DATSUN 510 1968 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 171 of 252

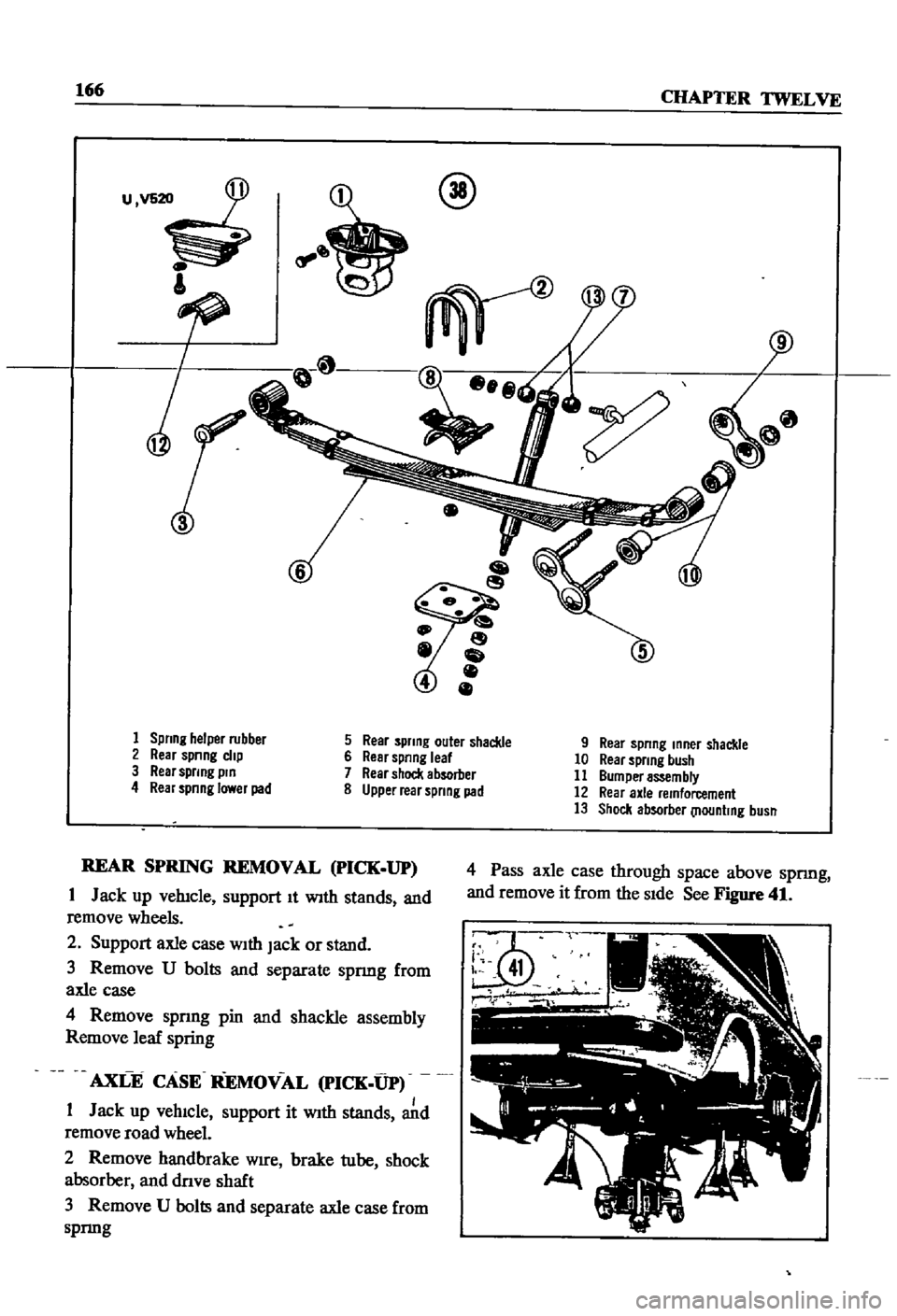

166

CHAPTER

TWELVE

u

@

1

Spring

helper

rubber

5

Rear

spring

outer

shackle

9

Rear

spring

mner

shackle

2

Rear

spnng

clip

6

Rear

spring

leaf

10

Rear

spring

bush

3

Rear

sprmg

pm

7

Rear

shock

absorber

11

Bumper

assembly

4

Rear

spnnglawerpad

8

Upper

rear

spring

pad

12

Rear

axle

remforcement

13

Shock

absorber

llountmg

busn

REAR

SPRING

REMOVAL

pICK

UP

1

Jack

up

vehicle

support

It

With

stands

and

remove

wheels

2

Support

axle

case

With

Jack

or

stand

3

Remove

U

bolts

and

separate

spnng

from

axle

case

4

Remove

spnng

pin

and

shackle

assembly

Remove

leaf

spring

AXLE

CASE

REMOVAL

PICK

UP

1

Jack

up

vehIcle

support

it

With

stands

Jd

remove

road

wheel

2

Remove

handbrake

Wire

brake

tube

shock

absorber

and

dnve

shaft

3

Remove

U

bolts

and

separate

axle

case

from

spnng

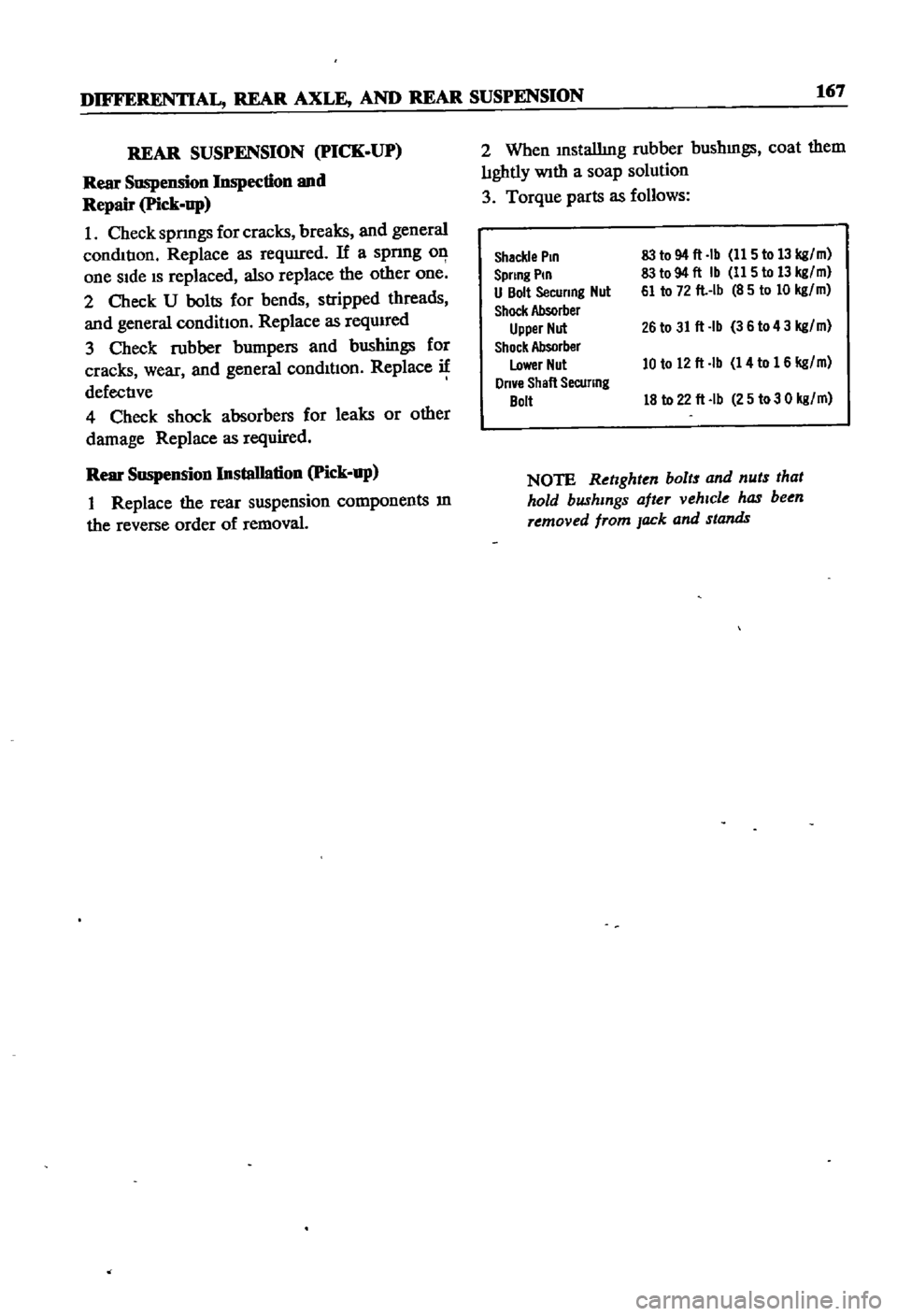

4

Pass

axle

case

through

space

above

spnng

and

remove

it

from

the

SIde

See

Figure

41

Page 172 of 252

DIFFERENTIAL

REAR

AXLE

AND

REAR

SUSPENSION

167

REAR

SUSPENSION

pICK

UP

Rear

Suspension

Inspection

nnd

Repair

Pick

up

1

Check

spnngs

for

cracks

breaks

and

general

conditIon

Replace

as

reqwred

If

a

spnng

on

one

Side

IS

replaced

also

replace

the

other

one

2

Check

U

bolts

for

bends

stripped

threads

and

general

conditIon

Replace

as

reqUIred

3

Check

rubber

bumpers

and

bushings

for

cracks

wear

and

general

condll1on

Replace

if

defecl1ve

4

Check

shock

absorbers

for

leaks

or

other

damage

Replace

as

required

Rear

Suspension

Installation

Pick

up

1

Replace

the

rear

suspension

components

m

the

reverse

order

of

removal

2

When

msta11mg

rubber

bushmgs

coat

them

hghtly

With

a

soap

solution

3

Torque

parts

as

follows

Shackle

Pin

Spnng

Pm

U

Bolt

Secunng

Nut

Shock

Absorber

Upper

Nut

Shock

Absorber

Lower

Nut

Dnve

Shalt

Secunng

Bolt

83

to

94

It

Ib

11

5

to

13

kg

m

83

to

94

It

Ib

115

to

13

kg

m

61

to

72

ItAb

85

to

10

kg

m

26

to

31

It

Ib

36

t04

3

kg

m

10

to

12

ft

Ib

1

4

to

1

6

kg

m

18

to

22

ft

Ib

25

to

30

kg

m

NOTE

Retighten

bolts

and

nuts

that

hold

bushmgs

after

vehicle

has

been

removed

from

Jack

and

stands

Page 173 of 252

CHAPTER

THIRTEEN

FRONT

AXLE

FRONT

SUSPENSION

AND

STEERING

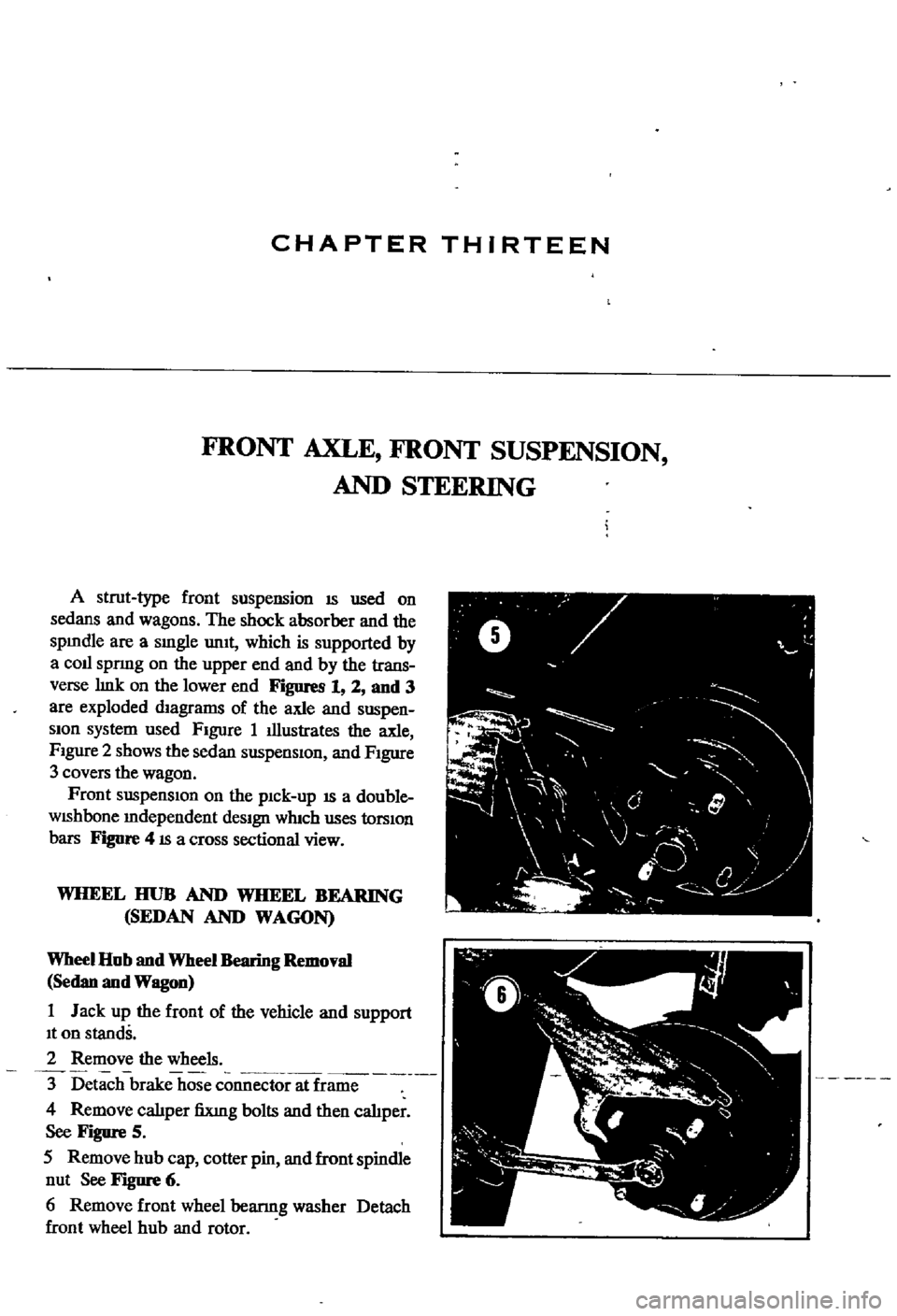

A

strut

type

front

suspension

IS

used

on

sedans

and

wagons

The

shock

absorber

and

the

spmdle

are

a

smgle

urnt

which

is

supported

by

a

coIl

spnng

on

the

upper

end

and

by

the

trans

verse

lInk

on

the

lower

end

Figures

1

2

nnd

3

are

exploded

dIagrams

of

the

axle

and

suspen

SIon

system

used

FIgure

1

Illustrates

the

axle

Figure

2

shows

the

sedan

suspenSlOn

and

FIgure

3

covers

the

wagon

Front

suspensIOn

on

the

pIck

up

IS

a

double

wIShbone

mdependent

deSign

which

uses

torsIon

bars

Figure

4

IS

a

cross

sectional

view

WHEEL

HUB

AND

WHEEL

BEARING

SEDAN

AND

WAGON

Wheel

Hub

nnd

Wheel

Bearing

Removal

Sednn

aud

Wagon

1

Jack

up

the

front

of

the

vehicle

and

support

It

on

stands

2

Remove

the

wheels

3

Detach

brake

hose

connector

at

frame

4

Remove

calIper

fiXlng

bolts

and

then

cahper

See

Figure

5

5

Remove

hub

cap

cotter

pin

and

front

spindle

nut

See

Figure

6

6

Remove

front

wheel

bearmg

washer

Detach

front

wheel

hub

and

rotor

ft

V

0

y

F

I

I

J

j

0

l

l

4

f

Page 174 of 252

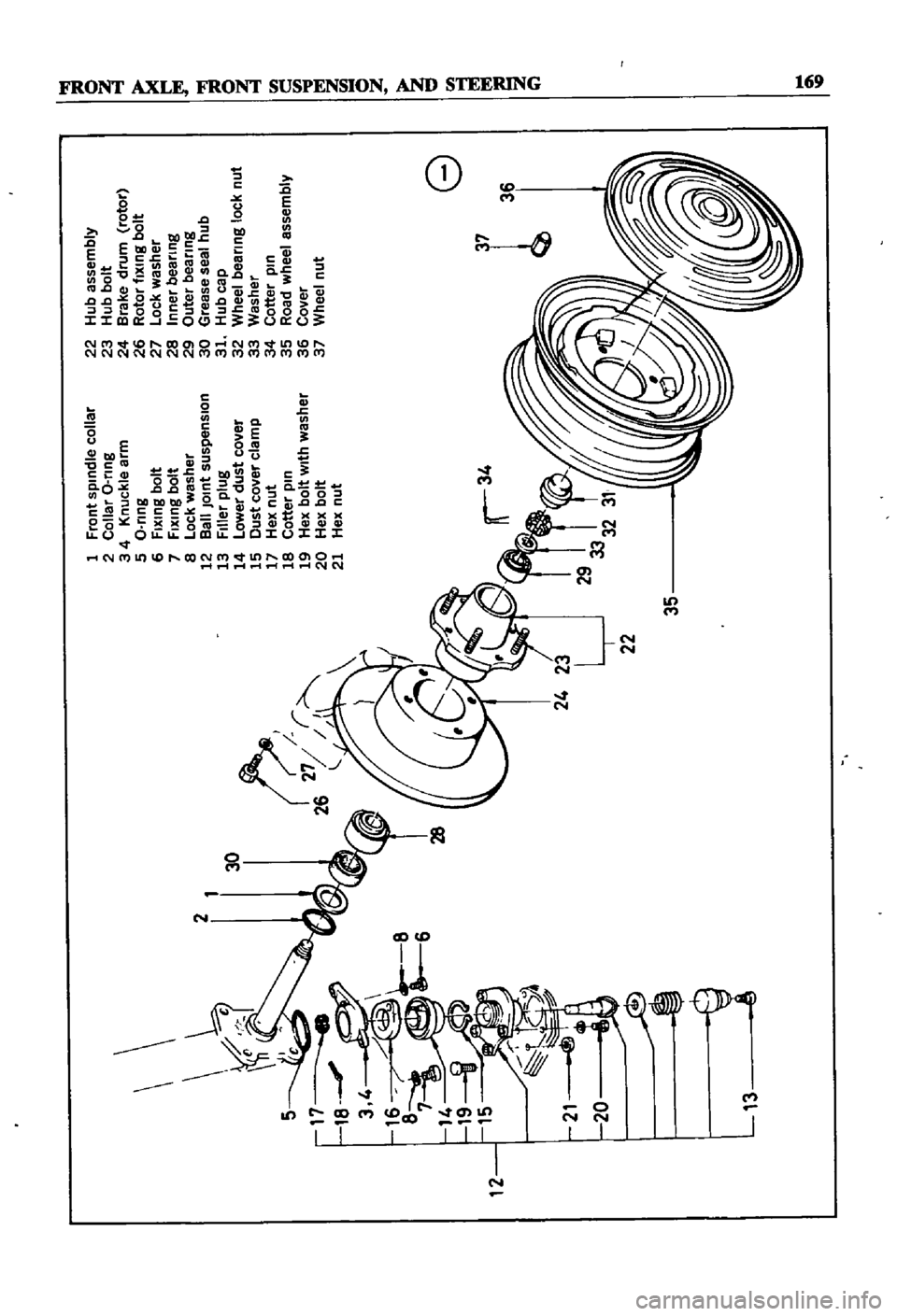

1

frollt

spllldle

collar

2

Collar

O

flllg

3

4

l

lIllcl

e

artn

5

O

flIIS

6

fllllllg

bolt

7

fllllllg

bolt

8

Ocl

washer

12

aalllo1llt

SIlSpellSIOIl

13

fIller

pIllS

14

Lower

dllst

cover

15

OIlSt

cover

clatnP

17

Iellllut

18

cotter

pIli

19

ell

bolt

with

washer

20

ell

bolt

21

Iellllllt

22

ub

assetnbly

23

Iub

bOlt

24

ara

e

drutn

rotor

26

Rotor

illllllS

bOlt

27

LOC

washer

28

IlIlIer

beaflllS

29

outer

beaflnS

30

Grease

seal

hub

31

Iubcap

32

Wheel

beaflnS

10C

nut

33

Washer

34

cotter

pili

35

Road

wheel

assetnbIV

36

cover

37

Wheel

nut

11

Page 175 of 252

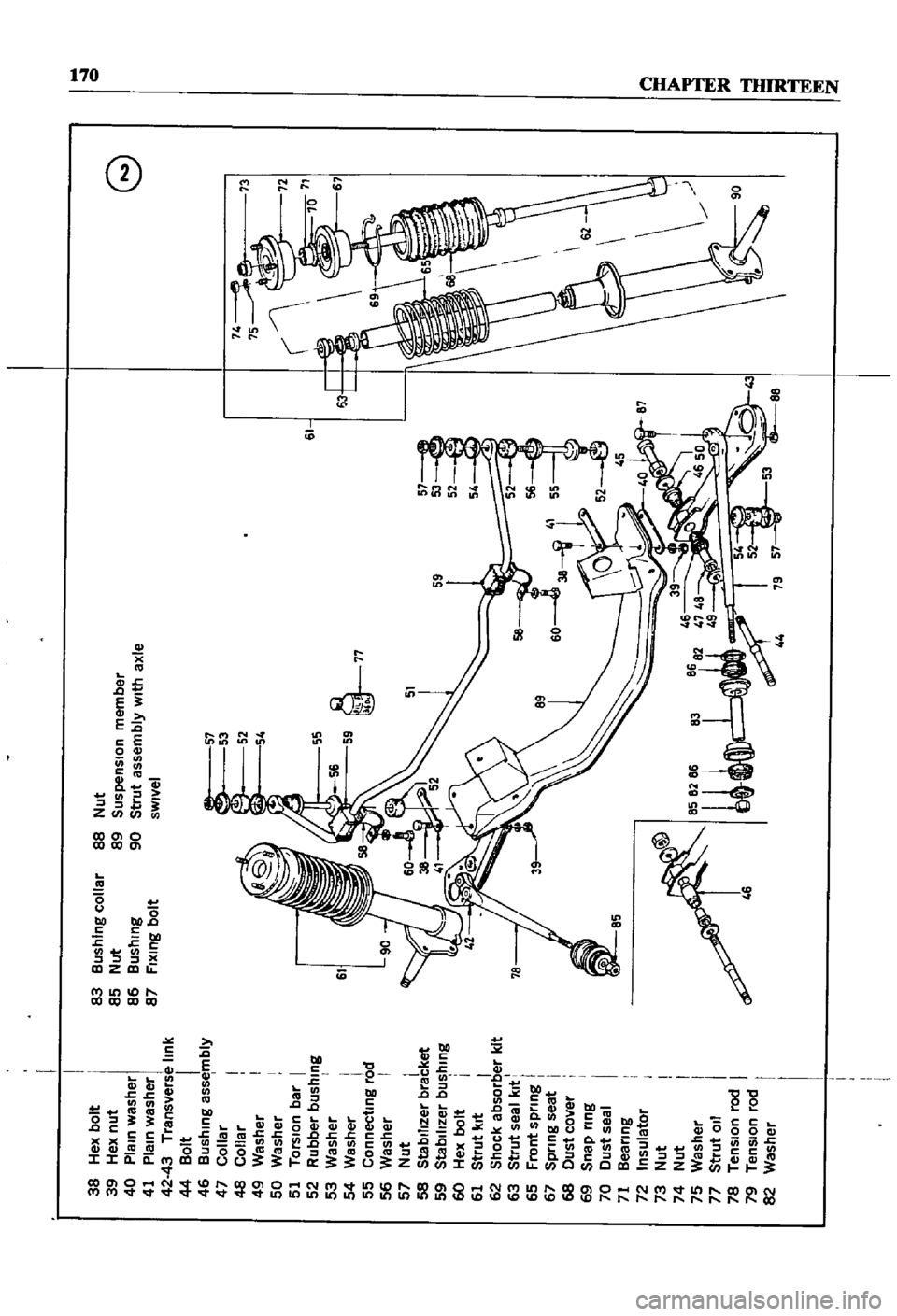

38

Hex

bolt

39

Hex

nut

40

Plain

washer

41

Plain

washer

42

43

Transverse

link

44

Bolt

I

46

Bushing

assembly

47

Collar

48

Collar

49

Washer

50

Washer

51

Torsion

bar

I

52

Rubber

bushing

53

Washer

I

54

Washer

55

Connecting

rod

56

Washer

I

57

Nut

i

58

Stabilizer

bracket

59

StabIlizer

bushing

60

Hex

bolt

i

61

Strut

kit

I

62

Shock

absorber

kit

63

Strut

sea

I

kit

I

65

Front

spnng

67

Spnng

seat

i

68

Dust

cover

69

Snap

rrng

I

70

Dust

seal

71

Bearing

72

Insulator

73

Nut

74

Nut

75

Washer

77

Strut

011

78

Tension

rod

79

Tension

rod

82

Washer

83

BushIng

collar

85

Nut

86

Bushing

87

FIxing

bolt

88

Nut

89

Suspension

member

90

Strut

assembly

with

axle

sWivel

0

61

61

55

59

11

63

46

8682

41

48

8S82

49

U

I

9

a

r

I

I

Page 176 of 252

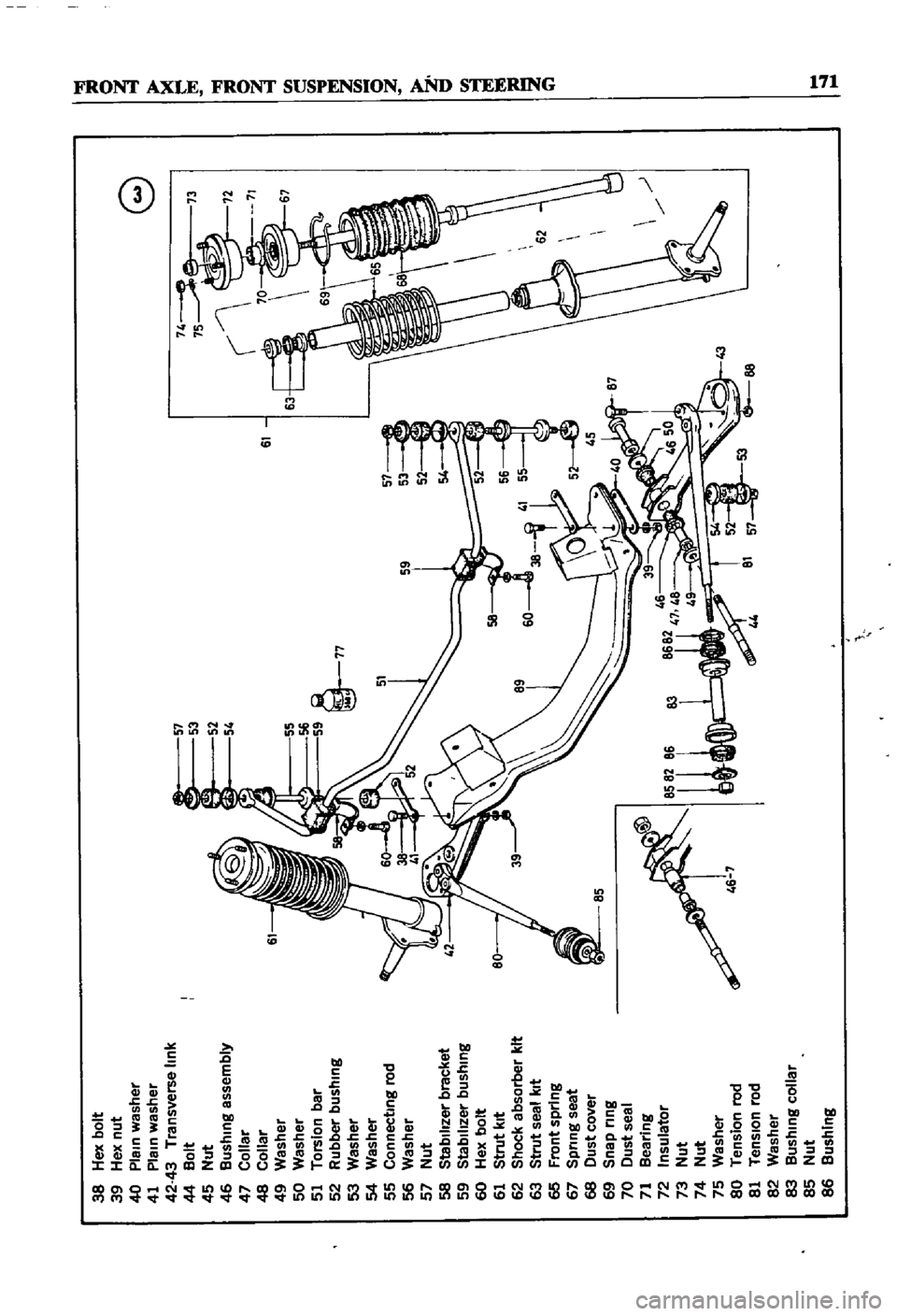

38

Hex

bolt

39

Hex

nut

40

Plain

washer

41

Plain

washer

42

43

Transverse

link

44

Bolt

45

Nut

46

Bushing

assembly

47

Collar

48

Collar

49

Washer

50

Washer

51

Torsion

bar

52

Rubber

bushing

53

Washer

54

Washer

55

Connecting

rod

56

Washer

57

Nut

58

Stabilizer

bracket

59

Stabilizer

bushing

60

Hex

bolt

61

Strut

kit

62

Shock

absorber

kit

63

Strut

seal

kit

65

Front

spring

67

Spnng

seat

68

Dust

cover

69

Snap

ring

70

Dust

seal

71

Bearing

72

Insulator

73

Nut

74

Nut

75

Washer

80

Tension

rod

81

TenSion

rod

82

Washer

83

Bushing

collar

85

Nut

86

Bushing

0

G

57

53

l

Fl

52

72

l

54

61

55

63

67

rI

l

56

c

l

59

rI

l

77

rI

l

51

57

59

53

46

8682

47

48

u

Page 177 of 252

17

CHAPTER

THIRTEEN

CD

7

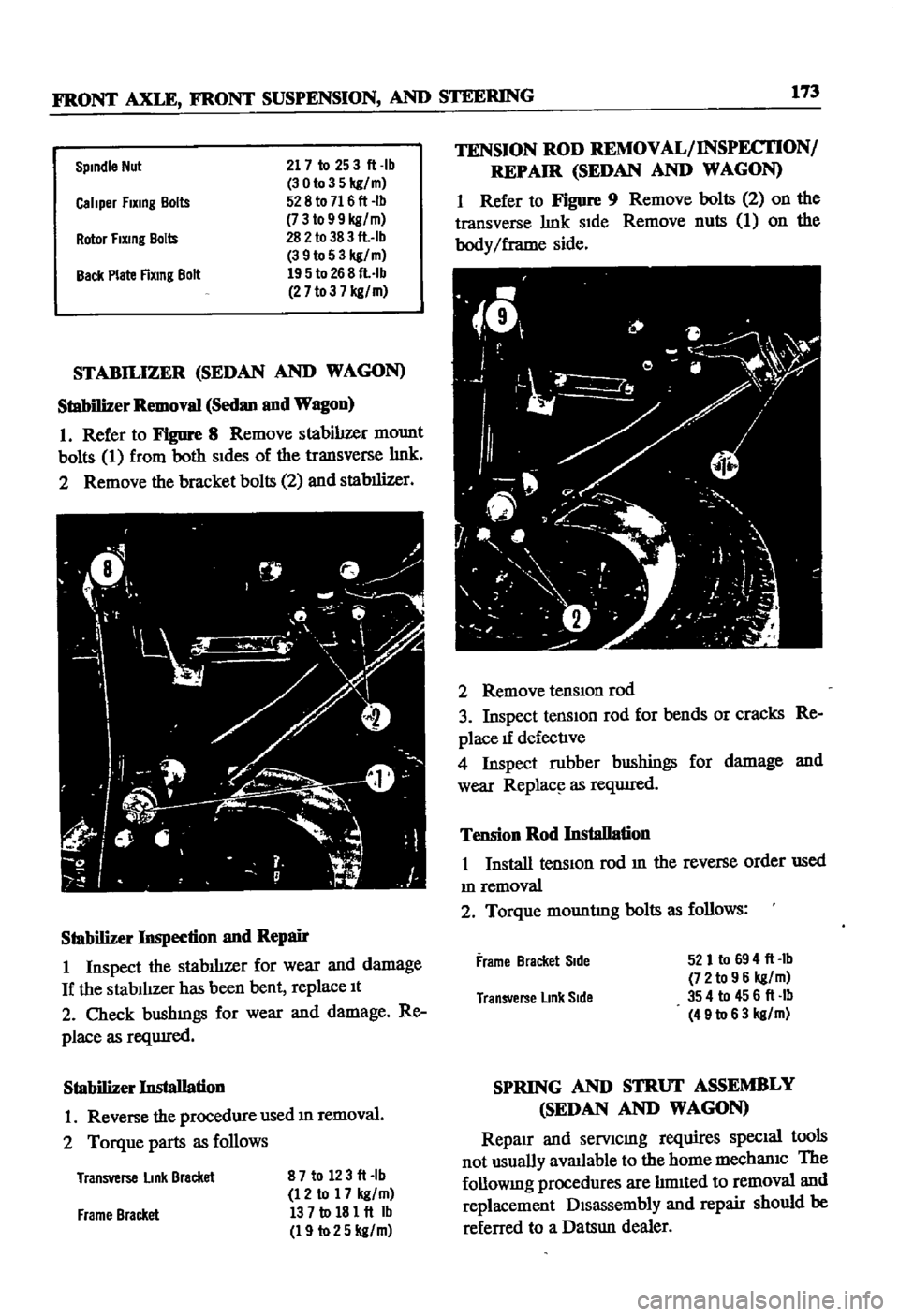

Remove

bearing

collar

and

extract

the

outer

beanng

cage

8

Use

a

screwdriver

to

remove

front

hub

grease

seal

and

imIer

bearmg

cage

9

Use

a

dnft

to

punch

out

the

outer

and

mner

race

of

the

outer

bearmgs

Punch

out

imIer

bearing

10

Detach

rotor

from

wheel

hub

as

shown

in

FJgUre

7

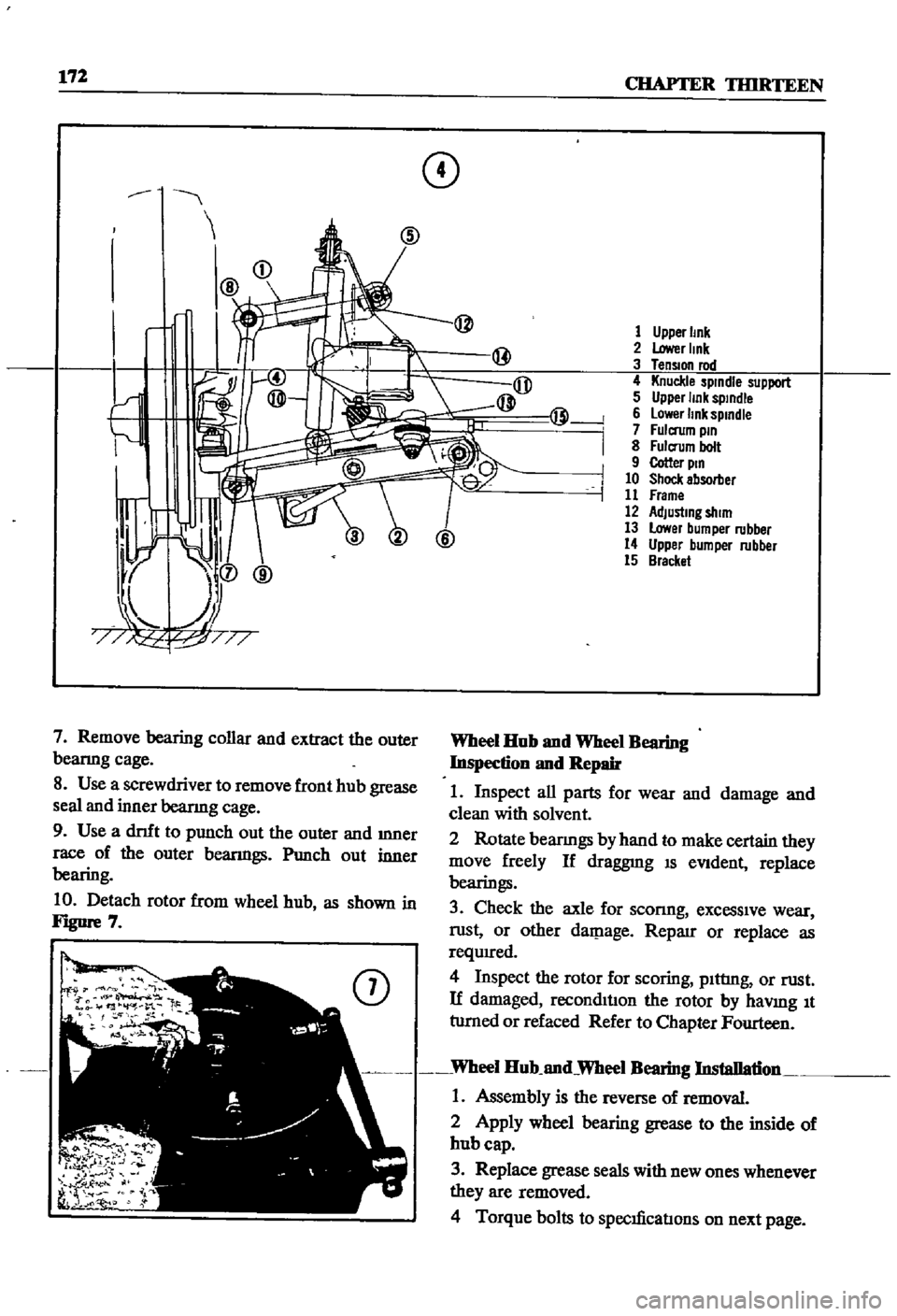

@

1

Upper

Imk

2

Lower

Imk

3

TenSIOn

rod

4

Knuckle

spindle

support

5

Upper

link

sptndle

6

lower

link

spmdle

7

Fulcrum

pm

8

Fulcrum

bolt

9

Cotter

ptn

10

Shock

absorber

11

Frame

12

AdJustmg

shim

13

Lower

bumper

rubber

14

Upper

bumper

rubber

15

Bracket

Wheel

Hub

nnd

Wheel

Bearing

Inspection

nnd

Repair

1

Inspect

all

parts

for

wear

and

damage

and

clean

with

solvent

2

Rotate

bearmgs

by

hand

to

make

certain

they

move

freely

If

draggnIg

IS

eVident

replace

bearings

3

Check

the

axle

for

sconng

excessive

wear

rust

or

other

daJP

age

Reparr

or

replace

as

requIred

4

Inspect

the

rotor

for

scoring

pIttIng

or

rust

If

damaged

reconditIon

the

rotor

by

haVlDg

It

tumed

or

refaced

Refer

to

Chapter

Fourteen

Wheel

Hub

nnd

Wheel

Bearing

Installation

1

Assembly

is

the

reverse

of

removal

2

Apply

wheel

bearing

grease

to

the

inside

of

hub

cap

3

Replace

grease

seals

with

new

ones

whenever

they

are

removed

4

Torque

bolts

to

specIficatIons

on

next

page

Page 178 of 252

FRONT

AXLE

FRONT

SUSPENSION

AND

STEERING

173

Spindle

Nut

21

7

to

253ft

Ib

30to35kg

m

528

to

716

ft

Ib

7

3

to

9

9

kg

m

282

to

38

3

fl

Ib

3

9to

5

3

kg

m

195

to

26

8

fl

b

2

7to3

7

kg

m

Caliper

FIXing

Bolts

Rotor

Flxmg

Bolls

Back

Plate

fiXIng

Boft

STABILIZER

SEDAN

AND

WAGON

SfBbilizer

Removal

Sednn

and

Wagon

1

Refer

to

Figure

8

Remove

stabilizer

mount

bolts

1

from

both

Sides

of

the

transverse

hnk

2

Remove

the

bracket

bolts

2

and

stabilizer

Stabilizer

Inspection

nnd

Repair

1

Inspect

the

stablhzer

for

wear

and

damage

If

the

stabilIzer

has

been

bent

replace

It

2

Check

bushmgs

for

wear

and

damage

Re

place

as

reqUIred

Stabilizer

Installation

1

Reverse

the

procedure

used

m

removal

2

Torque

parts

as

follows

Transverse

link

Bracket

87to

123ft

lb

12

to

17

kg

m

137tol81ft

Ib

19

to25

kg

m

Frame

Bracket

TENSION

ROD

REMOVAL

INSPECTION

REPAIR

SEDAN

AND

WAGON

1

Refer

to

Figure

9

Remove

bolts

2

on

the

transverse

hnk

SIde

Remove

nuts

1

on

the

body

Iframe

side

2

Remove

tensIOn

rod

3

Inspect

tensIOn

rod

for

bends

or

cracks

Re

place

1f

defective

4

Inspect

rubber

bushings

for

damage

and

wear

Replac

l

as

reqwred

Tension

Rod

Installation

1

Install

tension

rod

m

the

reverse

order

used

m

removal

2

Torque

mountIng

bolts

as

follows

Frame

Bracket

Side

521

to

694

ft

Ib

72

to

96

kg

m

354

to

456ft

Ib

49

to

63

kg

m

Transverse

LInk

Side

SPRING

AND

STRUT

ASSEMBLY

SEDAN

AND

WAGON

Repair

and

serVicmg

requires

SpecIal

tools

not

usually

avaJlable

to

the

home

mechaniC

The

followmg

procedures

are

hmIted

to

removal

and

replacement

Disassembly

and

repair

should

be

referred

to

a

Datsun

dealer

Page 179 of 252

174

CHAPTER

THIRTEEN

Spring

and

StnJt

Assembly

Removal

nnd

Installation

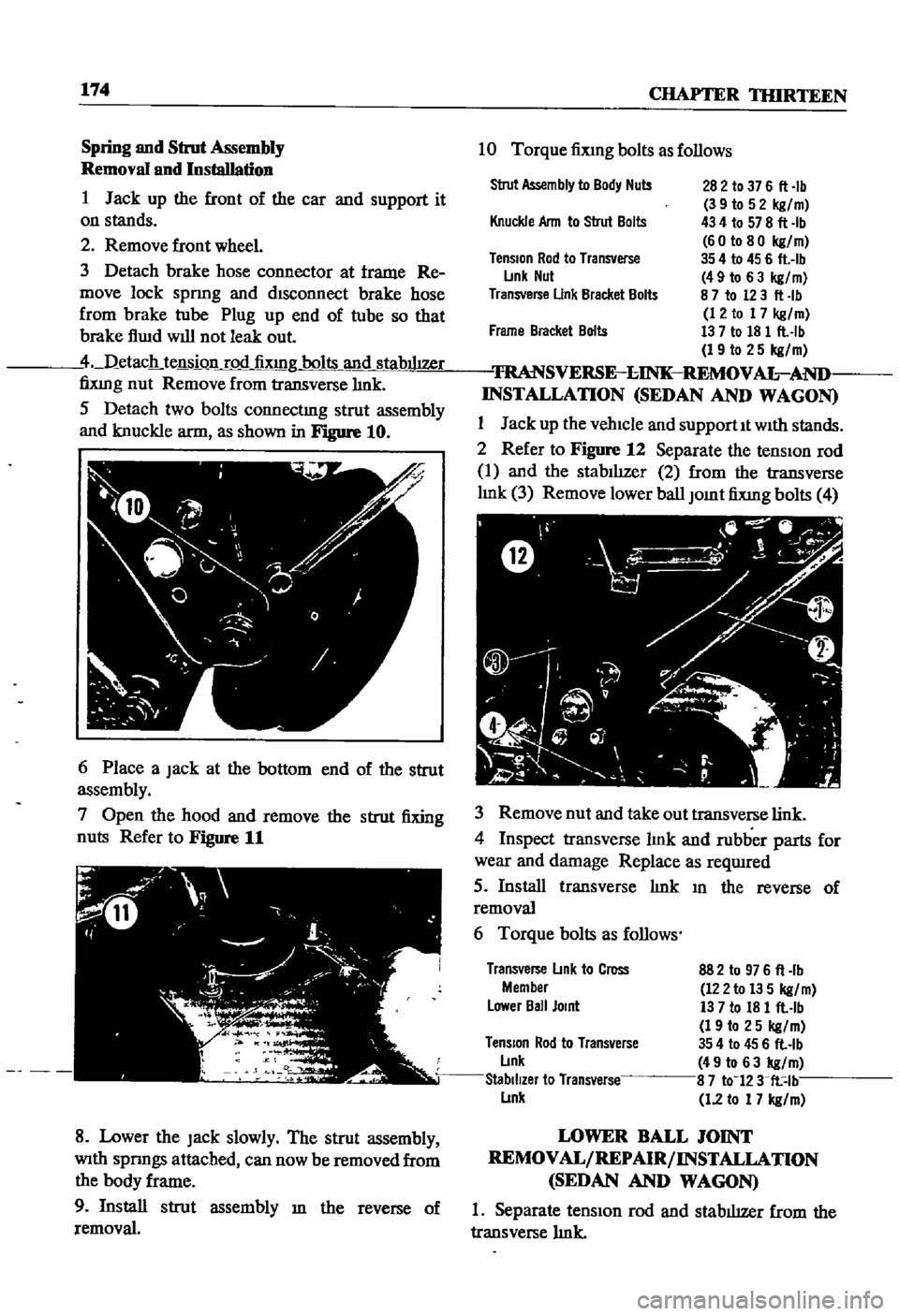

1

Jack

up

the

front

of

the

car

and

support

it

on

stands

2

Remove

front

wheel

3

Detach

brake

hose

connector

at

frame

Re

move

lock

spnng

and

disconnect

brake

hose

from

brake

tube

Plug

up

end

of

tube

so

that

brake

f1wd

will

not

leak

out

4

D

etacb

tensiQn

rod

fi

g

bolts

lld

stabilizer

fixmg

nut

Remove

from

transverse

hnk

5

Detach

two

bolts

connectmg

strut

assembly

and

knuckle

arm

as

shown

in

Figure

10

6

Place

a

Jack

at

the

bottom

end

of

the

strut

assembly

7

Open

the

hood

and

remove

the

strut

fixing

nuts

Refer

to

Figure

11

8

Lower

the

Jack

slowly

The

strut

assembly

With

spnngs

attached

can

now

be

removed

from

the

body

frame

9

Install

strut

assembly

m

the

reverse

of

removal

10

Torque

fiXlng

bolts

as

follows

Strut

Assembly

to

Body

Nuts

282

to

37

6

fl

Ib

3

9

to

5

2

kg

m

434

to

578

fl

Ib

60

to

80

kg

m

35

4

to

45

6

flAb

49

to

6

3

kg

m

8

7

to

123

fl

Ib

12

to

17

kg

m

13

7

to

18

1

flAb

19

to

25

kg

m

TRANSVERSE

l

INK

REMOV

AL

AND

INSTALLATION

SEDAN

AND

WAGON

1

Jack

up

the

vehicle

and

supportIt

With

stands

2

Refer

to

Figure

12

Separate

the

tensIOn

rod

1

and

the

stabIlIzer

2

from

the

transverse

hnk

3

Remove

lower

ball

Jomt

fixmg

bolts

4

Knuckle

Ann

to

Strut

Bolts

TenSion

Rod

to

Transverse

L

mk

Nut

Transverse

Unk

Bracket

Bolts

Frame

Bracket

Bolts

3

Remove

nut

and

take

out

transverse

link

4

Inspect

transverse

hnk

and

rubber

parts

for

wear

and

damage

Replace

as

reqwred

5

Install

transverse

hnk

III

the

reverse

of

removal

6

Torque

bolts

as

follows

Transverse

L

mk

to

Cross

Member

L

ower

Ball

Jomt

882

to

976

fl

lb

122

to

13

5

kg

m

13

7

to

18

1

flAb

19

to

25

kg

m

TenSion

Rod

to

Transverse

354

to

45

6

fl

lb

L

lnk

49

to

63

kg

m

Stabilizer

to

Transverse

8

7

to

123

fl

lb

L

lnk

1

2

to

17

kg

m

LOWER

BALL

JOINT

REMOVAL

REPAIR

INSTALLATION

SEDAN

AND

WAGON

1

Separate

tensIOn

rod

and

stabilizer

from

the

transverse

hnk

Page 180 of 252

FRONT

AXLE

FRONT

SUSPENSION

AND

STEERING

175

2

Remove

bolt

cormectIng

strut

and

knuckle

arm

3

Remove

cotter

pm

and

lower

ball

Joint

4

Separate

lower

ball

Jomt

from

knuckle

arm

5

Remove

bolts

for

lower

ball

Jomt

Separate

transverse

lmk

from

lower

ball

Joint

6

Inspect

ball

Jomt

and

dust

cover

for

wear

or

damage

Replace

as

requIred

If

end

play

m

the

aXial

dIrectIon

of

the

ball

Jomt

exceeds

00012

to

0

0136

m

0

03

to

0

6mm

replace

It

7

Install

ball

Jomt

m

the

reverse

of

removal

Grease

It

through

the

grease

mpple

Take

care

to

fill

the

caVity

slowly

so

that

grease

does

not

come

out

from

the

clamp

portIon

8

Torque

bolts

as

follows

Lower

Ball

JOint

to

Transverse

Link

Ball

Stud

Nut

13

7

to

18

1

fl

Ib

19

to

25

kgfm

398

to

55

0

fl

Ib

55

to

76

kgfm

43

4

to

57

8

flAb

60

to

80

kgfm

35

4

to

45

6

flAb

49

to

63

kgfm

87

to

12

3

fl

lb

12

to

17

kgfm

Knuckle

Ann

to

Strut

TenSion

Rod

to

Transverse

Link

Stabilizer

to

Transverse

Link

FRONT

SUSPENSION

ADJUSTMENT

AND

WHEEL

ALIGNMENT

SEDAN

AND

WAGON

Due

to

the

speclahzed

eqUIpment

required

front

suspensIOn

adJustment

and

wheel

ahgn

ment

should

be

referred

to

a

Datsun

dealer

or

front

end

speciahst

The

followmg

specmcations

apply

to

the

sedan

and

wagon

Sedan

Wagon

Caster

1

40

20

00

Camber

1

00

20

10

King

Pin

Incllnallon

8000

7050

Toe

In

0236

to

0

354

In

0118

to

0

236

In

6

to

9mm

3

to

6mm

Steenng

Angle

In

38

to

390

38

to

390

Steenng

Angle

Out

22030

to

330

30

220

30

to

330

30

Front

Axle

Removal

Pick

up

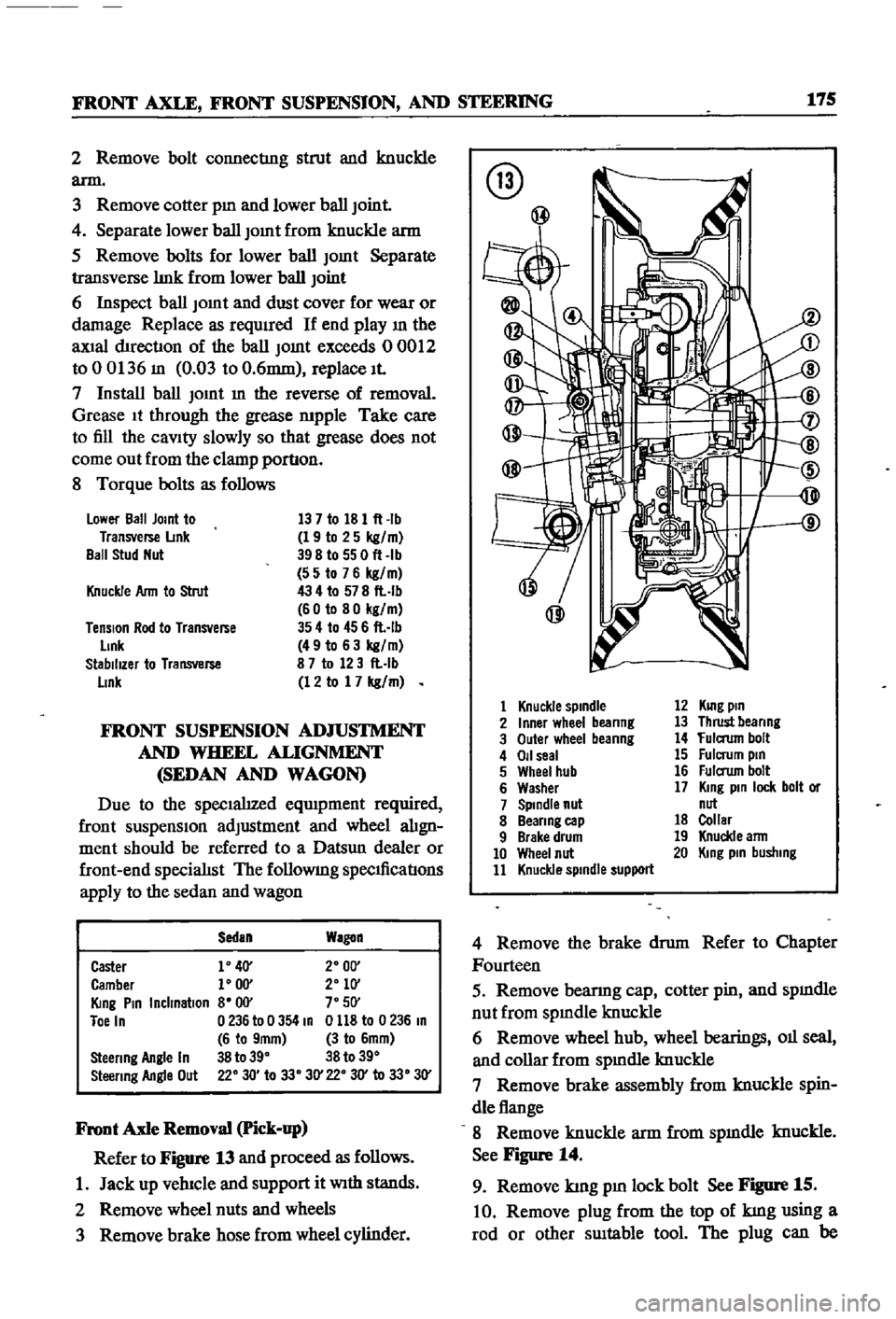

Refer

to

Figure

13

and

proceed

as

follows

1

Jack

up

vehIcle

and

support

it

With

stands

2

Remove

wheel

nuts

and

wheels

3

Remove

brake

hose

from

wheel

cylinder

@

@

1

Knuckle

spindle

2

Inner

wheel

beanng

3

Outer

wheel

beanng

4

011

seal

5

Wheel

hub

6

Washer

7

Spindle

nut

8

Beanng

cap

9

Brake

drum

10

Wheel

nut

11

Knuckle

spindle

support

12

KUlg

pin

13

Thrust

beanng

14

fulaum

bolt

15

Fulcrum

pin

16

Fulaum

bolt

17

King

pin

lock

bolt

or

nut

18

Collar

19

Knuckle

ann

20

King

pin

busllIng

4

Remove

the

brake

drum

Refer

to

Chapter

Fourteen

5

Remove

bearmg

cap

cotter

pin

and

spmdle

nut

from

spmdle

knuckle

6

Remove

wheel

hub

wheel

bearings

011

seal

and

collar

from

spmdle

knuckle

7

Remove

brake

assembly

from

knuckle

spin

dle

flange

8

Remove

knuckle

arm

from

spmdle

knuckle

See

Figure

14

9

Remove

kmg

pm

lock

bolt

See

Figure

15

10

Remove

plug

from

the

top

of

kmg

using

a

rod

or

other

SUItable

tool

The

plug

can

be