fuel cap DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 156 of 548

3

way

connector

ck

Air

@

Manometer

Carbon

canister

Emission

Control

System

400

mmH20

15

75

inH20

Check

valve

Fuel

filler

cap

r

EC091A

Fig

EC

I09

Checking

Evaporative

Emiuion

Control

Syatem

FUEL

CHECK

VALVE

I

Blow

air

through

connector

on

fuel

tank

side

A

considerable

resistance

should

be

felt

at

the

mouth

and

a

portion

of

air

flow

be

directed

toward

the

engine

2

Blow

air

through

connector

on

engine

side

Air

flow

should

be

smoothly

direct

ed

toward

fuel

tank

3

If

fuel

check

valve

is

suspected

of

not

being

properly

functioning

in

steps

I

and

2

above

replace

Engine

side

Fuel

tank

side

Q

Evaporative

fuel

flow

Fresh

air

flow

EC090A

Fig

EC

110

Checking

Fuel

Check

Valve

CARBON

CANISTER

PURGE

CONTROL

VALVE

Check

for

fuel

vapor

leakage

in

the

distributor

vacuum

line

at

diaphragm

of

carbon

canister

purge

control

valve

To

check

for

leakage

proceed

as

follows

I

Disconnect

rubber

hose

in

the

line

between

T

connector

and

carbon

canister

at

T

connector

2

Inhale

air

into

the

opening

of

rubber

hose

running

to

vacuum

hole

in

carbon

canister

and

ensure

that

there

is

no

leak

ET349

Fig

EC

lll

Checking

Carbon

Canister

Purge

Control

Valve

EC37

3

If

there

is

a

leak

remove

top

cover

from

purge

control

valve

and

check

for

dislocated

or

cracked

dia

phragm

If

necessary

replace

dia

phragrrt

kit

which

is

made

up

of

a

retainer

diaphragm

and

spring

i

ii

1

Cover

2

Diaphragm

3

Retainer

4

Diaphragm

spring

ET350

Fig

EC

112

Carbon

Canister

Purge

Control

Valve

FUEL

TANK

VACUUM

RELIEF

VALVE

Remove

fuel

filler

cap

and

see

it

functions

properly

I

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

ac

companied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

clicks

3

If

valve

is

clogged

or

if

no

resist

ance

is

felt

replace

cap

as

an

assem

bled

unit

O

ET500

Fig

EC

1l3

Fuel

Filler

Cap

Page 184 of 548

INSPECTION

TABLE

I

No

spark

occur

Check

high

tension

cable

NG

OK

Repair

and

lor

replace

ngine

Electrical

System

START

Check

sparking

performance

J

J

Sparks

oci

1u

IC

IGNITION

SYSTEM

OK

Check

power

supply

circuit

NG

Repair

and

or

replace

OK

Check

primary

circuit

Proceed

to

A

Proceed

to

A

NG

epair

an

or

replace

OK

Proceed

to

A

DISTRIBUTOR

ASSEMBLY

NG

lC

IGNITION

UNIT

AND

OR

PICK

UP

COIL

NG

Mealure

pick

up

coil

resistance

as

a

distributor

assembly

Except

approx

4000

Measure

igilition

coii

8terminalvoltage

Battery

voltage

t

OV

Measure

pick

up

coil

resistance

I

Ie

IGNITION

UNIT

NG

Except

approx

400n

Approx

400n

PICK

UP

COIL

NG

1

PICK

UP

COIL

OK

Replace

IC

IGNITION

Replace

I

UNI

NG

l

Meuure

pick

up

coil

resistance

Except

approx

4000

I

Check

sparking

performance

I

Replace

I

r

PICK

UP

COIL

NG

1

No

spark

occun

Sparks

occur

I

IC

IGNITION

flc

IGNITION

Proceed

to

A

Replace

UNIT

NG

i

UNIT

OK

Proceed

to

A

Replace

Proceed

to

A

CHECKING

PROCEDURE

Sparking

performance

check

L

Turn

ignition

switch

to

OFF

position

2

Disconnect

anti

dieseling

solenoid

valve

connector

to

cut

off

supply

of

fuel

to

engine

3

Disconnect

high

tension

cable

from

spark

plug

4

Keeping

high

tension

cable

end

4

to

5

mm

0

16

to

0

20

in

away

from

engine

block

rotate

starter

motor

and

check

whether

sparks

occur

across

the

clearance

JUDGMENT

Sparks

occur

IC

ignition

system

OK

In

this

case

IC

ignition

system

and

component

parts

need

not

be

checked

beyond

this

No

spark

occurs

IC

ignition

system

NG

In

case

of

NG

check

High

Tension

Cables

Nole

This

check

is

designed

to

deter

mine

only

ignition

spark

perform

ance

when

cranking

engine

If

test

results

are

satisfactory

Ibis

does

EE

26

I

Approx

400n

PICK

UP

COIL

OK

1C

IGNITION

UNIT

NG

I

Repair

and

or

replace

I

Proceed

to

A

Approx

400n

l

PICK

UP

COIL

OK

1

not

alwaY

indicate

performance

sufrlcienl

for

high

speed

operation

IOgh

tension

cable

check

Refer

to

Engine

Tune

up

for

Check

ing

Ignition

Wiring

Distributor

Cap

and

Rotor

JUDGMENT

If

high

tension

cable

is

OK

check

Power

SupplY

Circuit

If

high

tension

cable

is

NG

replace

cable

assembly

Page 195 of 548

Engine

Electrical

System

IV

IGNITION

CIRCUIT

When

engine

does

not

start

If

there

is

no

problem

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

cable

from

distributor

starting

engine

and

ob

serving

oondition

of

spark

that

occurs

between

high

tension

cable

and

engine

block

After

checking

this

repair

as

necessary

tery

and

anti

dieseliilg

wlenoid

valve

connector

to

cuI

off

supply

of

fuel

10

engine

Then

observe

the

condition

of

sparks

while

starter

motor

is

in

operation

Note

Turn

ignilion

switch

off

and

disconnect

ground

cable

from

bat

Condition

Location

Probable

cause

Corrective

action

No

spark

at

all

Distributor

Breakage

of

lead

wire

on

low

tension

side

Repair

Poor

insulation

of

cap

and

rotor

head

Replace

Open

pick

up

coil

Replace

Air

gap

wider

than

specification

Adjust

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

cable

Wire

coming

off

Repair

Faulty

insulation

Replace

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

Spark

length

Spark

plugs

Spark

plug

gap

too

wide

Correct

or

replace

More

than

6

mm

Too

much

carbon

Clean

or

replace

0

24

in

Broken

neck

of

insulator

Replace

Expiration

of

plug

life

Replace

Distributor

Air

gap

too

wide

Correct

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

EE

37

Page 325 of 548

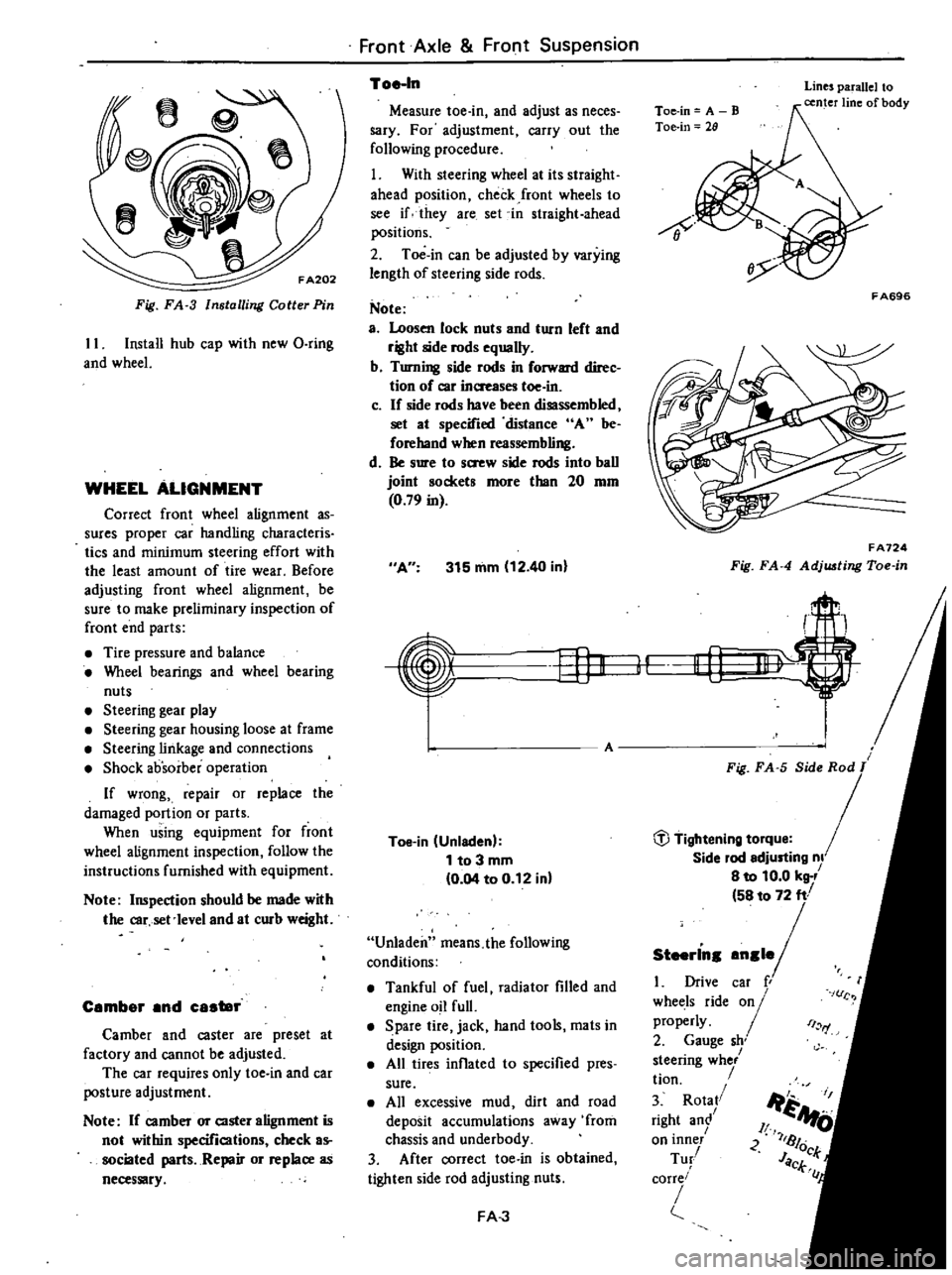

Fig

FA

3

Installing

Coller

Pin

II

Install

hub

cap

with

new

Q

ring

and

wheel

WHEEL

ALIGNMENT

Correct

front

wheel

alignment

as

sures

proper

car

handling

characteris

tics

and

minimum

steering

effort

with

the

least

amount

of

tire

wear

Before

adjusting

front

wheel

alignment

be

sure

to

make

preliminary

inspection

of

front

end

parts

Tire

pressure

and

balance

Wheel

bearings

and

wheel

bearing

nuts

Steering

gear

play

Steering

gear

housing

loose

at

frame

Steering

linkage

and

connections

Shock

absorber

operation

If

wrong

repair

or

replace

the

damaged

portion

or

parts

When

using

equipment

for

front

wheel

alignment

inspection

follow

the

instructions

furnished

with

equipment

Note

Inspection

should

be

made

with

the

car

set

Ievel

and

at

curb

weight

Cember

end

caster

Camber

and

caster

are

preset

at

factory

and

cannot

be

adjusted

The

car

requires

only

toe

in

and

car

posture

adjustment

Note

If

camber

or

caster

alignment

is

not

within

specifications

check

as

sociated

parts

Repair

or

replace

as

necessary

Front

Axle

Front

Suspension

Toe

In

Measure

toe

in

and

adjust

as

neces

sary

For

adjustment

carry

out

the

following

procedure

1

With

steering

wheel

at

its

straight

ahead

position

check

front

wheels

to

see

if

they

are

set

in

straight

ahead

positions

2

Toe

in

can

be

adjusted

by

varying

length

of

steering

side

rods

Note

a

Loosen

lock

nuts

and

turn

left

and

right

side

rods

equally

b

Turning

side

rods

in

forward

direc

tion

of

car

inaeases

toe

in

c

If

side

rods

have

been

disassembled

set

at

specified

distance

A

be

forehand

when

reassembling

d

Be

sure

to

s

w

side

rods

into

ball

joint

sockets

more

than

20

mm

0

79

in

A

315

mm

12

40

in

EfJK

Toe

in

Unladen

1

to

3

mm

0

04

to

0

12

in

Unladen

means

the

following

conditions

Tankful

of

fuel

radiator

filled

and

engine

oil

full

Spare

tire

jack

hand

tools

mats

in

design

position

All

tires

inflated

to

specified

pres

sure

All

excessive

mud

dirt

and

road

deposit

accumulations

away

from

chassis

and

underbody

3

After

correct

toe

in

is

obtained

tighten

side

rod

adjusting

nuts

FA

J

Toe

in

A

B

Toe

in

28

Lines

parallel

to

center

line

of

body

8

F

A696

FA724

Fig

FA

4

Adj

ting

Toe

in

r

II

Li

1

t

Fig

FA

5

Side

Rod

T

Side

lod

edjusting

nl

8

to

10

0

kg

58

to

72

ft

1

Drive

caf

r

whet

ls

ride

01

properly

2

Gauge

sh

steenng

whe

tion

3

Rota

right

an

on

lOner

Tu

corre

i

I

rf

c

Ji

1

A

JI

U

2

7181

JOck

CL

C

Page 410 of 548

Enr

in

e

Control

Fuel

l

c

I

xhaust

System

i

SEALING

COMPOuND

If

exhaust

tubes

are

separated

at

connection

to

renew

muffler

assembly

etc

use

the

Genuine

Nissan

Sealant

Exhaust

Sealant

Kit

20720

N2225

to

eliminate

gas

leakage

past

the

joint

Be

sure

to

observe

following

proce

dures

ee

Fig

FJ

r21

I

Wipe

clean

all

the

oontact

por

tions

of

tube

joints

allow

them

to

dry

thoroughly

2

Temporarily

mount

in

place

muf

fler

assembly

and

or

exhaust

tube

as

an

assembled

unit

on

the

car

i

Insert

the

male

tube

into

the

female

tube

fully

until

the

front

end

of

the

female

tube

touches

the

stopper

on

the

male

tube

A

55mm

2

17in

B

t

Smm

0

59i

AI

B

Il

L

l

F

E574

Fig

FE

19

Ex

unut

Tube

Connection

4

Torque

exhaust

tube

clip

securing

bolt

and

exhaust

tube

mounting

bolt

to

specifications

liJ

Tightening

torque

Exhaust

tube

clip

bolt

0

8

to

1

2

kg

m

15

8

to

8

7

h

bl

5

Squeeze

5

to

6

cc

0

31

to

0

37

cu

in

of

sealant

into

injector

from

the

sealant

tube

Be

sure

to

place

the

cap

back

to

the

sealant

tube

since

sealant

will

dry

Sealant

tube

A

5

to

6

cc

0

31

toO

37cuin

FEltl

Fig

FE

20

Squeezing

Senlant

to

Injector

6

Position

the

nozzle

of

injector

to

the

guide

and

press

it

there

firmly

Inject

sealant

slowly

until

sealant

be

gins

to

flow

out

of

the

slit

of

the

tube

This

indicates

that

the

bead

requires

no

further

sealant

Excessive

sealant

can

cause

a

clogged

tube

See

Fig

FE

22

After

injecting

wash

injector

thor

oughly

in

clean

water

to

remove

all

FE

12

FE109

Fig

FE

21

Exhaust

Sealant

Kit

traces

of

sealant

7

Start

the

engine

and

let

it

idle

slowly

for

ten

minutes

minilnum

to

harden

sealant

with

the

heat

of

ex

haust

gas

8

Check

the

oondition

of

sealant

before

driving

the

car

It

is

also

essen

tial

that

the

car

should

not

be

accel

erated

sharply

for

20

to

30

minutes

subsequent

to

this

operation

FE568

Fig

FE

22

Injecting

Seatant

Page 458 of 548

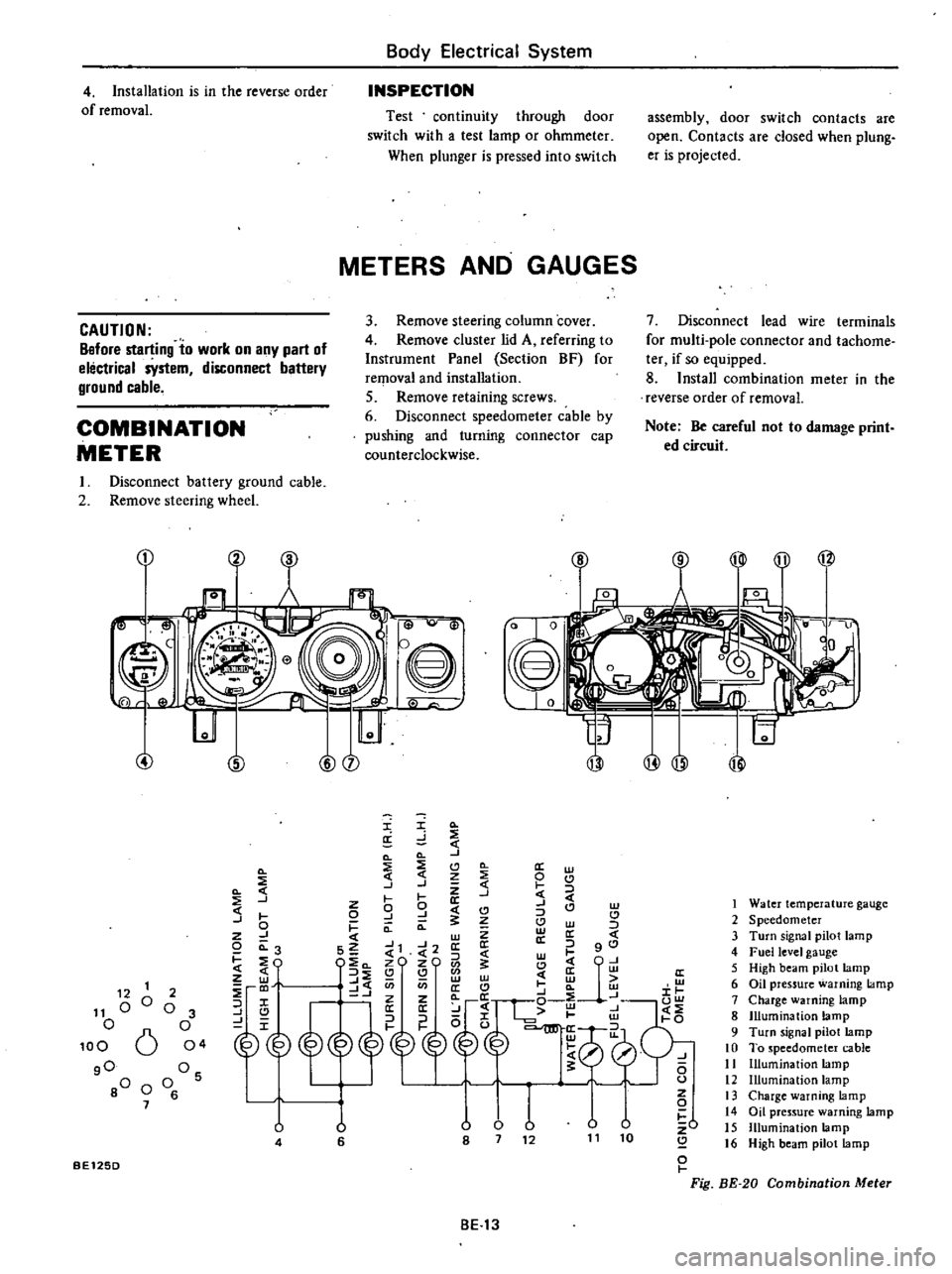

Body

Electrical

System

INSPECTION

4

Installation

is

in

the

reverse

order

of

removal

Test

continuity

through

door

switch

with

a

test

lamp

or

ohmmeter

When

plunger

is

pressed

into

switch

assembly

door

switch

contacts

are

open

Contacts

are

closed

when

plung

er

is

projected

METERS

AND

GAUGES

3

Remove

steering

column

cover

4

Remove

cluster

lid

A

referring

to

Instrument

Panel

Section

BF

for

reqlOval

and

installation

5

Remove

retaining

screws

6

Disconnect

speedometer

cable

by

pushing

and

turning

connector

cap

counterclockwise

7

Disconnect

lead

wire

terminals

for

multi

pole

connector

and

tachome

ter

if

so

equipped

8

Install

combination

meter

in

the

reverse

order

of

removal

CAUTION

Before

starting

to

work

on

any

part

of

electrical

sYstem

disconnect

battery

ground

cable

COMBINATION

METER

Note

Be

careful

not

to

damage

print

ed

circuit

I

Disconnect

battery

ground

cable

2

Remove

steering

wheel

CD

Cl

B

i

lJ

Q

@

8

0

I

0

w

@

@

I

Q

a

d

Q

Q

J

Q

2

Cl

0

a

w

Q

3

j

J

Z

t

0

J

W

C

I

0

9

J

CI

C

CI

J

0

I

Q

a

Cl

w

z

J

w

Z

a

c

o

0

3

S2

J1

J2

a

a

l

gO

C

4

l

w

I

EO

l

c

zO

zO

1

Cl

CjU

z

3

Q

Q

w

c

ffi

ffi

to

J

C

U

en

a

C

a

w

i

r

@

p

g10

l

0

U

lJ

v

v

zO

8

7

12

11

10

Q

o

I

Fig

BE

20

Combination

Meter

1

Water

temperature

gauge

2

Speedometer

3

Turn

signal

pilot

lamp

4

Fuel

level

gauge

5

High

beam

pilot

lamp

6

Oil

pressure

warning

lamp

7

Charge

warning

lamp

8

Illumination

lamp

9

Turn

signal

pilot

lamp

10

To

speedometer

cable

11

Illumination

lamp

12

Illumination

lamp

13

Charge

warning

lamp

14

Oil

pressure

warning

lamp

15

Illumination

lamp

16

High

beam

pilot

lamp

12

1

11

00

o

100

6

gO

80

0

7

2

o

3

o

04

Os

o

6

U

4

u

6

BE125D

BE13