battery DATSUN 210 1979 Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 186 of 548

JUDGMENT

OV

is

indicated

IC

ignition

unit

NG

But

condition

of

pick

up

coil

can

not

be

judged

Proceed

to

the

item

for

Pick

up

Coil

Check

Bat

tery

voltage

is

indicated

Condition

cannot

be

judged

Proceed

to

item

9

9

Remove

IC

ignition

unit

Refer

to

IC

ignition

Unit

for

re

moval

10

Measure

resistance

between

two

terminals

of

pick

up

coil

JUDGMENT

Approx

40011

are

indicated

The

ignition

coil

is

an

oil

filled

type

The

ignition

coil

case

is

filled

with

oil

which

has

good

insulating

and

heat

radiating

characteristics

The

ignition

coil

has

a

greater

ratio

between

the

primary

and

secondary

windings

to

step

up

battery

voltage

to

high

voltage

This

causes

stronger

sparks

to

jump

the

spark

plug

gap

The

cap

is

made

of

alkyd

resin

which

offers

high

resistance

to

electric

arc

and

increased

insulation

When

high

tension

cable

is

installed

to

ignition

coil

there

should

be

no

clearance

between

their

caps

Note

Do

not

disconnect

high

tension

cables

from

spark

plugs

during

en

gine

running

r

EE354

1

High

tension

cable

2

Rubber

cap

Fig

EE

74

Correct

Instalhltion

of

High

Tension

Cable

Engine

Electrical

System

Pick

up

coil

OK

IC

ignition

unit

NG

Approx

40011

are

not

indicated

Pick

up

coil

NG

Condition

of

IC

ignition

unit

can

not

be

judged

Proceed

to

item

11

II

Replace

faulty

pick

up

coil

with

new

one

12

Install

original

IC

ignition

unit

13

Check

parking

performance

JUDGMENT

Sparks

occur

IC

ignition

system

IC

ignition

unit

OK

No

spark

OCCUrs

IC

ignition

unit

NG

IGNITION

COIL

If

NG

replace

faulty

IC

ignition

unit

with

new

one

P1ck

up

coil

check

I

Make

sure

that

ignition

switch

is

in

OFF

position

2

Remove

IC

ignition

unit

Refer

to

IC

Ignition

Unit

for

removal

3

Measure

resistance

between

two

terminals

of

pick

up

coil

JUDGMENT

Approx

40011

are

indicated

OK

Approx

40011

are

not

indicated

NG

If

NG

replace

faulty

pick

up

coil

with

new

one

1

@

I

rJ

1

C

I

I

i

jllll

1

t

1

Rubber

cap

for

ignition

coil

2

Secondary

tenninal

3

Cap

4

Primary

terminal

5

Spring

6

Secondary

winding

EE

28

EE578

7

Primary

winding

8

Side

core

9

Insulator

10

Center

core

11

Segment

12

Case

Fig

EE

75

Ignition

Coit

Page 188 of 548

Engine

Electrical

System

SERVICE

DATA

AND

SPECII

ICATIONS

GENERAL

SPECIFICATIONS

BATTERY

Type

A

pplied

model

Capacity

V

AH

STARTING

MOTOR

Type

Applied

model

System

voltage

v

No

load

Terminal

voltage

v

Current

A

Revolution

rpm

ALTERNATOR

Type

Nominal

rating

Ground

pol

trity

Minimwn

revolution

under

no

load

When

14

volt

is

applied

Hot

output

current

PuUeyratio

Regulated

output

voltage

N50Z

NS70

U

S

A

Canada

U

S

A

Optional

12

60

12

65

SI14

160B

S1I4

163E

Non

reduction

gear

type

U

S

A

M

T

USA

A

T

US

A

M

T

Optional

12

11

5

Less

than

60

More

than

7

000

LR15049

V

A

1250

Negative

rpm

Less

than

1

000

A

rpm

More

than

40

2

500

50

5

000

2

06

v

144to15

0

EE

30

S1I4

253

Reduction

gear

type

Canada

U

S

A

Optional

11

Less

than

100

More

than

3

900

Page 189 of 548

Engine

Electrical

System

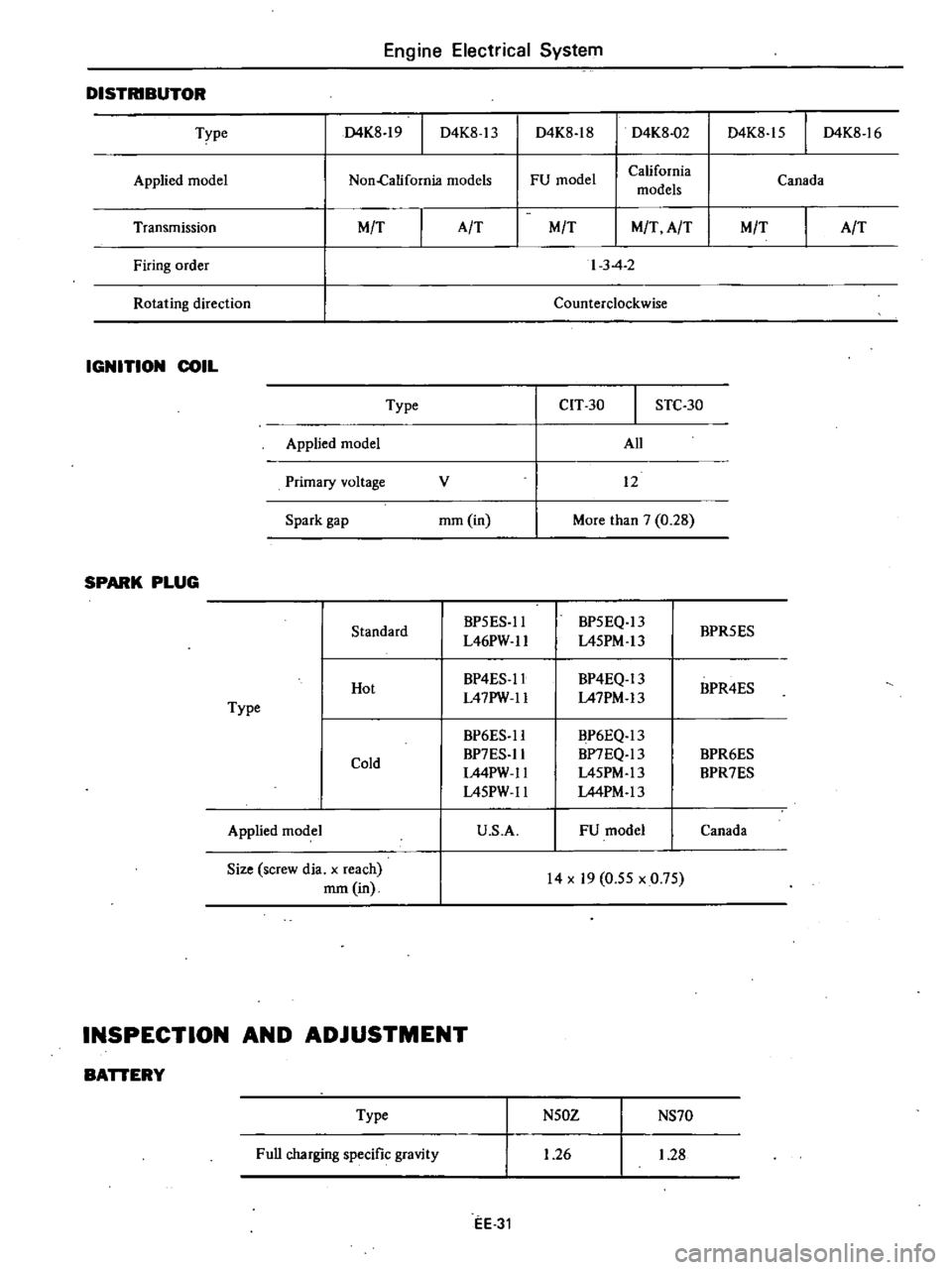

DISTRIBUTOR

D4K8

18

D4K8

15

I

D4K8

16

Type

D4K8

19

I

D4K8

13

D4K8

02

Applied

model

FU

model

California

models

Canada

Non

California

models

Transmission

MfT

Firing

order

Rotating

direction

IGNITION

COIL

Type

Applied

model

Primary

voltage

Spark

gap

SPARK

PLUG

Standard

Hot

Type

Cold

Applied

model

Size

screw

dia

x

reach

mm

in

AfT

MfT

MfT

AfT

MfT

AfT

I

3

4

2

Counterclockwise

cn

30

STC

30

All

v

12

mm

in

More

than

7

0

28

BP5ES

II

BP5EQ

13

BPR5ES

L46PW

1I

L45PM

13

BP4ES

1I

BP4EQ

13

BPR4ES

L47PW

1I

L47PM

13

BP6ES

1I

BP6EQ

13

BP7ES

1I

BP7EQ

13

BPR6ES

L44PW

1I

L45PM

13

BPR7ES

L45PW

1I

L44PM

13

U

S

A

FU

model

Canada

14

x

19

0

55

x

0

75

INSPECTION

AND

ADJUSTMENT

BATTERY

Type

Full

charging

specific

gravity

N50Z

NS70

1

26

1

28

EE

31

Page 192 of 548

Engine

Electrical

System

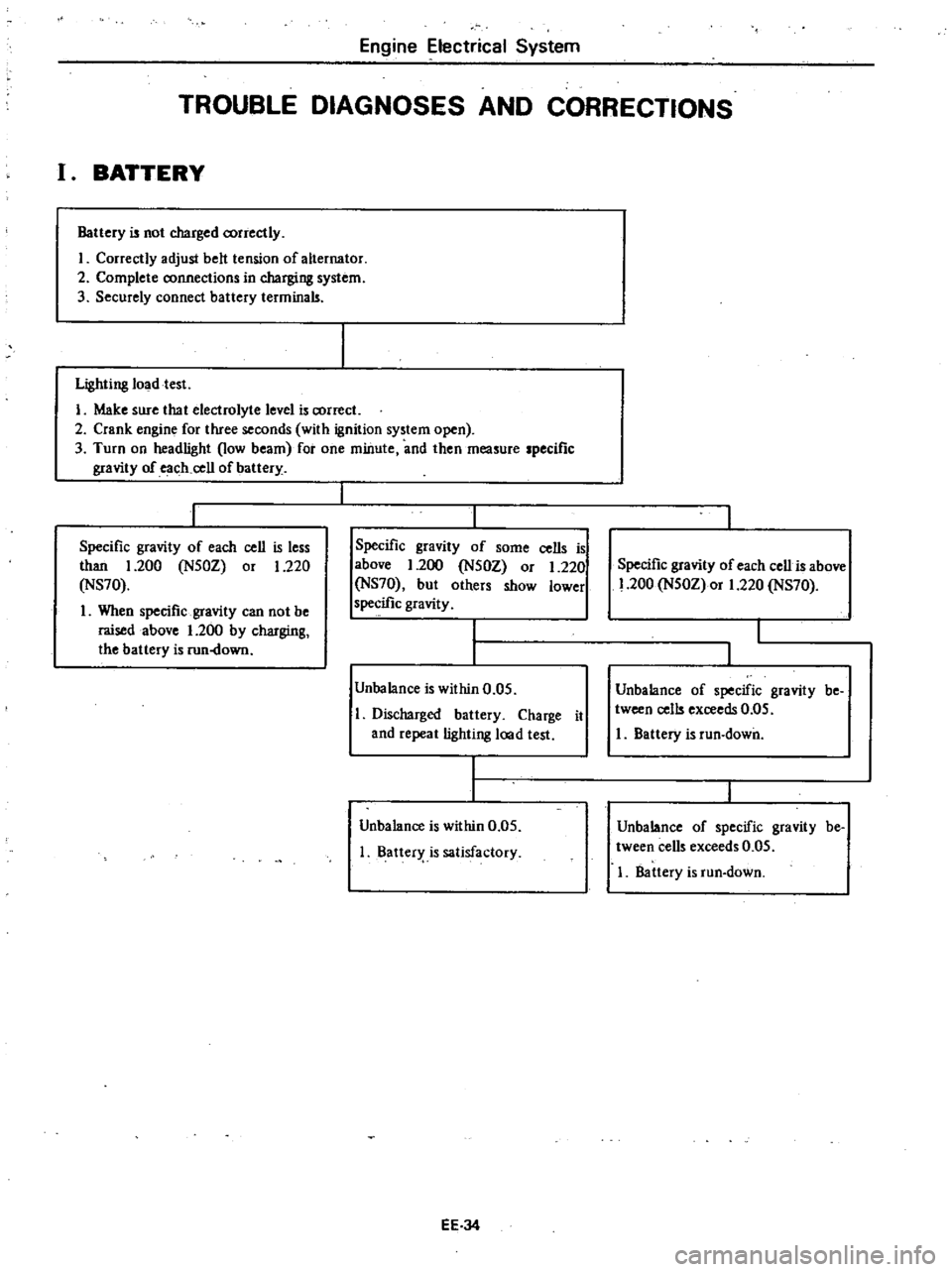

TROUBLE

DIAGNOSES

AND

CORRECTIONS

I

BATTERY

Battery

is

not

charged

correctly

I

Correctly

adjust

belt

tension

of

alternator

2

Complete

connections

in

charging

system

3

Securely

connect

battery

terminals

Lighting

Joadtest

I

Make

sure

that

electrolyte

level

is

correct

2

Crank

engine

for

three

seconds

with

ignition

system

open

3

Turn

on

headlight

low

beam

for

one

minute

and

then

measure

specific

gravity

of

each

cell

of

battery

Specific

gravity

of

each

cell

is

less

than

1

200

N50Z

or

1

220

NS70

1

When

specific

gravity

can

not

be

raised

above

1

200

by

charging

the

battery

is

run

down

Specific

gravity

of

some

cells

is

above

1

200

N50Z

or

1

220

NS70

but

others

show

lower

specific

gravity

Unbalance

is

within

0

05

Discharged

battery

Charge

it

and

repeat

lighting

lood

test

Unbalance

is

within

0

05

Batter

is

satisfactory

EE

J4

Specific

gravity

of

each

cell

is

above

1

200

N50Z

or

1

220

NS70

Unbalance

of

specific

gravity

be

tween

cells

exceeds

0

05

I

Battery

is

run

down

Unbalance

of

specific

gravity

be

tween

cells

exceeds

0

05

I

Battery

is

run

down

Page 193 of 548

Engine

Electrical

System

II

STARTING

MOTOR

Condition

Starting

motor

will

not

operate

Noisy

starting

motor

Starting

motor

cranks

lowly

Starting

motor

cranks

slowly

Starting

motor

operate

but

does

not

crank

engine

Starting

motor

will

not

disengage

even

if

ignition

switch

is

turned

off

Probable

cause

Discharged

battery

Damaged

solenoid

witch

Loose

connections

of

terminal

Damaged

field

coil

Damaged

brushes

Damaged

bearing

Damaged

annature

Loose

securing

bolt

Worn

pinion

gear

Poor

lubrication

Worn

commutator

Worn

brushes

Discharged

battery

Loose

connection

of

terminal

Worn

brushes

Locked

brushes

Loose

connections

of

terminal

Damaged

field

coil

Damaged

brushes

Damaged

bearing

Damaged

armature

Dirty

or

worn

commutator

Armature

rubs

field

coil

Damaged

splenoid

switch

Worn

pinion

Locked

pinion

guide

Worn

ring

gear

Damaged

sOlenoid

switch

Damaged

gear

teeth

EE

35

Corrective

action

Charge

or

repiace

battery

Repair

or

replace

solenoid

switch

Clean

and

tighten

terminal

Replace

yoke

Replace

brushes

Replace

bearing

Replace

armature

Tighten

Replace

Add

oil

Replace

Replace

Charge

Clean

and

tighten

Replace

Inspect

brush

pring

tension

or

repair

brush

holder

Clean

and

tighten

terminal

Replace

yoke

Replace

brushe

Replace

bearing

Replace

armature

Clean

and

repair

Repalce

assembly

Repair

or

replace

Replace

Repair

Replace

Repair

or

replace

Replace

damaged

gear

Page 199 of 548

REMOVAL

It

is

much

easier

to

remove

engine

and

transmission

as

a

single

unit

than

to

remove

alone

After

removal

engine

can

be

separated

from

the

transmission

assembly

WARNING

a

Place

wheel

chocks

in

fronl

of

front

wheels

and

in

rear

of

rear

wheels

b

Be

sure

to

hoist

engine

in

a

safe

manner

c

You

should

not

remove

engine

until

exhaust

system

has

com

pletely

cooled

off

Otherwise

you

may

burn

your

self

and

or

fire

may

break

out

in

fuel

line

Note

Fender

coven

should

be

used

to

protect

car

body

1

Disconnect

battery

ground

cable

from

battery

terminal

and

fusible

link

at

wire

connector

2

Remove

hood

as

follows

CAUTION

Have

an

assistant

help

you

so

as

to

prevent

damage

to

body

I

Mark

hood

hinge

locations

on

hood

to

facilitate

reinstallation

2

Support

hood

by

ltand

and

re

move

bolts

securing

it

to

hood

hinge

being

careful

not

to

let

hood

slip

when

bolts

are

removed

See

Fig

ER

2

3

Remove

hood

from

hood

hinge

f

Il

I

BF133A

Fig

ER

2

Removing

Hood

Remove

under

cover

Drain

radiator

coolant

and

engine

3

4

oil

5

Disconnect

upper

and

lower

hoses

from

radiator

and

disconnect

oil

cooler

hoses

automatic

transmission

only

6

Remove

four

bolts

securing

radia

Engine

Removal

Installation

tor

to

body

and

detach

radiator

after

removing

radiator

shroud

7

Remove

air

cleaner

assembly

from

carburetor

as

follows

1

Remove

fresh

air

duct

from

air

cleaner

2

Remove

hot

air

duct

from

air

cleaner

3

Loosen

air

cleaner

band

bolt

4

Disconnect

air

cleaner

to

air

pump

hose

at

air

cleaner

5

Disconnect

air

cleaner

ta

rocker

cover

hose

at

rocker

cover

6

Disconnect

air

cleaner

to

A

B

valve

hose

at

air

cleaner

7

Disconnect

air

cleaner

to

related

vacuum

hoses

at

air

cleaner

8

Disconnect

accelerator

control

wire

from

carburetor

9

Disconnect

the

following

cables

wires

and

hoses

Wire

to

auto

choke

heater

Wire

to

throttle

opener

cut

solenoid

or

throttle

switch

Wire

to

fuel

cut

solenoid

Wire

to

vacuum

switching

valve

High

tension

cable

between

igni

tion

coil

and

distributor

Battery

cable

to

starter

motor

Wire

to

distributor

Wire

to

thermal

transmitter

Wire

to

alternator

Engine

ground

cable

oil

pressure

switch

and

engine

harness

No

2

See

Fig

ER

3

o

1

Ground

cable

2

Engine

harness

No

2

3

Oil

pressure

switch

Fig

ER

3

EA368

Disconnecting

Cable

and

Wire

Fuel

hose

at

fuel

pump

and

fuel

return

hose

at

connection

Air

pump

air

cleaner

hose

Carbon

canister

hoses

Heater

inlet

and

outlet

hoses

if

so

equipped

ER

3

Vacuum

hose

of

brake

booster

at

intake

manifold

Air

conditioner

equipped

model

10

Remove

compressor

belt

To

remove

loosen

idler

pulley

nut

and

adjusting

bolt

1

Remove

air

pump

2

Remove

compressor

retaining

bolts

and

move

compressor

toward

fender

to

facilitate

removal

of

engine

Nole

Never

discharge

gas

from

com

pressor

while

work

is

being

per

formed

II

Compressor

EA478

Fig

ER

4

Location

of

Air

Compressor

3

Disconnect

vacuum

hose

of

air

conditioner

from

connector

of

intake

manifold

4

Remove

F

i

C

D

actuator

from

bracket

II

Remove

clutch

operating

cylin

der

from

clutch

housing

manual

trans

mission

only

dJ

Tightening

torque

Clutch

operating

cylinder

E

A3

to

clutch

housing

3

1

to

4

1

kg

22

to

30

ft

lbl

Fig

ER

5

Removing

Clutch

Operating

Cylinder

Page 201 of 548

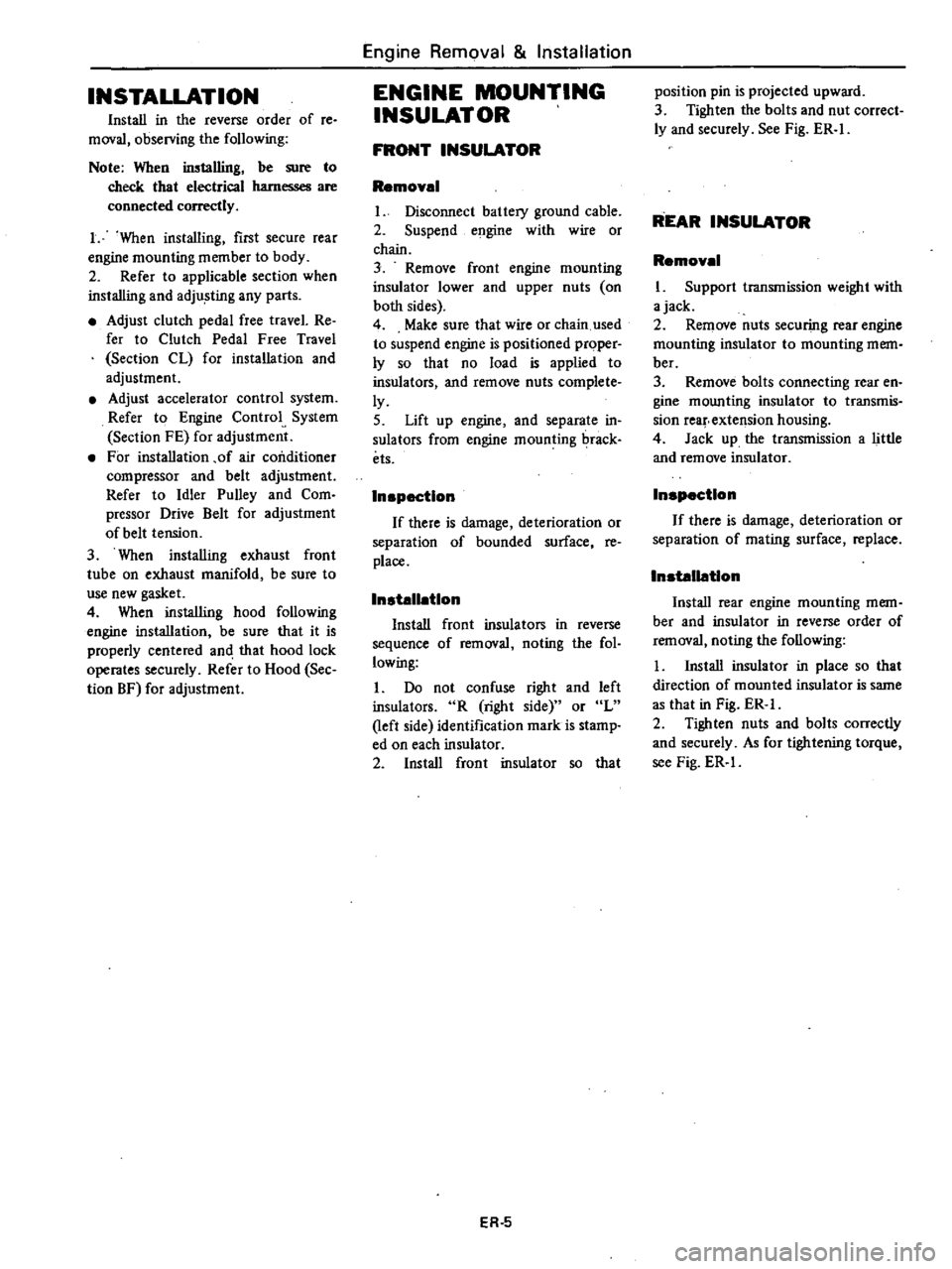

INSTALLATION

Install

in

the

reverse

order

of

re

moval

observing

the

following

Note

When

inslal1ing

be

sure

to

check

thaI

electrical

harnesses

are

connected

ly

1

When

installing

first

secure

rear

engine

mounting

member

to

body

2

Refer

to

applicable

section

when

installing

and

adjusting

any

parts

Adjust

clutch

pedal

free

travel

Re

fer

to

Clutch

Pedal

Free

Travel

Section

CL

for

installation

and

adjustment

Adjust

accelerator

control

system

Refer

to

Engine

Control

System

Section

FE

for

adjustment

For

installation

of

air

conditioner

compressor

and

belt

adjustment

Refer

to

Idler

Pulley

and

Com

pressor

Drive

Belt

for

adjustment

of

belt

tension

3

When

installing

exhaust

front

tube

on

exhaust

manifold

be

sure

to

use

new

gasket

4

When

installing

hood

following

engine

installation

be

sure

that

it

is

properly

centered

and

that

hood

lock

operates

securely

Refer

to

Hood

See

tion

BF

for

adjustment

Engine

Removal

Installation

ENGINE

MOUNTING

INSULATOR

FRONT

INSULATOR

Removal

Disconnect

battery

ground

cable

2

Suspend

engine

with

wire

or

chain

3

Remove

front

engine

mounting

insulator

lower

and

upper

nuts

on

both

sides

4

Make

sure

that

wire

or

chain

used

to

suspend

engine

is

positioned

prqper

ly

so

that

no

load

is

applied

to

insulators

and

remove

nuts

complete

ly

5

Lift

up

engine

and

separate

in

sulators

from

engine

mounting

rack

ets

Inspection

If

there

is

damage

deterioration

or

separation

of

bounded

surface

re

place

Installation

Install

front

insulators

in

reverse

sequence

of

removal

noting

the

fol

lowing

1

Do

not

confuse

right

and

left

insulators

R

right

side

or

L

left

side

identification

mark

is

stamp

ed

on

each

insulator

2

Install

front

insulator

so

that

ER

5

position

pin

is

projected

upward

3

Tighten

the

bolts

and

nut

correct

ly

and

securely

See

Fig

ER

I

REAR

INSULATOR

Removal

l

Support

transmission

weight

with

ajack

2

Remove

nuts

securing

rear

engine

mounting

insulator

to

mounting

mem

ber

3

Remove

bolts

connecting

rear

en

gine

mounting

insulator

to

transmis

sion

reaf

extension

housing

4

Jack

up

the

transmission

a

little

and

remove

insulator

Inspection

If

there

is

damage

deterioration

or

separation

of

mating

surface

replace

Installation

Install

rear

engine

mounting

mem

ber

and

insulator

in

reverse

order

of

removal

noting

the

following

I

Install

insulator

in

place

so

that

direction

of

mounted

insulator

is

same

as

that

in

Fig

ER

2

Tighten

nuts

and

bolts

correctly

and

securely

As

for

tightening

torque

see

Fig

ER

l

Page 219 of 548

I

ht

2nd

fork

r

2

3rd

top

fork

rod

3

Reverse

fork

rod

4

Retaining

pin

5

I

t

2nd

shift

fork

6

3rd

top

shift

fork

7

Checking

ball

plug

8

Check

ban

spring

9

Check

ball

10

Interlock

plunger

11

S

topper

ring

12

Shift

rod

A

bracket

13

Reverse

shift

fork

14

Lock

pin

15

Striking

lever

Manual

Transmission

16

Striking

rod

17

Return

spring

plug

18

Reverse

check

spring

19

Return

pring

20

Plunger

21

D

ring

22

Stopper

pin

bolt

23

Striking

guide

assembly

24

Striking

guide

oil

seal

REMOVAL

To

dismount

transmission

from

the

car

proceed

as

follows

Disconnect

battery

ground

cable

2

Remove

console

box

and

detach

rubber

boots

if

so

equipped

3

Place

transmission

control

lever

in

neutral

position

and

remove

it

m

TM781

Fig

MT

4

Removing

Control

Lever

@

@

25

Control

lever

bushing

26

Expansion

plug

27

Control

pin

bushing

28

Control

arm

pin

29

Control

lever

o

Tightening

torque

kg

m

ft

lb

@

0

5

to

0

8

3

6

tn

5

8

@

1

3

to

1

7

9

to

12

Fig

MT

3

F4W60L

Tra11lmiBSion

Shift

Control

Components

TM094A

4

Jack

up

the

car

and

support

its

weight

on

safety

stands

Use

a

hy

draulic

hoist

or

open

pit

if

available

Make

sure

that

safety

is

insured

5

Disconnect

front

exhaust

tube

and

remove

bolt

securing

exhaust

mounting

bracket

from

exhaust

front

tube

side

6

Disconnect

wires

from

reverse

back

up

lamp

switch

7

Disconnect

speedometer

cable

from

rear

extension

At

the

same

time

removey

top

detecting

switch

if

so

equipped

8

Remove

propeller

shaft

Refer

to

Removal

Section

PO

Note

Plug

up

the

opening

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

MT

3

9

Remove

clutch

operating

cylinder

from

transmission

case

10

Support

engine

by

placing

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

CAUTION

00

not

place

the

jack

under

the

oil

pan

drain

plug

11

Support

transmission

with

a

transmission

jack

12

Loosen

rear

engine

mount

se

curing

bolts

CD

temporarily

and

re

move

crossmember

mounting

bolts

V

Page 233 of 548

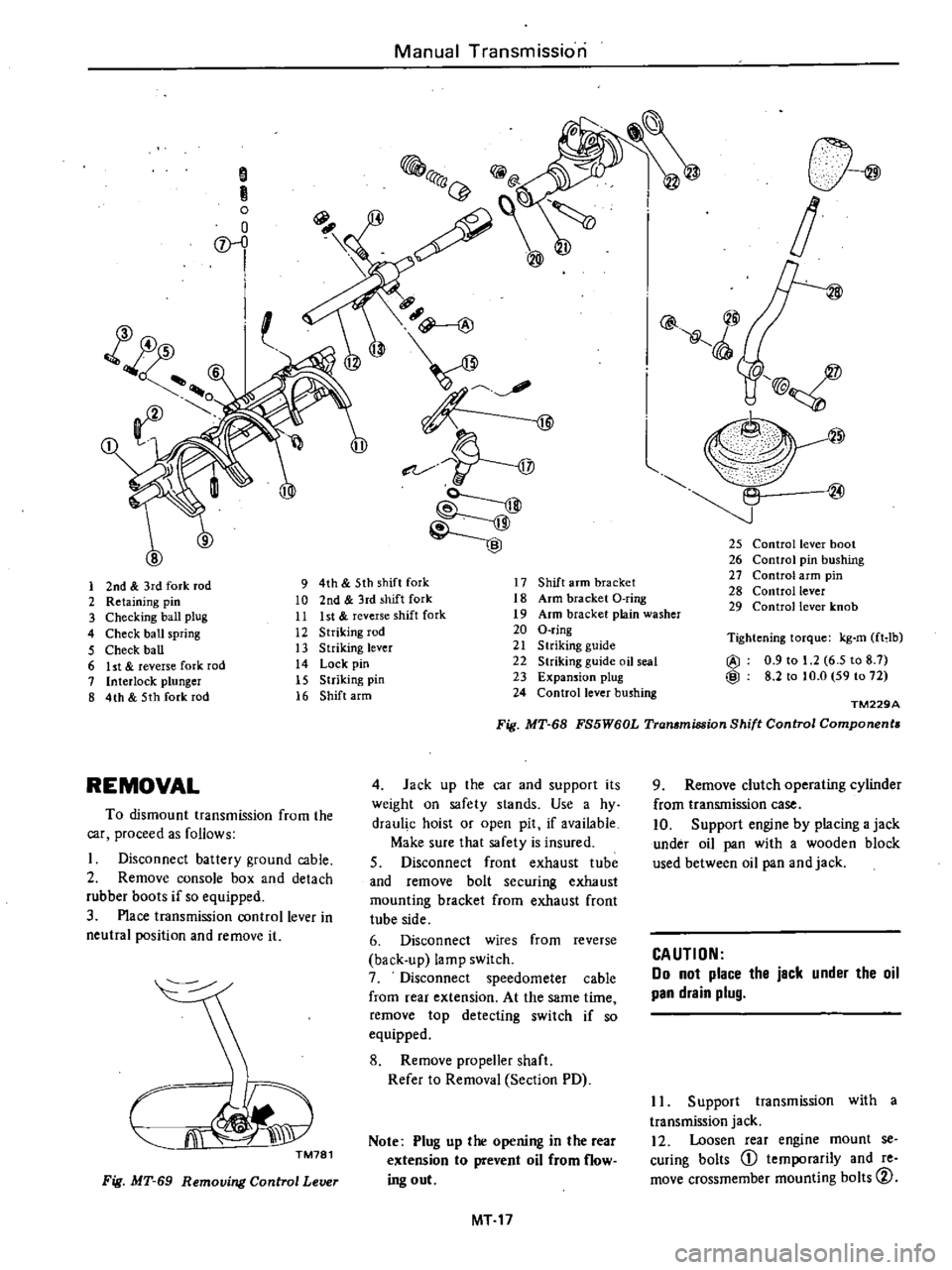

Manual

Transmission

S

R

o

o

D

l

@

@

l

@

l

25

Control

lever

boot

26

Control

pin

bushing

27

Control

arm

pin

28

Control

lever

29

Control

lever

knob

1

2nd

3rd

fork

rod

9

4th

5th

shift

fork

17

Shift

arm

bracket

2

Retaining

pin

10

2nd

3rd

shift

fork

18

Arm

bracket

O

ring

3

Checking

ball

plug

11

Ist

reverse

shift

fork

19

Arm

bracket

plain

washer

4

Check

ball

spring

12

Striking

rod

20

O

ring

5

Check

ball

13

Striking

lever

21

S

lriking

guide

6

ht

reverse

fork

rod

14

Lock

pin

22

Striking

guide

oil

seal

7

Interlock

plunger

15

Striking

pin

23

Expansion

plug

8

4th

5th

fork

rod

16

Shift

arm

24

Control

lever

bushing

Tightening

torque

kg

m

fHb

@

0

9

to

1

2

6

5

to

8

7

@

8

2

to

to

O

59

to

72

TM229A

Fig

MT

68

FS5W60L

Transmission

Shift

Control

Components

REMOVAL

4

Jack

up

the

car

and

supporl

its

weight

on

safety

slands

Use

a

hy

draul

c

hoist

or

open

pit

if

available

Make

sure

that

safety

is

insured

S

Disconnect

front

exhaust

tube

and

remove

bolt

securing

exhaust

mounting

bracket

from

exhaust

front

tube

side

6

Disconnect

wires

from

reverse

back

up

lamp

switch

7

Disconnect

speedometer

cable

from

rear

extension

At

the

same

time

remove

top

detecting

switch

if

so

equipped

8

Remove

propeller

shaft

Refer

to

Removal

Section

PD

To

dismount

transmission

from

the

car

proceed

as

follows

Disconnect

battery

ground

cable

2

Remove

console

box

and

detach

rubber

boots

if

so

equipped

3

Place

transmission

control

lever

in

neutral

position

and

remove

it

CJi

J

TM781

Note

Plug

up

the

opening

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

Fig

MT

69

Removing

Control

Lever

MT

17

9

Remove

clutch

operating

cylinder

from

transmission

case

10

Support

engine

by

placing

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

CAUTION

Do

not

place

the

jack

under

the

oil

pan

drain

plug

II

Support

transmission

with

a

transmission

jack

12

Loosen

rear

engine

mount

se

curing

bolts

CD

temporarily

and

re

move

crossmember

mounting

bolts

CV

Page 277 of 548

Automatic

Transmission

REMOVAL

AND

INSTALLATION

TRANSMISSION

ASSEMBLY

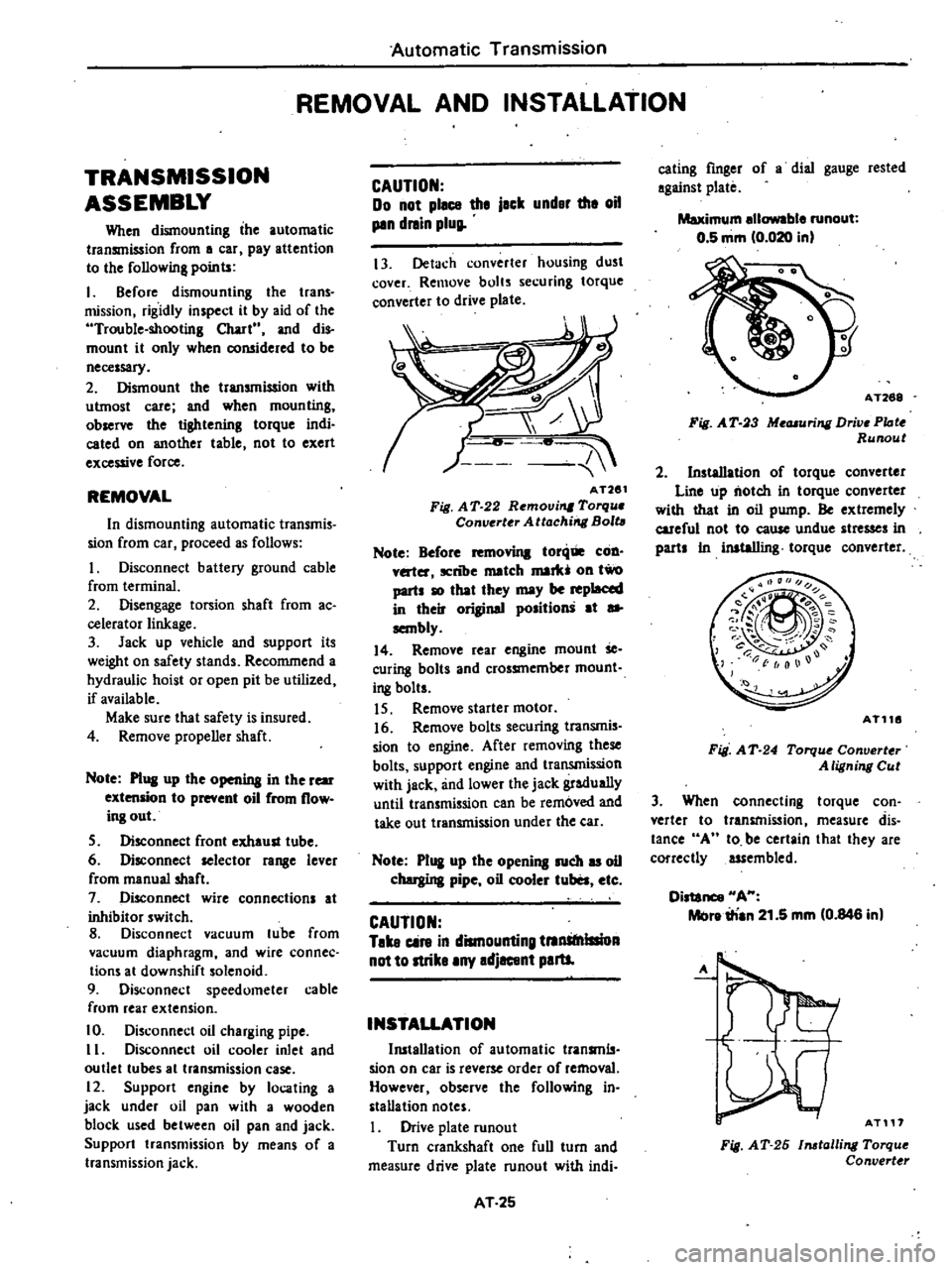

When

dismounting

the

automatic

transmission

from

a

car

pay

attention

to

the

following

points

I

Before

dismounting

the

trans

mission

rigidly

inspect

it

by

aid

of

the

Trouble

shooting

Chart

and

dis

mount

it

only

when

coll5idered

to

be

necessary

2

Dismount

the

transmission

with

utmost

care

and

when

mounting

observe

the

tightening

torque

indi

cated

on

another

table

not

to

exert

excessive

force

REMOVAL

In

dismounting

automatic

transmis

sion

from

car

proceed

as

follows

I

Disconnect

battery

ground

cable

from

terminal

2

Disengage

torsion

shaft

from

ac

eelerator

linkage

3

Jack

up

vehicle

and

support

its

weight

on

safety

stands

Recommend

a

hydraulic

hoist

or

open

pit

be

utilized

if

available

Make

sure

that

safety

is

insured

4

Remove

propeller

shaft

Note

Pl

ll

up

the

openina

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

S

Disconnect

front

exhaust

tube

6

Disconnect

selector

ra

8e

lever

from

manual

shaft

7

Disconnect

wire

connections

at

inhibitor

switch

8

Disconnect

vacuum

lube

from

vacuum

diaphragm

and

wire

connee

tions

at

downshift

solenoid

9

Disconnect

speedometer

cable

from

rear

exlension

10

Disconnect

oil

charging

pipe

II

Disconnect

oil

cooler

inlet

and

outlet

tubes

al

transmission

case

12

Support

engine

by

locating

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

Support

transmission

by

means

of

a

transmission

jack

CAUTION

Do

not

plecs

the

jack

under

the

oil

pin

dnin

plug

13

Detach

converter

housing

dust

cover

Remove

bolts

securing

torque

converter

to

drive

plate

AT261

Fig

A

T

22

Removi

Torqu

Converter

Attachirrg

Bolt

Note

Before

toni

COD

v

ter

ICnlJe

match

mark

011

two

parts

10

that

they

may

be

replaced

in

their

original

position

at

sa

sembly

14

Remove

rear

engine

mount

Se

curing

bolts

and

crossmember

mount

i

8

bolts

IS

Remove

starter

motor

16

Remove

bolts

securing

transmis

sion

to

engine

After

removing

these

bolts

support

engine

and

transmission

with

jack

and

lower

the

jack

gradually

until

transmission

can

be

removed

and

take

out

transmission

under

the

ear

Note

P1

I

up

the

opening

such

u

oil

chergina

pipe

oil

cooler

tuba

etc

CAUTION

Take

cin

in

dismounting

tnnStnlllioA

not

to

strike

any

adjacent

paru

INSTALLATION

Ill5tallation

of

automatic

transmls

sian

on

car

is

reverse

order

of

removal

However

observe

the

following

in

stallation

notes

Drive

plate

runout

Turn

crankshaft

one

full

turn

and

measure

drive

plate

runout

with

indi

AT

25

eating

finger

of

a

dial

gauge

rested

against

plate

Maximum

ellowable

runout

0

5

mm

0

020

in

AT268

Fig

A

T

3

Me

uring

Drive

PIote

Runout

2

Installation

of

torque

converter

Line

up

notch

in

torque

converter

with

that

in

oil

pump

Be

extremely

careful

not

to

eause

undue

stresses

in

parts

In

inataIIing

torque

converter

AT116

Fig

A

T

24

Torqu

Converter

A

ligning

Cut

3

When

connecting

torque

con

verter

to

transmission

measure

dis

tance

A

10

be

certain

that

they

are

correctly

assembled

Distance

HA

Melre

irian

21

5

mm

0

846

in

A

AT117

Fig

AT

26

1116talling

Torque

Convert

r