battery DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 170 of 548

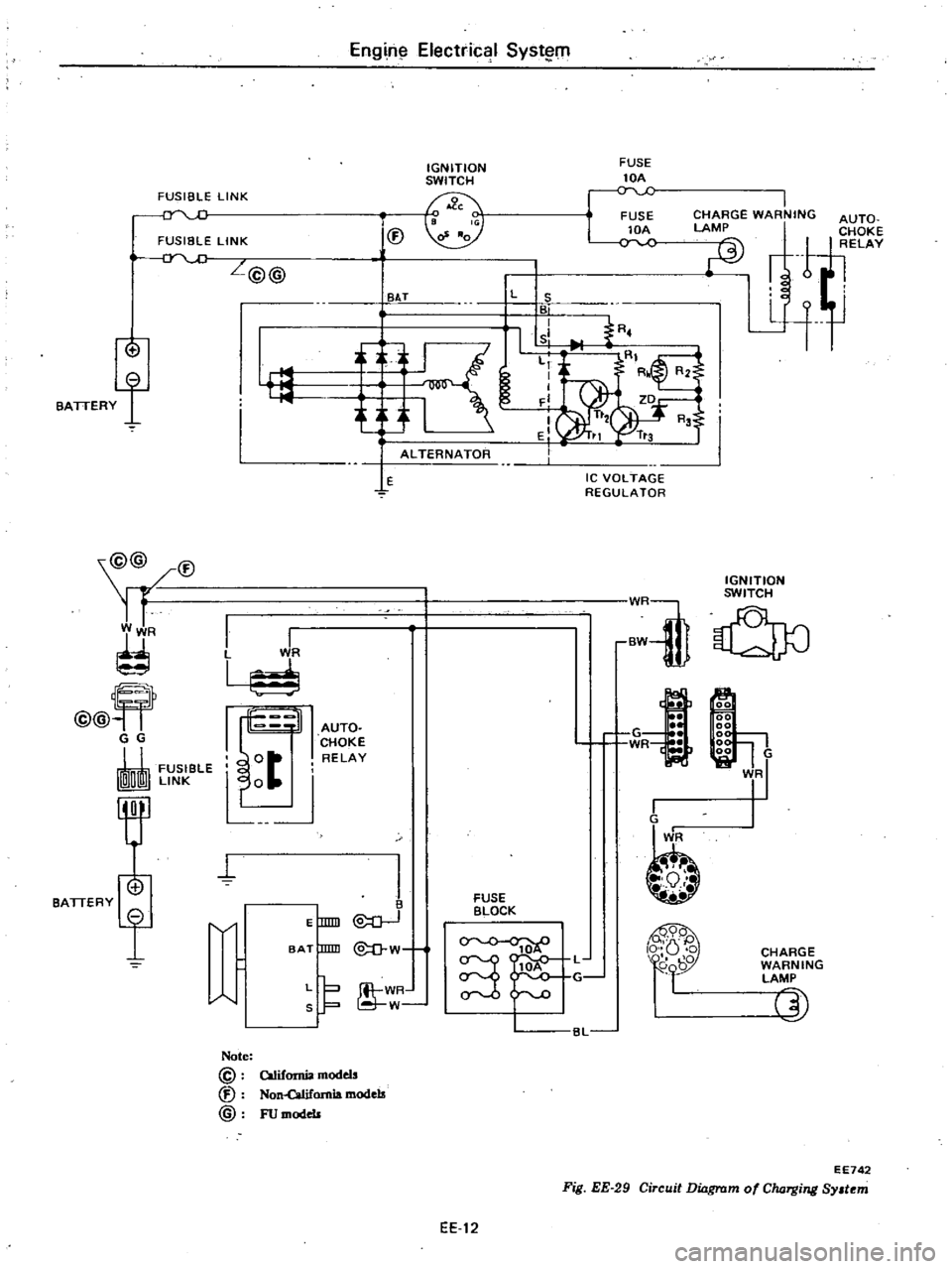

FUSIBLE

LINK

FUSIBLE

LINK

f

BATTERY

@@

V

R

@@

G

G

FUSleLE

ImrnI

LI

NK

MTI

I

En

g

n

l

Electrical

Syst

lOl

IGNITION

SWITCH

FUSE

lOA

o

v

FUSE

lOA

C

V

L@@

BAT

f

L

S

BI

I

I

sl

fRO

L

I

I

F

I

EI

i

K

a

ALTERNATOR

lE

Ie

VOLTAGE

REGULATOR

I

I

L

WR

I

1

d

I

t

J

t

IGNITION

WR

SWITCH

BW

U

0

AUTO

CHOKE

RELAY

G

1

WR

J

I

00

00

gg

1

00

VR

1

E

lDID

I

@

O

BAT

mID

W

J

WR

W

FUSE

BLOCK

CHARGE

WARNING

LAMP

5J

BL

Note

@

V

@

California

models

Non

Qilifomo

18

models

FU

models

Fig

EE

29

Circuit

Dinrswr

EE742

mofCIuJ

Tg

ng

Sy

t

m

EE

12

Page 172 of 548

REMOVAL

1

Disconnect

battery

negative

cable

2

Disconnect

two

lead

wires

and

oonnector

from

alternator

3

Loosen

adjusting

bolt

4

Remove

alternator

drive

belt

5

Remove

parts

associated

with

alternator

from

engine

6

Remove

alternator

from

car

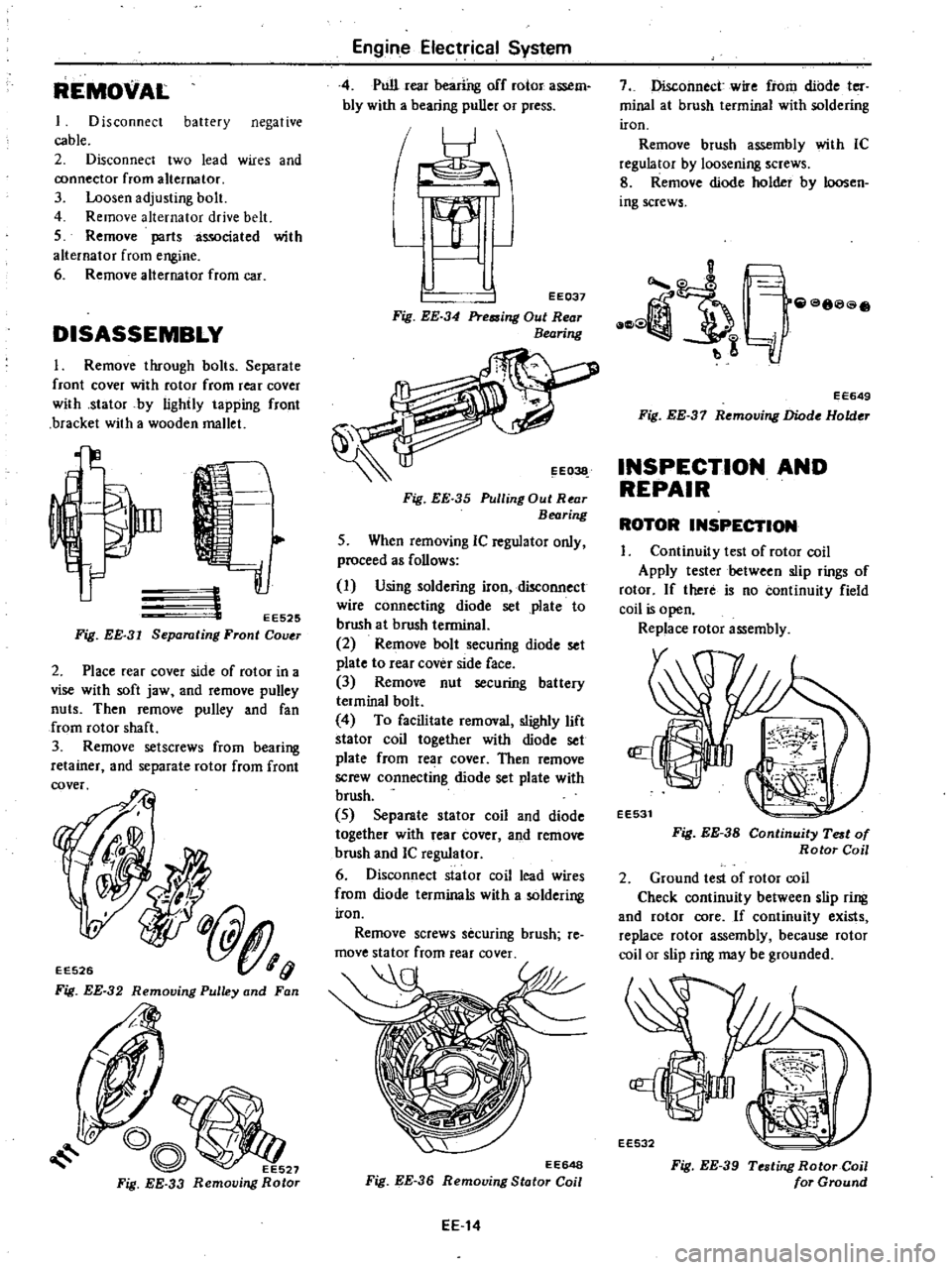

DISASSEMBLY

I

Remove

through

bolts

Separate

front

cover

with

rotor

from

rear

cover

with

stator

by

lightly

tapping

front

bracket

with

a

wooden

mallet

rnJ

J

i

EE525

Separating

Front

COI

T

Fig

EE

31

2

Place

rear

cover

side

of

rotor

in

a

vise

with

soft

jaw

and

remove

pulley

nuts

Then

remove

pulley

and

fan

from

rotor

shaft

3

Remove

setscrews

from

bearing

retainer

and

separate

rotor

from

front

EE526

Fig

EE

32

Removing

Pulley

and

Fan

tr

s

0

27

Fig

EE

33

Removing

Rotor

Engine

Electrical

System

4

Pull

rear

bearfug

off

rotor

assem

bly

with

a

bearing

puller

or

press

EE037

Fig

EE

34

Pressing

Out

Rear

Bearing

I

EO

Fig

EE

35

Pulling

Out

Rear

Bearing

5

When

removing

IC

regulator

only

proceed

as

follows

I

Using

soldering

iron

disconnect

wire

connecting

diode

set

plate

to

brush

at

brush

terminal

2

Remove

bolt

securing

diode

set

plate

to

rear

cover

side

face

3

Remove

nut

securing

battery

terminal

bolt

4

To

facilitate

removal

s1ighly

lift

stator

coil

together

with

diode

set

plate

from

re

r

cover

Then

remove

screw

connecting

diode

set

plate

with

brush

5

Separate

stator

coil

and

diode

together

with

rear

cover

and

remove

brush

and

IC

regulator

6

Disconnect

stator

coil

lead

wires

from

diode

terminals

with

a

soldering

iron

Remove

screws

securing

brush

re

move

stator

from

rear

cover

EE648

Fig

EE

36

Removing

Stator

Coil

EE

14

7

Disconnect

wire

from

diode

tor

minal

at

brush

terminal

with

soldering

iron

Remove

brush

assembly

with

IC

regulator

by

loosening

screws

8

Remove

diode

holder

by

loosen

ing

screws

acefii

li

E

E649

Fig

EE

37

Removing

Diode

Holder

INSPECTION

AND

REPAIR

ROTOR

INSPECTION

I

Continuity

test

of

rotor

coil

Apply

tester

between

slip

rings

of

rotor

If

there

is

no

continuity

field

coil

is

open

Replace

rotor

assembly

Fig

EE

38

Continuity

Test

of

Rotor

Coil

2

Ground

test

of

rotor

coil

Check

continuity

between

slip

ring

and

rotor

core

If

continuity

exists

replace

rotor

assembly

because

rotor

coil

or

slip

ring

may

be

grounded

EE532

Fig

EE

39

Te

ting

Rotor

Coil

for

Ground

Page 175 of 548

Engine

Electrical

System

6

Tighten

through

bolts

rfl

Tightening

torque

Through

bolts

60

to

70

kg

cm

52

to

61

in

lb

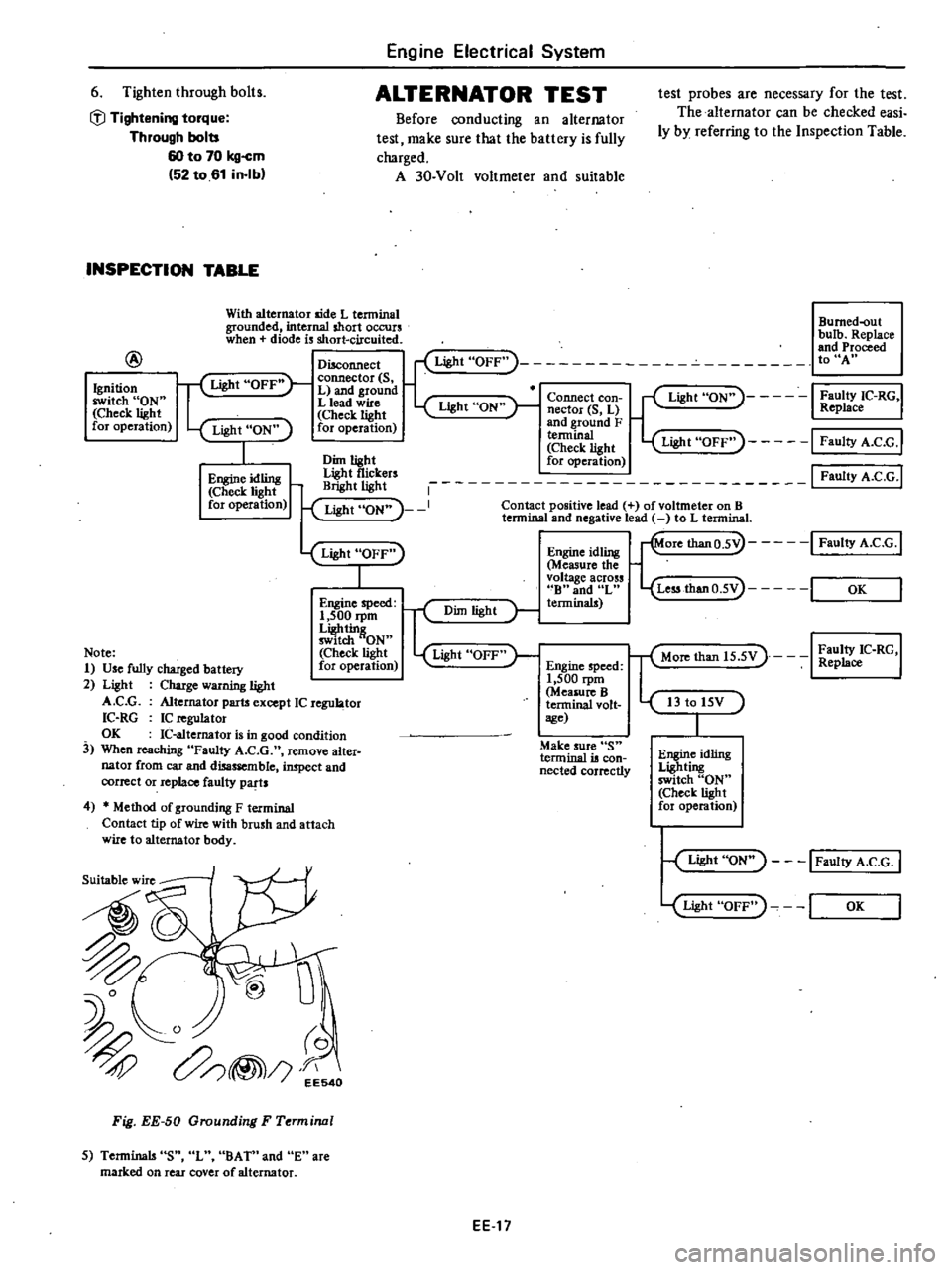

ALTERNATOR

TEST

Before

conducting

an

alternator

test

make

sure

that

the

battery

is

fully

charged

A

30

Volt

voltmeter

and

suitable

INSPECTION

TABLE

With

alternator

aide

L

tenninal

grounded

internal

short

occurs

when

diode

is

short

circuited

@

test

probes

are

necessary

for

the

test

The

alternator

can

be

checked

easi

ly

by

referring

to

the

Inspection

Table

Bumed

out

bulb

Replace

and

Proceed

toUA

Ignition

switch

ON

Check

light

for

operation

Disconnect

Light

OFF

f

Light

OFF

connector

S

L

and

ground

L

lead

wire

Light

ON

Check

light

for

operation

Light

ON

I

Faulty

IC

RG

Replace

Connect

con

nector

S

L

and

ground

F

a1light

Light

OFF

I

FaultyA

C

G

I

Dim

light

for

operation

tf

i

rs

1

I

Faulty

A

C

G

I

Light

ON

I

Contact

positive

lead

of

voltmeter

on

B

lennina

and

negative

lead

to

L

tenninal

Light

ON

1

Engine

idling

Check

light

for

operation

Light

OFF

I

Engine

idling

Measure

the

voltage

across

B

and

L

terminals

Engine

speed

1

500

rpm

Ligh

tin

switch

ON

Check

light

for

operation

r

Dim

light

Light

OFF

Note

1

Use

fully

charged

battery

2

Light

Charge

warning

light

A

C

G

Alternator

parts

except

IC

regu

tor

IC

RG

IC

n

guJator

OK

IC

altemator

is

in

good

condition

3

When

reaching

Faulty

A

C

G

remove

alter

nator

from

car

and

disassemble

inspect

and

correct

or

replace

faulty

parts

Engine

speed

1

500

rpm

Measure

B

terminal

volt

sge

Make

sure

S

terminal

is

con

nected

correctly

4

Method

of

grounding

F

terminal

Contact

tip

of

wire

with

brush

and

attach

wire

to

alternator

body

Suitable

wire

I

Fig

EE

50

Grounding

F

Terminal

5

Terminals

S

L

BA

Tn

and

E

are

marked

on

rear

cover

of

alternator

EEl7

More

thanO

5V

I

Faulty

A

e

G

1

Less

thanO

5V

I

OK

T

Mon

than

15

5V

I

Z

C

RG

I

I3

to

15V

Engine

idling

Lighting

switch

ON

Check

light

for

operation

Light

ON

I

Faulty

A

C

G

I

Light

OFF

I

OK

Page 176 of 548

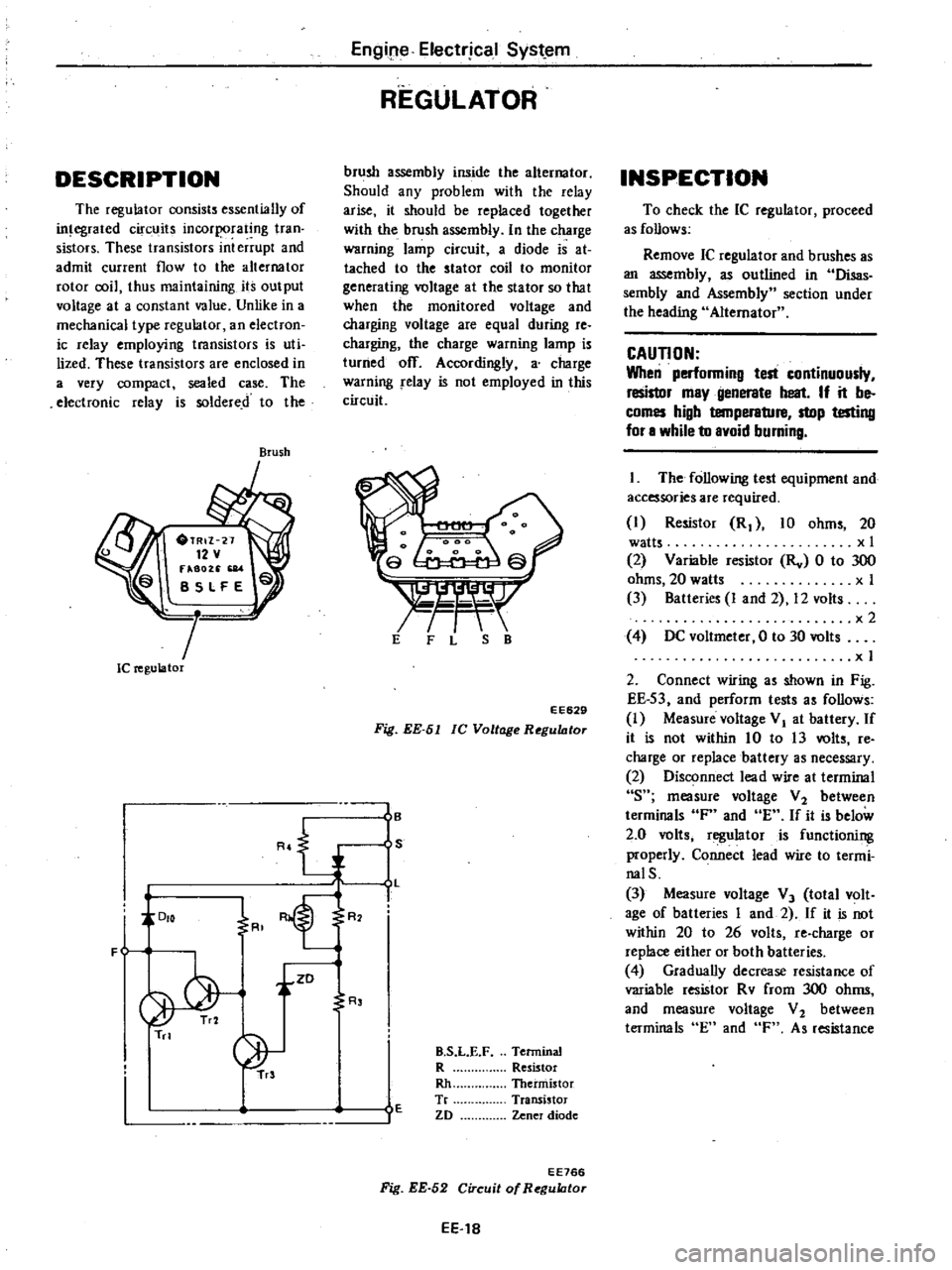

DESCRIPTION

The

regulator

consists

essentially

of

in

egrated

circuits

incorporating

tran

sistors

These

transistors

int

errupt

and

admit

current

flow

to

the

alternator

rotor

coil

thus

maintaining

its

output

voltage

at

a

constant

value

Unlike

in

a

mechanical

type

regulator

an

electron

ic

relay

employing

transistors

is

uti

lized

These

transistors

are

enclosed

in

a

very

compact

sealed

case

The

electronic

relay

is

soldered

to

the

Brush

Ie

regulator

R

J

DIO

F

i

ZD

Tn

Engipe

Electrjcal

Syst

em

REGULATOR

brush

assembly

inside

the

alternator

Should

any

problem

with

the

relay

arise

it

should

be

replaced

together

with

the

brush

assembly

In

the

charge

warning

lamp

circuit

a

diode

is

at

tached

to

the

stator

coil

to

monitor

generating

voltage

at

the

stator

so

that

when

the

monitored

voltage

and

charging

voltage

are

equal

during

re

charging

the

charge

warning

lamp

is

turned

off

Accordingly

a

charge

warning

relay

is

not

employed

in

this

circuit

s

r

t

E

F

L

S

B

EE629

Fig

EE

51

lC

Voltage

RegultJtor

I

B

S

L

I

R

R

E

B

S

L

E

F

Terminal

R

Resistor

Rh

Thermistor

Tr

Transistor

ZD

Zener

diode

EE766

Fig

EE

52

Circuit

of

RegultJtor

EE

18

INSPECTION

To

check

the

IC

regulator

proceed

as

follows

Remove

IC

regulator

and

brushes

as

an

assembly

as

outlined

in

Disas

sembly

and

Assembly

section

under

the

heading

Alternator

CAUTION

When

performing

test

continuously

resistor

may

generate

heat

If

it

be

comes

high

temperature

stop

testing

for

a

while

to

avoid

burning

The

following

test

equipment

and

accessories

are

required

I

Resistor

R

10

ohms

20

watts

x

I

2

Variable

resistor

Rv

0

to

300

ohms

20

watts

x

I

3

Batteries

I

and

2

12

volts

x2

4

DC

voltmeter

0

to

30

volts

x

I

2

Connect

wiring

as

shown

in

Fig

EE

S3

and

perform

tests

as

follows

I

Measure

voltage

VI

at

battery

If

it

is

not

within

10

to

13

volts

re

charge

or

replace

battery

as

necessary

2

Disconnect

lead

wire

at

terminal

s

measure

voltage

V

2

between

terminals

F

and

E

If

it

is

below

2

0

volts

regulator

is

functioning

properly

Connect

lead

wire

to

termi

nalS

3

Measure

voltage

V

3

total

volt

age

of

batteries

I

and

2

If

it

is

not

within

20

to

26

volts

re

charge

or

replace

either

or

both

batteries

4

Gradually

decrease

resistance

of

variable

resistor

Rv

from

300

ohms

and

measure

voltage

V

2

between

terminals

En

and

F

As

resistance

Page 178 of 548

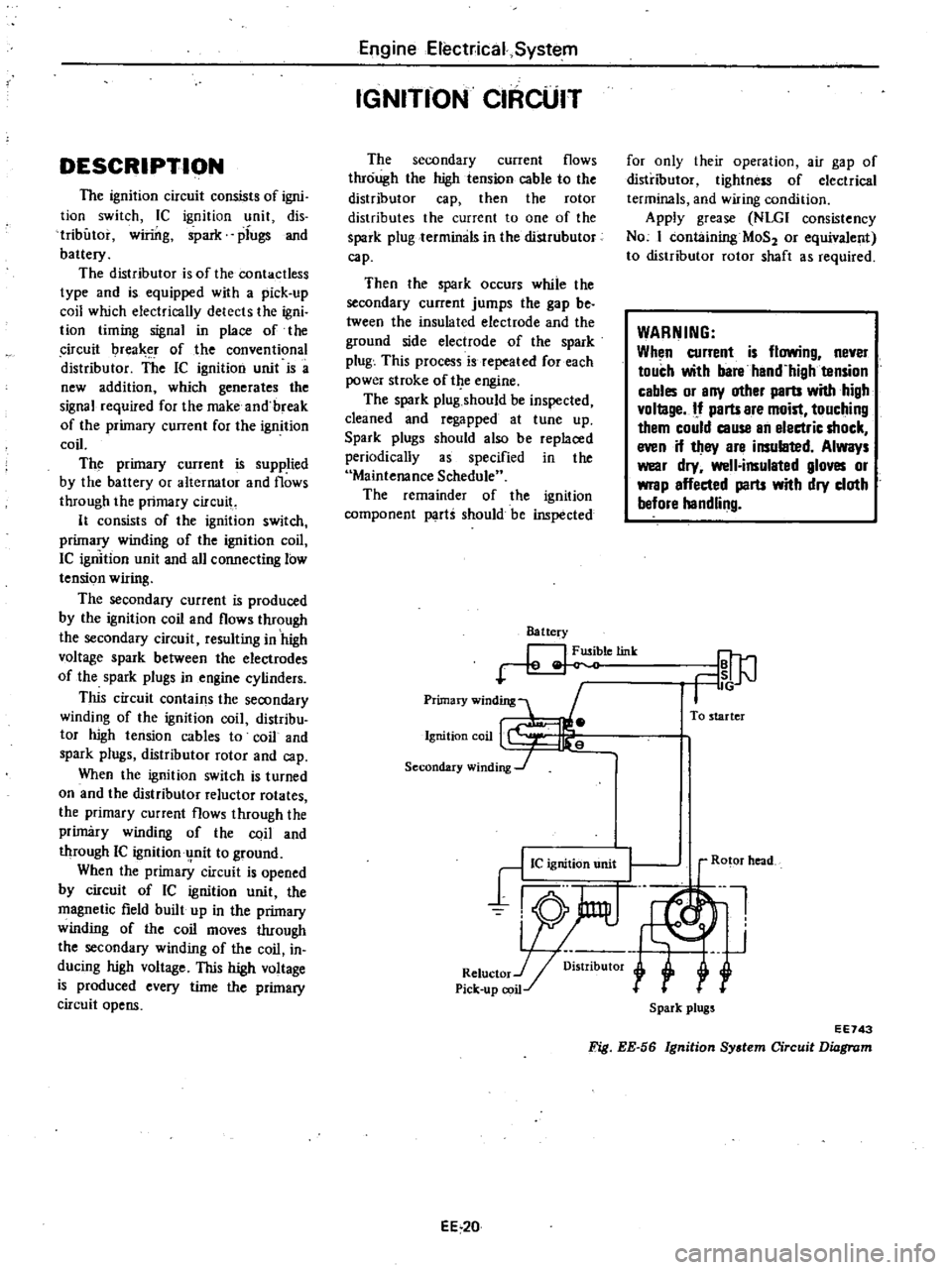

DESCRIPTION

The

ignition

circuit

consists

of

igni

tion

switch

Ie

ignition

unit

dis

tributor

winng

ipark

plugs

and

battery

The

distributor

is

of

the

contactless

type

and

is

equipped

with

a

pick

up

coil

which

electrically

detects

the

igni

tion

timing

signal

in

place

of

the

ircuit

I

rea

r

of

the

conventional

distributor

The

IC

ignition

unit

is

a

new

addition

which

generates

the

signal

required

for

the

make

and

break

of

the

primary

current

for

the

ignition

coil

The

primary

current

is

supplied

by

the

battery

or

alternator

and

flows

through

the

primary

circuit

It

consists

of

the

ignition

switch

primary

winding

of

the

ignition

coil

IC

ignition

unit

and

all

connecting

low

tension

wiring

The

secondary

current

is

produced

by

the

ignition

coil

and

flows

through

the

secondary

circuit

resulting

in

high

voltage

spark

between

the

electrodes

of

the

spark

plugs

in

engine

cylinders

This

circuit

contains

the

secondary

winding

of

the

ignition

coil

distribu

tor

high

tension

cables

to

coil

and

spark

plugs

distributor

rotor

and

cap

When

the

ignition

switch

is

turned

on

and

the

distributor

reluctor

rotates

the

primary

current

flows

through

the

primary

winding

of

the

coil

and

through

IC

ignitionu

nit

to

ground

When

the

primary

circuit

is

opened

by

circuit

of

IC

ignition

unit

the

magnetic

field

built

up

in

the

primary

winding

of

the

coil

moves

through

the

secondary

winding

of

the

coil

in

ducing

high

voltage

This

high

voltage

is

produced

every

time

the

primary

circuit

opens

EngineElect

ical

System

IGNITfON

CIRCUIT

The

secondary

current

flows

through

the

high

tension

cable

to

the

distributor

cap

then

the

rotor

distributes

the

current

to

one

of

the

spark

plug

terminals

in

the

distrubutor

cap

Then

the

spark

occurs

while

the

secondary

current

jumps

the

gap

be

tween

the

insulated

electrode

and

the

ground

side

electrode

of

the

spark

plug

This

process

is

repeated

for

each

power

stroke

of

t

e

engine

The

spark

plug

should

be

inspected

cleaned

and

regapped

at

tune

up

Spark

plugs

should

also

be

replaced

periodically

as

specified

in

the

Maintenance

Schedule

The

remainder

of

the

ignition

component

parti

should

be

inspected

Battery

letink

Primary

winding

1

Ignition

coil

Secondary

winding

J

for

only

their

operation

air

gap

of

distributor

tightness

of

electrical

terminals

and

wiring

condition

Apply

grease

NLGI

consistency

No

I

containing

MaS

or

equivalent

to

distributor

rotor

shaft

as

required

WARNING

When

current

is

flowing

never

touch

with

bare

hand

high

tension

cables

or

any

other

parts

with

high

vollage

If

parts

are

moist

touching

them

could

cause

an

electric

shock

even

if

they

are

insulated

Always

wear

dry

well

insulated

gloves

or

wrap

affected

parts

with

dry

cloth

before

handling

To

starter

EE

20

Ro

or

head

Ul

J

r

Spark

plugs

EE743

Fig

EE

56

Ignition

System

Circuit

Diagram

Page 179 of 548

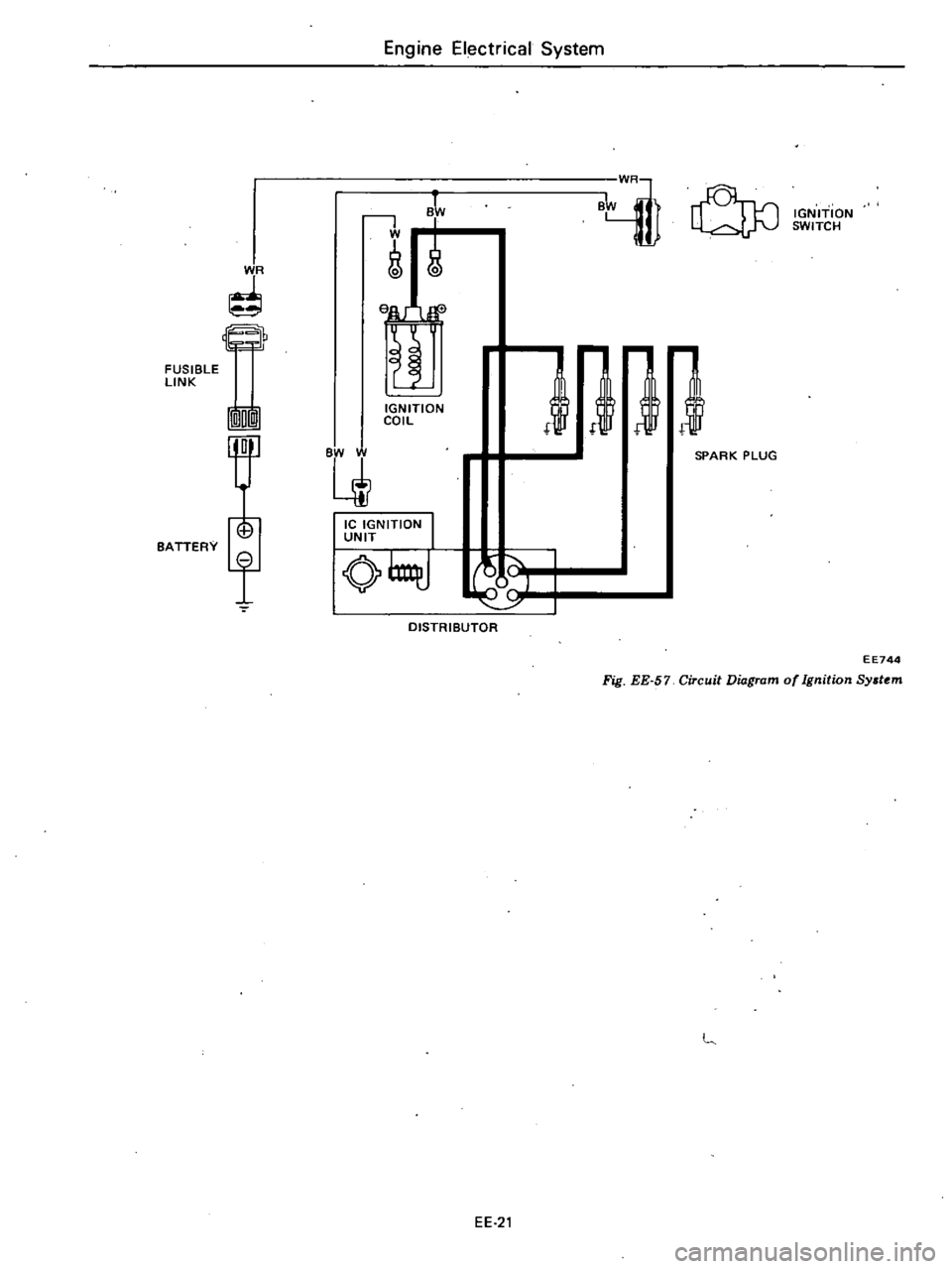

FUSIBLE

LINK

BATTERY

VIR

9

rID

B

V

II

H

Engine

Electrical

System

1

II

1l

IGNITION

COIL

IIC

IGNITION

I

UNIT

O

J

DISTRIBUTOR

EE

21

B4J

QJ

jl

SPARK

PLUG

IGNITiON

SWITCH

EE744

Fig

EE

57

Circuit

DiGgram

of

Ignition

Sy

tem

L

Page 182 of 548

ASSEMBLY

To

assemble

reverse

the

order

of

disassembly

Carefully

observe

the

fol

lowing

instructions

CAUTION

B

tfore

installi

lg

IC

ignition

unit

make

sure

mating

surfaces

of

IC

ignition

unit

and

distriblitor

are

clean

and

free

from

dust

sand

and

moisture

Align

match

marks

so

that

parts

are

assembled

to

their

original

posi

tions

2

Ensure

that

reluctor

is

properly

oriented

when

installing

on

shaft

Al

ways

drive

in

roll

pin

with

its

slit

toward

the

outer

end

of

shaft

See

Fig

EE

64

Be

sure

to

use

a

new

roll

pin

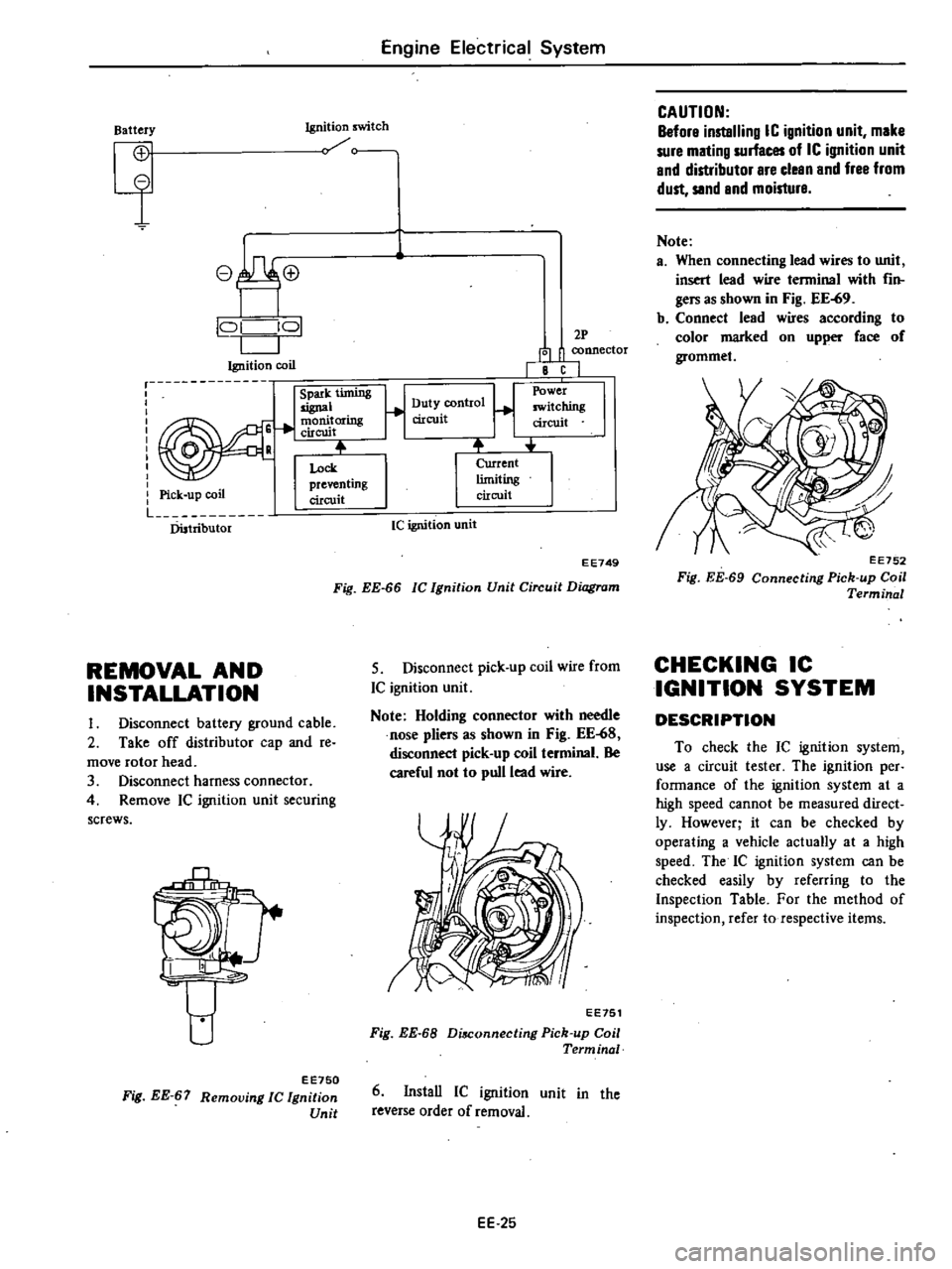

DESCRIPTION

The

IC

ignition

unit

utilizes

a

semi

conductor

IC

device

and

is

mounted

on

the

side

surface

of

the

distributor

The

IC

ignition

unit

has

the

fol

lOwing

circuits

Spark

timing

signal

monitoring

circuit

This

circuit

detects

the

ignition

signal

sent

from

the

distributor

pick

up

coil

and

amplifies

the

signal

2

Lock

preventing

circuit

This

circuit

cuts

off

the

ignition

coil

primary

current

when

the

ignition

switch

is

ON

and

the

engine

is

sta

tionary

If

the

ignition

coil

primary

current

is

allowed

to

flow

under

such

condi

tions

excessive

current

will

be

drawn

because

of

low

internal

resistance

of

the

ignition

coil

Engine

Electrical

System

r

5

EE747

Fig

EE

64

Driuing

in

Roll

Pin

3

When

installing

pinion

on

shaft

be

sure

to

install

pinion

gear

correctly

to

position

where

it

was

installed

4

Apply

grease

to

the

top

of

rotor

shaft

as

required

5

Check

the

operation

of

governor

before

installing

distributor

on

engine

Ie

IGNITION

UNIT

This

can

result

in

an

abnormal

temperature

rise

in

the

ignition

coil

or

discharged

battery

These

malfunc

tions

can

be

prevented

by

this

lock

preventing

circuit

3

Duty

control

circuit

This

circuit

controls

the

ratio

of

the

ignition

coil

primary

current

ON

OFF

time

periods

in

one

cycle

of

ignition

operation

111is

is

equivalent

to

the

dwell

angle

of

the

conventional

point

type

dis

tributor

In

order

to

provide

high

performance

spark

ruing

over

a

wide

range

of

driving

speeds

this

duty

can

be

controlled

by

the

source

voltage

and

the

ambient

temperature

as

well

as

by

the

engine

rpm

4

Power

switching

circuit

This

circuit

is

used

to

make

or

break

directly

the

primary

circuit

cur

EE

24

6

Properly

eenterstatOr

and

reluc

tor

before

tightening

Standard

air

gap

0

3

to

0

5

mm

0

012

to

0

020

in

0

3

to

0

5

mm

0

012

to

0

020

in

Fig

EE

65

EE748

Air

Gap

7

Adjust

ignition

timing

after

distri

butor

is

installed

on

engine

rent

of

the

ignition

coil

5

Current

limiting

circuit

This

circuit

controls

the

current

value

so

that

excessive

current

will

not

flow

through

the

power

switching

cir

cuit

To

ensure

efficient

operation

of

the

IC

ignition

unit

these

five

circuits

are

manufactured

in

one

assembly

as

shown

in

Fig

EE

66

The

semi

conductor

IC

is

utilized

for

all

these

circuits

except

the

power

switching

circuit

The

power

switching

circuit

uses

one

power

transistor

and

the

circuit

is

arranged

on

the

ceramic

substrate

together

with

resislors

capa

citors

and

diodes

Each

component

part

of

this

unit

is

highly

reliable

however

should

any

part

be

found

faulty

the

entire

as

sembly

musl

be

replaced

Page 183 of 548

Engine

Electrical

System

Battery

Ignition

switch

CG

1

e

@

P

L

JO

L

J

Ignition

coil

r

Spark

timing

signal

I

oni

1oring

Clfcwt

0

R

Lock

Pi

k

il

preventing

c

up

co

circuit

Ln

n

Distributor

2P

fJ

1I

connector

8C

H

uty

control

ClICUlt

Power

switching

circuit

Current

limiting

circuit

Ie

ignition

unit

EE749

Fig

EE

66

Ie

Ignition

Unit

Circuit

Diagram

REMOVAL

AND

INSTALLATION

5

Disconnect

pick

up

coil

wire

from

IC

ignition

unit

Note

Holding

connector

with

needle

nose

pliers

as

shown

in

Fig

EE

68

disconnect

pick

up

coil

terminal

Be

careful

not

to

pull

lead

wire

I

Disconnect

battery

ground

cable

2

Take

off

distributor

cap

and

re

move

rotor

head

3

Disconnect

harness

connector

4

Remove

Ie

ignition

unit

securing

screws

rf

I

I

EE751

Fig

EE

68

Di

Connecting

Pick

up

Coil

Term

inal

eE750

Fig

EE

67

Removing

Ie

Ignition

Unit

6

InstaU

IC

ignition

unit

in

the

reverse

order

of

removal

EE

25

CAUTION

Before

instelling

IC

ignition

unit

mike

sure

mlting

surfaces

of

IC

ignition

unit

end

distributor

Ire

cleen

and

free

from

dust

sand

and

moisture

Note

a

When

connecting

lead

wires

to

unit

insert

lead

wire

terminal

with

fin

ger

as

shown

in

Fig

EE

69

b

Connect

lead

wires

according

to

color

marked

on

upper

face

of

grommet

EE752

Fig

EE

69

Connecting

Pick

up

Coil

Terminal

CHECKING

IC

IGNITION

SYSTEM

DESCRIPTION

To

check

the

IC

ignition

system

use

a

circuit

tester

The

ignition

per

fannance

of

the

ignition

system

at

a

high

speed

cannot

be

measured

direct

ly

However

it

can

be

checked

by

operating

a

vehicle

actually

at

a

high

speed

The

IC

ignition

system

can

be

checked

easily

by

referring

to

the

Inspection

Table

For

the

method

of

inspection

refer

to

respective

items

Page 184 of 548

INSPECTION

TABLE

I

No

spark

occur

Check

high

tension

cable

NG

OK

Repair

and

lor

replace

ngine

Electrical

System

START

Check

sparking

performance

J

J

Sparks

oci

1u

IC

IGNITION

SYSTEM

OK

Check

power

supply

circuit

NG

Repair

and

or

replace

OK

Check

primary

circuit

Proceed

to

A

Proceed

to

A

NG

epair

an

or

replace

OK

Proceed

to

A

DISTRIBUTOR

ASSEMBLY

NG

lC

IGNITION

UNIT

AND

OR

PICK

UP

COIL

NG

Mealure

pick

up

coil

resistance

as

a

distributor

assembly

Except

approx

4000

Measure

igilition

coii

8terminalvoltage

Battery

voltage

t

OV

Measure

pick

up

coil

resistance

I

Ie

IGNITION

UNIT

NG

Except

approx

400n

Approx

400n

PICK

UP

COIL

NG

1

PICK

UP

COIL

OK

Replace

IC

IGNITION

Replace

I

UNI

NG

l

Meuure

pick

up

coil

resistance

Except

approx

4000

I

Check

sparking

performance

I

Replace

I

r

PICK

UP

COIL

NG

1

No

spark

occun

Sparks

occur

I

IC

IGNITION

flc

IGNITION

Proceed

to

A

Replace

UNIT

NG

i

UNIT

OK

Proceed

to

A

Replace

Proceed

to

A

CHECKING

PROCEDURE

Sparking

performance

check

L

Turn

ignition

switch

to

OFF

position

2

Disconnect

anti

dieseling

solenoid

valve

connector

to

cut

off

supply

of

fuel

to

engine

3

Disconnect

high

tension

cable

from

spark

plug

4

Keeping

high

tension

cable

end

4

to

5

mm

0

16

to

0

20

in

away

from

engine

block

rotate

starter

motor

and

check

whether

sparks

occur

across

the

clearance

JUDGMENT

Sparks

occur

IC

ignition

system

OK

In

this

case

IC

ignition

system

and

component

parts

need

not

be

checked

beyond

this

No

spark

occurs

IC

ignition

system

NG

In

case

of

NG

check

High

Tension

Cables

Nole

This

check

is

designed

to

deter

mine

only

ignition

spark

perform

ance

when

cranking

engine

If

test

results

are

satisfactory

Ibis

does

EE

26

I

Approx

400n

PICK

UP

COIL

OK

1C

IGNITION

UNIT

NG

I

Repair

and

or

replace

I

Proceed

to

A

Approx

400n

l

PICK

UP

COIL

OK

1

not

alwaY

indicate

performance

sufrlcienl

for

high

speed

operation

IOgh

tension

cable

check

Refer

to

Engine

Tune

up

for

Check

ing

Ignition

Wiring

Distributor

Cap

and

Rotor

JUDGMENT

If

high

tension

cable

is

OK

check

Power

SupplY

Circuit

If

high

tension

cable

is

NG

replace

cable

assembly

Page 185 of 548

Power

suppl

circuit

check

Make

sure

that

ignition

switch

is

in

OFF

position

2

Disconnect

Ie

ignition

unit

con

nector

from

unit

3

Turn

ignition

switch

to

ON

position

4

Measure

voltage

at

the

terminal

as

shown

in

Fig

EE

70

I

I

1

Fig

EE

70

EE734

Checking

Power

Supply

Circuit

5

Turn

ignition

switch

to

OFF

position

JUDGMENT

Battery

voltage

is

indicated

OK

In

this

case

check

Primary

Circuit

Battery

voltage

is

not

indicated

NG

In

case

of

NG

check

power

supply

wirings

fusible

link

ignition

switch

and

connecto

s

for

condition

and

con

tinuity

Primer

circuit

check

I

Make

sure

that

ignition

switch

is

in

0

FF

position

2

Disconnect

IC

ignition

unit

con

nector

from

unit

3

Turn

ignition

switch

to

ON

position

4

Measure

voltage

at

the

terminal

as

shown

in

Fig

EE

7I

1

I

r

1

EE735

Fig

EE

7I

Checking

Primary

Circuit

Engine

Electrical

System

5

Turn

ignition

switch

to

OFF

position

JUDGMENT

Battery

voltage

is

indicated

OK

In

this

case

proceed

to

the

step

for

IC

Ignition

Unit

and

Pick

up

Coil

Check

Battery

voltage

is

not

indicated

NG

If

NG

check

condition

and

con

tinuity

of

primary

circuit

wirings

and

connectors

If

results

of

these

inspec

tions

are

satisfactory

check

Ignition

Coil

Ignition

coil

check

I

Make

sure

that

ignition

switch

is

in

OFF

position

2

Disconnect

harness

connector

from

ignition

coil8terminal

3

Measure

resistance

between

and

8terminals

Resistance

1

range

C2J

j

EE567

Fig

EE

72

Checking

Ignition

Coil

Assem

bly

JUDGMENT

If

resistance

value

is

0

84

to

1

02n

OK

If

resistance

value

is

other

than

the

specified

value

NG

Ie

Ignition

unit

end

pick

up

coli

check

If

power

supply

circuit

primary

circuit

and

high

tension

cables

are

in

good

order

IC

ignition

unit

and

or

pick

up

coil

are

malfunctioning

I

Make

sure

that

ignition

switch

is

in

OFF

position

2

Remove

distributor

cap

and

ro

tor

EE

27

3

Measure

resistance

between

two

terminals

of

pick

up

coil

as

a

distribu

tor

assembly

with

a

circuit

tester

1

Tester

probes

2

Grommet

3

Ie

ignition

urnt

EE736

Fig

EE

73

Measuring

Pick

up

Coil

Resistance

4

Measure

resistance

by

reversing

polarity

of

circuit

tester

probes

JUDGMENT

Approx

400n

are

indicated

Pick

up

coil

OK

IC

ignition

unit

NG

In

this

case

replace

faulty

IC

igni

tion

unit

with

new

one

Approx

400n

are

not

indicated

Condition

cannot

be

judged

Thus

proceed

to

item

5

Note

If

resistance

is

approx

4OOn

no

further

inspection

is

required

replace

IC

ignition

unit

5

Make

sure

2

pin

IC

ignition

unit

connector

is

securely

connected

to

unit

6

Turn

ignition

switch

to

ON

position

7

Measure

voltage

at

ignition

coil

8

terminal

8

Turn

ignition

switch

to

OFF

position

CAUTION

Turn

ignition

switch

off

after

releasing

test

probe

of

circuit

tester

from

nega

tive

terminal

of

ignition

coil

Failure

to

do

this

could

result

in

damage

to

circuit

tester