lock DATSUN 510 1968 Service Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 185 of 252

180

CHAPTER

TIlIRTEEN

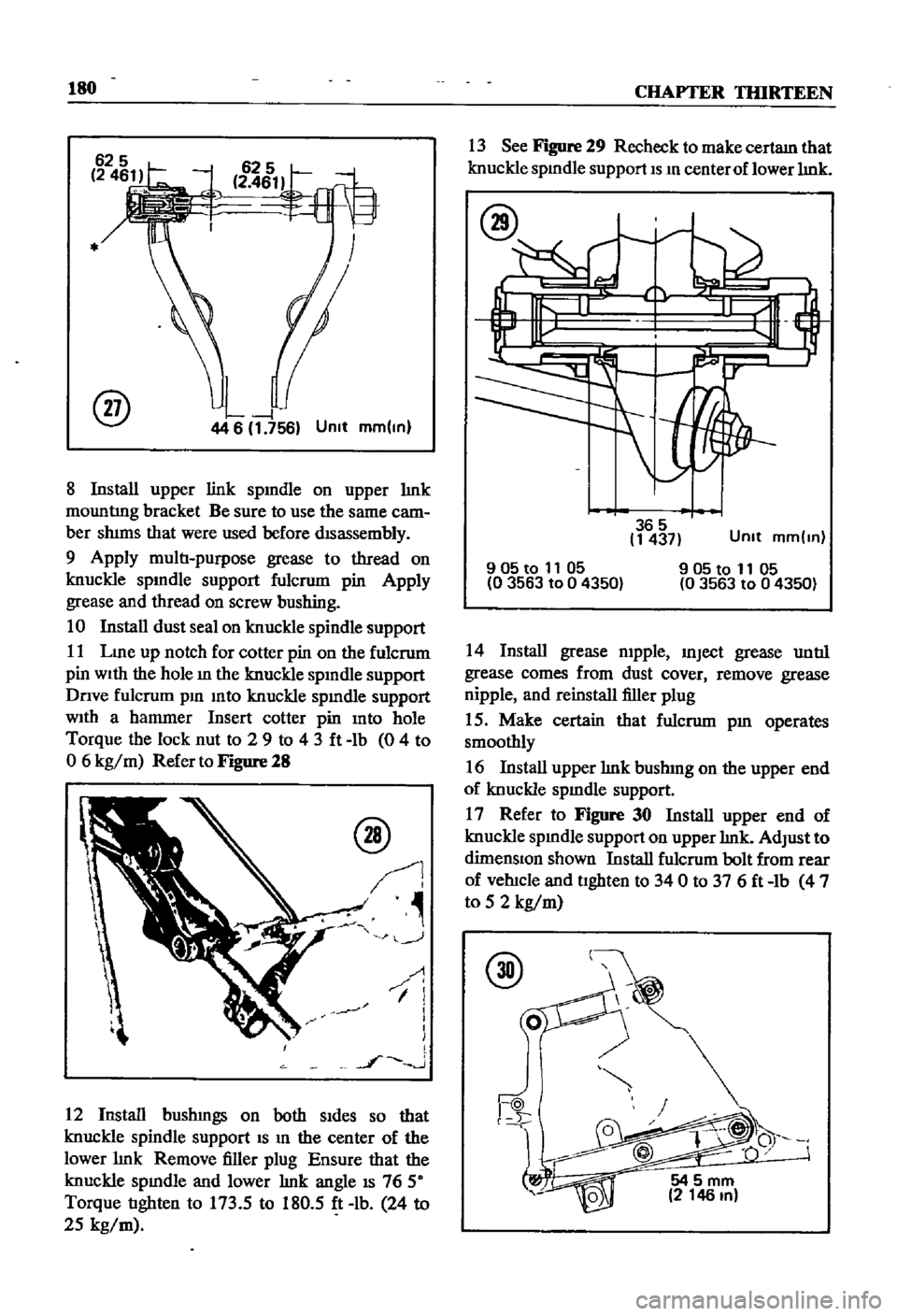

@

44

6

1

756

Unit

mm

ln

8

Install

upper

link

spmdle

on

upper

lmk

mountIng

bracket

Be

sure

to

use

the

same

cam

ber

shims

that

were

used

before

disassembly

9

Apply

multi

purpose

grease

to

thread

on

knuckle

spmdle

support

fulcrum

pin

Apply

grease

and

thread

on

screw

bushing

10

Install

dust

seal

on

knuckle

spindle

support

11

Lme

up

notch

for

cotter

pin

on

the

fulcrum

pin

With

the

hole

m

the

knuckle

spmdle

support

Dnve

fulcrum

pm

mto

knuckle

spmdle

support

With

a

hammer

Insert

cotter

pin

mto

hole

Torque

the

lock

nut

to

2

9

to

43ft

lb

0

4

to

o

6

kg

m

Refer

to

Figure

28

@

J

J

I

1

i

1

l

l

J

J

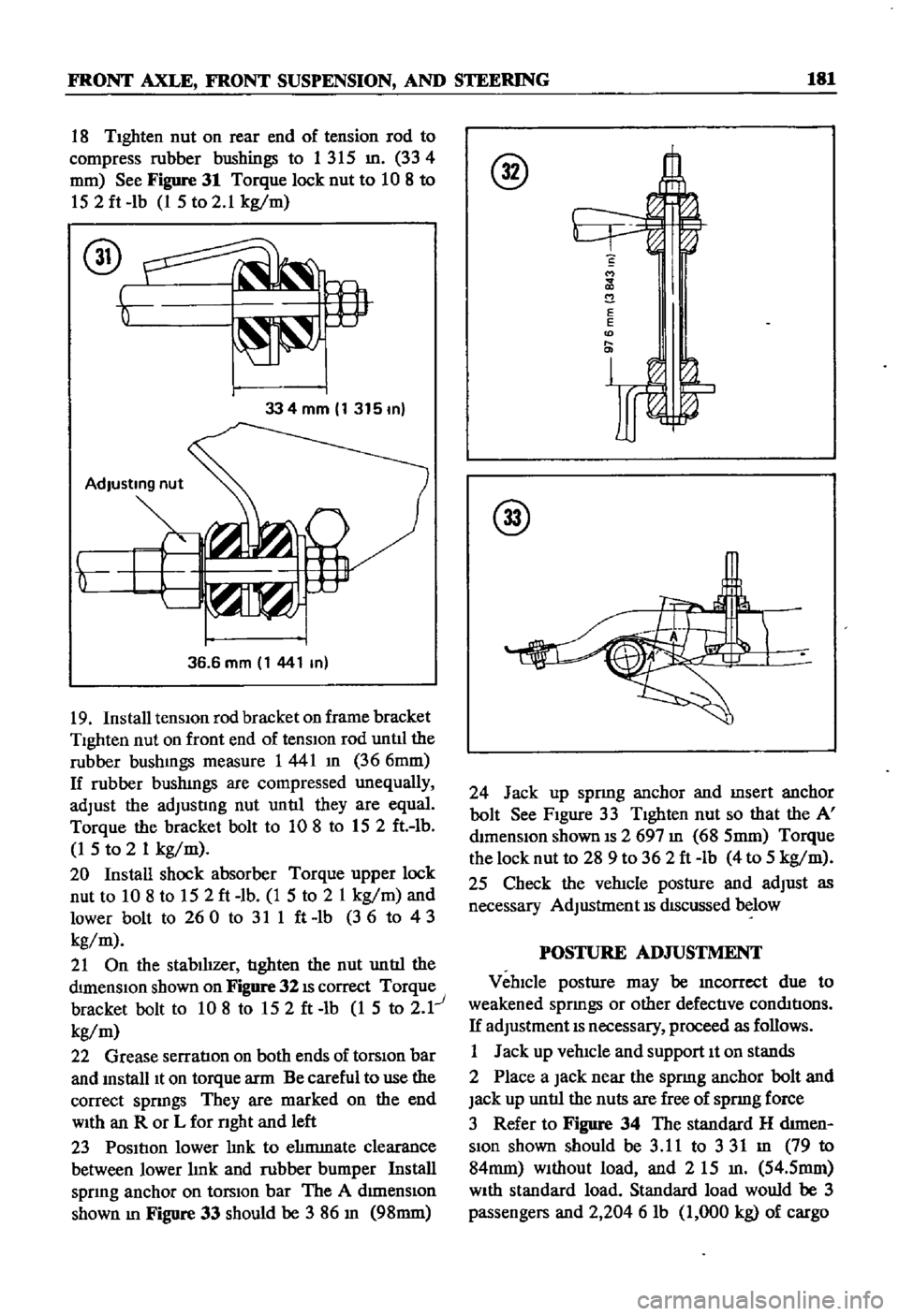

12

Install

bushmgs

on

both

Sides

so

that

knuckle

spindle

support

IS

m

the

center

of

the

lower

lmk

Remove

filler

plug

Ensure

that

the

knuckle

spmdle

and

lower

lmk

angle

IS

76

50

Torque

tighten

to

173

5

to

180

5

ft

lb

24

to

25

kg

m

13

See

Figure

29

Recheck

to

make

certam

that

knuckle

spmdle

support

IS

m

center

of

lower

lmk

365

1437

Unit

mm

ln

905to

11

05

0

3563

to

0

4350

905t01105

03563

to

04350

14

Install

grease

mpple

mJect

grease

until

grease

comes

from

dust

cover

remove

grease

nipple

and

reinstall

filler

plug

15

Make

certain

that

fulcrum

pm

operates

smoothly

16

Install

upper

lmk

bushmg

on

the

upper

end

of

knuckle

spmdle

support

17

Refer

to

Figure

30

Install

upper

end

of

knuckle

spmdle

support

on

upper

lmk

AdJust

to

dimenSIOn

shown

Install

fulcrum

bolt

from

rear

of

vehicle

and

tighten

to

340

to

376ft

lb

4

7

to

5

2

kg

m

@

54

5

mm

2

146

In

Page 186 of 252

FRONT

AXLE

FRONT

SUSPENSION

AND

STEERING

181

18

TIghten

nut

on

rear

end

of

tension

rod

to

compress

rubber

bushings

to

1

315

m

334

fi2

mm

See

Figure

31

Torque

lock

nut

to

10

8

to

152ft

lb

1

5

to

2

1

kg

m

334mm

1315m

36

6

mm

1

441

m

19

Install

tensiOn

rod

bracket

on

frame

bracket

Tighten

nut

on

front

end

of

tensIOn

rod

untll

the

rubber

bushmgs

measure

1441

m

366mm

If

rubber

bushmgs

are

compressed

unequally

adJust

the

adJusting

nut

until

they

are

equal

Torque

the

bracket

bolt

to

108

to

152

ft

lb

1

5

to

2

1

kg

m

20

Install

shock

absorber

Torque

upper

lock

nut

to

10

8

to

152ft

lb

1

5

to

2

1

kg

m

and

lower

bolt

to

260

to

311ft

lb

36

to

43

kg

m

21

On

the

stabilizer

tighten

the

nut

until

the

dimenSIOn

shown

on

Figure

32

IS

correct

Torque

bracket

bolt

to

10

8

to

152ft

lb

1

5

to

2

1

kg

m

22

Grease

serratIon

on

both

ends

of

torSiOn

bar

and

mstalllt

on

torque

arm

Be

careful

to

use

the

correct

spnngs

They

are

marked

on

the

end

WIth

an

R

or

L

for

nght

and

left

23

Position

lower

hnk

to

ehmmate

clearance

between

lower

hnk

and

rubber

bumper

Install

spnng

anchor

on

torsIOn

bar

The

A

dImenSiOn

shown

m

Figure

33

should

be

3

86

m

98mm

S

M

2

E

E

D

@

24

Jack

up

spnng

anchor

and

msert

anchor

bolt

See

Figure

33

Tighten

nut

so

that

the

A

mmenslon

shown

IS

2

697

m

68

5mm

Torque

the

lock

nut

to

28

9

to

362ft

lb

4

to

5

kg

m

25

Check

the

vehicle

posture

and

adJust

as

necessary

AdJustment

IS

dIScussed

below

POSTURE

AD

JUSTMENT

Vehicle

posture

may

be

mcorrcct

due

to

weakened

sprmgs

or

other

defective

conmtions

If

adJustment

IS

necessary

proceed

as

follows

1

Jack

up

vehicle

and

support

It

on

stands

2

Place

a

Jack

near

the

sprmg

anchor

bolt

and

Jack

up

until

the

nuts

are

free

of

spnng

force

3

Refer

to

Figure

34

The

standard

H

d1men

Slon

shown

should

be

3

11

to

331

m

79

to

84mm

Without

load

and

2

15

m

54

5mm

WIth

standard

load

Standard

load

would

be

3

passengers

and

2

204

6

lb

1

000

kg

of

cargo

Page 188 of 252

FRONT

AXLE

FRONT

SUSPENSION

AND

STEERING

183

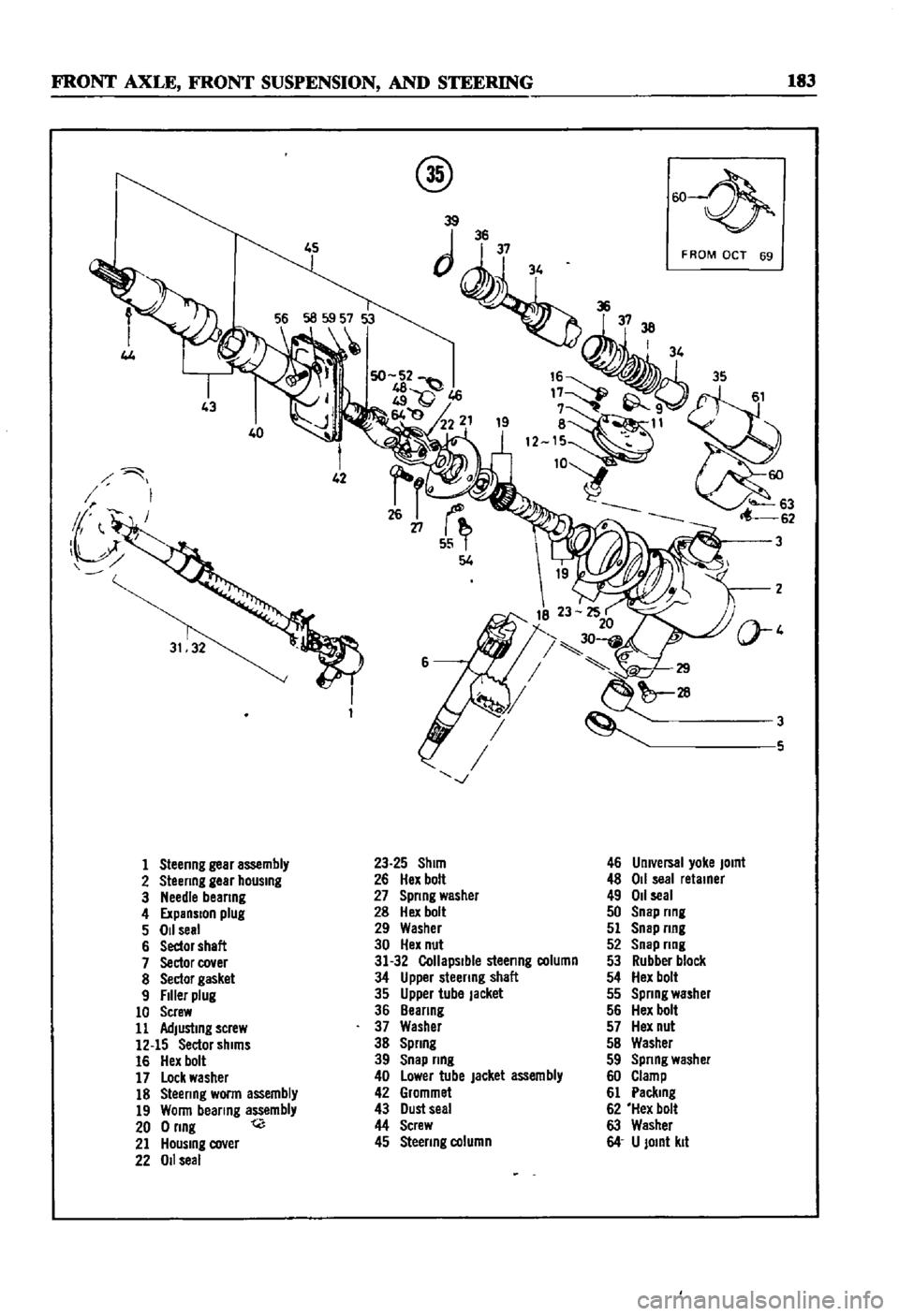

4J

40

1

Steenng

gear

assembly

2

Steenng

gear

hOUSing

3

Needle

beanng

4

ExpanSion

plug

5

011

seal

6

Sedor

shaft

7

Sector

cover

8

Sector

gasket

9

Filler

plug

10

Screw

11

Adjusting

screw

12

15

Sector

shims

16

Hex

bolt

17

Lock

washer

18

Steenng

worm

assembly

19

Wonn

bearing

assembly

200nng

t

21

HOUSing

cover

22

011

seal

@

w

39

JJii

3738

I

34

8

11

12

W63

62

23

25

Shim

26

Hex

bolt

27

Spnng

washer

28

Hex

bolt

29

Washer

30

Hex

nut

31

32

Collapsible

steenng

column

34

Upper

steenng

shaft

35

Upper

tube

Jacket

36

Beanng

37

Washer

38

Spnng

39

Snap

nng

40

Lower

tube

jacket

assembly

42

Grommet

43

Dust

seal

44

Screw

45

Steenng

column

F

ROM

OCT

69

3

3

5

46

Umversal

yoke

JOint

48

011

seal

retainer

49

011

seal

50

Snap

nng

51

Snap

nng

52

Snap

nng

53

Rubber

block

54

Hex

bolt

55

Spnng

washer

56

Hex

bolt

57

Hex

nut

5B

Washer

59

Spnng

washer

60

Clamp

61

Paclung

62

Hex

bolt

63

Washer

64

U

JOint

kit

Page 189 of 252

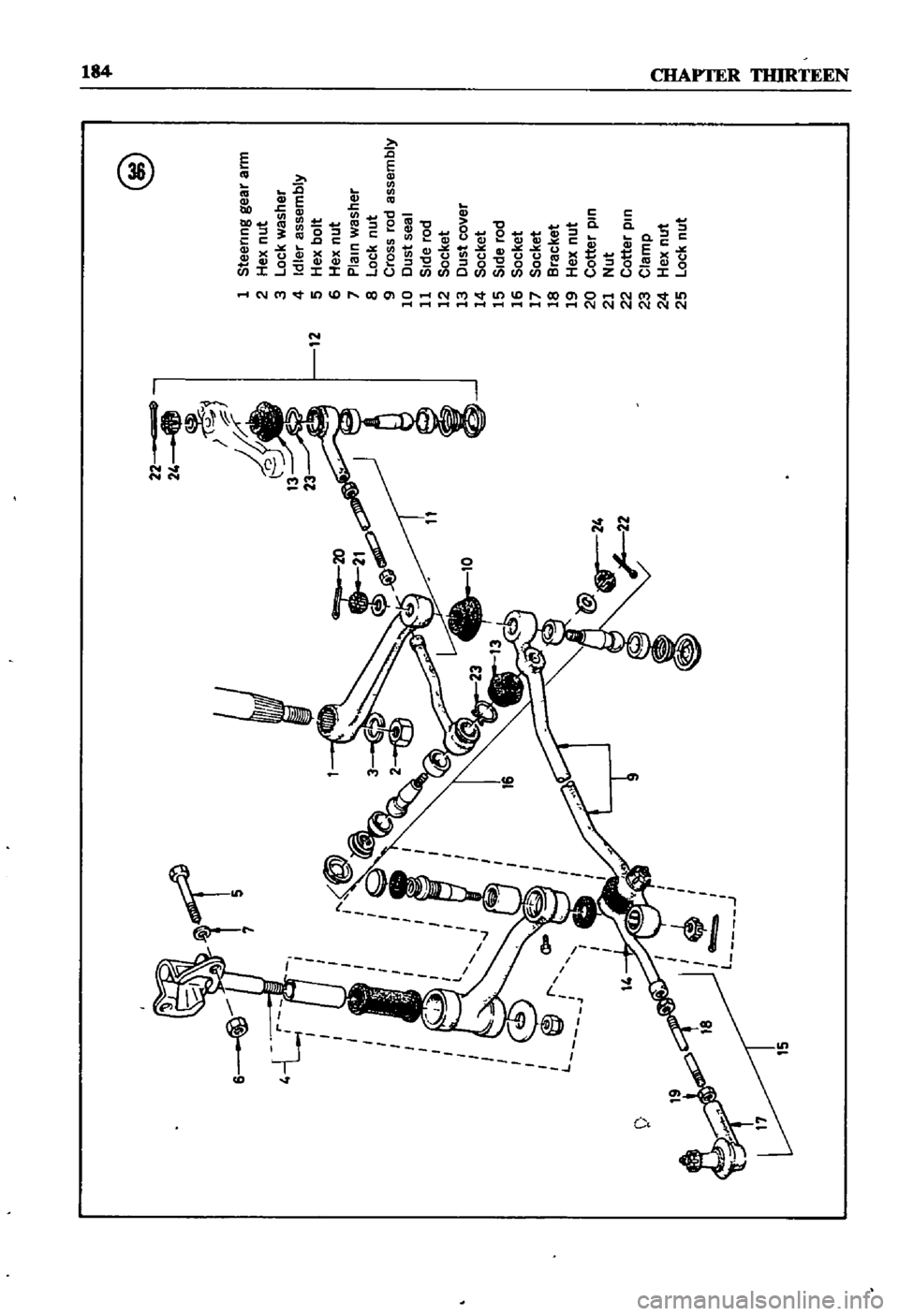

15

7

5

l

J

@

1

Steermg

gea

r

arm

2

Hex

nut

3

Lock

washer

4

Idler

assembly

12

5

Hex

bolt

6

Hex

nut

7

Plam

washer

8

Lock

nut

9

Cross

rod

assembly

10

Dust

seal

11

Side

rod

12

Socket

13

Dust

cover

14

Socket

15

Side

rod

16

Socket

17

Socket

18

Bracket

19

Hex

nut

20

Cotter

pm

21

Nut

22

Cotter

pm

23

Clamp

24

Hex

nut

25

Lock

nut

00

Page 190 of 252

NP

BRAND

3536

48

47

49

UP

TO

SEP

69

15

10

l

f

J

r

1

L

IZM

BRAND

39

39

AUTOMATIC

2

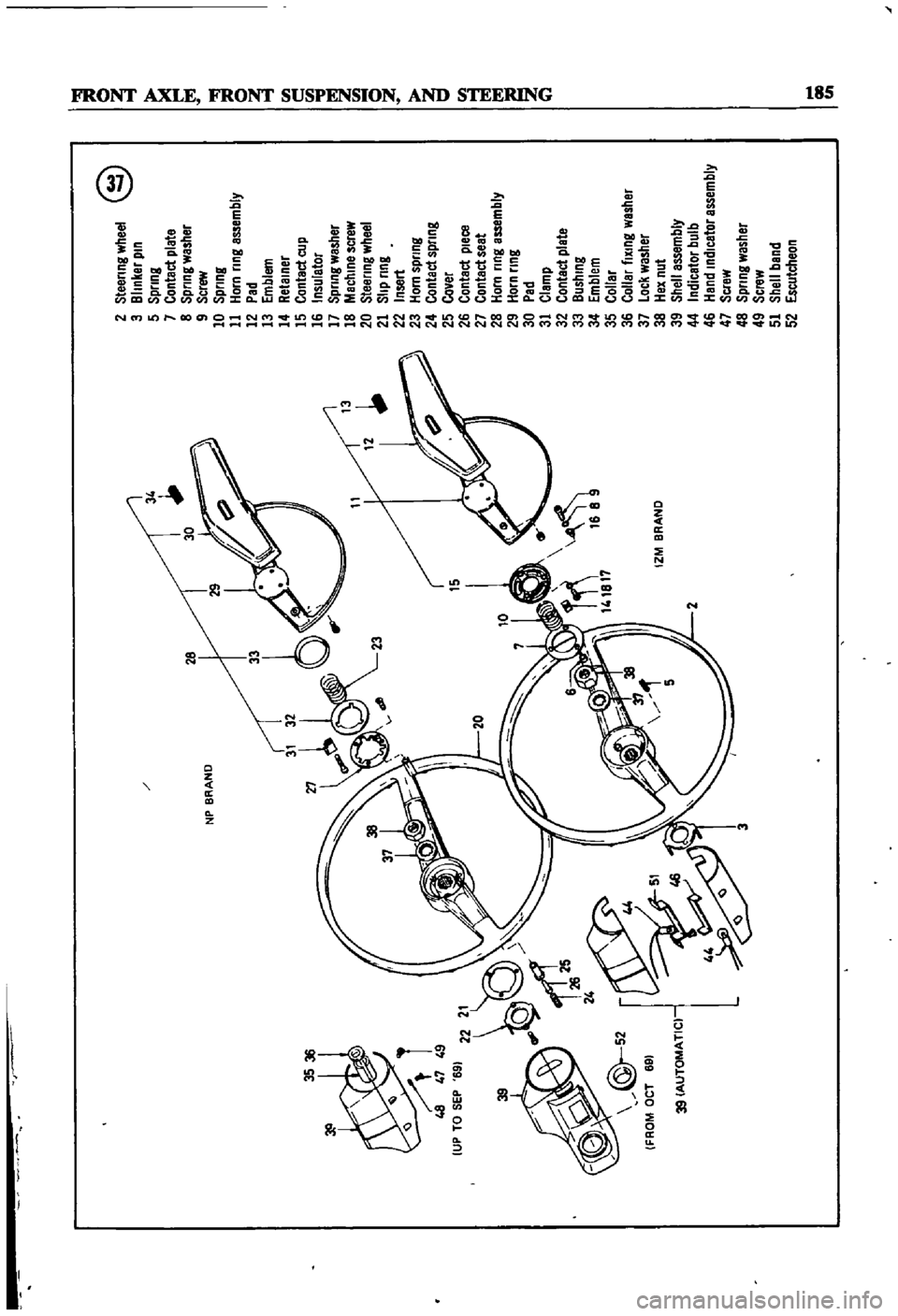

Steering

wheel

@

3

Blinker

pin

5

Spring

7

Contact

plate

8

Spring

washer

9

Screw

10

Spring

11

Horn

ring

assembly

12

Pad

13

Emblem

14

Retainer

15

Contact

cup

16

Insulator

17

Spring

washer

18

Machine

screw

20

Steering

wheel

21

Slip

ring

22

Insert

23

Horn

spring

24

Contact

spring

25

Cover

26

Contact

pleca

27

Contact

seat

28

Horn

ring

assembly

29

Horn

ring

30

Pad

31

Clamp

32

Contact

plate

33

Bushing

34

Emblem

35

Collar

36

Collar

fiXing

washer

37

Lock

washer

38

Hex

nut

39

Shell

assembly

44

Indicator

bulb

46

Hand

indicator

assembly

47

Scraw

48

Spring

washer

49

Screw

51

Shell

band

52

Escutcheon

o

I

l

I

l

i

J

I

Ci

l

QD

II

L

Page 199 of 252

v

194

CHAPTER

FOURTEEN

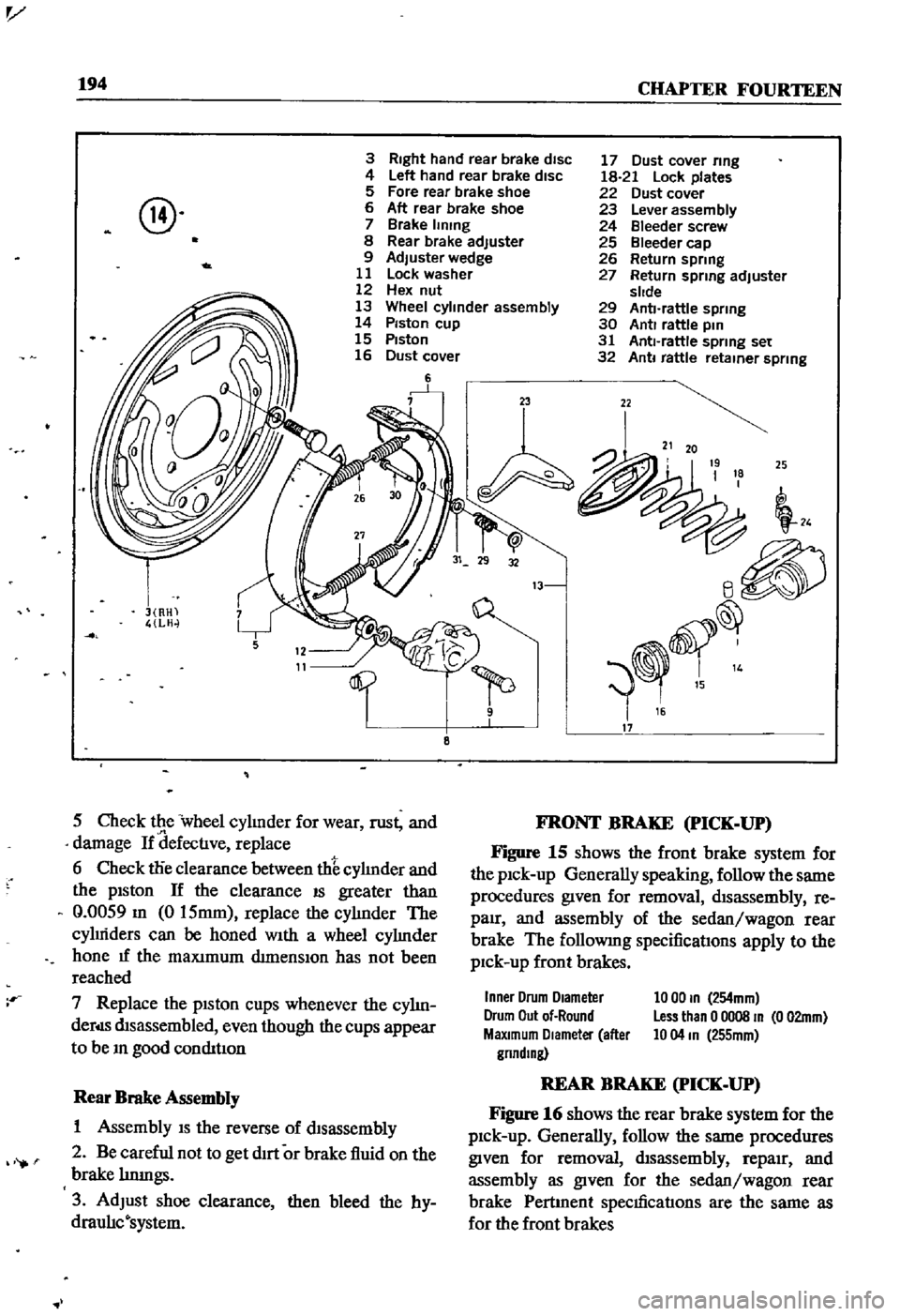

3

Right

hand

rear

brake

disc

4

Left

hand

rear

brake

disc

5

Fore

rear

brake

shoe

6

Aft

rear

brake

shoe

7

Brake

IImng

8

Rear

brake

adjuster

9

Adjuster

wedge

11

Lock

washer

12

Hex

nut

13

Wheel

cylinder

assembly

14

Piston

cup

15

Piston

16

Dust

cover

6

@

5

Check

the

wheel

cylinder

for

wear

rust

and

damage

If

defectIve

replace

6

Check

die

clearance

between

th

cyhnder

and

the

piston

If

the

clearance

18

greater

than

Q

0059

m

0

15mm

replace

the

cylinder

The

cyluiders

can

be

honed

With

a

wheel

cyhnder

hone

If

the

maXImum

dimensIOn

has

not

been

reached

7

Replace

the

piston

cups

whenever

the

cyhn

derds

disassembled

even

though

the

cups

appear

to

be

m

good

condition

Rear

Brake

Assembly

1

Assembly

IS

the

reverse

of

disassembly

2

Be

careful

not

to

get

dirt

or

brake

fluid

on

the

brake

hnnlgs

3

AdJust

shoe

clearance

then

bleed

the

hy

draulIc

system

17

Dust

cover

ring

18

21

Lock

plates

22

Dust

cover

23

Lever

assembly

24

Bleeder

screw

25

Bleeder

cap

26

Return

spring

27

Return

spring

adjuster

slide

29

Anti

rattle

spring

30

Anti

rattle

pin

31

Anti

rattle

spring

set

32

Anti

rattle

retainer

spring

23

22

24

e

17

a

25

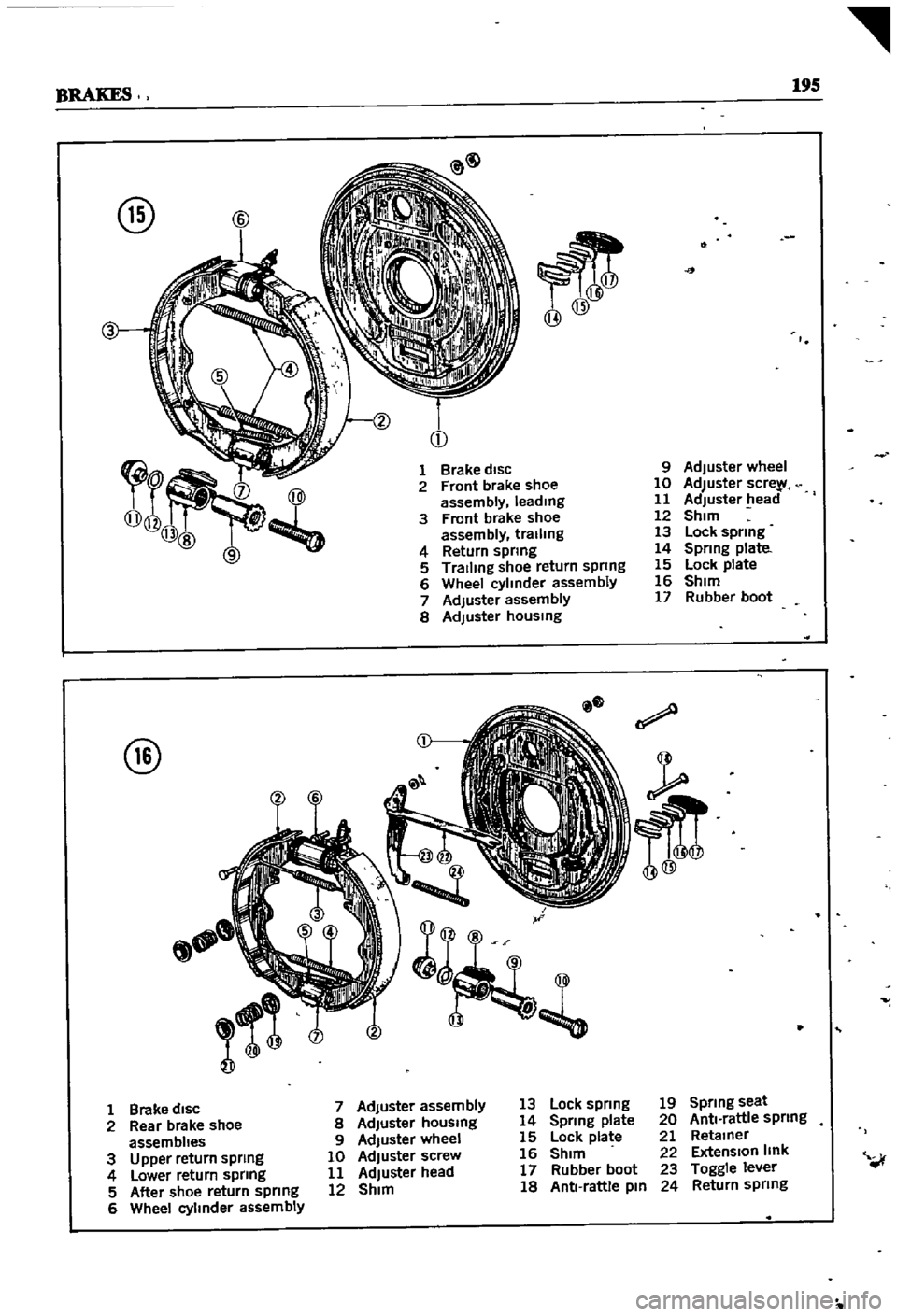

FRONT

BRAKE

pICK

UP

Figure

15

shows

the

front

brake

system

for

the

pick

up

Generally

speaking

follow

the

same

procedures

given

for

removal

disassembly

re

pair

and

assembly

of

the

sedan

wagon

rear

brake

The

followmg

specifications

apply

to

the

pick

up

front

brakes

Inner

Drum

Diameter

Drum

Out

of

Round

MaXimum

DIameter

after

gnndlng

10

00

In

254mm

Less

than

0

0008

In

0

02mm

10

04

In

255mm

REAR

BRAKE

pICK

UP

Figure

16

shows

the

rear

brake

system

for

the

pick

up

Generally

follow

the

same

procedures

given

for

removal

disassembly

repaIr

and

assembly

as

given

for

the

sedan

wagon

rear

brake

Pertment

specificatIons

are

the

same

as

for

the

front

brakes

Page 200 of 252

BRAKES

195

@

@

r

@

I

1

Brake

disc

9

Adjuster

wheel

2

Front

brake

shoe

10

Adjuster

scre

assembly

leadmg

11

Adjuster

lead

3

Front

brake

shoe

12

Shim

assembly

trallmg

13

Lock

spring

4

Return

spring

14

Spring

plate

5

Trailing

shoe

return

spring

15

Lock

plate

6

Wheel

cylinder

assembly

16

Shim

7

Adjuster

assembly

17

Rubber

boot

8

Adjuster

housmg

@

j

@@

1

Brake

disc

7

Adjuster

assembly

13

Lock

spring

19

Spring

seat

2

Rear

brake

shoe

8

Adjuster

housmg

14

Sprmg

plate

20

Ant

rattle

spring

assemblies

9

Adjuster

wheel

15

Lock

plate

21

Retamer

3

Upper

return

spring

10

Adjuster

screw

16

Shim

22

Extension

link

i

l

4

Lower

return

spring

11

Adjuster

head

17

Rubber

boot

23

Toggle

lever

5

After

shoe

return

sprmg

12

Shim

18

Anti

rattle

pm

24

Return

spring

6

Wheel

cylinder

assembly

Page 202 of 252

BRAKES

IV

197

I

Ensure

that

the

brake

flUid

reservOir

at

the

master

cylmder

IS

full

and

that

the

vent

m

the

cap

is

open

2

Connect

a

plastIc

or

rubber

tube

to

the

bleeder

valve

on

the

nght

rear

wheel

Suspend

the

other

end

of

the

tube

m

a

Jar

or

bottle

filled

With

a

few

Inches

of

clean

brake

flwd

During

the

remaInIng

steps

keep

thiS

end

submerged

at

all

times

and

never

let

the

level

in

the

brake

flUid

reservoir

drop

below

full

3

Open

the

bleeder

valve

on

the

nght

rear

wheel

about

one

turn

Have

an

asSistant

depress

the

brake

pedal

slowly

As

soon

as

the

pedal

is

all

the

way

down

close

the

bleeder

valve

and

let

the

pedal

up

Repeat

thiS

step

as

many

tImes

as

necessary

until

pure

flUid

WithOUt

au

bubbles

comes

from

the

tube

4

Bleed

the

remammg

wheels

m

the

followmg

order

left

rear

nght

front

and

left

front

Keep

checkmg

the

brake

flUid

reservoir

to

make

cer

tam

It

doesn

t

TWl

out

of

flUId

5

When

all

wheels

are

bled

fill

the

reservOIr

to

the

full

level

Never

reuse

the

brake

flwd

bled

from

the

system

or

any

that

has

been

lymg

around

Start

With

a

fresh

contaIner

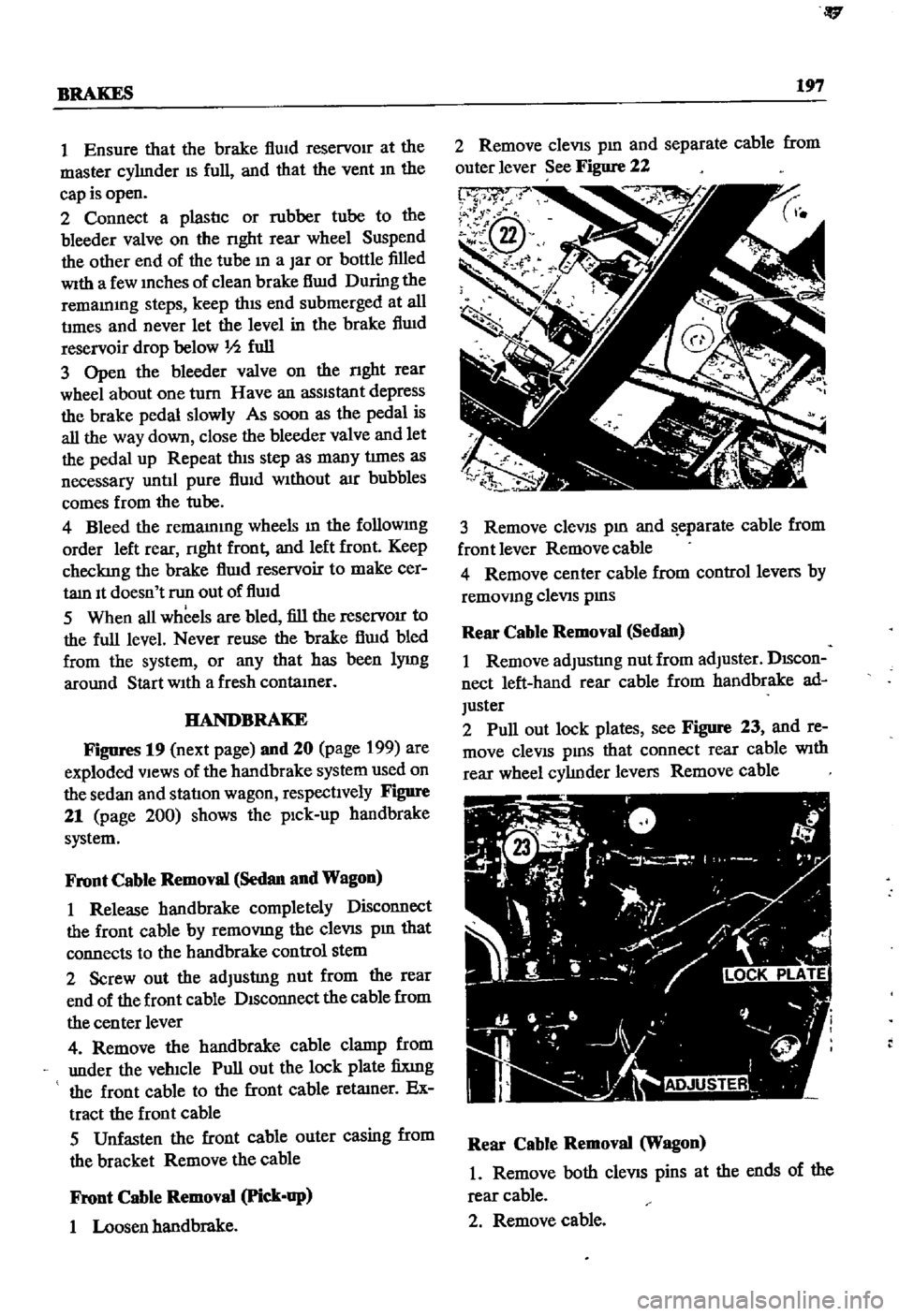

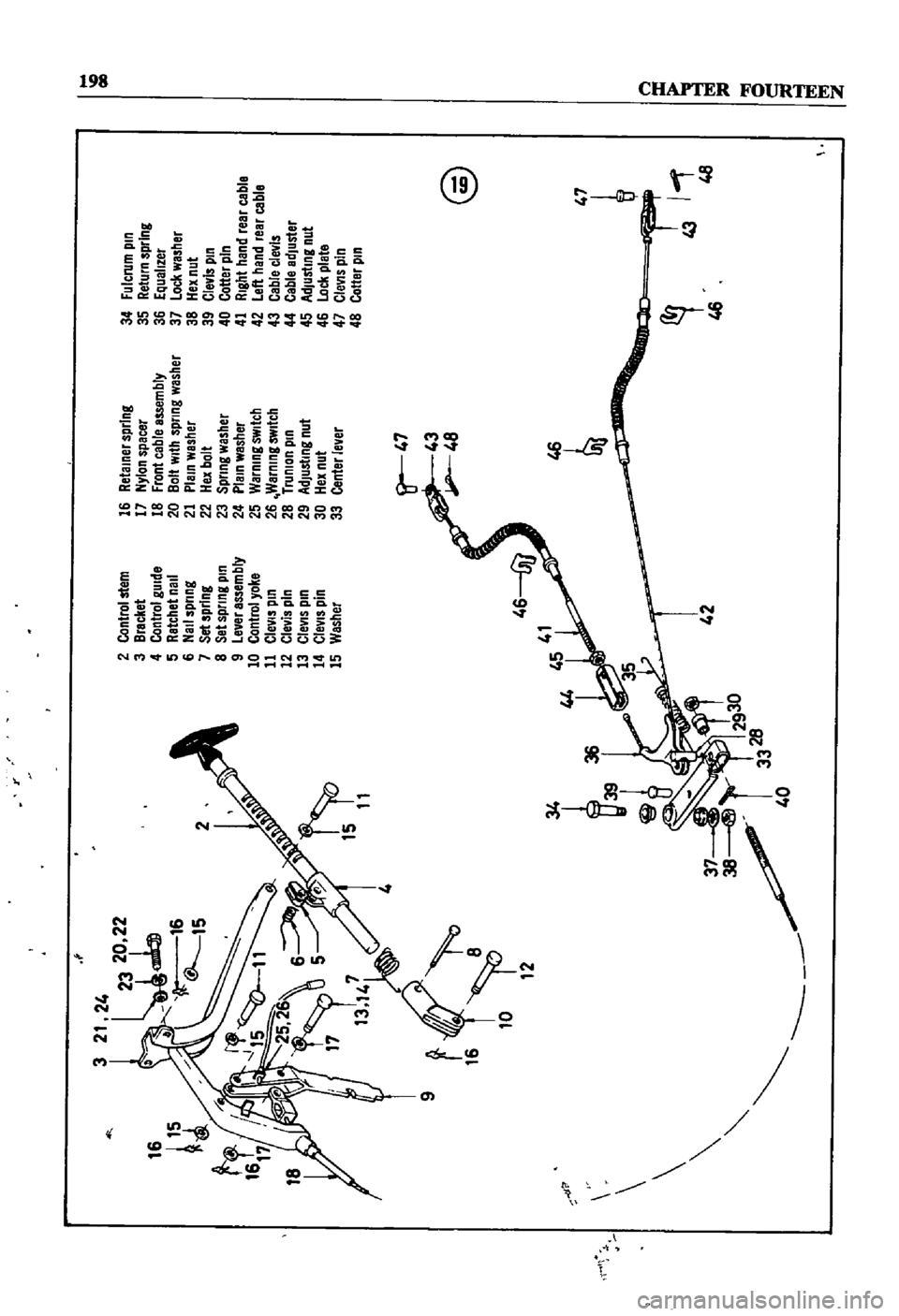

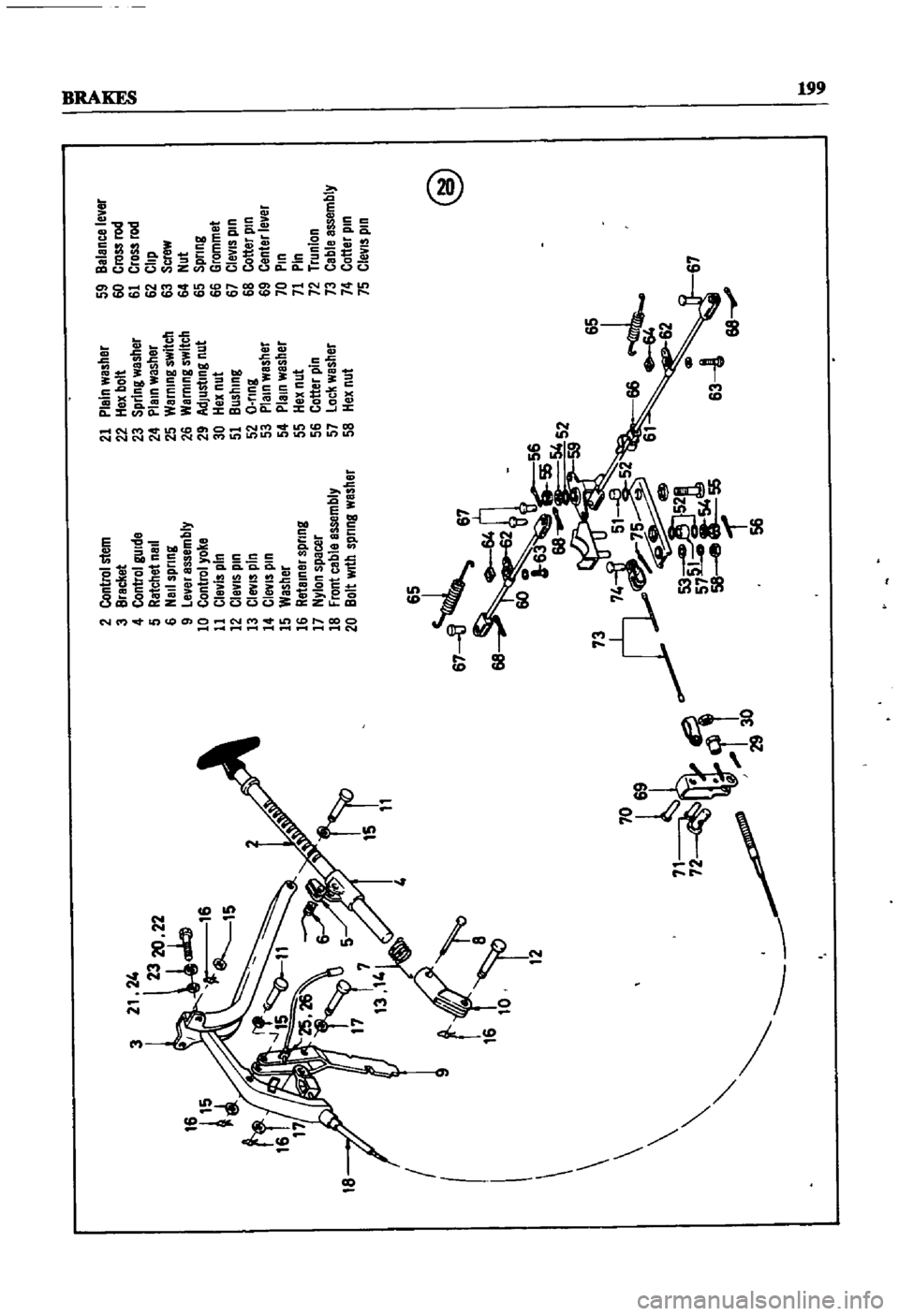

HANDBRAKE

Figures

19

next

page

and

20

page

199

are

exploded

views

of

the

handbrake

system

used

on

the

sedan

and

statIon

wagon

respectively

F1gDre

21

page

200

shows

the

pick

up

handbrake

system

Front

Cable

Removal

Sedan

and

Wagon

I

Release

handbrake

completely

Disconnect

the

front

cable

by

removmg

the

cleVIS

pm

that

connects

to

the

handbrake

control

stem

2

Screw

out

the

adJusting

nut

from

the

rear

end

of

the

front

cable

Disconnect

the

cable

from

the

center

lever

4

Remove

the

hand

brake

cable

clamp

from

under

the

verucle

Pull

out

the

lock

plate

fixmg

the

front

cable

to

the

front

cable

retamer

Ex

tract

the

front

cable

5

Unfasten

the

front

cable

outer

casing

from

the

bracket

Remove

the

cable

Front

Cable

Removal

Pick

up

I

Loosen

handbrake

2

Remove

cleVIS

pm

and

separate

cable

from

outer

lever

See

Figure

22

p

3

Remove

cleVIS

pm

and

eparate

cable

from

front

lever

Removecable

4

Remove

center

cable

from

control

levers

by

removmg

cleViS

pms

Rear

Cable

Removal

Sedan

I

Remove

adJusting

nut

from

adJuster

DIScon

nect

left

hand

rear

cable

from

handbrake

ad

Juster

2

Pull

out

lock

plates

see

Figure

23

and

re

move

cleVIS

pms

that

connect

rear

cable

With

rear

wheel

cylJnder

levers

Remove

cable

Rear

Cable

Removal

Wagon

1

Remove

both

cleVIS

pins

at

the

ends

of

the

rear

cable

2

Remove

cable

Page 203 of 252

f

I

I

3

21

24

22

2

Control

slem

16

Retainer

spring

34

Fulcrum

pin

3

Bracket

17

Nylon

spacer

35

Return

spring

16

4

Control

gUide

18

Front

cable

assembly

36

Equalizer

16

5

Ratchet

nail

20

Bolt

With

spring

washer

37

lock

washer

6

Nail

spnng

21

Plain

washer

38

Hex

nut

15

7

Set

sprIng

22

Hex

bolt

39

Clevls

pin

tr

8

Set

sprlOg

plO

23

Spring

washer

40

Cotter

pin

9

lever

assembly

24

Plain

washer

41

Right

hand

rear

cable

10

Control

yoke

25

Warmng

sWItch

42

left

hand

rear

cable

16

7

11

CleVIS

pm

26

Warnlng

SWitch

43

Cable

clevis

18

12

Clevis

pin

28

Truman

pin

44

Cable

adjuster

13

CleVIS

pin

29

Adjusting

nut

45

Adjusting

nut

14

CleVIS

pin

30

Hex

nut

46

lock

plate

15

Washer

33

Center

lever

47

CleVIS

pin

48

Cotter

pin

46

47

I

36

4

U39

I

11

43

48

J

I

l

ft

l

I

46

a

z

@

9

Page 204 of 252

18

I

70

I

69

72

lt

n

30

2

Control

stem

3

Bracket

4

Control

gUide

5

Ratchet

nail

6

NaIl

sprtng

9

Level

assembly

10

Control

yoke

11

Clevis

pin

12

ClevIs

pin

13

CleviS

pIn

1

CleviS

pIn

15

Washer

16

Retainer

spring

17

Nylon

spacer

18

Front

cable

assembly

20

Bolt

With

spring

washer

67

n

67

64

68

2

600

56

63

H

54

52

P73

74

i1

51

8

52

e

75

@

53

52a

57

55

58

8

56

21

Plain

washer

22

Hex

bolt

23

SprIng

washer

24

Plain

washer

25

Warning

switch

26

Warning

switch

29

Adjusting

nut

30

Hex

nut

51

Bushing

52

O

nng

53

Plain

washer

54

PlalO

washer

55

Hex

nut

56

Cotter

pIn

57

Lock

washer

58

Hex

nut

65

66

4

62

59

Balance

lever

60

Cross

rod

61

Cross

rod

62

Clip

63

Screw

64

Nut

65

Spring

66

Grommet

67

CleVIS

pin

68

Cotter

pin

69

Center

lever

70

Pin

71

Pin

72

Trunlon

73

Cable

assembly

74

Cotter

pin

75

CleVIS

pin

@

67

68

Ie

Ie