lever

to

N

and

operate

the

engine

at

approxi

mately

1

200

rpm

for

more

than

one

minute

to

cool

down

the

torque

con

verter

oil

and

coolant

6

Make

similar

staU

tests

in

ranges

2

I

and

R

CAUTION

The

dill

test

operstion

81

specified

in

i18m

4

should

be

I118de

within

fiv

lIeonds

If

it

tBkes

too

long

the

oil

If

and

the

cluti

hn

blllke

and

b

nd

elll

ly

I

Suf

ficient

cooling

time

should

be

given

r

eech

test

for

the

four

IlInges

0

Z

1

end

R

JUDGEMENT

High

stall

revolution

more

than

staitdard

revolution

If

the

engine

levolulion

in

stall

condi

ion

is

higher

than

the

standard

values

it

indicates

that

onc

or

more

clutches

in

the

transmission

are

slipping

and

therefore

no

further

test

is

required

For

the

following

abnormalities

the

respective

causes

are

presumed

High

rpm

in

all

ranges

low

line

pr

ssure

High

rpm

in

0

2

and

I

and

normal

rpm

in

6R

Rear

clutch

slipping

High

rpm

in

D

and

2

and

normal

rpm

in

One

way

clutch

slipping

High

Ipm

in

R

only

Front

clutch

or

low

and

reverse

brake

slipping

To

determine

which

is

slipping

front

clutch

or

low

and

reverse

brake

a

road

test

is

needed

If

while

coasting

after

starting

with

the

levcr

in

I

range

engine

braking

does

not

work

properly

the

low

and

reverse

brake

is

slipping

Otherwise

the

front

clutch

is

slipping

Slipping

of

the

band

brake

is

diffi

cuJt

to

ascertain

However

jf

it

occurs

with

the

lever

in

1

range

engine

AT

41

revolution

increases

up

to

the

same

level

as

in

1st

range

It

is

impossible

to

check

it

in

the

stall

test

2

Standard

stall

rnoluiion

If

the

engine

revoluiion

in

stall

ondition

is

within

he

standard

values

the

control

elements

are

nOf

mally

operating

in

the

ranges

D

2n

I

and

R

Also

the

engine

and

one

way

clutch

of

the

torque

converter

are

norinal

in

performance

and

operation

The

one

way

clutch

of

the

torque

converter

however

sometimes

sticks

This

is

determined

in

the

road

test

3

Lower

stall

revolution

than

lIand

ard

revolution

If

the

engine

revolution

in

stall

condition

is

lower

than

the

standard

values

it

indicates

that

the

engine

is

in

abnormal

condition

or

the

torque

con

verter

s

one

way

clutch

is

slipping

4

O

hers

I

If

the

accelerating

performance

is

poor

until

vehicle

speed

of

approxi

mately

SO

kmfh

30

MPH

is

attained

and

then

normal

beyond

that

speed

it

can

be

judged

that

the

torque

con

verte

c

s

one

way

clutch

is

slipping

2

If

the

torque

converter

sane

way

dutch

sticks

vehicle

speed

can

not

exceed

approximately

80

kmfh

SO

MPH

in

the

road

tesl

In

such

a

case

the

torque

converter

oil

tem

perature

rises

abnormally

and

so

special

care

is

required

3

If

the

transmission

does

not

op

erate

properly

at

all

vehicle

speeds

it

indicates

poor

engine

performance

ROAD

TEST

An

accurate

knowledge

of

the

au

to

matic

transmission

is

required

for

an

exact

diagnosis

II

is

recommended

that

a

diagnosis

guide

chart

with

the

standard

vehicle

speeds

for

each

stage

of

the

up

and

down

shiftings

be

prepared

Measured

vehicle

speeds

are

to

be

filled

in

the

adjoining

column

after

each

testing

Also

it

is

advisable

to

mount

a

stopper

for

positioning

the

throttle

opening

Page 295 of 548

CHECKING

SPEED

CHANGING

CONDITION

The

driver

s

feeling

during

gear

changes

should

also

be

checked

atten

lively

J

A

sharp

shock

or

unsrnoothness

is

felt

duting

a

gear

change

Tlus

indicates

that

the

throttle

pres

sure

is

too

high

or

some

valve

con

nected

to

the

throttle

is

faulty

2

A

gear

change

is

made

with

a

long

and

dragging

feeling

This

indicates

that

the

throttle

pres

sure

is

too

low

or

some

valve

con

nected

to

the

throttle

is

faulty

Automatic

Transmission

CHECKING

ITEMS

DURING

SPEED

CHANGE

I

In

D

range

gear

changes

DJ

D

D3

are

effected

In

R

range

the

speed

does

not

increase

2

The

kickdown

operates

properly

3

By

moving

the

lever

from

D

to

I

gearchangesD3

2

1

1

are

effected

In

the

ranges

j

and

I

the

engine

braking

works

prop

erly

4

In

I

the

speed

does

not

in

crease

S

Should

be

quickly

fixed

at

2

SHI

SCHEDULE

Non

Cellfornla

models

Sedan

end

Hetchbeck

1

2

1

l

2

I

I

2

L

3

1

1

1

0

E

I

Kickdown

range

I

T

7

87f

1

500

2

000

2

500

Output

shaft

speed

rpm

km

h

9

1P

29

30

4

0

50

6

0

70

80

MPH

6

1

0

io

30

40

5

0

California

models

All

models

and

Non

Callfornie

models

Wegon

0

E

c

E

3

00

11

81f

5

400

u

a

15

75

0

u

If

z

5

0

0

19

69

0

500

I

c

I

100

3

94

E

I

1

000

I

Kickdown

range

1

2

1

2

1

2

2

3

2

0

0

7

87

E

c

E

300

11

81

5

400

15

75

a

500

0

19

0

0

i

z

km

h

9

MPH

6

3

1

1

1

1

11

12

1

1

1

range

6

In

P

vehicle

can

be

parked

properly

If

any

malfunction

occurs

in

second

gear

during

the

road

test

thai

is

if

vehicle

shakes

drags

or

slings

while

shifting

up

from

D

directly

to

D3

or

in

shifting

up

from

D

to

D

the

braKe

band

should

be

ad

justed

If

these

troubles

remain

after

the

brake

band

is

adjusted

check

the

servo

piston

seal

for

oil

leakage

2

32

3

3

0

00

4

000

3

50

0

9

0

60

100

AT434

2

321

3

500

1

000

1

500

2

600

2

50

0

3

600

3

500

4

000

Output

shaft

speed

rpm

10

20

30

40

50

6

0

70

80

90

100

1

0

io

3

0

4

0

50

60

AT435

Fig

A

T

86

Shift

Schedule

AT

43

Page 296 of 548

LlNE

PRESSURE

TEST

When

any

slipping

occurs

in

clutch

or

brake

or

the

feeling

during

a

speed

change

is

not

correct

the

line

pressure

must

be

checked

Measuring

line

pressure

is

done

by

a

pressure

gatqle

attached

to

pressure

measuring

holea

after

removing

blind

pluga

locate

d

at

transmission

case

The

line

pressure

measurement

is

begun

at

idling

and

taken

step

by

step

by

enlarging

the

throttle

opening

Automatic

Transmission

For

line

pressure

data

when

shift

ing

gem

refer

to

Road

Test

1

A

sharp

shock

in

up

shifting

or

too

high

changing

speeds

are

caused

mostly

by

too

high

throttle

pressure

2

Slipping

or

incaPability

of

opera

tion

is

mostly

due

to

oil

pressure

leakage

within

the

gear

trains

or

spool

valve

LINE

PRESSURE

GOVERNOR

FEED

PRESSURE

Non

Cellfornill

models

Seden

and

Halchbeck

At

idling

Range

At

stall

test

R

Une

pressure

kg

em

psi

Range

3

0

to

5

5

43

to

7S

3

0

to

4

0

43

to

57

6

0

to

12

0

S5to

171

o

2

R

D

3

0

to

4

0

43

to

57

2

snSOSSOOI

CD

AT454

1

Line

pressure

2

Governorpressure

3

Servo

release

prenure

Fig

AT

87

Mecuuring

Line

Pre

Line

pressure

kg

cm2

psi

14

0

to

16

0

199

to

22S

94

to

11

0

134

to

156

10

0

to

12

0

142

to

171

94

to

11

0

134

to

156

At

idling

California

models

All

models

end

Non

Callfornill

modela

Wa

on

At

stall

test

R

Line

pressure

kg

cm

psi

Range

Range

R

o

4

2

to

5

6

60

to

SO

3

2

to

3

S

46

to

54

D

2

6

0

to

II

7

S5

to

166

2

3

2

to

3

S

46

to

54

AT44

Une

pressure

kg

cm2

psi

143

to

16

2

203

to

230

9

9

to

11

1

141

to

15S

10

2

to

II

7

145

to

166

9

9

to

11

1

14110

15S

Page 297 of 548

JUDGEMENT

IN

MEASURING

LINE

PRESSURE

Low

idling

line

pressure

in

the

ranges

D

2

R

and

P

This

can

be

attributed

to

trouble

in

the

pressure

supply

system

or

too

low

output

of

power

caused

by

I

A

worn

oil

pump

2

An

oil

pressure

leak

in

the

oil

pump

valve

body

or

case

3

A

sticking

regulator

valve

2

Low

idling

line

pressure

i

n

cer

tain

ranges

only

This

is

presumably

caused

by

an

oil

leak

in

the

devices

or

circuits

con

nected

to

the

relevant

ranges

I

When

there

is

an

oil

leaJi

in

the

rear

clutch

and

governor

the

line

pressure

in

on

2

and

I

are

low

but

the

pressure

i

nonnal

in

R

2

When

an

oil

leak

occurs

in

the

low

and

reverse

brake

circuit

the

line

pressure

in

oR

and

P

are

low

b

t

the

pressure

is

normal

in

0

2

and

I

3

High

idling

line

pressure

Thi

is

presumably

caused

by

an

increased

aC

1ulT

t

rott

e

pr

ssure

owing

to

a

leak

in

the

vacuum

tube

or

diaphragin

or

by

an

increased

line

Automatic

Transmission

pressure

due

to

a

sticking

regulator

valve

Vacuum

leakage

is

checked

by

directly

measuring

the

negative

pres

sure

after

removing

the

vacuum

pipe

A

puncture

of

the

vacuum

dia

phragm

can

be

easily

ascertained

because

the

torque

converter

oil

is

absorbed

into

the

engine

and

the

exhaust

pipe

emits

white

smoke

4

Item

to

be

checked

when

the

Ii

e

pressure

is

increasing

In

this

c

1eck

the

line

pressure

should

be

measured

with

vacuums

of

300

mmHg

Il

SI

inHg

and

0

mmHg

0

inHg

in

accordance

with

the

staIl

test

procedure

i

If

the

line

pressure

does

not

in

crease

despite

the

vacuum

decrease

check

whether

the

vacuum

rod

is

i

corporated

2

If

the

line

pressure

does

not

meet

tile

standard

iUs

caused

mostly

by

a

sticking

pressure

regulating

valve

pres

sure

regulating

valve

plug

or

amplifier

TROUBLE

SHOOTING

CHART

INSPECTING

ITEMS

I

Inspection

with

automatic

trans

mission

on

vehicle

AT

45

A

Oil

level

B

Range

select

linkage

C

Inhibitor

switch

and

wiring

D

Vacuum

diaphragm

and

piping

E

Downshift

solenoid

kickdown

switch

and

wiring

F

Engine

idling

rpm

G

Oil

pressure

throttle

H

Engine

stall

rpm

I

Rear

lubrication

J

Control

valve

manual

K

Governor

valve

L

Band

servo

M

Transmission

air

check

N

Oil

quality

o

Ignition

switch

and

starter

motor

P

Engine

adjustment

and

brake

in

spection

2

Inspection

after

inspecting

auto

matic

transmission

on

vehicle

m

Rear

clutch

n

Front

clutch

q

Band

brake

r

Low

and

reverse

brake

s

Oil

pump

t

Leakage

of

oil

passage

u

One

way

clutch

of

troque

converter

v

One

way

clutch

of

transmission

w

Front

clutch

check

ball

x

Parking

linkage

y

Planetary

gear

Page 301 of 548

Automatic

Transmission

TROUBLE

SHOOTING

GUIDE

FOR

3N71B

AUTOMATIC

TRANSMISSION

Ordel

Test

item

Checking

Oil

level

gauge

j

Downshift

solenoid

3

Manual

linkage

4

Inhibitor

switch

5

Engine

idling

rpm

6

Vacuum

pressure

of

vacuum

pipe

7

Operation

in

each

range

g

Creep

of

vehicle

Stall

test

1

Oil

pressure

before

t

sting

2

Stall

test

3

Oil

pressure

after

teSling

Road

test

L

Slow

acceleration

Ist

2nd

2nd

3rd

2

Quick

acceleration

Ist

2nd

2nd

3rd

3

Kick

down

operation

3rd

2nd

or

2nd

1st

Procedure

Check

gauge

for

oil

level

and

leakage

before

and

after

each

test

Check

for

sound

of

operating

solenoid

when

depressing

accelerator

pedal

fully

with

ignition

key

ON

Check

by

shifting

into

P

R

N

0

2

and

ranges

with

selector

lever

Check

whether

starter

operates

in

N

and

p

ranges

only

and

whether

reverse

lamp

operates

in

R

range

only

Check

whether

idling

rpm

meet

slandard

Check

whether

vacuum

pressure

is

more

than

450

mmHg

17

72

inHg

in

idling

and

whether

it

decreases

with

increasing

rpm

Check

whether

transmission

engages

positively

by

shifting

N

0

N

2

N

to

I

and

N

R

range

while

idling

with

brake

applied

Check

whether

there

is

any

creep

in

0

2

and

R

ranges

Measure

line

pressures

in

D

2

I

and

R

range

while

idling

Measure

engine

rpm

and

line

pressure

in

0

2

t

and

R

ranges

during

full

throttle

operation

Note

Temperature

of

torque

con

erter

oil

used

in

test

should

be

from

6

to

lOO

C

140

to

2120F

i

e

suf

ficiently

1

up

but

not

o

heeted

CAUTION

To

cool

oil

between

IIch

mil

test

for

OH

ZH

1

H

Ind

RH

nnges

idle

engine

i

e

rpm

It

Ibout

1

200

rpm

for

more

thin

1

minutll

in

P

nnge

MeeRlr

ment

time

mUlt

not

be

more

then

5

seconds

Same

as

item

1

Check

vehicle

speeds

and

engine

rpm

in

shifting

up

1

st

2nd

range

and

2nd

3rd

range

while

running

with

lever

in

D

range

and

engine

vacuum

pressure

of

about

200

mmHg

7

87

inHg

Same

as

item

1

above

except

with

engine

vacuum

pressure

of

o

mrnHg

0

inHg

i

e

in

position

just

before

kickdown

Check

whether

the

kickdown

operates

and

measure

the

time

delays

while

running

at

30

40

50

60

70

km

h

19

25

31

37

43

MPH

in

OJ

range

AT

49

Page 302 of 548

Oldel

Others

Automatic

Transmission

Test

item

4

Shift

down

Or

O

O

5

Shift

down

Or

I

1

6

Shift

down

0

2

7

Shift

up

1

1

8

Shift

up

or

down

when

start

ing

in

2

ranae

9

Parking

Abnormal

shock

oil

leakage

Procedure

Check

vehicle

speeds

and

engine

rpm

in

shifting

down

from

3rd

2nd

1st

sequentiaUy

while

coasting

with

accelerater

pedal

released

in

0

range

and

engine

vacuum

pressure

of

about

450

mmHg

17

72

inHg

Check

for

shifti

ng

do

n

I

I

nd

engine

blaking

and

further

for

shifting

down

I

I

and

engine

braking

tel

shifting

the

leyer

into

I

range

with

the

accelerator

pedal

released

and

the

engine

vacuum

pressure

of

0

mmHg

0

inHg

while

driving

at

about

50

km

h

30

MPH

in

0

range

Check

for

quick

shifting

down

OJ

2

and

engine

braking

after

shifting

the

lever

into

2

range

while

driving

at

about

50

km

h

30

MPH

in

0

range

Further

chec

for

locking

of

the

transmission

i

2nd

gear

ratio

regardless

of

vehicle

sPeed

Check

for

failure

of

the

transmission

to

shift

up

during

acceleration

when

starting

in

range

Check

the

transmission

for

not

shifting

up

or

down

during

acceleration

or

deceleration

when

starting

in

2

range

Confirm

that

yehicle

will

notmoye

on

grade

when

shifting

to

pn

range

Enter

into

record

conditions

observed

durq

these

lests

such

as

gear

noise

abnormal

clutch

noise

and

acceleration

performance

AT

50

Page 308 of 548

Rropeller

Shaft

Differential

Carrier

PROPELLER

SHAFT

INSPECTION

GENERAL

INSPECTION

I

Check

propeller

shaft

tube

sur

Cace

for

dents

or

cracks

If

damaged

replace

with

an

assembly

2

Check

journal

for

axial

play

If

there

is

play

replace

propeller

shaft

mbly

Note

JournaI

cannot

be

disassem

bled

PROPELLER

SHAFT

VIBRATION

To

check

and

correct

an

unbal

anced

propeller

shaCt

proceed

as

Col

lows

L

Remove

undercoating

and

other

foreign

material

which

could

upset

shaft

balance

and

check

shaft

vibra

tion

by

road

test

2

If

shaft

vibration

is

noted

during

road

test

disconnect

propeller

shaft

et

differential

carrier

companion

flange

rotate

companion

flange

180

degrees

and

reinstall

propeller

shaft

ff

3

Again

check

shaft

vibration

If

vibration

still

persists

replace

propel

ler

shaft

assembly

REMOVAL

AND

INSTALLATION

REMOVAL

I

Raise

car

on

hoist

Put

match

malks

both

on

propeller

shaft

and

companion

flange

so

that

shaft

can

be

reinstalled

in

its

original

position

2

Remove

bolts

connecting

pro

peller

shaft

to

companion

flange

PD459

Fig

PD

2

Removing

Propeller

Shaft

PD

2

Tightening

torque

kg

m

ft

b

@

2

410

3

3

1710

24

PD468

Fig

PD

l

PropellerSha

t

3

Draw

out

propeller

shall

sleeve

yoke

from

transmission

by

moving

shaft

realWard

passing

it

under

rear

axle

Plug

up

rear

end

of

rear

extension

housing

to

prevent

oil

leakage

Note

Remove

propeller

aheCt

care

Cully

so

as

not

to

demege

spline

sleeve

yoke

and

rear

oil

seal

INSTALLAnON

To

inS

aJI

reverse

the

foregoing

removal

prOCedure

CAUTION

Align

propeller

shift

with

com

penion

fllnge

of

differentiel

Clrrier

ulling

reference

marks

prl

1Cribed

in

Remova

procedure

and

tightsn

them

with

bolts

Failure

to

do

so

could

resuh

in

driving

vibration

fJ

Tightening

tOlquo

Propellol

sheft

to

companion

f1enge

bolts

2

4

to

3

3

kg

m

117

to

24

ft

b

Page 309 of 548

Propeller

Shaft

Differential

Carrier

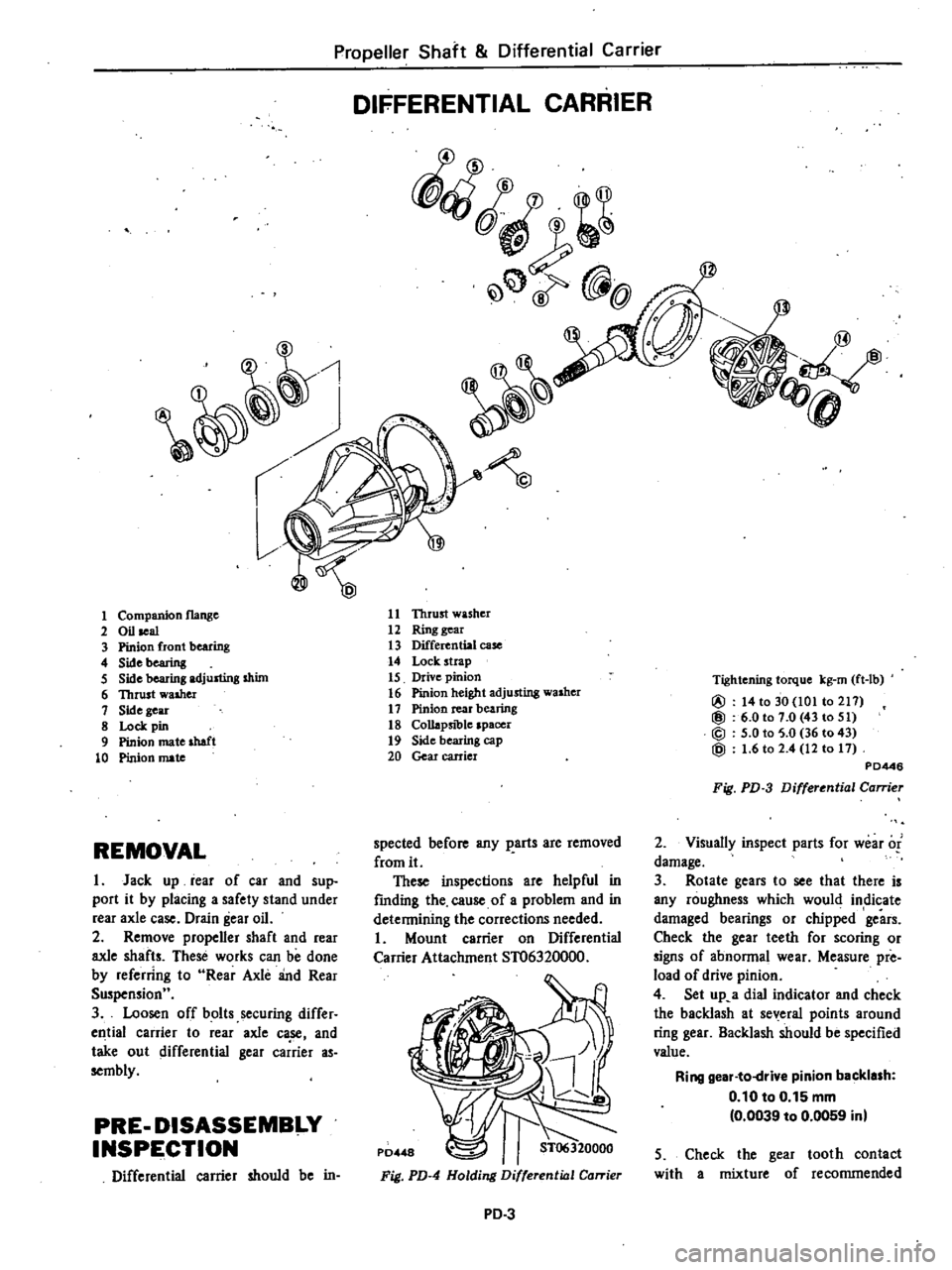

DIFFERENTIAL

CARRIER

fQ

@

1

11

Thrust

washer

12

Ring

gear

13

Differential

case

14

Lock

strap

15

Drive

pinion

16

Pinion

height

adjusting

washer

17

Pinion

rear

bearing

18

Collapsible

spacer

19

Side

bearing

cap

20

Gear

carrier

1

Companion

flange

2

Oil

seal

3

Pinion

front

bearing

4

Sidebearing

5

Side

bearing

adjusting

shim

6

Thrust

walher

1

Side

gear

8

Lock

pin

9

Pinion

mate

shaft

10

Pinion

mate

Tightening

torque

kg

rn

ft

lb

@

14

to

30

101

to

211

@

6

0101

0

43

to

51

@

5

0

to

5

0

36

to

43

@

1

6

to

2

4

12

to

11

PD446

Fig

PD

3

Differential

Carrier

2

Visuany

inspect

parts

for

wear

of

damage

3

Rotate

gears

to

see

that

there

is

any

roughness

which

would

indicate

damaged

bearings

or

chipped

gears

Check

the

gear

teeth

for

scoring

or

signs

of

abnonnal

wear

Measure

pre

load

of

drive

pinion

4

Set

up

a

dial

indicator

and

check

the

backlash

at

several

points

around

ring

gear

Backlash

should

be

specified

value

Ring

gear

to

drive

pinion

backlash

0

10

to

0

15

mm

0

0039

to

0

0059

inl

spected

before

any

parts

are

removed

from

it

These

inspections

are

helpful

in

fmding

the

cause

of

a

problem

and

in

detennining

the

corrections

needed

Mount

carrier

on

Differential

Carrier

Attachment

ST06320000

REMOVAL

I

Jack

up

rear

of

car

and

sup

port

it

by

placing

a

safety

stand

under

rear

axle

case

Drain

gear

oil

2

Remove

propener

shaft

and

rear

axle

shafts

These

works

can

be

done

by

referring

to

Rear

Axle

and

Rear

Suspensionu

3

Loosen

off

bolts

securing

differ

ell

tial

carrier

to

rear

axle

ca

se

and

take

out

differential

gear

carrier

as

sembly

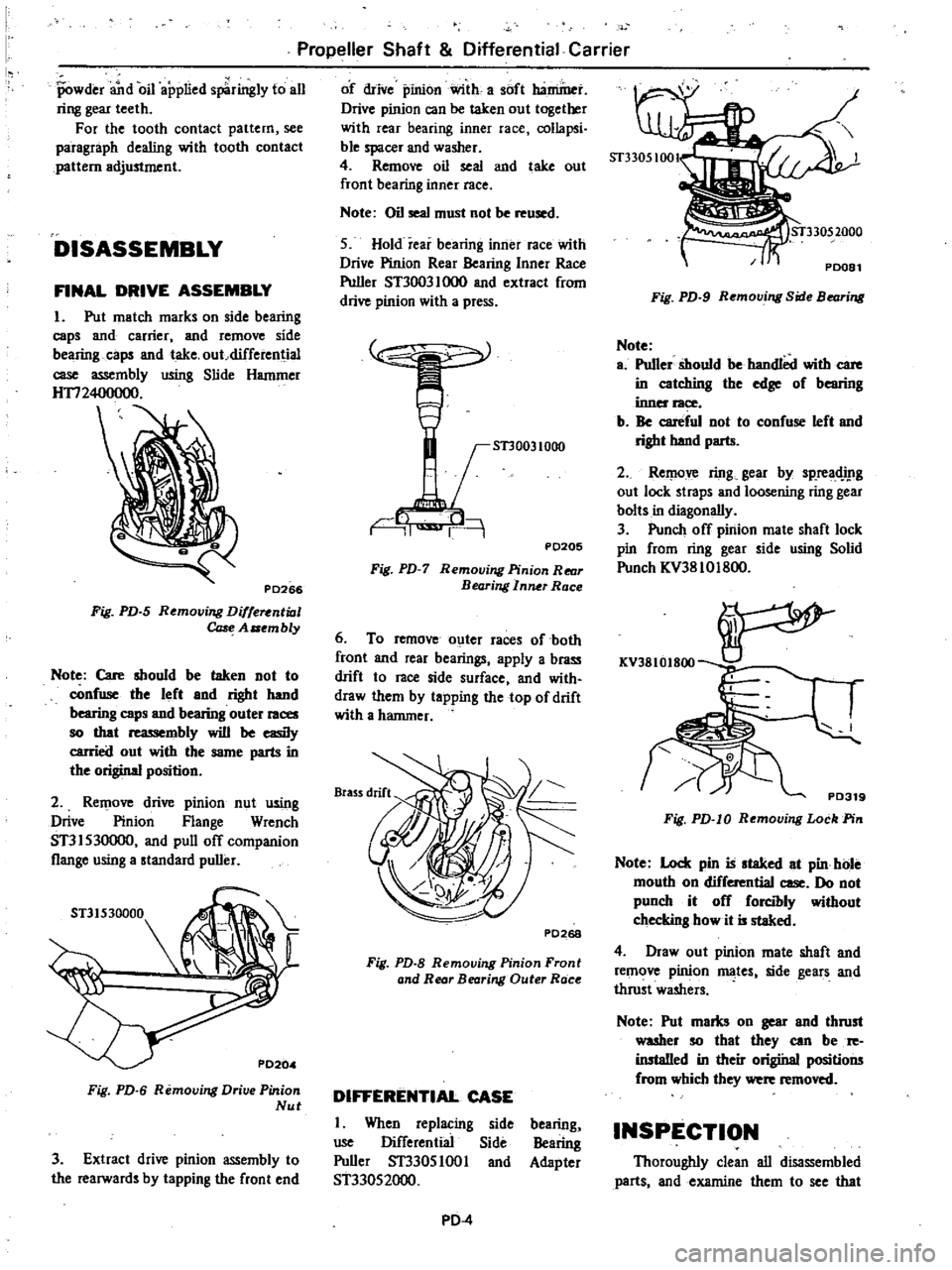

PRE

DISASSEMBI

Y

INSPE

CTION

Differential

carrier

should

be

in

5

Check

the

gear

tooth

contact

with

a

mixture

of

recommended

Fig

PD

4

Holding

Differential

Carrier

PD

3

Page 310 of 548

I

powder

and

oil

applied

sp

hingly

to

all

ring

gear

teeth

For

the

tooth

contact

pattern

see

paragraph

dealing

with

tooth

contact

pattern

adjustl1ll

nt

DISASSEMBLY

FINAL

DRIVE

ASSEMBLY

I

Put

match

marks

on

side

bearing

caps

and

carrier

and

remove

side

bearing

caps

and

take

out

differential

case

assembly

using

Slide

Hammer

HTI2400000

PD266

Fig

PD

5

Removing

Diffe

ntial

Ca

e

A

embly

Note

Care

should

be

taken

not

to

confWle

the

left

end

right

hand

bearing

caps

and

bearing

outer

races

so

that

reassembly

will

be

easily

carried

out

with

the

same

parts

in

the

original

position

2

Rel

love

drive

pinion

nut

using

Drive

Pinion

Flange

Wrench

ST31530000

and

pull

off

companion

flange

using

a

standard

puller

Fig

PD

6

Removing

Drive

Pinion

Nut

3

Extract

drive

pinion

assembly

to

the

rearwards

by

tapping

the

front

end

Propeller

Shaft

Differential

Carrier

of

drive

pinion

with

a

soft

baminet

Drive

pinion

can

be

taken

out

together

with

rear

bearing

inner

race

collapsi

ble

spacer

and

washer

4

Remove

oil

seal

and

take

out

front

bearing

inner

race

Note

Oil

seal

must

not

be

reused

5

Hold

rear

bearing

inner

race

with

Drive

Pinion

Rear

Bearing

Inner

Race

Puller

ST30031000

and

extract

from

drive

pinion

with

a

press

STJ0031000

r

1

i

9

PD205

Fig

PD

7

Removing

Pinion

Rear

Bearing

I

nfUr

Race

6

To

remove

outer

races

of

both

front

and

rear

bearings

apply

a

brass

drift

to

race

side

surface

and

with

draw

them

by

tapping

the

top

of

drift

with

a

hammer

PD268

Fig

PD

B

Removing

Pinion

Front

and

Rear

Bearing

Outer

Race

DIFFERENTIAL

CASE

I

When

replacing

side

Wle

Differenliai

Side

Puller

ST3305

1001

and

ST33052000

bearing

Bearing

Adapter

PD

4

Fig

PD

9

Removing

Side

Bearing

Note

a

Puller

should

be

bandlOd

with

care

in

catching

the

edge

of

bearing

inner

race

b

Be

careful

not

to

confuse

left

and

right

band

parts

2

Rel

love

ring

gear

by

sp

readJ

lg

out

lock

straps

and

loosening

ring

gear

bolts

in

diagonally

3

Punch

off

pinion

mate

shaft

lock

pin

from

ring

gear

side

using

Solid

Punch

KV3810Ig00

KV3810I800

PD319

Fig

PD

I0

Removing

Lock

Pin

Note

Lock

pin

is

slaked

et

pin

hole

mouth

on

differential

case

Do

not

punch

it

off

forcibly

without

checking

how

it

is

staked

4

Draw

out

pinion

mate

shaft

and

remove

pinion

ID3

tes

side

gears

and

thrust

washers

Note

Put

mams

on

gear

end

thrust

waaher

so

that

they

can

be

re

installed

in

their

origiital

positions

from

which

they

were

removed

INSPECTION

Thoroughly

clean

all

disassembled

parts

and

examine

them

to

see

that