differential DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 310 of 548

I

powder

and

oil

applied

sp

hingly

to

all

ring

gear

teeth

For

the

tooth

contact

pattern

see

paragraph

dealing

with

tooth

contact

pattern

adjustl1ll

nt

DISASSEMBLY

FINAL

DRIVE

ASSEMBLY

I

Put

match

marks

on

side

bearing

caps

and

carrier

and

remove

side

bearing

caps

and

take

out

differential

case

assembly

using

Slide

Hammer

HTI2400000

PD266

Fig

PD

5

Removing

Diffe

ntial

Ca

e

A

embly

Note

Care

should

be

taken

not

to

confWle

the

left

end

right

hand

bearing

caps

and

bearing

outer

races

so

that

reassembly

will

be

easily

carried

out

with

the

same

parts

in

the

original

position

2

Rel

love

drive

pinion

nut

using

Drive

Pinion

Flange

Wrench

ST31530000

and

pull

off

companion

flange

using

a

standard

puller

Fig

PD

6

Removing

Drive

Pinion

Nut

3

Extract

drive

pinion

assembly

to

the

rearwards

by

tapping

the

front

end

Propeller

Shaft

Differential

Carrier

of

drive

pinion

with

a

soft

baminet

Drive

pinion

can

be

taken

out

together

with

rear

bearing

inner

race

collapsi

ble

spacer

and

washer

4

Remove

oil

seal

and

take

out

front

bearing

inner

race

Note

Oil

seal

must

not

be

reused

5

Hold

rear

bearing

inner

race

with

Drive

Pinion

Rear

Bearing

Inner

Race

Puller

ST30031000

and

extract

from

drive

pinion

with

a

press

STJ0031000

r

1

i

9

PD205

Fig

PD

7

Removing

Pinion

Rear

Bearing

I

nfUr

Race

6

To

remove

outer

races

of

both

front

and

rear

bearings

apply

a

brass

drift

to

race

side

surface

and

with

draw

them

by

tapping

the

top

of

drift

with

a

hammer

PD268

Fig

PD

B

Removing

Pinion

Front

and

Rear

Bearing

Outer

Race

DIFFERENTIAL

CASE

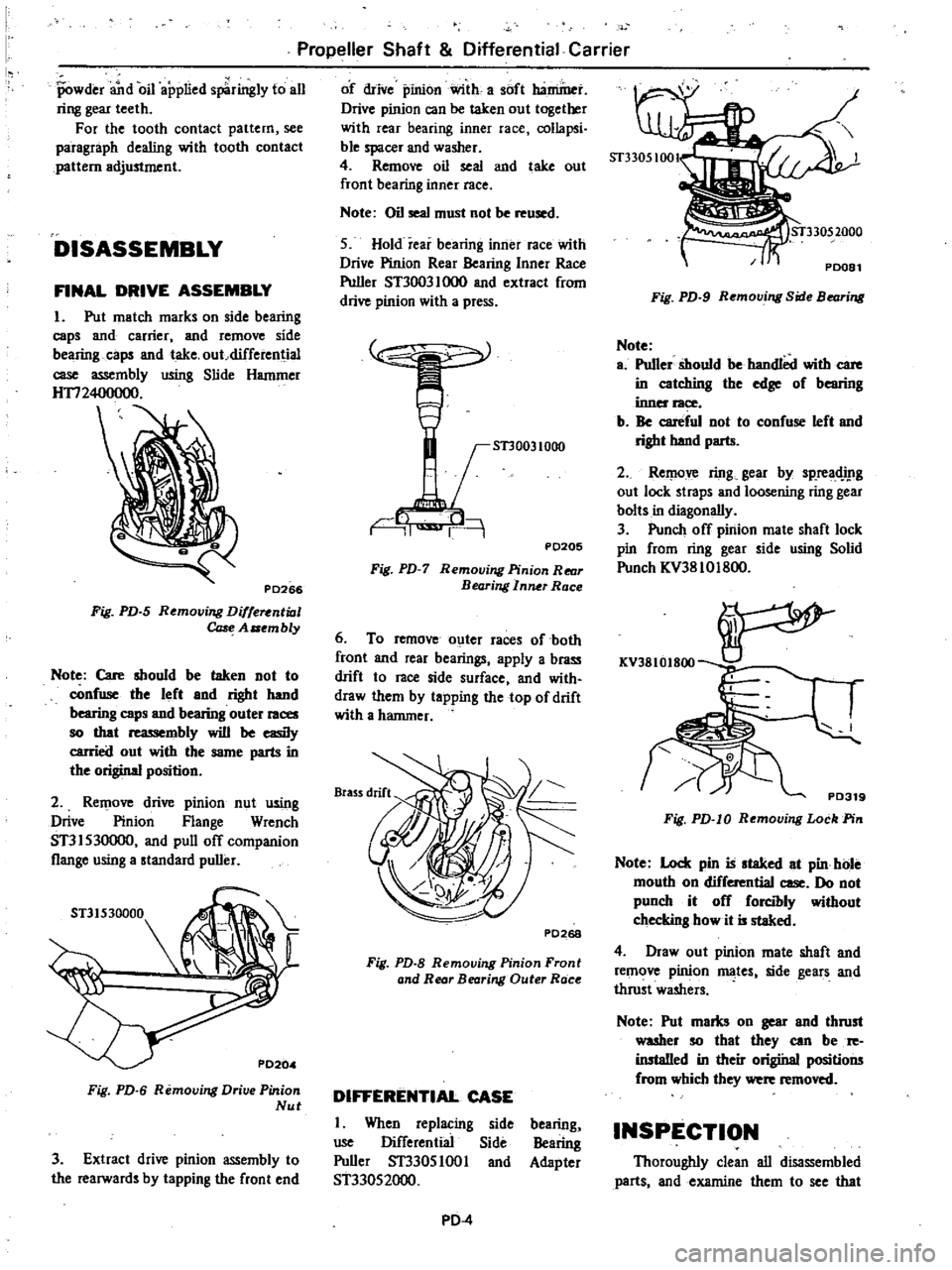

I

When

replacing

side

Wle

Differenliai

Side

Puller

ST3305

1001

and

ST33052000

bearing

Bearing

Adapter

PD

4

Fig

PD

9

Removing

Side

Bearing

Note

a

Puller

should

be

bandlOd

with

care

in

catching

the

edge

of

bearing

inner

race

b

Be

careful

not

to

confuse

left

and

right

band

parts

2

Rel

love

ring

gear

by

sp

readJ

lg

out

lock

straps

and

loosening

ring

gear

bolts

in

diagonally

3

Punch

off

pinion

mate

shaft

lock

pin

from

ring

gear

side

using

Solid

Punch

KV3810Ig00

KV3810I800

PD319

Fig

PD

I0

Removing

Lock

Pin

Note

Lock

pin

is

slaked

et

pin

hole

mouth

on

differential

case

Do

not

punch

it

off

forcibly

without

checking

how

it

is

staked

4

Draw

out

pinion

mate

shaft

and

remove

pinion

ID3

tes

side

gears

and

thrust

washers

Note

Put

mams

on

gear

end

thrust

waaher

so

that

they

can

be

re

installed

in

their

origiital

positions

from

which

they

were

removed

INSPECTION

Thoroughly

clean

all

disassembled

parts

and

examine

them

to

see

that

Page 311 of 548

they

are

worn

damaged

or

otherwise

faulty

and

how

they

are

affected

Re

pair

or

replace

all

faulty

parts

which

ever

is

necessary

1

Check

gear

teeth

for

scoring

cracking

or

chipping

and

make

sure

that

tooth

contact

pattern

indicates

correct

meshing

depth

If

any

fault

is

evident

replace

parts

as

required

Note

Drive

pinion

and

ring

gear

are

supplied

for

replacement

as

a

set

therefore

should

either

part

be

damaged

replece

as

a

set

2

Check

pinion

shaft

and

pinion

mates

for

scores

and

signs

of

wear

and

replace

as

required

F

oUow

the

same

procedure

for

side

gear

and

their

seats

on

differential

case

3

Inspect

all

bearing

races

and

roU

ers

for

scoring

chipping

or

evidence

of

excessive

wear

They

should

be

in

tiptop

condition

such

as

not

worn

and

with

mirror

like

surfaces

Replace

if

there

is

a

shadow

of

doubt

on

their

efficiency

as

an

incorrect

bearing

op

eration

may

result

in

noises

and

gear

seizure

4

Inspect

thrust

washer

faces

SmaU

faults

can

be

corrected

with

sand

paper

If

pinion

mate

to

de

gear

backlash

exceeds

specified

value

re

place

thrust

washers

Pinion

mate

to

side

gear

backlash

0

10

to

0

20

mm

0

0039

to

0

0079

in

5

Inspect

gear

carrier

and

differ

ential

case

for

cracks

or

distortion

If

either

condition

is

evident

replace

Jaulty

parts

6

As

a

general

rule

oil

seal

should

be

replaced

at

each

disassembly

ASSEMBLY

AND

ADJUSTMENT

Assembly

can

be

done

in

the

reverse

order

of

disassembly

The

foUowing

directions

for

adjustment

and

usage

of

special

tools

enable

to

obtain

a

perfect

differential

operation

Propeller

Shaft

Differential

Carrier

PRECAUTIONS

IN

REASSEMBLY

I

Arrange

shims

washers

and

the

like

to

install

them

correctly

2

Thoroughly

clean

the

surfaces

on

which

shims

washers

bearings

and

bearing

caps

are

installed

3

Apply

gear

oil

when

installing

bearings

4

Pack

grease

cavity

between

lips

when

fitting

oil

seal

ASSEMBLY

OF

DIFFERENTIAL

CASE

1

Assemble

pinion

mates

side

gears

and

thrust

washers

in

differential

case

2

Fit

pinion

shaft

to

differential

case

so

that

it

meets

lock

pin

hole

3

Adjust

pinion

mate

to

ide

gear

backlash

or

the

clearance

between

the

rear

face

of

side

gear

and

thrust

washer

to

the

specified

value

by

selecting

side

gear

thrust

washer

Pinion

mate

to

side

gear

backlash

0

10

to

0

20

mm

10

0039

to

0

0079

in

PD023

Fig

PD

l1

Measuring

Clearance

Side

gear

thrust

washer

Thickness

mm

in

0

785

0

0309

0

835

0

0329

0

885

0

0348

4

Lock

pinion

shaft

lock

pin

using

a

punch

after

it

is

secured

into

place

5

Apply

oil

to

gear

tooth

surfaces

and

thrust

surfaces

and

check

if

they

turn

properly

6

Place

ring

gear

on

differential

case

and

install

bolts

and

lock

straps

Tor

que

bolts

to

specification

and

bend

up

lock

straps

PO

5

tiJ

Tightening

torque

Ring

gear

bolt

6

0

to

7

0

kg

m

43

to

51

ft

Ib

CAUTION

e

Use

only

genuine

ring

gear

bolts

end

new

lock

straps

b

Tighten

bolts

in

criss

crilss

fashion

lightly

tapping

around

bolt

heads

with

a

hammer

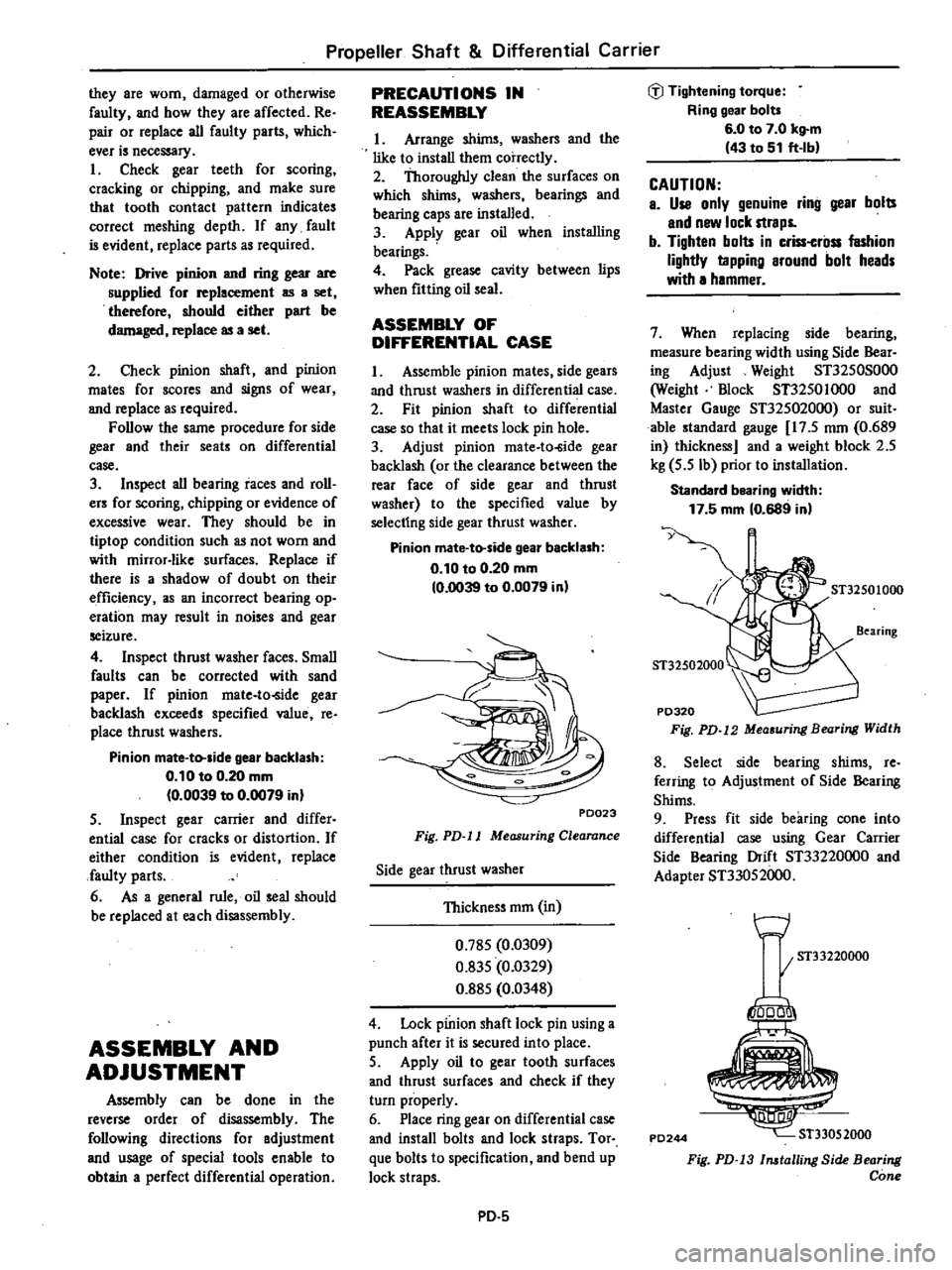

7

When

replacing

side

bearing

measure

bearing

width

using

Side

Bear

ing

Adjust

Weight

ST3250S000

Weight

mock

ST3250

I

000

and

Master

Gauge

ST325020oo

or

suit

able

standard

gauge

17

5

nun

0

689

in

thickness

and

a

weight

block

2

5

kg

5

5

Ib

prior

to

installation

Standald

bearing

width

17

5

mm

10

689

in

y

ST32501000

8

Select

side

bearing

shims

re

ferring

to

Adjustment

of

Side

Bearing

Shims

9

Press

fit

side

bearing

cone

into

differential

case

using

Gear

Carrier

Side

Bearing

Drift

ST33220oo0

and

Adapter

ST33052000

w

I

ST33220000

PD244

1000

ST33052000

Fig

PD

13

lnatalling

Side

Bearing

Cone

Page 312 of 548

ADJUSTMENT

OF

DRIVE

PINION

HEIGHT

Adjust

the

pinion

height

with

wash

er

provided

between

rear

bearing

inner

race

and

the

back

of

piliion

gear

J

Press

fit

front

and

rear

bearing

outer

races

into

gear

carrier

using

Drive

Pinion

Outer

Race

Drift

STJ070

I

000

and

Bar

ST30611000

2

Fit

rear

bearing

on

gear

carrier

and

install

Dwnmy

Shaft

on

rear

bear

ing

and

place

Height

Gauge

on

gear

carrier

STJII21000

Height

gauge

KV38

103500

Height

gauge

spacer

ST3

II

22000

Dummy

shaft

KV3gl03600

Dummy

shaft

spacer

ST3112tOOO

PD461

Fig

PD

14

AqjUlting

Pinion

Height

3

Measure

the

clearance

N

be

tween

the

tip

end

of

height

gauge

and

the

end

surface

of

dummy

shaft

using

a

thickness

gauge

P0322

Fig

PD

15

Meo

uring

Clearance

4

The

proper

thickness

of

pinion

height

adjusting

washers

can

be

obtain

ed

from

the

following

formula

Propeller

Shaft

Differential

Carrier

T

W

N

HxO

01

OJ8

Where

T

Required

thickness

of

pinion

heightedjusting

w

shers

W

Thickness

of

temporarily

insert

ed

washer

mm

Be

sure

to

use

washer

of

2

74

0

1079

or

2

77

0

1091

or

2

80

0

1102

mm

in

thick

ness

N

Measured

clearance

between

height

gauge

and

dummy

shaft

face

mm

H

Figure

marked

on

the

drive

pinion

head

Note

e

Figure

H

is

e

dimensional

variation

in

units

of

1

100

mm

egainst

stand

ard

measurement

b

If

value

signifying

H

is

not

given

regard

it

as

zero

and

compute

Head

number

Hl

P0186

Set

number

Fig

PD

16

Variation

Number

on

Drive

Pinion

Examples

of

calculation

EX

I

W

2

74mmN

0

30mmH

1

T

W

N

H

x

0

01

0

18

2

74

0

30

I

x

0

01

OJ8

3

04

0

19

2

85

The

correct

washer

thickness

is

2

86

mm

EX

2

W

2

77

mm

N

0

21

mm

H

0

T

W

N

HxO

01

OJ8

2

77

0

21

OxO

0I

OJ8

2

98

0

18

2

80

The

correct

washer

thickness

is

2

g0

mm

PD

6

EX

3

W

2

80

mm

N

0

48

mm

H

2

T

W

N

HxO

OI

OJg

2

80

OA8

2

x

0

01

OJ8

3

28

0

20

3

08

The

correct

washer

thickness

is

3

07

mm

Pinion

height

adjusting

washer

Thickness

mm

in

2

74

OJ

079

3

01

0

1185

2

77

OJ09I

3

04

0

1197

2

80

OJ

102

3

07

0

1209

2

83

0

1114

3

10

0

1220

2

86

OJ

126

3J3

0

1232

2

89

0

1138

3

16

0

1244

2

92

OJ

150

3

19

0

1256

2

95

0

1161

3

22

OJ

268

2

98

0

1173

3

25

O

l2g0

5

Fit

detennined

pinion

height

ad

justing

washer

in

drive

pinion

and

press

fit

rear

bearing

inner

race

in

it

using

Drive

Pinion

Bearing

Drift

Bar

STJ0600000

Note

After

assembly

check

to

see

thet

tooth

contact

is

correct

If

Dot

readjust

ADJUSTMENT

OF

DRIVE

PINION

PRELOAD

Adjust

the

preload

of

drive

pinion

with

collapsible

spacer

This

procedure

has

nothing

to

do

with

thickness

of

pinion

height

ad

justing

washer

Note

Collapsible

spacer

oil

seal

and

pinion

nut

cannot

be

reused

I

After

adjusting

pinion

height

lubricate

front

bearing

with

gear

oil

and

place

it

in

gear

carrier

2

Install

a

new

oil

seal

in

gear

carrier

using

Oil

Seal

Fitting

Tool

ST33400001

Lubricate

cavity

between

seal

lips

with

recommended

multi

purpose

grease

when

installing

3

Place

a

new

collapsible

spacer

on

Page 313 of 548

drive

pinion

arid

lubricate

pinion

rear

bearing

with

gear

oil

4

Insert

companion

flange

into

oil

seal

and

hold

it

firmly

against

pinion

front

bearing

cone

From

the

rear

of

the

gear

carrier

insert

drive

pinion

into

companion

flange

5

Ascertain

that

threaded

portion

of

drive

pinion

and

new

drive

p

ion

nut

are

free

from

oil

or

grease

6

Holding

companion

flange

with

Drive

Pinion

Flange

Wrench

STJ1530000

tighten

nut

and

then

pull

drive

pinion

into

front

bearing

cone

and

into

flange

As

drive

pinion

is

pulled

into

front

bearing

cone

drive

pinion

end

play

is

reduced

While

there

is

still

end

play

in

drive

pinion

companion

flange

and

cone

will

be

fell

to

bottom

out

This

indicates

that

bearing

cone

and

com

panion

flange

have

bottomed

on

col

lap

ible

spacer

From

this

point

a

much

greater

torque

must

be

applied

to

turn

pinion

nut

since

spacer

must

be

collapsed

Also

from

this

point

nut

hould

be

tightened

very

slowly

and

drive

pinion

end

play

checked

often

0

that

pinion

bearing

preload

does

not

exceed

the

limits

When

the

drive

pinion

end

play

has

been

eliminated

the

specified

preload

i

being

approached

CAUTION

00

not

decrease

preload

by

loosen

ing

pinion

nut

This

will

remove

compression

between

pinion

front

end

rear

bearing

cones

and

collapsibla

spacer

and

may

permit

front

bear

ing

cone

to

turn

on

drive

pinion

Moreover

nut

becomes

loose

7

Turn

drive

pinion

in

both

direc

lions

several

times

to

set

bearing

rollers

Then

adjust

bearing

preload

to

specification

using

Preload

Gauge

STJ127S000

iil

Tightening

tOlque

Pinion

nut

14

to

30

kg

m

101

to

217

ft

lb

D

iY8

pinion

preload

with

oil

seal

6

0

to

8

0

kg

cm

5

2

to

6

9

in

Ib

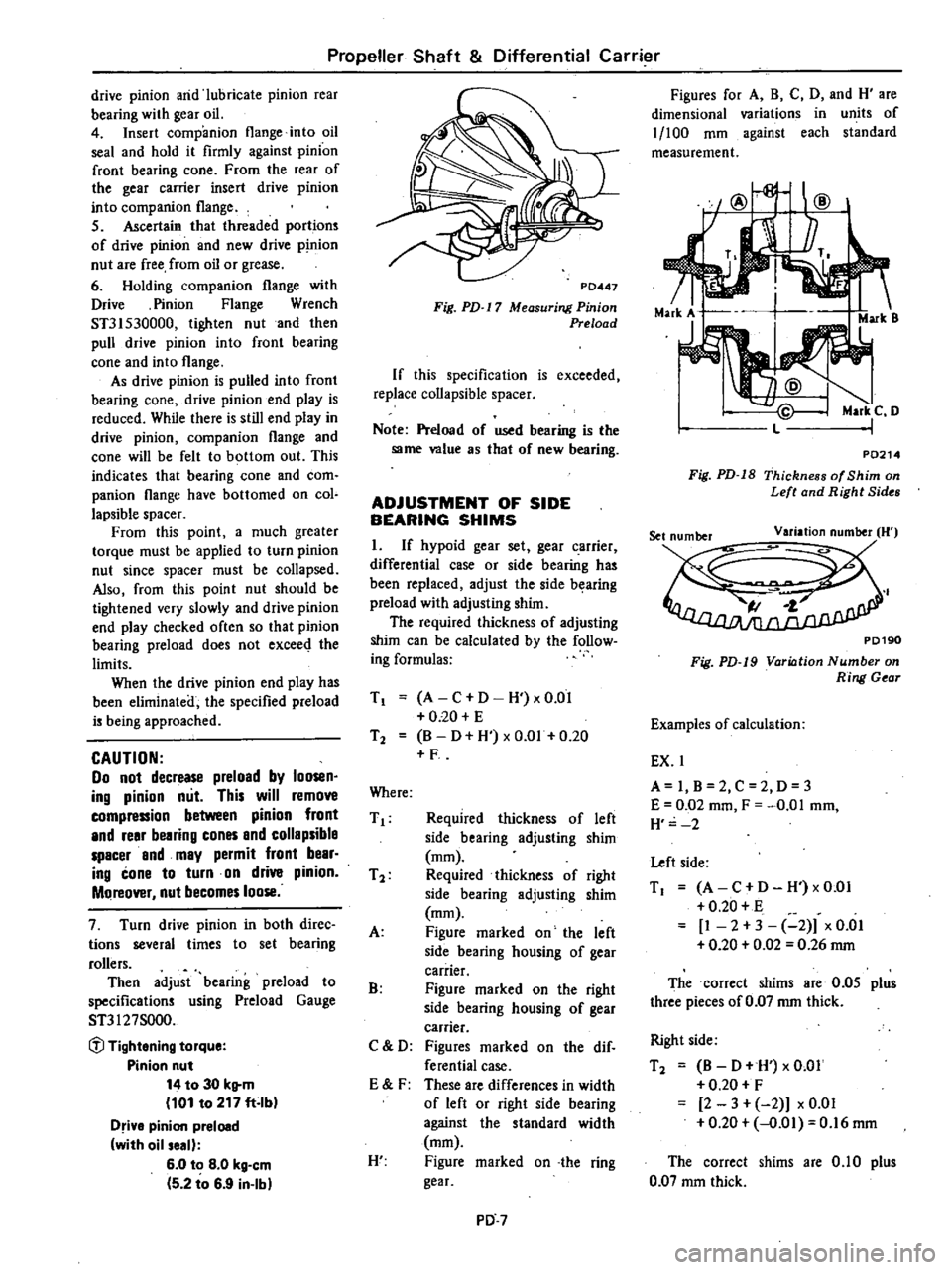

Propeller

Shaft

Differential

Carrier

P0447

Fig

PD

17

Measuring

Pinion

Preload

If

this

specification

is

exceeded

replace

collapsible

spacer

Note

Preload

of

used

bearing

is

the

same

value

as

that

of

new

bearing

ADJUSTMENT

OF

SIDE

BEARING

SHIMS

I

If

hypoid

gear

set

gear

carrier

differential

case

or

side

bearing

ha

been

replaced

adjust

the

ide

bearing

preload

with

adjusting

him

The

required

thickness

of

adjusting

shim

can

be

calculated

by

the

follow

ing

formulas

T

A

C

D

H

xO

OI

020

E

T2

B

D

H

xO

Ol

0

20

F

Where

T

Required

thickness

of

left

side

bearing

adjusting

shim

mm

T

2

Required

thickness

of

right

side

bearing

adjusting

shim

mm

A

Figure

marked

on

the

left

side

bearing

housing

of

gear

carrier

B

Figure

marked

on

the

right

side

bearing

housing

of

gear

carrier

C

D

Figures

marked

on

the

dif

ferential

case

E

F

These

are

differences

in

width

of

left

or

right

side

bearing

against

the

tandard

width

mm

H

Figure

marked

on

the

ring

gear

PD

7

Figures

for

A

B

C

D

and

H

are

dimensional

variations

in

units

of

1

100

mm

against

each

standard

measurement

F

MarkS

MarkC

D

L

P0214

Fig

PD

18

Thickness

of

Shim

on

Left

and

Right

Sides

PD190

Fig

PD

19

Variation

Number

on

Ring

Gear

Examples

of

calculation

EX

1

A

I

B

2

C

2

D

3

E

0

02

mm

F

0

01

mm

H

2

Left

side

T

A

C

D

H

xO

OI

0

20

E

I

2

3

2

x

0

01

0

20

0

02

0

26

rnm

The

correct

shims

are

0

05

plus

three

pieces

of

0

07

mm

thick

Right

side

T2

B

D

W

xO

QI

0

20

F

2

3

2

x

0

01

0

20

0

01

0

16

mm

The

correct

shims

are

0

10

plus

0

07

mm

thick

Page 314 of 548

EX

2

A

0

B

3

C

I

D

2

E

O

I

F

0

08

H

I

Left

side

T

A

C

D

H

xO

OI

0

20

E

0

H

2

1

x

0

01

0

20

0

11

0

0

20

0

1

0

31

The

correct

shims

are

0

10

plus

lI

re

e

pi

ce

s

of

9

Q7

I

Il1I

thick

Right

side

T2

B

D

H

xO

OI

020

F

3

2

I

xO

01

0

20

0

08

0

02

0

20

0

08

0

30

The

correct

shims

are

0

10

plus

0

20

mm

thick

Note

If

w1ues

sigoifying

A

B

C

D

and

H

are

not

giVen

regard

them

as

zero

end

compote

After

essembly

clteek

to

see

that

preload

and

backlesb

ere

correct

If

not

readjust

Side

bearing

adjusting

shim

Thickness

mm

in

0

05

0

0020

0

07

0

0028

0

1

0

0

0039

0

20

0

0079

0

50

0

0197

2

Fit

determined

side

bearing

ad

justing

shim

on

differential

case

and

press

fit

left

and

right

side

bearing

inner

races

on

it

using

Side

Bearing

Drift

ST3322OO00

and

Adapter

ST33052000

3

Install

differential

case

assembly

into

gear

carrier

tapping

with

a

rubber

mallet

4

Align

mark

on

bearing

cap

with

that

on

gear

carrier

and

install

bearing

cap

on

carrier

And

tighten

bolts

to

specified

torque

Propeller

Shaft

Differential

Carrier

@Tightenirig

tOrque

Side

bealingcap

bolts

5

0

to

6

0

kg

m

36

to

43

ft

b

5

M

easure

L

dimension

between

left

and

right

bearing

cap

edges

with

a

micrometer

e

cljmension

153

40

to

153

45

mm

6

0394

to

6

0413

inl

PD271

Fig

PD

20

Measuring

L

Dimension

6

Measure

ring

gear

to

drive

pinion

backlash

If

backlash

is

too

smaU

decrease

thickness

of

left

shim

and

increase

thickness

of

right

shim

by

the

same

amount

If

backlash

is

too

great

reverse

the

above

procedure

Ring

gear

to

drive

pinion

backlash

0

10

to

0

15

mm

0

0039

to

0

0059

in

PD272

Fig

PD

21

Mea

uring

Backlash

7

At

the

same

time

check

side

bearing

preload

Bearing

preload

should

be

specified

torque

If

preload

does

not

accord

with

tJiis

specification

adjust

it

with

side

bear

ing

shims

PD

B

Side

bealing

preload

8

to

10

kg

cm

6

9

to

8

7

in

bl

At

ring

geer

bolt

1

5

to

1

9

kg

3

3

to

4

2

Ibl

8

Check

and

adjust

the

tooth

con

t

c

pattern

of

ring

gear

and

drive

pinion

I

Thoroughly

clean

ring

and

drive

pinion

gear

teeth

2

Paint

ring

gear

teeth

lightly

and

evenly

with

a

mixture

of

recommend

ed

powder

and

oil

of

a

suitable

consist

ency

to

produce

a

contactpaUern

3

Rotate

pinion

through

several

revolutions

in

the

forward

and

reverse

direction

until

a

definite

contact

pat

tern

i

developed

on

ring

gear

4

When

contact

pattern

is

in

correct

readjust

thickness

oLadjust

ing

shim

Be

sure

to

wipe

off

powder

com

pletely

upon

completion

of

adjust

ment

5

Incorrect

contact

pattern

of

teeth

can

be

adjusted

in

the

foUowing

manner

Contact

pettern

a

Heel

contact

To

correct

increase

thickness

of

drive

pinion

adjusting

washer

in

order

to

bring

drive

pinion

close

to

ring

gear

P0193

Fig

PD

22

Heel

Contact

b

Toe

contact

To

correct

reduce

thickness

of

drive

pinion

adjusting

washer

in

order

to

make

drive

pinion

go

away

from

ring

gear

t

PD194

Fig

PD

23

Toe

Contact

Page 315 of 548

c

Flank

contact

Adjust

in

the

same

manner

as

in

b

t

P019S

Fig

PD

24

Flank

Contact

d

Face

contact

Adjust

in

the

same

manner

as

in

3

cf

P0196

Fig

PD

25

Face

Contact

e

Correct

tooth

contact

P0197

Fig

PD

26

Correct

Contact

Note

Change

in

thickness

of

adjust

ing

WlI8her

is

accompanied

by

change

in

backlash

Check

it

when

insteIIing

gear

Propeller

Shaft

Differential

Carrier

INSTALLATION

Installation

can

be

done

in

the

re

verse

order

of

removal

ifl

Tightening

torque

Gear

carrier

to

rear

axle

case

fixing

bolt

1

7

to

2

4

kg

m

12

to

17

ft

lbl

Drain

and

filler

plug

6

to

10

kg

m

43

to

72

ft

lbl

Gear

oil

quantity

0

9

liter

1

U

US

pt

1

Imp

pt

Note

a

Discard

gear

carrier

gasket

after

remom

Do

not

apply

sealant

to

the

gasket

b

Apply

sealant

to

bolts

securing

gear

carrier

case

to

rear

axle

housing

REPLACEMENT

OF

FRONT

OIL

SEAL

When

replacing

front

oil

seal

do

as

follows

1

Remove

differential

carrier

assem

bly

and

mount

it

on

Differential

Car

rier

Attachment

ST06320000

This

work

can

be

done

by

referring

to

Removal

procedure

2

Remove

side

bearing

caps

and

take

out

differential

case

assembly

Remove

drive

pinion

nut

and

extract

drive

pinion

assembly

Remove

oil

seal

These

works

can

be

done

by

re

ferring

to

Disassembly

procedure

PD

9

3

Install

a

new

oil

seal

in

gear

car

rier

using

Oil

Seal

Fitting

Tool

ST3340000l

Lubricate

cavity

between

seal

lips

with

recommended

multi

purpose

grease

when

installing

4

Place

a

new

collapsible

spacer

on

drive

pinion

and

lubricate

pinion

rear

bearing

with

gear

oil

5

Insert

companion

flange

into

oil

seal

Insert

drive

pinion

into

com

panion

flange

from

rear

of

gear

carrier

and

secure

them

in

position

by

tightening

nut

to

given

torque

con

firming

specified

preload

These

works

can

be

done

by

re

ferring

to

Adjustment

of

Drive

Pinion

Preload

procedure

6

Install

differential

case

assembly

into

gear

carrier

Measure

L

dimen

sion

backlash

with

specification

adjust

them

with

side

bearing

shims

The

works

can

be

done

by

re

ferring

to

Adjustment

of

Side

Bearing

Shims

procedure

7

Reinstall

differential

gear

carrier

assembly

rear

axle

shafts

and

pro

peller

shaft

Fill

up

differential

carrier

with

correct

gear

oil

CAUTION

a

Replacement

of

front

oil

seal

with

differential

carrier

assembly

install

ed

on

car

must

not

be

ellowed

due

to

used

collapsible

spacer

on

iu

model

b

Whenever

front

oil

seal

is

replaced

collepsible

spacer

must

be

replaced

Page 316 of 548

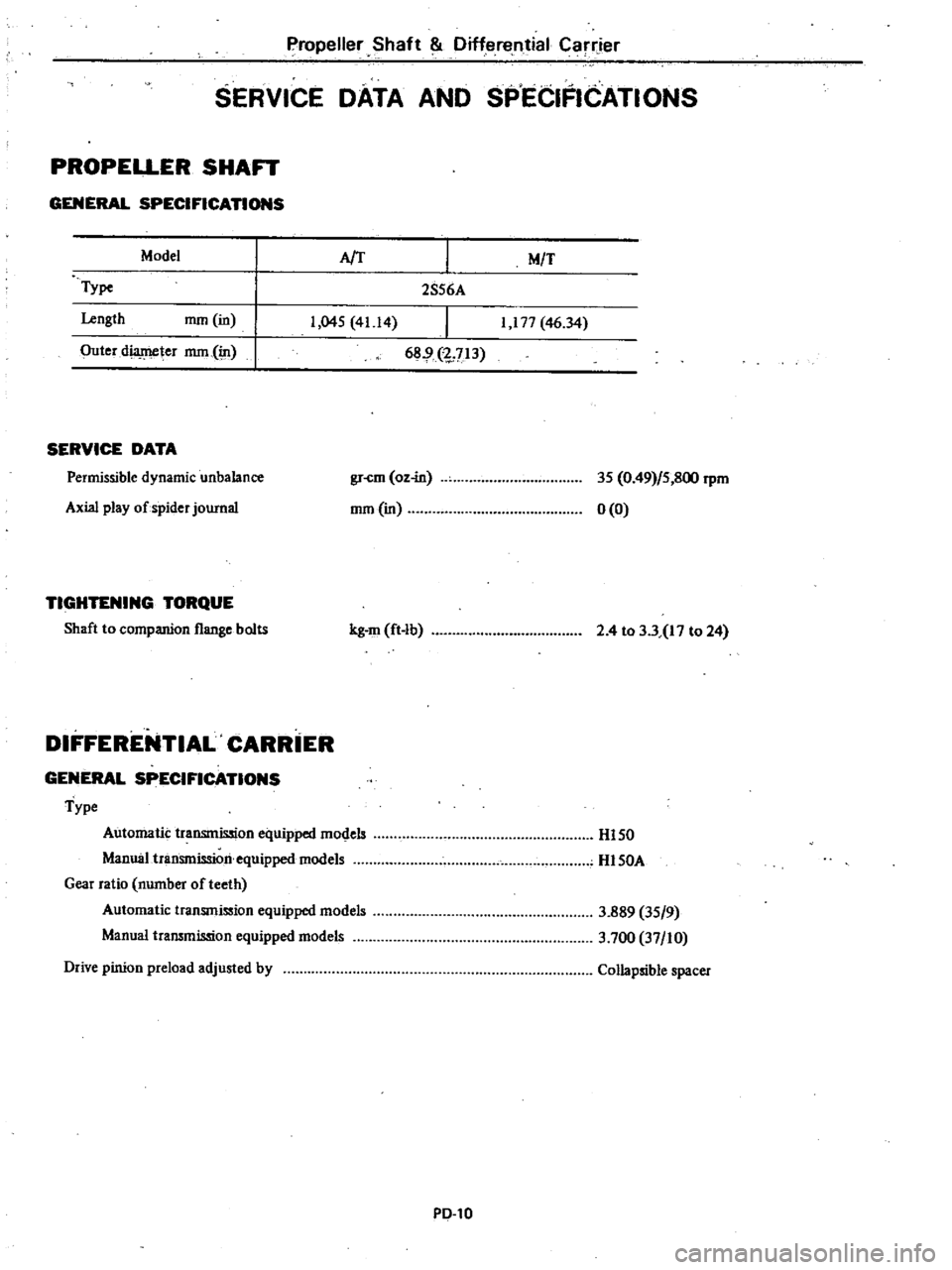

Propeller

Shaft

Diffe

ntial

Carrier

SERVICE

DATA

AND

SPECIFICATIONS

PROPEL1

ER

SHAFT

GENERAL

SPECIRCATIONS

Model

A

T

M

T

Type

Length

rnrn

in

2856A

1

045

4Ll4

1

177

46

34

68

1

713

Outer

dil

lluJ

er

rnrn

jn

SERVICE

DATA

Permissible

dynamic

unbalance

gr

cm

oz

in

rnrn

in

Axial

play

of

spider

journal

TIGHTENING

TORQUE

Shaft

to

companion

flange

bollS

kg

fil

ft

lb

DIFFERENTIAL

CARRiER

GENERAL

SPECIFICATIONS

Type

Automatic

transmission

equipped

models

Manual

transmission

equipped

models

Gear

ratio

number

of

teeth

Automatic

transmission

equipped

models

Manual

transmission

equipped

models

Drive

pinion

preload

adjusted

by

PO

tO

35

0

49

5

800

rpm

0

0

2

4

to

3

3l17

to

24

HI50

HI50A

3

889

35

9

3

700

37

10

Collapsible

spacer

Page 317 of 548

Propeller

Shaft

Differential

Carrier

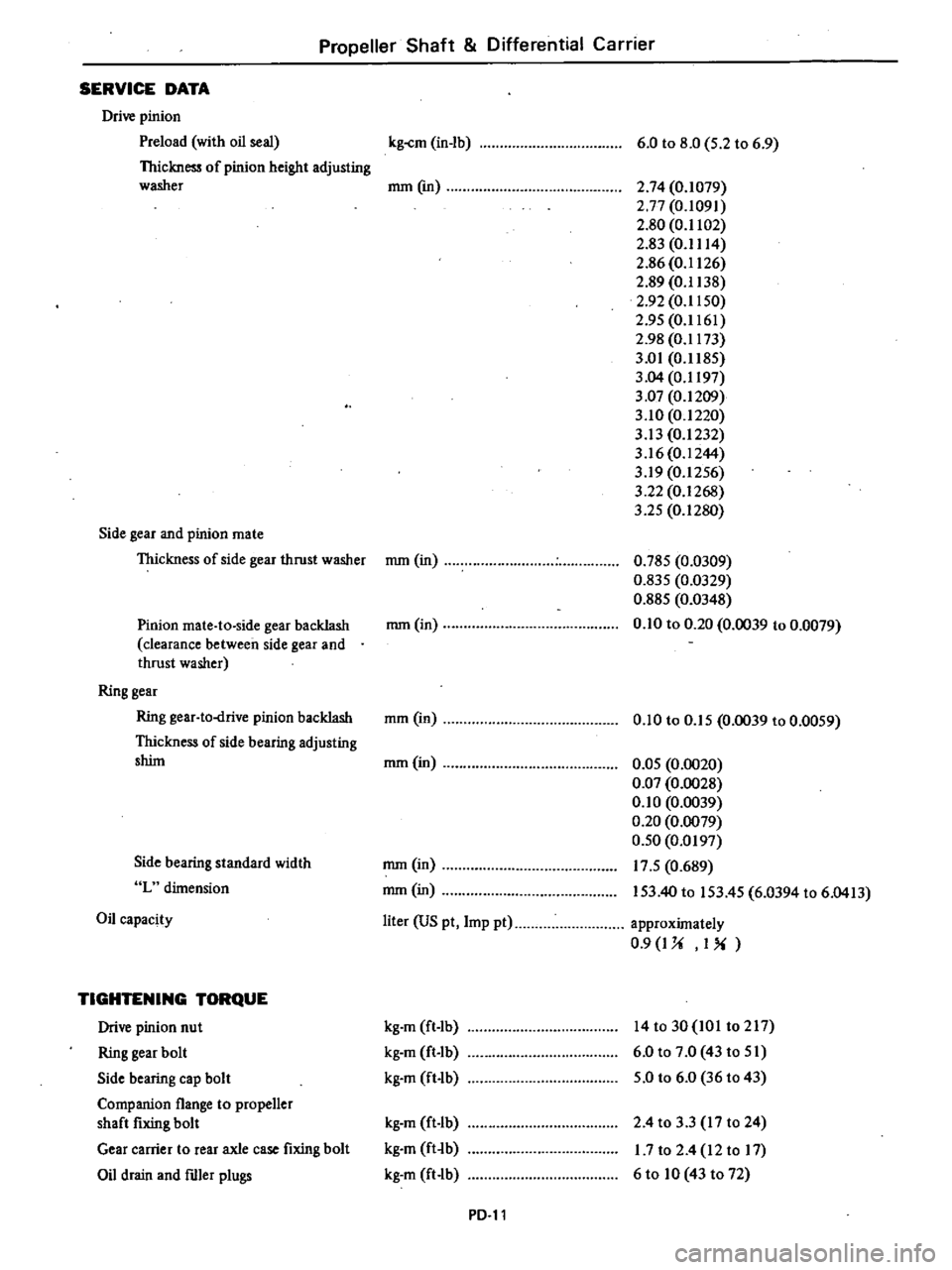

SERVICE

DATA

Drive

pinion

Preload

with

oil

seal

Thickness

of

pinion

height

adjusting

washer

Side

gear

and

pinion

mate

Thickness

of

side

gear

thrust

washer

Pinion

mate

to

side

gear

backlash

clearance

between

side

gear

and

thrust

washer

Ring

gear

Ring

gear

to

drive

pinion

backlash

Thickness

of

side

bearing

adjusting

shint

Side

bearing

standard

width

L

dimension

Oil

capacity

TIGHTENING

TORQUE

Drive

pinion

nut

Ring

gear

bolt

Side

bearing

cap

bolt

Companion

flange

to

propener

shaft

fixing

bolt

Gear

carrier

to

rear

axle

case

fixing

bolt

Oil

drain

and

ftller

plugs

kg

cm

in

lb

6

0

to

8

0

5

2

to

6

9

mm

em

2

74

0

1079

2

77

0

1091

2

80

0

1102

2

g3

0

1114

2

86

0

1126

2

89

0

1138

2

92

0

1150

2

95

0

1161

2

98

0

1173

3

01

0

1185

3

04

0

1197

3

07

0

1209

3

10

0

1220

3

13

0

1232

3

16

0

1244

3

19

0

1256

3

22

0

1268

3

25

0

1280

mm

in

0

785

0

0309

0

835

0

0329

0

885

0

0348

0

10

to

0

20

0

0039

to

0

0079

mmOn

mm

in

0

10

to

0

15

0

0039

to

0

0059

mm

in

0

05

0

0020

0

Q7

0

0028

0

10

0

0039

0

20

0

0079

0

50

0

0197

17

5

0

689

153

40

to

153

45

6

0394

to

6

0413

mm

in

mm

in

liter

US

pt

Imp

pt

approximately

0

9

I

U

I

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

lb

14to30

IOI

t0217

6

0

to

7

0

43

to

51

5

0

to

6

0

36

to

43

kg

m

ft

Ib

kg

m

ft

b

kg

m

ft

lb

2

4

to

3

3

17

to

24

1

7

to

2

4

12

to

17

6

to

10

43

to

72

PD

ll

Page 318 of 548

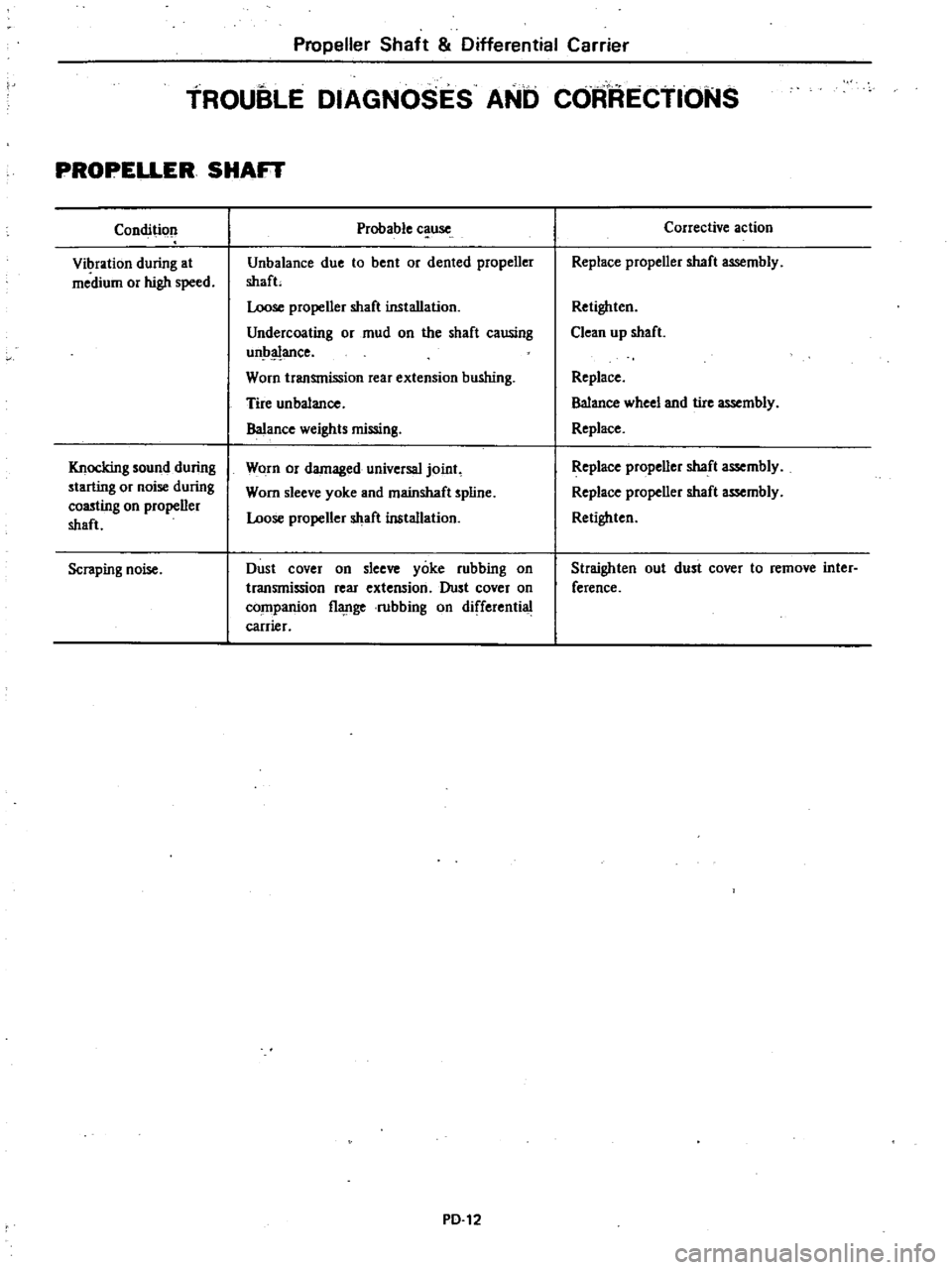

Propeller

Shaft

Differential

Carrier

TROUBLE

DIAGNOSES

AND

CORRECTIONS

PROPELLER

SHAFT

Condition

Vibration

during

at

medium

or

high

speed

Knocking

sound

during

starting

or

noise

during

coasting

on

propeller

shaft

Scraping

noise

Probable

cause

Unbalance

due

to

bent

or

dented

propeller

shafL

Loose

propeller

shaft

installation

Undercoating

or

mud

on

the

shaft

causing

unb

ance

Worn

transmission

rear

extension

bushing

Tire

unbalance

Balance

weights

missing

Worn

or

damaged

universal

joint

Worn

sleeve

yoke

and

meinshaft

spline

Loose

propeller

shaft

installation

Dust

cover

on

sleeve

yoke

rubbing

on

transmission

rear

extension

Dust

cover

on

companion

flange

rubbing

on

differential

carrier

PD

12

Corrective

action

Replace

propener

shaft

assembly

Retighten

Clean

up

shaft

Replace

Balance

wheel

and

tire

assembly

Replace

Replace

propeller

shaft

assembly

Replace

propeller

shaft

assembly

Retighten

Straighten

out

dust

cover

to

remove

inter

ference

Page 319 of 548

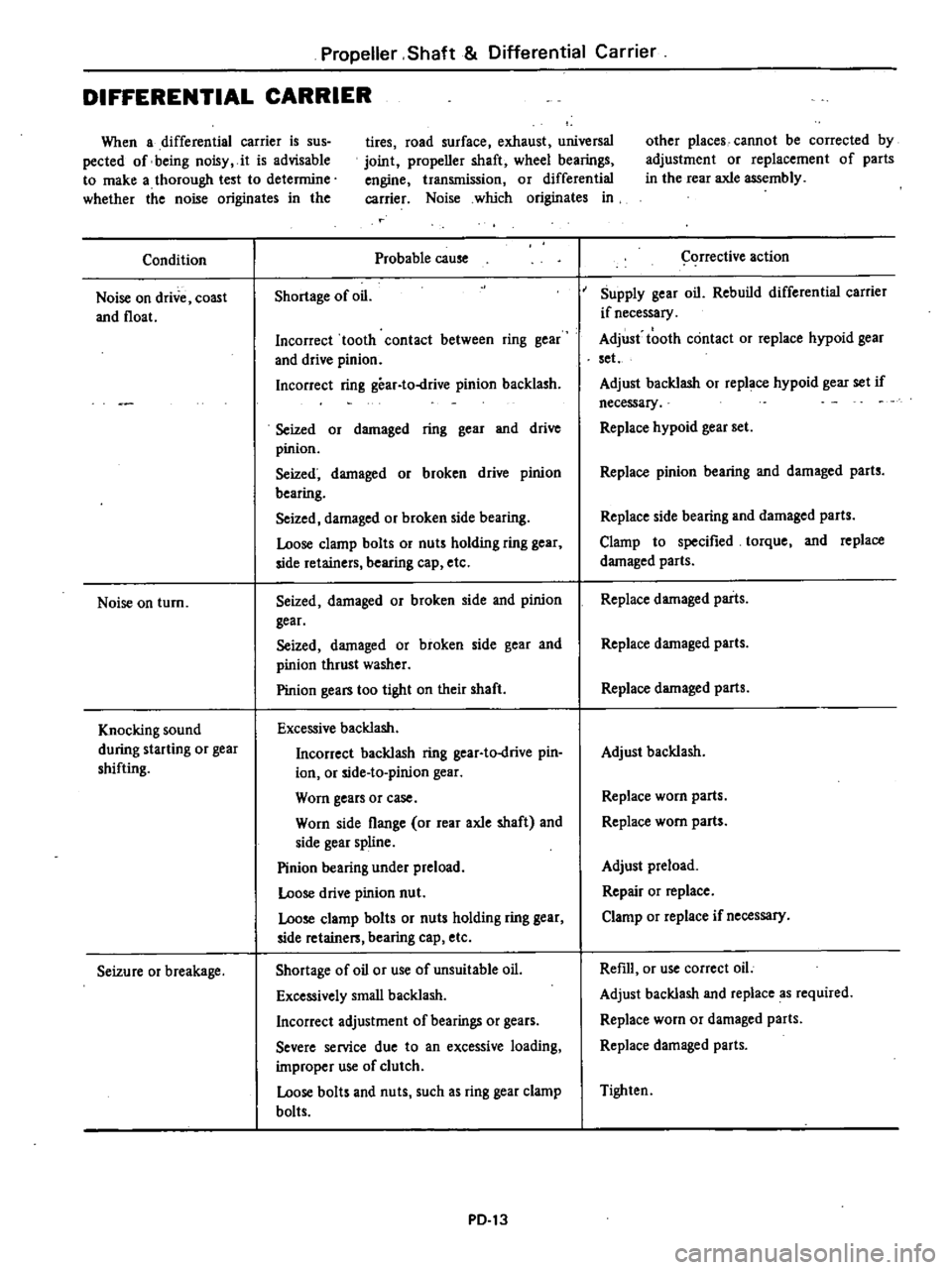

Propeller

Shaft

Differential

Carrier

DIFFERENTIAL

CARRIER

When

a

differential

carrier

is

sus

pected

of

being

noisy

it

is

advisable

to

make

a

thorough

test

to

determine

whether

the

noise

originates

in

the

tires

road

surface

exhaust

universal

joint

propeller

shaft

wheel

bearings

engine

transmission

or

differential

carrier

Noise

which

originates

in

Condition

Noise

on

drive

coast

and

float

Noise

on

turn

Knocking

sound

during

starting

or

gear

shifting

Seizure

or

breakage

Probable

cause

Shortage

of

oil

Incorrect

tooth

contact

between

ring

gear

and

drive

pinion

Incorrect

ring

gear

to

drive

pinion

backlash

Seized

or

damaged

ring

gear

and

drive

pinion

Seized

damaged

or

broken

drive

pinion

bearing

Seized

damaged

or

broken

side

bearing

Loose

clamp

bolts

or

nuts

holding

ring

gear

side

retainers

bearing

cap

etc

Seized

damaged

or

broken

side

and

pinion

gear

Seized

damaged

or

broken

side

gear

and

pinion

thrust

washer

Pinion

gears

too

tight

on

their

shaft

Excessive

backlash

Incorrect

backlash

ring

gear

to

drive

pin

ion

or

side

ta

pinion

gear

Worn

gears

or

case

Worn

side

flange

or

rear

axle

shaft

and

side

gear

spline

Pinion

bearing

under

preload

Loose

drive

pinion

nut

Loose

clamp

bolts

or

nuts

holding

ring

gear

side

retainers

bearing

cap

etc

Shortage

of

oil

or

use

of

unsuitable

oil

Excessively

small

backlash

Incorrect

adjustment

of

bearings

or

gears

Severe

service

due

to

an

excessive

loading

improper

use

of

clutch

Loose

bolts

and

nuts

such

as

ring

gear

clamp

bolts

PD

13

other

places

cannot

be

corrected

by

adjustment

or

replacement

of

parts

in

the

rear

axle

assembly

orrective

action

Supply

gear

oil

Rebuild

differential

carrier

if

necessary

Adjust

tooth

contact

or

replace

hypoid

gear

set

Adjust

backlash

or

replace

hypoid

gear

set

if

necessary

Replace

hypoid

gear

set

Replace

pinion

bearing

and

damaged

parts

Replace

side

bearing

and

damaged

parts

Clamp

to

specified

torque

and

replace

damaged

parts

Replace

damaged

parts

Replace

damaged

parts

Replace

damaged

parts

Adjust

backlash

Replace

worn

parts

Replace

worn

parts

Adjust

preload

Repair

or

replace

Clamp

or

replace

if

necessary

Refill

or

use

correct

oil

Adjust

backlash

and

replace

as

required

Replace

worn

or

damaged

parts

Replace

damaged

parts

Tighten