washer fluid DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 285 of 548

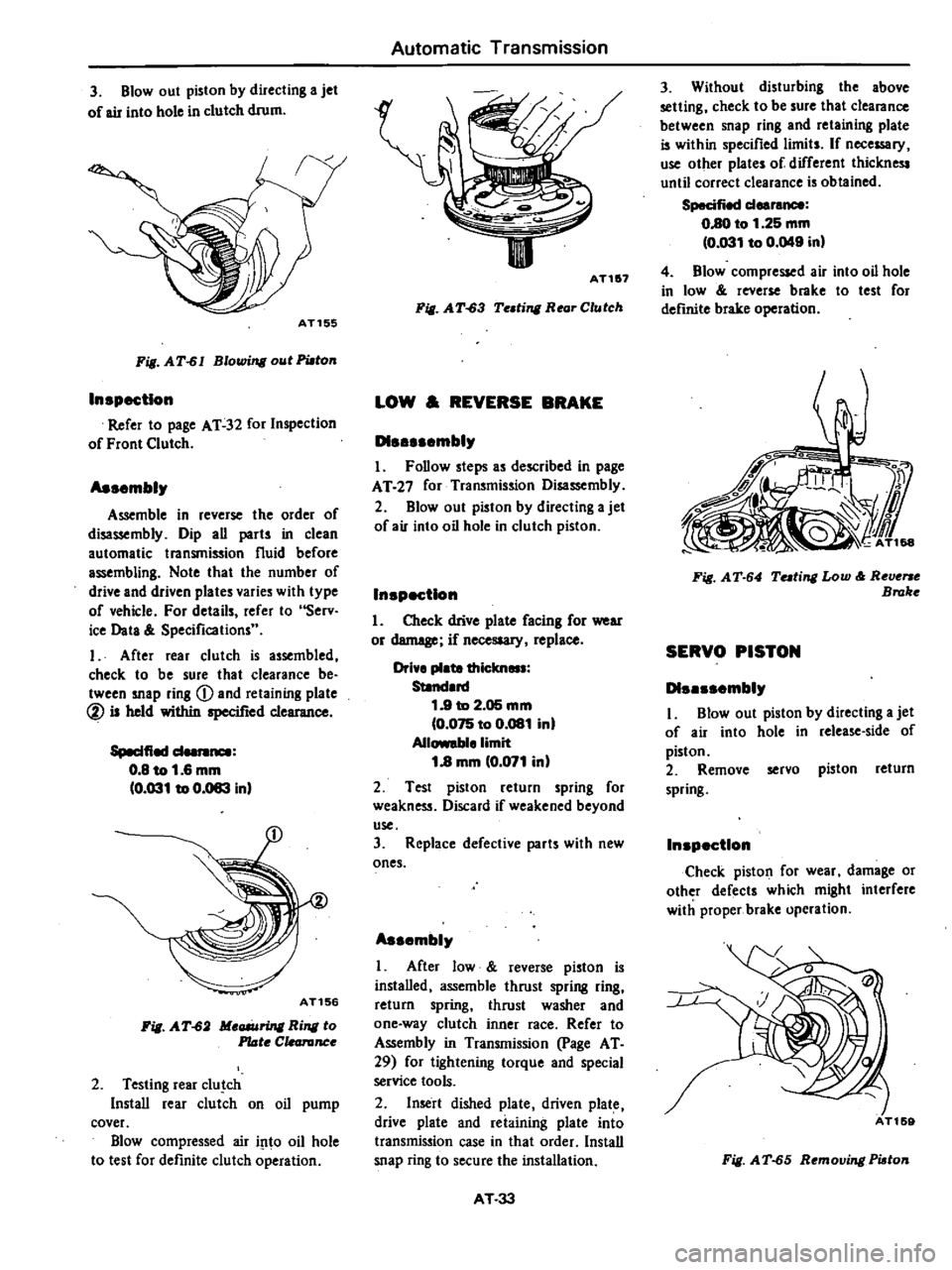

3

Blowout

piston

by

directing

a

jet

of

air

into

hole

in

clutch

drum

AT155

Fig

AT

61

Blowing

out

PWton

In

pectlon

Refer

to

page

AT

32

for

Inspection

of

Front

Clutch

As

mbly

Assemble

in

reverse

the

order

of

disassembly

Dip

all

parts

in

clean

automatic

transmission

fluid

before

assembling

Note

that

the

number

of

drive

and

driven

plates

varies

with

type

of

vehicle

For

details

refer

to

Serv

ice

Data

Specifications

I

After

rear

clutch

is

assembled

check

to

be

sure

that

clearance

be

tween

snap

ring

Q

and

retaining

plate

@

is

held

within

specified

clearance

Speelfied

d

0

8

to

1

6

mm

0

031

to

0

083

inl

AT156

Fig

AT

62

Meaiuring

Ring

to

Plate

C

canInce

2

Testing

rear

c1u

ch

Install

rear

clutch

on

oil

pump

cover

Blow

compressed

air

i

1to

oil

hole

to

test

for

definite

clutch

operation

Automatic

Transmission

II

AT1

7

Fill

A

T

63

Te

ting

Rear

Clutch

LOW

REVERSE

BRAKE

D1

mbly

I

Follow

steps

as

described

in

page

AT

27

for

Transmission

Disassembly

2

Blowout

piston

by

directing

a

jet

of

air

into

oil

hole

in

clutch

piston

In

pectlon

1

Check

drive

plate

facing

for

wear

or

demege

if

necesaary

replace

Drive

plate

thielm

Standard

1

9

to

2

05

mm

0

075

to

0

081

in

Allowable

limit

1

8

mm

0

071

inl

2

Test

piston

return

spring

for

weakness

Discard

if

weakened

beyond

use

3

Replace

defective

parts

with

new

ones

As

mbly

I

After

low

reverse

piston

is

installed

assemble

thrust

spring

ring

return

spring

thrust

washer

and

one

way

clutch

inner

race

Refer

to

Assembly

in

Transmission

page

AT

29

for

tightening

torque

and

special

service

tools

2

Insert

dished

plate

driven

plate

drive

plate

and

reiaining

plate

into

transmission

case

in

that

order

Install

snap

ring

to

secure

the

installation

AT

33

3

Without

disturbing

the

above

setting

check

to

be

sure

that

clearance

between

snap

ring

and

retaining

plate

is

within

specified

limits

If

nece

ry

use

other

plates

of

different

thickness

until

correct

clearance

is

obtained

Specified

deereM8

0

80

to

1

25

mm

0

031

to

0

049

inl

4

Blow

compressed

air

into

oil

hole

in

low

roverse

brake

to

test

for

deftnite

brake

operation

Fill

AT

64

Tuting

Low

Reverse

Broke

SERVO

PISTON

D1

mbly

I

Blowout

piston

by

dilecting

a

jet

of

air

into

hole

in

release

side

of

piston

2

Remove

servo

piston

return

spring

In

p

ctlon

Check

piston

for

wear

damage

or

other

defects

which

might

interfere

with

proper

brake

opcration

Fig

AT

65

Removing

Piaton

Page 287 of 548

Fig

AT

70

MeG6Uring

Clearonce

Clearance

between

seal

ring

and

ring

groove

Stendard

0

04

to

0

16

mm

10

002

to

0

006

in

I

31earance

Seal

ring

w

I

J

7

r

11

AT1

5

II

Fig

AT

71

MeG6Uring

Clearance

As

mblr

L

Set

up

pump

housing

with

inner

and

outer

pump

gears

on

it

2

Using

Oil

Pump

Assembling

Gauge

ST2SS80001

instan

pump

cover

to

pump

houaing

AT166

Fig

AT

72

Centering

Oil

Pump

3

Temporarily

tighten

pump

secur

ing

bolts

4

Set

the

cunout

of

oil

pump

cover

within

specified

total

indicator

read

ing

Automatic

Transmission

Total

indicator

reading

Lell

than

0

07

mm

10

0028

inl

ST2SSBOOOl

AT264

Fig

AT

73

Me

ring

Runout

S

Tighten

pump

securing

bolts

to

specified

torque

r

Tightening

torque

Oil

pump

housing

to

oil

pump

cover

0

6

to

0

8

kg

m

14

3

to

5

8

ft

Ibl

Note

Be

sure

to

align

con

ter

housini

securing

bolt

holes

6

Again

check

the

runout

of

oil

pump

cover

Note

When

former

Oil

Pump

As

sembling

Gauge

is

to

be

used

make

a

screw

hole

in

side

of

it

PLANETARY

CARRIER

The

planetary

carrier

cannot

be

divided

into

its

individual

components

If

any

part

of

component

is

defec

tive

replace

the

carrier

as

a

unit

In

p

ctlon

Check

clearance

between

pinion

washer

and

planetary

carrier

with

a

feeler

Standard

d

0

20

to

0

70

mm

0

008

to

0

028

in

AT

35

uan

r

J

II

I

AT1S7

Fig

AT

74

MeG6Uring

Pinion

Waaher

to

CanUr

Clearance

Replace

if

over

0

80

mm

0

031

in

CONTROL

VALVE

Tlte

control

valve

assembly

consists

of

many

precision

parts

and

requires

extreme

care

when

it

has

to

be

re

moved

and

serviced

It

is

good

practice

to

place

parts

in

a

part

rack

so

that

they

can

be

reassembled

in

valve

body

in

their

proper

positions

Added

care

should

also

be

exercised

to

prevent

springs

and

other

small

parts

from

being

sca

ttered

and

lost

Before

assembly

dip

all

parts

in

clean

automatic

transmission

fluid

and

check

to

be

certain

that

they

are

free

of

lint

and

other

minute

particles

If

clutch

or

band

is

burnt

or

if

oil

becomes

fouled

the

control

valve

as

sembly

should

be

disassembled

and

flushed

DI

mblr

I

Remove

bolts

and

nuts

which

retain

oil

strainer

Bolts

may

be

re

moved

with

a

screwdriver

but

it

is

recommended

that

Hexagon

Wrench

lIT61000S00

and

Spinner

Handle

lIT623S0000

b

used

Page 463 of 548

CAUTION

a

Be

sure

to

use

only

windshield

washing

solution

Never

mix

soap

powder

or

deter

gent

with

solution

b

To

avoid

improper

windshield

washer

operation

do

not

operate

windshield

washer

continuously

for

more

than

30

seconds

or

without

washer

fluid

Normally

windshield

washer

should

be

operated

for

10

seconds

or

less

at

one

time

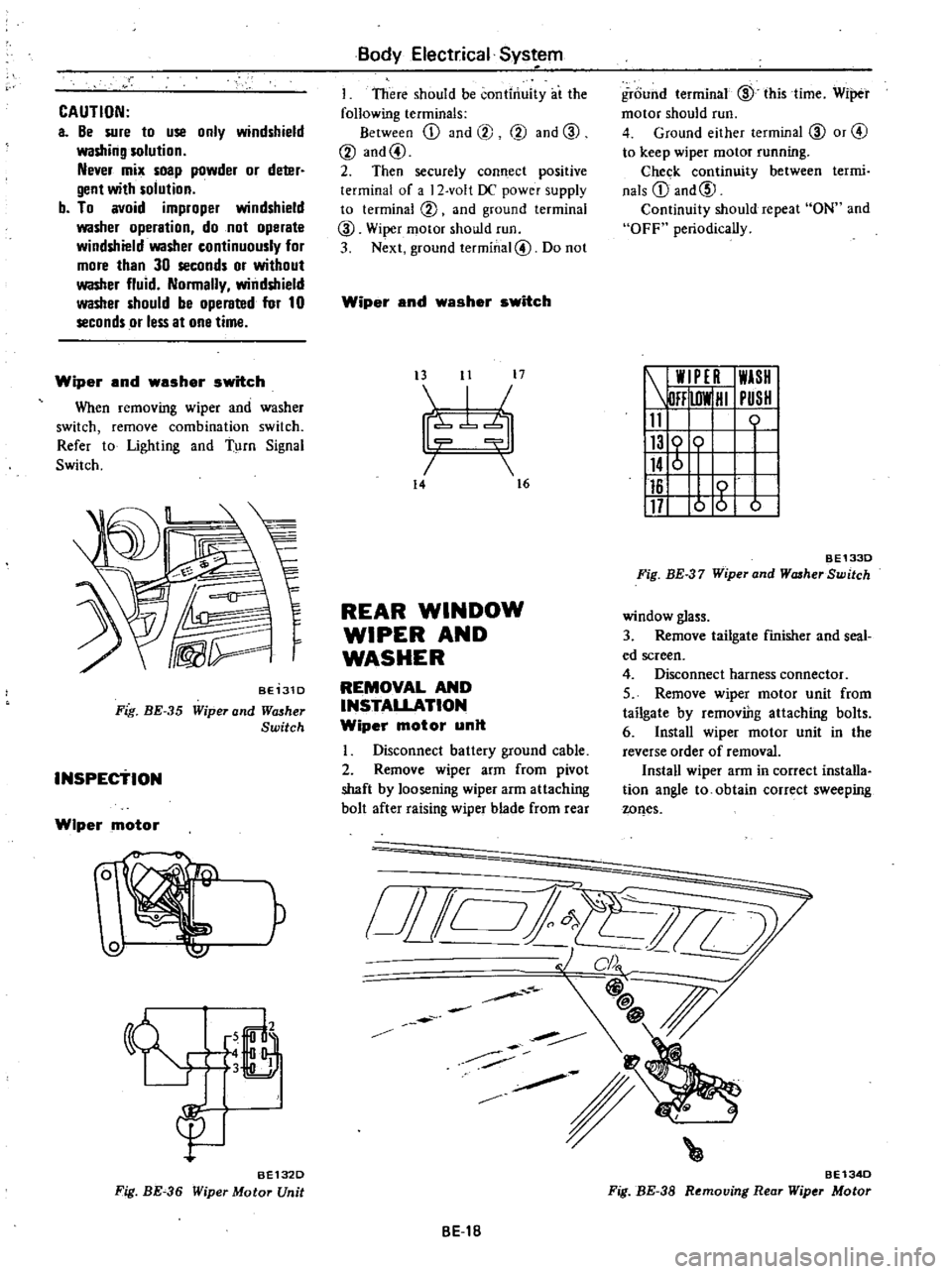

Wiper

and

washer

switch

When

removing

wiper

and

washer

switch

remove

combination

switch

Refer

to

Lighting

and

Turn

Signal

Switch

BE131D

Fig

BE

35

Wiper

and

Wll5her

Switch

INSPEctiON

Wiper

motor

W

P

6

LJ

3

B

gu

BE132D

Fig

BE

36

Wiper

Motor

Unit

Body

Electrical

Sys

em

I

There

should

be

continuity

at

the

following

terminals

Between

ill

and

@

@

and

CID

@

and@

2

Then

securely

connect

positive

terminal

of

a

2

volt

DC

power

supply

to

terminal

@

and

ground

terminal

CID

Wiper

motor

should

run

3

Next

ground

terminal@

Do

not

Wiper

and

washer

switch

t3

11

17

I

7b

14

16

REAR

WINDOW

WIPER

AND

WASHER

REMOVAL

AND

INSTALLATION

Wiper

motor

unit

Disconnect

battery

ground

cable

2

Remove

wiper

arm

from

pivot

shaft

by

loosening

wiper

arm

attaching

bolt

after

raising

wiper

blade

from

rear

o

i

Jill

BE1B

ground

terminal

CID

this

time

Wiper

motor

should

run

4

Ground

either

terminal

CID

or

@

to

keep

wiper

motor

running

Chec

k

continuity

between

termi

nals

ill

and@

Continuity

should

repeat

ON

and

OFF

periodically

W

PE

I

WASH

DFF

lOW

HI

PUSH

11

0

116

117

o

g

b

BE1330

Fig

BE

37

Wiper

and

WcuherSwitch

window

glass

3

Remove

tailgate

finisher

and

seal

ed

screen

4

Disconnect

harness

connector

5

Remove

wiper

motor

unit

from

tailgate

by

removiDg

attaching

bolts

6

Install

wiper

motor

unit

in

the

reverse

order

of

removal

Install

wiper

arm

in

correct

installa

tion

angle

to

obtain

correct

sweeping

wQes

BE134D

Fig

BE

38

Removing

Rear

Wiper

Motor

Page 498 of 548

Body

Electrical

System

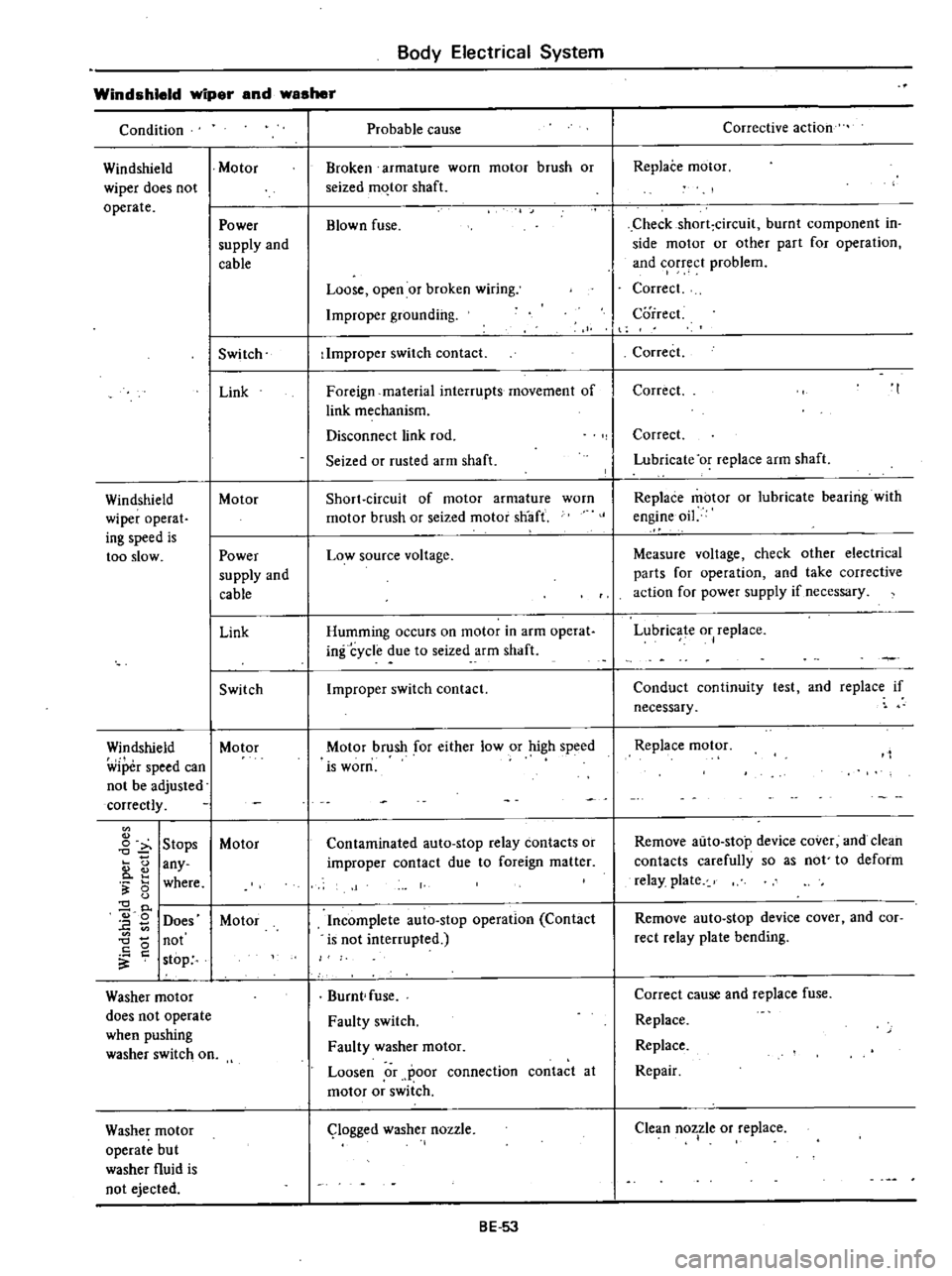

Condition

Windshield

wiper

and

washer

Probable

cause

Windshield

Motor

wiper

does

not

operate

Windshield

wiper

operat

ing

speed

is

too

slow

Power

supply

and

cable

Switch

Link

Motor

Power

supply

and

cable

Link

Switch

Windshield

Motor

wiper

speed

can

not

be

adjusted

correctly

o

o

fi

5

2

0

E

0

0

Stops

any

where

Does

not

stop

Washer

motor

does

not

operate

when

pushing

washer

switch

on

Washer

motor

operate

bu

t

washer

fluid

is

not

ejected

Motor

Motor

Broken

armature

worn

motor

brush

or

seized

m

tor

shaft

Blown

fuse

Loose

open

or

broken

wiring

Improper

grounding

Improper

switch

contact

Foreign

material

interrupts

movement

of

link

mechanism

Disconnect

link

rod

Seized

or

rusted

arm

shaft

Short

circuit

of

motor

armature

worn

motor

brush

or

seized

motor

snaft

Low

source

voltage

Humming

occurs

on

motor

in

arm

operat

infcycle

due

to

seized

arm

shaft

Improper

switch

contact

Motor

brush

for

either

low

or

high

speed

is

worn

Contaminated

auto

stop

relay

contacts

or

improper

contact

due

to

foreign

matter

Incomplete

auto

stop

operation

Contact

is

not

interrupted

Burnt

fuse

Faulty

switch

Faulty

washer

motor

Loosen

or

poor

connection

contact

at

motor

or

switch

logged

washer

nozzle

BE

53

Corrective

action

Replace

motor

Checkshort

circuit

burnt

component

in

side

motor

or

other

part

for

operation

and

corr

ct

problem

Correct

Correct

I

t

Correct

Correct

Correct

Lubricate

or

replace

arm

shaft

Replace

motor

or

lubricate

bearing

with

engine

oil

Measure

voltage

check

other

electrical

parts

for

operation

and

take

corrective

action

for

power

supply

if

necessary

Lubricate

or

replace

Conduct

continuity

test

and

replace

if

necessary

Replace

motor

Remove

auto

stop

device

cover

and

clean

contacts

carefully

so

as

not

to

deform

relay

plate

Remove

auto

stop

device

cover

and

cor

rect

relay

plate

bending

Correct

cause

and

replace

fuse

Replace

Replace

Repair

Clean

nozzle

or

replace

I