Head light DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 516 of 548

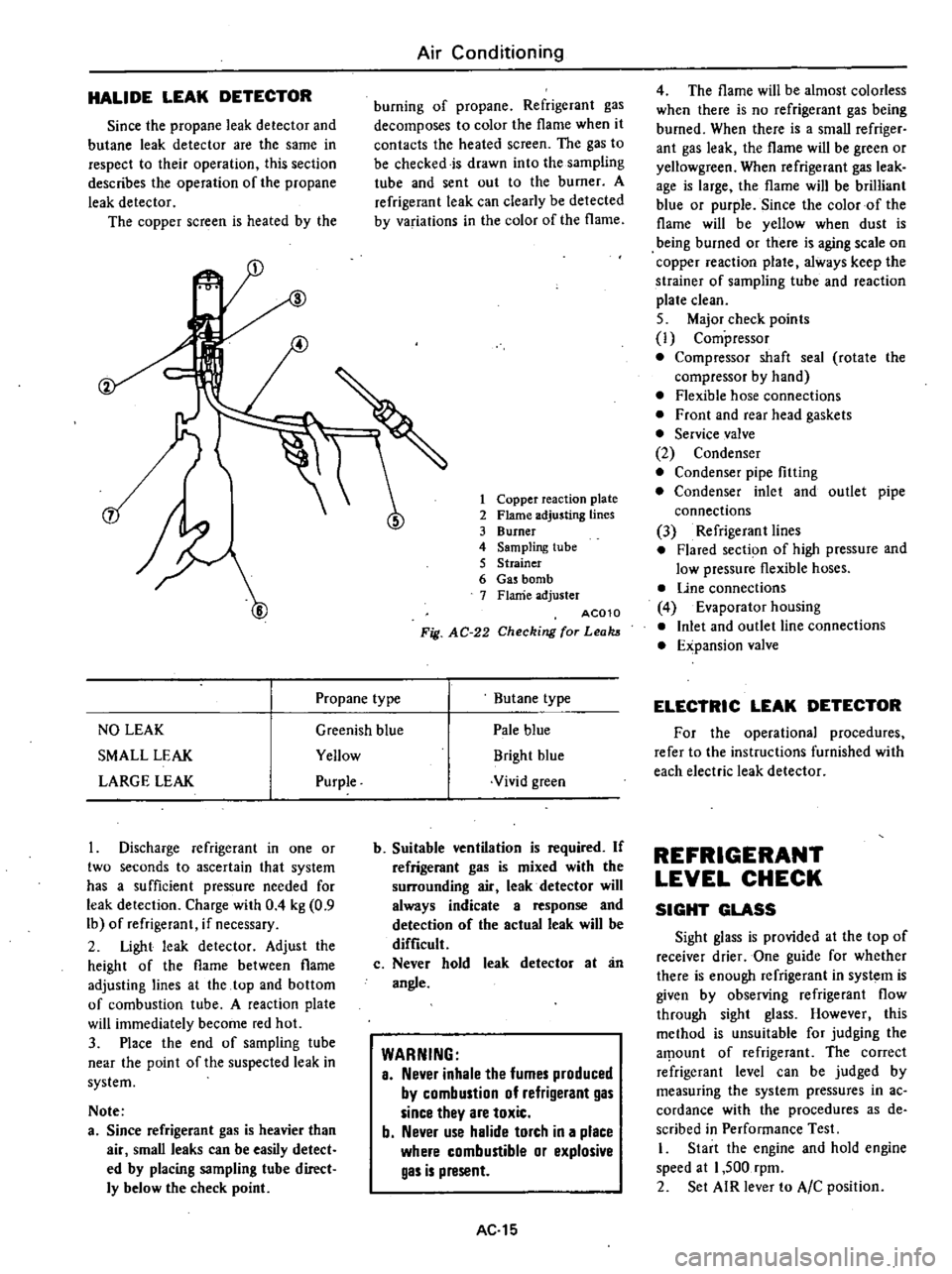

HALIDE

LEAK

DETECTOR

Since

the

propane

leak

detector

and

butane

leak

detector

are

the

same

in

respect

to

their

operation

this

section

describes

the

operation

of

the

propane

leak

detector

The

copper

screen

is

heated

by

the

Air

Conditioning

burning

of

propane

Refrigerant

gas

decomposes

to

color

the

flame

when

it

contacts

the

heated

screen

The

gas

to

be

checked

is

drawn

into

the

sampling

tube

and

sent

out

to

the

burner

A

refrigerant

leak

can

clearly

be

detected

by

variations

in

the

color

of

the

flame

1

Copper

reaction

plate

2

Flame

adjusting

lines

3

Burner

4

Sampling

tube

5

Strainer

6

Gas

bomb

7

Flame

adjuster

AC010

Fig

AC

22

Checking

for

Leaks

4

The

flame

will

be

almost

colorless

when

there

is

no

refrigerant

gas

being

burned

When

there

is

a

small

refriger

ant

gas

leak

the

flame

will

be

green

or

yellowgreen

When

refrigerant

gas

leak

age

is

large

the

flame

will

be

brilliant

blue

or

purple

Since

the

color

of

the

flame

will

be

yellow

when

dust

is

being

burned

or

there

is

aging

scale

on

copper

reaction

plate

always

keep

the

strainer

of

sampling

tube

and

reaction

plate

clean

5

Major

check

points

l

Compressor

Compressor

shaft

seal

rotate

the

compressor

by

hand

Flexible

hose

connections

Front

and

rear

head

gaskets

Service

valve

2

Condenser

Condenser

pipe

fitting

Condenser

inlet

and

outlet

pipe

connections

3

Refrigerant

lines

Flared

section

of

high

pressure

and

low

pressure

flexible

hoses

Une

connections

4

Evaporator

housing

Inlet

and

outlet

line

connections

Expansion

valve

Propane

type

Butane

type

ELECTRIC

LEAK

DETECTOR

NO

LEAK

Greenish

blue

Pale

blue

For

the

operational

procedures

SMALL

LEAK

Yellow

Bright

blue

refer

to

the

instructions

furnished

with

LARGE

LEAK

Purple

Vivid

green

each

electric

leak

detector

Discharge

refrigerant

in

one

or

two

seconds

to

ascertain

that

system

has

a

sufficient

pressure

needed

for

leak

detection

Charge

with

0

4

kg

0

9

Ib

of

refrigeranl

if

necessary

2

Light

leak

detector

Adjust

the

height

of

the

flame

between

flame

adjusting

lines

at

the

top

and

bottom

of

combustion

tube

A

reaction

plate

will

immediately

become

red

hot

3

Place

the

end

of

sampling

tube

near

the

point

of

the

suspected

leak

in

system

Note

a

Since

refrigerant

gas

is

heavier

than

air

small

leaks

can

be

easily

detect

ed

by

placing

sampling

tube

direct

ly

below

the

check

point

b

Suitable

ventilation

is

required

If

refrigerant

gas

is

mixed

with

the

surrounding

air

leak

detector

will

always

indicate

a

response

and

detection

of

the

actual

leak

will

be

difficult

c

Never

hold

leak

detector

at

an

angle

WARNING

a

Never

inhale

the

fumes

produced

by

combustion

of

refrigerant

gas

since

they

are

toxic

b

Never

use

halide

torch

in

a

place

where

combustible

or

explosive

gas

is

present

AC

15

REFRIGERANT

LEVEL

CHECK

SIGHT

GLASS

Sight

glass

is

provided

at

the

top

of

receiver

drier

One

guide

for

whether

there

is

enough

refrigerant

in

syst

m

is

given

by

observing

refrigerant

flow

through

sight

glass

However

this

method

is

unsuitable

for

judging

the

aJTlount

of

refrigerant

The

correct

refrigeranl

level

can

be

judged

by

measuring

the

system

pressures

in

ac

cordance

with

the

procedures

as

de

scribed

in

Performance

Test

1

Start

the

engine

and

hold

engine

speed

al

1

500

rpm

2

Set

AIR

lever

to

AlC

position

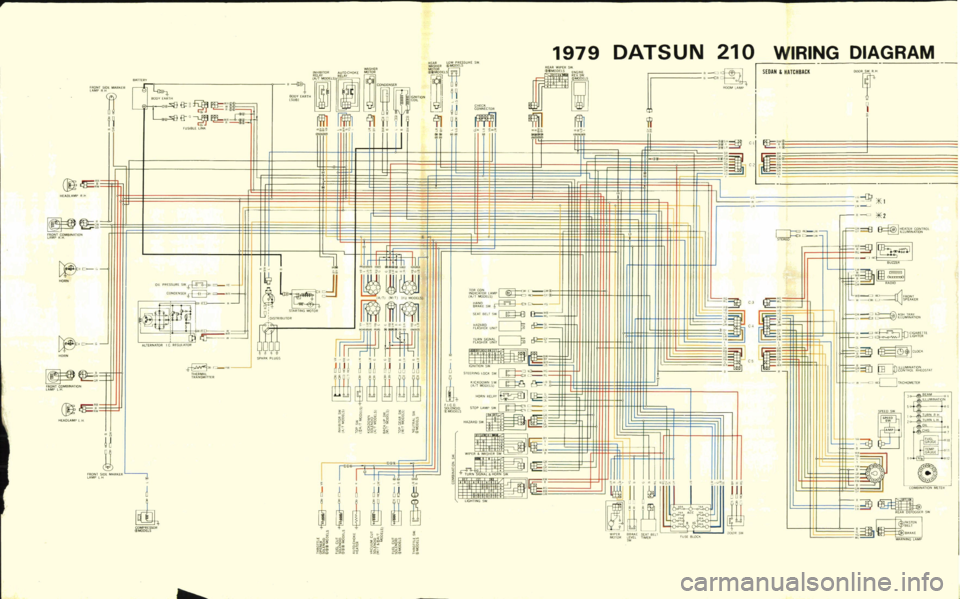

Page 546 of 548

J

E

HEA

DLAMPIlH

fRQNT

COMO

uION

lAMP

IlH

c

D

HORN

I

fIlONTCOHIB

ATION

lAMPLH

Z

I

HEADLAMP

lH

fIlO

SlOE

MAIlKEII

l

PIIH

II

i

Jl

fllONT

SIDE

MARKER

LAMP

lH

BATTERY

fl

d

Wi

1

f

FUSlBlElINI

J

CO

OENSEII

C

Il

LrEFlhATOR

litn

J

HiERMM

TIlANSMITTUi

j

m

COMPIIESSO

MOOELS

BOOVU

1l1H

SUB

L

J

DISTIlIBUTOR

SPAllA

PLUGS

0

0

Ii

0

t

E

i

w

a

E

g

8

J

0

w

u

g

r

I

J

j

H

U

oo

i@

5

2

@

Ww

W

W

ai

o

ww

i

woO

a

i

Jwt

o

o

2

0

i

i

52

1

w

0

JwO

WJ

1979

FILAR

WIPEIl

SW

I

g

aml

ffll

CD

1o

i

CHECK

CONNECTOR

m

TOROON

r

O

L

GW

f

nttJ

p

ar

G

HAND

G

BIl

IUSW

SE

u

am

sw

J8

eI

8

HAZ

IlD

n

Gl

flASHER

UNITL

Y

G

TUIlN5IGN

l

flASHEIlUN

O

ow

w

IGHIIION

SW

LO

STEERINGlOCIISW

KICKOOWNSW

r

Ol

0

1

DOHS

L

d

CJ

CJ

R

I

I

STOPlAIOIP

SW

c

L

J

d

q

c

m

HAZARDSW

g

L

WIPER

WASHEII

SW

r

o

IIE

lURN

SlGNAl

HOIlN

SW

iE

lIGHTING

SW

DATSUN

210

I

II

I

W

PEII

BIIAIIE

SEAl

BEll

IoIOIOR

LEVU

TI

ElI

w

FUSE

BlOC

6

DJ

liDO

LAMP

W

l

l

HlP

i

1

iY

ow

0

L

ill

iJUlf

1IE

l1l

WWPIIESSUIIE

SW

WASHEII

MODElS

1f

II

Wm

I

TI

U

jJ

rm

fII

91n

l

j

Ii

W

I

w

j

S

e

000

Sv

WIRING

DIAGRAM

SEDAN

HATCHBACK

i

I

ow

ow

f

I

GiD

1

2

w

F

w

0

Wt

f

F

fo

e

l

lL

9

rr

hS

lHlAlllI

CONllIOl

lllUIOI

NATI

lI

I

i

l1iKiI

l

w

ijij

ijf

r

r

10

o

mm

WI

llj

H

n

lJ

6

Jffi

@

Fie

D

SOLENOID

1

IoIODElS

C3

t

11

I

lG

lG

B

LII

W

W

C

c

G

G

GY

0

I

Ii

II

I

BUZZEll

m

lm

1

RADIO

rj

S

J

F

OHI

cJD

L

SPEAKE

G

J

ASHT

AT

G

c

lllU

NATI

N

Gl

J

C

GAIIE11

R

J

UGHI

Gs

JTn

fllU

ATIl

r

CO

IlDLIIHEOSTA

J

aa

TAC

lllI

Jo

l

lAr

hI

4

I

TIINIIH

TUIINll1

3E1

I

o

G8

J

ReO

ow

0

COhlBIN

TI

NlIIHER

Il

IILO

II

DHOGGEII

sw

1

P