stop start DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 450 of 548

m

c

n

to

l

l

I

g

iF

0

1

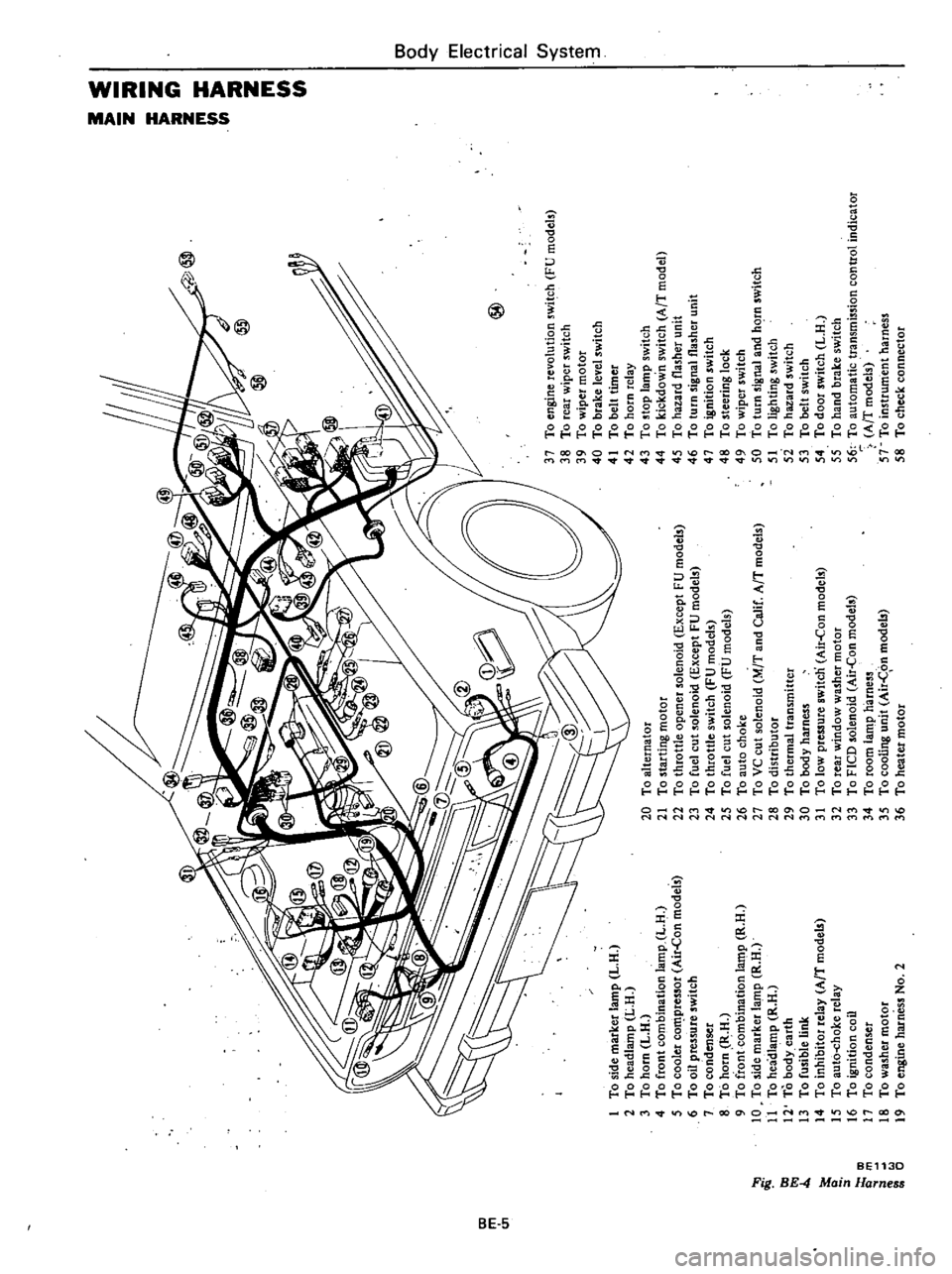

To

side

marker

lamp

L

H

2

To

headlamp

L

H

3

To

horn

L

H

4

To

front

combination

lamp

L

H

5

To

cooler

co

pressor

Air

Con

models

6

To

oil

pressure

switch

7

To

condenser

8

To

horn

R

H

9

To

front

combination

la

t11p

R

H

10

To

side

marker

lamp

R

H

11

To

headlamp

R

H

12

To

body

earth

13

To

fusible

link

14

To

inhibitor

relay

AfT

model

15

To

aut6

choke

relay

16

To

ignition

coil

17

To

condenser

18

To

washer

motor

19

To

engine

harness

No

2

@

20

To

alternator

21

To

starting

motor

22

To

throttle

opener

solenoid

Except

FU

models

23

To

fuel

cut

solenoid

Except

FU

models

24

To

throttle

switch

FU

models

25

To

fuel

cut

solenoid

FU

models

26

To

auto

choke

27

To

VC

cut

solenoid

M

T

and

Calif

AfT

models

28

To

distributor

29

To

thermal

transmitter

30

To

body

harness

31

To

low

pressure

switcn

Air

Con

models

32

To

rear

window

washer

motor

33

To

FICO

solenoid

Air

Con

models

34

To

room

lamp

harness

35

To

cooling

unit

Air

C

on

models

36

To

heater

motor

37

To

engine

revolution

switch

FU

models

38

To

rear

wiper

switch

39

To

wiper

motor

40

To

brake

level

switch

41

To

belt

timer

42

To

horn

relay

43

To

stop

lamp

switch

44

To

kickdown

switch

AfT

model

45

To

hazard

flasher

unit

46

To

turn

signal

flasher

unit

47

To

ignition

switch

48

To

steering

lock

49

To

wiper

switch

50

To

turn

signal

and

hC

rn

switch

51

To

lighting

switch

5i

To

hazard

switch

53

To

belt

switch

54

To

door

switch

L

H

55

To

hand

brake

switch

56

To

automatic

transmission

control

indicator

AfT

models

57

To

instrument

harness

58

To

check

connector

I

0

i

a

z

Z

G

z

tIl

tIl

a

Z

Il

I

to

o

Co

m

16

n

n

OJ

1

3

Page 454 of 548

Body

Electrical

System

ELECTRICAL

UNIT

OF

LIGHTING

SYSTEM

CAUTION

Before

starting

to

work

on

any

part

of

electrical

system

disconnect

battery

ground

cable

BULB

SPECIFICATIONS

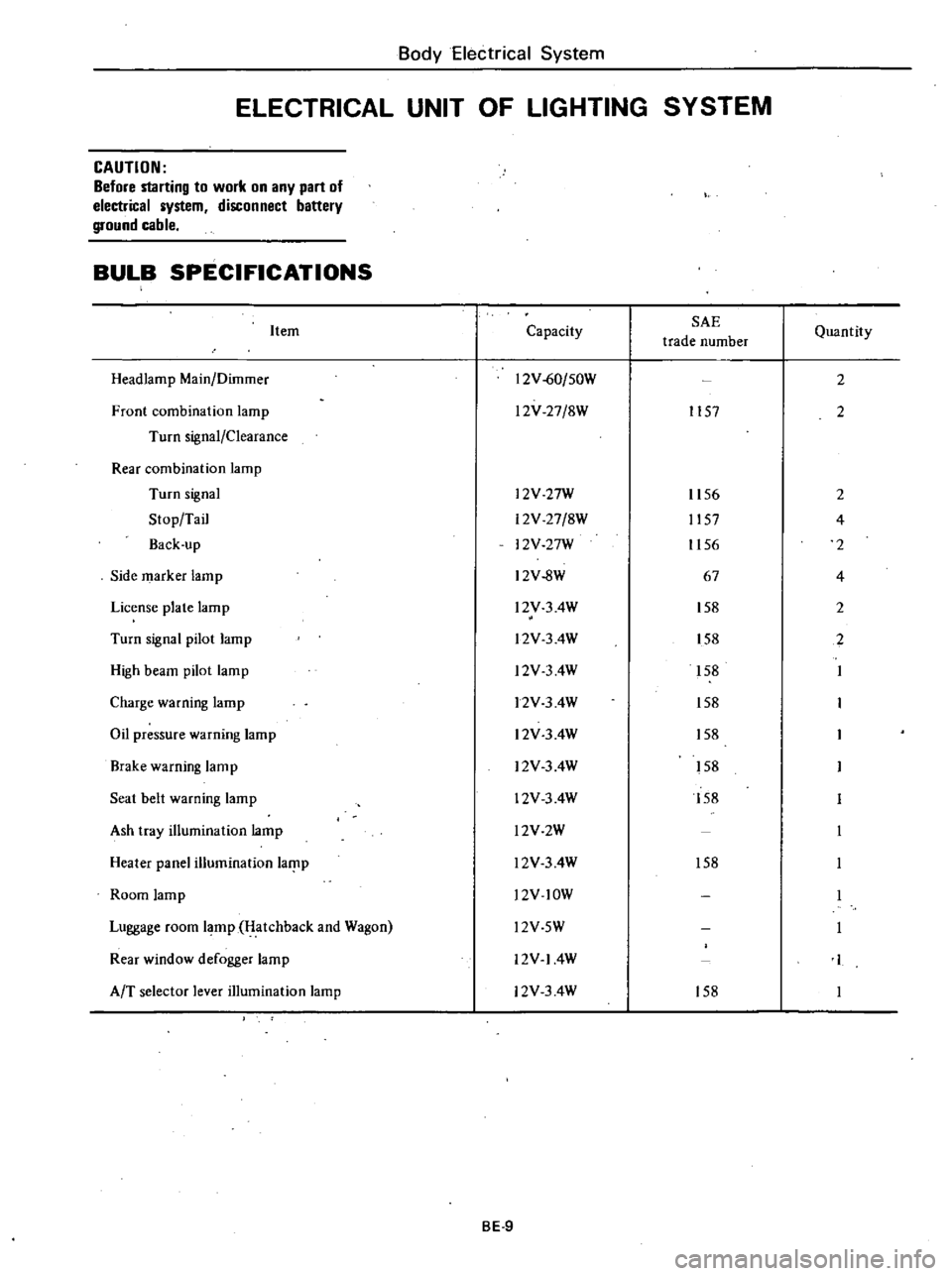

Item

Headlamp

Main

Dilnmer

Front

combination

lamp

Turn

signal

Clearance

Rear

combination

lamp

Turn

signal

Stop

Tail

Back

up

Side

marker

lamp

License

plate

lamp

Turn

signal

pilot

lamp

High

beam

pilot

lamp

Charge

warning

lamp

Oil

pressure

warning

lamp

Brake

warning

lamp

Seat

belt

warning

lamp

Ash

tray

illumination

lamp

Heater

panel

illumination

laf

lp

Room

lamp

Luggage

room

lamp

Hatchback

and

Wagon

Rear

window

defogger

lamp

AfT

selector

lever

illumination

lamp

Capacity

SAE

trade

number

12V

60

50W

l2V

27

8W

1157

l2V

27W

12V

27

8W

12V

27W

12V

8W

l2V

3

4W

l2V

3

4W

l2V

3

4W

12V

3

4W

12V

3

4W

12V

3

4W

12V

3

4W

l2V2W

l2V

3

4W

l2V

lOW

Quantity

2

2

1156

2

1157

4

1156

2

67

4

158

2

158

2

158

158

158

158

158

158

l2V

5W

12V

14W

12V

3

4W

158

BE

9

Page 457 of 548

Body

Electrical

System

ELECTRICAL

UNIT

OF

SIGNAL

SYSTEM

CAUTION

Before

startill1l

to

work

on

any

part

of

electrical

system

disconnect

battery

ground

cable

TURN

SIGNAL

SWITCH

Refer

to

combination

switch

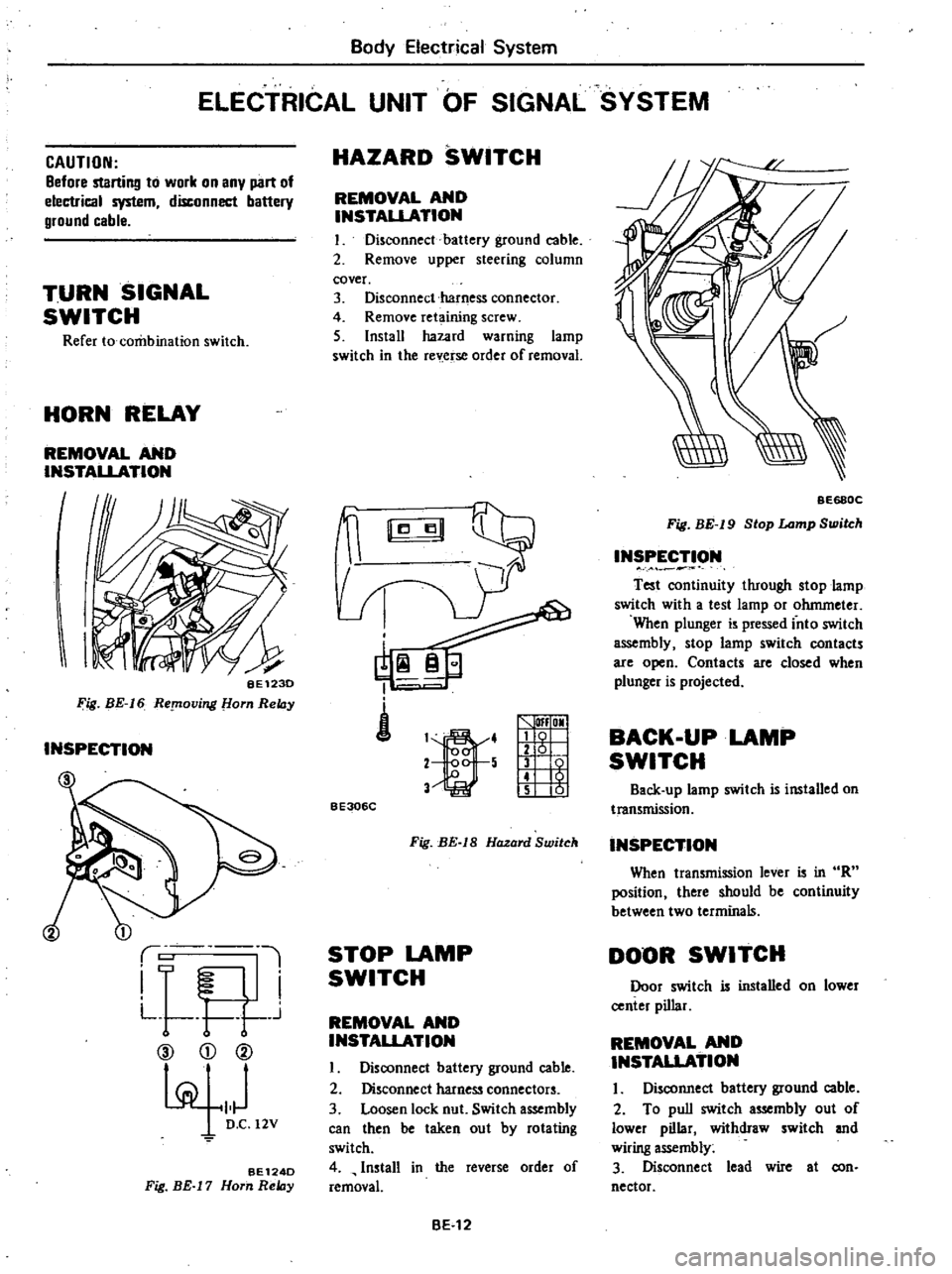

HORN

RELAY

REMOVAL

AND

INSTALLATION

I

I

BE123D

Fig

BE

16

ReplOving

om

ReIDy

INSPECTION

1

i

L

l

I

F

I

L

t

r

j

CV

CD

@

pi

101

D

C

12V

BE124D

Fig

BE

17

Horn

ReIDy

HAZARD

SWITCH

REMOVAL

AND

INSTAUATION

I

Disconnect

battery

ground

cable

2

Remove

upper

steering

column

cover

3

Disconnect

harness

connector

4

Remove

ret

ining

screw

5

Install

hazard

warning

lamp

switch

in

the

rev

erse

order

of

removal

i

1

4

2

5

V

lfI

OMI

g

1

t

5

01

BE306C

Fig

BE

IS

Hazard

Switch

STOP

LAMP

SWITCH

REMOVAL

AND

INSTALLATION

I

Disoonnect

battery

ground

cable

2

Disconnect

harness

connectors

3

Loosen

lock

nut

Switch

assembly

can

then

be

taken

out

by

rotating

switch

4

Install

in

the

reverse

order

of

removal

BE

12

BE68QC

Fig

BE

19

Stop

Lamp

Switch

INSPECTION

Test

oontinuity

through

stop

lamp

switch

with

a

test

lamp

or

ohmmeter

When

plunger

is

pressed

into

switch

assembly

stop

lamp

switch

contacts

are

open

Contacts

are

closed

when

plunger

is

projected

BACK

UP

LAMP

SWITCH

Back

up

lamp

switch

is

installed

on

transmission

INSPECTION

When

transmission

lever

is

in

R

position

there

should

be

continuity

between

two

terminals

DOOR

SWITCH

Door

switch

is

installed

on

lower

center

pillar

REMOVAL

AND

INSTAUATION

I

Disconnect

battery

ground

cable

2

To

pull

switch

assembly

out

of

lower

pillar

withdraw

switch

and

wiring

assembly

3

Disconnect

lead

wire

at

con

nector

Page 513 of 548

Air

COl

ditioning

2

When

refrigerant

has

been

dis

charged

to

a

pressure

approaching

at

mospheric

pressure

connect

center

charging

hose

to

a

vacuum

pump

3

Close

both

valves

of

manifold

gauge

fully

Then

start

vacuum

pump

4

Open

low

pressure

valve

and

suck

old

refrigerant

ftom

system

See

Fig

AC

16

5

When

low

pressure

gauge

reading

has

reached

to

approximately

500

nunHg

20

inHg

slowly

open

high

pressure

valve

First

step

To

Low

pressure

service

valve

To

High

pressure

service

valve

rtl

Second

step

To

Low

pressure

service

valve

To

High

pressure

service

valve

f

AC182A

Fig

AC

16

Evacuating

System

First

and

Second

Steps

AC

12

6

When

pressure

insill

system

h

as

dropped

to

710

mmHg

28

inHg

fully

close

both

of

valves

of

manifold

gauge

and

stop

vacuum

pump

Let

stand

it

for

5

to

10

minutes

in

this

state

and

confirm

that

the

reading

does

not

rise

Note

a

The

low

pressure

gauge

reads

lower

by

25

mmHg

I

inHg

per

a

300

m

1

000

ft

elevation

Perfonn

evacu

alion

according

to

the

following

table

Elevation

m

ft

0

0

300

1

000

600

2

000

900

3

000

Vacuum

of

system

nunHg

inHg

710

28

685

27

660

26

635

25

Note

Values

show

reading

of

the

low

pressure

gauge

b

The

rate

of

ascension

of

the

low

pressure

gauge

should

be

less

than

25

mmHg

I

inHg

in

five

min

utes

If

the

pressure

rises

or

the

specified

negative

pressure

can

not

be

obtained

lhere

is

a

leak

in

the

system

In

this

case

immediately

charge

system

with

refrigerant

and

repair

the

leak

de

scribed

in

the

following

J

Charge

system

with

a

can

of

refrigerant

about

0

4

kg

0

9Ib

Re

fer

to

Charging

Refrigerant

2

Check

for

refrigerant

leakige

with

a

leak

detector

Repair

any

leak

ages

found

Refer

to

Checking

for

Leaks

3

Discharge

refrigerant

again

and

then

evacuate

system

CHARGING

REFRIGERANT

I

Install

manifold

gauge

to

system

Refer

to

Handling

Manifold

Gauge

Page 518 of 548

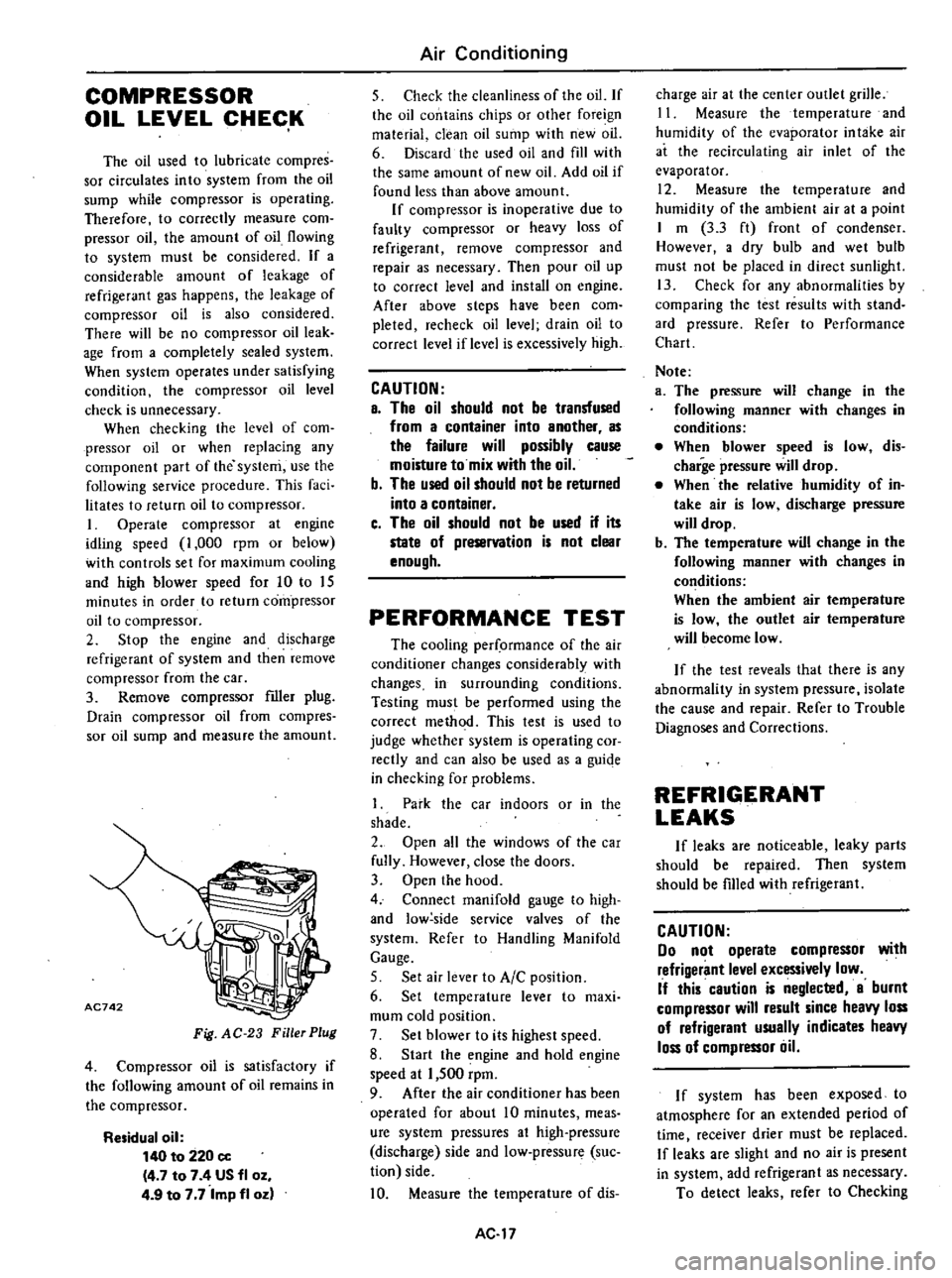

COMPRESSOR

OIL

LEVEL

CHECK

The

oil

used

to

lubricate

compres

sor

circulates

into

system

from

the

oil

sump

while

compressor

is

operating

Therefore

to

correctly

measure

com

pressor

oil

the

amount

of

oil

flowing

to

system

must

be

considered

If

a

considerable

amount

of

leakage

of

refrigerant

gas

happens

the

leakage

of

compressor

oil

is

also

considered

There

will

be

no

compressor

oil

leak

age

from

a

completely

sealed

system

When

system

operates

under

satisfying

condition

the

compressor

oil

level

check

is

unnecessary

When

checking

the

level

of

com

pressor

oil

or

when

replacing

any

component

part

of

the

system

use

the

following

service

procedure

This

facio

litates

to

return

oil

to

compressor

1

Operate

compressor

at

engine

idling

speed

I

OOO

rpm

or

below

with

controls

set

for

maximum

cooling

and

high

blower

speed

for

10

to

15

minutes

in

order

to

return

com

pressor

oil

to

compressor

2

Stop

the

engine

and

discharge

refrigerant

of

system

and

then

remove

compressor

from

the

car

3

Remove

compressor

filler

plug

Drain

compressor

oil

from

compres

sor

oil

sump

and

measure

the

amount

AC742

Fig

AC

23

Filler

Plug

4

Compressor

oil

is

satisfactory

if

the

following

amount

of

oil

remains

in

the

compressor

Residual

oil

140

to

220

cc

4

7

to

7

4

US

fl

oz

4

9

to

7

7

Imp

fl

oz

Air

Conditioning

5

Check

the

cleanliness

of

the

oil

If

the

oil

contains

chips

or

other

foreign

material

clean

oil

sump

with

new

oil

6

Discard

the

used

oil

and

fill

with

the

same

amount

of

new

oil

Add

oil

if

found

less

than

above

amount

If

compressor

is

inoperative

due

to

faulty

compressor

or

heavy

loss

of

refrigerant

remove

compressor

and

repair

as

necessary

Then

pour

oil

up

to

correct

level

and

install

on

engine

After

above

steps

have

been

com

pleted

recheck

oil

level

drain

oil

to

correct

level

if

level

is

excessively

high

CAUTION

a

The

oil

should

not

be

transfused

from

a

container

into

another

as

the

failure

will

possibly

cause

moisture

to

mix

with

the

oil

b

The

used

oil

should

not

be

returned

into

a

container

c

The

oil

should

not

be

used

if

its

state

of

preservation

is

not

clear

enough

PERFORMANCE

TEST

The

cooling

per

ormance

of

the

air

conditioner

changes

considerably

with

changes

in

surrounding

conditions

Testing

must

be

performed

using

the

correct

method

This

test

is

used

to

judge

whether

system

is

operating

cor

rectly

and

can

also

be

used

as

a

guiqe

in

checking

for

problems

1

Park

the

car

indoors

or

in

the

shade

2

Open

all

the

windows

of

the

car

fully

However

close

the

doors

3

Open

the

hood

4

Connect

manifold

gauge

to

high

and

low

side

service

valves

of

the

system

Refer

to

Handling

Manifold

Gauge

5

Set

air

lever

to

AIC

position

6

Set

temperature

lever

to

maxi

mum

cold

position

7

Set

blower

to

its

highest

speed

8

Start

the

engine

and

hold

engine

speed

at

1

500

rpm

9

After

the

air

conditioner

has

been

operated

for

about

10

minutes

meas

ure

system

pressures

at

high

pressure

discharge

side

and

low

pressure

suc

tion

side

10

Measure

the

temperature

of

dis

AC

17

charge

air

at

the

center

outlet

grille

11

Measure

the

temperature

and

humidity

of

the

evaporator

in

take

air

at

the

recirculating

air

inlet

of

the

evaporator

12

Measure

the

temperature

and

humidity

of

the

ambient

air

at

a

point

I

m

3

3

ft

front

of

condenser

However

a

dry

bulb

and

wet

bulb

must

not

be

placed

in

direct

sunlight

13

Check

for

any

abnormalities

by

comparing

the

test

results

with

stand

ard

pressure

Refer

to

Performance

Chart

Note

a

The

pressure

will

change

in

the

following

manner

with

changes

in

conditions

When

blower

speed

is

low

dis

charge

pressure

will

drop

When

the

relative

humidity

of

in

take

air

is

low

discharge

pressure

will

drop

b

The

temperature

will

change

in

the

following

manner

with

changes

in

conditions

When

the

ambient

air

temperature

is

low

the

outlet

air

temperature

will

become

low

If

the

test

reveals

that

there

is

any

abnormality

in

system

pressure

isolate

the

cause

and

repair

Refer

to

Trouble

Diagnoses

and

Corrections

REFRIGERANT

LEAKS

If

leaks

are

noticeable

leaky

parts

should

be

repaired

Then

system

should

be

fIlled

with

refrigerant

CAUTION

00

not

operate

compressor

with

refrigerant

level

excessively

low

If

this

caution

is

neglected

a

burnt

compressor

will

result

since

heavy

loss

of

refrigerant

usually

indicates

heavy

loss

of

compressor

liil

I

f

system

has

been

exposed

to

atmosphere

for

an

extended

period

of

time

I

receiver

drier

must

be

replaced

If

leaks

are

slight

and

no

air

is

present

in

system

add

refrigerant

as

necessary

To

detect

leaks

refer

to

Checking