service schedule DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 14 of 548

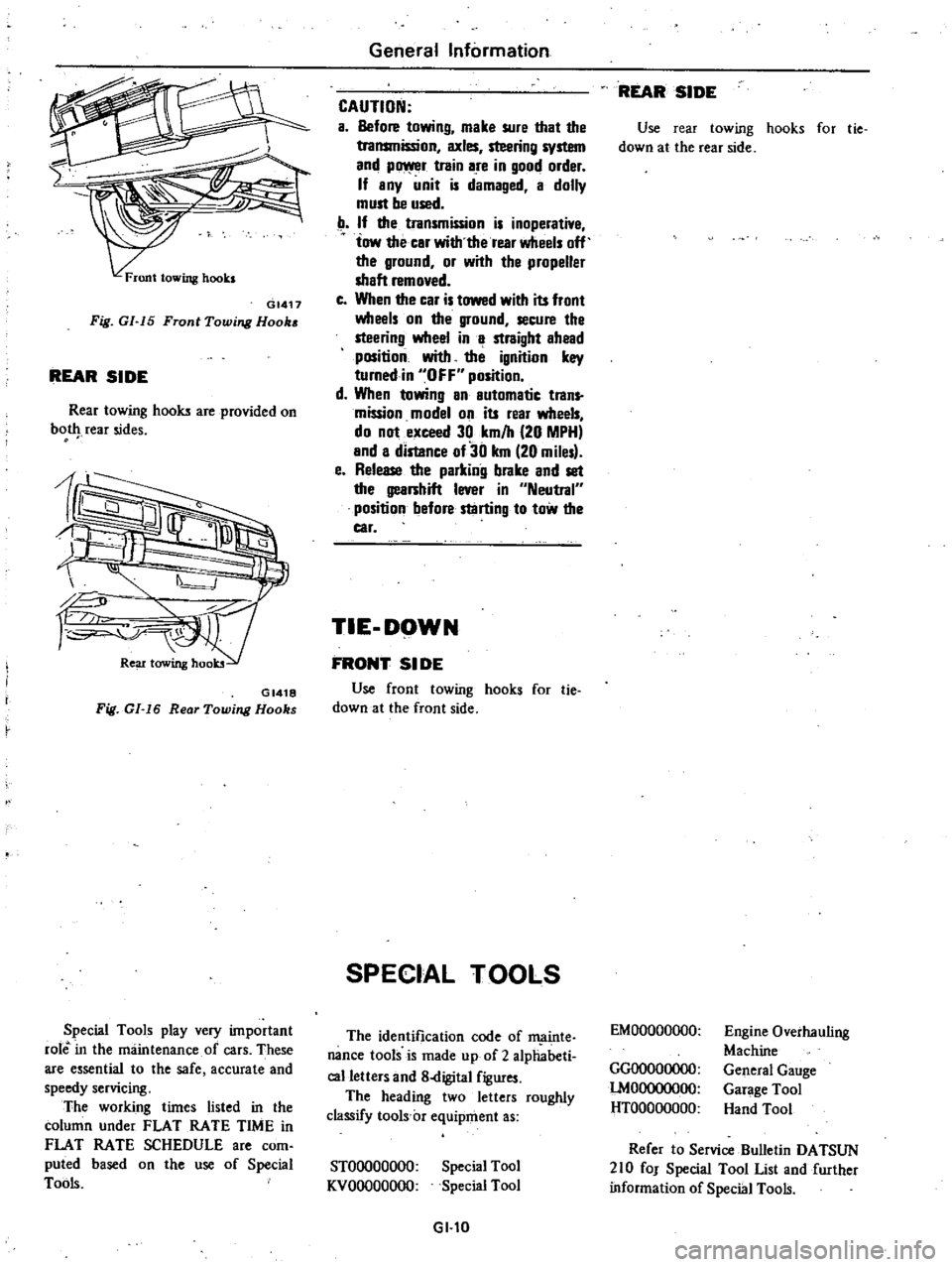

GI417

Fig

GI

15

Front

Towing

Hook

REAR

SIDE

Rear

towing

hooks

are

provided

on

bot

rear

sides

GI418

Fig

GI

16

Rear

Towing

Hooks

Special

Tools

play

very

important

role

in

the

maintenance

of

cars

These

are

essential

to

the

safe

accurate

and

speedy

servicing

The

working

times

listed

in

the

column

under

FLAT

RATE

TIME

in

FLAT

RATE

SCHEDULE

are

com

puted

based

on

the

use

of

Special

Tools

General

Information

CAUTION

a

Before

towing

make

sure

that

the

transmission

axles

steering

system

and

p

r

train

are

in

good

order

If

any

unit

is

damaged

a

dolly

must

be

used

If

the

transmission

is

inoperative

tow

the

car

with

the

rear

wheels

off

the

ground

or

with

the

propeller

shaft

removed

c

When

the

car

is

towed

with

its

front

wheels

on

the

ground

secure

the

steering

wheel

in

a

straight

ahead

position

with

the

ignition

key

turnedin

OFF

position

d

When

towing

an

automatic

trans

mission

model

on

its

rear

wheels

do

not

exceed

30

km

h

20

MPH

and

a

distance

of30

km

20

miles

e

Release

the

parking

brake

and

set

the

gearshift

lever

in

Neutral

position

before

starting

to

tow

the

car

TIE

DOWN

FRONT

51

DE

Use

front

towing

hooks

for

tie

down

at

the

front

side

SPECIAL

TOOLS

The

identification

code

of

ffi

linte

nance

tools

is

made

up

of

2

alphabeti

calletters

and

8

digital

figures

The

heading

two

letters

roughly

classify

tools

c

equipment

as

STOOOOOOOO

KVOOOOOOOO

Special

Tool

Special

Tool

GI

l0

REAR

SIDE

Use

rear

towing

hooks

for

tie

down

at

the

rear

side

EMOOOOOOOO

GGOOOOOOOO

lMOOOOOOOO

HTOOOOOOOO

Engine

Overhauling

Machine

General

Gauge

Garage

Tool

Hand

Tool

Refer

to

Service

Bulletin

DATSUN

210

fOJ

Special

Tool

List

and

further

information

of

Special

Tools

Page 181 of 548

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

Cap

and

rotor

head

should

be

in

spected

periodically

as

specified

in

the

Main

teoanee

Schedule

Remove

cap

and

clean

all

dust

and

carbon

deposits

from

cap

and

rotor

from

time

to

time

If

cap

is

cracked

or

is

leaking

replace

wi

th

a

new

one

ADVANCE

MECHANISMS

SpecHlcatlons

Refer

to

Service

Data

and

Specifica

tions

for

distributor

Vacuum

advance

mechanism

mechanical

parts

If

vacuum

advance

mechanism

fails

to

operate

properly

check

for

the

followin

B

items

and

correct

the

mal

function

as

required

I

Check

vacuum

inlet

for

signs

of

leakage

at

its

connection

If

necessary

retighten

or

replace

with

a

new

one

2

Check

vacuum

diaphragm

for

air

leak

If

leak

is

found

replace

vacuum

controUer

assembly

3

Inspect

breaker

plate

for

smooth

moving

If

plate

does

not

move

smoothly

this

condition

could

be

due

to

sticky

steel

balls

or

pivot

Apply

grease

to

steel

halls

or

if

necessary

replace

breaker

plate

as

an

assembly

Centrifugal

advance

mechanical

parts

When

cause

of

engine

malfunction

is

traced

to

centrifugal

advance

mecha

nical

parts

use

distributor

tester

to

check

its

characteristics

If

nothing

is

wrong

with

its

charac

teristics

conceivable

causes

are

faulty

or

abnormal

wear

of

driving

part

or

others

So

do

not

disassemble

it

In

the

event

of

improper

character

istics

check

closely

rotor

shaft

assem

bly

governor

weight

and

shaft

If

any

of

the

above

parts

are

mal

functioning

replace

the

parts

Engine

Electrical

System

DISASSEMBLY

AND

ASSEMBLY

DISASSEMBLY

I

Take

off

cap

and

remove

rotor

head

2

Remove

Ie

ignition

unit

Refer

to

IC

Ignition

Unit

for

removal

and

in

stallation

3

Remove

stator

and

magnet

by

removing

stator

securing

screws

4

Remove

vacuum

controller

by

removing

securing

screws

EE746

Fig

EE

59

Removing

Vacuum

Controller

5

Using

two

pry

bars

or

suitable

puller

pry

reluctor

from

shaft

CAUTION

When

removing

reluctor

be

careful

not

10

distort

or

damage

the

teeth

6

Remove

roll

pin

7

Remove

pick

up

coil

assembly

8

Remove

breaker

plate

setscrews

and

remove

breaker

plate

assembly

EE703

Fig

EE

60

Removing

Breaker

Plate

Setscrews

9

Punch

knock

pin

out

and

remove

pinion

EE

23

EE704

Fig

EE

61

Removing

Knock

Pin

10

Remove

rotor

shaft

and

drive

shaft

assembly

EE705

Fig

EE

62

Removing

Rotor

Shaft

and

Drive

Shaft

Assembly

11

Mark

rotor

shaft

and

drive

shaft

Remove

packing

from

the

top

of

rotor

shaft

and

unscrew

rotor

shaft

setscrew

Remove

rotor

shaft

EE706

Fig

EE

63

Removing

Rotor

Shaft

12

Mark

one

of

the

governor

springs

and

its

bracket

Also

mark

one

of

the

governor

weights

and

its

pivot

pins

13

Carerully

unhook

and

remove

governor

springs

14

Remove

governor

weights

A

r

ply

grease

to

guvernor

weights

after

disassembling