DATSUN B110 1969 Service User Guide

Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 11 of 136

l

aiDteDaDce

UDe

up

Install

a

timing

lIght

on

No

1

cyhnder

spark

plug

WIre

and

Install

a

tachometer

Set

Idhng

ipeed

to

approximately

800

rpm

Check

19mtlOn

tImmg

If

It

IS

50BTDC

Before

Top

of

Dead

Center

by

the

use

of

tlmmg

hght

If

necessary

adjust

It

as

follows

Loosen

iet

screw

to

such

an

extent

that

dlstnbutor

can

be

moved

by

hand

AdJu

it

IgmtlOn

tIming

to

50BTDC

Lock

dlstnbutor

set

screw

and

make

sure

that

tlmmg

IS

correct

IgnitIOn

tImmg

degreel

50

B

T

DC

Distributor

Breaker

Point

Check

dlstnbutor

breaker

pomts

for

abnormal

pItting

and

wear

Replace

If

necessary

Make

wre

they

are

In

correct

ahgnment

for

full

con

tact

and

that

pOint

dwell

and

gap

are

correct

Clean

and

apply

dlstnbutor

grease

to

cam

and

WIck

Note

Do

not

apply

grease

excessively

Dl

tI

IbutOl

POint

gap

0

018

to

0

022

In

Dwell

angle

49

to

55

degrees

Condenser

Clean

outlet

of

condenser

lead

WIre

and

check

for

loose

set

screw

RetIghten

If

necessary

Check

condenber

capacIty

With

a

capacity

meter

Fig

7

Checking

Igmllon

timing

Condenser

msulatlOn

resistance

may

be

also

checked

usmg

a

tester

by

adjusting

ItS

range

to

measure

large

resIstance

value

When

con

denser

IS

normal

the

tester

pomter

swmgs

largely

and

rapidly

and

moves

gradually

back

to

the

Infimte

SIde

When

the

pomter

does

not

stay

still

or

It

pomts

zero

m

reSIstance

replacement

IS

necessary

Condenser

capacIty

022

J

F

MIcro

Farad

Condenser

InsulatIOn

resIstance

5

Mn

Mega

ohms

Spark

Plugs

Remove

and

clean

plugs

In

a

sand

blast

cleaner

Inspect

each

spark

plug

Make

iure

that

they

are

of

the

specified

heat

range

In

ipect

msulator

for

cracks

and

chIps

Check

both

center

and

ground

electrodes

If

they

are

excessIVely

worn

replace

WIth

new

spark

plugs

File

center

electrode

flat

Set

the

gap

to

0031

to

0035

m

USIng

the

proper

adjustIng

tool

Tighten

plugs

to

11

0

to

150

ft

Ib

torque

CARBURETOR

Idle

mixture

adjustment

requIres

the

use

of

a

CO

meter

When

preparIng

to

adjust

Idle

mixture

It

IS

essential

to

have

the

meter

thoroughly

warmed

and

cahbrated

Warm

up

the

engme

suffiCiently

ContInue

engIne

operatIOn

for

one

mmute

un

der

ldhng

speed

I

i

I

I

I

I

I

I

ETOQ4

Fig

8

Checking

dlstnbutor

POint

gap

Page 12 of 136

aiDteDaDce

UDe

up

Adjust

throttle

adjusting

screw

so

that

engme

speed

1S

800

rpm

m

N

positIOn

for

automatic

transmIssIOn

Check

IgnitIOn

tlmmg

If

necessary

adjust

1t

to

the

specIficatIOns

IgnitIOn

timing

50

800

rpm

Adjust

Idle

adjusting

screw

so

that

CO

percen

tage

IS

1

5

t0

5

ff

Repeat

the

adjustments

as

desctlbed

In

steps

3

above

so

that

CO

percentage

IS

15

t0

5

ff

at

800

rpm

Cautions

a

On

automatic

transmission

equipped

model

check

must

be

done

in

the

D

position

Be

sure

to

apply

parking

brake

and

to

lock

both

front

and

rear

wheels

wIth

wheel

chocks

b

Hold

brake

pedal

while

stepping

down

on

accelerator

pedal

Otherwise

car

will

rush

out

dangerously

On

automatic

transmISSIOn

eqUIpped

model

make

sure

that

the

adjustment

has

been

made

wIth

the

selector

lever

In

N

posItion

And

then

check

the

specificatIOns

with

the

lever

In

D

posItion

Insure

that

CO

percent

and

Idle

speed

are

as

follows

Idle

rpm

650

Idle

Limiter

Cap

CO

percentage

Do

not

remove

this

Idle

hm1ter

cap

unless

necessary

If

this

Unit

IS

removed

It

IS

I

with

lever

In

D

PoSitIOn

1

5

t

0

5

k

necessary

to

re

adJust

It

at

the

time

of

In

If

necessary

adjust

by

progIesslvely

turmng

stallatlon

To

adjust

proceed

as

follows

throttle

adJustlng

screw

and

Idle

adJustmg

Make

sure

that

the

percentage

oLCO

contents

screw

until

correct

adjustments

are

made

satisfies

the

specifications

I

I

I

I

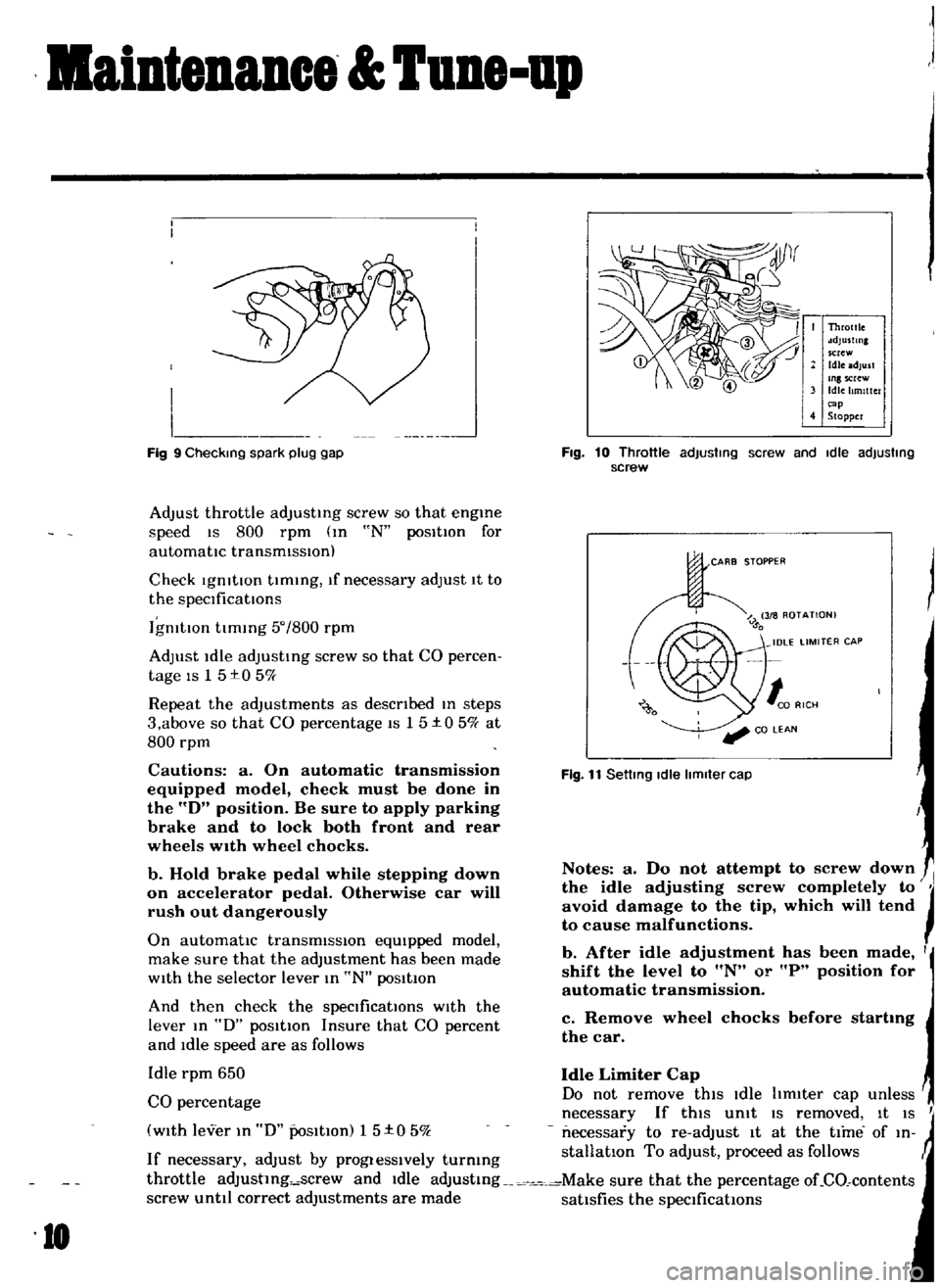

J

Fig

9

Checking

spark

plug

gap

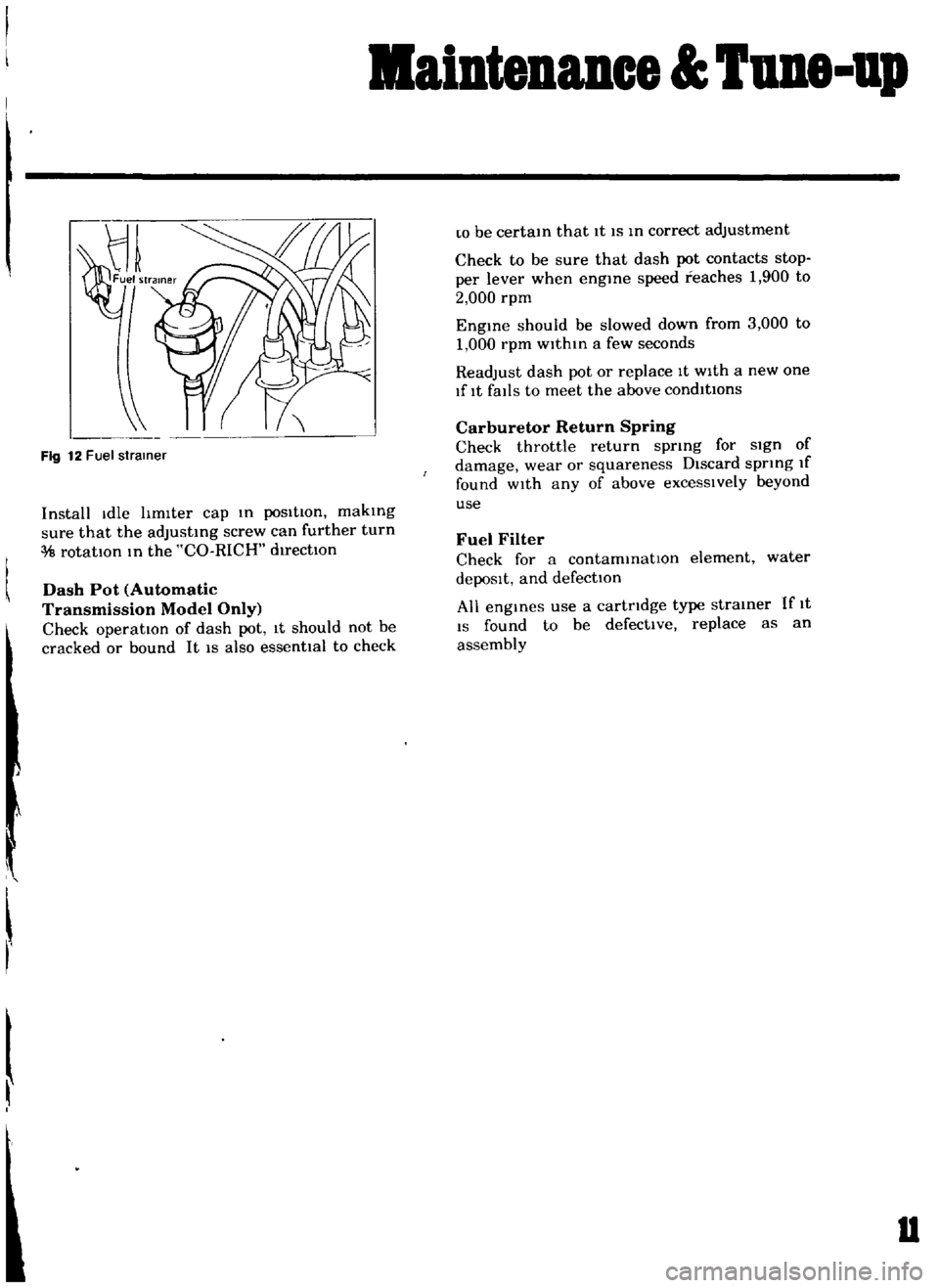

10

Throttle

sdJustlnl

screw

Idle

adjust

Inlscrew

Idle

Itmlttc

r

cap

4

Stopper

Fig

10

Throttle

adjusting

screw

and

Idle

adjusting

screw

CARB

STOPPER

Fig

11

Setting

Idle

limiter

cap

Notes

a

Do

not

attempt

to

screw

down

the

idle

adjusting

screw

completely

to

JI

avoid

damage

to

the

tip

which

will

tend

to

cause

malfunctions

b

After

idle

adjustment

has

been

made

I

shift

the

level

to

N

or

P

position

for

automatic

transmission

c

Remove

wheel

chocks

before

startmg

the

car

Page 13 of 136

aiDtenuce

TUDe

up

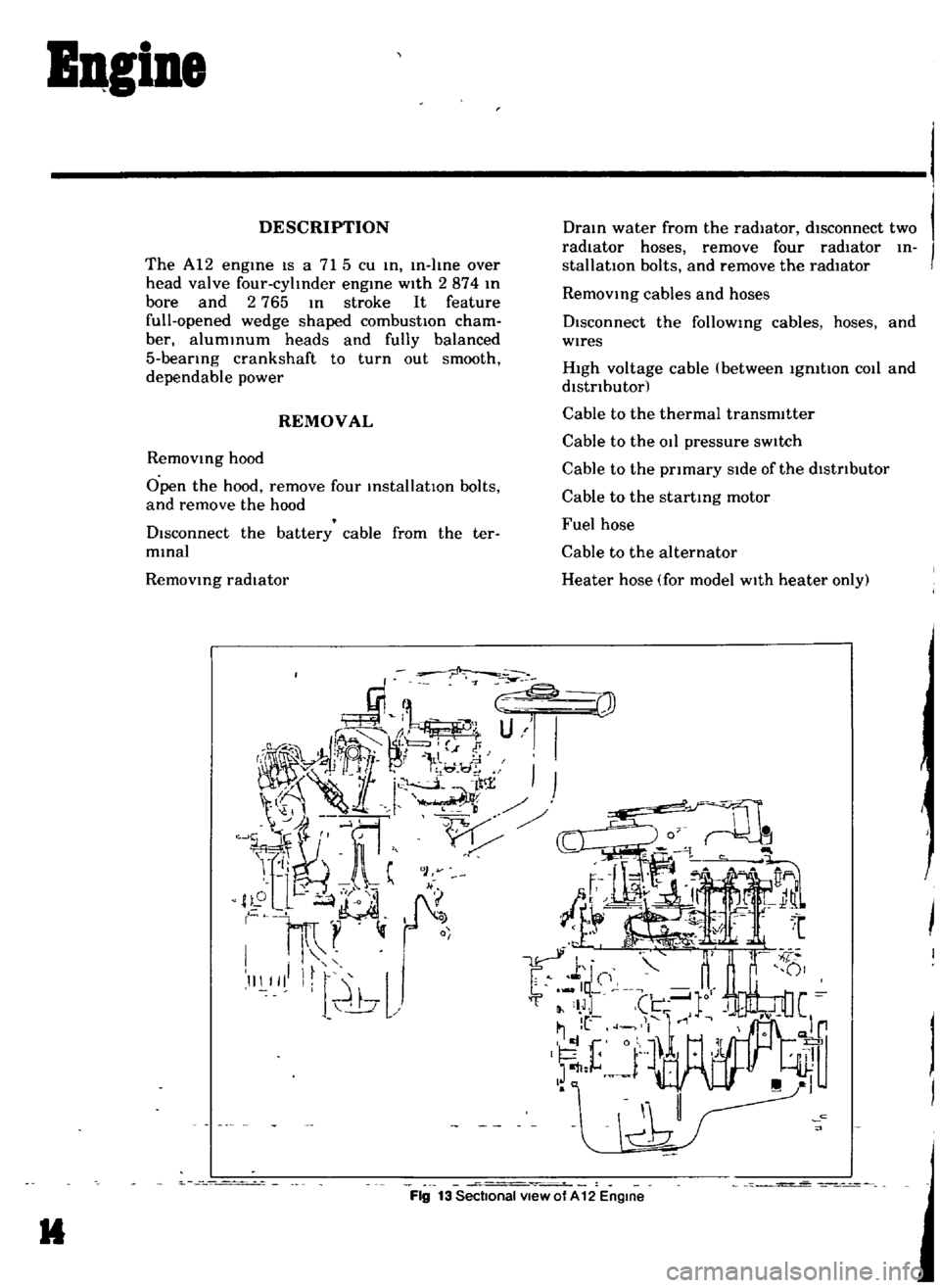

Fig

12

Fuel

strainer

Install

Idle

hmlter

cap

m

posItion

makmg

sure

that

the

adJustmg

screw

can

further

turn

rotatIOn

m

the

CO

RICH

d1rectlOn

Dash

Pot

Automatic

Transmission

Model

Only

Check

operation

of

dash

pot

It

should

not

be

cracked

or

bound

It

IS

also

essenttal

to

check

r

w

be

certam

that

It

IS

m

correct

adjustment

Check

to

be

sure

that

dash

pot

contacts

stop

per

lever

when

engme

speed

reaches

1

900

to

2

000

rpm

Engme

should

be

slowed

down

from

3

000

to

1

000

rpm

within

a

few

seconds

Readjust

dash

pot

or

replace

It

with

a

new

one

lflt

falls

to

meet

the

above

condItions

Carburetor

Return

Spring

Check

throttle

return

sprmg

for

sign

of

damage

wear

or

squareness

Discard

spring

If

found

wIth

any

of

above

excessIvely

beyond

use

Fuel

Filter

Check

for

a

contammatlOn

element

water

depoSIt

and

defection

All

engmes

use

a

cartridge

type

strainer

If

1t

IS

found

to

be

defective

replace

as

an

assembly

u

Page 14 of 136

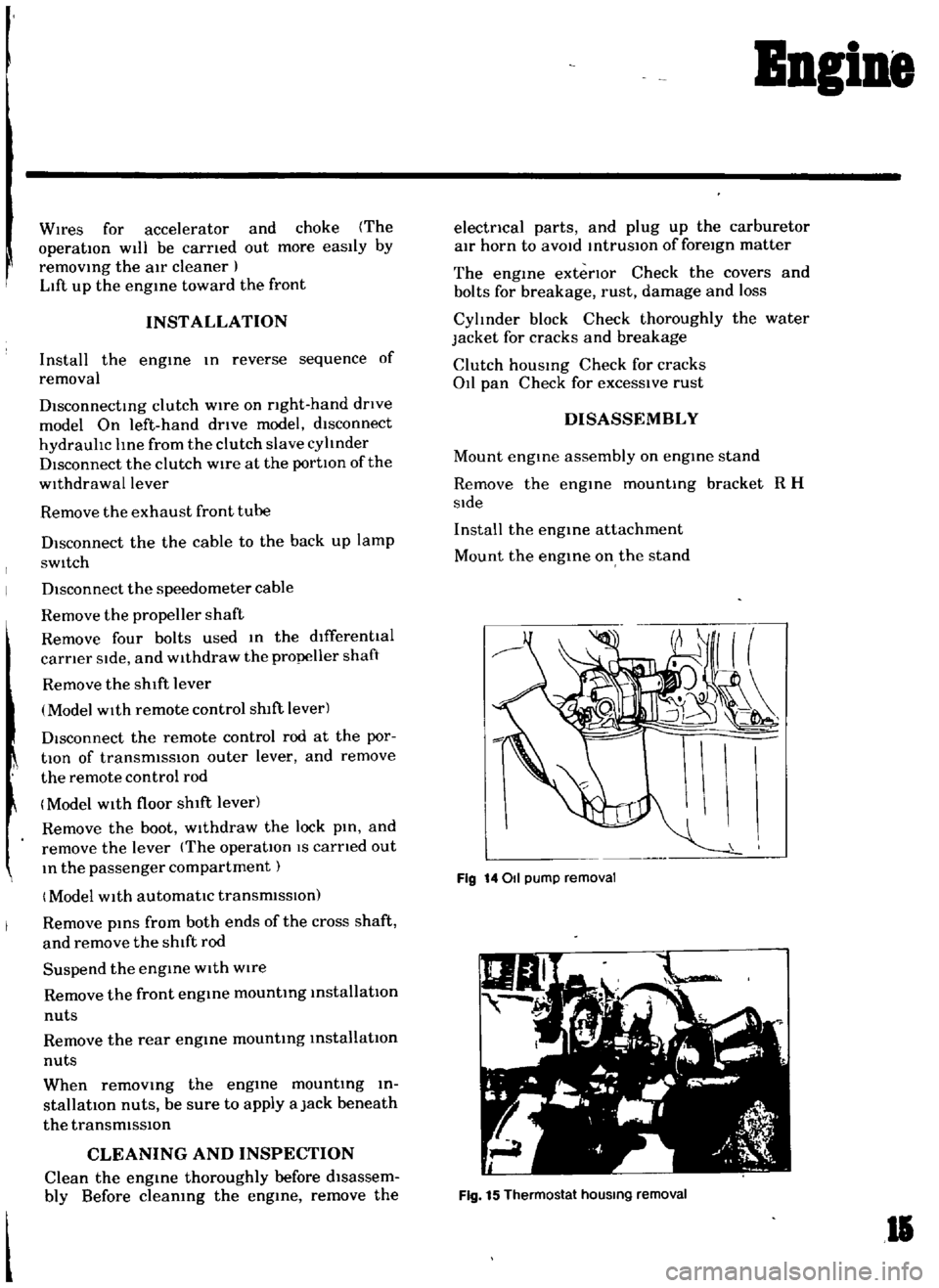

IQgiDe

DESCRIPTION

The

A12

engme

IS

a

715

cu

m

In

I

me

over

head

valve

four

cyltnder

engine

with

2874

m

bore

and

2

765

m

stroke

It

feature

full

opened

wedge

shaped

combustIOn

cham

ber

alummum

heads

and

fully

balanced

5

bearmg

crankshaft

to

turn

out

smooth

dependable

power

REMOVAL

Removmg

hood

Open

the

hood

remove

four

mstallatlOn

bolts

and

remove

the

hood

Disconnect

the

battery

cable

from

the

ter

mmal

Removmg

radIator

Dram

water

from

the

radiator

disconnect

two

radIator

hoses

remove

four

radIator

m

stallatlOn

bolts

and

remove

the

radiator

Removmg

cables

and

hoses

Disconnect

the

followmg

cables

hoses

and

wires

High

voltage

cable

between

Igmtton

COlI

and

distributor

Cable

to

the

thermal

transmitter

Cable

to

the

011

pressure

sW1tch

Cable

to

the

primary

Side

of

the

distributor

Cable

to

the

startmg

motor

Fuel

hose

Cable

to

the

alternator

Heater

hose

for

model

With

heater

only

I

Fig

13

Sectional

view

of

A

12

Engine

It

Page 15 of 136

Bngine

WIres

for

accelerator

and

choke

The

operatIOn

Will

be

carned

out

more

easily

by

removing

the

a1r

cleaner

Lift

up

the

engine

toward

the

front

INST

ALLA

TION

Install

the

engine

In

reverse

sequence

of

removal

Disconnecting

clutch

wire

on

nght

hand

dnve

model

On

left

hand

dnve

model

disconnect

hydraulIc

line

from

the

clutch

slave

cylInder

DIsconnect

the

clutch

WIre

at

the

JXlrtlOn

of

the

wIthdrawal

lever

Remove

the

exhaust

front

tube

Disconnect

the

the

cable

to

the

back

up

lamp

SWItch

D1sconnect

the

speedometer

cable

Remove

the

propeller

shaft

Remove

four

bolts

used

In

the

differential

carner

SIde

and

Withdraw

the

propeller

shaft

Remove

the

shift

lever

Model

With

remote

control

shIft

lever

Disconnect

the

remote

control

rod

at

the

JXlr

tlOn

of

transmiSSIOn

outer

lever

and

remove

the

remote

control

rod

Model

With

floor

Sh1ft

lever

Remove

the

boot

WIthdraw

the

lock

pin

and

remove

the

lever

The

operatIOn

IS

carned

out

In

the

passenger

compartment

Model

With

automatic

transmiSSIOn

Remove

pinS

from

both

ends

of

the

cross

shaft

and

remove

the

shIft

rod

Suspend

the

engine

With

wire

Remove

the

front

engine

mounting

installation

nuts

Remove

the

rear

engine

mounting

installation

nuts

When

removing

the

engine

mounting

in

stallation

nuts

be

sure

to

apply

a

Jack

beneath

the

transmiSSIOn

CLEANING

AND

INSPECTION

Clean

the

engine

thoroughly

before

disassem

bly

Before

cleaning

the

engine

remove

the

l

electncal

parts

and

plug

up

the

carburetor

air

horn

to

aVOid

intrusIOn

of

foreign

matter

The

engine

extenor

Check

the

covers

and

bolts

for

breakage

rust

damage

and

loss

CylInder

block

Check

thoroughly

the

water

Jacket

for

cracks

and

breakage

Clutch

hOUSing

Check

for

cracks

011

pan

Check

for

excessive

rust

DISASSEMBLY

Mount

engine

assembly

on

engine

stand

Remove

the

engine

mounting

bracket

R

H

Side

Install

the

engine

attachment

Mount

the

engine

on

the

stand

Fig

14011

pump

removal

Fig

15

Thermostat

hOUSing

removal

II

Page 16 of 136

Bngine

Remove

the

altel

nator

and

engine

mounting

bracket

L

H

slde

Remove

the

crankshaft

pulley

Remove

the

011

pump

together

With

the

011

filtel

Remove

the

high

tensIOn

cable

wIth

the

dlstnbutor

cap

on

Remove

the

spark

plugs

Remove

the

dlstllbutor

assembly

Remove

the

carburetor

Remove

the

rocker

cover

Remove

the

thermo

itat

houslllg

Remove

the

manifolds

Remove

the

water

pump

Remove

the

fuel

pump

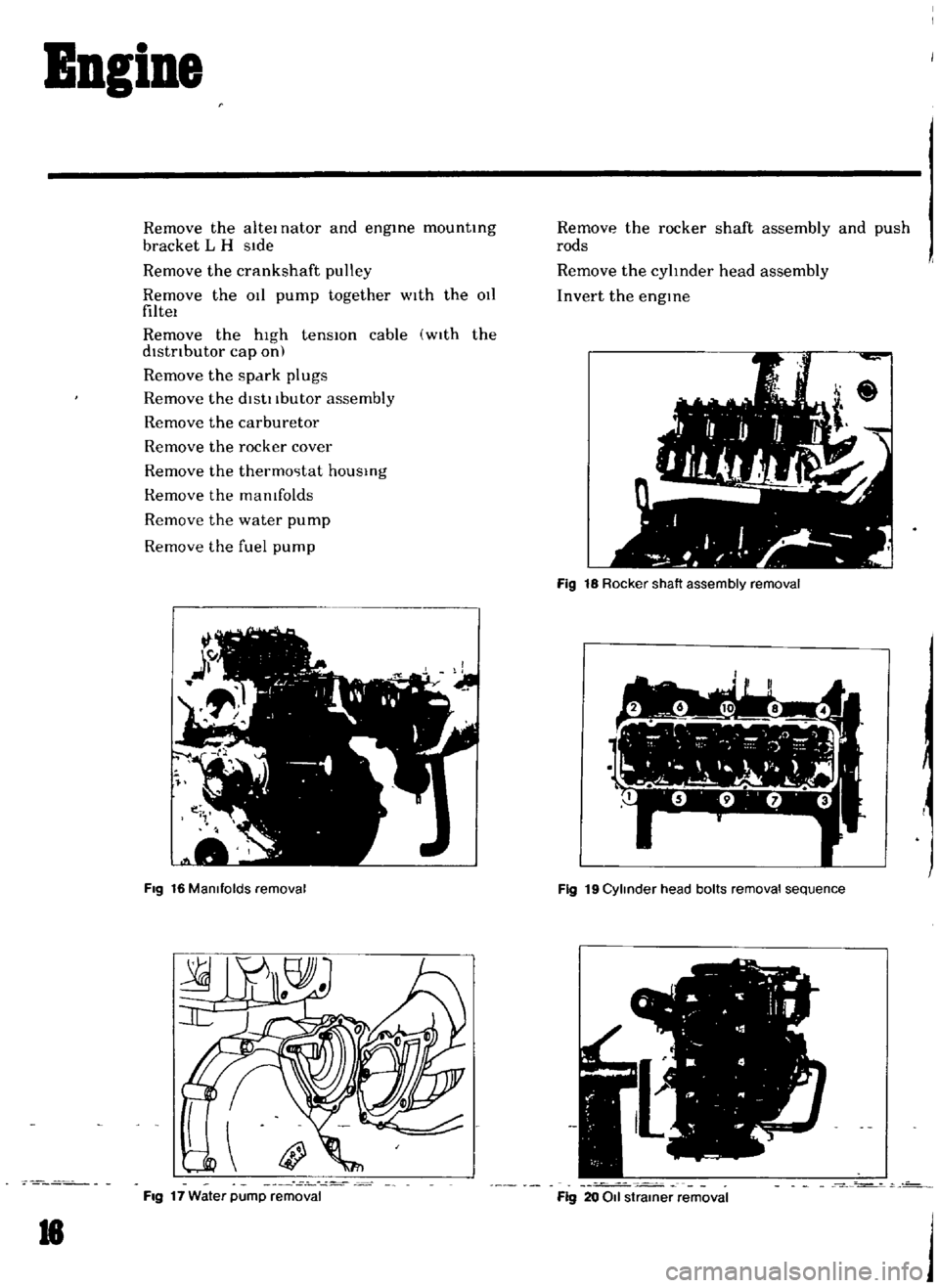

Fig

16

Manifolds

removal

Fig

17

Water

pump

removal

18

Remove

the

rocker

shaft

assembly

and

push

rods

Remove

the

cylInder

head

assembly

Invert

the

engine

Fig

18

Rocker

shaft

assembly

removal

7

1

l

I

h

Y

r

I

w

L

1

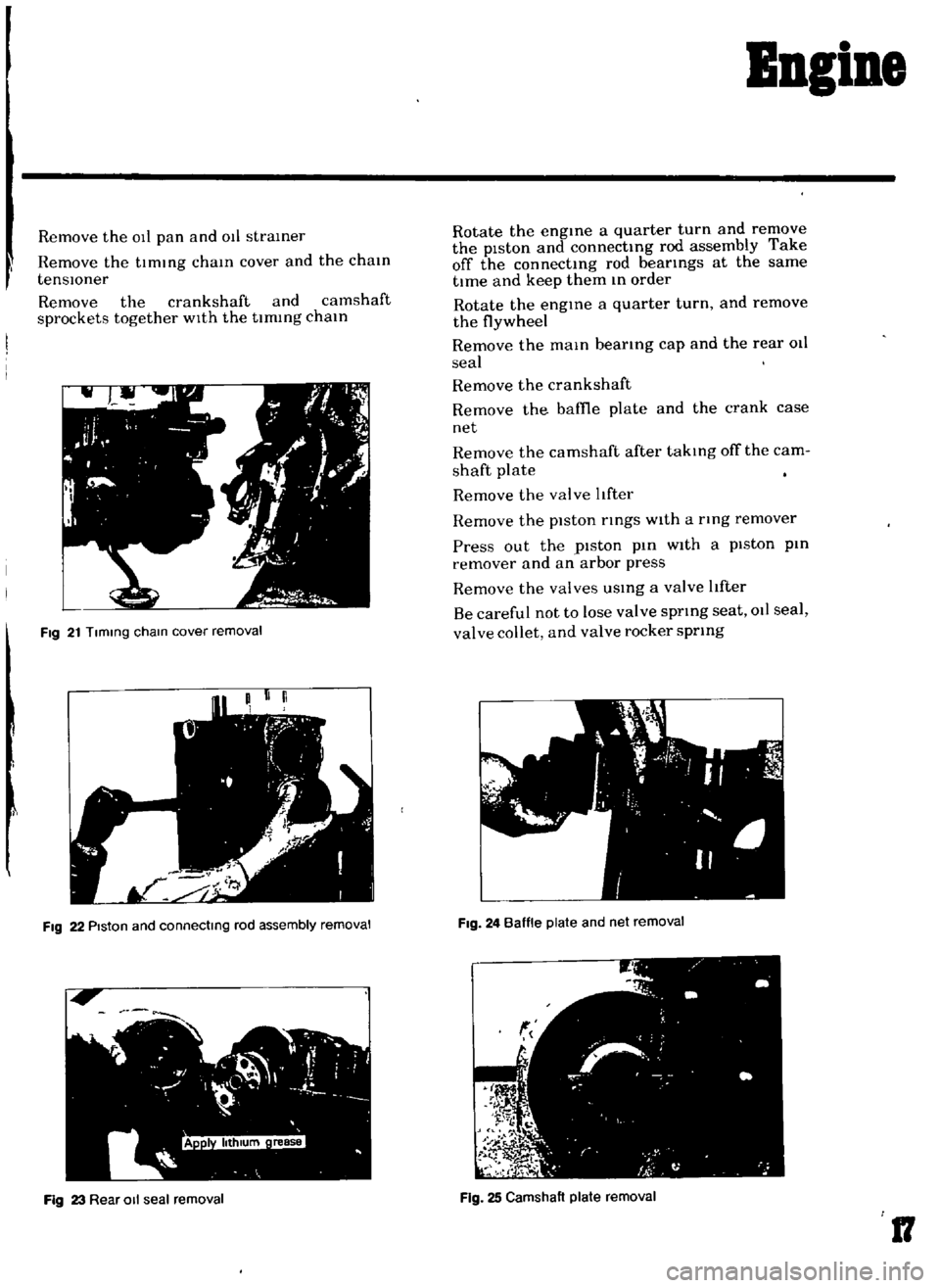

Fig

19

Cylinder

head

bolts

removal

sequence

o

Fig

20

011

strainer

removal

j

Page 17 of 136

Bneine

Remove

the

011

pan

and

011

straIner

Remove

the

tImIng

chaIn

cover

and

the

chaIn

tenSlOner

Remove

the

crankshaft

and

camshaft

sprockets

together

WIth

the

timing

chaIn

Fig

21

Tlmmg

cham

cover

removal

I

FIg

22

PIston

and

connectmg

rod

assembly

removal

Fig

23

Rear

011

seal

removal

Rotate

the

engIne

a

quarter

turn

and

remove

the

piston

and

connectIng

rod

assembly

Take

off

the

connectIng

rod

beatings

at

the

same

tIme

and

keep

them

In

order

Rotate

the

engIne

a

quarter

turn

and

remove

the

flywheel

Remove

the

maIn

bearIng

cap

and

the

rear

011

seal

Remove

the

crankshaft

Remove

the

baffie

plate

and

the

crank

case

net

Remove

the

camshaft

after

takIng

off

the

cam

shaft

plate

Remove

the

valve

tfter

Remove

the

piston

rIngs

With

a

tlng

remover

Press

out

the

piston

pIn

With

a

piston

pin

remover

and

an

arbor

press

Remove

the

valves

USIng

a

valve

tfter

Be

careful

not

to

lose

valve

sprIng

seat

011

seal

valve

collet

and

valve

rocker

sprIng

FIg

24

Baffle

plate

and

net

removal

Fig

25

Camshaft

plate

removal

17

Page 18 of 136

Bogioe

0

WAI

CI

o

o

WAIl

Cl

I

Fig

26

Valve

components

FIg

27

Cylinder

head

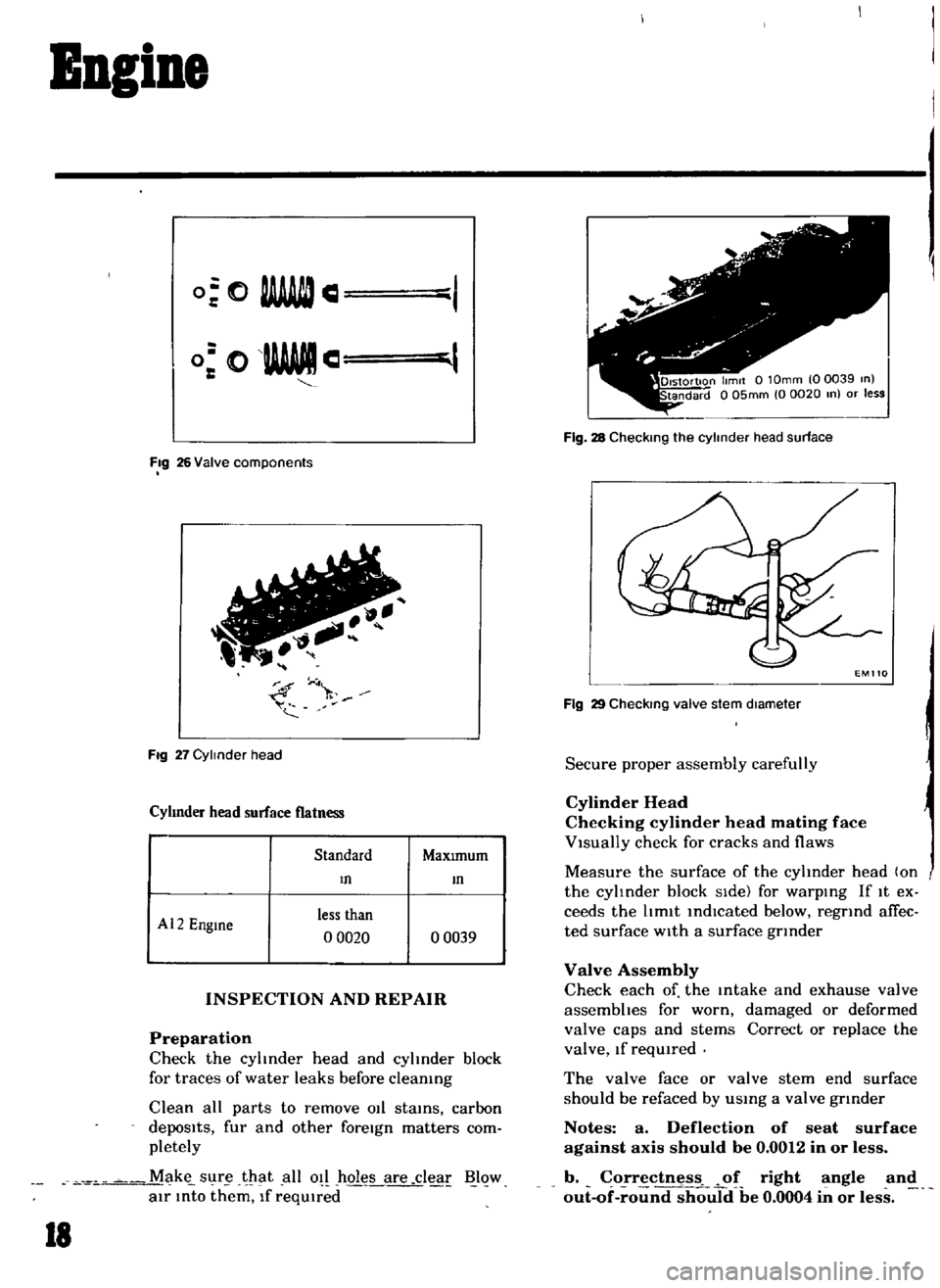

Cyhnder

head

surface

flatness

Standard

MaxImum

m

m

Al2

Engme

less

than

o

0020

o

0039

INSPECTION

AND

REPAIR

Preparation

Check

the

cyhnder

head

and

cylinder

block

for

traces

of

water

leaks

before

cleaning

Clean

all

parts

to

remove

011

stains

carbon

depoSits

fur

and

other

foreIgn

matters

com

pletely

M

k

s

lr

1at

all

o

hol

Lare

clear

Blow

air

Into

them

If

reqUIred

18

Fig

28

Checking

the

cylinder

head

surface

Fig

29

CheckIng

valve

stem

dIameter

Secure

proper

assembly

carefully

Cylinder

Head

Checking

cylinder

head

mating

face

VIsually

check

for

cracks

and

flaws

Measure

the

surface

of

the

cyhnder

head

on

the

cyhnder

block

SIde

for

warping

If

It

ex

ceeds

the

hmlt

indIcated

below

regrind

afTec

ted

surface

wIth

a

surface

grinder

Valve

Assembly

Check

each

of

the

Intake

and

exhause

valve

assembhes

for

worn

damaged

or

deformed

valve

caps

and

stems

Correct

or

replace

the

valve

If

reqUIred

The

valve

face

or

valve

stem

end

surface

should

be

refaced

by

usmg

a

valve

gtlnder

Notes

a

Deflection

of

seat

surface

against

axis

should

be

0

0012

in

or

less

b

o

rr

ctnes

f

right

angle

and

out

of

round

should

be

0

0004

in

or

less

Page 19 of 136

IBglne

Note

When

the

valve

head

has

been

reduced

to

0

0197

in

or

less

in

thickness

replace

the

valve

Grinding

allowance

for

the

valve

stem

end

surface

is

0

0197

in

or

less

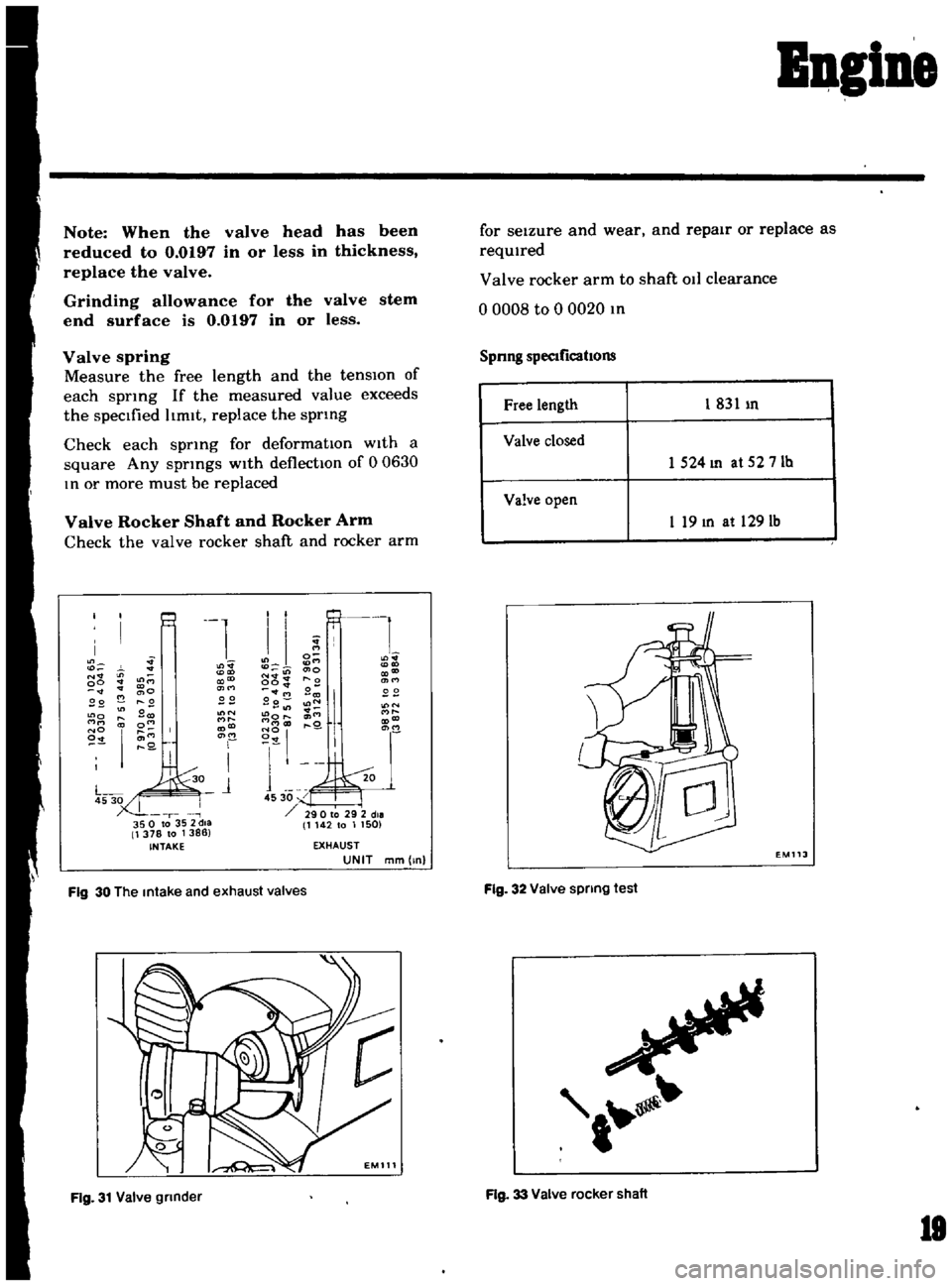

Valve

spring

Measure

the

free

length

and

the

tensIOn

of

each

spnng

If

the

measured

value

exceeds

the

specIfied

hmlt

replace

the

sprlllg

Check

each

spnng

for

deformatIOn

with

a

square

Any

sprmgs

w1th

deflectIOn

of

0

0630

III

or

more

must

be

replaced

Valve

Rocker

Shaft

and

Rocker

Arm

Check

the

valve

rocker

shaft

and

rocker

arm

1

N

in

00

9E

22

N

o

NO

I

I

I

I

1

I

I

Ll

gE

N

cno

CX

co

00

r

o

171M

OtM

Be

22

Bo

l

N

11

lit

l

o

cnM

l

Q

1

45

30

290

to

29

2

die

1142

to

1

1501

N

I

350

to

35

2dla

1

378

to

1386

INTAKE

EXHAUST

UNIT

mm

lnl

Fig

30

The

Intake

and

exhaust

valves

Fig

31

Valve

grinder

for

seizure

and

wear

and

repair

or

replace

as

required

Valve

rocker

arm

to

shaft

011

clearance

o

0008

to

0

0020

III

Spnng

specIficatIOns

Free

length

1

831

In

Valve

closed

1

524

In

at

52

7

Ib

Valve

open

I

19

III

at

1291b

EM

J

Fig

32

Valve

spring

test

Fig

33

Valve

rocker

shaft

lB

Page 20 of 136

Bn

in1l

If

camshaft

bearmg

clearance

IS

exceSS1ve

replace

the

camshaft

bearmgs

with

service

parts

When

valve

contact

surface

of

the

valve

rocker

arm

IS

worn

excessively

m

step

repair

by

means

of

a

valve

grinder

or

replace

Grinding

allowance

for

valve

contact

surface

of

the

valve

rocker

arm

IS

0

0197

In

or

less

Valve

Lifter

and

Push

Rod

Check

the

valve

hfter

for

wear

seizure

and

bevel

edge

contact

and

repair

or

replace

as

reqUIred

Measure

clearance

between

the

hfter

hole

on

the

cyhnder

block

and

valve

hfter

and

replace

the

valve

hfter

when

clearance

ex

ceeds

the

hmlt

Check

the

push

rod

for

bendmg

and

damage

and

repair

or

replace

as

reqUIred

Camshaft

and

Camshaft

Bearing

Measure

mner

dIameter

of

the

camshaft

bearing

and

outer

diameter

of

the

camshaft

Journal

Standard

MaxlIDum

m

m

Valve

hfter

hfter

hole

o

0059

o

0008

to

0

0020

clearance

limit

0151010

00059

m

Standard

003

to

0071010

00012

to

00027

m

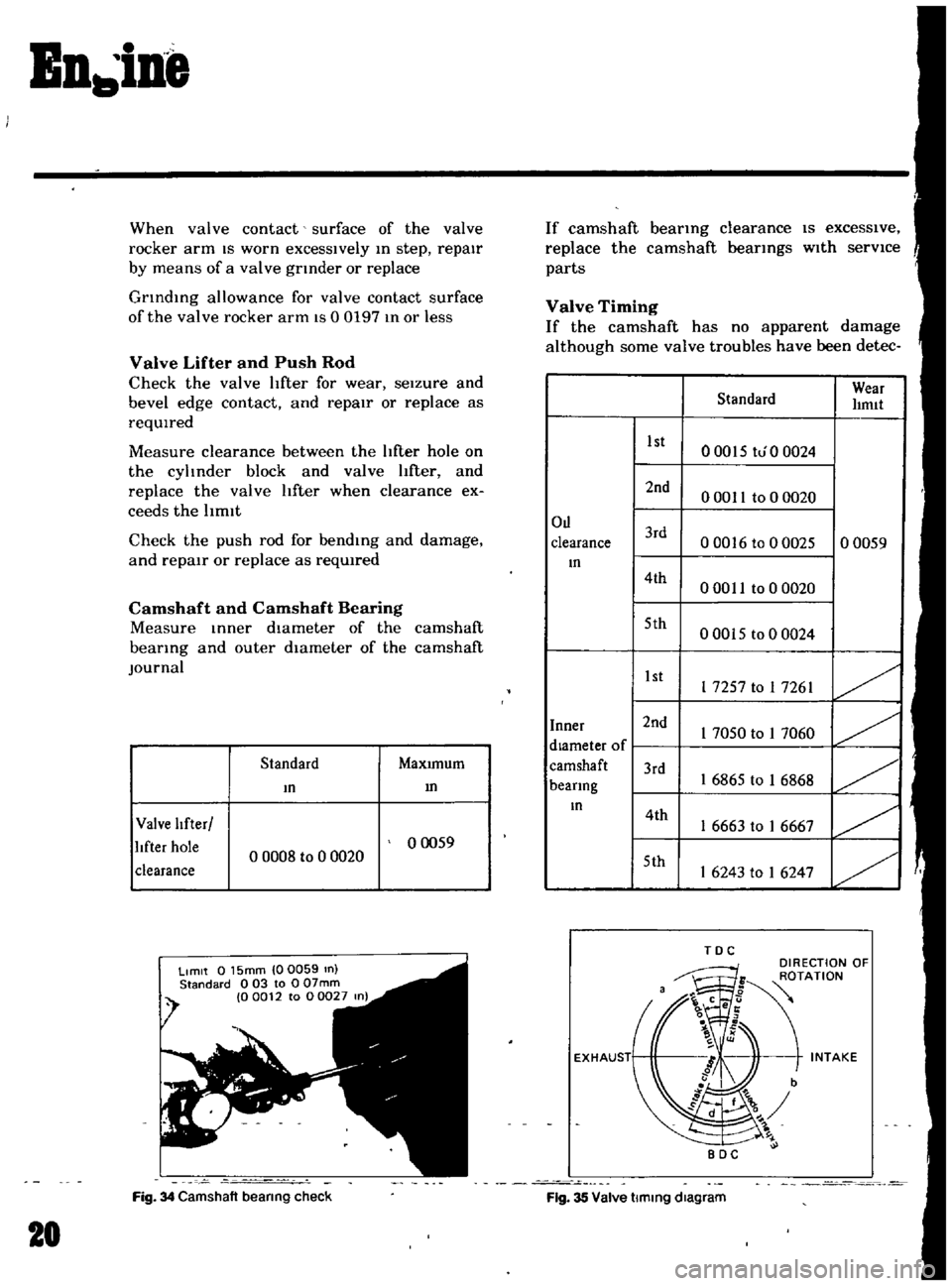

Fig

34

Camshaft

bearing

check

20

Valve

Timing

If

the

camshaft

has

no

apparent

damage

although

some

valve

troubles

have

been

detec

Standard

Wear

hm1t

1st

00015luOO024

2nd

00011

to

0

0020

Ot

3rd

clearance

00016

to

00025

o

0059

In

4th

00011

to

0

0020

5th

00015

toO

0024

1st

1

7257

to

I

7261

Inner

2nd

1

7050

to

1

7060

diameter

of

camshaft

3rd

beanng

1

6865

to

1

6868

m

4th

I

6663

to

I

6667

5th

1

6243

to

1

6247

TDC

DIRECTION

OF

ROTATION

EXHAUST

INTAKE

BDC

Fig

35

Valve

timing

diagram