differential DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 6 of 548

f

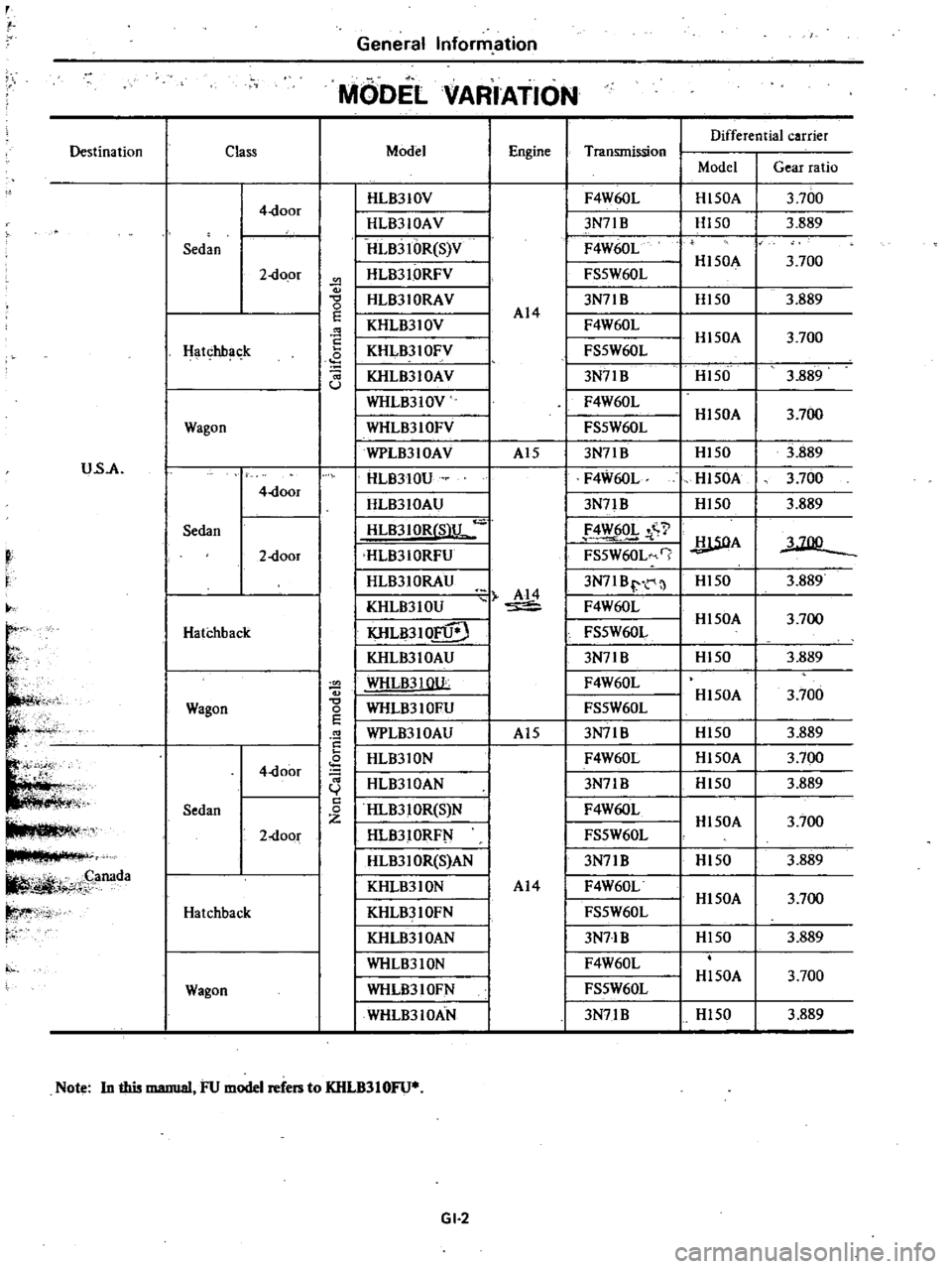

Destination

u

s

A

t

f

l

c

J

r

If

i

i

c

1J

ll

d

Canada

I

C

f

Sedan

Hatchba

k

Wagon

Sedan

HatChback

Wagon

Sedan

Hatchback

Wagon

Class

4

door

2

do

or

I

4

door

2

door

4

door

2

door

General

Inform

ation

MODEL

VARIATION

Model

Engine

I

HL8310V

I

HLB310AV

IHLB3IOR

S

V

I

HLB310RFV

I

i

I

HLB310RAV

I

KHLB310V

I

KHLB310FV

J

I

KHLB310AV

I

WHLB310V

I

WHLB310FY

WPLB310AV

HLB310U

I

HLB310AU

I

HLB3IOR

S

lL

IHLB310RFU

I

HLB310RAU

AI4

I

KHLB310U

I

KHLB310FU

O

I

KHLB310AU

I

WHLB3

WU

g

WHLB310FU

E

WPLB310AU

HLB310N

HLB310AN

c

HLB310R

S

N

HLB310RF

I

HLB3IOR

S

AN

KHLB310N

KHLB310FN

KHLB310AN

WHL83

ION

WHLB310FN

WHLB310AN

Note

In

this

manual

FU

model

refers

to

KHLB310FU

GI

2

I

I

I

Transmission

AI4

F4W60L

I

3N7lB

I

F4W60L

I

FS5W60L

I

3N71B

I

F4W60L

J

FS5W60L

I

3N71B

I

F4W60L

FS5W60L

3N71B

I

F4W60L

I

3N71

B

I

4

Y

6Q

I

FS5W60L

J

I

3N7IBr

I

F4W60L

I

FS5W60L

3N71B

F4W60L

FS5W60L

3N7IB

F4W60L

3N71B

F4W60L

FS5W60L

3N71B

F4W60L

FS5W60L

I

3N71B

I

F4W60L

I

FS5W60L

I

3N7lB

AI5

AI5

AI4

Differential

carrier

Model

Gear

ratio

Hl50A

H150

Hl50A

Hl50

HI50A

H150

Hl50A

Hl50

HI50A

Hl50

UOA

Hl50

Hl50A

HI50

HI50A

HI50

HI50A

HI50

H150A

HI50

HI50A

Hl50

Hl50A

Hl50

3

700

3

889

3

700

3

889

3

700

3

889

3

700

3

889

3

700

3

889

3

700

I

3

889

3

700

3

889

3

700

3

889

3

700

3

889

3

700

3

889

3

700

3

889

3

700

3

889

Page 9 of 548

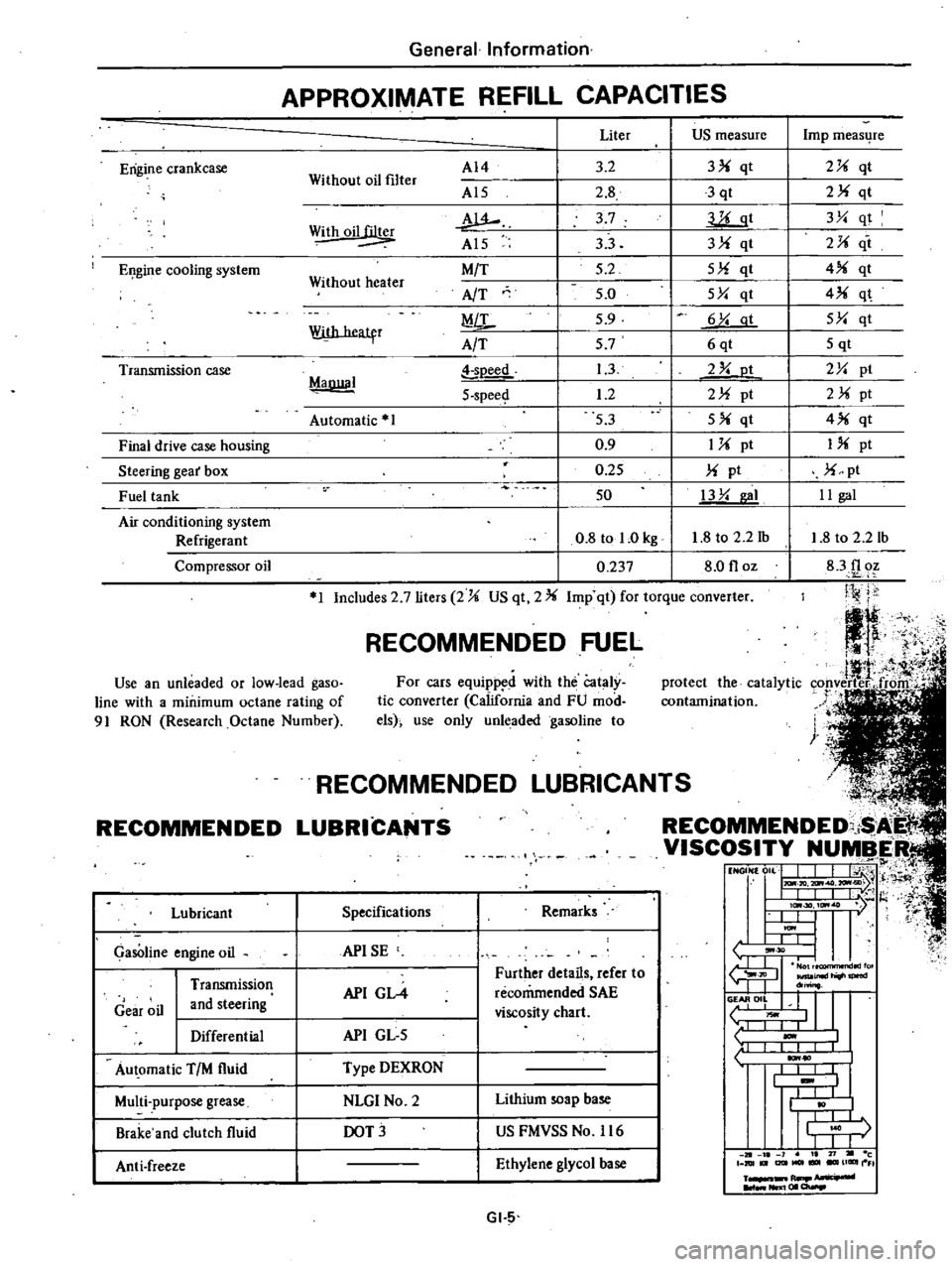

Erigine

crankcase

EI

gine

cooling

system

Transmission

case

Final

drive

case

housing

Steering

gear

box

Fuel

tank

Air

conditioning

system

Refrigerant

Compressor

oil

f

tl

It

J

4

i

1

protect

the

catalytic

cop

verter

froitr

contamination

t

n

General

Information

APPROXIMATE

REFILL

CAPACITIES

Without

oil

filter

AI4

Al5

w

Al5

M

T

AfT

MiL

A

T

Liter

US

measure

3

2

3

qt

2

8

3

qt

3

7

llLgt

33

3

qt

5

2

5

qt

5

0

5Y

qt

5

9

6

Y

at

57

6qt

1

3

2

Y

ot

1

2

2

pt

53

5

qt

0

9

1

pt

0

25

pt

50

13

Y

I

0

8

tol

Okg

1

8

to

2

2

1b

0

237

8

0

floz

Withoil

Without

heater

With

heatfr

MaDllal

soeed

5

spee

Automatic

1

1

Includes

2

7

liters

2

US

qt

2

Imp

qt

for

torque

converter

RECOMMENDED

FUEL

Use

an

unleaded

or

low

lead

gaso

line

with

a

minimum

octane

rating

of

91

RON

Research

Octane

Number

For

cars

equipp

d

with

the

Cataly

tic

converter

California

and

FU

mod

els

use

only

unleaded

gasoline

to

RECOMMENDED

Lubricant

GasOline

engine

oil

Gear

oil

Transmission

and

steering

Differential

Au

omatic

TIM

fluid

Multi

purpose

grease

Brake

and

clutch

fluid

Anti

freeze

L

NDED

LUBRICAN

COMMENDED

i

I

VISCOSITY

NUMBER

t1

NGON

0

L

J

I

j

H

I

IlL

I

t

l

I

lc

30

ItM

7

l

t

U

I

ItM

I

L

L

tJ

30

I

I

fu

JIl

inld

do

o

II

L

liOwl

1

I

I

1

10

I

I

I

I

t

I

I

j

r

I

I

J

1

21

l

1

I

71

c

DIUt

I2lItMOl

UGIIII

FI

R

NIl

I

01

a

Specifications

Remarks

APISE

API

GL4

Further

details

refer

to

recommended

SAE

viscosity

chart

API

GL

5

Type

DEXRON

NLGI

No

2

Lithium

soap

base

DOT

US

FMVSS

No

116

Ethylene

glycol

base

GI

5

Imp

meas4re

2

qt

2

qt

3Y

qt

2

it

4

qt

4

q

5Y

qt

5

qt

2Y

pt

2

pt

4

qt

I

pt

pt

II

gal

1

8

to

2

2

lb

83f1

oz

Ji

j

j

Page 12 of 548

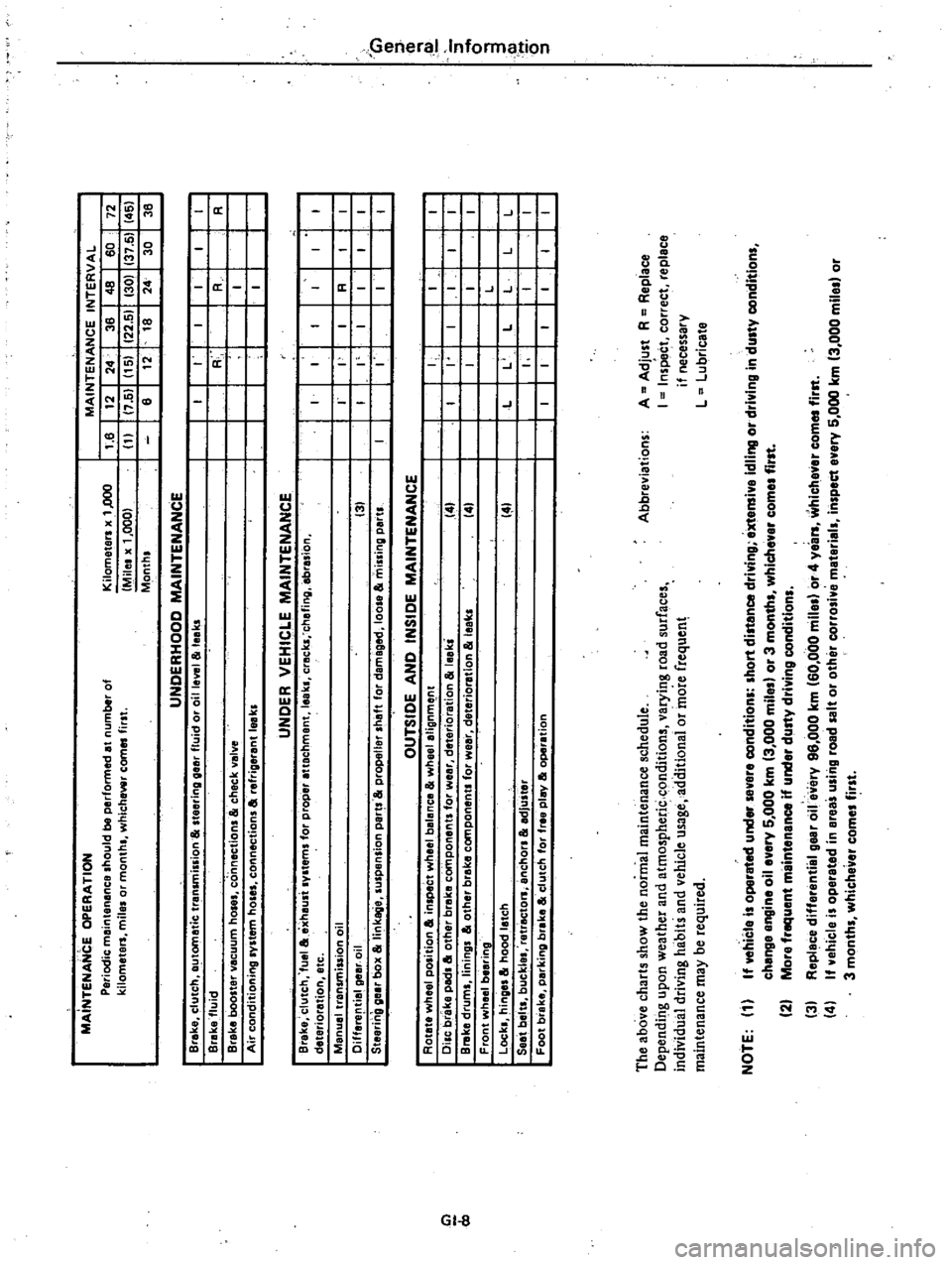

MAiNTENANCE

OPERATION

Periodic

maintenance

should

be

performed

at

number

of

kilometers

mila

or

month

whichewr

comes

first

Kilometers

1

000

Mile

x

1

000

M

3nthl

MAINTENANCE

INTERVAL

1

6

I

12

I

24

I

36

I

48

I

60

72

111

117

611

11511122

511

30

1137

5

45

I

6

I

12

r

16

I

24

I

30

36

UNDERHOOD

MAINTENANCE

Gl

The

above

charts

show

the

normal

maintenance

schedule

Dependir

tg

upon

weather

and

atmospheric

conditions

varying

road

surfaces

individual

driving

habits

and

vehicle

usage

additionai

or

more

frequen

maintenance

may

be

required

Abbreviations

A

Adjust

R

Replace

I

Inspe

t

correct

replace

if

necessary

L

Lubricate

NOTE

1

If

vehicle

i

operated

under

evere

conditions

hort

distance

driving

extensive

idling

or

driving

in

du

ty

condition

change

angine

oil

every

5

000

km

3

000

mile

or

3

month

whlchevar

come

first

2

More

frequent

maintenance

if

under

dusty

driving

condition

3

Replace

differential

gear

oile

ery

96

000

km

60

000

mila

or

4

years

whichaver

com

first

4

If

vehicle

i

operated

in

ereas

u

ing

road

alt

or

other

corro

ive

material

inspect

evary

5

000

km

3

000

mile

or

3

months

whichever

comes

first

Page 13 of 548

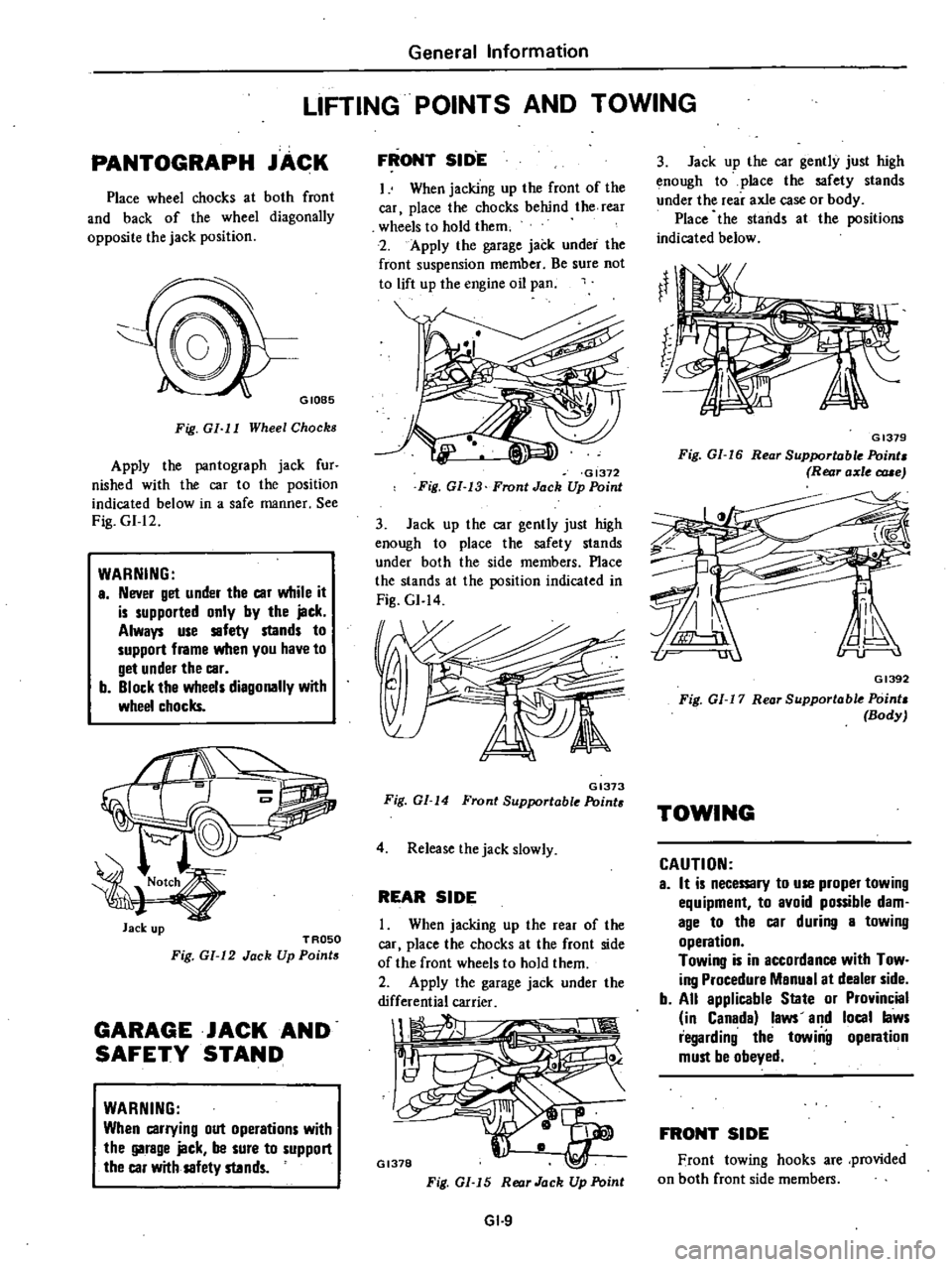

General

Information

LIFTING

POINTS

AND

TOWING

PANTOGRAPH

JACK

Place

wheel

chocks

at

both

front

and

back

of

the

wheel

diagonally

opposite

the

jack

position

GIOB5

Fig

GI

I

I

Wheel

Chocks

Apply

the

pantograph

jack

fur

nished

with

the

car

to

the

position

indicated

below

in

a

safe

manner

See

Fig

GI

12

WARNING

a

Never

get

under

the

car

while

it

is

supported

only

by

the

jack

Always

use

safety

stands

to

support

frame

when

you

have

to

get

under

the

car

b

Block

the

wheels

diagonally

with

wheel

chocks

Jack

up

TROSO

Fig

GI

12

Jack

Up

Points

GARAGE

JACK

AND

SAFETY

STAND

WARNING

When

carrying

out

operations

with

the

garage

jack

be

sure

to

support

the

car

with

safety

stands

FRONT

SID

E

I

When

jacking

up

the

front

of

the

car

place

the

chocks

behind

the

rear

wheels

to

hold

them

2

Apply

the

garage

jack

under

the

front

suspension

member

Be

sure

not

to

lift

up

the

engine

oil

pan

GI372

Fig

GI

13

Front

Jack

Up

Point

3

Jack

up

the

car

gently

just

high

enough

to

place

the

safety

stands

under

both

the

side

members

Place

the

stands

at

the

position

indicated

in

Fig

GI

14

GI373

Fig

GI

14

Front

Supportable

Point

4

Release

the

jack

slowly

REAR

SIDE

When

jacking

up

the

rear

of

the

car

place

the

chocks

at

the

front

side

of

the

front

wheels

to

hold

them

2

Apply

the

garage

jack

under

the

differential

carrier

1

1

Il

GI378

Fig

GI

15

Rear

Jack

Up

Point

GI

9

3

Jack

up

the

car

gently

just

high

enough

to

place

the

safety

stands

under

the

rear

axle

case

or

body

Place

the

stands

at

the

positions

indicated

below

GI379

Fig

GI

16

Rear

Supportable

Point

Rear

axle

c

rue

GI392

Fig

01

17

Rear

Supportable

Point

Body

TOWING

CAUTION

a

It

is

necemry

to

use

proper

towing

equipment

to

avoid

possible

dam

age

to

the

car

during

a

towing

operation

Towing

is

in

accordance

with

Tow

ing

Procedure

Manual

at

dealer

side

b

All

applicable

State

or

Provincial

in

Canada

laws

and

local

laws

regarding

the

towiilg

operation

must

be

obeyed

FRONT

SIDE

Front

towing

hooks

are

provided

on

both

front

side

members

Page 63 of 548

CYLINDER

BLocK

t

60

2

36

20

0

79

I

100

CI

94

rJ

L

II

E9

I

Unit

mm

in

EM479

Cylinder

liner

for

service

4

0

0

157

Undersize

4

5

0

177

Undersize

Engine

MechanicliIl

Surface

flatness

Inner

diameter

Cylinder

bore

Out

of

round

X

V

Taper

A

B

Differential

in

inner

diameter

between

cylinders

Piston

to

cylinder

block

clearance

Outside

diameter

80

00

to

80

05

3

1496

to

3

1515

80

50

to

80

55

3

1692

to

3

1712

PISTON

PISTON

RING

AND

PISTON

PIN

Piston

e

e

5

51

co

ED

I

H

EM4S0

Standard

Over

size

0

50

0

0197

1

00

0

0394

EM

26

Standard

Less

than

0

05

0

0020

76

000

to

76

050

2

9921

to

2

994i

Less

than

O

oI5

0

0006

Less

than

O

oI5

0

0006

Less

than

0

05

0

OO20

0

025

to

0

045

0

0010

to

0

0018

Unit

riun

in

Inside

diameter

75

50

to

75

60

2

9724

to

2

9763

Piston

diameter

Unit

mm

in

Wear

limit

0

1

0

0039

0

20

0

0079

0

20

0

0079

Unit

mm

in

75

967

to

76

017

2

9908

to

2

9927

76

467

to

76

517

3

0105

to

3

0124

76

967

to

77

017

3

0301

to

3

0321

Page 168 of 548

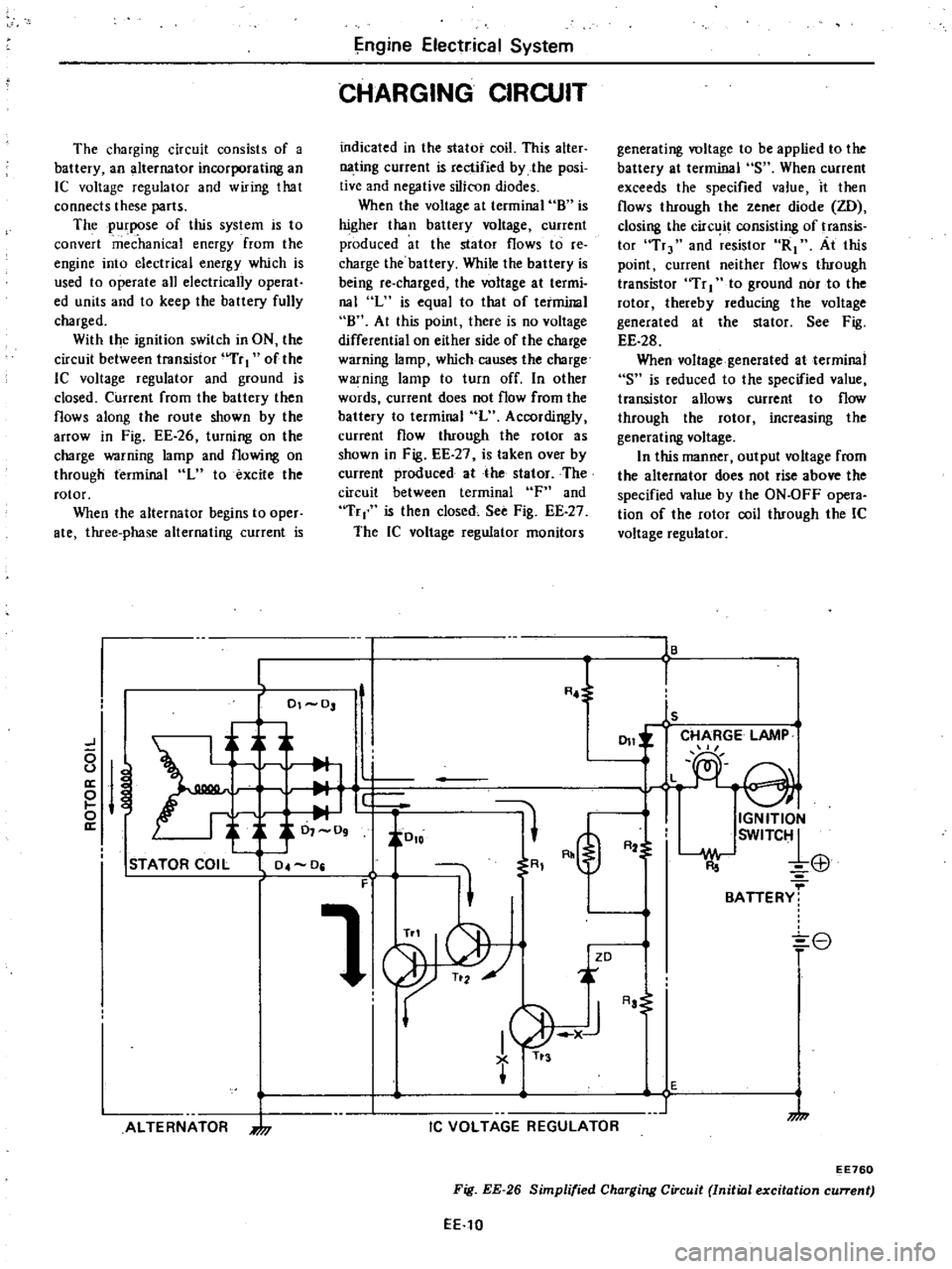

The

charging

circuit

consists

of

a

battery

an

alternator

incorporating

an

IC

voltage

regulator

and

wiring

that

connects

these

parts

The

purpose

of

this

system

is

to

convert

mec

hanka

energy

from

the

engine

into

electrical

energy

which

is

used

to

operate

all

electrically

operat

ed

units

and

to

keep

the

battery

fully

charged

With

the

ignition

switch

in

ON

the

circuit

between

transistor

uTr

I

of

the

lC

voltage

regulator

and

ground

is

closed

Current

from

the

battery

then

flows

along

the

route

shown

by

the

arrOW

in

Fig

EE

26

turning

on

the

charge

warning

lamp

and

flowing

on

through

terminal

L

to

excite

the

rotor

When

the

alternator

begins

to

oper

ate

three

phase

alternating

current

is

ngine

Elect

ical

System

CHARGING

CIRCUIT

indicated

in

the

stator

coil

This

alter

nating

current

is

rectified

by

the

posi

tive

and

negative

silicon

diodes

When

the

voltage

at

terminal

8

is

higher

than

battery

voltage

current

produced

at

the

stator

flows

to

re

charge

the

battery

While

the

battery

is

being

re

charged

the

voltage

at

termi

nal

L

is

equal

to

that

of

terminal

8

At

this

point

there

is

no

voltage

differential

on

either

side

of

the

charge

warning

lamp

which

causes

the

charge

warning

lamp

to

turn

off

In

other

words

current

does

not

flow

from

the

battery

to

terminal

L

Accordingly

current

flow

through

the

rotor

as

shown

in

Fig

EE

27

is

taken

over

by

current

produced

at

the

stator

The

circuit

between

terminal

F

and

Tr

is

then

closed

See

Fig

EE

27

The

IC

voltage

regulator

monitors

generating

voltage

to

be

applied

to

the

battery

at

terminal

S

When

current

exceeds

the

specified

value

it

then

flows

through

the

zener

diode

ZD

closing

the

circ

it

consisting

of

transis

tor

Tr

and

resistor

R1

At

this

point

current

neither

flows

through

transistor

Tr

I

to

ground

nor

to

the

rotor

thereby

reducing

the

voltage

generated

at

the

stator

See

Fig

EE

28

When

voltage

generated

at

terminal

S

is

reduced

to

the

specified

value

transistor

allows

current

to

flow

through

the

rotor

increasing

the

generating

voltage

In

this

manner

output

voltage

from

the

alternator

does

not

rise

above

the

specified

value

by

the

ON

OFF

opera

tion

of

the

rotor

coil

through

the

IC

voltage

regulator

16

L

R

l

I

01

0

ls

CHARGE

LAMP

J

011

L

e

0

u

a

M

e

i

J

0

io

o

IGNITION

a

0

09

SWITC1

R2

El1

STATOR

COIL

04

0

R

F

1

BATTERY

8

ZD

ALTERNATOR

7

I

1

AJ

TI

3

IC

VOLTAGE

REGULATOR

Aa

E

1

7

EE760

Fig

EE

26

Simplified

Charging

Circuit

Initial

excitation

current

EE

10

Page 249 of 548

TIGHTENING

TORQUE

Ball

pin

Striking

lever

lock

nut

S

llft

arm

bracket

Mainshaft

bearing

retainer

screw

Mainshaft

lock

nut

Rear

extension

installation

bolt

Stopper

pin

bolt

Front

cover

installation

bolt

Speedometer

sleeve

lock

ing

plate

bolt

Top

detecting

switch

Reverse

lamp

switch

Neutral

switch

Return

spring

plug

Gear

oil

filler

plug

Gear

oil

drain

plug

Transmission

to

engine

installation

bolt

Tr

msmissiori

to

engihe

rear

plate

installation

bolt

Transmission

to

gusset

installation

bolt

Starting

motor

to

trans

inissi

n

installation

bolt

Rear

mounting

insulator

to

transmission

installation

bolt

Crossmember

mounting

bolt

Rear

engine

mount

installation

bolt

Clutch

operating

cylinder

installation

bolt

Propeller

shaft

to

differential

carrier

Control

lever

pin

installation

nut

Exhaust

mounting

bracket

to

exhaust

front

tube

FU

model

only

Manual

Transmission

F4W60L

2

0

to

3

0

14

to

22

0

9

to

1

2

6

5

to

8

7

0

7

to

1

0

5

1

to

7

2

1

6

to

2

2

12

to

16

0

5

to

0

8

3

6

to

5

8

1

0

to

1

6

7

to

12

0

3

to

0

5

2

2

to

3

6

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

0

5

to

1

0

3

6

to

7

2

2

5

to

4

0

18

to

29

2

5

to

4

0

18

to

29

1

6

to

2

2

12Jo

16

1

6

to

2

2

12

t

16

4

6

to

6

1

33

to

44

3

0

to

4

0

22

to

29

0

9

to

1

2

6

5

to

8

7

3

2

to

4

3

23

to

31

0

9

to

1

2

6

5

to

8

7

3

1

to

4

1

22

to

30

2

4

to

3

3

17

to

24

1

3

to

1

7

9

to

12

3

2

to

4

3

23

to

31

MT33

Unit

kg

m

ft

lb

FS5W60L

2

0

to

3

0

14

to

22

0

9

to

1

2

6

5

to

8

7

8

2

to

10

0

59

to

72

0

8

to

1

3

5

8

to

9

4

10

0

to

11

0

72

to

80

1

6

to

2

2

12

to

16

1

0

to

1

6

7

to

12

0

3

to

0

5

2

2

to

3

6

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

0

5

to

1

0

3

6

to

7

2

2

5

to

4

0

18

to

29

i

5

to

4

0

18

to

29

1

6

to

2

2

12

to

16

1

6

to

2

2

12

to

16

4

6

to

6

1

33

to

44

3

0

to

4

0

22

to

29

0

9

to

1

2

6

5

to

8

7

3

2

to

4

3

23

to

31

0

9

to

1

2

6

5

to

8

7

3

1

to

4

1

22

to

30

2

4

to

3

3

17

to

24

1

3

to

1

7

9

to

12

3

2

to

4

3

23

to

31

Page 307 of 548

DATSUN

2JO

Model

83

J

0

Series

SECTIONPD

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

CONTENTS

PROPELLER

SHAFT

INSPECTION

GENERAL

INSPECTION

PROPEllER

SHAFT

VIBRATION

REMOVAL

AND

INSTAllATION

REMOVAL

INSTAllATION

DIFFERENTIAL

CARRIER

REMOVAL

PRE

DISASSEMBl

Y

INSPECTION

DISASSEMBLY

FINAL

DRIVE

ASSEMBLY

DIFFERENTIAL

CASE

INSPECTION

ASSEMBl

Y

AND

ADJUSTMENT

PRECAUTIONS

IN

REASSEMBLY

ASSEMBLY

OF

DIFFERENTIAL

CASE

ADJUSTMENT

OF

DRIVE

PINION

HEIGHT

ADJUSTMENT

OF

DRIVE

PINION

PRELOAD

PD

2

PD

2

PD

2

PD

2

PD

2

PD

2

PD

2

PD

3

PD

3

PD

3

PD

4

PD

4

PD

4

PD

4

PD

5

PD

5

PD

5

PD

6

PD

6

AQJUSTMENT

OF

SIDE

BEARING

SHIMS

INSTAllATION

REPLACEMENT

OF

FRONT

Oil

SEAL

SERVICE

DATA

AND

SPECIFICATIONS

PROPEllER

SHAFT

GENERAL

SPECIFICATIONS

SERVICE

DATA

TIGHTENING

TORQUE

DIFFERENTIAL

CARRIER

GENERAL

SPECIFICATIONS

SERVICE

DATA

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

PROPEllER

SHAFT

DIFFERENTIAL

CARRIER

SPECIAL

SERVICE

TOOLS

PD

7

PD

9

PD

9

PD

lO

PD

lO

PD

lO

PD

lO

PD

lO

PD

l0

PD

lO

PD

ll

PD

ll

PD

12

PD

12

PD

13

PD

15

Page 308 of 548

Rropeller

Shaft

Differential

Carrier

PROPELLER

SHAFT

INSPECTION

GENERAL

INSPECTION

I

Check

propeller

shaft

tube

sur

Cace

for

dents

or

cracks

If

damaged

replace

with

an

assembly

2

Check

journal

for

axial

play

If

there

is

play

replace

propeller

shaft

mbly

Note

JournaI

cannot

be

disassem

bled

PROPELLER

SHAFT

VIBRATION

To

check

and

correct

an

unbal

anced

propeller

shaCt

proceed

as

Col

lows

L

Remove

undercoating

and

other

foreign

material

which

could

upset

shaft

balance

and

check

shaft

vibra

tion

by

road

test

2

If

shaft

vibration

is

noted

during

road

test

disconnect

propeller

shaft

et

differential

carrier

companion

flange

rotate

companion

flange

180

degrees

and

reinstall

propeller

shaft

ff

3

Again

check

shaft

vibration

If

vibration

still

persists

replace

propel

ler

shaft

assembly

REMOVAL

AND

INSTALLATION

REMOVAL

I

Raise

car

on

hoist

Put

match

malks

both

on

propeller

shaft

and

companion

flange

so

that

shaft

can

be

reinstalled

in

its

original

position

2

Remove

bolts

connecting

pro

peller

shaft

to

companion

flange

PD459

Fig

PD

2

Removing

Propeller

Shaft

PD

2

Tightening

torque

kg

m

ft

b

@

2

410

3

3

1710

24

PD468

Fig

PD

l

PropellerSha

t

3

Draw

out

propeller

shall

sleeve

yoke

from

transmission

by

moving

shaft

realWard

passing

it

under

rear

axle

Plug

up

rear

end

of

rear

extension

housing

to

prevent

oil

leakage

Note

Remove

propeller

aheCt

care

Cully

so

as

not

to

demege

spline

sleeve

yoke

and

rear

oil

seal

INSTALLAnON

To

inS

aJI

reverse

the

foregoing

removal

prOCedure

CAUTION

Align

propeller

shift

with

com

penion

fllnge

of

differentiel

Clrrier

ulling

reference

marks

prl

1Cribed

in

Remova

procedure

and

tightsn

them

with

bolts

Failure

to

do

so

could

resuh

in

driving

vibration

fJ

Tightening

tOlquo

Propellol

sheft

to

companion

f1enge

bolts

2

4

to

3

3

kg

m

117

to

24

ft

b

Page 309 of 548

Propeller

Shaft

Differential

Carrier

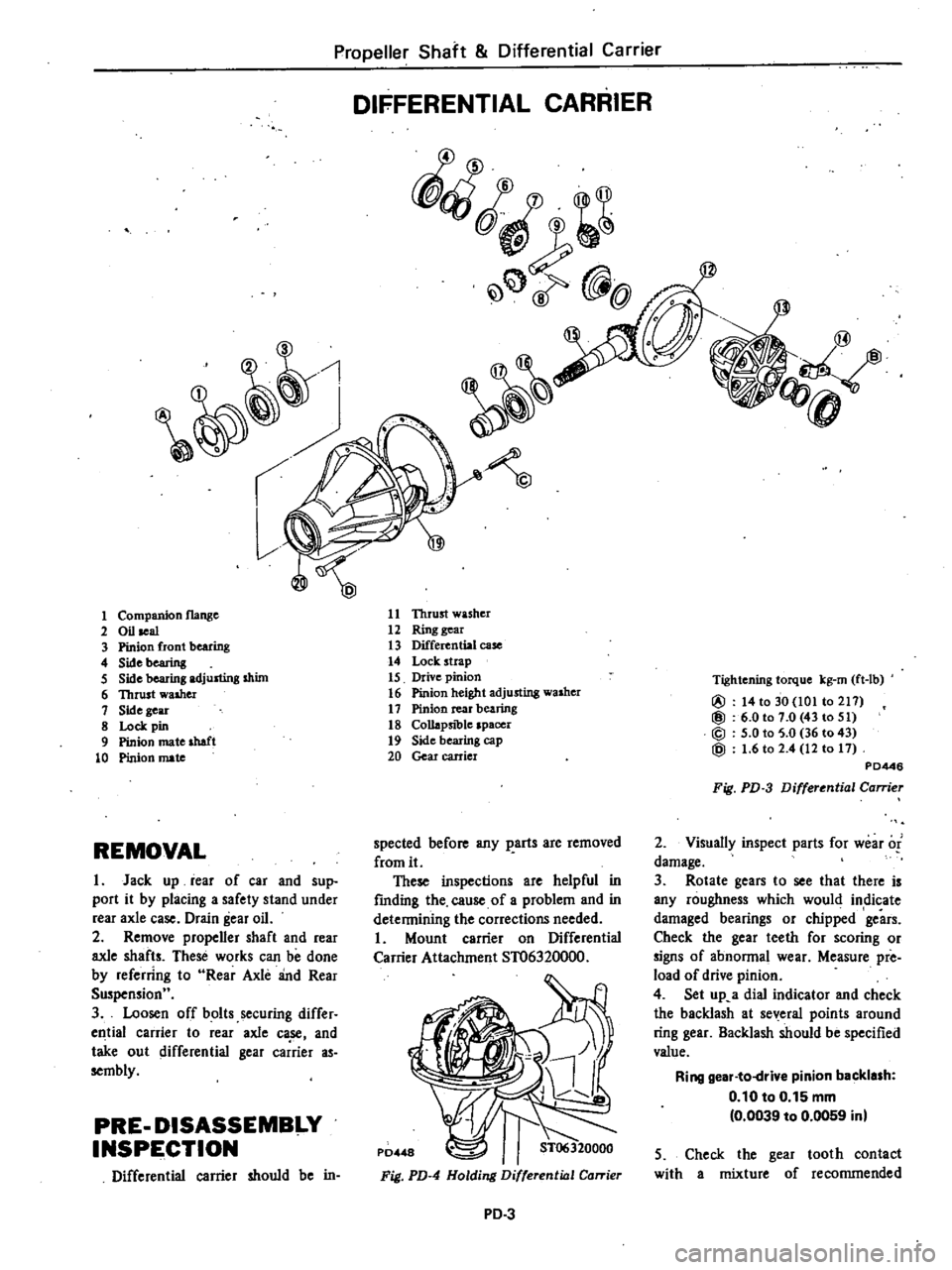

DIFFERENTIAL

CARRIER

fQ

@

1

11

Thrust

washer

12

Ring

gear

13

Differential

case

14

Lock

strap

15

Drive

pinion

16

Pinion

height

adjusting

washer

17

Pinion

rear

bearing

18

Collapsible

spacer

19

Side

bearing

cap

20

Gear

carrier

1

Companion

flange

2

Oil

seal

3

Pinion

front

bearing

4

Sidebearing

5

Side

bearing

adjusting

shim

6

Thrust

walher

1

Side

gear

8

Lock

pin

9

Pinion

mate

shaft

10

Pinion

mate

Tightening

torque

kg

rn

ft

lb

@

14

to

30

101

to

211

@

6

0101

0

43

to

51

@

5

0

to

5

0

36

to

43

@

1

6

to

2

4

12

to

11

PD446

Fig

PD

3

Differential

Carrier

2

Visuany

inspect

parts

for

wear

of

damage

3

Rotate

gears

to

see

that

there

is

any

roughness

which

would

indicate

damaged

bearings

or

chipped

gears

Check

the

gear

teeth

for

scoring

or

signs

of

abnonnal

wear

Measure

pre

load

of

drive

pinion

4

Set

up

a

dial

indicator

and

check

the

backlash

at

several

points

around

ring

gear

Backlash

should

be

specified

value

Ring

gear

to

drive

pinion

backlash

0

10

to

0

15

mm

0

0039

to

0

0059

inl

spected

before

any

parts

are

removed

from

it

These

inspections

are

helpful

in

fmding

the

cause

of

a

problem

and

in

detennining

the

corrections

needed

Mount

carrier

on

Differential

Carrier

Attachment

ST06320000

REMOVAL

I

Jack

up

rear

of

car

and

sup

port

it

by

placing

a

safety

stand

under

rear

axle

case

Drain

gear

oil

2

Remove

propener

shaft

and

rear

axle

shafts

These

works

can

be

done

by

referring

to

Rear

Axle

and

Rear

Suspensionu

3

Loosen

off

bolts

securing

differ

ell

tial

carrier

to

rear

axle

ca

se

and

take

out

differential

gear

carrier

as

sembly

PRE

DISASSEMBI

Y

INSPE

CTION

Differential

carrier

should

be

in

5

Check

the

gear

tooth

contact

with

a

mixture

of

recommended

Fig

PD

4

Holding

Differential

Carrier

PD

3