check oil DATSUN 210 1979 Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 279 of 548

Automatic

Transmission

MAJOR

REPAIR

OPERATION

SERVICE

NOTICE

FOR

DISASSEMBLY

AND

ASSEMBLY

I

It

is

advisable

that

repair

opera

tions

be

carried

out

in

a

dust

proof

room

2

Due

to

the

differences

of

the

engine

capacities

the

specifications

of

component

parts

for

each

model

s

transmission

may

be

different

They

do

however

have

common

adjust

ment

and

repair

procedures

as

well

as

cleaning

and

inspection

procedures

outlined

hereinafter

3

During

repair

operations

refer

to

Service

Data

and

Specific3ti

H1s

see

tion

for

the

correct

parts

for

each

model

4

Before

removing

any

of

subas

semblies

thoroughly

clean

the

outside

of

the

transmission

to

prevent

dirt

from

entering

the

mechanical

parts

5

Do

not

use

a

waste

rag

Use

a

nylon

or

paper

cloth

6

After

disassembling

wash

all

dis

assembled

parts

and

examine

them

to

see

if

there

3re

any

worn

damaged

or

defective

parts

and

how

they

are

affected

Refer

to

Service

Data

for

the

extent

of

damage

that

justifies

replacement

7

As

a

rule

packings

seals

and

similar

parts

once

disassembled

should

be

replaced

with

new

ones

TORQUE

CONVERTER

The

torque

converter

is

a

welded

construction

and

can

not

be

disas

sembled

INSPECTION

I

Check

torque

convert

for

any

sign

of

damage

bending

oil

leak

or

deformation

If

necessary

replace

2

Remove

rust

from

pilots

and

bosses

completely

If

torque

converter

oil

is

fouled

or

contaminated

due

to

burnt

clutch

flush

the

torque

converter

as

follows

I

Drain

oil

in

torque

converter

2

Pour

non

lead

gasoline

or

kero

sene

into

torque

converter

approxi

mately

0

5

liter

I

J

V

S

pt

U

Imp

pt

3

Blow

air

into

torque

converter

and

flush

and

drain

out

gasoline

4

Fill

torque

converter

with

torque

converter

oil

approximately

0

5

liter

I

J

V

S

pt

U

Imp

pt

5

Again

blow

air

into

torque

con

verter

and

drain

torque

converter

oil

TRANSMISSION

DISASSEM

LY

I

Drain

oil

from

the

end

of

rear

extension

Mount

transmission

on

Transmission

Case

Stand

ST07g70000

or

ST07860000

Remove

oil

pan

AT118

Fig

A

T

26

R

movin

g

Oil

Pan

2

Remove

bolts

securing

converter

housing

to

transmission

case

Remove

torque

converter

housing

3

Remove

speedometer

pinion

sleeve

bolt

Withdraw

pinion

4

Remove

downshift

solenoid

and

vacuum

diaphragm

Do

not

leave

dia

phragm

rod

at

this

stage

of

dis

assembly

Rod

is

assembled

in

top

of

vacuum

diaphragm

Fig

A

T

27

Dowmhift

Solenoid

and

Vacuum

Diaphragm

AT

27

5

Remove

bolts

which

hold

valve

body

to

transmission

case

Fig

AT

28

Removing

Valve

Body

6

Loosen

lock

nut

CV

on

piston

stem

CD

Then

tighten

piston

stem

in

order

to

prevent

front

clutch

drum

from

falling

when

oil

pump

is

withdrawn

AT121

Fig

AT

29

Loosening

Band

Se11

Jo

7

Pull

out

input

shaft

8

Withdraw

oil

pump

using

Sliding

Hammer

ST25850000

Do

not

allow

front

clutch

to

come

out

of

position

and

drop

onto

floor

AT122

Fig

AT

30

Removing

Oil

Pump

Page 282 of 548

ITU

lmQO

d

fJ

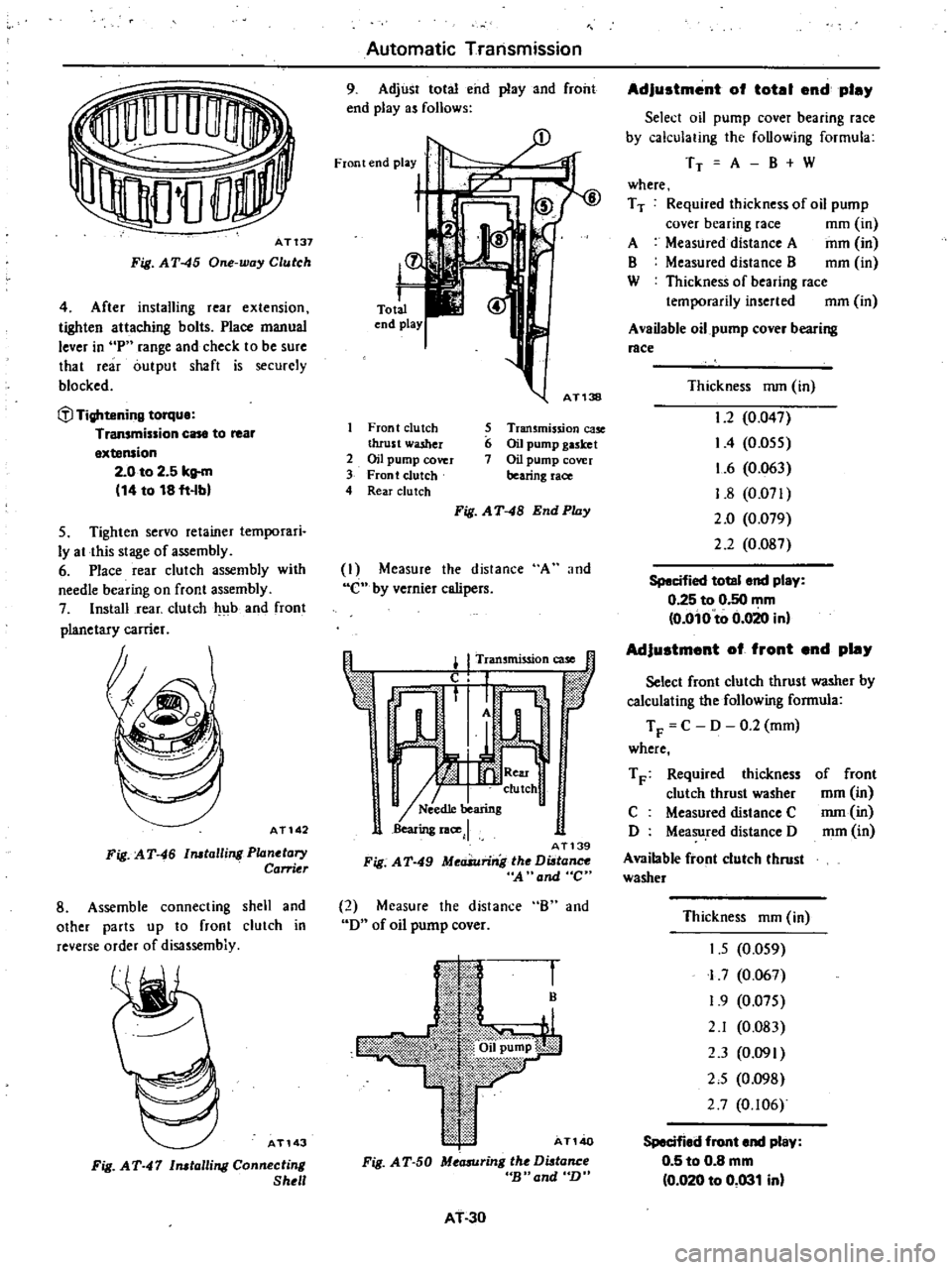

AT137

Fig

A

T

45

One

way

Cluleh

4

After

installing

rear

extension

tighten

attaching

bolts

Place

manual

lever

in

P

range

and

check

to

be

sure

that

rear

outpul

shaft

is

securely

blocked

fl

Tightening

torque

Transmission

case

to

rear

extension

2

0

to

2

5

kg

m

14

to

18

fHbl

5

Tighten

servo

retainer

temporari

Iy

at

this

stage

of

assembly

6

Place

rear

clutch

assembly

with

needle

bearing

on

front

assembly

7

Install

rear

clutch

4

lb

and

front

planetary

carrier

AT142

Fig

AT

46

talling

Planetary

Carrier

8

Assemble

connecting

shell

and

other

parts

up

to

front

clutch

in

reverse

order

of

disassembiy

AT143

Fig

AT

47

talling

Canneetin

Shell

Automatic

Transmission

9

Adjust

total

end

play

and

front

end

playas

follows

Front

end

play

t

Zl

L

r

Total

end

play

AT138

Front

clutch

5

Transmission

ca5e

thrust

washer

6

Oil

pump

gasket

2

OH

pump

cover

7

Oil

pump

cover

3

Front

clutch

bearing

race

4

Rear

clu

tch

Fig

AT

48

End

Play

I

Measure

the

distance

A

and

C

by

vernier

calipers

I

I

Tran

mission

case

t

f

l

1

I

n

0

tic

r

1

A

W

I

I

II

clulch

I

N

ed1e

bearing

Bearing

lace

J

AT139

Fig

A

T

49

MeaSuring

the

Di

tance

A

and

C

2

Measure

the

distance

B

and

D

of

oil

pump

cover

B

AT140

Fig

A

T

50

Measuring

the

Di

tance

cB

and

n

AT

30

Adjustment

of

totel

end

pley

Select

oil

pump

cover

bearing

race

by

calculating

thc

following

formula

TT

A

B

W

where

T

T

Required

thickness

of

oD

pump

cover

bearing

race

mm

in

A

Measured

distance

A

mm

in

B

Measured

distance

B

mm

in

W

Thickness

of

bearing

race

temporarily

inserted

mm

in

A

vaDable

oil

pump

cover

bearing

race

Thickness

nun

in

1

2

0

047

I

4

0

055

1

6

0

063

1

8

0

071

2

0

0

079

2

2

0

Og7

Specified

totel

end

play

0

25

to

0

50

mm

o

oio

to

0

020

inl

Adjustment

of

front

end

pley

Select

front

clutch

thrust

washer

by

calculating

the

following

formula

T

F

C

D

0

2

mm

where

T

F

Required

thickness

clutch

thrust

washer

C

Measured

distance

C

D

Measu

red

distance

D

Available

front

clutch

thrust

washer

of

front

mm

in

nun

in

mm

in

Thickness

mm

in

1

5

0

059

I

7

0

067

1

9

0

075

2

1

0

083

2

3

0

091

2

5

0

098

2

7

0

106

Specified

front

end

pley

0

5

to

0

8

mm

0

020

to

0

031

inl

Page 283 of 548

Note

L

C

llTect

thid

ness

of

bearing

race

end

thrust

washer

is

always

the

one

which

is

nearest

the

calculated

one

b

InsteJled

thid

noss

of

oil

pump

gasket

is

0

4

mm

0

016

in

10

Check

to

b

sure

that

brake

servo

piston

moves

freely

For

detailed

procedure

refer

to

page

AT

33

for

Servo

Piston

Use

care

to

prevent

piston

from

coming

out

of

place

dur

ing

testing

since

servo

retainer

is

not

tightened

at

this

point

of

assembly

II

Make

sure

that

brake

band

strut

is

correctly

installed

Tighten

piston

stem

Back

off

two

full

turns

end

secure

with

lock

nul

l

l

Tightening

torqUl

Piston

stem

1

2

to

1

5

kg

m

9

to

11

ft

lbl

Piston

tem

lock

nut

1

5

to

4

0

kg

m

11

to

29

ft

lbl

Available

diaphragm

rod

Distance

measured

L

mm

in

Under

25

55

1

0059

25

65

to

26

05

1

0098

to

1

0256

26

15

to

26

55

1

0295

to

1

0453

26

65

to

27

05

1

0492

to

1

0650

Over

27

15

1

0689

COMPONENT

PARTS

The

transmission

consists

of

many

all

parts

that

are

quite

alike

in

oonstruction

yet

machined

to

very

close

tolerances

When

disassembling

parts

be

sure

to

place

them

in

order

in

part

rack

so

they

can

be

restored

in

the

unit

in

their

proper

positions

It

is

also

very

important

to

perform

func

lional

test

whenever

it

is

designated

Automatic

Transmission

12

After

inhibitor

switch

is

in

stalled

check

to

be

sure

that

it

op

erates

properly

in

each

range

For

detailed

procedure

refer

to

page

AT

40

for

Checking

and

Adjusting

lnhibi

tor

Switch

13

Check

the

length

L

between

case

end

to

rod

end

of

vacuum

throttle

valve

fully

pushed

in

Then

select

adequate

diaphragm

rod

of

corre

sponding

measured

length

1

11f1

n

1

11

1

1

f

c

dllidf

i

L

AT145

Fig

A

T

51

M

asuring

the

Dutance

L

Diaphragm

rod

length

mm

in

29

0

1

142

295

1

161

30

0

I

181

30

5

1

201

31

0

1

220

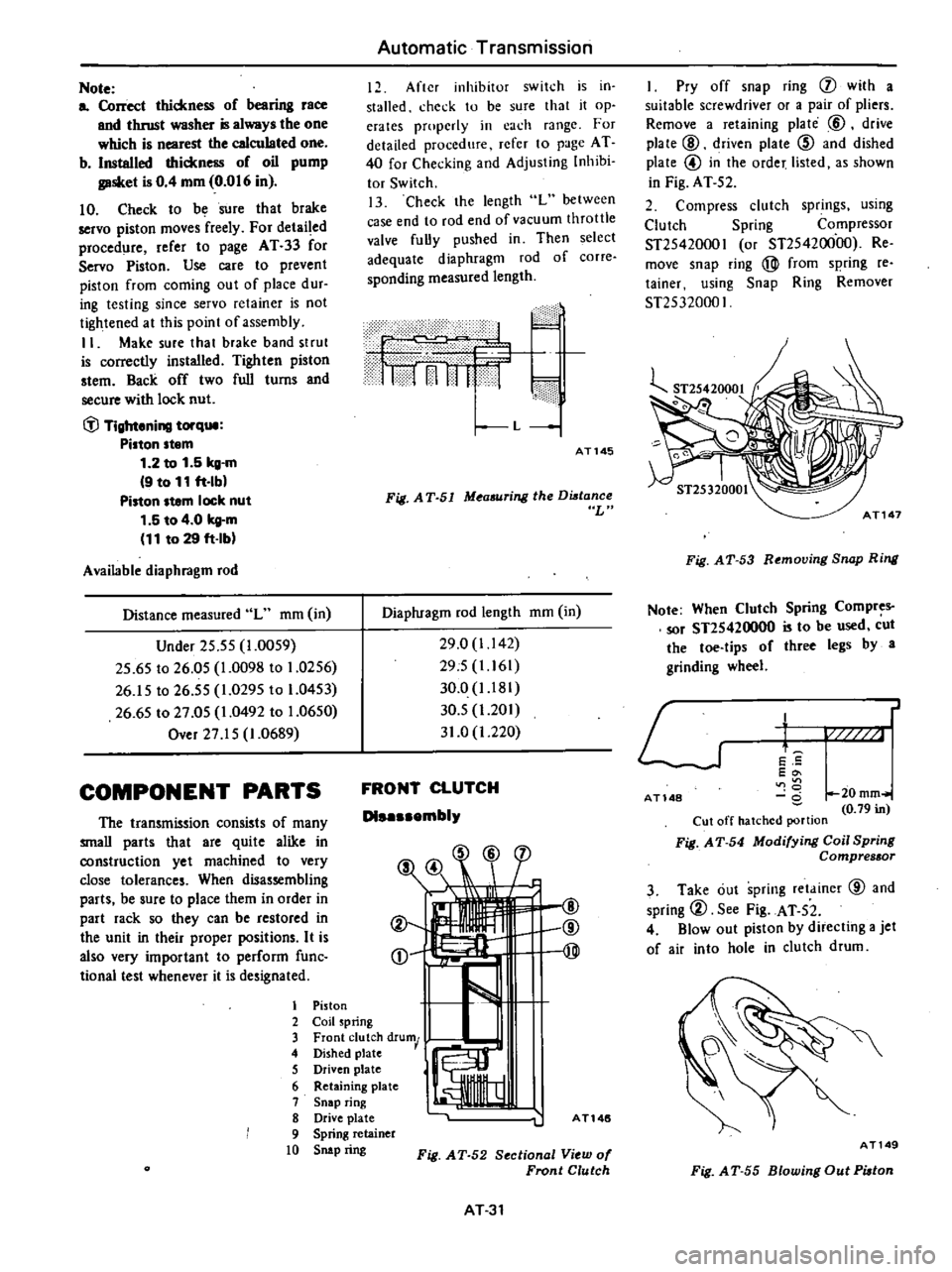

FRONT

CLUTCH

Dl

mbly

@

@

@

I

Piston

2

Coil

spring

3

Front

clutch

drum

4

Dished

plate

5

Driven

plate

I

6

R

I

etammg

plate

7

Snap

ring

8

Drive

plate

A

T146

9

Spring

retainer

10

Snip

ring

Fig

AT

52

Section

1

View

of

Fronl

Clulch

AT31

I

Pry

off

snap

ring

j

with

a

suitable

screwdriver

or

a

pair

of

pliers

Remove

a

retaining

plate

@

drive

plate

@

driven

plate

@

and

dished

plate

@

in

the

order

listed

as

shown

in

Fig

AT

52

2

Compress

clutch

springs

using

Clutch

Spring

Compressor

ST25420001

or

ST25420000

Re

move

snap

ring

@

from

spring

reo

tainer

using

Snap

Ring

Remover

ST25320001

Fig

AT

53

Removing

Snap

Ring

Note

When

Clutch

Spring

Compres

sor

ST2S420000

is

to

be

used

cut

the

toe

tips

of

three

legs

by

a

grinding

wheel

L

J

t

E

5

Eo

U

0

20mm

0

79

in

Cut

off

hatched

portion

Fig

A

T

54

Modifying

Coil

Spring

Compressor

AT

148

3

Take

out

spring

retainer

@

and

spring

2

See

Fig

AT

52

4

Blowout

piston

by

directing

a

jet

of

air

into

hole

in

clutch

drum

AT149

Fig

A

T

55

Blowing

Out

Piolon

Page 284 of 548

Insp

ctIon

I

Check

for

signs

of

wear

or

dam

age

to

clutch

drive

plate

facing

If

found

worn

or

damaged

excessively

discard

Drive

plm

th

Standen

1

5

to

1

66mm

0

059

to

O

Inl

Allowable

limit

1A

mm

0

065

inl

2

Check

fOI

weer

on

snap

ring

and

for

weakened

or

broken

coil

spring

If

necessary

replace

with

new

ones

Spring

retainer

should

also

be

in

spected

fOI

warpage

sembi

1

Assembly

is

in

reverse

the

order

of

disassembly

Dip

all

parts

in

clean

automatic

transmission

fluid

before

installing

Fig

AT

56

l

ting

Clutch

PIlIte

2

After

clutch

is

a

embled

make

sure

th

t

clearance

between

snap

ring

CD

and

retaining

plate

V

is

held

within

specified

limits

If

necessary

lIy

with

other

retaining

plate

having

different

thickness

until

correct

clear

ance

is

obteined

S

1

deerence

1

6

to

2

0

mm

0

063

to

0

079

inl

Automatic

Transmission

Awilable

reteiningplate

Thickness

mm

in

10

6

0

417

10

8

0

425

11

0

0

433

11

2

0441

II

4

0

449

11

6

0

457

AT151

Fig

AT

67

Me

ring

Ring

to

PIlIte

Cleo

3

Testing

front

clutch

With

front

clutch

assembled

on

oil

pump

cover

direct

a

jet

of

air

into

hole

in

clutch

drum

for

definite

clutch

operation

AT152

Fig

AT

58

Taring

Front

Clutch

AT

32

REAR

a

UTCH

D1

mbl

AT313

1

Rear

clutch

drum

6

Snap

rina

2

Piston

7

SpriDa

3

Dished

plate

8

SDap

riJlI

4

Coil

sprina

9

Dri

plate

5

Rctainins

plate

10

Iltmm

plate

Fig

AT

59

Sectional

VielD

0

Rear

Clutch

1

Take

out

snap

ring

@

retaining

plate

@

drivc

plate

@

driven

plate

@

and

dished

plate

ID

Same

tech

nique

can

be

applied

as

in

disas

sembling

front

clutch

2

Remove

snap

ring

from

coil

spring

retainer

ST2S3200l

X

Fi6

AT

60

Remouing

SruJP

Ring

Page 285 of 548

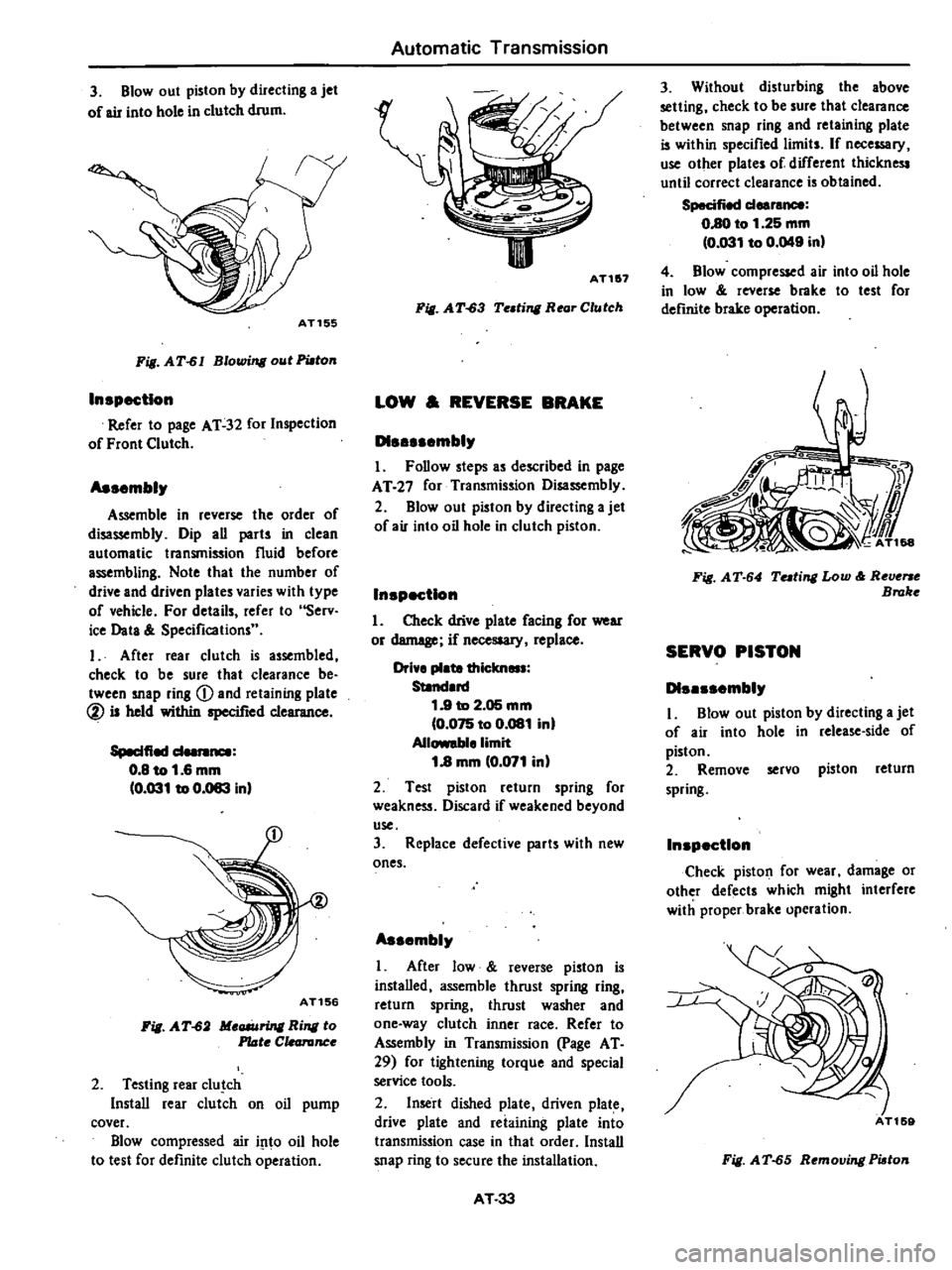

3

Blowout

piston

by

directing

a

jet

of

air

into

hole

in

clutch

drum

AT155

Fig

AT

61

Blowing

out

PWton

In

pectlon

Refer

to

page

AT

32

for

Inspection

of

Front

Clutch

As

mbly

Assemble

in

reverse

the

order

of

disassembly

Dip

all

parts

in

clean

automatic

transmission

fluid

before

assembling

Note

that

the

number

of

drive

and

driven

plates

varies

with

type

of

vehicle

For

details

refer

to

Serv

ice

Data

Specifications

I

After

rear

clutch

is

assembled

check

to

be

sure

that

clearance

be

tween

snap

ring

Q

and

retaining

plate

@

is

held

within

specified

clearance

Speelfied

d

0

8

to

1

6

mm

0

031

to

0

083

inl

AT156

Fig

AT

62

Meaiuring

Ring

to

Plate

C

canInce

2

Testing

rear

c1u

ch

Install

rear

clutch

on

oil

pump

cover

Blow

compressed

air

i

1to

oil

hole

to

test

for

definite

clutch

operation

Automatic

Transmission

II

AT1

7

Fill

A

T

63

Te

ting

Rear

Clutch

LOW

REVERSE

BRAKE

D1

mbly

I

Follow

steps

as

described

in

page

AT

27

for

Transmission

Disassembly

2

Blowout

piston

by

directing

a

jet

of

air

into

oil

hole

in

clutch

piston

In

pectlon

1

Check

drive

plate

facing

for

wear

or

demege

if

necesaary

replace

Drive

plate

thielm

Standard

1

9

to

2

05

mm

0

075

to

0

081

in

Allowable

limit

1

8

mm

0

071

inl

2

Test

piston

return

spring

for

weakness

Discard

if

weakened

beyond

use

3

Replace

defective

parts

with

new

ones

As

mbly

I

After

low

reverse

piston

is

installed

assemble

thrust

spring

ring

return

spring

thrust

washer

and

one

way

clutch

inner

race

Refer

to

Assembly

in

Transmission

page

AT

29

for

tightening

torque

and

special

service

tools

2

Insert

dished

plate

driven

plate

drive

plate

and

reiaining

plate

into

transmission

case

in

that

order

Install

snap

ring

to

secure

the

installation

AT

33

3

Without

disturbing

the

above

setting

check

to

be

sure

that

clearance

between

snap

ring

and

retaining

plate

is

within

specified

limits

If

nece

ry

use

other

plates

of

different

thickness

until

correct

clearance

is

obtained

Specified

deereM8

0

80

to

1

25

mm

0

031

to

0

049

inl

4

Blow

compressed

air

into

oil

hole

in

low

roverse

brake

to

test

for

deftnite

brake

operation

Fill

AT

64

Tuting

Low

Reverse

Broke

SERVO

PISTON

D1

mbly

I

Blowout

piston

by

dilecting

a

jet

of

air

into

hole

in

release

side

of

piston

2

Remove

servo

piston

return

spring

In

p

ctlon

Check

piston

for

wear

damage

or

other

defects

which

might

interfere

with

proper

brake

opcration

Fig

AT

65

Removing

Piaton

Page 286 of 548

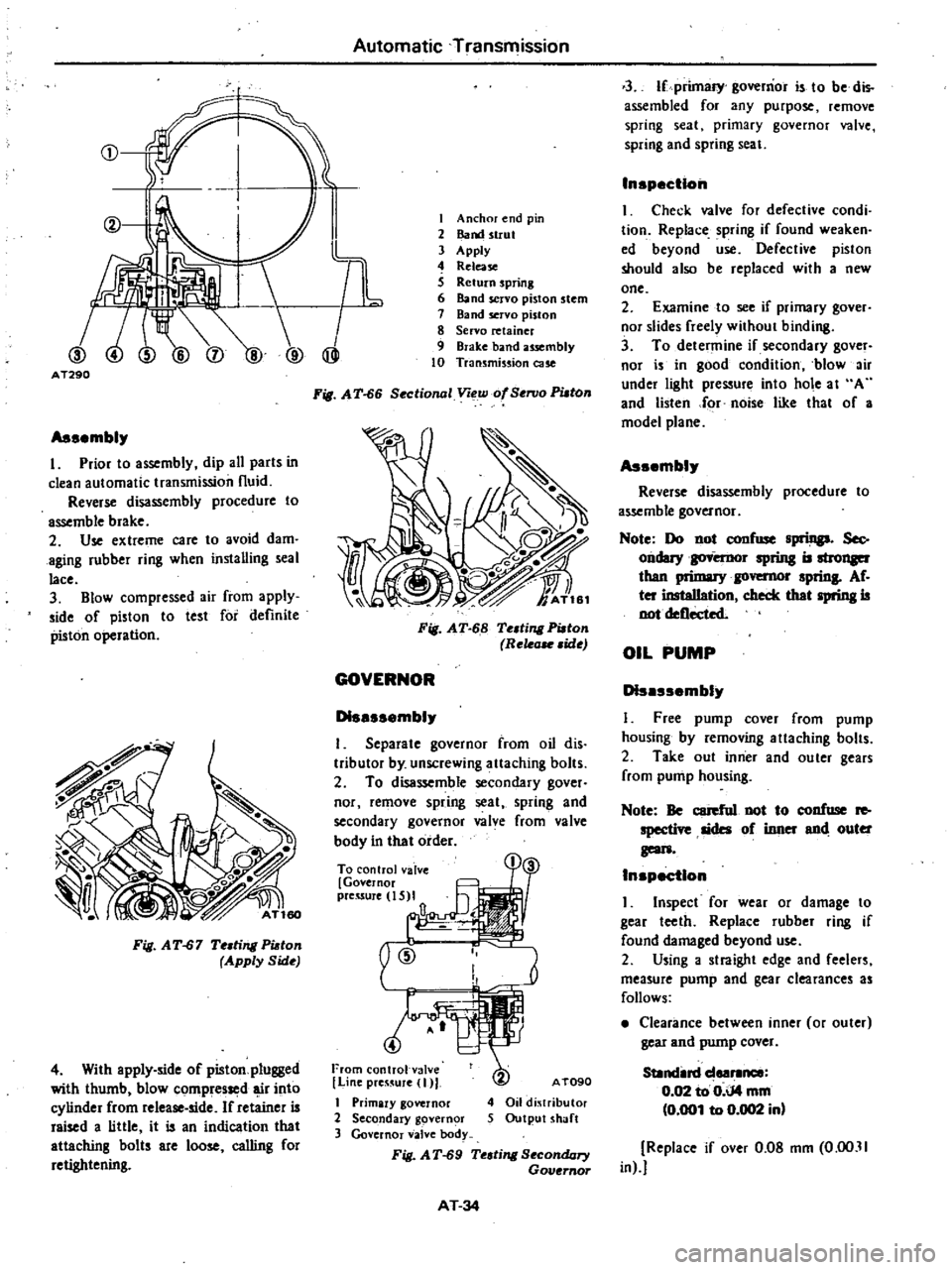

CD

@

I

I

TL

@

@

AT290

Assembl

I

Prior

to

assembly

dip

all

parts

in

clean

automatic

transmission

fluid

Reverse

disassembly

procedure

to

assemble

brake

2

Use

extreme

care

to

avoid

dam

aging

rubber

ring

when

installing

seal

lace

3

Blow

compressed

air

from

apply

side

of

piston

to

test

for

definite

piston

operation

Fig

AT

67

Te

ling

Pi

ton

Apply

Side

4

With

apply

side

of

piston

plugged

with

thumb

blow

compressed

r

into

cylinder

from

release

side

If

retainer

is

raised

a

little

it

is

an

indication

that

attaching

bolts

are

loose

calling

for

retightening

Automatic

Transmission

I

Anchor

end

pin

2

Band

strut

3

Apply

4

Release

S

Return

spring

6

Band

servo

piston

stem

7

Band

servo

piston

8

Servo

retainer

9

Brake

band

usembly

10

Transmission

cue

Fig

A

T

66

Sectional

Voew

of

SenJo

PUlOn

Fig

AT

68

Te

ting

Pi

ton

Rele

ide

GOVERNOR

D1sessembl

I

Separate

governor

from

oil

dis

tributor

by

unscrewing

attaching

bolts

2

To

disassemble

secondary

gover

nor

remove

spring

seat

spring

and

secondary

governor

valve

from

valve

body

in

that

order

To

control

valve

Governor

preuure

IS

I

a

@

From

control

val

e

I

Line

preS

UJe

I

I

Primary

governor

2

Secondary

govern

r

3

Governor

valve

body

Fig

AT

69

Te

ling

SecondQry

Governor

AT090

4

Oil

dj

tributor

5

Output

shaft

AT

34

3

If

primary

governor

is

to

be

dis

assembled

for

any

purpose

remove

spring

seat

primary

governor

valve

spring

and

spring

seal

Inspection

I

Check

valve

for

defective

condi

tion

Replace

spring

if

found

weaken

ed

beyond

use

Defective

piston

should

also

be

replaced

with

a

new

one

2

Examine

to

see

if

primary

gover

nor

slides

freely

without

binding

3

To

determine

if

secondary

gover

nor

is

in

good

condition

blow

ir

under

light

pressure

into

hole

at

A

and

listen

for

noise

like

thaI

of

a

model

plane

Assembl

Reverse

disassembly

procedure

to

assemble

governor

Note

Do

not

confuse

spriDp

Sec

ondary

spring

is

than

1

governor

sprinS

Af

ter

insteIIation

check

thet

spring

is

not

deflected

OIL

PUMP

D1sessembl

I

Free

pump

cover

from

pump

housing

by

removing

allaching

bolts

2

Take

out

inner

and

ouler

gears

from

pump

housing

Note

Be

cerefnl

not

to

confuse

Ie

specti

sides

of

inner

end

outer

geon

Inspection

I

Inspect

for

wear

or

damage

to

gear

teeth

Replace

rub

bel

ring

if

found

damaged

beyond

use

2

Using

a

straight

edge

and

feelers

measure

pump

and

gear

clearances

as

follows

Clearance

between

inner

or

outer

gear

and

pump

cover

SUndin

deer1lnee

0

02

to

0

iJ4

mm

0

001

to

0

002

in

Replace

if

over

0

08

mm

0

00

11

in

Page 287 of 548

Fig

AT

70

MeG6Uring

Clearonce

Clearance

between

seal

ring

and

ring

groove

Stendard

0

04

to

0

16

mm

10

002

to

0

006

in

I

31earance

Seal

ring

w

I

J

7

r

11

AT1

5

II

Fig

AT

71

MeG6Uring

Clearance

As

mblr

L

Set

up

pump

housing

with

inner

and

outer

pump

gears

on

it

2

Using

Oil

Pump

Assembling

Gauge

ST2SS80001

instan

pump

cover

to

pump

houaing

AT166

Fig

AT

72

Centering

Oil

Pump

3

Temporarily

tighten

pump

secur

ing

bolts

4

Set

the

cunout

of

oil

pump

cover

within

specified

total

indicator

read

ing

Automatic

Transmission

Total

indicator

reading

Lell

than

0

07

mm

10

0028

inl

ST2SSBOOOl

AT264

Fig

AT

73

Me

ring

Runout

S

Tighten

pump

securing

bolts

to

specified

torque

r

Tightening

torque

Oil

pump

housing

to

oil

pump

cover

0

6

to

0

8

kg

m

14

3

to

5

8

ft

Ibl

Note

Be

sure

to

align

con

ter

housini

securing

bolt

holes

6

Again

check

the

runout

of

oil

pump

cover

Note

When

former

Oil

Pump

As

sembling

Gauge

is

to

be

used

make

a

screw

hole

in

side

of

it

PLANETARY

CARRIER

The

planetary

carrier

cannot

be

divided

into

its

individual

components

If

any

part

of

component

is

defec

tive

replace

the

carrier

as

a

unit

In

p

ctlon

Check

clearance

between

pinion

washer

and

planetary

carrier

with

a

feeler

Standard

d

0

20

to

0

70

mm

0

008

to

0

028

in

AT

35

uan

r

J

II

I

AT1S7

Fig

AT

74

MeG6Uring

Pinion

Waaher

to

CanUr

Clearance

Replace

if

over

0

80

mm

0

031

in

CONTROL

VALVE

Tlte

control

valve

assembly

consists

of

many

precision

parts

and

requires

extreme

care

when

it

has

to

be

re

moved

and

serviced

It

is

good

practice

to

place

parts

in

a

part

rack

so

that

they

can

be

reassembled

in

valve

body

in

their

proper

positions

Added

care

should

also

be

exercised

to

prevent

springs

and

other

small

parts

from

being

sca

ttered

and

lost

Before

assembly

dip

all

parts

in

clean

automatic

transmission

fluid

and

check

to

be

certain

that

they

are

free

of

lint

and

other

minute

particles

If

clutch

or

band

is

burnt

or

if

oil

becomes

fouled

the

control

valve

as

sembly

should

be

disassembled

and

flushed

DI

mblr

I

Remove

bolts

and

nuts

which

retain

oil

strainer

Bolts

may

be

re

moved

with

a

screwdriver

but

it

is

recommended

that

Hexagon

Wrench

lIT61000S00

and

Spinner

Handle

lIT623S0000

b

used

Page 289 of 548

Automatic

Transmission

Inspection

I

Check

valves

for

sign

of

burning

tension

if

necessary

replace

5

Check

oil

passages

in

valve

body

and

if

necessary

replace

4

Examine

for

any

sign

of

damage

for

sign

of

damage

and

other

condi

2

Check

to

be

certain

that

oil

or

score

marks

on

separate

plate

If

tions

which

might

interfere

with

prop

strainer

is

in

good

condition

If

found

left

unheerlcd

oil

will

bypass

correct

er

valve

operation

damaged

in

any

manner

discard

oil

passages

causing

many

types

of

6

Check

bolts

for

stripped

threads

3

Test

valve

springs

for

weakened

abnormalities

in

the

system

Replace

as

required

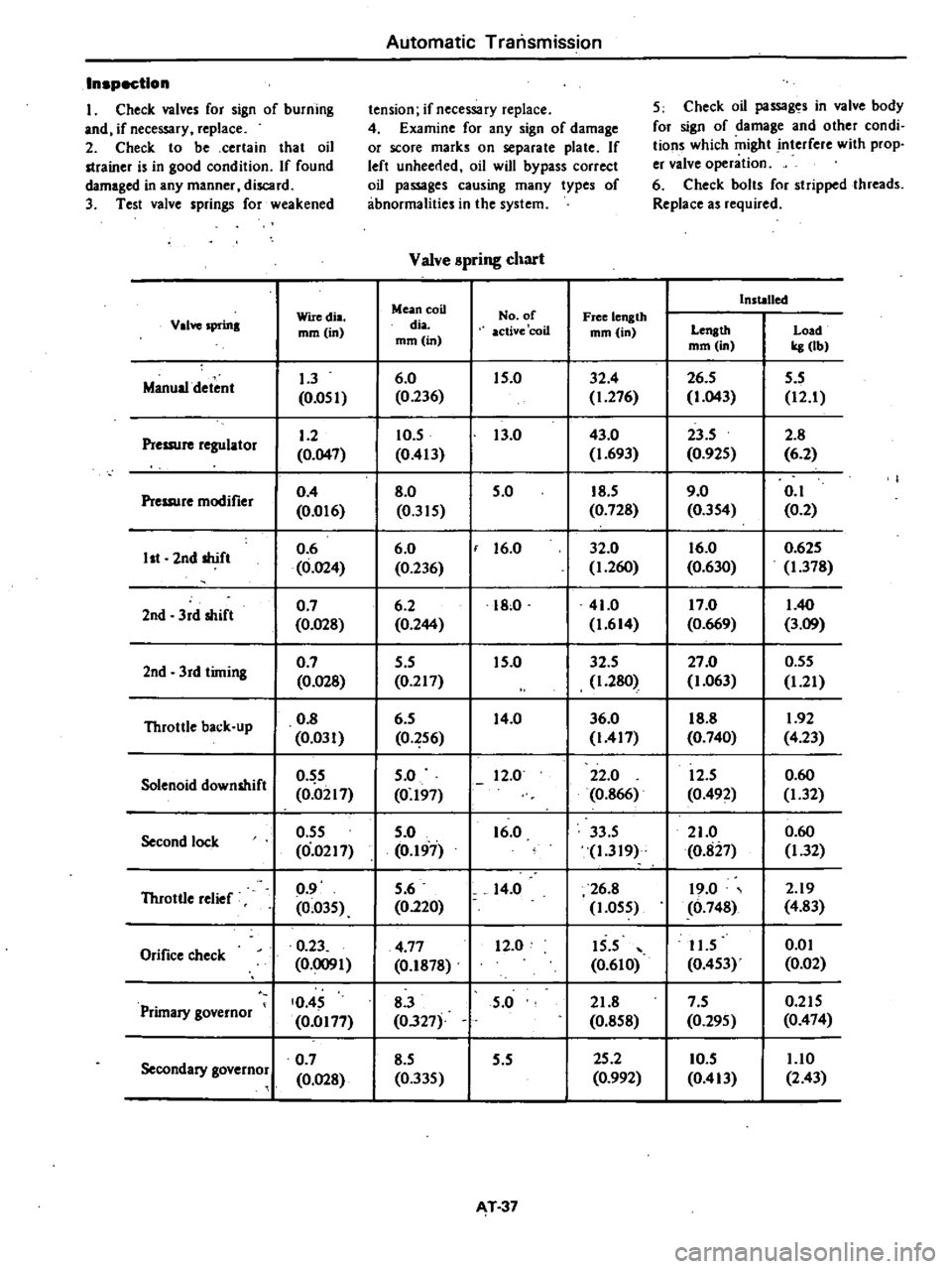

Valve

spring

chart

Mean

coil

Installed

Wiredia

No

of

Free

length

Valve

sprma

mm

in

dia

active

coil

mm

in

Length

Load

mm

in

mm

in

kg

lbl

Manual

detent

1

3

6

0

15

0

32

4

26

5

5

5

0

051

0

236

1

276

1

043

12

1

Pressure

regulator

1

2

10

5

13

0

43

0

23

5

2

8

0

047

0

413

1

693

0

925

6

2

Pressure

modifier

0

4

8

0

5

0

18

5

9

0

0

1

0

01

6

0

315

0

728

0

354

0

2

2nd

shift

0

6

6

0

f

16

0

32

0

16

0

0

625

1st

0

024

0

236

1

260

0

630

1

378

2nd

3rd

shift

0

7

6

2

18

0

41

0

17

0

1

40

0

028

0

244

1

614

0

669

3

09

2nd

3rd

timing

0

7

5

5

15

0

32

5

27

0

0

55

0

028

0

217

1

280

1

063

1

21

Throttle

back

up

0

8

6

5

14

0

36

0

18

8

1

92

0

031

0

256

1417

0

740

4

23

Solenoid

downshift

0

5

5

0

12

0

22

0

12

5

0

60

0

0217

0

197

0

866

0

492

1

32

Second

lock

0

55

5

0

16

0

33

5

21

0

0

60

0

0217

0

197

1

319

0

827

1

32

Throttle

relief

0

9

5

6

14

0

26

8

19

0

2

19

0

035

0

220

1

055

0

74g

4

83

Orifice

check

0

23

4

77

12

0

15

5

11

5

om

0

0091

0

lg78

0

610

0

453

0

02

Primary

governor

0

45

8

3

5

0

21

8

7

5

0

215

0

0177

0327

0

858

0

295

0

474

Secondary

governor

0

7

8

5

5

5

25

2

10

5

1

10

0

028

0

335

0

992

0

413

2

43

T

37

Page 290 of 548

0

1

1W

I

u

1

AT172

Fig

AT

8

1

ValveSpring

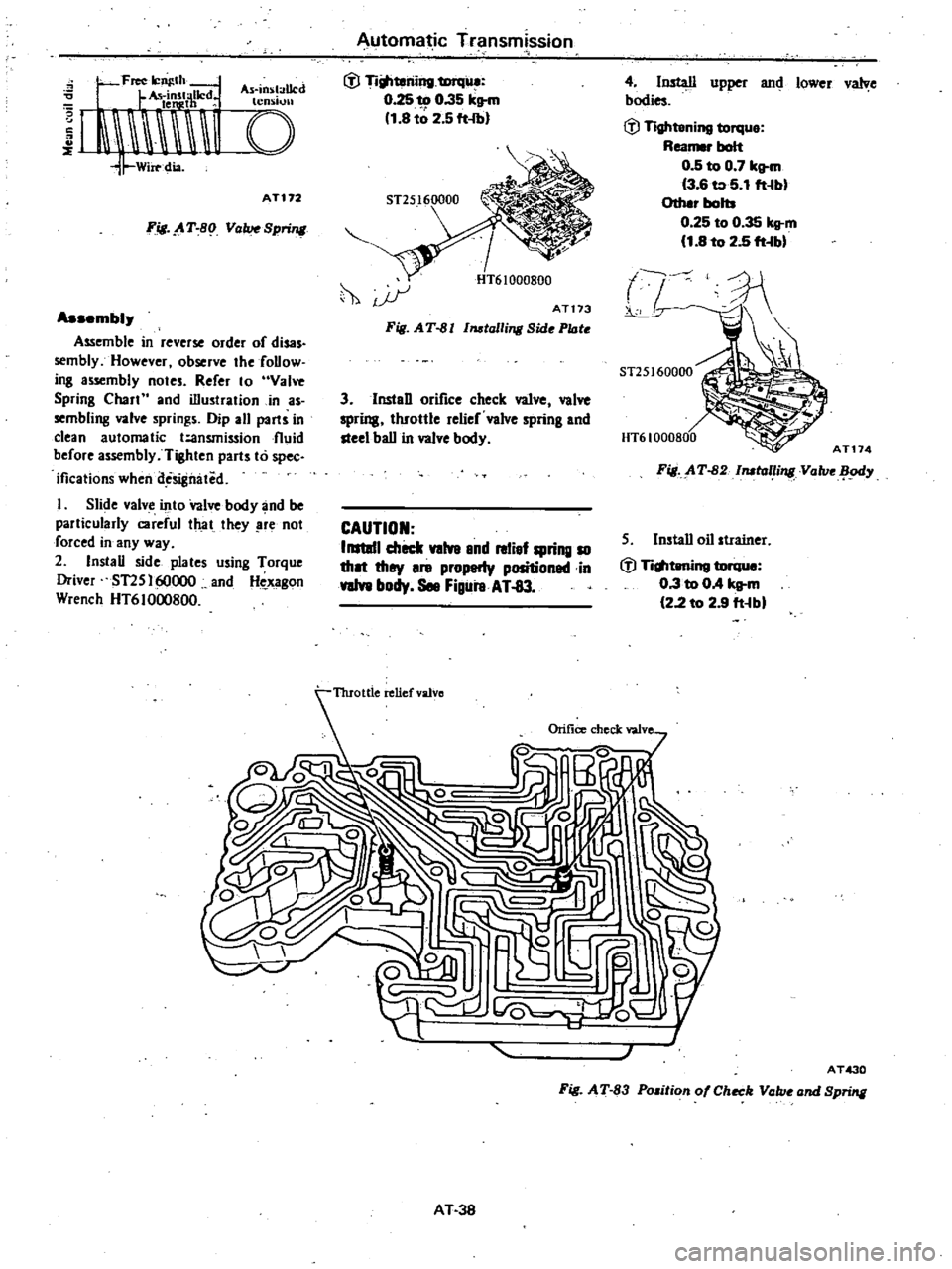

Assembly

Assemble

in

reverse

order

of

disas

semblyHowever

observe

the

follow

ing

assembly

notes

Refer

10

Valve

Spring

Chall

and

illustration

in

as

sembling

valve

springs

Dip

all

pailS

in

clean

automatic

t

ansmission

fluid

before

assembly

Tighten

parts

to

spec

ificalions

when

des

gmited

I

Slide

valve

into

Valve

body

and

be

palticularIy

careful

that

they

re

not

forced

in

any

way

2

Install

side

plates

using

Torque

Driver

ST2S

160000

and

Hc

xagon

Wrench

HT61000800

Automa

ic

Transm

ssion

tV

Ti

teriing

tmqile

0

25

to

0

35

kll

m

1

8

t

2

5

ft

lbl

4

InsWl

upper

and

lower

valve

bodies

tV

Tightening

torque

Reamer

bait

0

5

to

0

7

kll

m

13

6

to

5

1

ft

bl

Other

bolb

0

25

to

0

35

kg

m

11

8

to

2

5

ft

bl

hi

ST25160000

AT174

0

u

r

ATt73

HT61000800

Fig

AT

82

llIOlalli

Value

ody

S

Install

oil

strainer

tV

Titlltening

torque

0

3

to

OA

kg

m

122

to

2

9

ft

bl

Fig

AT

81

Il1Otalli

Side

Plate

3

lnstaD

orifice

check

valve

valve

spring

throttle

relief

valve

spring

and

steel

ball

in

valve

body

CAUTION

IIIItIII

check

valve

8nd

relief

spring

10

tho

they

8re

properly

positionadin

valve

body

See

Figure

AT

83

J

AT430

Fig

AT

83

Position

of

Check

Value

and

Spring

AT

38

Page 291 of 548

Automatic

Transmission

TROUBLE

DIAGNOSIS

AND

ADJUSTMENT

Since

mo

automatic

transmission

troubles

can

be

repaired

by

simple

adjustment

do

not

disassemble

im

media

tely

Firstly

inspect

and

adjust

the

auto

D1

3tic

transmission

in

place

utilizing

the

Trouble

Shooting

Chart

If

the

trouble

can

not

be

solved

by

this

procedure

remove

and

disas

semble

the

automatic

tlllnsmission

It

is

advisable

to

check

overhaul

and

repair

each

part

in

the

order

listed

in

the

Trouble

Shooting

Chart

In

the

Trouble

Shooting

Chart

the

diagnosis

items

are

arranged

ac

cording

to

difficulty

from

easy

to

difficult

therefore

please

follow

these

items

The

tlllnsmission

should

riot

be

removed

unless

necessary

2

Tests

and

adjustments

should

be

inade

on

the

basil

of

standard

values

and

the

data

Should

be

recorded

INSPECTION

AND

ADJUSTMENT

BEFORE

TROUBLE

DIAGNOSIS

TESTING

INSTRUMENT

FOR

INSPECTION

I

Engine

t

chometer

2

Vacuum

gauge

3

Oil

pressure

gauge

It

is

convenieni

to

install

these

instruments

in

a

way

that

allows

meas

urements

to

be

made

from

the

driver

s

seat

CHECKING

OIL

LEVEL

In

checkIng

the

automatic

transmis

sion

the

oil

level

and

the

condition

of

oil

around

the

oil

level

gauge

should

be

examined

every

S

ooo

Ion

3

000

miles

This

is

an

easy

and

effective

trouble

shooting

procedure

since

some

changes

in

oil

condition

are

often

linked

with

developed

troubles

For

instance

Lack

of

oil

causes

defective

opera

tion

by

making

the

clutches

and

brakes

slip

resulting

in

severe

wear

This

is

because

the

oil

pump

sucks

air

causing

oil

foaming

thus

rapidly

deteriorating

the

oil

quality

and

pro

ducing

sludge

and

varnish

Excessive

oil

is

also

bad

because

of

oil

foaming

caused

by

the

gears

stirring

up

the

oil

During

high

speed

driving

excessive

oil

in

the

transmission

often

hlows

out

from

the

brealher

Me

urlns

011

level

To

check

the

nuid

leyel

sian

Ihe

engine

and

run

it

until

normal

operat

ing

temperatures

oil

temperature

SO

to

800C

122

to

1160F

Approxi

mately

ten

minute

of

operation

will

raise

the

temperature

to

this

range

and

engine

idling

conditions

are

stabi

lized

Then

apply

the

brakes

and

move

the

transmission

shift

lever

through

aU

drive

positions

and

place

it

in

park

P

position

In

his

inspec

tion

the

car

must

be

placc

d

on

a

level

surface

The

amount

of

the

oil

varies

with

the

temperature

As

a

rule

the

oil

level

must

be

measured

after

its

tempera

ture

becomes

sufficiently

high

I

Fill

the

oil

to

the

line

H

The

difference

of

capacities

between

both

H

and

L

is

approximately

0

4

liter

J

U

S

pt

Y

Imp

pt

and

therefore

do

not

fill

beyond

the

line

H

2

When

topping

up

and

changing

oil

care

should

be

taken

to

prevent

mixing

the

oil

with

dusl

and

water

In

pectlns

oU

condition

The

condition

of

oil

sticking

to

the

level

gauge

indicates

whether

to

OVOl

haul

and

repair

the

transmission

or

luok

for

Ihe

defective

part

If

the

oil

has

deteriorated

to

a

varnish

ike

quality

it

causes

the

con

trol

valve

to

stick

Blackened

oil

indi

cates

a

burned

clutch

brake

band

etc

AT

39

In

these

cases

the

transmission

must

be

repaired

CAUTION

I

In

checking

oil

IlVal

use

special

piper

Cloth

tohandla

the

18V81

llIugi

Ind

be

careful

not

to

let

the

scraps

of

paper

end

cloth

stick

to

the

IlIUp

b

U

lutomatic

transmission

fluid

having

OEXRON

ida

ons

only

in

the

3N71

B

eutomatic

trans

mission

c

Pay

IttBntion

blcau

the

oil

to

be

used

differs

from

that

used

in

the

Nissen

Full

Autometic

TllInsmis

sion

3N71A

N8V8r

mill

thl

oils

Note

Insert

the

gauge

fully

and

take

it

out

quickly

before

splesbing

oil

edheres

to

the

gauge

Then

observe

the

level

INSPECTION

AND

REPAIR

OF

OIL

LEAKAGE

When

oil

leakage

takes

place

the

portion

near

the

leakage

is

covered

with

oil

presenting

difficulty

in

detecting

the

spot

Therefore

the

places

where

oil

seals

and

gaskets

are

equipped

are

enumerated

below

Converter

housing

Rubber

ring

of

oil

pump

housing

Oil

seal

of

oil

pump

housing

Oil

seal

of

engine

crankshaft

Bolts

of

converter

housing

to

case

2

Transmission

and

rear

extension

Junction

of

transmission

and

rear

extension

Oil

cooler

tube

connectors

Oil

pan

Oil

pressure

inspection

holes

See

Fig

AT

81

Mounting

portion

of

vacuum

dia

phragm

and

downshift

solenoid

Breather

and

oil

charging

pipe

Speedometer

pinion

sleeve

Oil

seal

of

rear

extension

To

exactly

locate

Ihe

place

of

oil

leakage

proceed

as

follows