DATSUN 510 1968 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 131 of 252

126

CHAPTER

TEN

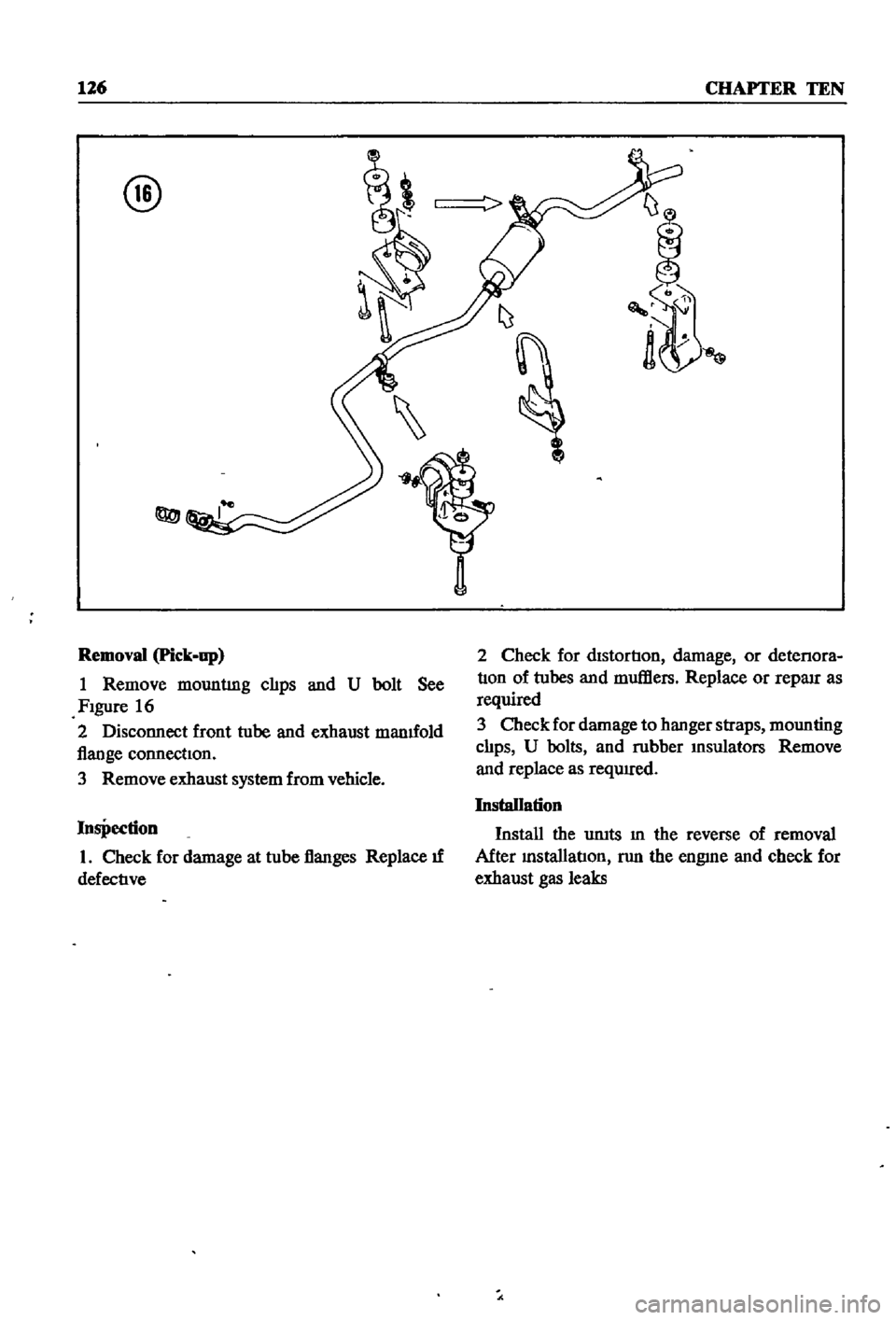

@

r

Removal

Pick

up

1

Remove

mountlng

clIps

and

U

bolt

See

FIgure

16

2

Disconnect

front

tube

and

exhaust

manuold

flange

connectIon

3

Remove

exhaust

system

from

vehicle

Inspection

1

Check

for

damage

at

tube

flanges

Replace

u

defectIve

2

Check

for

dIstortIon

damage

or

detenora

tIon

of

tubes

and

mufHers

Replace

or

reparr

as

required

3

Check

for

damage

to

hanger

straps

mounting

clIps

U

bolts

and

rubber

Insulators

Remove

and

replace

as

requrred

Installation

Install

the

umts

m

the

reverse

of

removal

After

InstallatIon

nm

the

engme

and

check

for

exhaust

gas

leaks

Page 132 of 252

CHAPTER

ELEVEN

CLUTCH

TRANSMISSION

AND

DRIVESHAFf

CLUTCH

i

es

ription

Datsun

uses

a

single

dry

dtsc

clutch

with

dIaphragm

spring

The

major

components

are

clutch

cover

pressure

plate

dIaphragm

spring

and

WIre

nngs

The

clutch

dISC

has

riveted

plates

on

both

surfaces

and

coll

spnngs

arranged

in

a

link

The

coll

springs

absorb

shock

to

soften

and

smooth

clutch

engagement

Figure

1

next

page

is

an

exploded

diagram

of

the

clutch

assembly

Clutch

Removal

The

transmIssion

must

be

separated

from

the

engme

to

remove

tlte

clutch

assembly

This

can

be

done

by

removmg

the

transmISSIon

and

engme

from

the

vehicle

as

a

umt

or

by

remoVIng

the

transmiSSIon

separately

Removal

of

the

engine

and

transmissIOn

IS

descnbed

In

Chapter

Six

Removal

of

the

transmISSIon

only

IS

descnbed

later

in

tills

chapter

Outcb

Disassembly

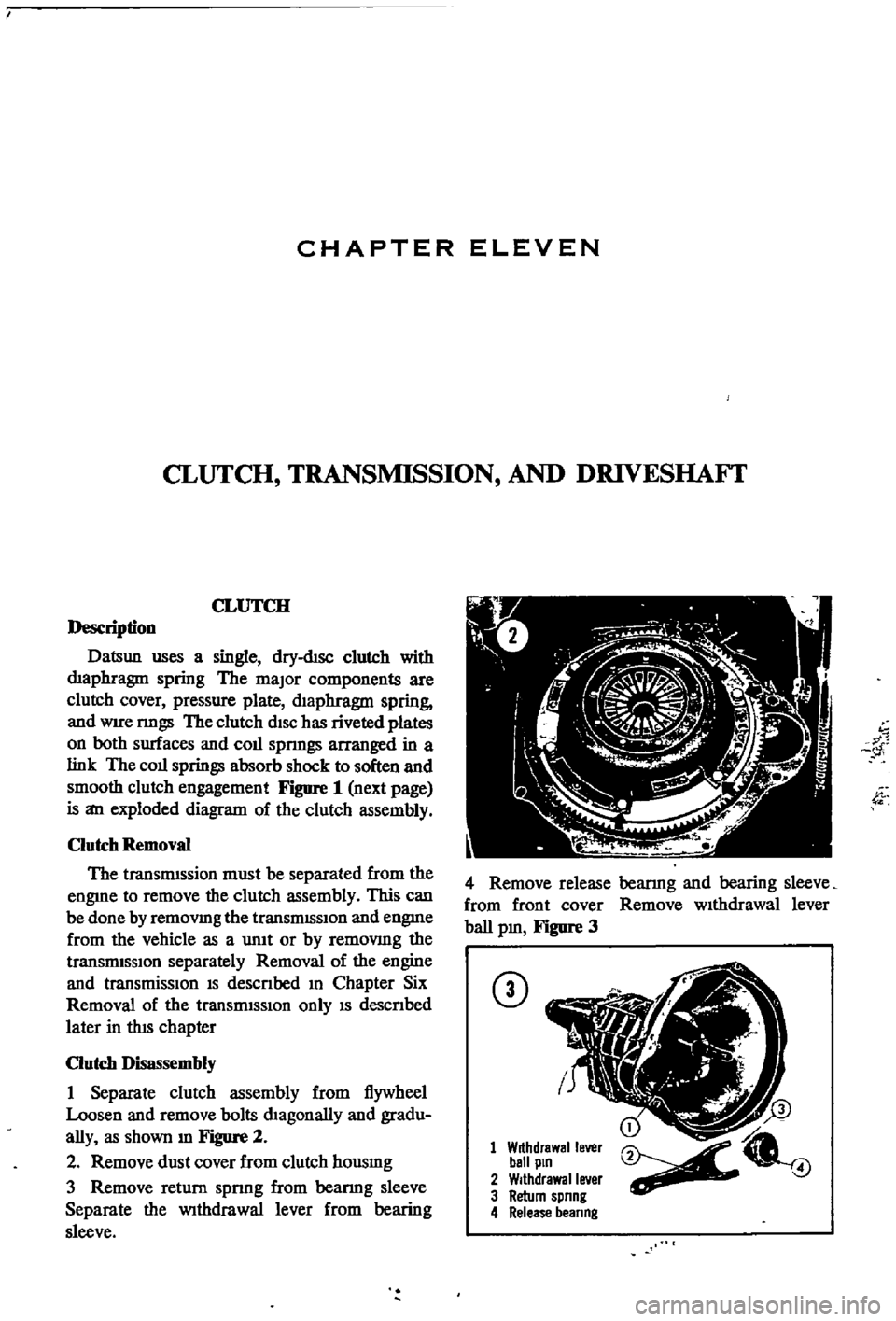

1

Separate

clutch

assembly

from

flywheel

Loosen

and

remove

bolts

dIagonally

and

gradu

ally

as

shown

m

Figure

2

2

Remove

dust

cover

from

clutch

housmg

3

Remove

return

spnng

from

beanng

sleeve

Separate

the

Withdrawal

lever

from

bearing

sleeve

w

1

4

Remove

release

bearmg

and

bearing

sleeve

from

front

cover

Remove

wIthdrawal

lever

ball

pm

Figure

3

CD

1

Withdrawal

lever

ball

pin

2

Withdrawal

lever

3

Return

spnng

4

Release

beanng

4

Page 133 of 252

128

CHAPTER

ELEVEN

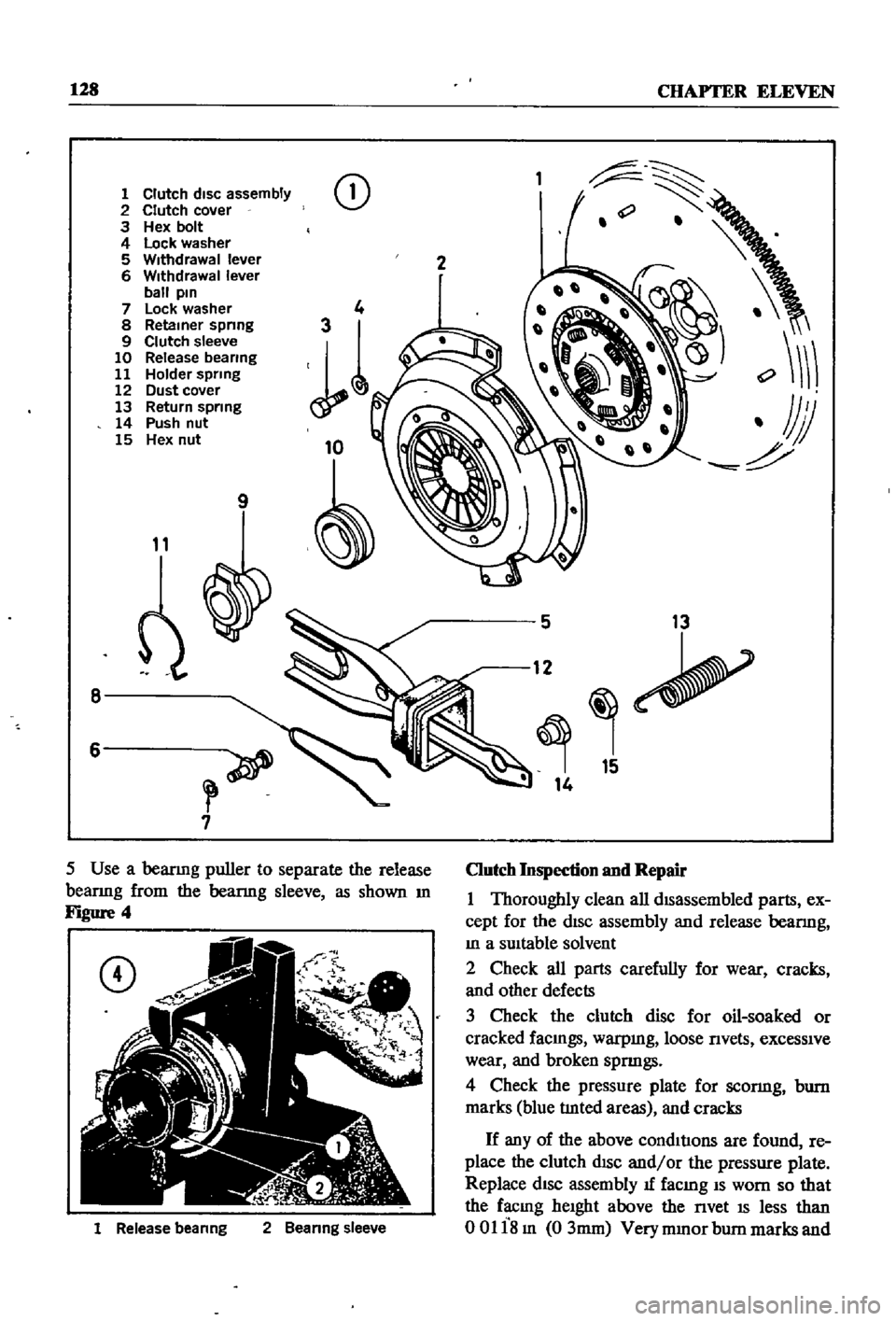

1

Clutch

disc

assembly

2

Clutch

cover

3

Hex

bolt

4

Lock

washer

5

Withdrawal

lever

6

Withdrawal

lever

ball

pin

7

Lock

washer

8

Retainer

spnng

9

Clutch

sleeve

10

Release

bearing

11

Holder

spring

12

Dust

cover

13

Return

spring

14

Push

nut

15

Hex

nut

CD

9

11

8

6

7

1

Release

beanng

2

Beanng

sleeve

2

5

13

12

15

14

Clutch

Inspection

and

Repair

1

Thoroughly

clean

all

dISassembled

parts

ex

cept

for

the

dISc

assembly

and

release

bearmg

In

a

SUItable

solvent

2

Check

all

parts

carefully

for

wear

cracks

and

other

defects

3

Check

the

clutch

disc

for

oil

soaked

or

cracked

faCIngs

warpmg

loose

nvets

exceSSIve

wear

and

broken

spnngs

4

Check

the

pressure

plate

for

sconng

bum

marks

blue

tlnted

areas

and

cracks

If

any

of

the

above

condItIons

are

found

re

place

the

clutch

dISC

and

or

the

pressure

plate

Replace

dISC

assembly

1f

facmg

IS

worn

so

that

the

facmg

heIght

above

the

nvet

IS

less

than

00118m

03mm

Very

mmor

bum

marks

and

Page 134 of 252

CLUTCH

TRANSMISSION

AND

DRIVESHAFI

129

scratches

on

the

pressure

plate

may

be

removed

with

crocus

cloth

If

the

source

of

clutch

trouble

IS

still

not

evl

dent

take

the

pressure

plate

and

disc

to

a

compe

tent

garage

to

check

the

pressure

plate

finger

release

height

and

nmout

Never

attempt

to

ad

just

the

fingers

or

dismantle

the

pressure

plate

Without

proper

tools

and

experience

Check

the

release

bearing

by

holdmg

the

Inner

race

and

rotatmg

the

outer

race

With

hght

pres

sure

applied

If

the

bearing

is

rough

or

noisy

replace

it

CAUTION

Never

clean

the

release

bearing

In

solvent

It

IS

prelubriCflted

at

the

fac

tory

Simply

wipe

with

a

Unt

free

cloth

If

the

release

bearing

shows

any

signs

of

loss

of

lubncant

install

a

new

bearing

Replace

the

sleev

lu

SignS

of

wear

are

evident

Clutch

Reassembly

1

Be

sure

your

hands

are

clean

for

the

initIal

assembly

2

Inspect

the

clutch

facings

pressure

plate

and

flywheel

to

be

sure

they

are

free

from

grease

oil

and

other

foreIgn

material

3

TIghtly

fit

release

bearmg

onto

the

bearing

sleeve

When

beanng

IS

mstalled

turn

bearmg

With

a

finger

to

make

sure

It

operates

smoothly

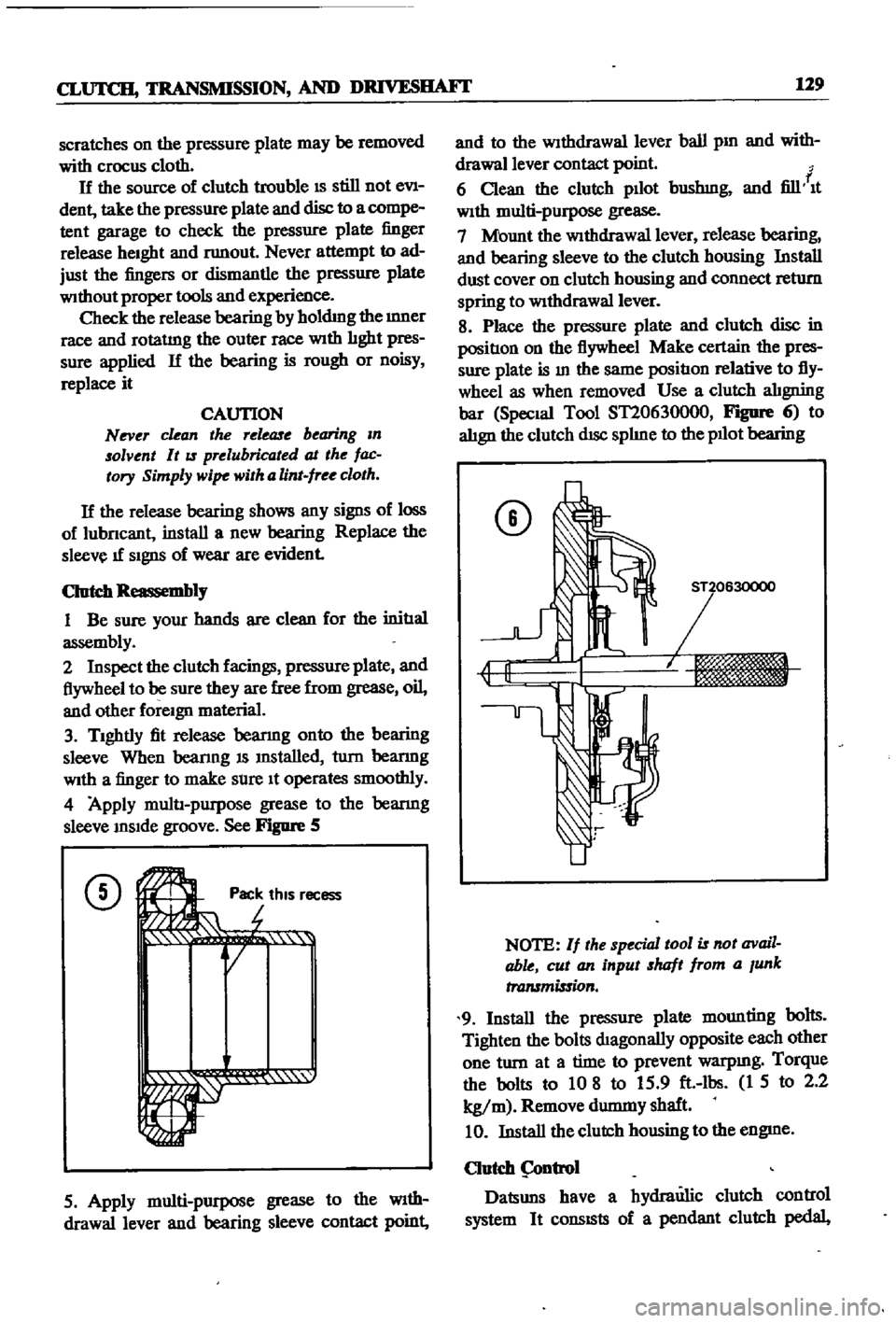

4

Apply

multI

purpose

grease

to

the

bearmg

sleeve

InSIde

groove

See

Figure

5

CD

Ji

rot

Pac

thiS

r

r

r

1

1i

QI

ecess

5

Apply

multi

purpose

grease

to

the

WIth

drawallever

and

bearing

sleeve

contact

point

and

to

the

Withdrawal

lever

ball

pm

and

with

drawallever

contact

point

f

6

Clean

the

clutch

pllot

bushmg

and

fill

It

With

multi

purpose

grease

7

Mount

the

WithdraWal

lever

release

bearing

and

bearing

sleeve

to

the

clutch

housing

Install

dust

cover

on

clutch

housing

and

connect

return

spring

to

WithdraWal

lever

8

Place

the

pressure

plate

and

clutch

disc

in

positIon

on

the

flywheel

Make

certain

the

pres

sure

plate

is

In

the

same

positIon

relative

to

fly

wheel

as

when

removed

Use

a

clutch

alIgning

bar

Special

Tool

ST20630000

FIgDfe

6

to

alIgn

the

clutch

dISc

splIne

to

the

pllot

bearing

CD

NOTE

If

the

special

tool

is

not

avail

able

cut

an

input

shaft

from

a

Junk

transmission

9

Install

the

pressure

plate

mounting

bolts

Tighten

the

bolts

dIagonally

opposite

each

other

one

turn

at

a

time

to

prevent

warpmg

Torque

the

bolts

to

10

8

to

15

9

ft

lbs

1

5

to

2

2

kg

m

Remove

durmny

shaft

10

Install

the

clutch

housing

to

the

engme

Clutch

ntrol

Datsuns

have

a

hydraulic

clutch

control

system

It

consISts

of

a

pendant

clutch

pedal

Page 135 of 252

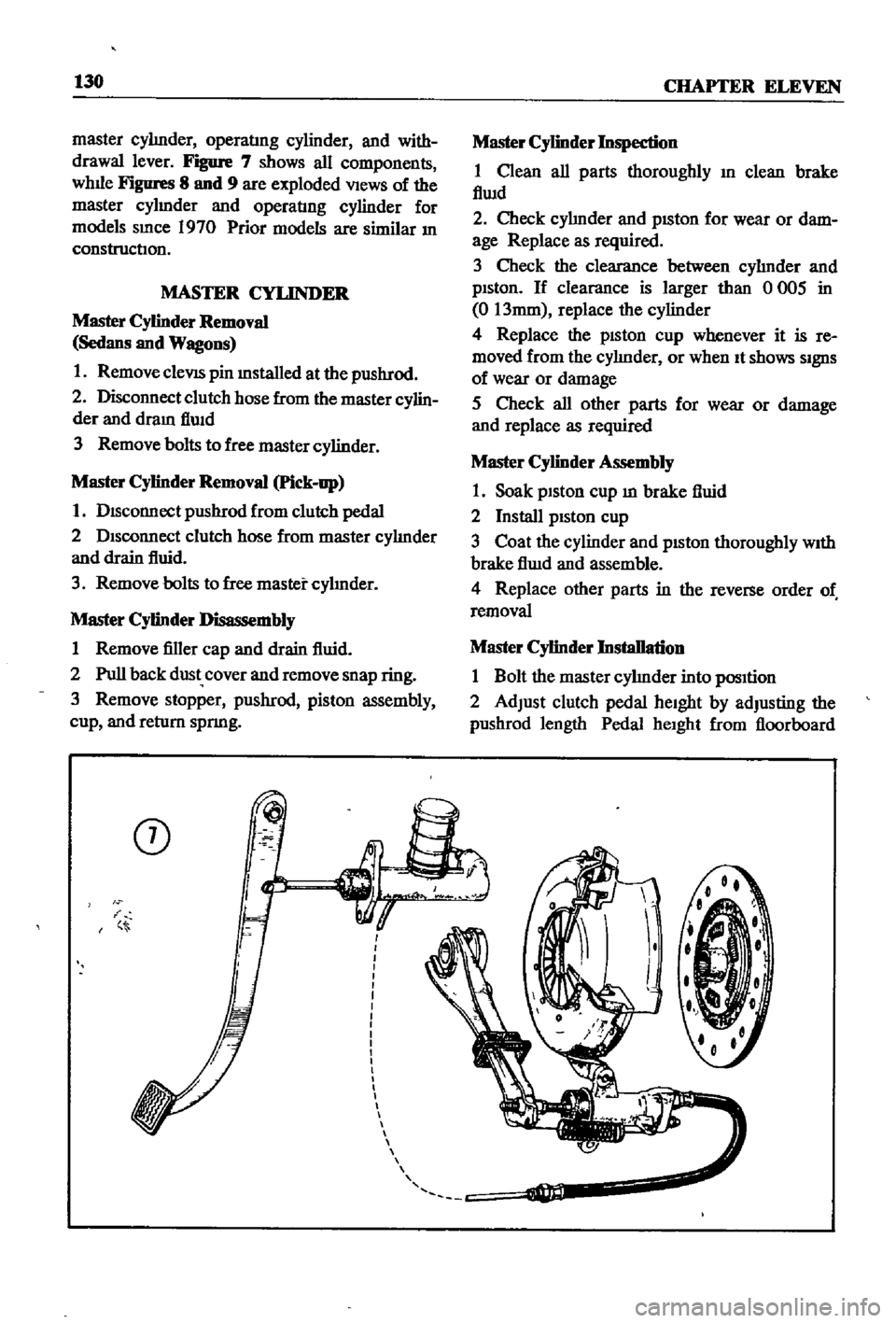

130

CHAPTER

ELEVEN

master

cylInder

operatlng

cylinder

and

with

drawal

lever

Figure

7

shows

all

components

whlle

Figures

8

and

9

are

exploded

VIews

of

the

master

cylmder

and

operatIng

cylinder

for

models

smce

1970

Prior

models

are

similar

In

construction

MASTER

CYLINDER

Master

Cylinder

Removal

Sedans

and

Wagons

1

Remove

cleVIS

pin

mstalled

at

the

pushrod

2

Disconnect

clutch

hose

from

the

master

cylin

der

and

dram

flwd

3

Remove

bolts

to

free

master

cylinder

Master

Cylinder

Removal

Pick

up

1

DIsconnect

pushrod

from

clutch

pedal

2

DIsconnect

clutch

hose

from

master

cylInder

and

drain

fluid

3

Remove

bolts

to

free

master

cylInder

Master

Cylinder

Disassembly

1

Remove

filler

cap

and

drain

fluid

2

Pull

back

dust

cover

and

remove

snap

ring

3

Remove

stopper

pushrod

piston

assembly

cup

and

return

spnng

CD

i

Master

Cylinder

Inspection

1

Clean

all

parts

thoroughly

In

clean

brake

flwd

2

Check

cylInder

and

pISton

for

wear

or

dam

age

Replace

as

required

3

Check

the

clearance

between

cylInder

and

pIston

If

clearance

is

larger

than

0

005

in

0

13mm

replace

the

cylinder

4

Replace

the

pISton

cup

whenever

it

is

re

moved

from

the

cylInder

or

when

It

shows

SIgnS

of

wear

or

damage

5

Check

all

other

parts

for

wear

or

damage

and

replace

as

required

Master

Cylinder

Assembly

1

Soak

piston

cup

m

brake

fluid

2

Install

pIston

cup

3

Coat

the

cylinder

and

pIston

thoroughly

WIth

brake

flwd

and

assemble

4

Replace

other

parts

in

the

reverse

order

of

removal

Master

Cylinder

Installation

1

Bolt

the

master

cylInder

into

pOSItion

2

Adjust

clutch

pedal

heIght

by

adjusting

the

pushrod

length

Pedal

heIght

from

floorboard

Page 136 of 252

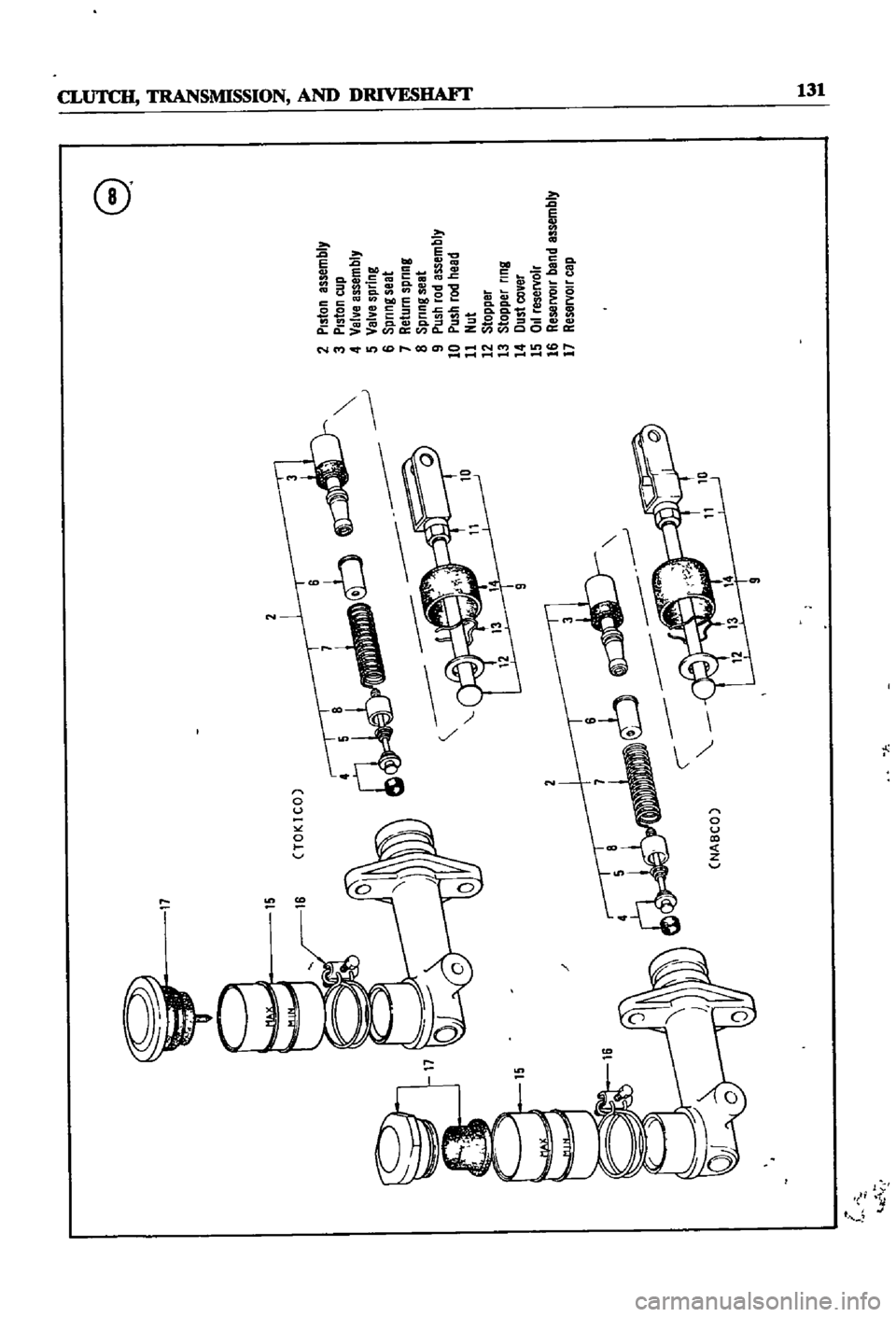

e

j

11

i

Il

Il

15

2

Tl

CTOKICO

2

Piston

assembly

3

Piston

cup

4

Valve

assembly

CI

5

Val

e

spring

I

6

Spnng

seat

7

Return

spring

8

Spnng

seat

9

Push

rod

assembly

10

Push

rod

head

11

Nut

12

Stopper

13

Stopper

ring

14

Dust

cover

15

0

reservoir

2

rl

16

Reservoir

bend

assembly

17

ReservOir

cap

NABCO

1

k

IN

Page 137 of 252

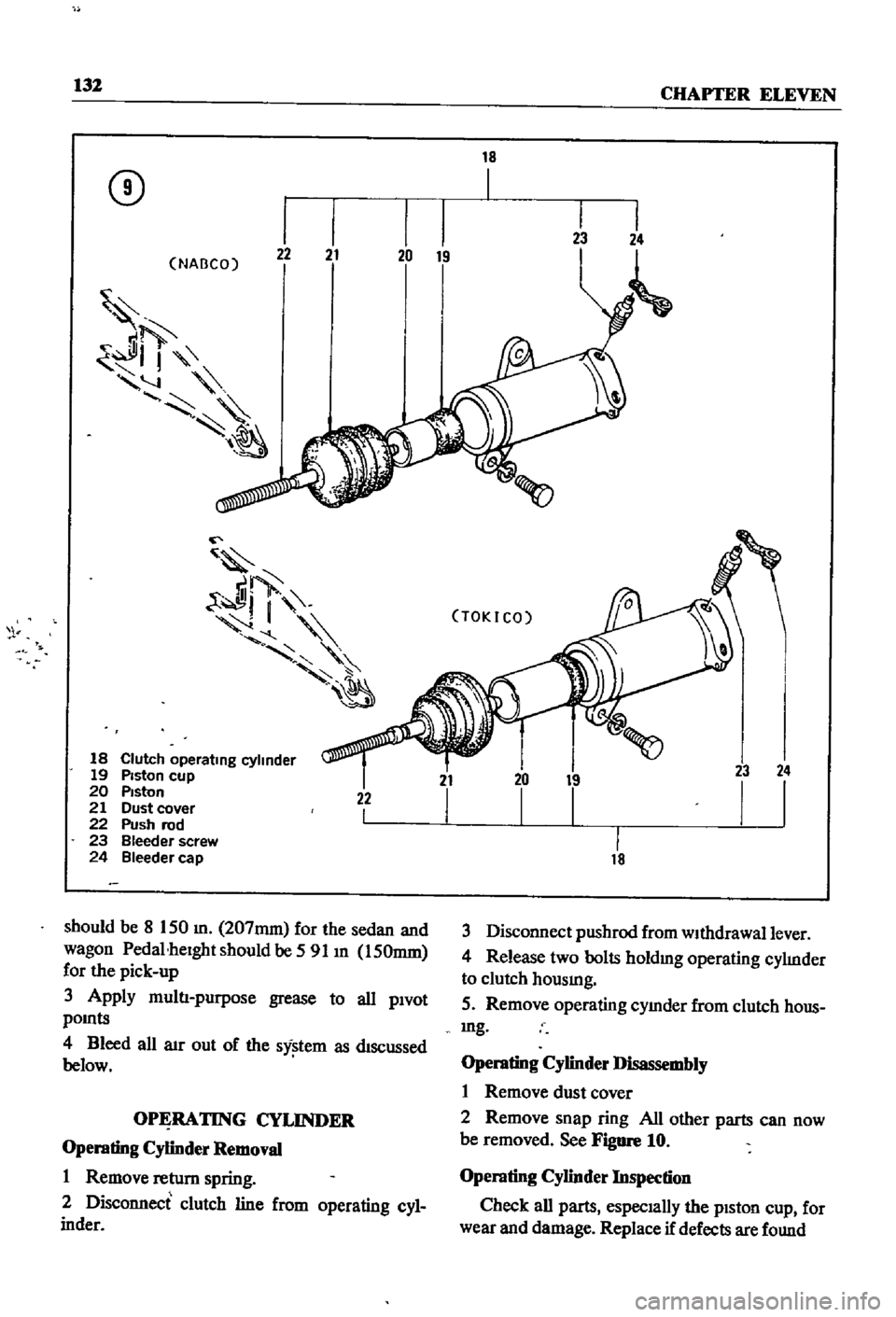

132

CHAPTER

ELEVEN

CD

NAnCO

22

20

21

r

i

T

l

C

r

Jl

i

i

18

Clutch

operating

cylinder

19

Piston

cup

20

PIston

21

Dust

cover

22

Push

rod

23

Bleeder

screw

24

Bleeder

cap

22

I

should

be

8

150

m

207mm

for

the

sedan

and

wagon

Pedal

heIght

should

be

591

m

150mm

for

the

pick

up

3

Apply

multI

purpose

grease

to

all

PIvot

pOInts

4

Bleed

all

aIr

out

of

the

sy

tem

as

dIscussed

below

OPERATING

CYLINDER

Operating

CyHnder

Removal

1

Remove

retum

spring

2

Disconnect

clutch

line

from

operating

cyl

inder

18

Ii

TOKICO

21

I

LL

18

23

24

I

I

3

Disconnect

pushrod

from

wIthdrawal

lever

4

Release

two

bolts

holdmg

operating

cylInder

to

clutch

hOUSIng

5

Remove

operating

cymder

from

clutch

hous

mg

Operating

CyHnder

Disassembly

1

Remove

dust

cover

2

Remove

snap

ring

All

other

parts

can

now

be

removed

See

Figure

10

Operating

CyHnder

Inspection

Check

all

parts

especIally

the

pIston

cup

for

wear

and

damage

Replace

if

defects

are

found

Page 138 of 252

CLUTCH

TRANSMISSION

AND

DRlVESIIAFI

133

C

8

Q@J

@

C

Operating

Cylinder

Reassembly

1

Soak

pISton

cup

m

brake

flUid

and

Install

It

In

the

same

pOSitIOn

as

before

removal

2

Apply

brake

flUid

to

the

cylInder

and

pIston

before

mstalImg

piston

3

Replace

all

parts

m

the

reverse

order

of

removal

Operating

Cylinder

Installation

1

RemstallatIon

IS

the

reverse

of

removal

2

Bleed

aIr

from

the

hydraulIc

system

3

Adjust

the

pushrod

so

that

withdrawal

lever

end

play

IS

0

0787

to

0

1181

In

2

0

to

3

Omm

Procedures

for

the

adjustment

are

given

below

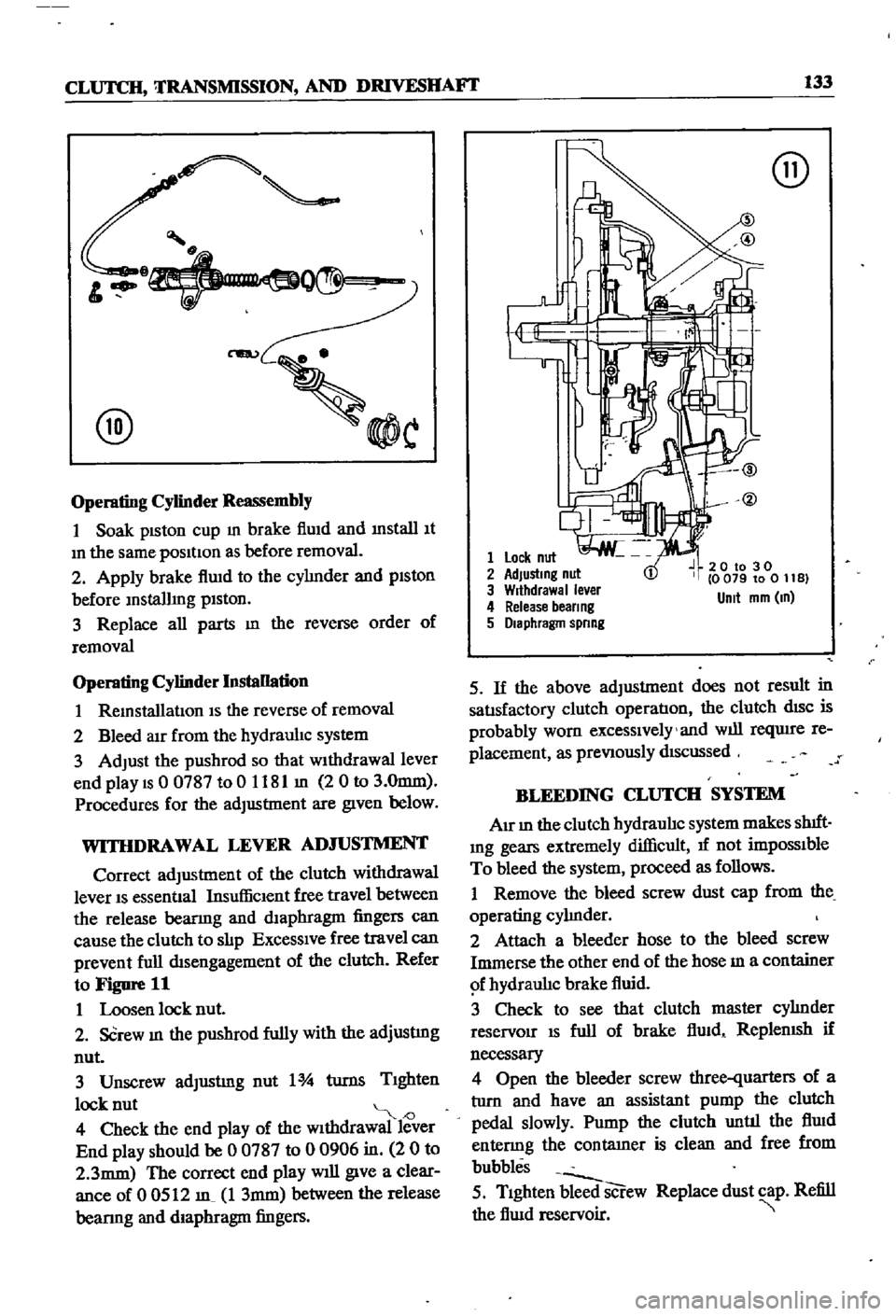

WITHDRAWAL

LEVER

AD

JUSTMENT

Correct

adjustment

of

the

clutch

withdrawal

lever

IS

essentIal

InsufficIent

free

travel

between

the

release

bearmg

and

dIaphragm

fingers

can

cause

the

clutch

to

slIp

ExceSSIve

free

travel

can

prevent

full

dISengagement

of

the

clutch

Refer

to

Figure

11

1

Loosen

lock

nut

2

SCrew

In

the

pushrod

fully

with

the

adjustmg

nut

3

Unscrew

adJustmg

nut

1

turns

TIghten

lock

nut

J

4

Check

the

end

play

of

the

wIthdrawal

lever

End

play

should

be

0

0787

to

0

0906

in

2

0

to

2

3mm

The

correct

end

play

will

give

a

clear

ance

of

0

0512

m

1

3mm

between

the

release

bearmg

and

diaphragm

fingers

@

1

Lock

nut

2

AdJustmg

nut

3

Wrthdrawal

ever

4

Release

beer

ng

5

Diaphragm

spnng

20

to

30

0

079

to

0

11

B

Unit

mm

m

5

If

the

above

adjustment

does

not

result

in

satIsfactory

clutch

operatIon

the

clutch

dISC

is

probably

worn

excessIvely

and

will

reqUire

re

placement

as

preVIously

dIScussed

BLEEDING

CLUTCH

SYSTEM

AIr

In

the

clutch

hydraulIc

system

makes

shIft

Ing

gears

extremely

difficult

1f

not

impOSSIble

To

bleed

the

system

proceed

as

follows

1

Remove

the

bleed

screw

dust

cap

from

the

operating

cylInder

2

Attach

a

bleeder

hose

to

the

bleed

screw

Immerse

the

other

end

of

the

hose

m

a

container

f

hydraulIc

brake

fluid

3

Check

to

see

that

clutch

master

cylInder

reservoir

IS

full

of

brake

flUid

ReplenISh

if

necessary

4

Open

the

bleeder

screw

three

quarters

of

a

tlIrn

and

have

an

assistant

pump

the

clutch

pedal

slowly

Pump

the

clutch

until

the

flUid

entenng

the

contatner

is

clean

and

free

from

bubbles

5

TIghten

bleed

screw

Replace

dust

cap

Refill

the

flUid

reservoir

Page 139 of 252

134

CHAPTER

ELEVEN

CLUTCH

SERVICE

DATA

AND

SPECIF1CATIONS

Table

1

proVIdes

serVIce

data

and

specifica

tIons

for

the

clutch

system

TRANSMISSION

Description

Datsuns

are

eqUIpped

with

either

an

auto

matic

or

manual

transrmSSIOn

Due

to

the

com

pleXity

of

the

unIt

and

the

need

for

special

tools

and

knowledge

overhaul

of

the

automatic

trans

mISSIon

is

not

covered

In

thIS

manual

Auto

matIc

transmISSIOn

checks

and

adjustments

are

given

later

m

thIS

chapter

Reparr

and

mainte

nance

should

be

referred

to

a

Datsun

dealer

or

qualIfied

mechamc

The

manual

transmission

is

a

four

forward

Table

1

speed

unlt

controlled

With

a

floor

mounted

lever

It

consIsts

of

transrmSSIOn

case

rear

extensIOn

housing

and

gear

assembly

The

clutch

housmg

and

transmissIOn

case

are

a

sIngle

unIt

The

rear

extension

housmg

is

detachable

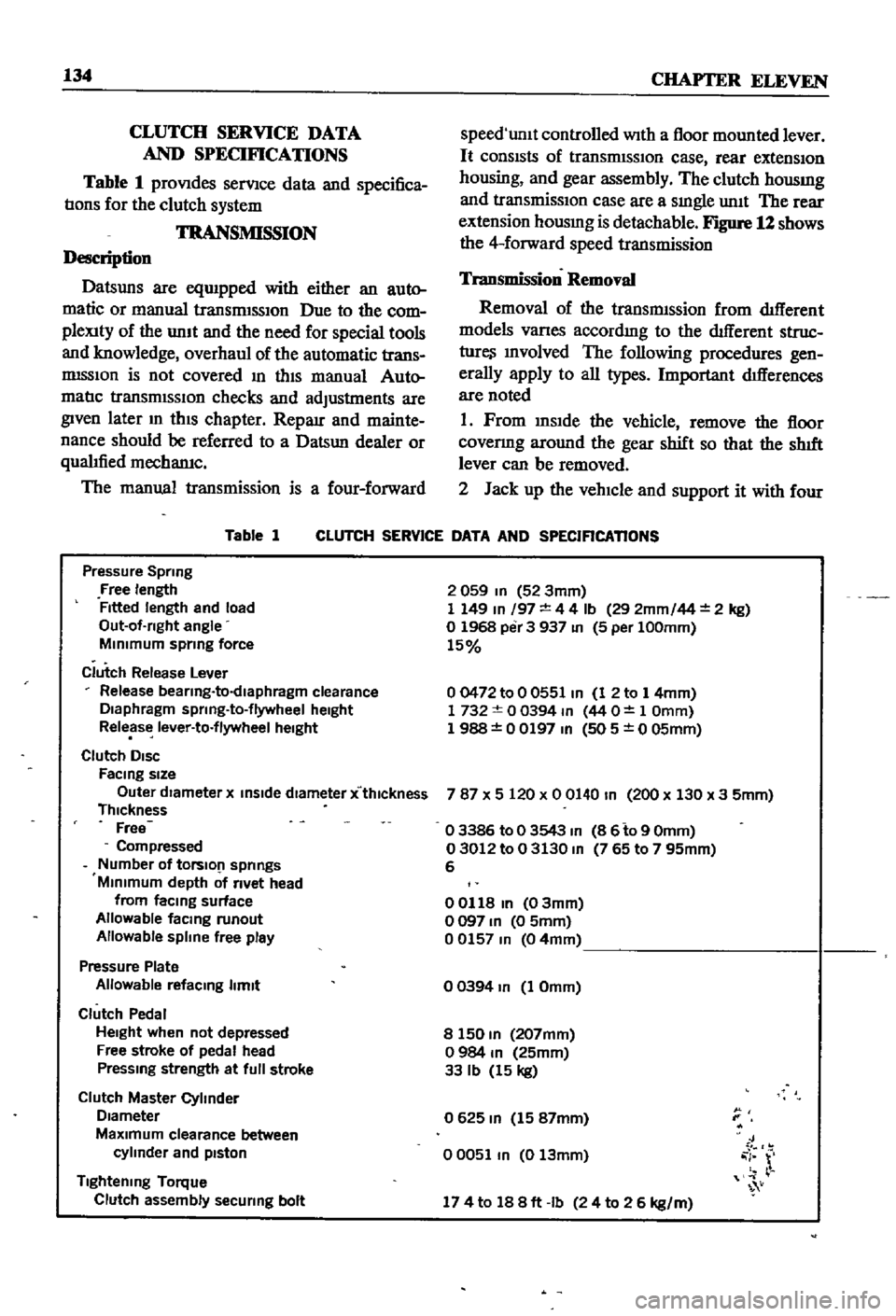

Figure

12

shows

the

4

forward

speed

transmission

Transmission

Removal

Removal

of

the

transmIssion

from

dIfferent

models

Varles

accordmg

to

the

dIfferent

struc

ture

Involved

The

following

procedures

gen

erally

apply

to

all

types

Important

dIfferences

are

noted

1

Prom

InsIde

the

vehicle

remove

the

floor

covenng

around

the

gear

shift

so

that

the

shIft

lever

can

be

removed

2

Jack

up

the

vehIcle

and

support

it

with

four

CLUTCH

SERVICE

DATA

AND

SPECIFICATIONS

Pressure

Spring

Free

length

Fitted

length

and

load

Out

of

rlght

angle

MInimum

sprmg

force

Clutch

Release

Lever

Release

bearlng

to

dlaphragm

clearance

Diaphragm

sprlng

to

flywheel

height

Release

lever

to

flywheel

height

Clutch

DISC

FaCing

size

Outer

dIameter

x

inSide

diameter

x

thlckness

Thickness

Free

Compressed

Number

of

tOrslO

1

springs

Minimum

depth

of

rivet

head

from

faCing

surface

Allowable

facmg

runout

Allowable

spline

free

play

Pressure

Plate

Allowable

refacmg

limit

Clutch

Pedal

Height

when

not

depressed

Free

stroke

of

pedal

head

Pressmg

strength

at

full

stroke

Clutch

Master

Cylinder

Diameter

MaXimum

clearance

between

cylinder

and

pIston

Tightening

Torque

Clutch

assembly

securing

bolt

2

059

In

52

3mm

1

149

In

197

4

4

Ib

29

2mm

44

2

kg

o

1968

per

3

937

In

5

per

100mm

15

00472

to

0

0551

In

1

2

to

1

4mm

1732

0

0394

m

44

O

1

Omm

1

988

0

0197

In

505

0

05mm

787

X

5

120

x

0

0140

In

200

x

130

x

3

5mm

o

3386

to

0

3543

m

8

6

to

9

Omm

03012

to

0

3130

m

765

to

7

95mm

6

00118

In

03mm

o

097

In

0

5mm

00157

m

04mm

o

0394

In

1

Omm

8

150

m

207mm

o

984

m

25mm

33

Ib

15

kg

0625

m

15

87mm

00051

m

0

13mm

J

i

r

174

to

188ft

Ib

24

to

2

6

kg

m

Page 140 of 252

CLUTCH

TRANSMISSION

AND

DRIVESIIAFI

135

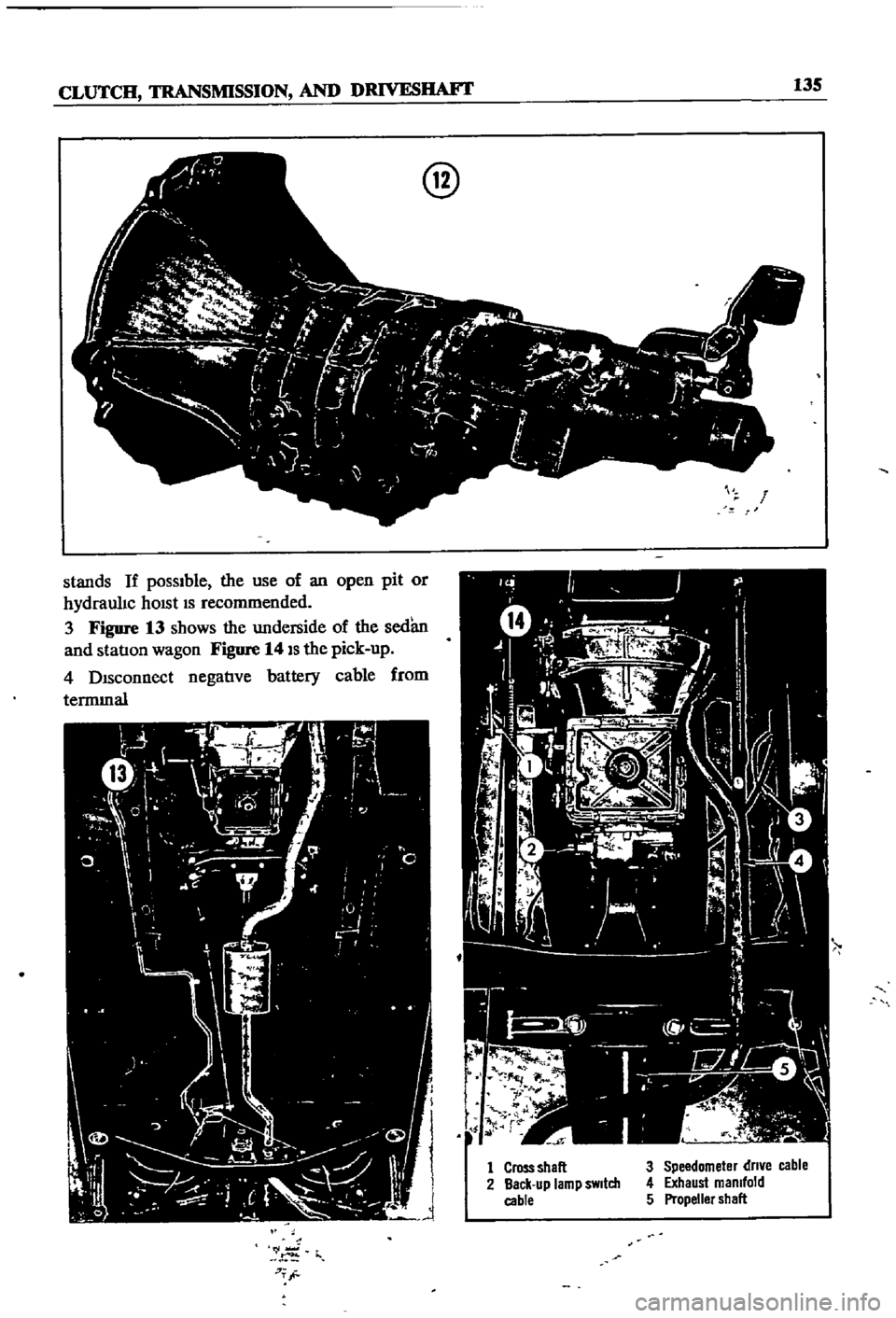

stands

If

possible

the

use

of

an

open

pit

or

hydraulIc

hOISt

IS

recommended

3

Figure

13

shows

the

underside

of

the

sedan

and

statIon

wagon

Figure

14

IS

the

pick

up

4

DIsconnect

negatIve

battery

cable

from

termInal

r

j

7T

@

r

1

Cross

shall

2

Back

up

lamp

sWitch

cable

3

Speedometer

dn

e

cable

4

Exhaust

manifold

5

Propeller

shall