cooling DATSUN 210 1979 Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 533 of 548

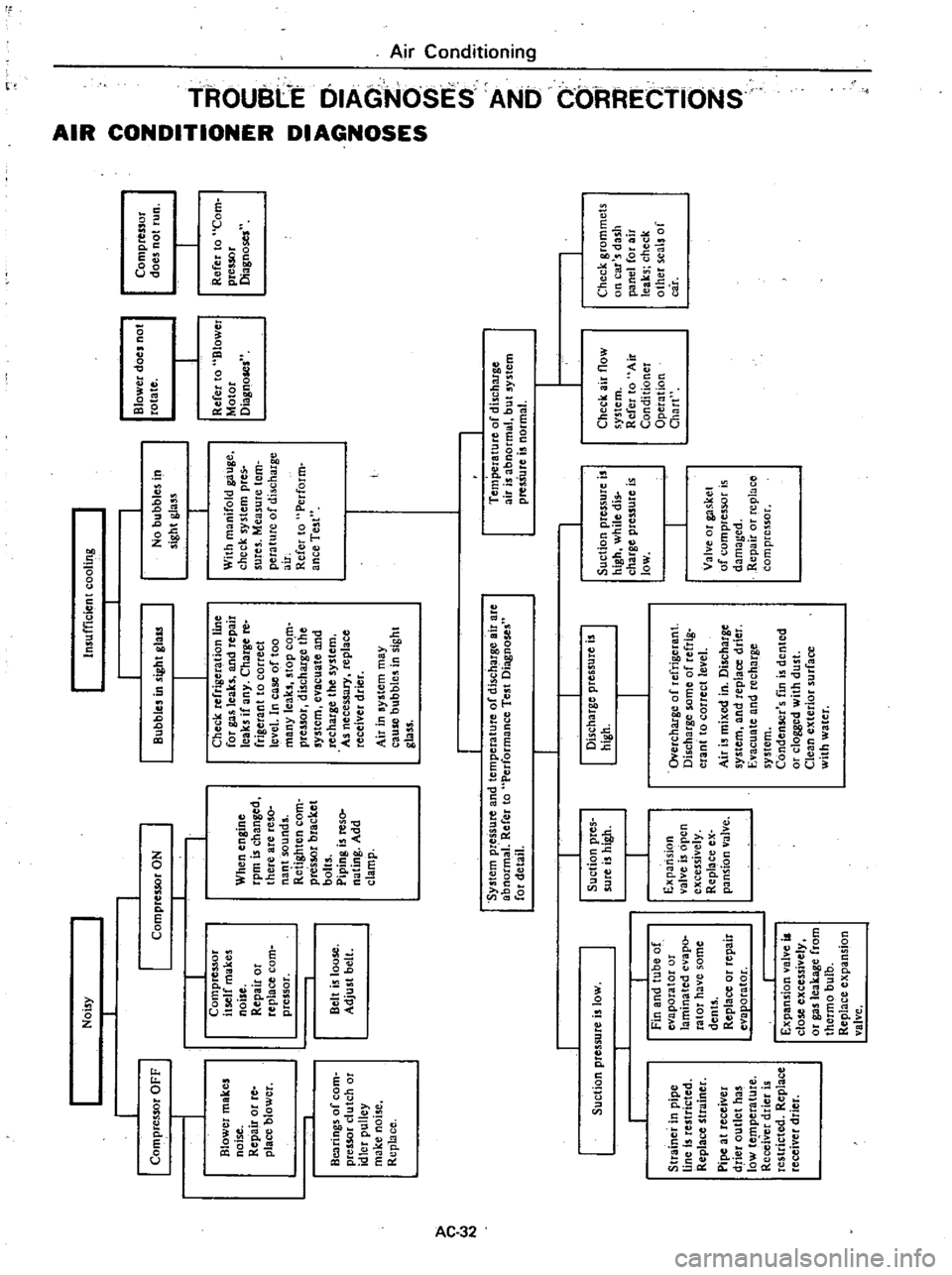

Com

pressor

OFF

I

I

Blower

makes

noise

Repair

or

re

place

blower

Bearings

of

com

pressor

clutch

or

idler

pulley

make

noise

Replace

C

l

W

Noisy

Compressor

itself

makes

noise

Repair

or

replace

com

pressor

Belt

is

loose

Adjust

belt

Suction

pressure

is

low

Strainer

in

pipe

Line

Is

restricted

Replace

strainer

Pipe

at

receiver

drier

outlet

has

low

temperature

Receiver

drier

is

restricted

Replace

receiver

drier

I

Fin

and

tube

of

evaporator

or

laminated

evapo

rator

have

some

dents

Replace

or

repair

evaporator

Expansion

valve

is

close

excessively

or

gas

leakage

from

thermo

bulb

Replace

expansion

valve

Compressor

ON

J

I

When

engine

rpm

is

changed

there

are

reso

nant

sounds

Retighten

com

pre

ssor

bracket

bolts

Piping

is

reso

nating

Add

clamp

Insufficient

cooling

Bubbles

in

sight

glaS

Check

refrigeration

line

for

gas

leaks

and

repair

leaks

if

any

Charge

re

frigerant

to

correct

level

In

case

of

too

many

leaks

stop

com

pressor

discharge

the

system

evaCUate

and

recharge

the

system

As

necessary

replace

receiver

drier

Air

in

system

may

cause

bubbles

in

sight

glass

System

pressure

and

temperature

of

discharge

air

llre

abnormal

Refer

to

Performance

Test

Diagnoses

for

detail

Suction

pres

sure

is

high

Expansion

valve

is

open

excessively

Replace

ex

pansion

valve

Discharge

pressure

is

high

Overcharge

of

refrigerant

Discharge

some

of

refrig

erani

to

correct

level

Air

is

mixed

in

Discharge

system

and

replace

drier

Evacuate

and

recharge

system

Condenser

s

fin

is

dented

or

clogged

with

dust

Clean

exterior

surface

with

water

No

bubbles

in

sight

glass

With

manifold

gauge

check

system

pres

sures

Measure

tem

perature

of

discharge

air

Refer

to

Perform

ance

Test

Blower

does

not

rotate

Refei

to

Blower

Motor

Diagnoses

Temperature

of

discharge

air

is

abnormal

but

system

pres5ure

is

normal

Suction

pressure

iJ

high

while

dis

charge

pressure

is

low

Valve

or

gasket

of

compressor

is

damaged

Repair

or

replace

compreuor

Check

air

flow

system

Refer

to

Air

Conditioner

Operation

Chart

Compressor

does

not

run

Refer

to

Com

pressor

Diagnoses

Check

grommets

on

car

s

dash

panel

for

air

leaks

check

other

seal

of

car

Page 538 of 548

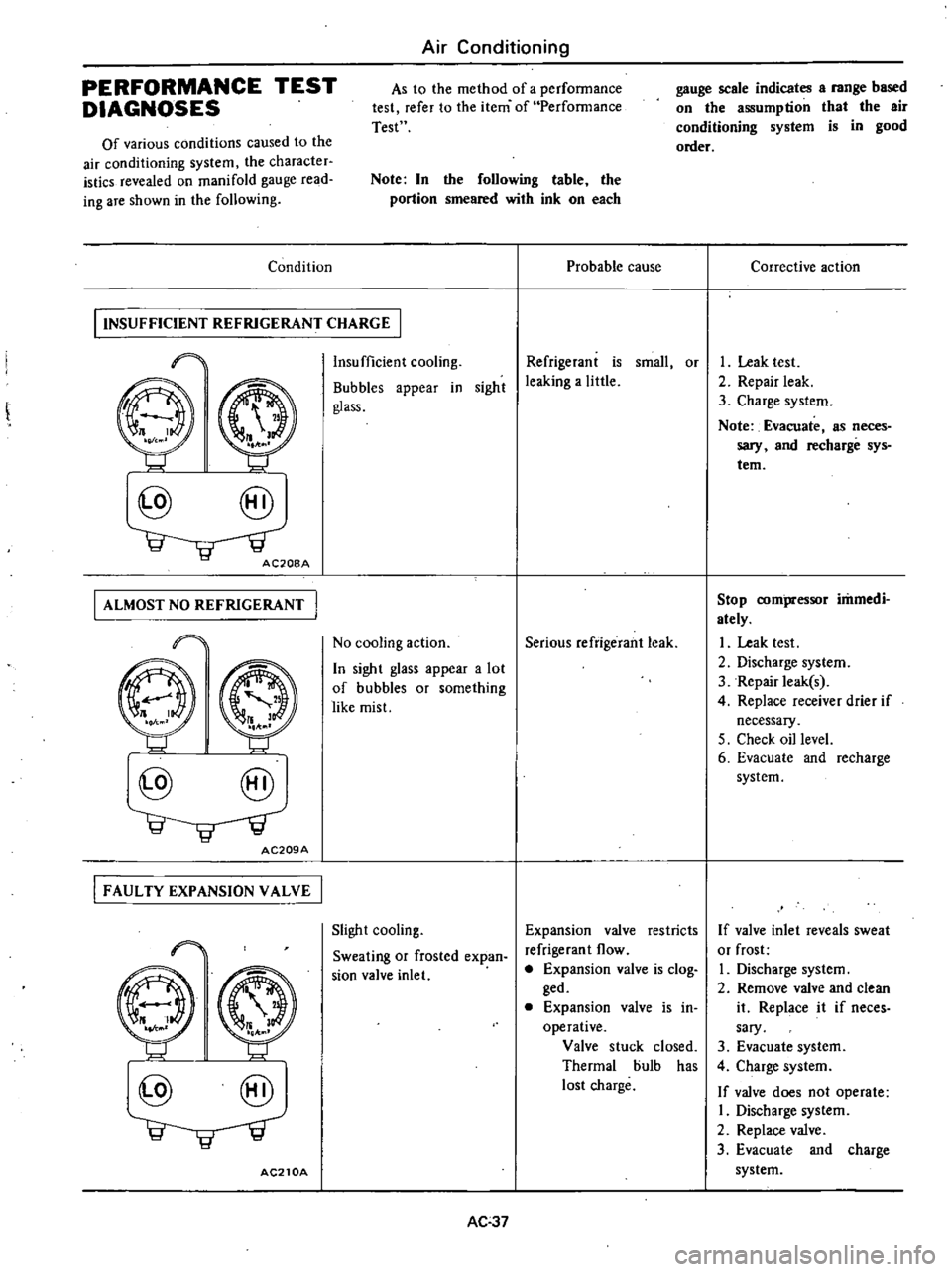

PERFORMANCE

TEST

DIAGNOSES

Of

various

conditions

caused

to

the

air

conditioning

system

the

character

istics

revealed

on

manifold

gauge

read

ing

are

shown

in

the

following

Condition

Air

Conditioning

As

to

the

method

of

a

perfonnance

test

refer

to

the

item

of

Perfonnance

Test

Note

In

the

following

table

the

portion

smeared

with

ink

on

each

I

INSUFFICIENT

REFRIGERANT

CHARGE

I

I

@

@

08A

I

ALMOST

NO

REFRIGERANT

i

@

@

AC209A

I

FAULTY

EXPANSION

VALVE

I

I

@

@

AC210A

Insufficient

cooling

Bubbles

appear

in

sight

glass

Probable

cause

Refrigerant

is

small

or

leaking

a

little

No

cooling

action

Serious

refrigerant

leak

In

sight

glass

appear

a

lot

of

bubbles

or

something

like

mist

Slight

cooling

Sweating

or

frosted

expan

sion

valve

inlet

AC37

Expansion

valve

restricts

refrigerant

flow

Expansion

valve

is

clog

ged

Expansion

valve

is

in

operative

Valve

stuck

closed

Thermal

bulb

has

lost

charge

gauge

scale

indicates

a

range

based

on

the

assumption

that

the

air

conditioning

system

is

in

good

order

Corrective

action

I

Leak

test

2

Repair

leak

3

Charge

system

Note

Evacuate

8S

neces

sary

and

recharge

sys

tem

Stop

rompressor

immedi

ately

I

Leak

test

2

Discharge

system

3

Repair

leak

s

4

Replace

receiver

drier

if

necessary

5

Check

oilleve

6

Evacuate

and

recharge

system

If

valve

inlet

reveals

sweat

or

frost

I

Discharge

system

2

Remove

valve

and

clean

it

Replace

it

if

neces

sary

3

Evacuate

system

4

Charge

system

If

valve

does

not

operate

I

Discharge

system

2

Replace

valve

3

Evacuate

and

charge

system

Page 539 of 548

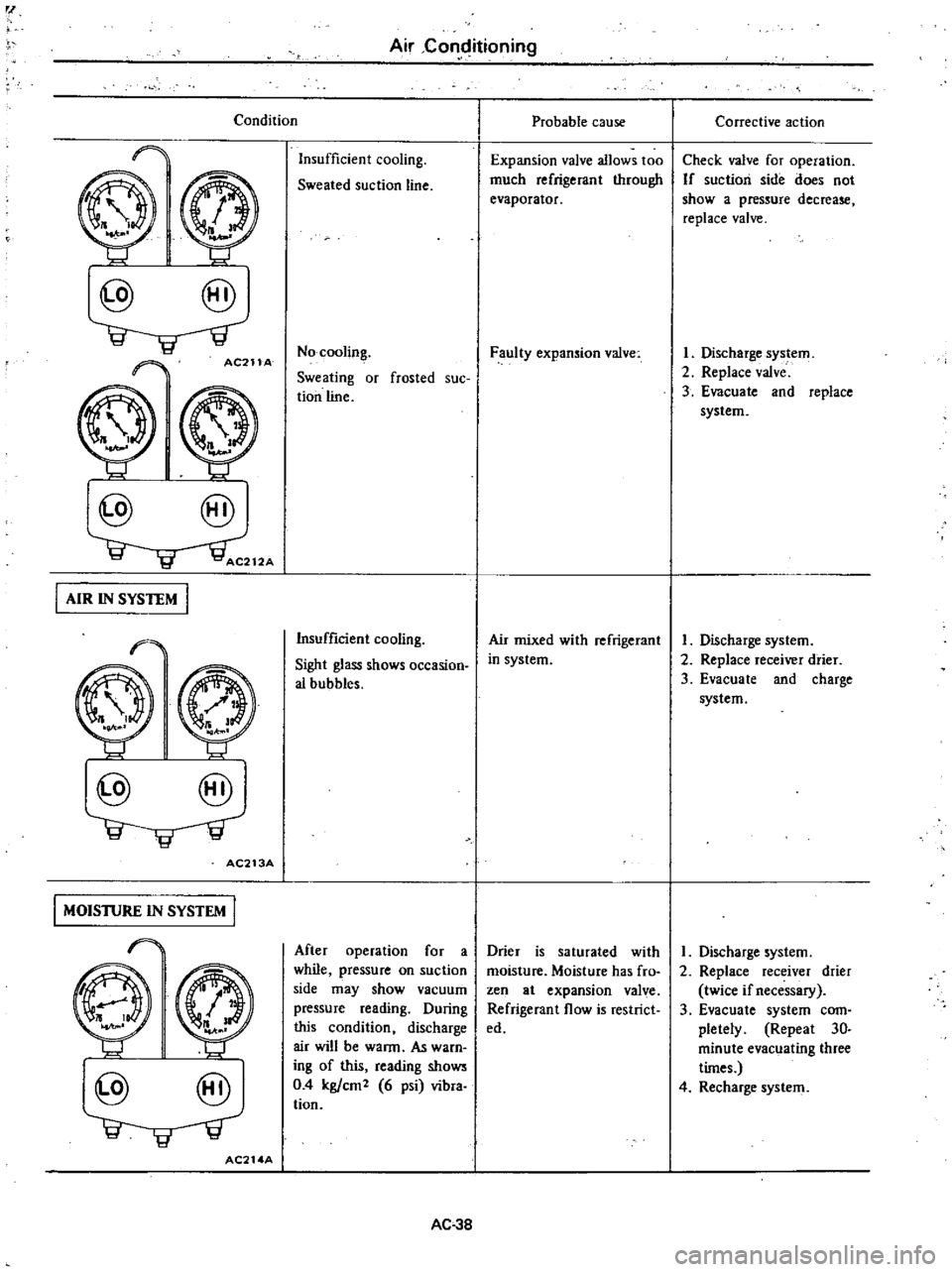

r

l

Condition

6

@

@

AC211

A

o

@

g

@

fj

212A

I

AIR

IN

SYSTEM

r

l

lI

IJI

I

J

ole

I

i

@

@

AC213A

I

MOISTIJRE

IN

SYSTEM

I

@

@

AC214A

Air

Co

itioning

Insufficient

cooling

Sweated

suction

line

No

cooling

Sweating

or

frosted

sue

tion

line

Insufficient

cooling

Sight

glass

shows

occasion

al

bubbles

After

operation

for

a

while

pressure

on

sllction

side

may

show

vacuum

pressure

reading

During

this

condition

discharge

air

will

be

wann

As

warn

ing

of

this

reading

shows

0

4

kg

cm2

6

psi

vibra

tion

AC

38

Probable

cause

Expansion

valve

allows

too

much

refrigerant

through

evaporator

F

aul

ty

expansion

valve

Air

mixed

with

refrigerant

in

system

Drier

is

saturated

with

moisture

Moisture

has

fro

zen

at

expansion

valve

Refrigerant

flow

is

restrict

ed

Corrective

action

Check

valve

for

operation

If

suction

side

does

not

show

a

pressure

decrease

replace

valve

I

Discharge

system

2

Replace

valve

3

Evacuate

and

replace

system

I

Discharge

system

2

Replace

receiver

drier

3

Evacuate

and

charge

system

I

Discharge

system

2

Replace

receiver

drier

twice

if

necessary

3

Evacuate

system

com

pletely

Repeat

30

minute

evacuating

three

times

4

Recharge

system

Page 540 of 548

Condition

I

FAULTY

CONDENSER

I

I

@

@

AC215A

I

HIGH

PRESSURE

liNE

BLOCKED

I

r

@

@

AC216A

I

FAULTY

COMPRESSOR

I

r

j

@

rg

AC217A

Air

Conditioning

o

cooling

action

engine

may

overheat

Bubbles

appear

in

sight

glass

of

drier

Suction

line

is

very

hot

Insufficient

cooling

Frosted

high

pressure

liquid

line

Insufficient

cooling

AC

39

Probable

cause

Condenser

is

often

found

not

functioning

well

Drier

clogged

or

restric

tion

in

high

pressure

line

Internal

problem

in

com

pressor

or

damaged

gasket

and

valve

Corrective

action

Check

fan

belt

and

fluid

coupling

Check

condenser

for

dirt

accumulation

Check

engine

coqling

system

for

overheat

Check

for

refrigerant

overcharge

Note

If

pressure

remains

high

in

spite

of

aU

above

actions

taken

re

move

and

inspect

the

condenser

for

possible

oil

clogging

I

Discharge

system

2

Remove

receiver

drier

or

strainer

and

replace

it

3

Evacuate

and

charge

system

I

Discharge

system

2

Remove

and

check

compressor

3

Repair

or

replace

com

pressor

4

Check

oil

level

5

Replace

receiver

drier

6

Evacuate

and

charge

system

Page 541 of 548

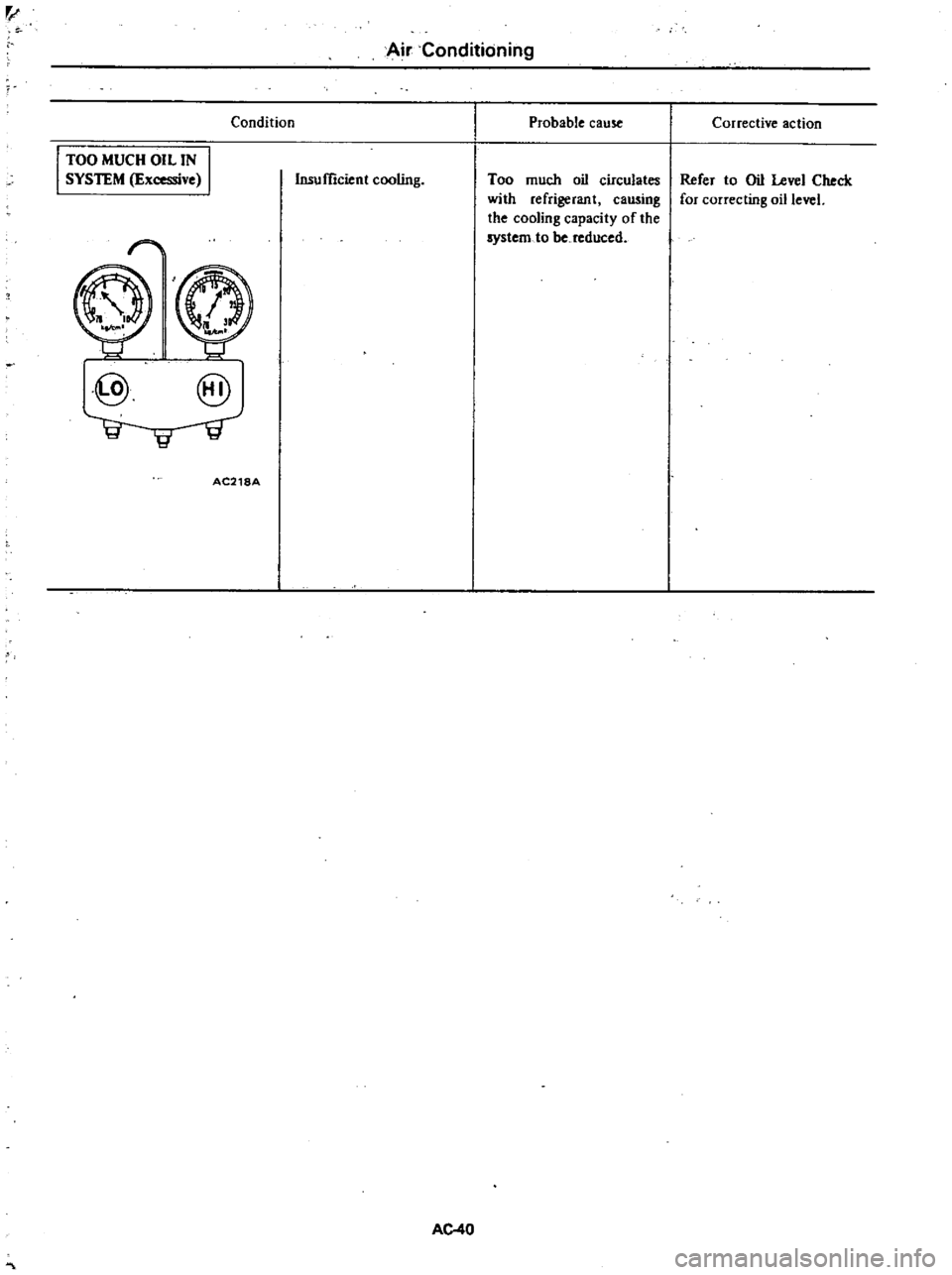

r

Air

Conditioning

Condition

TOO

MUCH

OIL

IN

I

SYSTEM

Excessive

lostlfficient

cooling

r

i

@

g

@

Ti

AC218A

Probable

cause

Too

much

oil

circulates

with

refrigerant

causing

the

cooling

capacity

of

the

aystem

to

be

reduced

AC40

Corrective

action

Refer

to

Oil

Level

Check

for

correcting

oil

level

Page 542 of 548

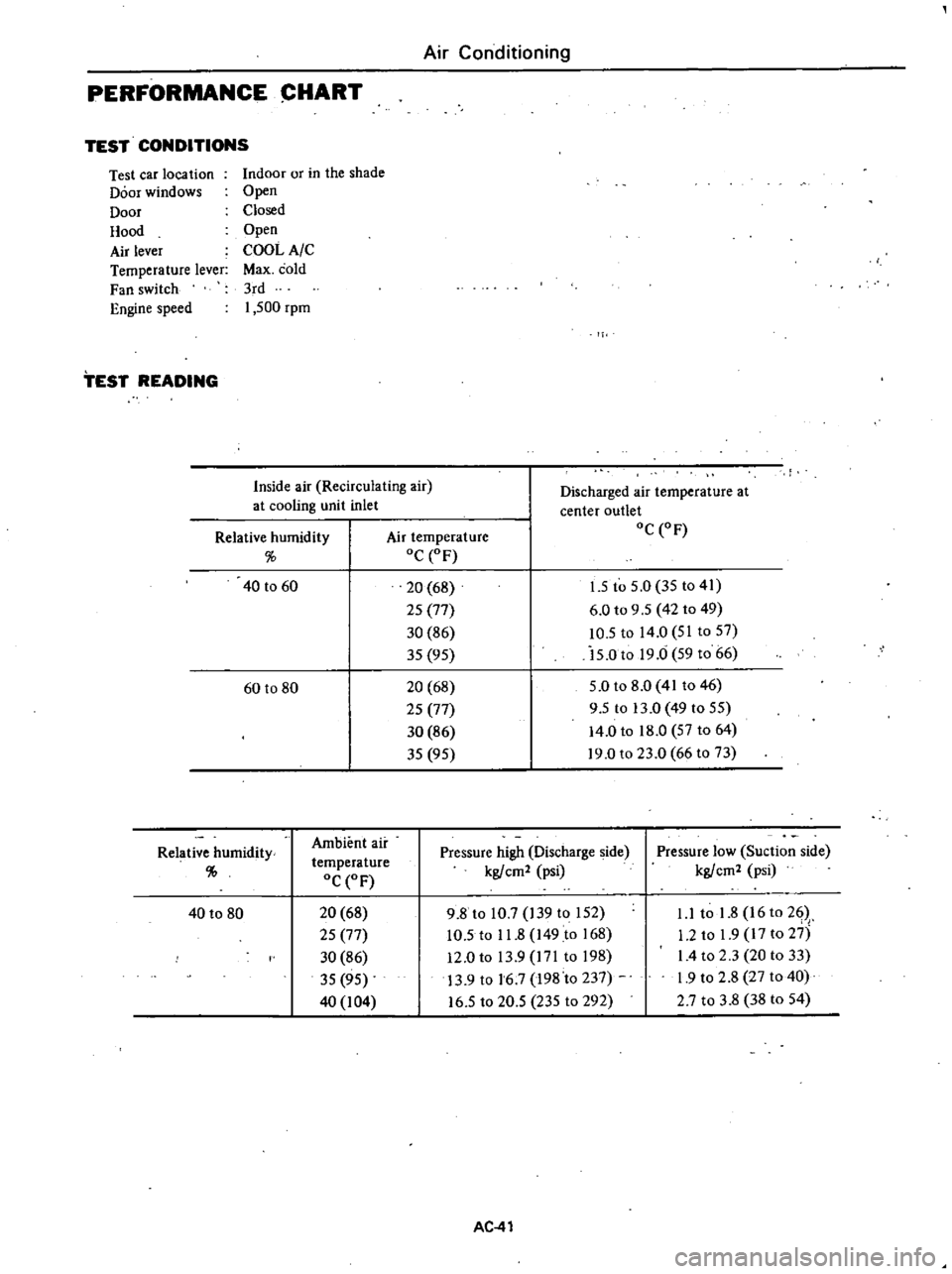

PERFORMANCE

CHART

TEST

CONDITIONS

Test

car

location

Door

windows

Door

Hood

Air

lever

Temperature

lever

Fan

switch

Engine

speed

Indoor

or

in

the

shade

Open

Closed

Open

COOL

Ale

Max

cold

3rd

1

500

rpm

TEST

READING

Air

Conditioning

Inside

air

Recirculating

air

at

cooling

unit

inlet

Relative

humidity

40

to

60

60

to

80

Relative

humidity

Ambient

air

temperature

oe

OF

40

to

80

20

68

25

77

30

86

35

95

40

104

Discharged

air

temperature

at

center

outlet

oe

OF

Air

temperature

oC

OF

20

68

25

77

30

86

35

95

20

68

25

77

30

86

35

95

1

5

to

5

0

35

to

41

6

0

to

9

5

42

to

49

10

5

to

14

0

51

to

57

i5

O

to

19

6

59

to

66

5

0

to

8

0

41

to

46

9

5

to

13

0

49

to

55

14

0

to

18

0

57

to

64

19

0

to

23

0

66

to

73

Pressure

high

Discharge

side

kg

cm2

psi

Pressure

low

Suction

side

kg

cm

2

psi

9

8

to

10

7

139

to

152

10

5

to

11

8

149

to

168

12

0

to

13

9

171

to

198

13

9

to

16

7

198

to

237

16

5

to

20

5

235

to

292

1

1

to

1

8

16

to

26

ii

1

2

to

1

9

17

to

27

14

to

2

3

20

to

33

1

9

to

2

8

27

to

40

2

7

to

3

8

38

to

54

AC

41