Electrical DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 164 of 548

REMOVAL

AND

INSTALLATION

Disconnect

battery

ground

cable

Disconnect

harness

connector

and

battery

cable

at

magnetic

switch

2

Remove

bolts

securing

starting

motor

to

transmission

case

Pull

start

iog

motor

forward

and

remove

it

3

Inst

1I

starting

motor

in

reverse

order

of

removal

DISASSEMBLY

NON

REDUCTION

GEAR

TYPE

I

Disconnect

connecting

plate

from

M

terminal

of

magnetic

switch

Re

move

two

screws

securing

magnetic

switch

and

remove

magnetic

switch

assembly

2

Remove

dust

cover

E

ring

and

thrust

washer

s

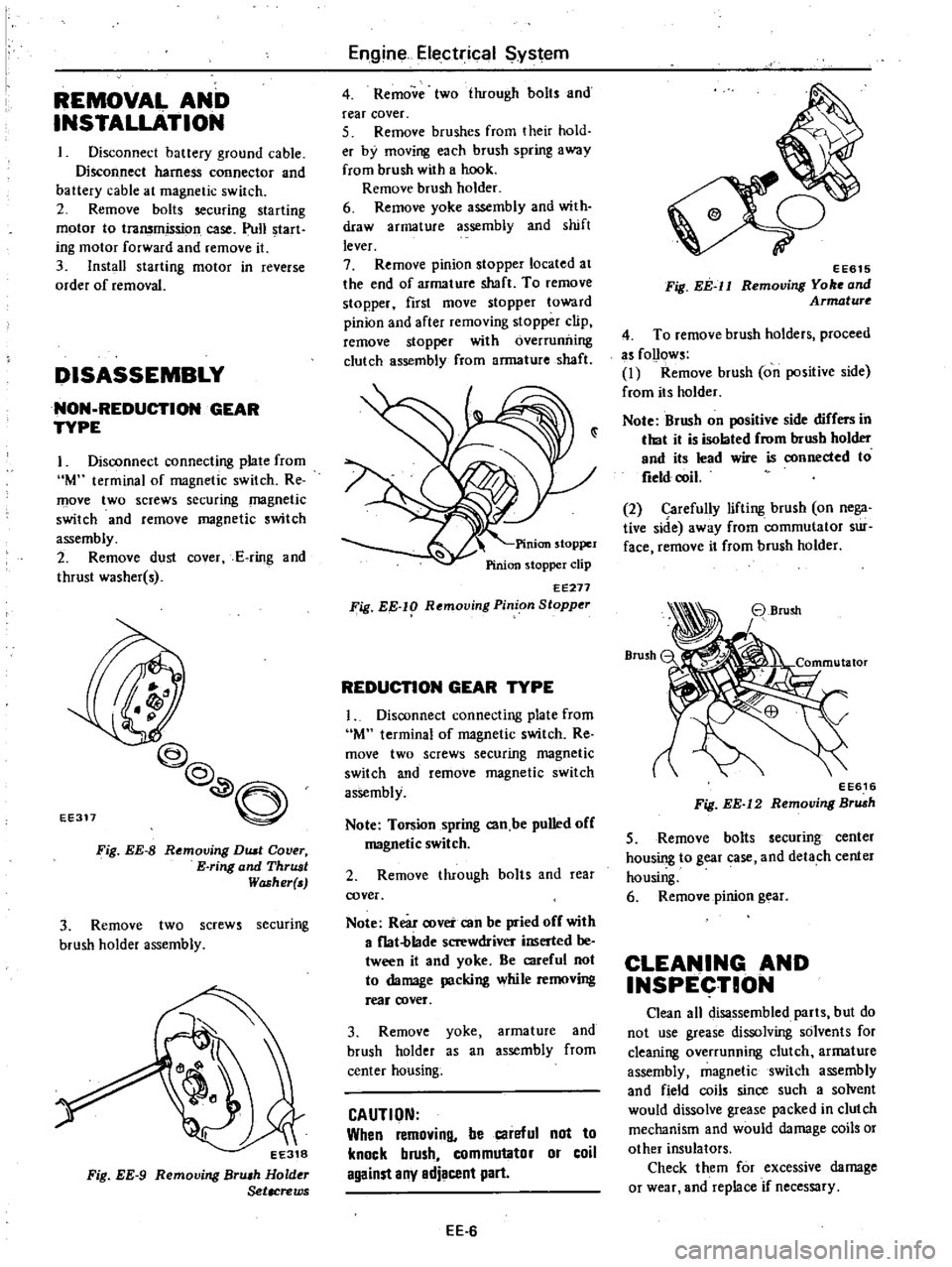

EE311

@@

O

Fig

EE

8

Removing

DUll

Cover

E

ring

and

ThrUJJt

Washer

3

Remove

two

screws

securing

brush

holder

assembly

EE318

Fig

EE

9

Removing

Bru

h

Hold

Setacrews

Engine

Electrical

ystem

4

Remove

two

ihrough

bolts

and

rear

cover

5

Remove

brushes

from

their

hold

er

by

moving

each

brush

spring

away

from

brush

with

a

hook

Remove

brush

holder

6

Remove

yoke

assembly

and

with

draw

armature

assembly

and

shift

lever

7

Remove

pinion

stopper

located

at

the

end

of

armature

shaft

To

remove

stopper

first

move

stopper

toward

pinion

and

after

removing

stopper

clip

remove

stopper

with

overruniling

clutch

assembly

from

armature

shaft

EE271

Fig

EE

lg

Rf

moving

Pinion

Stopper

REDUCTION

GEAR

TYPE

1

Disconnect

connecting

plate

from

M

terminal

of

magnetic

switch

Re

move

two

screws

securing

magnetic

switch

and

remove

magnetic

switch

assembly

Note

Torsion

spring

can

be

pulled

off

magnetic

switch

2

Remove

through

baIts

and

rea

cover

Note

Rear

cover

can

be

pried

off

with

a

f1at

blade

screwdriver

inserted

be

tween

it

and

yoke

Be

careful

not

to

damage

packing

while

removing

reaf

cover

3

Remove

yoke

armature

and

brush

holder

as

an

assembly

from

center

housing

CAUTION

When

removing

be

careful

not

to

knock

brush

commutator

or

coil

against

any

adjacent

part

EE

6

o

7

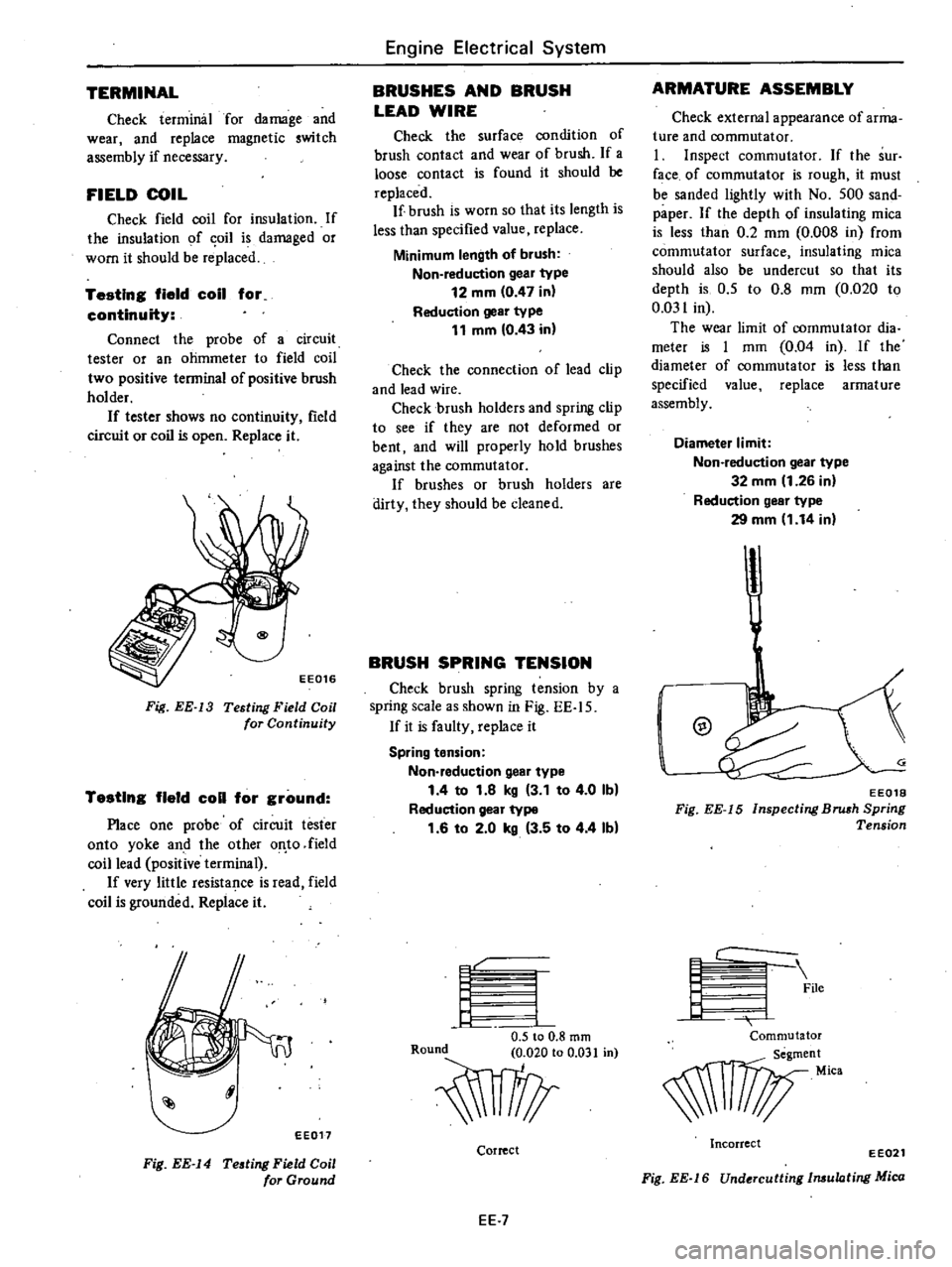

EE615

Fig

EE

ll

Removing

Yo

and

Armature

4

To

remove

brush

holders

proceed

as

follows

I

Remove

brush

on

positive

side

from

its

holder

Note

Brush

on

positive

side

differs

in

that

it

is

isolated

from

brush

holder

and

its

lead

wire

is

connected

to

field

coil

2

Carefully

lifting

brush

on

nega

tive

side

away

from

commutator

sur

face

remove

it

from

brush

holder

EE616

Fig

EE

12

Removing

Br

h

5

Remove

bolts

securing

center

housing

to

gear

case

and

detach

center

housing

6

Remove

pinion

gear

CLEANING

AND

INSPECTION

Clean

all

disassembled

parts

but

do

not

use

grease

dissolving

solvents

for

cleaning

overrunning

clutch

armature

assembly

magnetic

switch

assembly

and

field

coils

since

such

a

solvent

would

dissolve

grease

packed

in

clutch

mechanism

and

would

damage

coils

or

other

insulators

Check

them

for

excessive

damage

or

wear

and

replace

if

necessary

Page 165 of 548

TERMINAL

Check

terminal

for

damage

and

wear

and

replace

magnetic

switch

assembly

if

necessary

FIELD

COIL

Check

field

coil

for

insulation

If

the

insulation

of

oil

is

damaged

or

worn

it

should

be

replaced

Testing

field

coil

for

continuity

Connect

the

probe

of

a

circuit

tester

or

an

ohmmeter

to

field

coil

two

positive

terminal

of

positive

brush

holder

If

tester

shows

no

continuity

field

circuit

or

coil

is

open

Replace

it

Fig

EE

13

Testing

Field

Coil

for

Continuity

Testing

field

coli

for

ground

Place

one

probe

of

circuit

tester

onto

yoke

and

the

other

of

to

field

coil

lead

positive

terminal

If

very

little

resistance

is

read

field

coil

is

grounded

Replace

it

I

EE017

Fig

EE

14

Testing

Field

Coil

for

Ground

Engine

Electrical

System

BRUSHES

AND

BRUSH

LEAD

WIRE

Check

the

surface

condition

of

brush

contact

and

wear

of

brush

If

a

loose

contact

is

found

it

should

be

replaced

If

brush

is

worn

so

that

its

length

is

less

than

specified

value

replace

Minimum

length

of

brush

Non

reduction

gear

type

12

mm

0

47

in

Reduction

gear

type

11

mm

0

43

in

Check

the

connection

of

lead

clip

and

lead

wire

Check

brush

holders

and

spring

clip

to

see

if

they

are

not

deformed

or

bent

and

will

properly

hold

brushes

against

the

commutator

If

brushes

or

brush

holders

are

dirty

they

should

be

cleaned

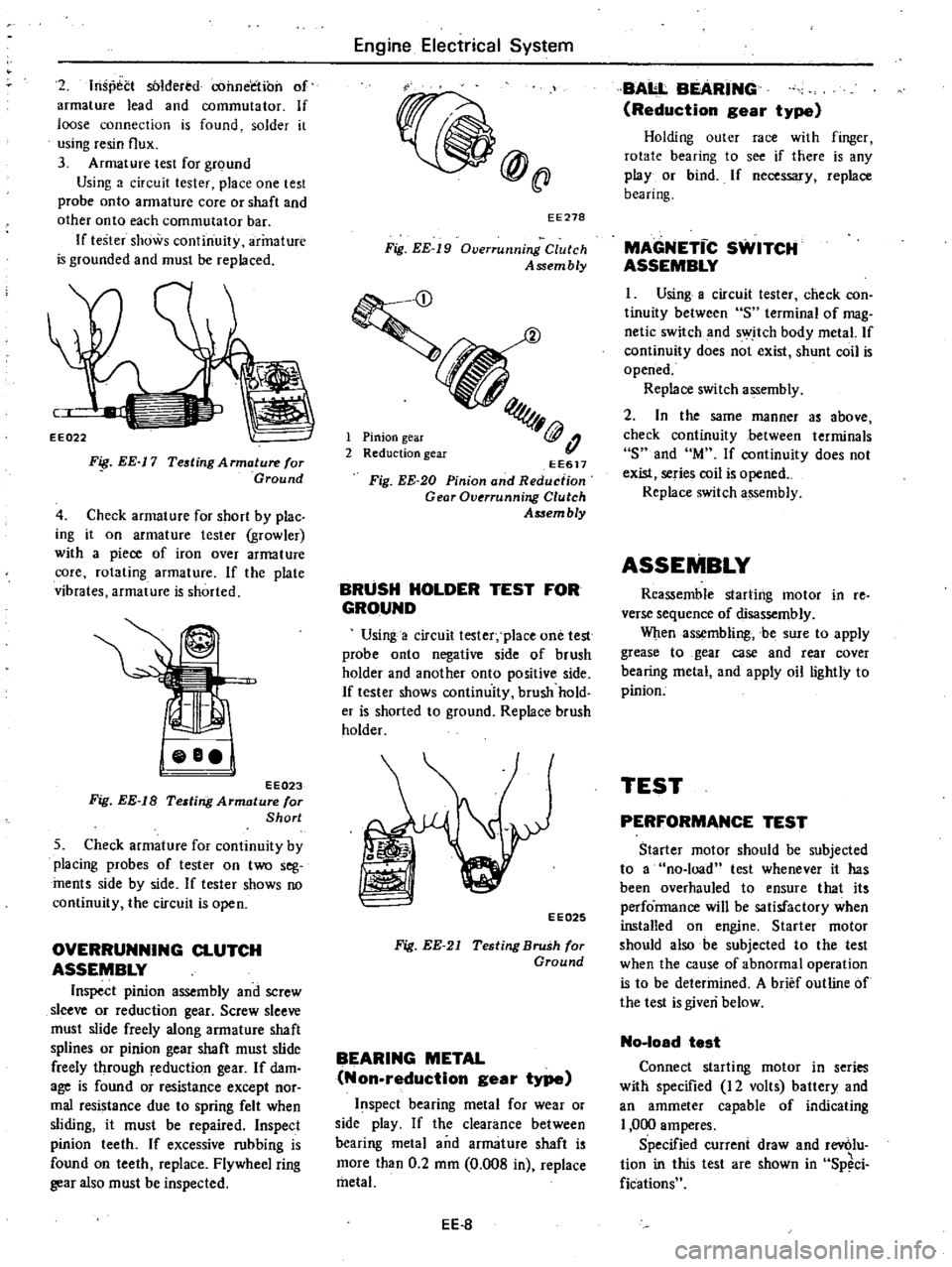

BRUSH

SPRING

TENSION

Check

brush

spring

tension

by

a

spring

scale

as

shown

in

Fig

EE

l

5

If

it

is

faulty

replace

it

Spring

tension

Non

reduction

geaf

type

1

4

to

1

8

kg

3

1

to

4

0

Ib

Reduction

gear

type

1

6

to

2

0

kg

3

5

to

4

4

Ib

I

r

4

1

0

5

to

0

8

rom

O

iO

Correct

EE

7

ARMATURE

ASSEMBLY

Check

external

appearance

of

arma

ture

and

oommutator

I

Inspect

commutator

If

the

sur

face

of

commutator

is

rough

it

must

be

sanded

lightly

with

No

500

sand

paper

If

the

depth

of

insulating

mica

is

less

than

0

2

mm

0

008

in

from

commutator

surface

insulating

mica

should

also

be

undercut

so

that

its

depth

is

0

5

to

0

8

mm

0

020

to

0

031

in

The

wear

limit

of

commutator

dia

meter

is

I

mm

0

04

in

If

the

diameter

of

commutator

is

less

than

specified

value

replace

armature

assembly

Diameter

limit

Non

reduction

gear

type

32

mm

1

26

in

Reduction

gear

type

29

mm

1

14

in

I

@

EE018

Fig

EE

15

Inspecting

Bnah

Spring

Tension

c

I

File

Commutator

nt

I

1

11

Mica

Incorrect

EE021

Fig

EE

16

Undercutting

Imulating

Mica

Page 166 of 548

2

Inspect

silldered

conneetibn

of

armature

lead

and

commutator

If

loose

connection

is

found

solder

it

using

resin

flux

3

Armature

test

for

ground

Using

a

circuit

tester

place

one

test

probe

onto

armature

core

or

shaft

and

other

onto

each

commutator

bar

If

tester

shows

continuity

armature

is

grounded

and

must

be

replaced

L

L

I

EE022

F

EE

17

Teating

Armature

for

Ground

4

Check

armature

for

short

by

plac

ing

it

on

armature

tester

growler

with

a

piece

of

iron

over

arma

t

ure

core

rotating

armature

If

the

plate

vibrates

armature

is

shorted

jeBel

EE023

Fig

EE

18

Testing

Armature

or

Short

5

Check

armature

for

continuity

by

placing

probes

of

tester

on

two

seg

ments

side

by

side

If

tester

shows

no

continuity

the

circuit

is

open

OVERRUNNING

CLUTCH

ASSEMBLY

Inspect

pinion

assembly

and

screw

sleeve

or

reduction

gear

Screw

sleeve

must

slide

freely

along

armature

shaft

splines

or

pinion

gear

shaft

must

slide

freely

through

reduction

gear

If

dam

age

is

found

or

resistance

except

nor

mal

resistance

due

to

spring

felt

when

sliding

it

must

be

repaired

Inspect

pinion

teeth

If

excessive

rubbing

is

found

on

teeth

replace

Flywheel

ring

gear

also

must

be

inspected

Engine

Electrical

System

@

ll

EE278

Fig

EE

19

Overrunning

Clutch

Assembly

1

Pinion

gear

2

Reduction

gear

EE617

Fig

EE

20

Pinion

and

Reduction

Gear

Overrunni11C

Clutch

AS5em

bly

BRUSH

HOLDER

TEST

FOR

GROUND

Using

a

circuit

tester

place

one

test

probe

onto

negative

side

of

brush

holder

and

another

onto

positive

side

If

tester

shows

continuity

brush

hold

er

is

shorted

to

ground

Replace

brush

holder

EE025

Fig

EE

21

Testing

Brush

for

Ground

BEARING

METAL

Non

reduction

gear

type

spect

bearing

metal

for

wear

or

side

play

If

the

clearance

between

bearing

metal

and

armature

shaft

is

more

than

0

2

mm

0

008

in

replace

metal

EE

8

BAI

L

BEARING

Reduction

gear

type

Holding

outer

race

with

finger

rotate

bearing

to

see

if

there

is

any

play

or

bind

If

necessary

replace

bearing

MAGNETic

SWITCH

ASSEMBLY

I

Using

a

circuit

tester

check

con

tinuity

between

S

terminal

of

mag

netic

switch

and

switch

body

metal

If

continuity

does

not

exist

shunt

coil

is

opened

Replace

switch

assembly

2

In

the

same

manner

as

above

check

continuity

between

terminals

S

and

M

If

continuity

does

not

exist

series

coil

is

opened

Replace

switch

assembly

ASSEMBLY

Reassemble

starting

motor

in

re

verse

sequence

of

disassembly

When

assembling

be

sure

to

apply

grease

to

gear

case

and

rear

cover

bearing

metal

and

apply

oil

lightly

to

pinion

TEST

PERFORMANCE

TEST

Starter

motor

should

be

subjected

to

a

no

load

test

whenever

it

has

been

overhauled

to

ensure

that

its

perfo

rmance

will

be

satisfactory

when

installed

on

engine

Starter

motor

should

also

be

subjected

to

the

test

when

the

cause

of

abnormal

operation

is

to

be

determined

A

brief

outline

of

the

test

is

given

below

No

loadtest

Connect

starting

motor

in

series

willi

specified

12

volts

battery

and

an

ammeter

capable

of

indicating

1

000

amperes

Specified

current

draw

and

rev6lu

tion

in

this

test

are

shown

in

Sp

ci

Cications

Page 167 of 548

Starting

motor

S

DIAGNOSES

OF

TEST

I

Low

speed

with

no

load

and

high

current

draw

may

result

from

the

following

I

Tight

dirty

or

worn

bearings

2

Bent

armature

shaft

or

loosened

field

probe

3

Shorted

armature

Check

armature

further

4

A

grounded

armature

or

field

a

Remove

input

terminal

b

Raise

two

negative

side

brushes

from

commutator

c

Using

a

circuit

tester

place

one

probe

onto

input

terminal

and

the

other

onto

yoke

d

If

tester

indicates

continuity

raise

the

other

two

brushes

and

check

field

and

armature

separately

to

deter

mine

whether

field

or

armature

is

grounded

2

Failure

to

operate

with

high

cur

rent

draw

may

be

caused

by

the

following

I

A

grounded

or

open

field

coil

Inspect

the

connection

and

trace

circuit

with

a

circuit

tester

2

Armature

coil

does

not

operate

Inspect

commutator

for

excessive

burning

In

this

case

arc

may

occur

on

damaged

commutator

when

motor

is

operated

with

no

load

3

Burned

out

commutator

bar

Weak

brush

spring

tension

broken

Engine

Electrical

System

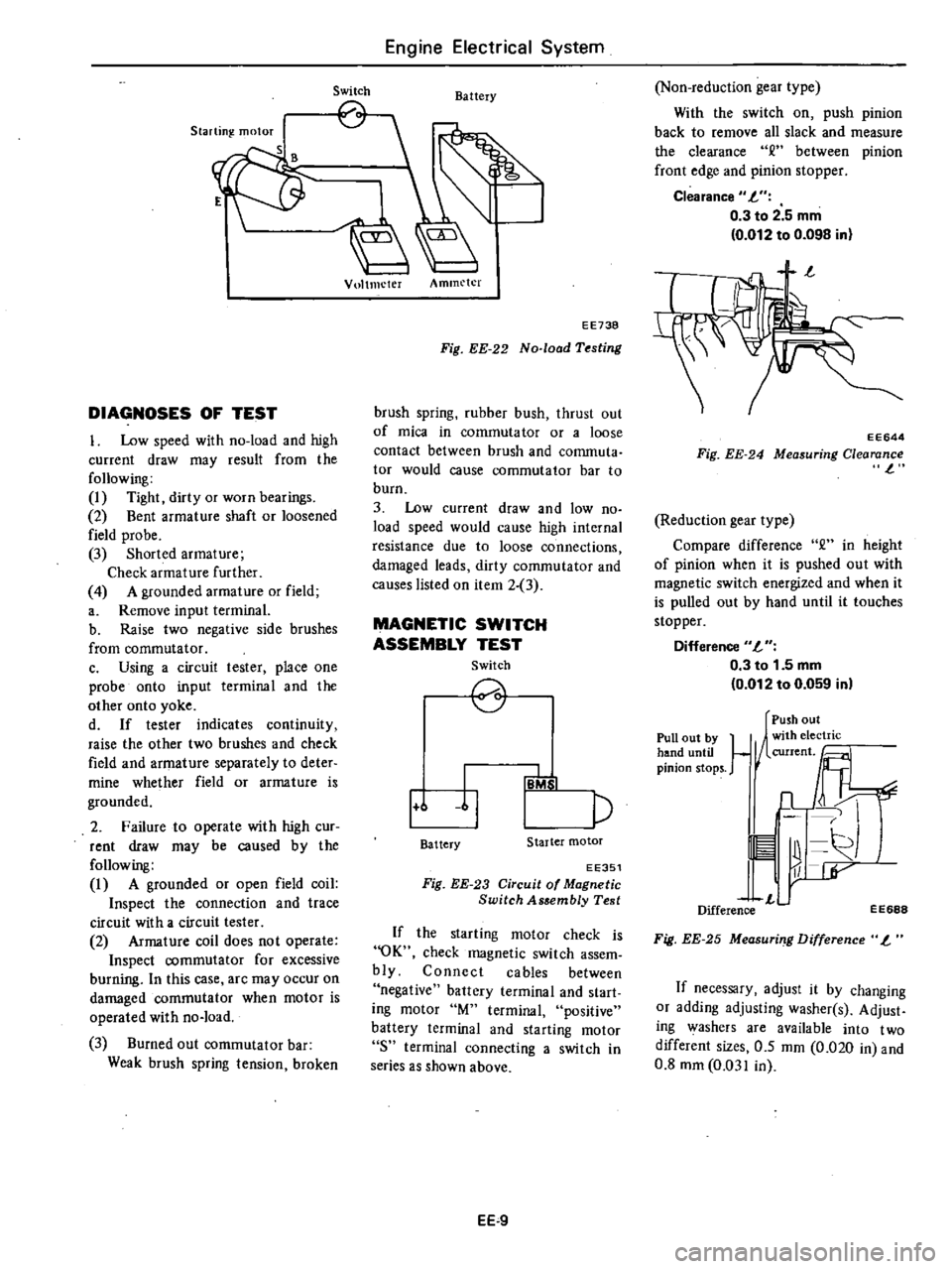

Switch

Battery

Vultmeter

Ammeter

EE738

Fig

EE

22

No

load

Testing

brush

spring

rubber

bush

thrust

out

of

mica

in

commuta

tor

or

a

loose

contact

between

brush

and

conunuta

tor

would

cause

commutator

bar

to

burn

3

Low

current

draw

and

low

no

load

speed

would

cause

high

internal

resistance

due

to

loose

connections

damaged

leads

dirty

commutator

and

causes

listed

on

item

2

3

MAGNETIC

SWITCH

ASSEMBLY

TEST

Switch

2

1

6

11

p

IB

b

I

Battery

Starter

motor

EE351

Fig

EE

23

Circuit

of

Magnetic

Switch

Assembly

Test

If

the

starting

motor

check

is

OK

check

magnetic

switch

assem

bly

Connect

cables

between

negative

battery

terminal

and

start

ing

motor

M

terminal

positive

battery

terminal

and

starting

motor

8

terminal

connecting

a

switch

in

series

as

shown

above

EE

9

Non

reduction

gear

type

With

the

switch

on

push

pinion

back

to

remove

all

slack

and

measure

the

clearance

between

pinion

front

edge

and

pinion

stopper

Clearance

L

0

3

to

2

5

mm

0

012

to

0

098

in

EE644

Fig

EE

24

Measuring

Clearance

l

Reduction

gear

type

Compare

difference

2

in

height

of

pinion

when

it

is

pushed

out

with

magnetic

switch

energized

and

when

it

is

pulled

out

by

hand

until

it

touches

stopper

Difference

L

0

3

to

1

5

mm

0

012

to

0

059

in

Pull

out

by

hand

until

pinion

stops

Push

out

1

1

n

11

r

L

Difference

EE688

Fig

EE

25

Measuri

g

Difference

L

If

necessary

adjust

it

by

changing

or

adding

adjusting

washer

s

Adjust

ing

washers

are

available

into

two

different

sizes

0

5

mm

0

020

in

and

0

8

mm

0

031

in

Page 168 of 548

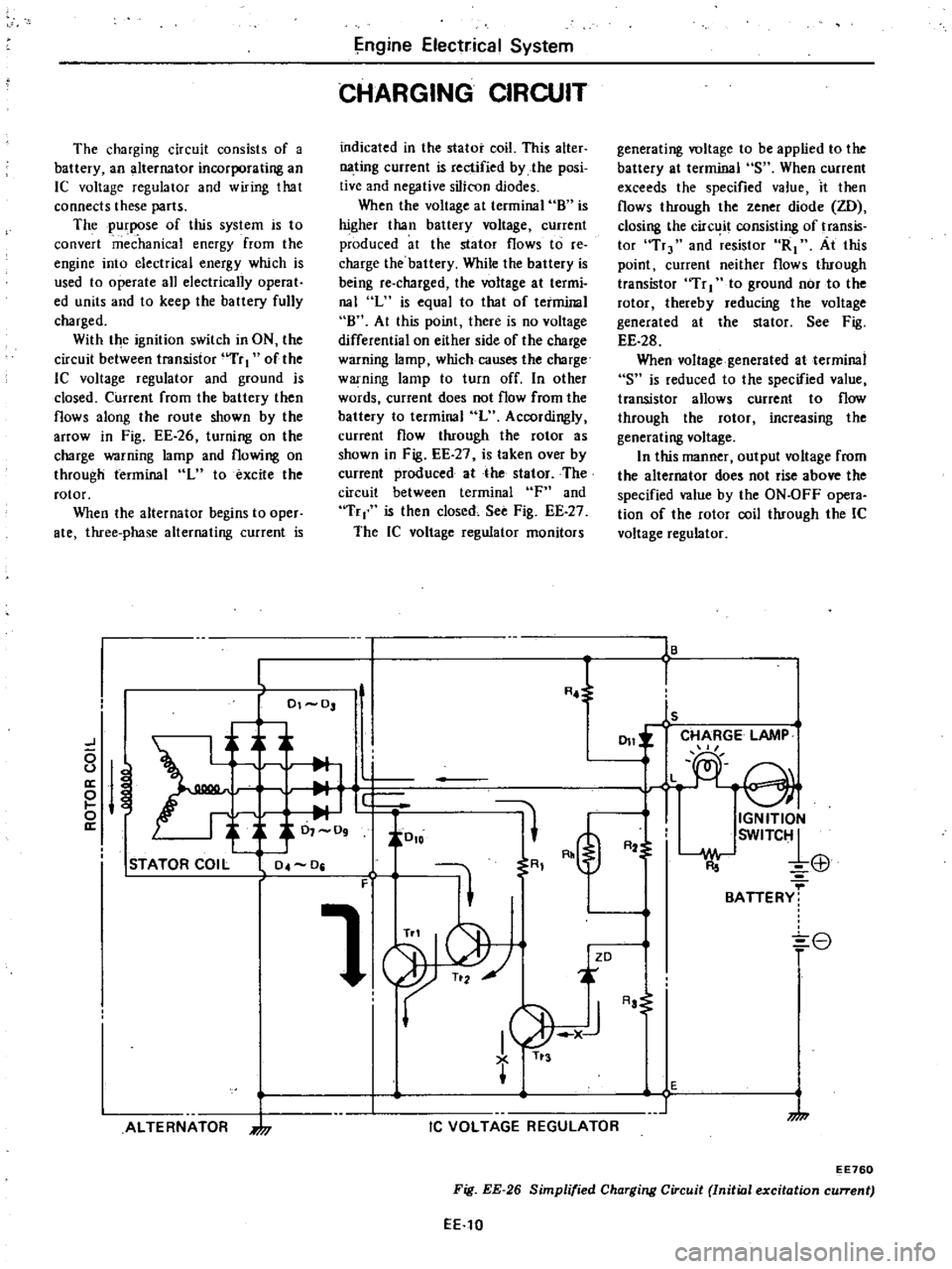

The

charging

circuit

consists

of

a

battery

an

alternator

incorporating

an

IC

voltage

regulator

and

wiring

that

connects

these

parts

The

purpose

of

this

system

is

to

convert

mec

hanka

energy

from

the

engine

into

electrical

energy

which

is

used

to

operate

all

electrically

operat

ed

units

and

to

keep

the

battery

fully

charged

With

the

ignition

switch

in

ON

the

circuit

between

transistor

uTr

I

of

the

lC

voltage

regulator

and

ground

is

closed

Current

from

the

battery

then

flows

along

the

route

shown

by

the

arrOW

in

Fig

EE

26

turning

on

the

charge

warning

lamp

and

flowing

on

through

terminal

L

to

excite

the

rotor

When

the

alternator

begins

to

oper

ate

three

phase

alternating

current

is

ngine

Elect

ical

System

CHARGING

CIRCUIT

indicated

in

the

stator

coil

This

alter

nating

current

is

rectified

by

the

posi

tive

and

negative

silicon

diodes

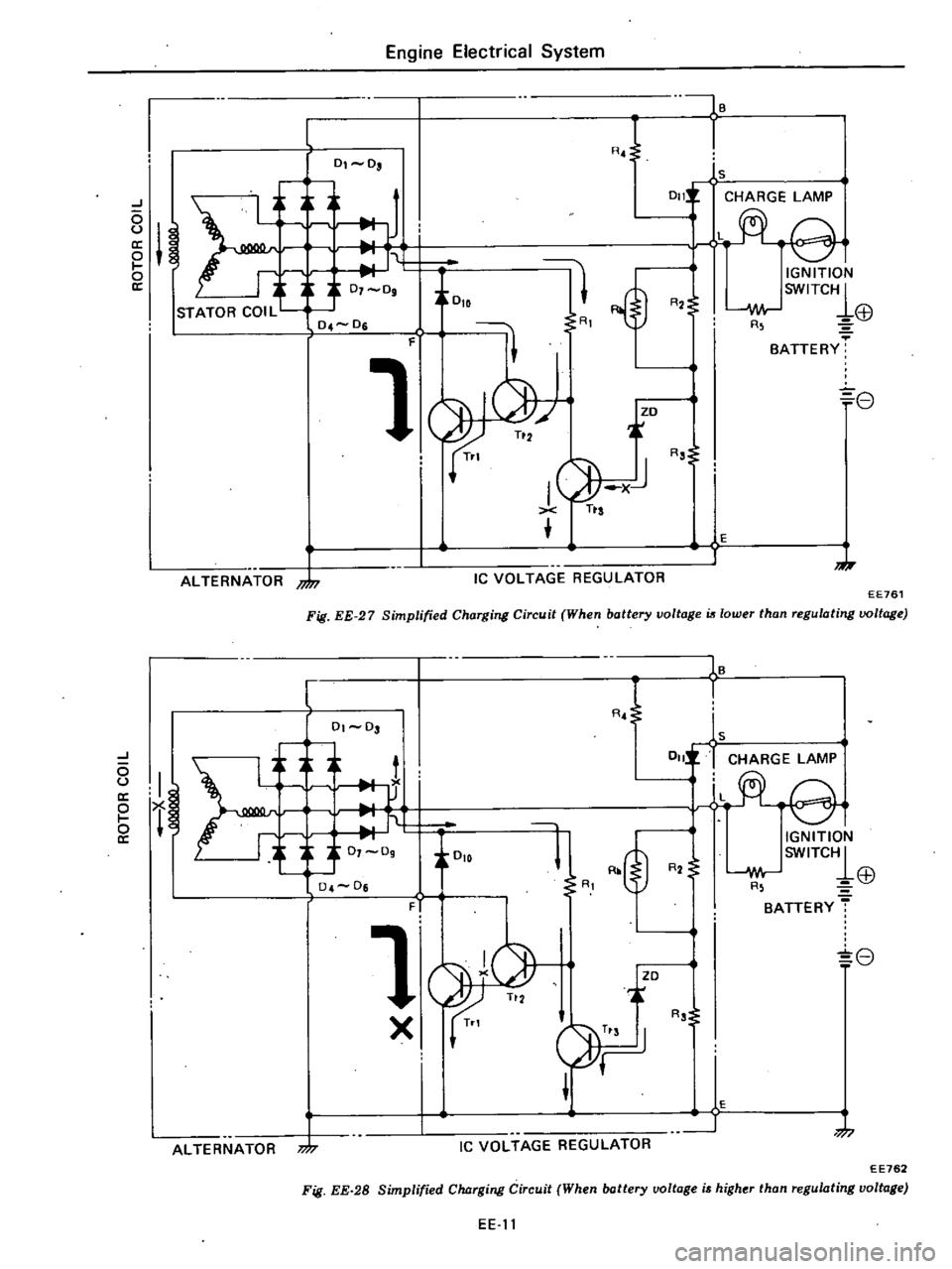

When

the

voltage

at

terminal

8

is

higher

than

battery

voltage

current

produced

at

the

stator

flows

to

re

charge

the

battery

While

the

battery

is

being

re

charged

the

voltage

at

termi

nal

L

is

equal

to

that

of

terminal

8

At

this

point

there

is

no

voltage

differential

on

either

side

of

the

charge

warning

lamp

which

causes

the

charge

warning

lamp

to

turn

off

In

other

words

current

does

not

flow

from

the

battery

to

terminal

L

Accordingly

current

flow

through

the

rotor

as

shown

in

Fig

EE

27

is

taken

over

by

current

produced

at

the

stator

The

circuit

between

terminal

F

and

Tr

is

then

closed

See

Fig

EE

27

The

IC

voltage

regulator

monitors

generating

voltage

to

be

applied

to

the

battery

at

terminal

S

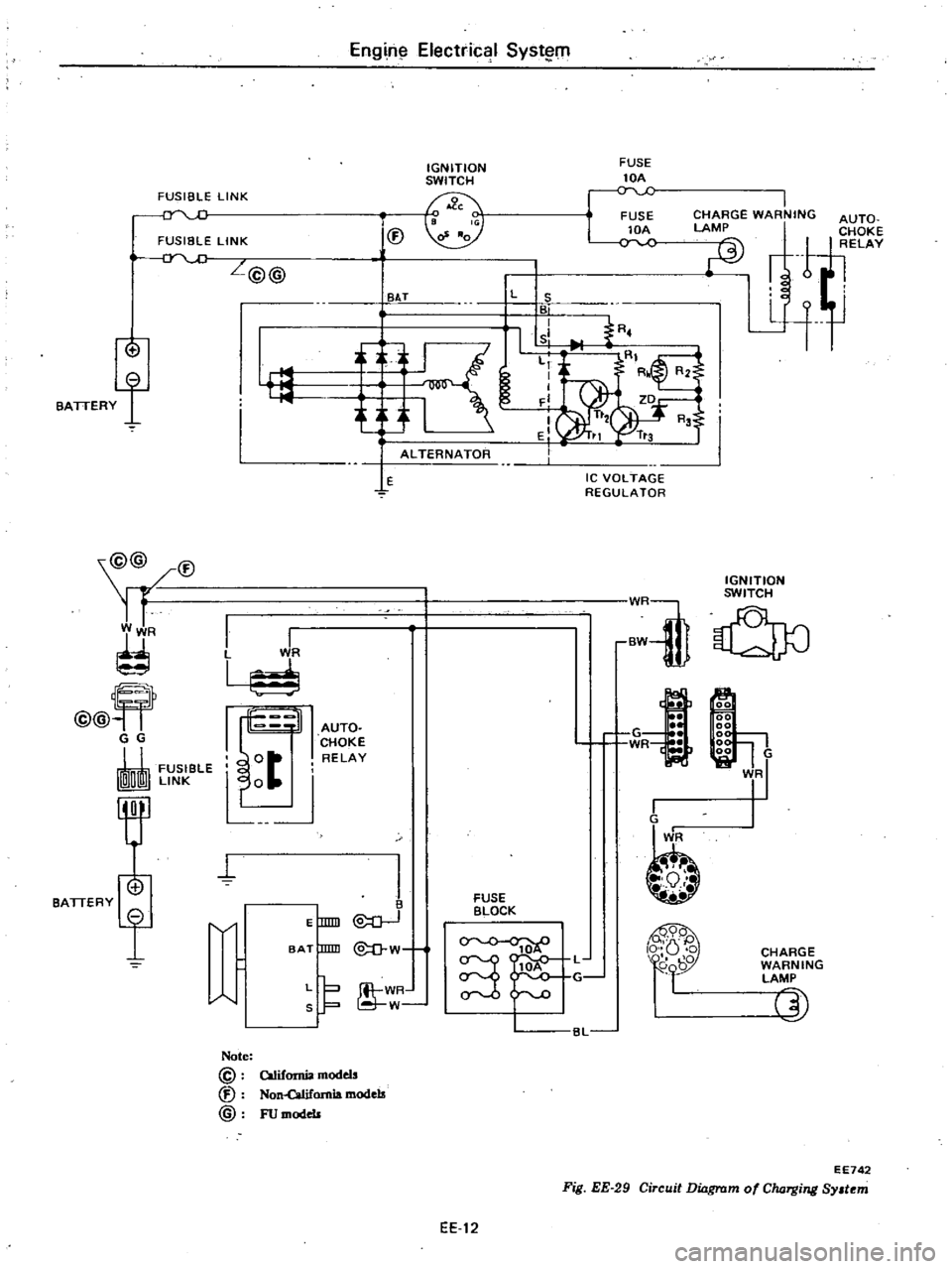

When

current

exceeds

the

specified

value

it

then

flows

through

the

zener

diode

ZD

closing

the

circ

it

consisting

of

transis

tor

Tr

and

resistor

R1

At

this

point

current

neither

flows

through

transistor

Tr

I

to

ground

nor

to

the

rotor

thereby

reducing

the

voltage

generated

at

the

stator

See

Fig

EE

28

When

voltage

generated

at

terminal

S

is

reduced

to

the

specified

value

transistor

allows

current

to

flow

through

the

rotor

increasing

the

generating

voltage

In

this

manner

output

voltage

from

the

alternator

does

not

rise

above

the

specified

value

by

the

ON

OFF

opera

tion

of

the

rotor

coil

through

the

IC

voltage

regulator

16

L

R

l

I

01

0

ls

CHARGE

LAMP

J

011

L

e

0

u

a

M

e

i

J

0

io

o

IGNITION

a

0

09

SWITC1

R2

El1

STATOR

COIL

04

0

R

F

1

BATTERY

8

ZD

ALTERNATOR

7

I

1

AJ

TI

3

IC

VOLTAGE

REGULATOR

Aa

E

1

7

EE760

Fig

EE

26

Simplified

Charging

Circuit

Initial

excitation

current

EE

10

Page 169 of 548

J

o

u

o

ll

ALTERNATOR

nJn

l

0

0

Engine

Electrical

System

F

00IB

RJ

1

1s

0111

CHARGE

LAMP

rt

ei

tOlD

11

1

IGNITION

SWITC1

R2

i

I

oJor

EB

R

BATTERY

f

3

07

09

0

4

0

1

8

r

I

G

XiJ

Tts

R

o

s

o

E

1

J

IC

VOLTAGE

REGULATOR

Fig

EE

27

Simplified

Charging

Circ14it

When

battery

voltage

is

lower

than

regulating

voltage

EE761

I

h

it

r

f

1

0

0

J

o

U

ll

o

I

o

cr

ALTERNATOR

m

l

01

03

1

X

RJ

16

I

1s

OIlI

r

CHARGE

LAMP

L

l

@

R2

IGNITION

SWITCH1

w

Lp

R

l

Q7

BATTERY

T

8

T

F

i

R

j

JZO

RS

E

J

7

Ie

VOLTAGE

REGULATOR

EE762

Fig

EE

28

Simplified

Cluzrging

Circuit

When

battery

voltage

i

higher

than

regulating

voltage

EE

11

Page 170 of 548

FUSIBLE

LINK

FUSIBLE

LINK

f

BATTERY

@@

V

R

@@

G

G

FUSleLE

ImrnI

LI

NK

MTI

I

En

g

n

l

Electrical

Syst

lOl

IGNITION

SWITCH

FUSE

lOA

o

v

FUSE

lOA

C

V

L@@

BAT

f

L

S

BI

I

I

sl

fRO

L

I

I

F

I

EI

i

K

a

ALTERNATOR

lE

Ie

VOLTAGE

REGULATOR

I

I

L

WR

I

1

d

I

t

J

t

IGNITION

WR

SWITCH

BW

U

0

AUTO

CHOKE

RELAY

G

1

WR

J

I

00

00

gg

1

00

VR

1

E

lDID

I

@

O

BAT

mID

W

J

WR

W

FUSE

BLOCK

CHARGE

WARNING

LAMP

5J

BL

Note

@

V

@

California

models

Non

Qilifomo

18

models

FU

models

Fig

EE

29

Circuit

Dinrswr

EE742

mofCIuJ

Tg

ng

Sy

t

m

EE

12

Page 171 of 548

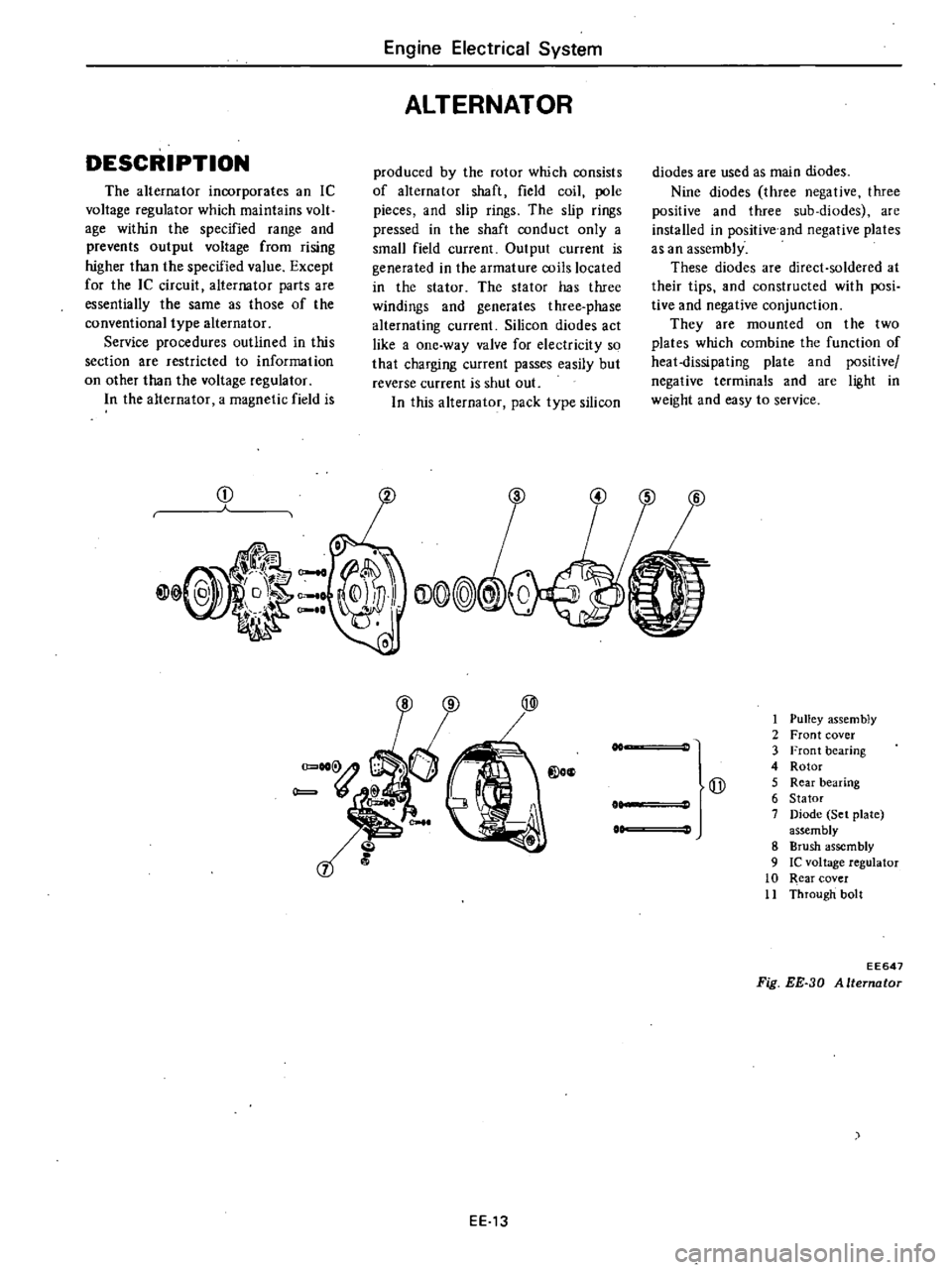

DESCRIPTION

The

alternator

incorporates

an

Ie

voltage

regulator

which

maintains

volt

age

within

the

specified

range

and

prevents

output

voltage

from

rising

higher

than

the

specified

value

Except

for

the

Ie

circuit

alternator

parts

are

essentially

the

same

as

those

of

the

conventional

type

alternator

Service

procedures

outlined

in

this

section

are

restricted

to

information

on

other

than

the

voltage

regulator

In

the

alternator

a

magnetic

field

is

CD

Engine

Electrical

System

ALTERNATOR

produced

by

the

rotor

which

consists

of

alternator

shaft

field

coil

pole

pieces

and

slip

rings

The

slip

rings

pressed

in

the

shaft

conduct

only

a

small

field

current

Output

current

is

generated

in

the

armature

coils

located

in

the

stator

The

stator

has

three

windings

and

generates

three

phase

alternating

current

Silicon

diodes

act

like

a

one

way

valve

for

electricity

so

that

charging

current

passes

easily

but

reverse

current

is

shut

out

In

this

alternator

pack

type

silicon

diodes

are

used

as

main

diodes

Nine

diodes

three

negative

three

positive

and

three

sub

diodes

are

installed

in

positive

and

negative

plates

as

an

assembly

These

diodes

are

direct

soldered

at

their

tips

and

constructed

with

posi

tive

and

negative

conjunction

They

are

mounted

on

the

two

plates

which

combine

the

function

of

heat

dissipating

plate

and

positive

negative

terminals

and

are

light

in

weight

and

easy

to

service

EE13

1

Pulley

assem

bly

2

Front

cover

3

Front

bearing

4

Rotor

Qj

5

Rear

bearing

6

Stator

7

Diode

Set

plate

assembly

8

Brush

assembly

9

Ie

voltage

regulator

10

Rear

cover

11

Through

bolt

EE647

Fig

EE

30

Alternator

Page 172 of 548

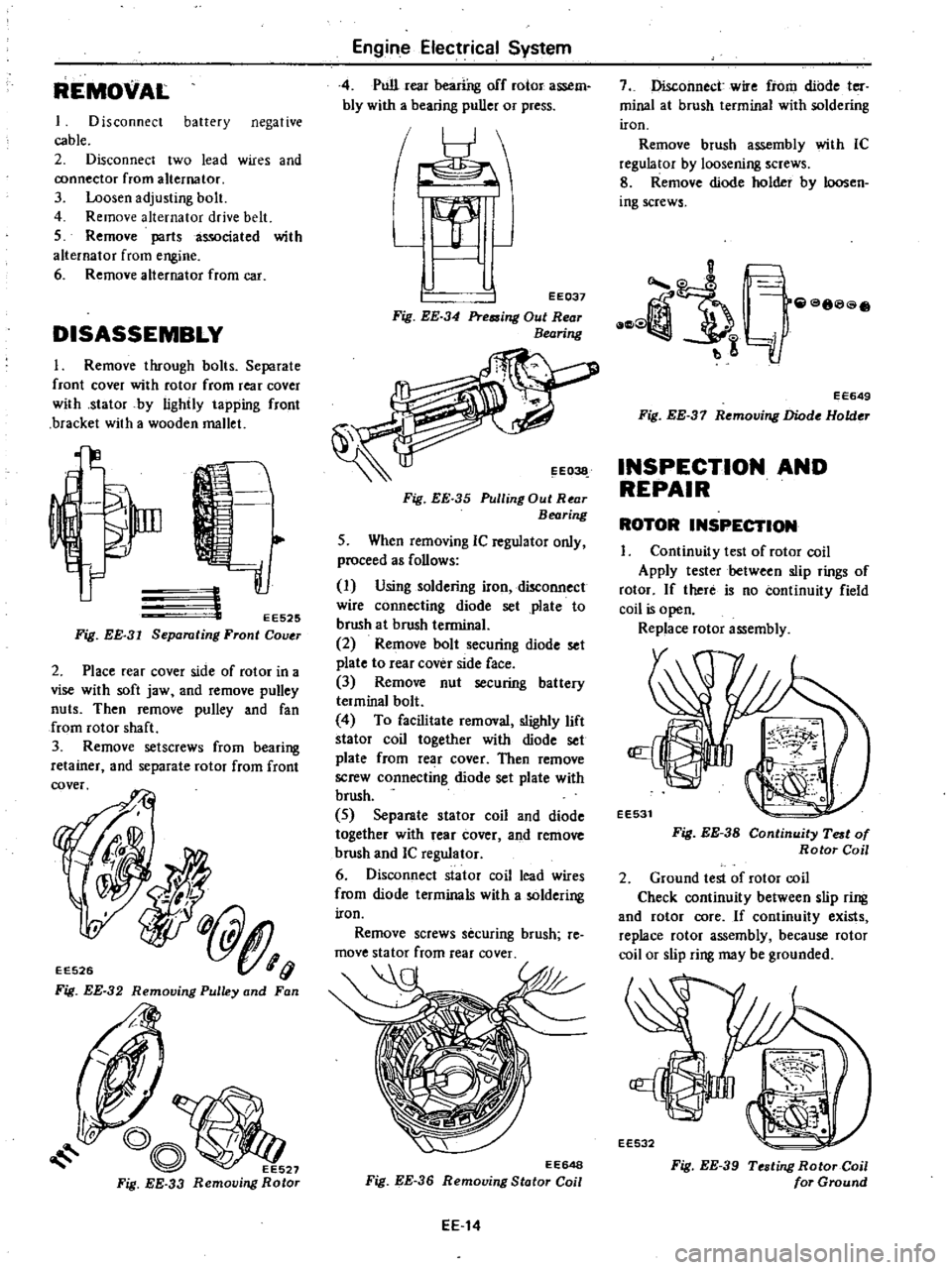

REMOVAL

1

Disconnect

battery

negative

cable

2

Disconnect

two

lead

wires

and

oonnector

from

alternator

3

Loosen

adjusting

bolt

4

Remove

alternator

drive

belt

5

Remove

parts

associated

with

alternator

from

engine

6

Remove

alternator

from

car

DISASSEMBLY

I

Remove

through

bolts

Separate

front

cover

with

rotor

from

rear

cover

with

stator

by

lightly

tapping

front

bracket

with

a

wooden

mallet

rnJ

J

i

EE525

Separating

Front

COI

T

Fig

EE

31

2

Place

rear

cover

side

of

rotor

in

a

vise

with

soft

jaw

and

remove

pulley

nuts

Then

remove

pulley

and

fan

from

rotor

shaft

3

Remove

setscrews

from

bearing

retainer

and

separate

rotor

from

front

EE526

Fig

EE

32

Removing

Pulley

and

Fan

tr

s

0

27

Fig

EE

33

Removing

Rotor

Engine

Electrical

System

4

Pull

rear

bearfug

off

rotor

assem

bly

with

a

bearing

puller

or

press

EE037

Fig

EE

34

Pressing

Out

Rear

Bearing

I

EO

Fig

EE

35

Pulling

Out

Rear

Bearing

5

When

removing

IC

regulator

only

proceed

as

follows

I

Using

soldering

iron

disconnect

wire

connecting

diode

set

plate

to

brush

at

brush

terminal

2

Remove

bolt

securing

diode

set

plate

to

rear

cover

side

face

3

Remove

nut

securing

battery

terminal

bolt

4

To

facilitate

removal

s1ighly

lift

stator

coil

together

with

diode

set

plate

from

re

r

cover

Then

remove

screw

connecting

diode

set

plate

with

brush

5

Separate

stator

coil

and

diode

together

with

rear

cover

and

remove

brush

and

IC

regulator

6

Disconnect

stator

coil

lead

wires

from

diode

terminals

with

a

soldering

iron

Remove

screws

securing

brush

re

move

stator

from

rear

cover

EE648

Fig

EE

36

Removing

Stator

Coil

EE

14

7

Disconnect

wire

from

diode

tor

minal

at

brush

terminal

with

soldering

iron

Remove

brush

assembly

with

IC

regulator

by

loosening

screws

8

Remove

diode

holder

by

loosen

ing

screws

acefii

li

E

E649

Fig

EE

37

Removing

Diode

Holder

INSPECTION

AND

REPAIR

ROTOR

INSPECTION

I

Continuity

test

of

rotor

coil

Apply

tester

between

slip

rings

of

rotor

If

there

is

no

continuity

field

coil

is

open

Replace

rotor

assembly

Fig

EE

38

Continuity

Test

of

Rotor

Coil

2

Ground

test

of

rotor

coil

Check

continuity

between

slip

ring

and

rotor

core

If

continuity

exists

replace

rotor

assembly

because

rotor

coil

or

slip

ring

may

be

grounded

EE532

Fig

EE

39

Te

ting

Rotor

Coil

for

Ground

Page 173 of 548

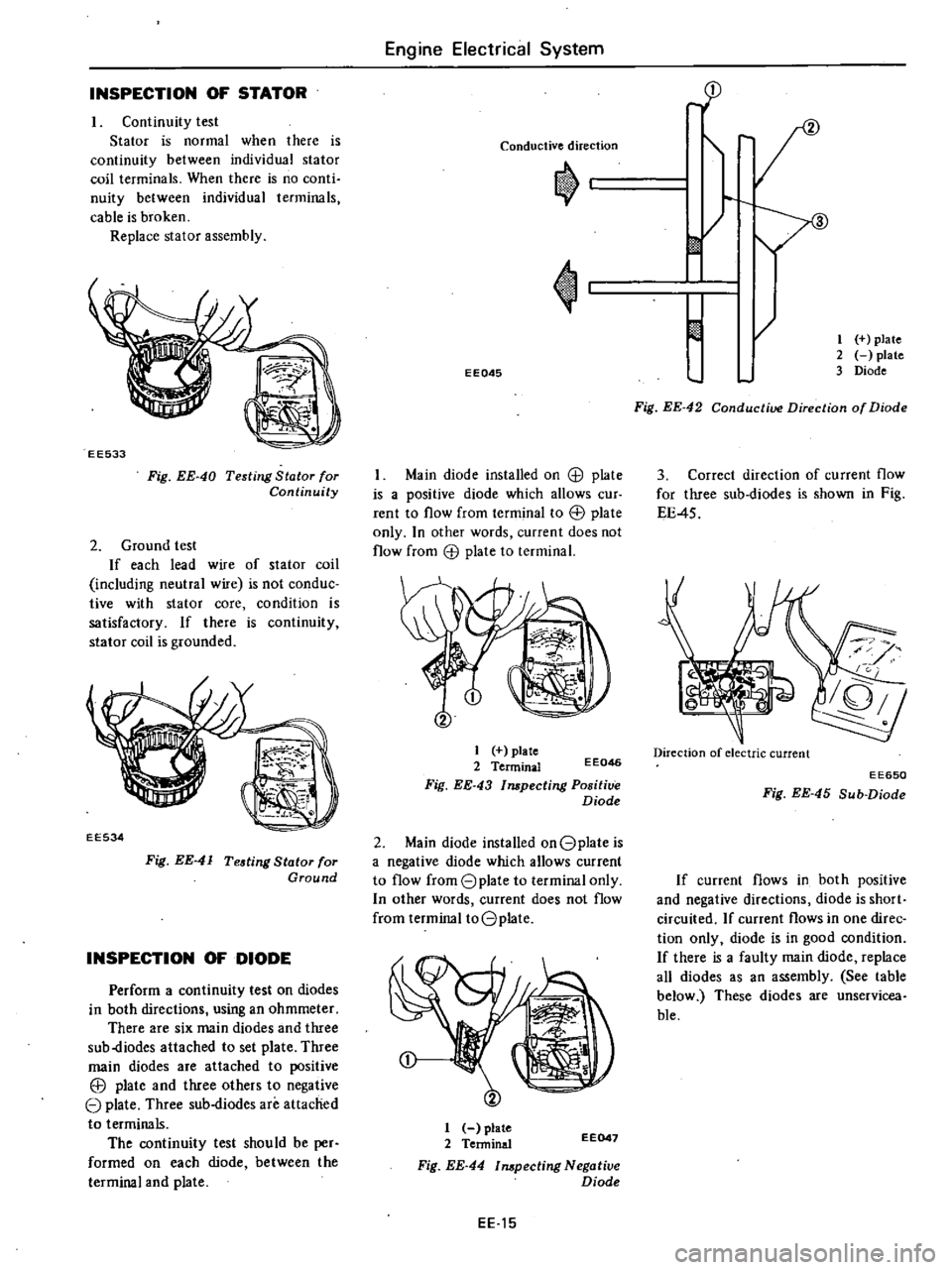

INSPECTION

OF

STATOR

Continuity

test

Stator

is

normal

when

there

is

continuity

between

individual

stator

coil

terminals

When

there

is

no

conti

nuity

between

individual

terminals

cable

is

broken

Replace

stator

assembly

EE533

Fig

EE

40

Testing

Stator

for

Continuity

2

Ground

test

If

each

lead

wire

of

stator

coil

including

neutral

wire

is

not

conduc

tive

with

stator

core

condition

is

satisfactory

If

there

is

continuity

stator

coil

is

grounded

EE534

Fig

EE

41

Testing

Stator

for

Ground

INSPECTION

OF

DIODE

Perform

a

continuity

test

on

diodes

in

both

directions

using

an

ohmmeter

There

are

six

main

diodes

and

tluee

sub

diodes

attached

to

set

plate

Three

main

diodes

are

attached

to

positive

EEl

plate

and

three

others

to

negative

8

plate

Three

sub

diodes

are

attached

to

terminals

The

continuity

test

should

be

per

formed

on

each

diode

between

the

terminal

and

plate

Engine

Electrical

System

Conductive

direction

EE045

Main

diode

installed

on

8

plate

is

a

positive

diode

which

allows

cur

rent

to

flow

from

terminal

to

EEl

plate

only

In

other

words

current

does

not

flow

from

8

plate

to

terminal

1

plate

2

Terminal

Fig

EE

43

Impecting

Positive

Diode

EE046

2

Main

diode

installed

on

Gplate

is

a

negative

diode

which

allows

current

to

flow

from

Gplate

to

terminal

only

In

other

words

current

does

not

flow

from

terminal

toGplate

1

plate

2

Tenninal

Fig

EE

44

Impecting

Negatiue

Diode

EE047

EE

15

rp

m

1

plate

2

ptate

3

Diode

Fig

EE

42

Conductive

Direction

of

Diode

3

Correct

direction

of

current

flow

for

three

sub

diodes

is

shown

in

Fig

EE

4S

Direction

of

electric

current

EE650

Fig

EE

45

Sub

Diode

If

current

flows

in

both

positive

and

negative

directions

diode

is

short

circuited

If

current

flows

in

one

direc

tion

only

diode

is

in

good

condition

If

there

is

a

faulty

main

diode

replace

all

diodes

as

an

assembly

See

table

below

These

diodes

are

unservicea

ble