DATSUN 510 1968 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 141 of 252

136

CHAPTER

ELEVEN

5

DIsconnect

and

remove

starter

motor

from

flywheel

housmg

as

descnbe4

In

Chapter

NIne

6

Dls

onnect

handbrake

WIre

at

equalIzer

pIVOt

See

Figure

15

sedan

and

wagon

I

j

7

Loosen

the

two

exhaust

center

p1pe

clamps

and

turn

the

premuffier

complete

With

center

pIpe

to

the

left

as

shown

m

FJgure

16

sedan

and

wagon

f

W

y

I

0

Y

h

0

ilo

8

DIsconnect

front

exhaust

tube

from

exhaust

man1fold

pICk

up

9

Rem

ye

four

bolts

from

companion

flange

of

gear

carner

and

detach

dnve

shaft

See

Figure

17

Seal

the

end

of

rear

extensIon

housmg

to

prevent

011

leakage

1

0

Dlsconn

i

gpeedometer

drive

cable

from

rear

extensIOn

as

shown

In

Figure

18

11

On

models

s

quipped

disconnect

neutral

gear

sWitch

third

gear

sWitch

and

reverse

gear

sWItch

as

shown

in

Figure

19

next

page

f

t

iT

l

t

t

W

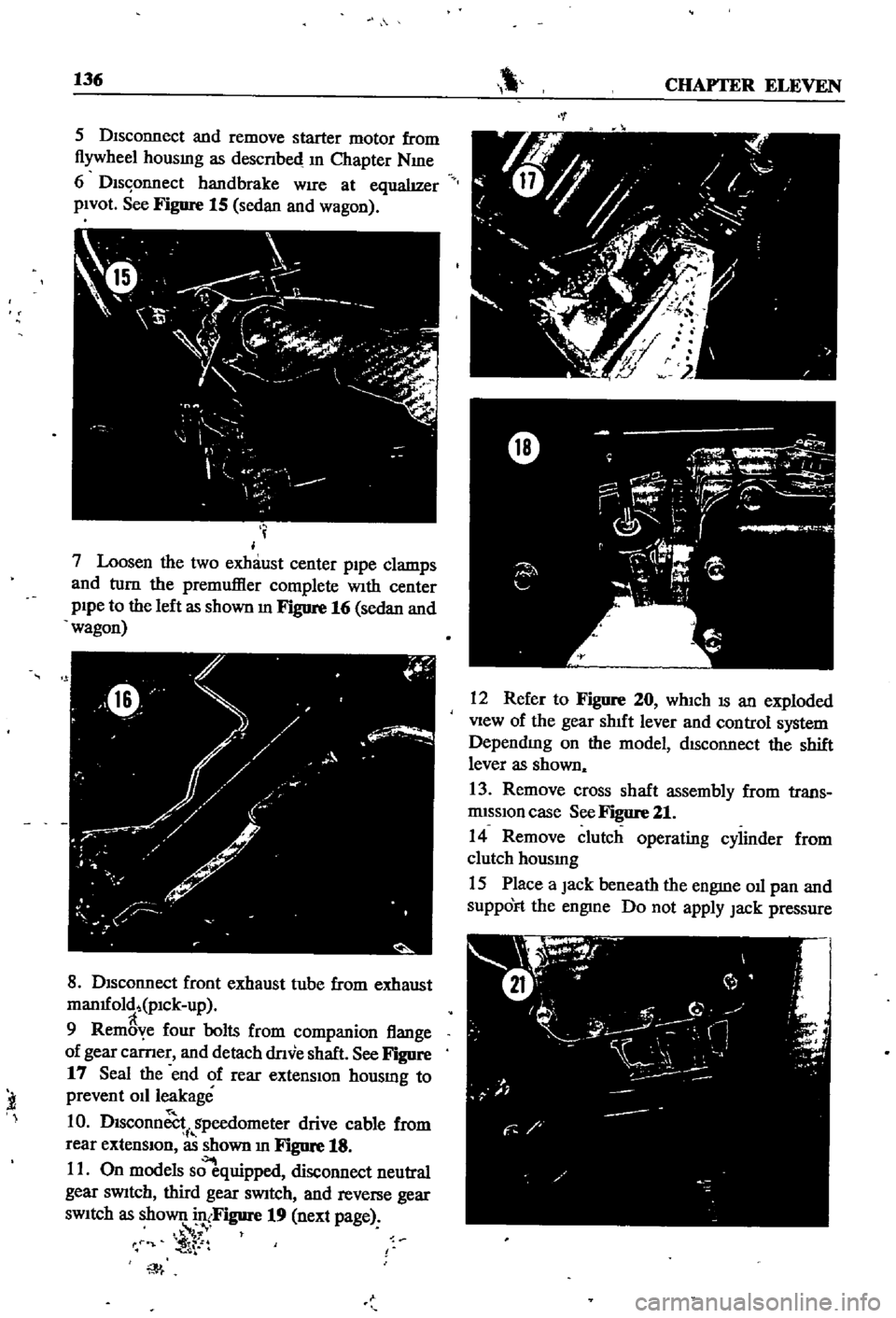

12

Refer

to

Figure

20

whIch

IS

an

exploded

View

of

the

gear

shIft

lever

and

control

system

DependIng

on

the

model

dISconnect

the

shift

lever

as

shown

13

Remove

cross

shaft

assembly

from

trans

rmsslOn

case

See

Figure

21

14

Remove

clutch

operating

cylinder

from

clutch

housmg

15

Place

a

Jack

beneath

the

engme

011

pan

and

SuppOFt

the

engme

Do

not

apply

Jack

pressure

Page 142 of 252

M

I

CL

SMISSION

AND

DRIVESIIAF1

137

i@

v

l

ll

r

1

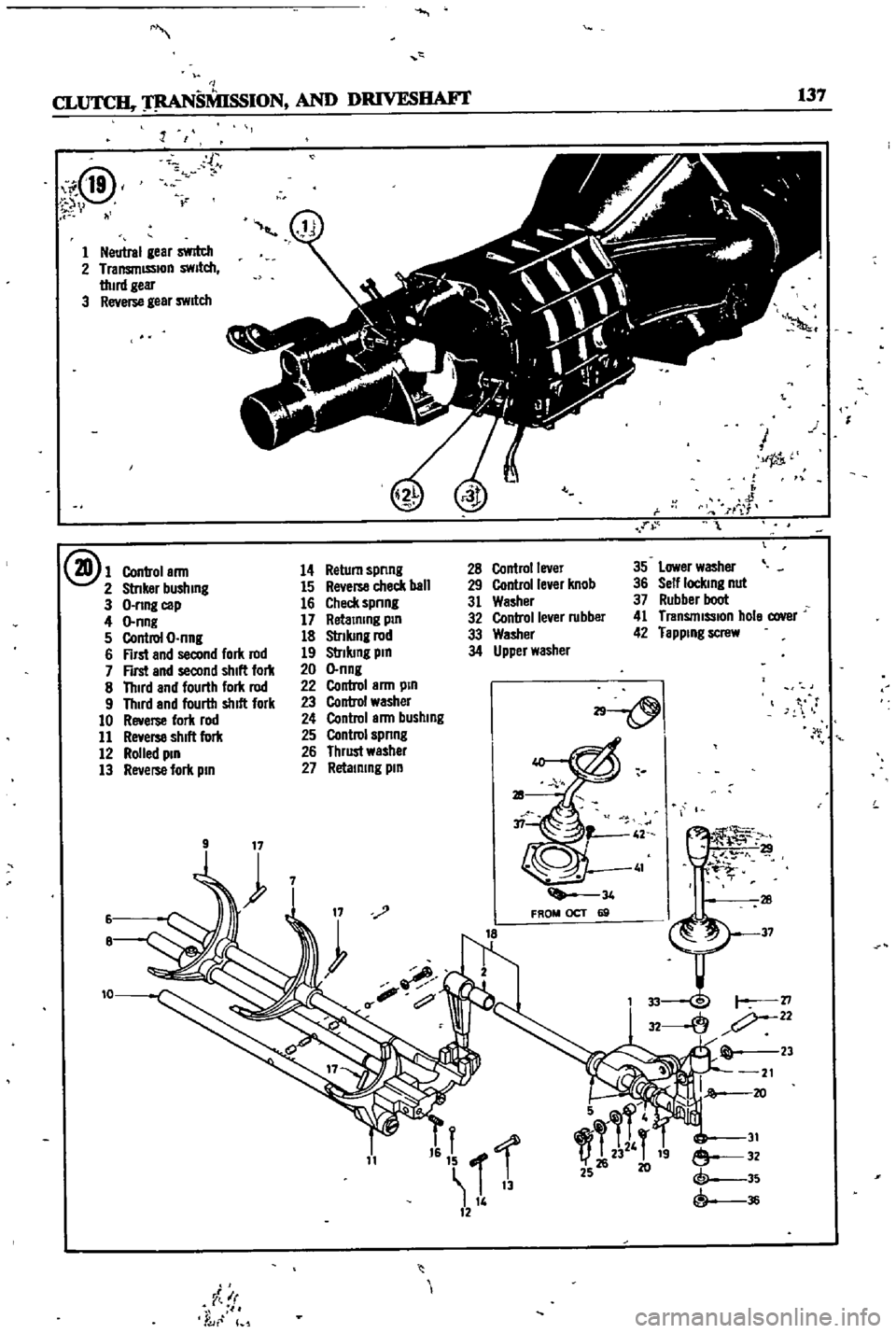

Neutral

gear

swrtch

2

TransmISSIon

swllch

thud

geu

3

Reverse

gear

SWitch

@1

Control

arm

14

Return

spnng

2

StnkBr

bushmg

15

Re

erse

check

ball

3

O

nng

cep

16

Check

spnng

4

O

nng

17

Retalmng

pm

5

Control

O

nng

18

Slnlung

rod

6

First

and

second

fork

rod

19

Slnlung

pm

7

First

and

second

shill

fork

20

O

nng

8

Thud

and

fourth

lork

rod

22

Control

arm

pm

9

Third

and

fourth

shill

fork

23

Control

washer

10

Reverse

fork

rod

24

Control

arm

bushmg

11

Reverse

shill

fork

25

Control

spnng

12

Rolled

pm

26

Thrust

wesher

13

Reverse

fork

pm

27

Retammg

pm

9

0

11

f

Ir

foUr

1

i

1

k

jl

n

1

1

l

28

Control

lever

35

Lower

washer

29

Control

lever

knob

36

Self

lockmg

nut

31

Washer

37

Rubber

boot

32

Controlle

er

rubber

41

Tnmsmlsslon

hole

cover

33

Washer

42

Tappmg

screw

34

Upper

washer

29

c

28

37

16

t

f

f

1

I

13

1

12

5

T

2V

T

19

25

26

20

31

e

32

@

35

@

36

Page 143 of 252

138

CHAFfER

ELEVEN

to

dram

plug

Use

a

block

of

wood

between

the

011

pan

and

the

Jack

16

Remove

two

bolts

attaching

the

transmIS

sion

to

the

rear

engine

mount

Place

a

Jack

under

the

transmISSIon

and

support

the

transmissIOn

Remove

four

bolts

holdmg

the

rear

engme

cross

member

to

the

body

sedan

and

wagon

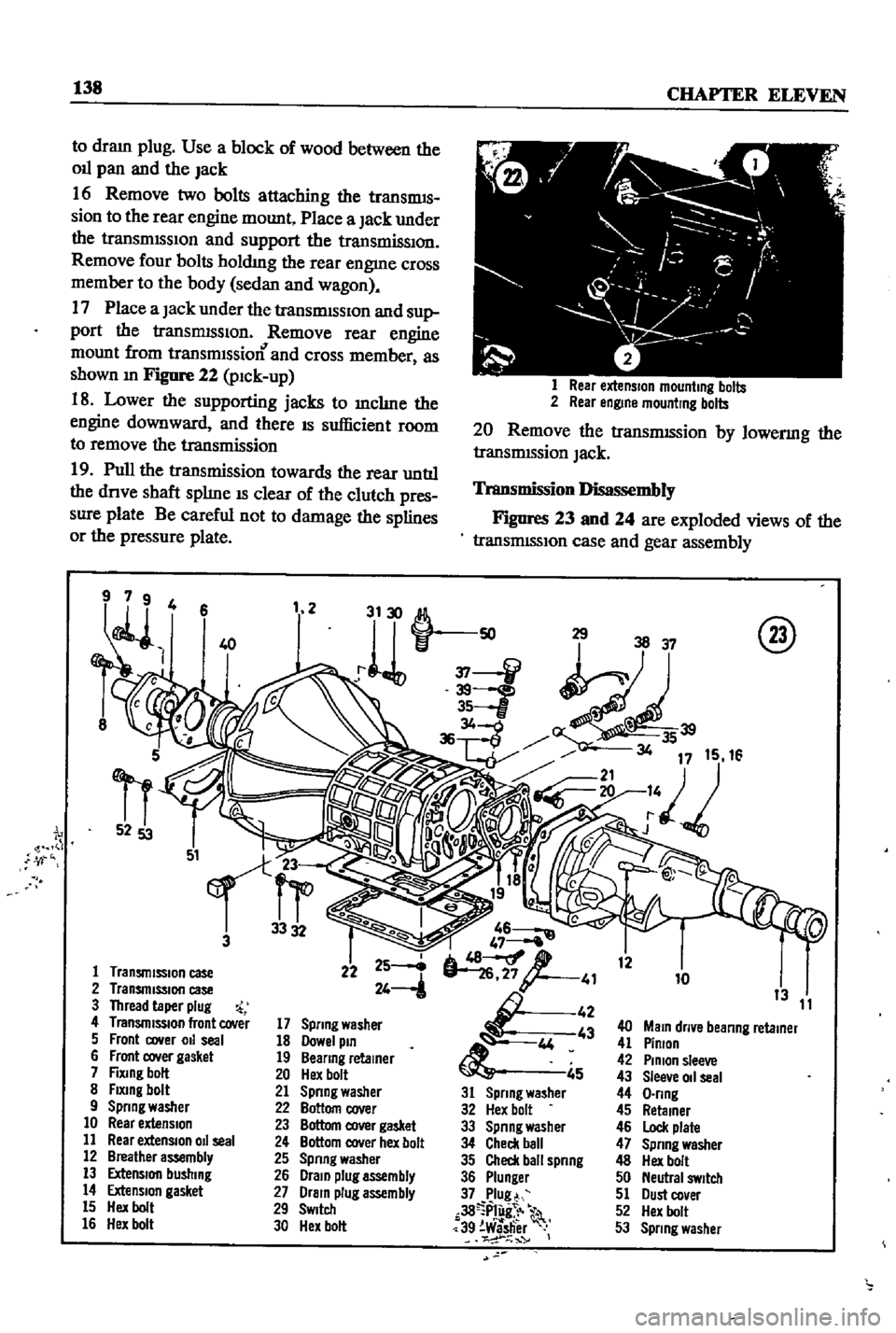

17

Place

a

Jack

under

the

transmISSIon

and

sup

port

the

transmISSIon

Remove

rear

engine

mount

from

transmlssiod

and

cross

member

as

shown

In

Figure

22

pIck

up

18

Lower

the

supporting

jacks

to

mclme

the

engine

downward

and

there

IS

sufficient

room

to

remove

the

transmission

19

Pull

the

transmission

towards

the

rear

until

the

dnve

shaft

splme

IS

clear

of

the

clutch

pres

sure

plate

Be

careful

not

to

damage

the

splines

or

the

pressure

plate

6

40

t

I

j

fI

1

2

fr

l

3332

3

1

TransmiSSion

case

2

TransmiSSion

case

3

Thread

taper

plug

t

4

TransmiSSion

Iront

cover

5

Front

cover

011

seal

6

Front

cover

gasket

7

fixmg

bolt

8

Flxmg

bolt

9

Spnng

washer

10

Rear

extension

11

Reer

extenSIon

011

seal

12

Breather

assembly

13

Extension

bushmg

14

Extension

gasket

15

Hex

bolt

16

Hex

bolt

17

Spllng

washer

18

Dowel

pm

19

Beallng

retainer

20

Hex

bolt

21

Spnng

washer

22

Bottom

cover

23

Bottom

cover

gasket

24

Bottom

cover

hex

bolt

25

Spnng

washer

26

Drem

plug

essembly

27

Dram

plug

assembly

29

SwItch

30

Hex

bolt

l

r

I

J

J

I

n

S

T

r

re

l

1

Rear

extension

mountmg

bolts

2

Rear

engme

mounting

bolts

20

Remove

the

transmISsion

by

lowenng

the

transmISsion

Jack

Transmission

Disassembly

Figures

23

and

24

are

exploded

views

of

the

transrmSSlon

case

and

gear

assembly

@

46

47

6

i

4826J

1

41

44

5

31

Spring

washer

32

Hex

bolt

33

Spnng

washer

34

Check

ball

35

Check

ball

spnng

36

Plunier

37

Plug

r

38

P1

g

39

Washer

o

12

10

13

11

40

MaIO

dllve

beanng

retamer

41

Pinion

42

PInion

sleeve

43

Sleeve

011

seal

44

O

lIng

45

Retamer

46

Lock

plate

47

Spnng

washer

48

Hex

bolt

50

Neutral

SWitch

51

Dust

co

er

52

Hex

bolt

53

Sprmg

washer

Page 144 of 252

CLUTCH

TRANSMISSION

AND

DRIVESHAFI

139

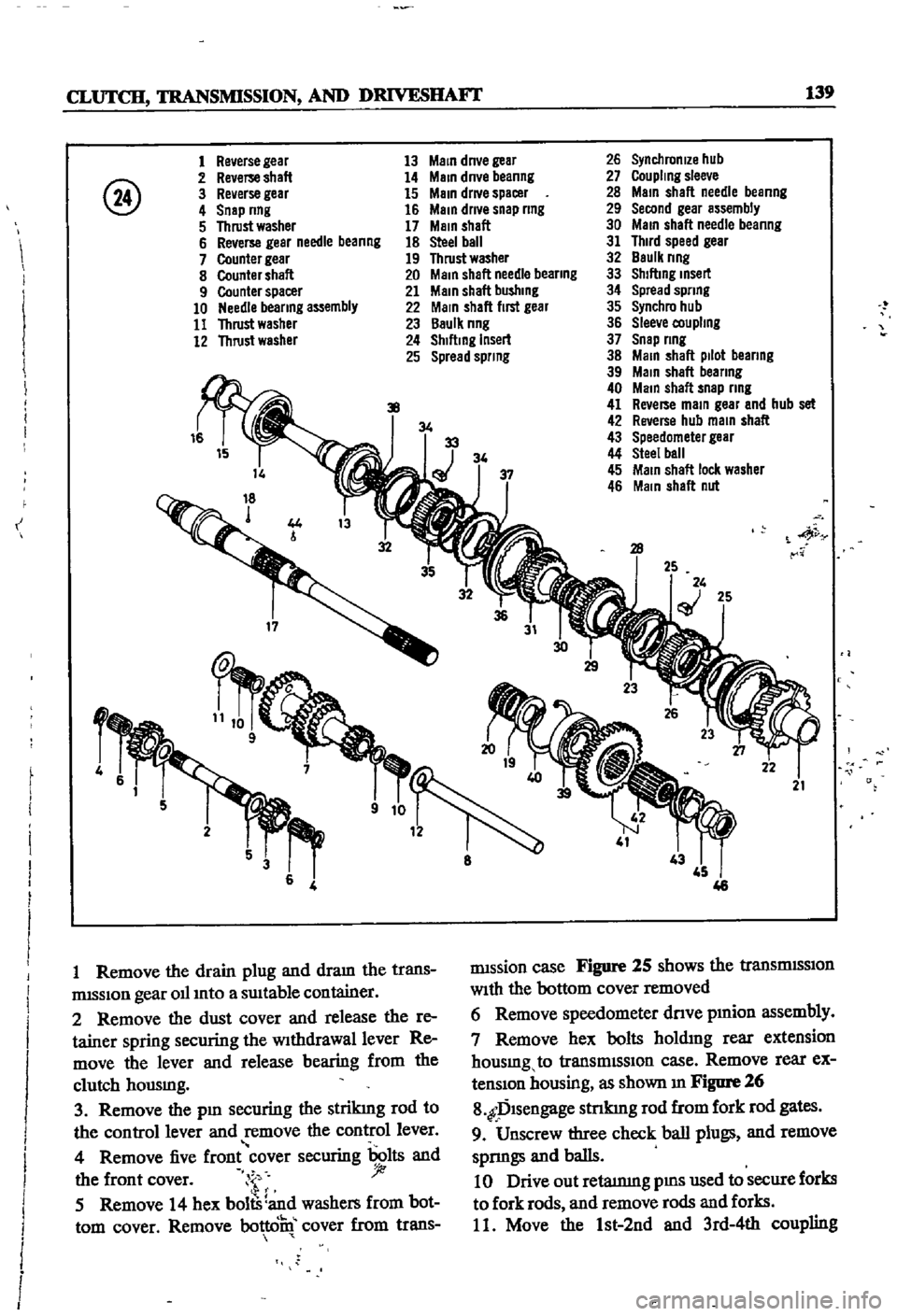

@

1

Re

erse

gear

2

Re

erse

shaft

3

Reverse

gear

4

Snep

nng

5

Thrust

washer

6

Reverse

gear

needle

beanng

7

Counter

gear

8

Counter

shaft

9

Counter

spacer

10

Needle

bearing

assembly

11

Thrust

washer

12

Thrust

washer

J

f

I

I

I

I

I

I

I

I

I

I

J

I

I

i

I

f

4

rm

9

13

MaIO

dnve

gear

14

MaIO

dn

e

beanng

15

MaIO

drl

e

spacer

16

MelO

drl

e

snap

ring

17

MaIO

shaft

18

steel

ball

19

Thrust

washer

20

MaIO

shaft

needle

bearing

21

Meln

shaft

bushlOg

22

MaIO

shaft

flm

gear

23

Baulk

nng

24

Sh

ftlOg

Insert

25

Spread

sprlOg

9

1

Remove

the

drain

plug

and

dram

the

trans

rmSSlon

gear

011

Into

a

SUItable

container

2

Remove

the

dust

cover

and

release

the

re

tainer

spring

securing

the

Withdrawal

lever

Re

move

the

lever

and

release

bearing

from

the

clutch

housmg

3

Remove

the

pIn

securing

the

strikmg

rod

to

the

control

lever

and

remove

the

control

lever

4

Remove

five

front

cover

securing

bolts

and

the

front

cover

i

j

5

Remove

14

hex

bolts

and

washers

from

bot

tom

cover

Remove

bottcifu

cover

from

trans

I

I

I

I

I

I

i

i

J

34

34

26

Synchronize

hub

27

CoupllOg

slee

e

28

MaIO

shaft

needle

beanng

29

Second

gear

assembly

30

MaIO

shaft

needle

beanng

31

Third

speed

gear

32

Baulk

nng

33

ShlftlOg

IOsert

34

Spread

spring

35

Synchro

hub

36

Slee

e

coupllOg

37

Snep

nng

38

MaIO

shaft

pilot

beanng

39

Main

shaft

bearing

40

MaIO

shaft

snap

ring

41

Re

erse

maIO

gear

and

hub

set

42

Rwerse

hub

maIO

shaft

43

Speedometer

gear

44

Steel

ball

45

MaIO

sheft

loc

l

washer

46

MaIO

shaft

nut

28

iy

25

25

21

rmssion

case

Figure

25

shows

the

tranSmISSIon

With

the

bottom

cover

removed

6

Remove

speedometer

dnve

pmion

assembly

7

Remove

hex

bolts

holdmg

rear

extension

housmg

to

transmISSIon

case

Remove

rear

ex

tenSIon

housing

as

shown

m

Figure

26

8

fDlsengage

stnkmg

rod

from

fork

rod

gates

9

Unscrew

three

check

ball

plugs

and

remove

sprmgs

and

balls

10

Drive

out

retatnmg

pms

used

to

secure

forks

to

fork

rods

and

remove

rods

and

forks

11

Move

the

1st

2nd

and

3rd

4th

coupling

Page 145 of 252

140

CHAPTER

ELEVEN

@

sleeve

into

gear

at

the

same

tune

This

will

lock

the

mam

shaft

Release

the

main

shaft

nut

12

Withdraw

the

counter

shaft

and

remove

the

counter

gear

with

the

two

needle

roller

bearings

and

spacers

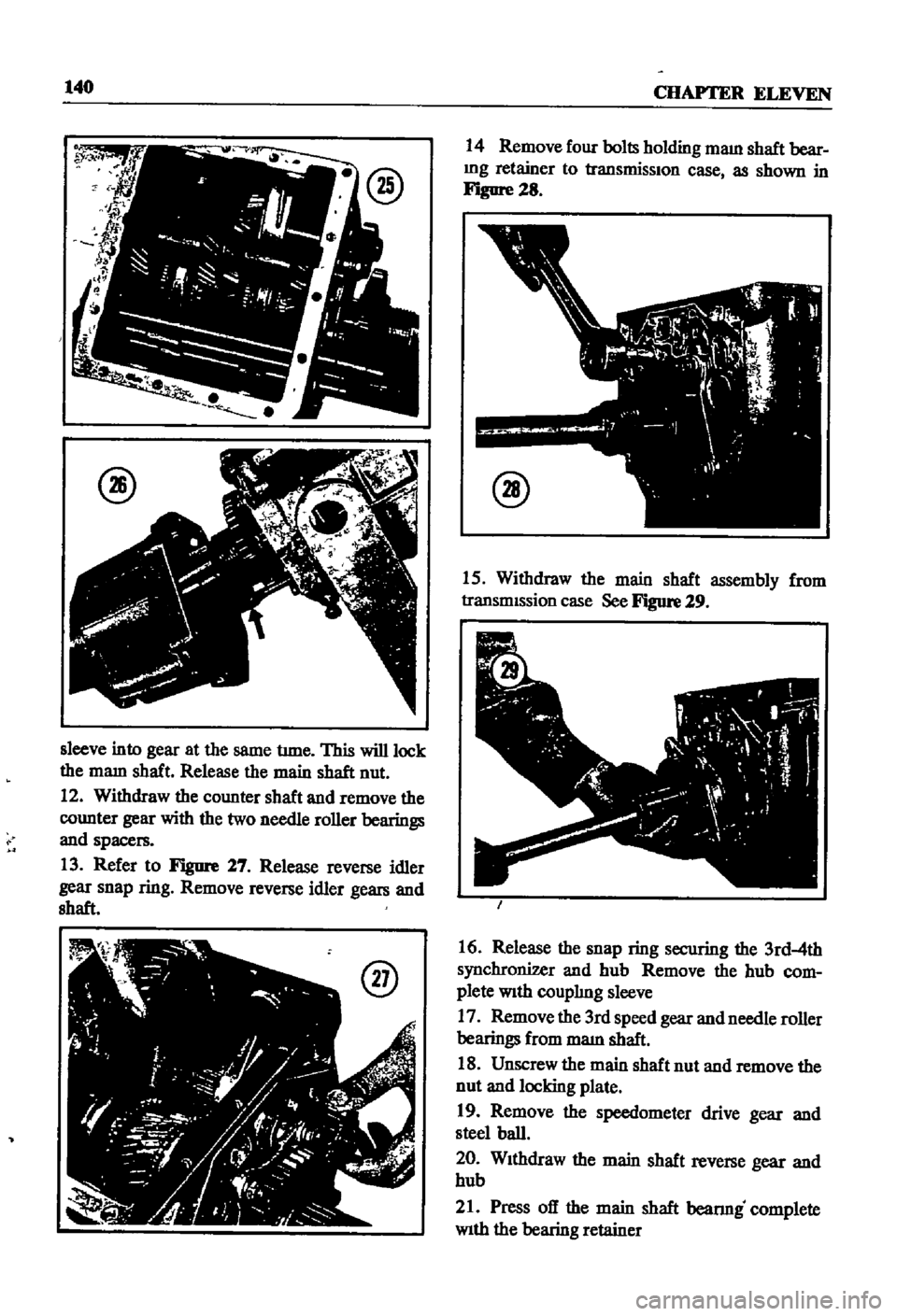

13

Refer

to

Figure

27

Release

reverse

idler

gear

snap

ring

Remove

reverse

idler

gears

and

shaft

@

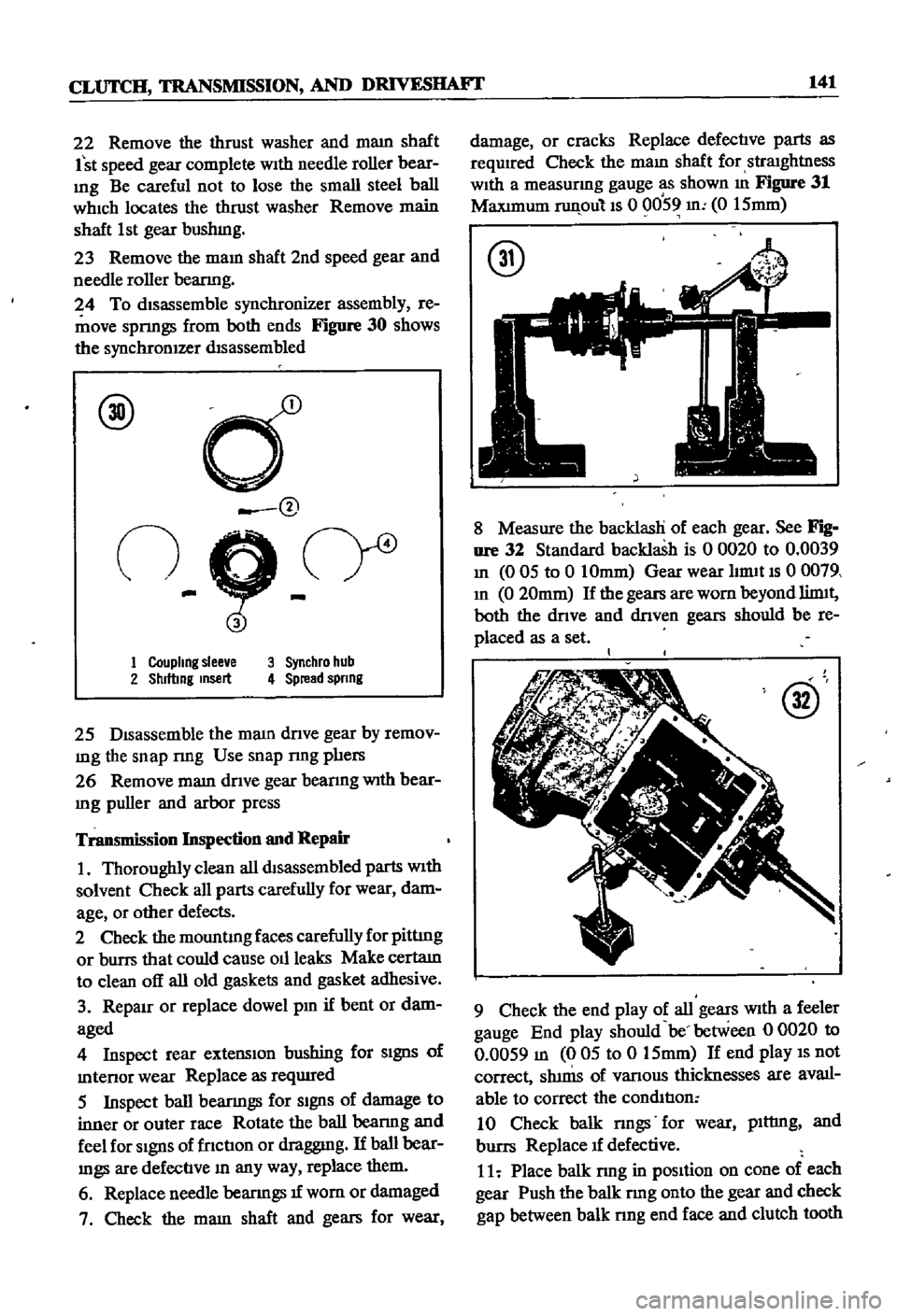

14

Remove

four

bolts

holding

maIn

shaft

bear

Ing

retainer

to

transmissIOn

case

as

shown

in

Figure

28

@

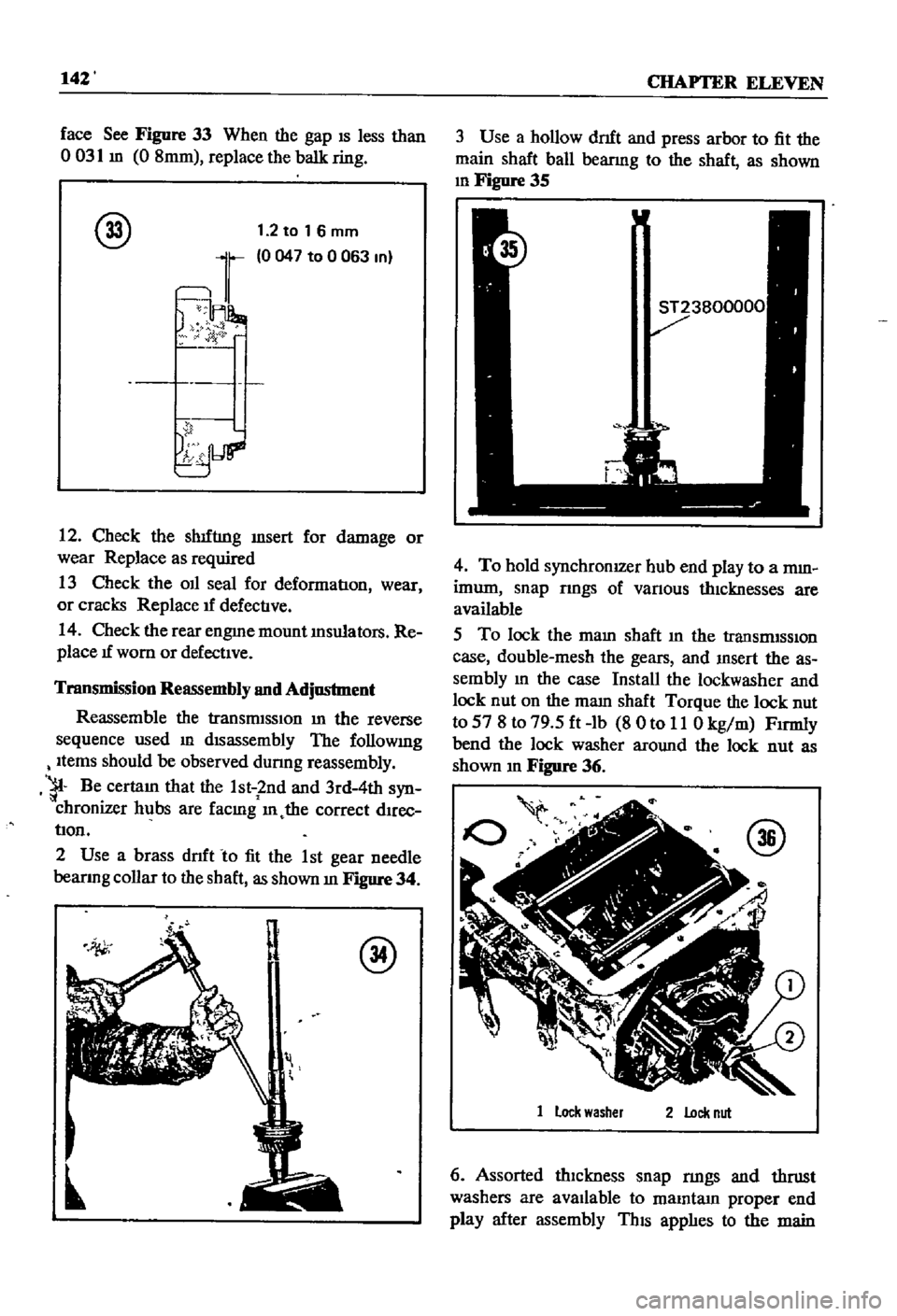

15

Withdraw

the

main

shaft

assembly

from

transmIssion

case

See

Figure

29

16

Release

the

snap

ring

securing

the

3rd

4th

synchronizer

and

hub

Remove

the

hub

com

plete

With

couplIng

sleeve

17

Remove

the

300

speed

gear

and

needle

roller

bearings

from

maIn

shaft

18

Unscrew

the

main

shaft

nut

and

remove

the

nut

and

locking

plate

19

Remove

the

speedometer

drive

gear

and

steel

ball

20

WIthdraw

the

main

shaft

reverse

gear

and

hub

21

Press

off

the

main

shaft

bearmg

complete

With

the

bearing

retainer

Page 146 of 252

CLUTCH

TRANSMISSION

AND

DRlVESHAFI

141

22

Remove

the

thrust

washer

and

mam

shaft

1st

speed

gear

complete

With

needle

roller

bear

mg

Be

careful

not

to

lose

the

small

steel

ball

which

locates

the

thrust

washer

Remove

main

shaft

1st

gear

bushmg

23

Remove

the

mam

shaft

2nd

speed

gear

and

needle

roller

bearmg

24

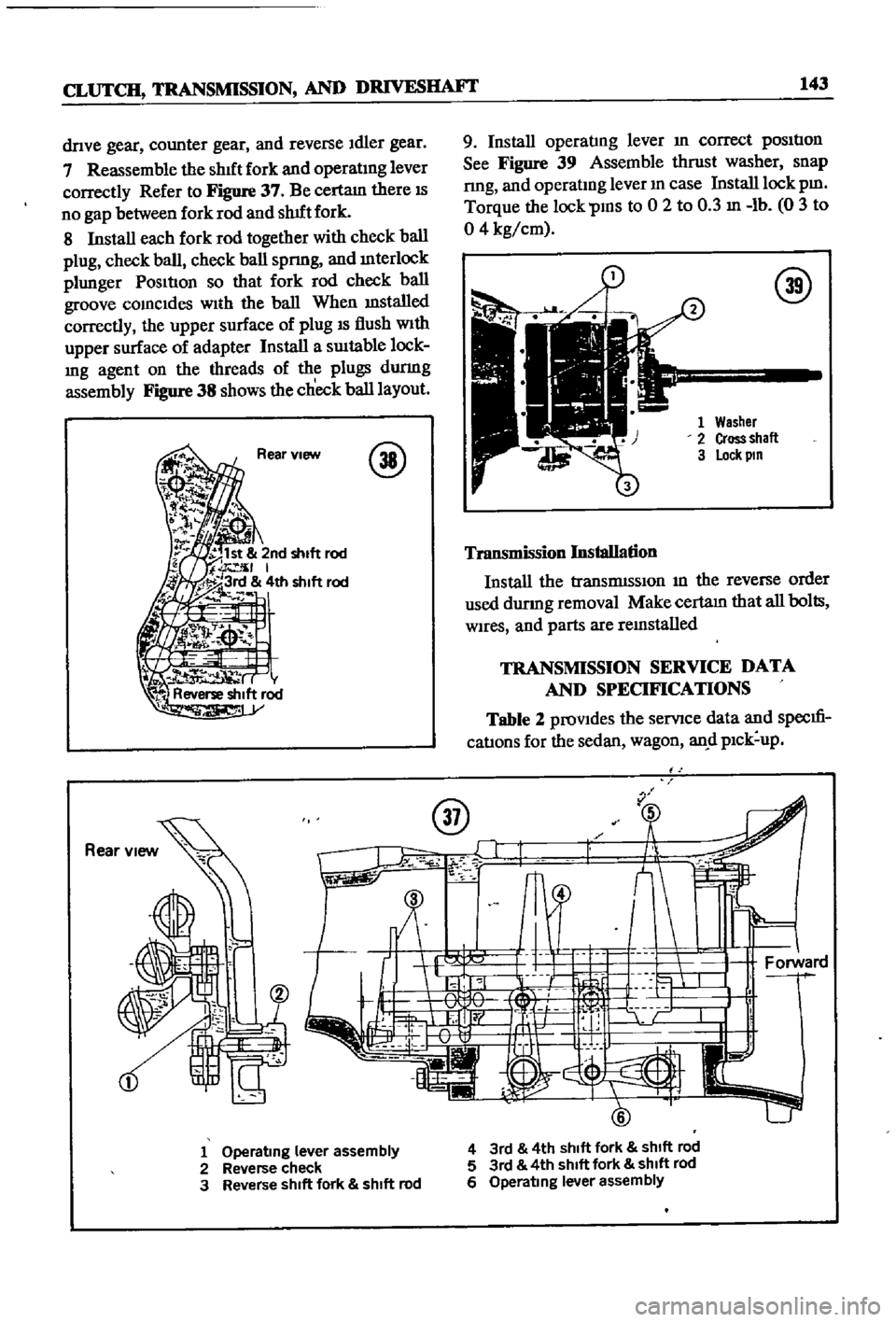

To

dISassemble

synchronizer

assembly

re

move

sprmgs

from

both

ends

Figure

30

shows

the

synchronIZer

dIsassembled

@

d

@

n

9

cr

1

Coupling

slee

e

3

Synchro

hub

2

Shlftmg

msert

4

Spread

spnng

25

DIsassemble

the

mam

dnve

gear

by

remov

mg

the

snap

nng

Use

snap

nng

phers

26

Remove

mam

dnve

gear

bearmg

With

bear

Ing

puller

and

arbor

press

Transmission

Inspection

and

Repair

1

Thoroughly

clean

all

dtsassembled

parts

With

solvent

Check

all

parts

carefully

for

wear

dam

age

or

other

defects

2

Check

the

mountIng

faces

carefully

for

pittIng

or

burrs

that

could

cause

011

leaks

Make

certatn

to

clean

off

all

old

gaskets

and

gasket

adhesive

3

RepaIr

or

replace

dowel

pm

if

bent

or

dam

aged

4

Inspect

rear

extensIon

bushing

for

SIgnS

of

mtenor

wear

Replace

as

reqUIred

5

Inspect

ball

bearmgs

for

SIgnS

of

damage

to

inner

or

outer

race

Rotate

the

ball

bearmg

and

feel

for

SIgnS

of

fnctIon

or

draggmg

If

ball

bear

mgs

are

defectIve

In

any

way

replace

them

6

Replace

needle

bearIngs

1f

wom

or

damaged

7

Check

the

mam

shaft

and

gears

for

wear

damage

or

cracks

Replace

defectIve

parts

as

required

Check

the

maIn

shaft

for

straIghtness

WIth

a

measurmg

gauge

as

shown

m

Figure

31

MaxImum

runpulls

0

0059

m

0

15mm

@

8

Measure

the

backlasH

of

each

gear

See

Fig

nre

32

Standard

backlash

is

0

0020

to

0

0039

In

0

05

to

0

10mm

Gear

wear

hrmt

IS

0

0079

In

0

20mm

If

the

gears

are

worn

beyond

limtt

both

the

dnve

and

dnven

gears

should

be

re

placed

as

a

set

@

9

Check

the

end

play

of

all

gears

WIth

a

feeler

gauge

End

play

should

be

between

0

0020

to

0

0059

m

005

to

0

15mm

If

end

play

IS

not

correct

Sh1nIS

of

vanous

thicknesses

are

avail

able

to

correct

the

condItIon

10

Check

balk

nngs

for

wear

plttmg

and

burrs

Replace

1f

defective

11

Place

balk

rmg

in

pOSItion

on

cone

of

each

gear

Push

the

balk

rmg

onto

the

gear

and

check

gap

between

balk

nng

end

face

and

clutch

tooth

Page 147 of 252

142

CHAPTER

ELEVEN

face

See

Figure

33

When

the

gap

IS

less

than

o

031

m

0

8mm

replace

the

balk

ring

@

1

2

to

1

6

mm

0047

to

0

063

In

12

Check

the

sh1fnng

msert

for

damage

or

wear

Replace

as

required

13

Check

the

OIl

seal

for

deformatIon

wear

or

cracks

Replace

1f

defectIve

14

Check

the

rear

engme

mount

Insulators

Re

place

1f

worn

or

defectIve

Transmission

Reassembly

and

Adjustment

Reassemble

the

transmISSIon

In

the

reverse

sequence

used

ill

dIsassembly

The

followmg

Items

should

be

observed

dunng

reassembly

1

Be

certaIn

that

the

1st

2nd

and

3rd

4th

syn

chronizer

hubs

are

facmg

ill

the

correct

dIrec

tIon

2

Use

a

brass

dnft

to

fit

the

1

st

gear

needle

bearlOg

collar

to

the

shaft

as

shown

In

Figure

34

il

@

3

Use

a

hollow

dnft

and

press

arbor

to

fit

the

main

shaft

ball

bearmg

to

the

shaft

as

shown

10

Figure

35

4

To

hold

synchronIZer

hub

end

play

to

a

mm

imum

snap

rmgs

of

vanous

thIcknesses

are

available

5

To

lock

the

malO

shaft

m

the

transrmSSlOn

case

double

mesh

the

gears

and

msert

the

as

sembly

10

the

case

Install

the

lockwasher

and

lock

nut

on

the

mam

shaft

Torque

the

lock

nut

to

57

8

to

79

5

ft

lb

8

0

to

11

0

kg

m

Fumly

bend

the

lock

washer

around

the

lock

nut

as

shown

In

Figure

36

1

lock

washer

2

Lock

nut

6

Assorted

thIckness

snap

nngs

and

thrust

washers

are

avallable

to

malOtam

proper

end

play

after

assembly

ThIS

applIes

to

the

main

Page 148 of 252

CLUTCH

TRANSMISSION

AND

DRlVESHAFI

143

dnve

gear

counter

gear

and

reverse

Idler

gear

7

Reassemble

the

shIft

fork

and

operatIng

lever

correctly

Refer

to

Figure

37

Be

certam

there

IS

no

gap

between

fork

rod

and

shUt

fork

8

Install

each

fork

rod

together

with

check

ball

plug

check

ball

check

ball

spnng

and

mterlock

plunger

PosItIon

so

that

fork

rod

check

ball

groove

comcldes

wIth

the

ball

When

mstalled

correctly

the

upper

surface

of

plug

IS

flush

With

upper

surface

of

adapter

Install

a

sUItable

lock

Ing

agent

on

the

threads

of

the

plugs

durmg

assembly

Figure

38

shows

the

check

ball

layout

@

9

Install

operatIng

lever

In

correct

pOSItIon

See

Figure

39

Assemble

thrust

washer

snap

nng

and

operatlDg

lever

m

case

Install

lock

pm

Torque

the

lock

PIDS

to

0

2

to

0

3

In

lb

0

3

to

04

kg

cm

@

Washer

Cross

shall

lock

pm

Transmission

Installation

Install

the

tranSmISSIon

m

the

reverse

order

used

durmg

removal

Make

certam

that

all

bolts

Wires

and

parts

are

remstalled

TRANSMISSION

SERVICE

DATA

AND

SPECIFICATIONS

Table

2

proVIdes

the

servlce

data

and

specm

catIons

for

the

sedan

wagon

an

d

pIck

up

u

1

Operating

lever

assembly

2

Reverse

check

3

Reverse

shift

fork

shift

rod

4

3rd

4th

shift

fork

shift

rod

5

3rd

4th

shIft

fork

shift

rod

6

Operating

lever

assembly

Page 149 of 252

144

CHAPTER

ELEVEN

TAANSMISSlON

SERVICE

DATA

AND

SPECIRCATIONS

Table

2

r

General

SpecificatIOns

Gear

Ratlo

1st

2nd

3rd

4th

Reverse

011

capacity

Detail

SpeCIfications

Gear

backlash

Replacement

standard

Gear

end

play

Balk

ring

cone

clearance

Replacement

standard

5

tl

viV

t

O

5

0

If

3657

2558

1419

1000

3638

3

6

pints

Tightening

Torque

ft

Ib

kg

m

Engine

transmission

installation

bolt

Front

cover

transmission

installation

bolt

Rear

extensIon

transmIssion

installation

bolt

Main

shaft

tlghtel

lng

bolt

Companion

flange

tightening

nut

Rear

engine

mount

installation

bolt

Filler

plug

Drain

plug

Back

up

lamp

sWItch

Bottom

cover

bolt

Speedometer

pinion

bolt

Interlock

plug

Operating

lever

Reverse

check

Control

lever

installatIOn

bolt

00020

to

0

0039

In

005

to

0

10mm

o

0079

In

0

20mm

o

0020

to

0

0059

In

0

05

to

0

15mm

00472

to

0

0630

In

1

2

to

1

6mm

00315

In

08mm

174

to

20

2

24

to

2

8

5

8

to

7

2

0

8

to

1

0

10

1

to

130

1

4

to

1

8

57

8t079

5

80to

11

0

72

3

to

101

2

100

to

140

239

to

27

5

3

3

to

38

18

1

to

25

3

25

to

3

5

14

5

to

21

7

20

to

3

0

14

5

to

21

7

2

0

to

3

0

5

8

to

7

2

0

8

to

1

0

2

2

to

2

9

03

to

0

4

123

to

15

2

1

7

to

2

1

22

to

2

9

0

3

to

0

4

14

5

to

21

7

20

to

3

0

13

7

to

15

9

1

9

to

2

2

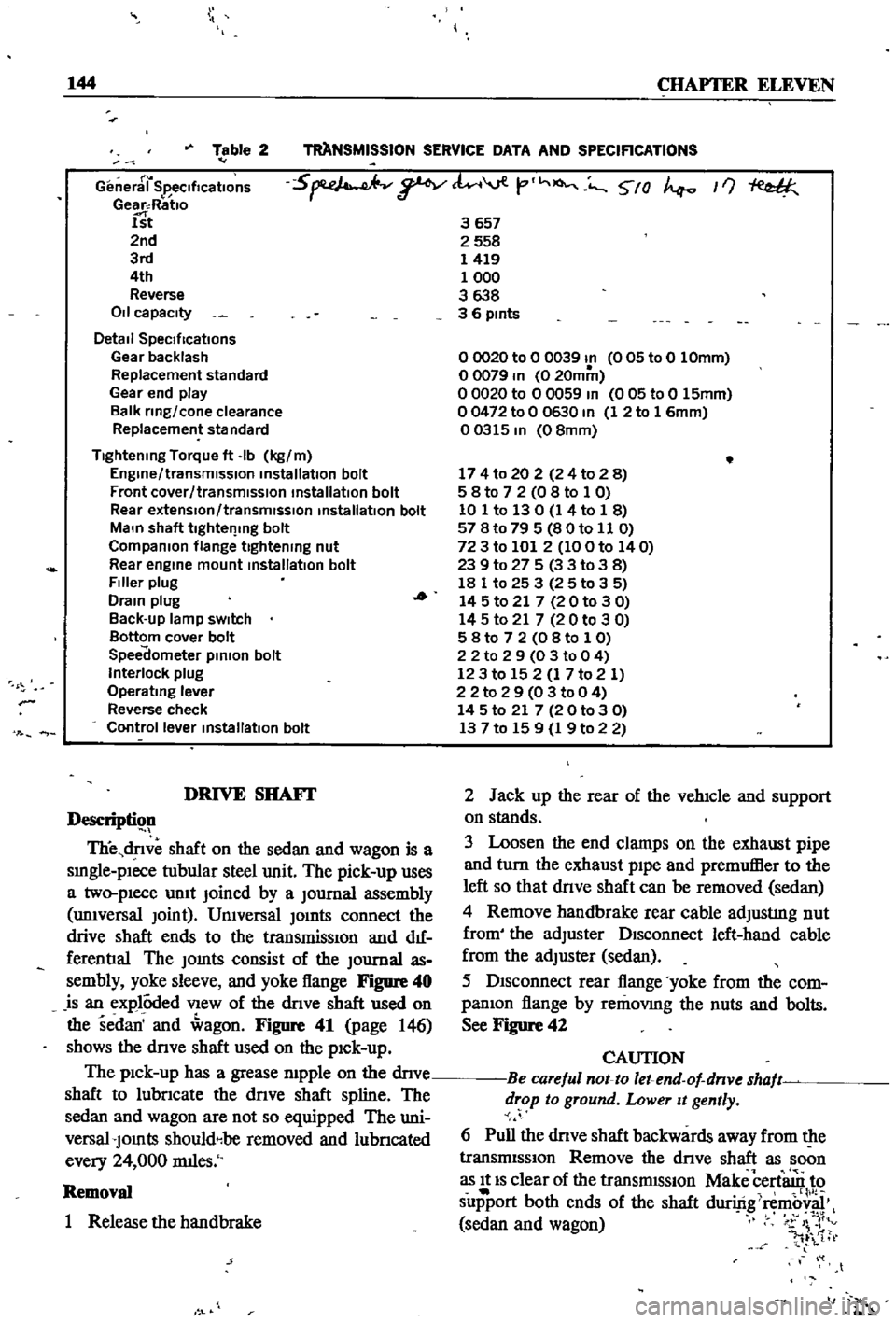

DRIVE

SHAFf

Descripti

ll

TIie

dnve

shaft

on

the

sedan

and

wagon

is

a

smgle

plece

tubular

steel

unit

The

pick

up

uses

a

two

pIece

umt

Joined

by

a

Journal

assembly

unIversal

Joint

UnIversal

Jomts

connect

the

drive

shaft

ends

to

the

transmissIOn

and

d1f

ferentIal

The

Jomts

consist

of

the

Journal

as

sembly

yoke

sleeve

and

yoke

flange

Figure

40

is

an

explOded

VIew

of

the

dnve

shaft

used

on

the

sedan

and

agon

Figure

41

page

146

shows

the

dnve

shaft

used

on

the

pIck

up

The

pIck

up

has

a

grease

mpple

on

the

dnve

shaft

to

lubncate

the

dnve

shaft

spline

The

sedan

and

wagon

are

not

so

equipped

The

uni

versal

Jomts

shouldebe

removed

and

lubncated

every

24

000

rmles

Removal

1

Release

the

handbrake

j

2

Jack

up

the

rear

of

the

vehIcle

and

support

on

stands

3

Loosen

the

end

clamps

on

the

exhaust

pipe

and

turn

the

exhaust

pIpe

and

premuffier

to

the

left

so

that

dnve

shaft

can

be

removed

sedan

4

Remove

handbrake

rear

cable

adjustIng

nut

from

the

adjuster

DIsconnect

left

hand

cable

from

the

adjuster

sedan

5

DIsconnect

rear

flange

yoke

from

the

com

panIon

flange

by

removmg

the

nuts

and

bolts

See

Figure

42

CAUTION

Be

careful

not

to

let

end

of

dnve

shaft

drop

to

ground

Lower

It

gently

6

Pull

the

dnve

shaft

backwards

away

from

the

transmISSIon

Remove

the

dnve

shaft

as

soon

as

It

IS

clear

of

the

transmISSIon

Make

cert

n

to

support

both

ends

of

the

shaft

duriftgi

mb

sedan

and

wagon

v

4

1tr

l

t

t

Page 150 of 252

CLUTCH

TRANSMISSION

AND

DRIVESIIAFT

145

r

@

l

S

St

P

t

ii

t

1

1

1

0

8

12

3

5

8

12

13

i

f

p

1

2

5

7

Remove

mounting

bolts

from

both

transmis

sion

and

dllIerential

gear

case

Remove

bearing

mounting

bracket

Lower

drive

shaft

to

ground

pick

up

J

iw

sembly

The

drive

shaft

is

a

balanced

unIt

and

must

be

marked

as

to

parts

location

before

dIS

assembly

Mark

the

relative

positions

of

the

drive

shaft

sleeve

yoke

flange

yoke

and

other

parts

so

they

can

be

reassembled

m

their

origmal

positions