lock DATSUN 510 1968 Service Manual Online

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 205 of 252

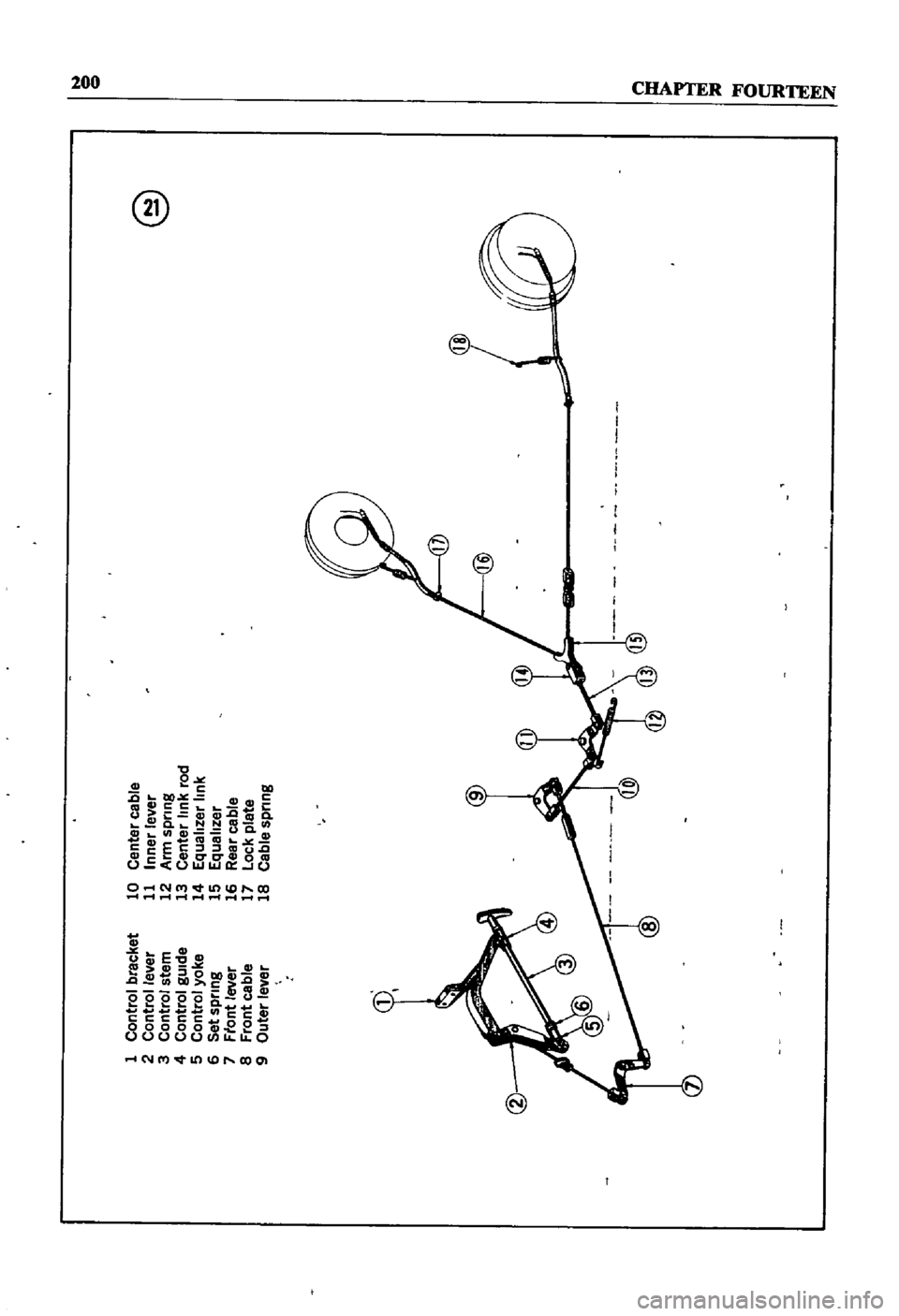

1

Control

bracket

2

Control

ever

3

Control

stem

4

Control

gUide

5

Control

yoke

6

Set

spring

7

Ffont

lever

8

Front

cable

9

Outer

lever

g

10

Center

cable

11

Inner

lever

12

Arm

spring

13

Center

link

rod

14

Equalizer

Imk

15

Equalizer

16

Rear

cable

17

Lock

plate

18

Cable

sprmg

@

a

lI

l

l

o

Page 206 of 252

BRAKES

ZOI

Cross

Rod

Removal

Wagon

I

Remove

the

pull

off

spnngs

at

each

end

of

the

cross

rods

2

RelI

ove

clevis

pms

and

cross

rods

Rear

Cable

Removal

Pick

op

1

Remove

cleVIS

pm

and

disconnect

equalizer

from

equal1zer

link

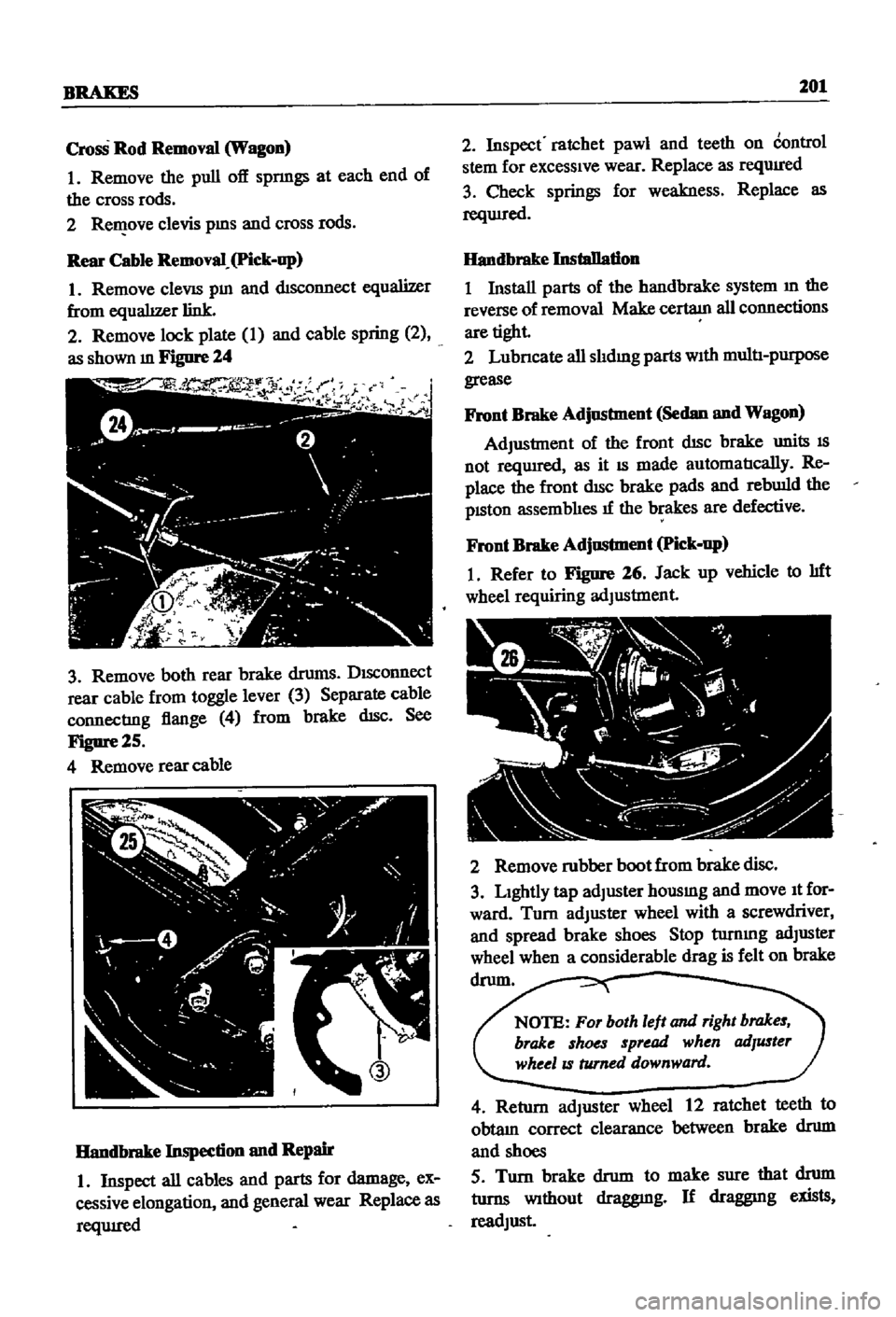

2

Remove

lock

plate

1

and

cable

spring

2

as

shown

ill

Figure

24

3

Remove

both

rear

brake

drums

DISConnect

rear

cable

from

toggle

lever

3

Separate

cable

connecting

flange

4

from

brake

dIsc

See

Figure

25

4

Remove

rear

cable

Handbrake

Inspection

and

Repair

1

Inspect

all

cables

and

parts

for

damage

ex

cessive

elongation

and

general

wear

Replace

as

reqUlred

I

2

Inspect

ratchet

pawl

and

teeth

on

control

stem

for

excessive

wear

Replace

as

reqUIred

3

Check

springs

for

weakness

Replace

as

reqUIred

Handbrake

Installation

I

Install

parts

of

the

handbrake

system

m

the

reverse

of

removal

Make

certam

all

connections

are

tight

2

Lubncate

all

slIdmg

parts

With

muItl

purpose

grease

Front

Brake

Adjustment

Sedan

and

Wagon

AdJustment

of

the

front

dIsc

brake

units

18

not

reqwred

as

it

18

made

automatIcally

Re

place

the

front

dISC

brake

pads

and

rebwld

the

pISton

assemblJes

If

the

brakes

are

defective

Front

Brake

Adjustment

Pick

up

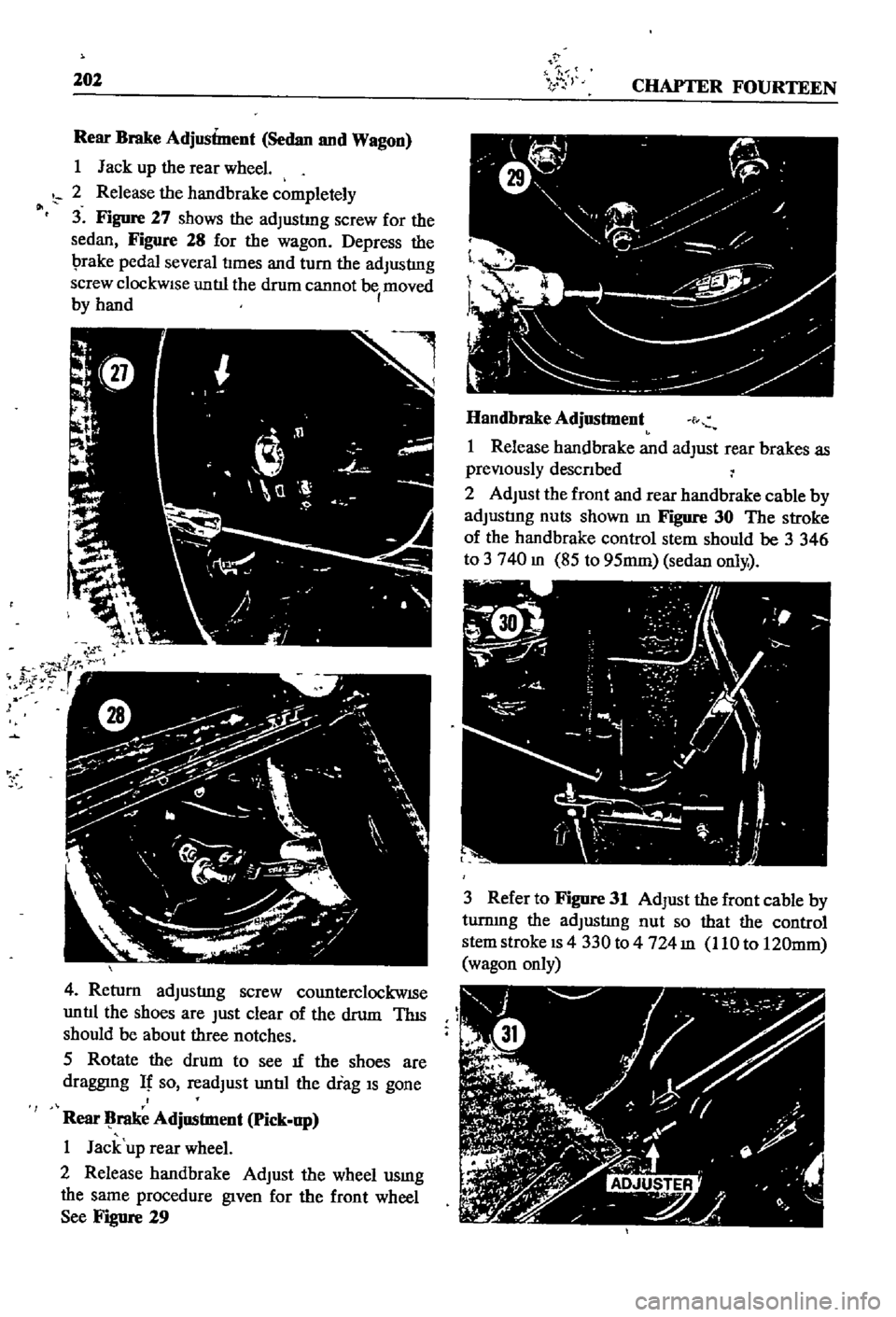

I

Refer

to

Figure

26

Jack

up

vehicle

to

lIft

wheel

requiring

adJustment

2

Remove

rubber

boot

from

brake

disc

3

Lightly

tap

adJuster

housmg

and

move

It

for

ward

Turn

adJuster

wheel

with

a

screwdriver

and

spread

brake

shoes

Stop

turnmg

adJuster

wheel

when

a

considerable

drag

is

felt

on

brake

drum

NOTE

For

both

left

and

right

brakes

brake

shoes

spread

when

adJuster

wheelIS

turned

downward

4

Return

adJuster

wheel

12

ratchet

teeth

to

obtam

correct

clearance

between

brake

drum

and

shoes

5

Turn

brake

drum

to

make

sure

that

drum

turns

Without

draggmg

If

draggmg

exists

readJust

Page 207 of 252

202

h

l

CHAPTER

FOURTEEN

Rear

Brake

Adjustment

Sedan

and

Wagon

I

Jack

up

the

rear

wheel

2

Release

the

handbrake

completely

3

Figure

27

shows

the

adJustmg

screw

for

the

sedan

Figure

28

for

the

wagon

Depress

the

I

rake

pedal

several

tImes

and

turn

the

adJusting

screw

clockWise

untIl

the

drum

cannot

be

moved

I

by

hand

4

Return

adJusting

screw

counterclockwISe

untIl

the

shoes

are

Just

clear

of

the

drum

ThIS

should

be

about

three

notches

5

Rotate

the

drum

to

see

If

the

shoes

are

draggmg

It

so

readJust

untIl

the

drag

IS

gone

Rear

rake

Adjnstment

pick

np

I

Jack

up

rear

wheel

2

Release

handbrake

AdJust

the

wheel

usmg

the

same

procedure

given

for

the

front

wheel

See

Figure

29

Handbrake

Adjnstment

f

I

Release

handbrake

and

adJust

rear

brakes

as

preViously

descnbed

2

AdJust

the

front

and

rear

handbrake

cable

by

adJustIng

nuts

shown

m

Figure

30

The

stroke

of

the

handbrake

control

stem

should

be

3

346

to

3

740

m

85

to

95mm

sedan

only

3

Refer

to

Figure

31

AdJust

the

front

cable

by

turnmg

the

adJusting

nut

so

that

the

control

stem

stroke

IS

4

330

to

4724

m

110

to

120mm

wagon

only

Page 208 of 252

BRAKES

203

4

32

shows

the

adJusting

pomts

for

the

pick

up

With

rear

cable

stretched

adJust

equal

IZer

link

With

adJust

screw

A

so

that

L

dimensiOn

Is

1

161

m

295mm

Lock

adJust

screw

wlth

locknut

5

AdJust

front

cable

adJust

screw

8

so

that

control

stem

stroke

IS

3

15

to

394

m

80

to

100mm

Lock

adJust

screw

With

lock

nut

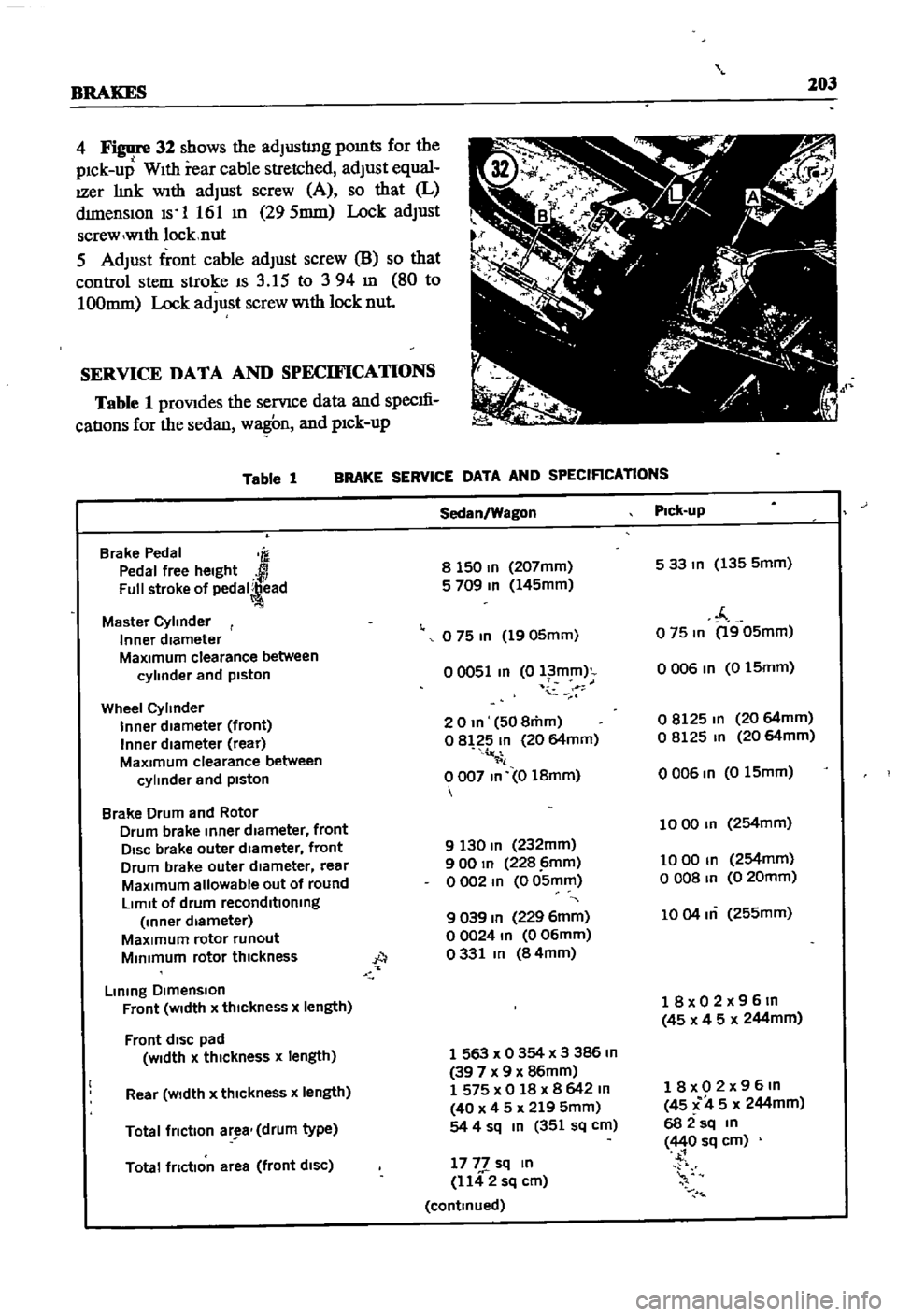

SERVICE

DATA

AND

SPECIFICATIONS

Table

1

prOVides

the

servIce

data

and

specm

catIons

for

the

sedan

wa

n

and

pick

up

Table

1

BRAKE

SERVICE

DATA

AND

SPECIRCATlONS

Brake

Pedal

m

Pedal

free

height

Full

stroke

of

pedal

ead

Master

Cylinder

Inner

diameter

MaXImum

clearance

between

cylinder

and

piston

Wheel

Cylinder

Inner

diameter

front

Inner

diameter

rear

MaXimum

clearance

between

cylinder

and

piston

Brake

Drum

and

Rotor

Drum

brake

Inner

diameter

front

DISC

brake

outer

diameter

front

Drum

brake

outer

diameter

rear

MaXimum

allowable

out

of

round

LImit

of

drum

reconditioning

Inner

diameter

MaXimum

rotor

runout

MInimum

rotor

thickness

A

Lining

DImenSion

Front

WIdth

x

thIckness

x

length

Front

dISC

pad

Width

x

thickness

x

length

Rear

Width

x

thickness

x

length

Total

friction

ar

a

drum

type

Total

friction

area

front

diSC

Sedan

Wagon

Pick

up

8

150

In

207mm

533m

135

5mm

5

709

In

145mm

f

o

75

In

1905mm

o

75

In

1905mm

00051

In

0

l

mm

o

006

In

0

15mm

i

20m

508mm

08125

m

20

64mm

o

8

2

In

20

64mm

o

8125

In

20

64mm

il

0007

In

0

18mm

0006

In

015mm

1000

In

254mm

9

130

In

232mm

900

In

228

imm

1000

In

254mm

o

002

m

0

05mm

o

008

In

0

20mm

9

039

In

229

6mm

1004

m

255mm

00024

In

006mm

0331

In

84mm

18x02x96m

45

x

4

5

x

244mm

1

563

x

0

354

x

3

386

In

39

7

x

9

x

86mm

1

575

x

0

18

x

8

642

m

40

x

4

5

x

219

5mm

54

4

sq

In

351

sq

cm

18x02x96m

45

C

4

5

x

244mm

682sq

m

440

sq

cm

1777

sq

In

1142

sq

cm

continued

Page 210 of 252

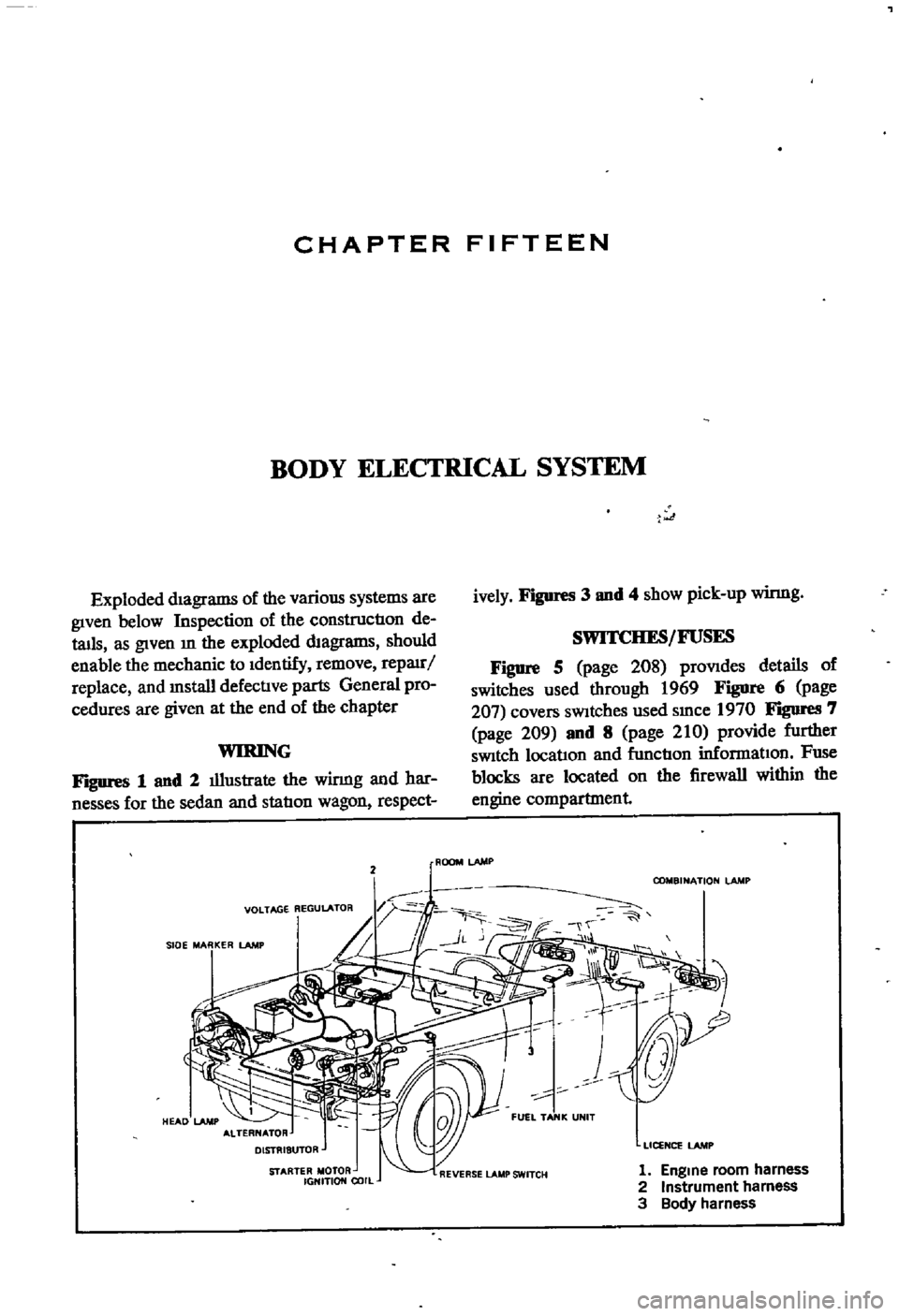

CHAPTER

FIFTEEN

BODY

ELECTRICAL

SYSTEM

Exploded

diagrams

of

the

various

systems

are

given

below

Inspection

of

the

constructIon

de

tails

as

given

m

the

exploded

diagrams

should

enable

the

mechanic

to

Identify

remove

repauj

replace

and

mstall

defectIve

parts

General

pro

cedures

are

given

at

the

end

of

the

chapter

WIRING

FJgUres

1

and

2

illustrate

the

winng

and

har

nesses

for

the

sedan

and

statIon

wagon

respect

2

VOLTAGE

REGULATOR

JOE

MARKER

l

AMJ

STARTER

MOTOR

IGHITION

COIL

t

ively

Figures

3

and

4

show

pick

up

winng

SWITCHES

FUSES

Figure

5

page

208

prOVides

details

of

switches

used

through

1969

Figure

6

page

207

covers

SWitches

used

smce

1970

FIgDI

eS

7

page

209

and

8

page

210

provide

further

SWitch

locatlon

and

fnnctIon

informatIon

Fuse

blocks

are

located

on

the

firewall

within

the

engine

compartment

ROOM

LAMP

COMBINATION

lAMP

LICENCE

lAMP

1

Engme

room

harness

2

Instrument

harness

3

Body

harness

Page 214 of 252

44

y

l

l

42

43

r

48

cr

23

41

f

Jj

it

d

F

1L

f7

IF

f

0

l

Q

U

lJ

37

1

2S

26

38

A

3S

36

G

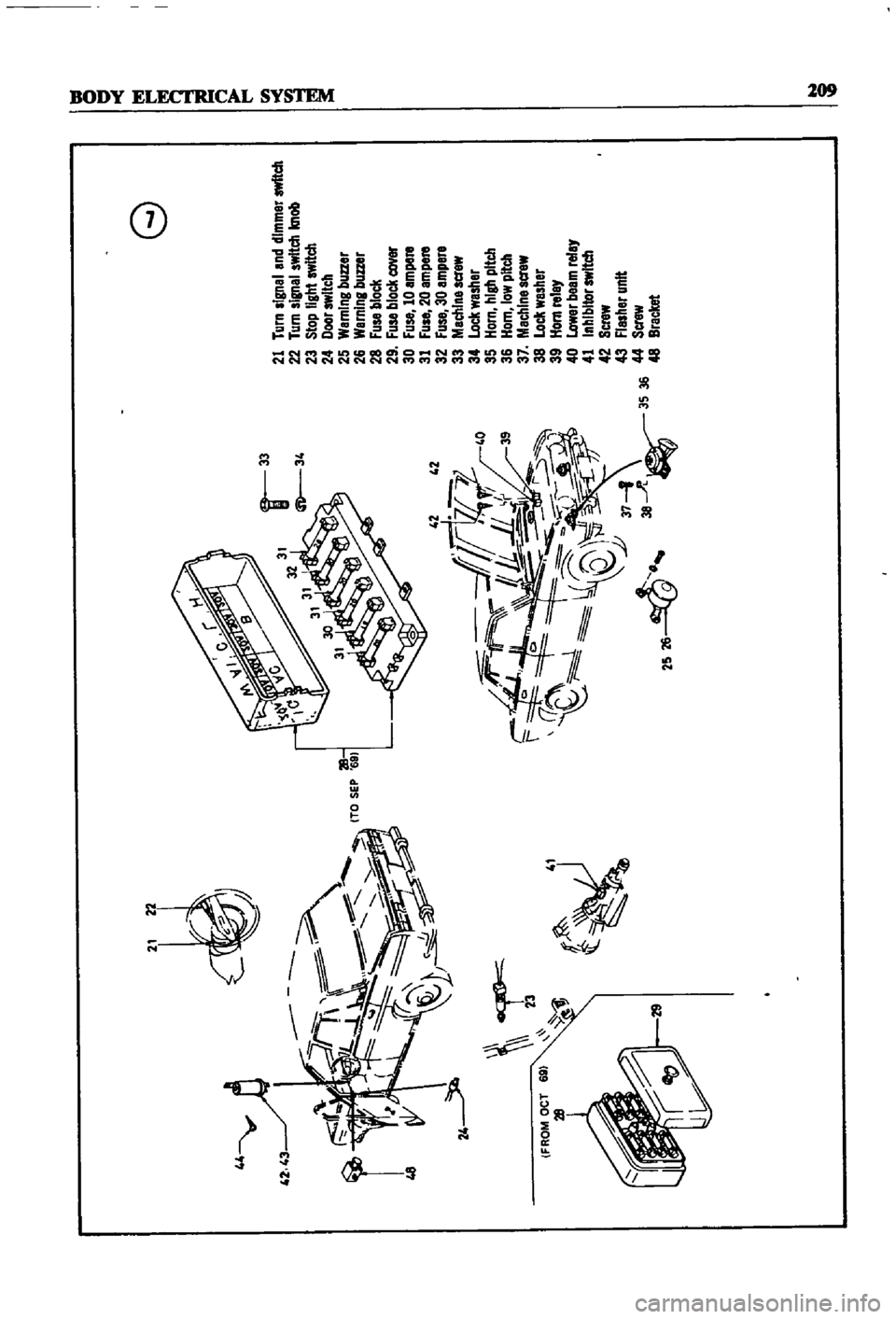

21

Turn

signal

and

dimmer

switch

22

Turn

signal

switch

knob

23

Stop

light

switch

24

Door

switch

25

WarnIng

buzzer

26

Warning

buzzer

28

Fuse

block

29

Fuse

block

cover

30

Fuse

10

ampere

31

Fuse

20

ampere

32

Fuse

30

ampere

33

Machlnescrew

34

Lock

washer

35

Horn

hIgh

pitch

36

Horn

low

pitch

37

Machine

acrew

38

Lock

washer

39

Horn

relay

40

Lower

beem

relay

41

Inhibitor

switch

42

Screw

43

Flasher

unit

44

Screw

48

Bracket

o

i

Page 216 of 252

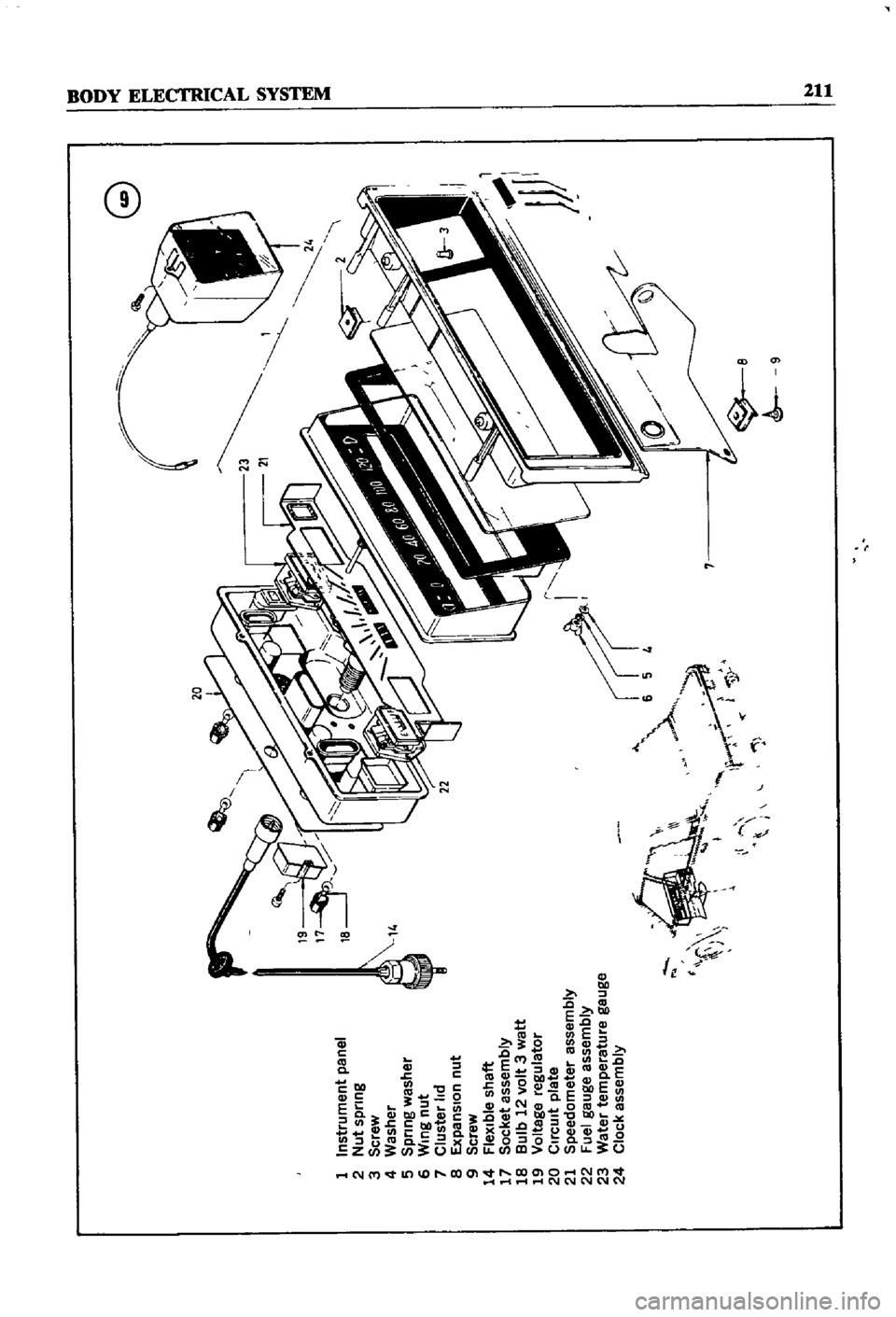

19

1

18

1

1

2

3

S

6

7

8

9

14

17

18

19

20

21

22

23

24

InstrUment

paoel

Nut

sptlng

screW

Washer

sptlng

washer

Wing

nut

Cluster

ld

f

lpanslon

out

screW

fle

j

ble

s

1afl

SOcKet

assembly

aulb

12

volt

3

watt

I

oltage

regulator

CIrcuit

plate

speedometer

assembly

fuel

gauge

assembly

Water

temperature

gauge

ClOCK

assemblY

Jt

I

f

J

1

J

fX

v

J

G

11

6

n

a

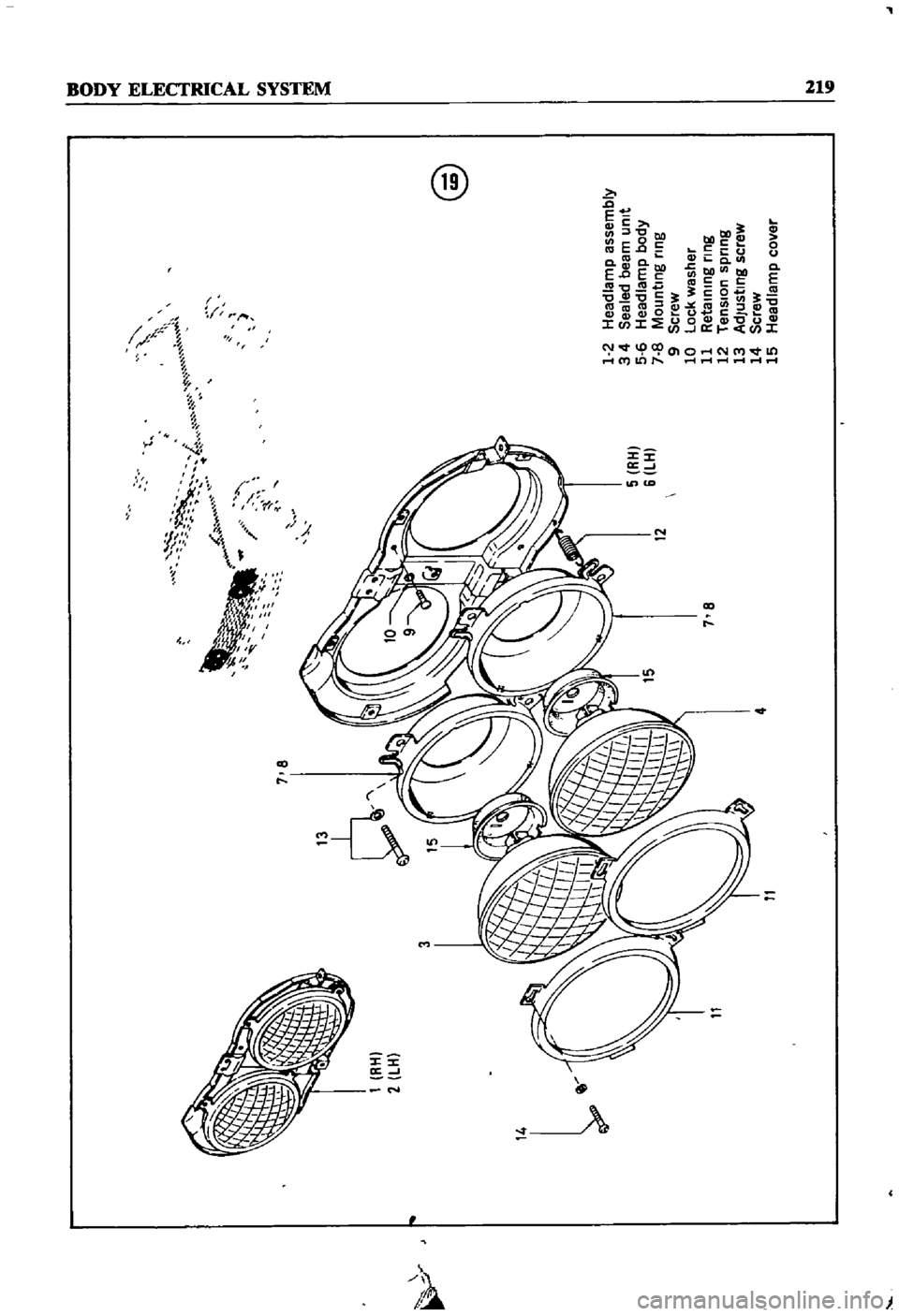

Page 224 of 252

co

L

i

j

14

l

7

8

1

RII

2

LH

3

4

@

12

5

RH

6

LH

1

2

Headlamp

assembly

3

4

Sealed

beam

Untt

5

6

Headlamp

body

7

8

Mounting

nng

9

Screw

10

Lock

washer

11

Retaining

nng

12

TenSIon

spnng

13

Adjusting

screw

14

Screw

15

Headlamp

cover

o

t

j

l

l

t

I

l

i

N

Cl

oil

Page 230 of 252

CHAPTER

SIXTEEN

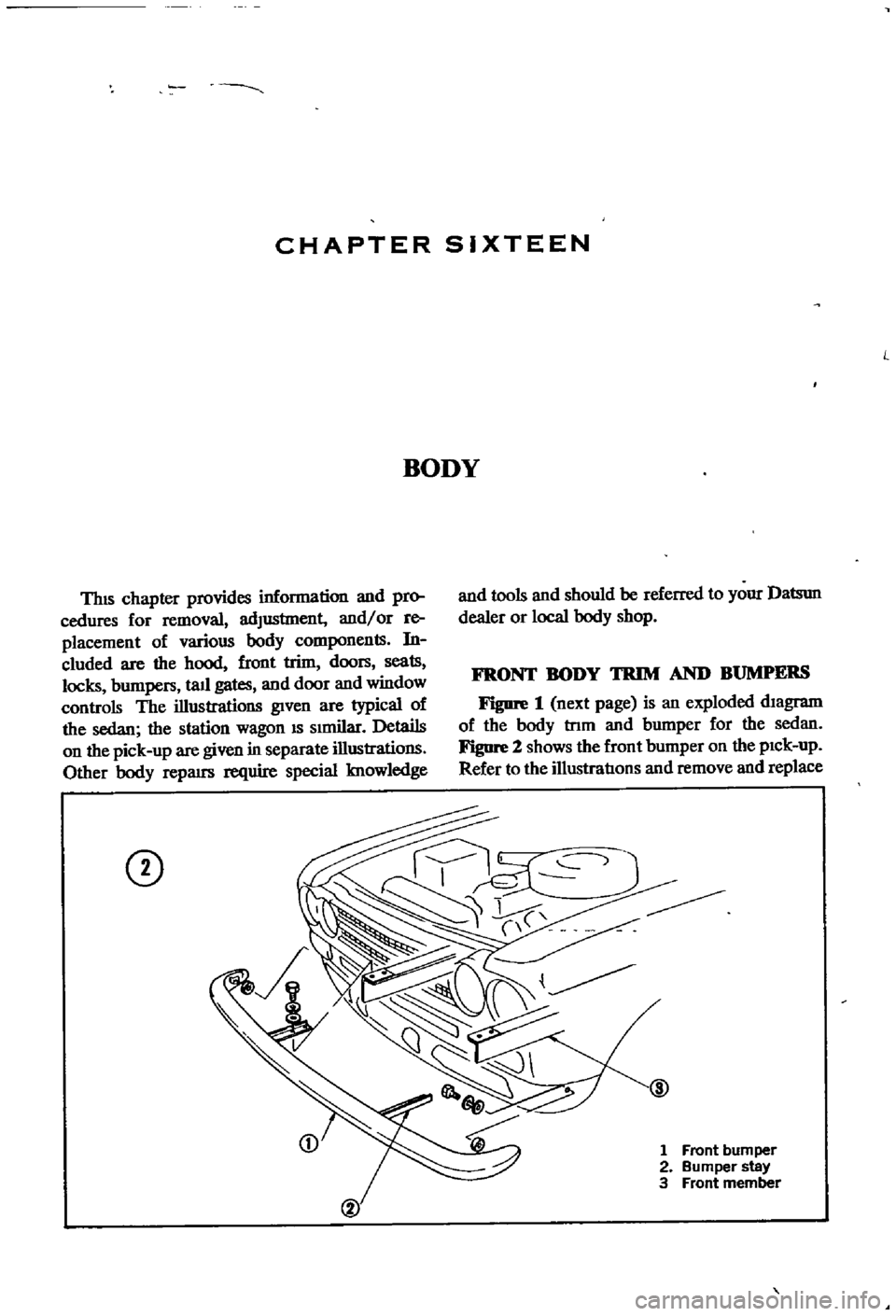

ThIS

chapter

provides

infOrnl8tion

and

pro

cedures

for

removal

adJustment

and

or

re

placement

of

various

body

components

in

cluded

are

the

hood

front

trinl

doors

seats

locks

bumpers

tail

gates

and

door

and

window

controls

The

illustrations

given

are

typical

of

the

sedan

the

station

wagon

IS

similar

Details

on

the

pick

up

are

given

in

separate

illustrations

Other

body

repairs

require

special

knowledge

CD

L

BODY

and

tools

and

should

be

referred

to

your

Datsun

dealer

or

local

body

shop

FRONT

BODY

TRIM

AND

BUMPERS

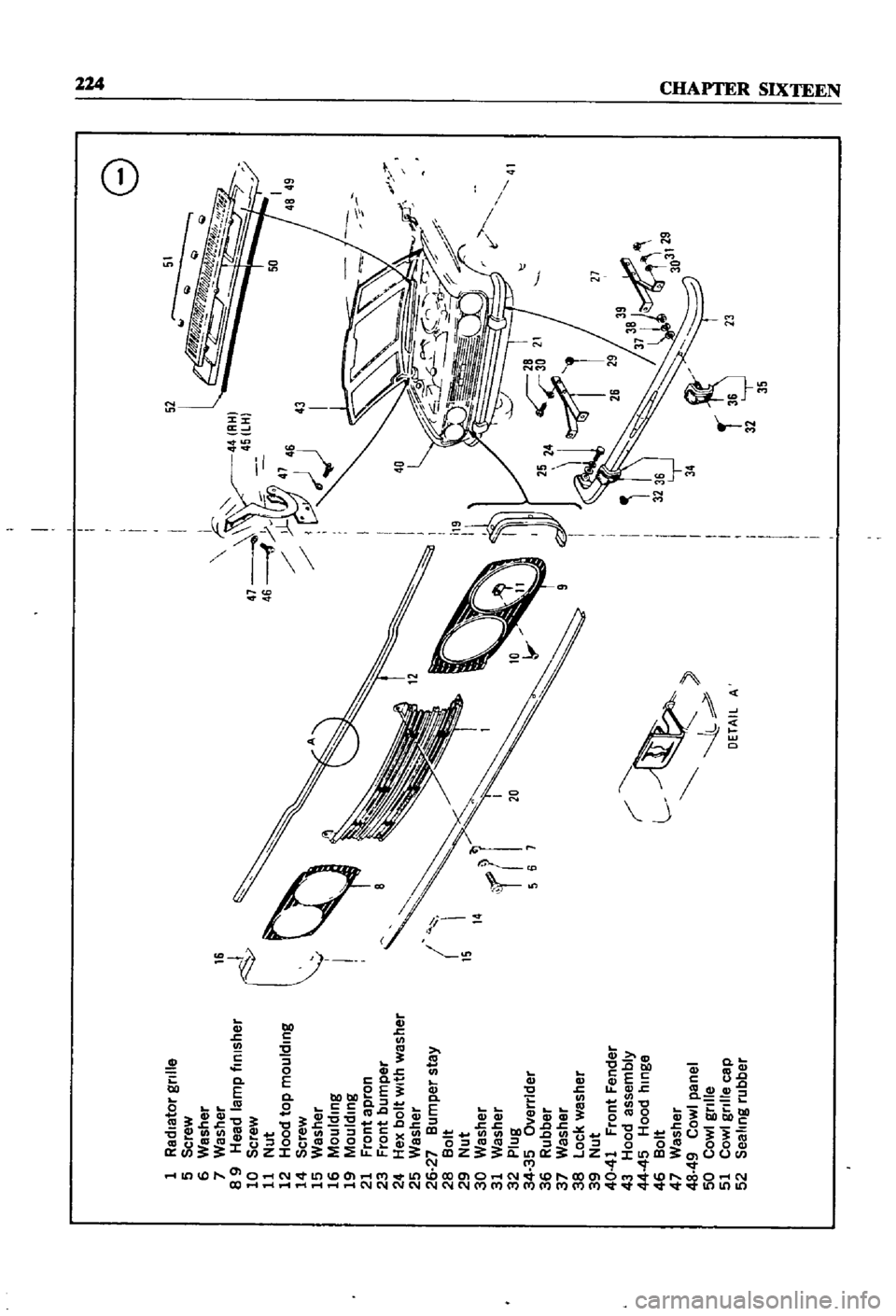

Figure

1

next

page

is

an

exploded

diagram

of

the

body

tnm

and

bumper

for

the

sedan

Figure

2

shows

the

front

bumper

on

the

pick

up

Refer

to

the

illustratIons

and

remove

and

replace

1

Front

bumper

2

Bumper

stay

3

Front

member

Page 231 of 252

1

Radiator

grille

5

Screw

6

Washer

7

Washer

8

9

Head

lamp

finIsher

10

Screw

11

Nut

12

Hood

top

moulding

14

Screw

15

Washer

16

Moulding

19

Moulding

21

Front

apron

23

Front

bumper

24

Hex

bolt

with

washer

25

Washer

26

27

Bumper

stay

28

Bolt

29

Nut

30

Washer

31

Washer

32

Plug

34

35

Overrlder

36

Rubber

37

Washer

38

Lock

washer

39

Nut

40

41

Front

Fender

43

Hood

assembly

44

45

Hood

hinge

46

Bolt

47

Washer

48

49

Cowl

panel

50

Cowl

grille

51

Cowl

grille

cap

52

Sealing

rubber

52

1

14

V

27

r

l

DETAIL

A

23

8

41

t

l