DATSUN B110 1969 Service Owner's Guide

Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 31 of 136

BDgiDe

TIghtening

torque

40

to

43

ft

Ib

Install

the

push

rod

Install

the

rocker

haft

assembly

and

tighten

the

I

ocker

haft

bracket

bolts

to

the

specIfied

torque

Tightening

torque

15

to

18

ft

lb

Note

TIghtening

operation

should

be

made

gradually

10

separating

two

or

three

stages

and

outwardly

from

the

center

bracket

In

tall

the

Intake

and

exhaust

mamfolds

TIghtening

torque

65

to

10

ft

lb

AdJu

t

valve

clemance

wIth

the

specIfied

dlmenblOn

Install

the

rocker

cover

and

carburetor

assem

bly

I

n

tdll

the

watel

pump

and

thermostat

Tlghtemng

tOl

que

65

to

10

ft

lb

I

nstall

the

crankshaft

pulley

Tighten

the

crank

pulley

bolt

to

the

specIfied

torque

TIghtenIng

torque

109

to

116

ft

lb

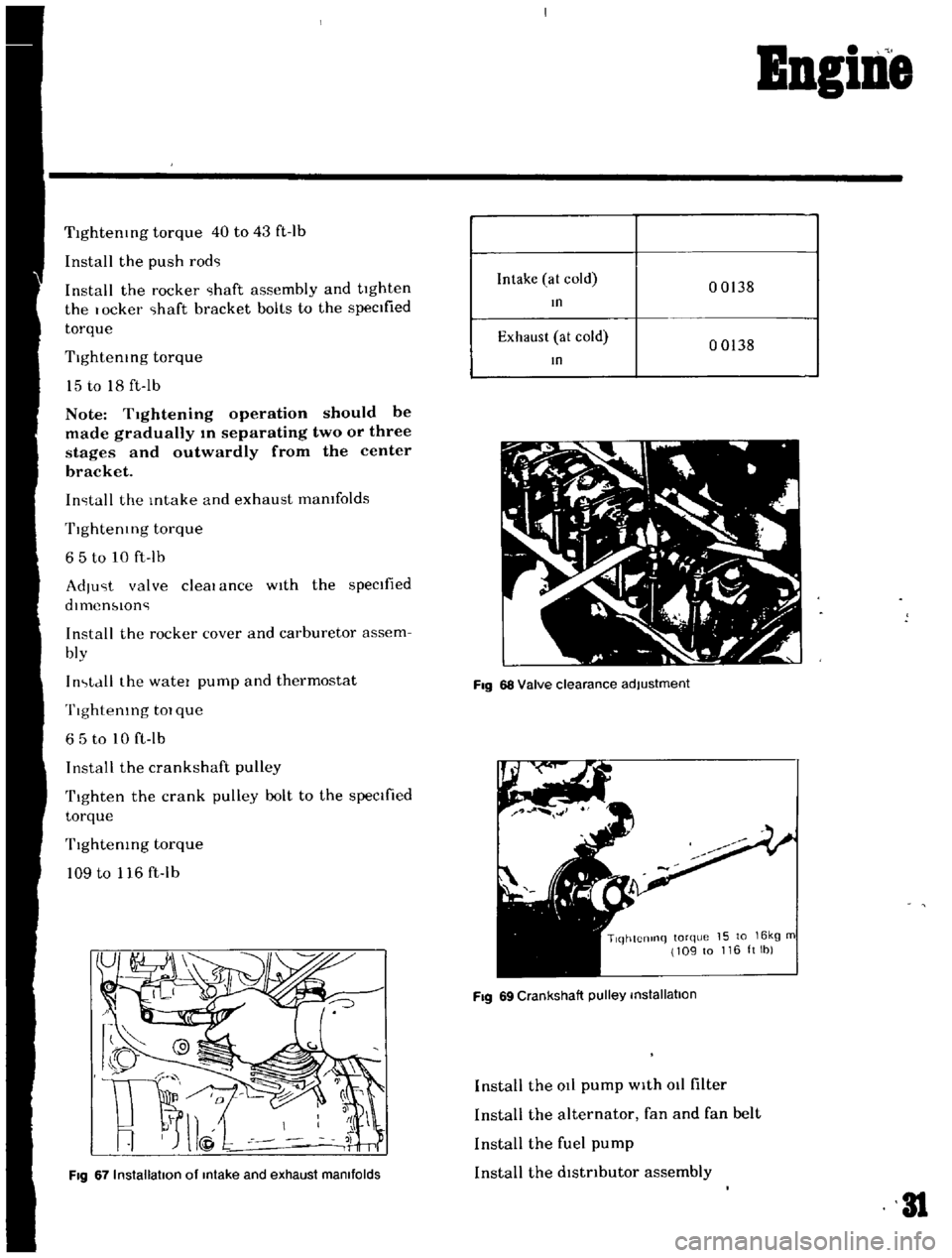

Fig

67

Installation

of

Intake

and

exhaust

manifolds

Intake

at

cold

00138

In

Exhaust

at

cold

00138

In

Fig

68

Valve

clearance

adjustment

TlqhtCnlnq

torque

15

to

16kg

m

109

to

116ltlb

Fig

69

Crankshaft

pulley

installation

Install

the

at

pump

with

011

filter

Install

the

alternator

fan

and

fan

belt

Install

the

fuel

pump

Install

the

dlstnbutor

assembly

31

Page 32 of 136

BBgiBe

Fig

70

Tlmmg

mark

Fig

71

Dlstnbutor

mstallatlon

Notes

a

Set

the

No

1

piston

to

its

top

dead

center

of

the

compression

stroke

b

Before

installation

return

the

distributor

rotqr

approximately

60

degrees

from

Its

regular

position

Insert

the

assembly

meshing

the

distributor

drive

gear

and

driven

gear

After

installation

the

distributor

rotor

should

come

into

contact

wIth

the

mark

on

the

rotor

cap

fittmg

as

shown

in

the

Figure

Install

the

spark

plugs

and

connect

the

distrIbutor

to

plug

high

tensIOn

lead

wire

Install

the

fuel

hoses

and

tubes

Install

the

clutch

cover

assembly

Install

the

engme

shngers

and

crankcase

ven

tilatIOn

hose

Fig

72

Removal

of

011

pump

TrochoId

Fig

73011

pump

OIL

PUMP

Removal

Engine

in

vehlCIe

Dram

engme

OIl

Remove

the

front

stabilIzer

Remove

the

splash

shield

board

Detach

the

011

pump

body

together

with

drIve

gear

spmdle

Disassembly

PrIor

to

dlsassembhng

check

to

determme

that

the

pump

IS

defective

Take

out

a

total

of

2

bolts

securmg

the

pump

cover

to

the

pump

body

The

outer

and

mner

Dlsmount

the

engme

from

the

workmg

stand

rotors

and

drive

shaft

can

then

be

dlsassem

Install

the

engme

mountmgs

bled

32

Page 33 of 136

ApplYing

a

sUItable

wrench

or

spanner

loosen

off

the

regulator

valve

Note

a

When

placmg

the

valve

m

a

VIse

use

extreme

care

not

to

dIstort

the

pump

body

and

cover

in

the

jaws

b

Do

not

pull

out

the

drive

shaft

pin

securing

the

drIven

shaft

and

inner

rotor

The

shaft

is

press

fitted

to

the

rotor

with

the

pin

calked

Inspection

and

Repair

Clean

the

dIsassembled

parts

with

cleamng

solvent

and

Inspect

for

defects

Inspect

the

dnve

rotor

shaft

for

excessIve

wear

and

scores

and

check

the

follOWing

clearances

SIde

clearance

between

outer

and

Inner

rotors

0

0047

In

or

below

Tip

clearance

00016

to

0

0047

In

Clearance

between

outer

rotor

and

body

o

0059

to

0

0083

In

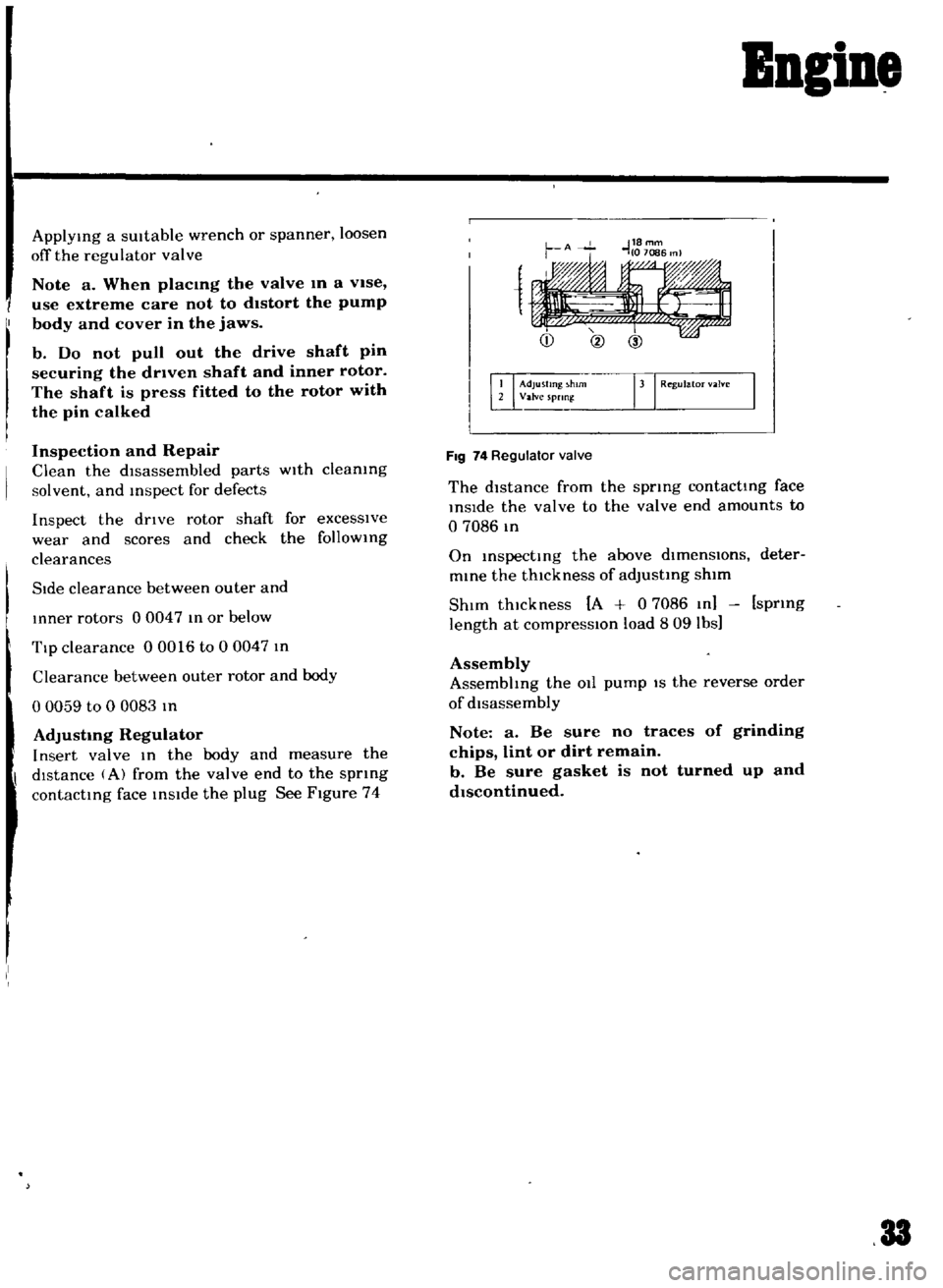

AdjustIng

Regulator

Insert

valve

In

the

body

and

measure

the

dIstance

A

from

the

valve

end

to

the

spnng

contacting

face

inside

the

plug

See

Figure

74

Bngine

1

Adjusting

h

rn

rJ

Regul

m

Valve

spnn

FIg

74

Regulator

valve

The

distance

from

the

spring

contacting

face

inSide

the

valve

to

the

valve

end

amounts

to

o

7086

m

On

inspecting

the

above

dlmenslOns

deter

mine

the

thickness

of

adjusting

shim

ShIm

thickness

A

0

7086

In

spring

length

at

compresslOn

load

809

lbs

Assembly

Assembhng

the

011

pump

IS

the

reverse

order

of

disassembly

Note

a

Be

sure

no

traces

of

grinding

chips

lint

or

dirt

remain

b

Be

sure

gasket

is

not

turned

up

and

dIscontinued

33

Page 34 of 136

11

1

r

t

i

4lI

t

it

j

t

rt

l

I

it

t

8

J

A

l

t

ty

1

1

J

t

1

r

t

d

V

i

f

r

1

t

r

p

J

i

K

l

j

F

p

ll

t

f

i1

AP

J

l

v

i

I

j

ll

f

r

f

1ll

0

0

l

t

l

l

pJ

Page 35 of 136

Bleatriall

System

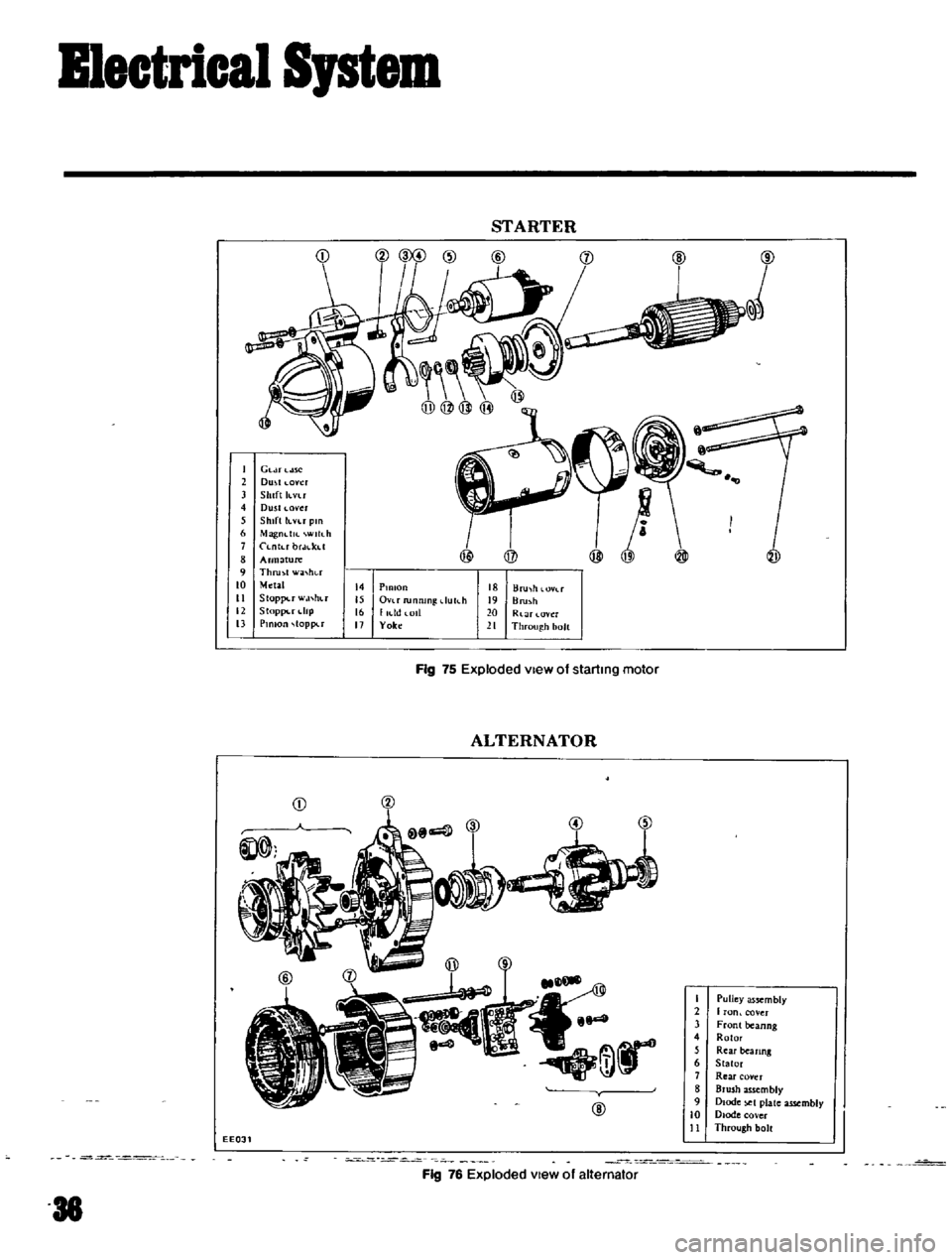

STARTER

I

Gl

U

ne

2

Dmt

oyer

3

Shift

h

vu

4

Dusll

ovcr

5

Shift

knr

pm

6

Magndlf

Wlllh

1

Lntubr

f

t

8

Arlll

ture

9

Thru

ot

w

L

ht

t

to

Metal

it

Stoppu

w

l

hu

12

Stoppt

rdlP

13

Pinion

toppu

@

@

@

@

I

15

16

17

Pmlon

Ovu

rumuRl

dukb

I

KId

lOll

Yok

18

Uru

h

19

Bru

l

b

20

Rl

ar

t

r

11

Through

bolt

Fig

75

Exploded

view

of

starting

motor

ALTERNATOR

CD

@OO

@

@

@

I

Pulley

assembly

2

f

on

cover

3

Front

beanng

4

Rotor

5

Rear

beanng

6

Stator

1

Rea

r

covet

8

Brush

assembly

9

Diode

t

plate

assembly

10

Diode

cover

11

Through

bolt

EE031

Fig

76

Exploded

view

of

alternator

Page 36 of 136

B1eetrical

Iptem

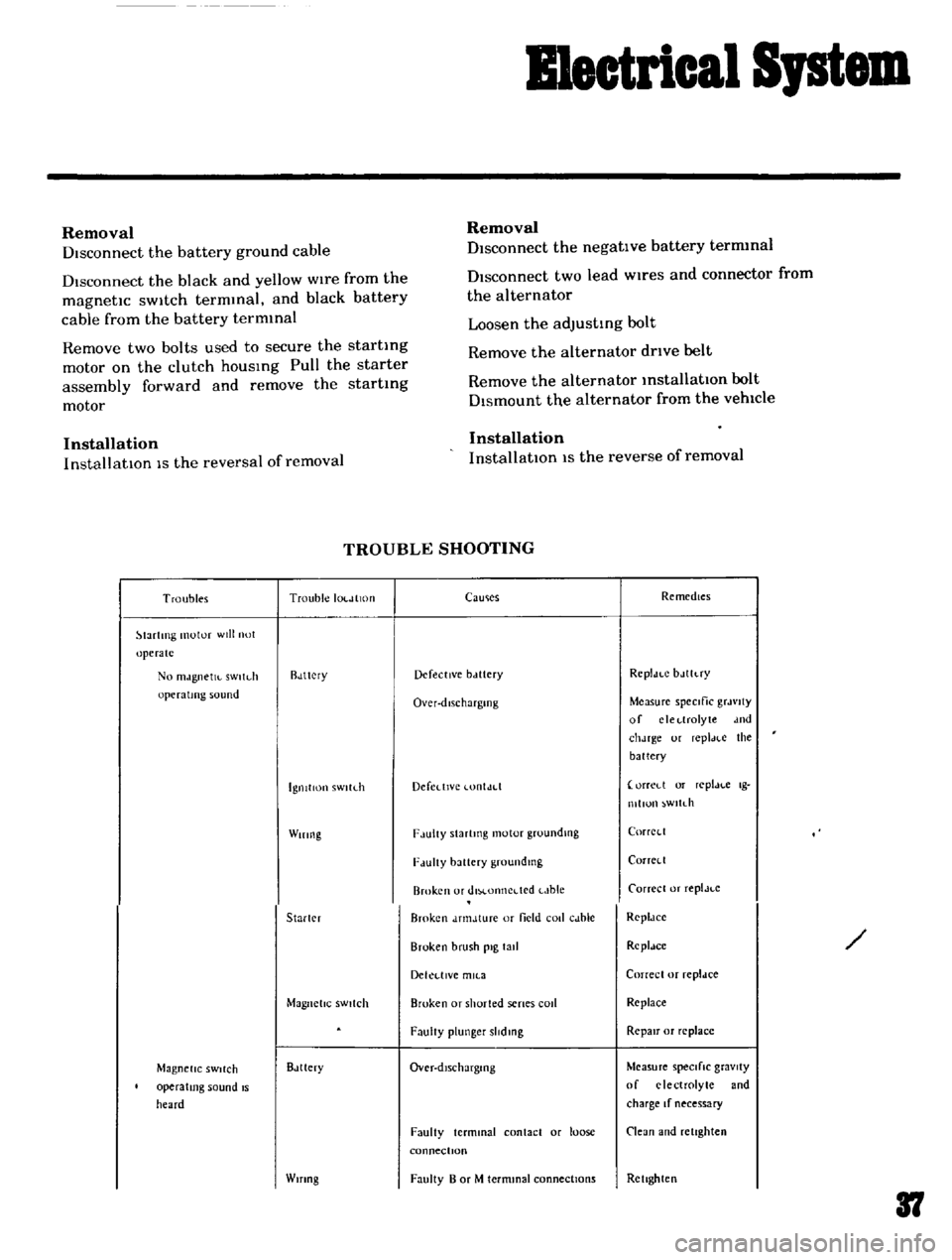

Removal

DIsconnect

the

battery

ground

cable

Disconnect

the

black

and

yellow

wIre

from

the

magnetic

sWitch

termmal

and

black

battery

cable

from

the

battery

termmal

Remove

two

bolts

used

to

secure

the

startmg

motor

on

the

clutch

housing

Pull

the

starter

assembly

forward

and

remove

the

starting

motor

Installation

InstallatlOn

IS

the

reversal

of

removal

Removal

Disconnect

the

negatIve

battery

termmal

DIsconnect

two

lead

wires

and

connector

from

the

alternator

Loosen

the

adjusting

bolt

Remove

the

alternator

drIve

belt

Remove

the

alternator

installation

bolt

Dismount

the

alternator

from

the

vehIcle

Installation

InstallatlOn

1S

the

reverse

of

removal

TROUBLE

SHOOTING

Troubles

Trouble

IOl

JlltHI

lartlTlg

motor

will

not

operate

No

mJgnetJl

sWltdl

operating

sound

Rdttcry

IgnitIon

sWltLh

Wiring

Starler

Magnetic

SWitch

Magnetic

SWitch

operating

sound

IS

heard

Bdttery

Wifing

CaUlies

Remedies

Defective

bclttery

Rcpldt

C

bJlh

ry

Over

dlschargmg

Measure

speCific

grJvlty

of

clcl

lrolyte

dnd

chJrge

ur

repl

H

e

the

battery

Defedlvc

lontJd

orreLl

or

replJl

c

Ig

mllun

wltdl

F

lulty

Slartmg

motor

groundlllg

CorrCl

l

F

lUlty

battery

groundmg

Corrcll

Broken

or

dlM

onncdcd

t

Jble

Carrece

or

replJt

c

Broken

dnnJture

or

field

coli

cJble

RcpldCC

Broken

brush

pig

tall

Rcpldce

Dekl

llVe

mll

3

Correcl

or

repldce

Broken

or

shorted

senes

cod

Replace

FaulIy

plunger

slidmg

RepaIr

or

replace

Over

dlschargmg

Measure

speCifiC

gravity

of

electrolyte

and

charge

If

necessary

Faulty

terminal

contact

or

loose

connectIOn

Clean

and

retighten

Faulty

B

or

M

termmal

connections

Rellghten

37

Page 37 of 136

Bmetrlcal

Spt

The

startmg

motor

rotates

PinIOn

gear

does

not

mtermec

h

with

flOg

gear

Pillion

mtermeshes

with

nng

gc

lT

Startmg

motor

roldles

Jud

pillion

Intermeshes

With

ring

gc

n

but

r

l

IlIan

IS

tou

slow

Startmg

motor

Magnetic

SWitch

Rmg

gear

Startmg

motor

Startmg

motor

Battery

Wiring

IgnitIOn

sWltl

h

Sldelmg

motor

38

Shorted

armature

or

field

cOIl

Worn

brush

or

Improper

spring

pressure

Contaminated

commutator

or

de

fective

mica

Faulty

brush

connection

Seized

metal

Armature

contacted

With

pole

core

Insufficient

plunger

L

dimenSIOn

Faulty

contact

Brok

en

or

shorted

shunt

call

wire

Worn

teeth

Weakened

pinion

sleeve

sprmg

Worn

pm

IOn

teeth

FJulty

plOlOJl

slldmg

Dropped

oft

lever

pill

EXl

hr

plunger

L

dlll1en

IOn

Defel

tlve

over

runnmg

dutch

Over

dlscharglOg

Improper

or

lome

termmdl

con

Lid

Improperly

tightened

connection

Rough

Lontact

urtJce

Shorted

armdture

COil

or

field

cOIl

Worn

brush

or

I11sufficlCnt

spnng

pressure

Conldmmated

Lomrnutator

or

Im

proper

brush

LonldLl

DercLllVe

nllca

Lack

or

metallubneallon

Armature

Lontdcted

With

pole

core

Repair

or

replace

Repair

or

replace

Cledn

or

repair

Repair

Replace

RepJlr

or

replace

AdjUst

ReplJee

Replace

ReplJee

Replnee

Rcpldce

RepJlr

Rep

m

Adjust

Re

place

Charge

battery

Repall

l11d

retIghten

Rellghten

RepJIr

or

replaLc

Repair

or

replace

Repair

or

replace

Repair

Repau

Repdlf

or

replace

Repair

or

replace

Page 38 of 136

llectrical

Spt

When

Harting

lWltch

I

IgllltlUn

iwltch

FJuhy

rctuflung

Repldce

set

10

OFf

the

slJrl

motor

do

nut

MJgnclK

Wltdl

Seiad

contJr

l

Repldcc

IIlg

I

op

Shorted

1

011

Replace

Faulty

plunger

slidmg

Replace

StJflillg

motOr

Pillion

does

not

dlsengJge

from

the

Repair

or

replace

nng

gedr

smoothly

Pinion

sphne

dot

110t

disengage

Repan

or

replJce

moothly

SCl7Cd

pinIOn

metal

Replace

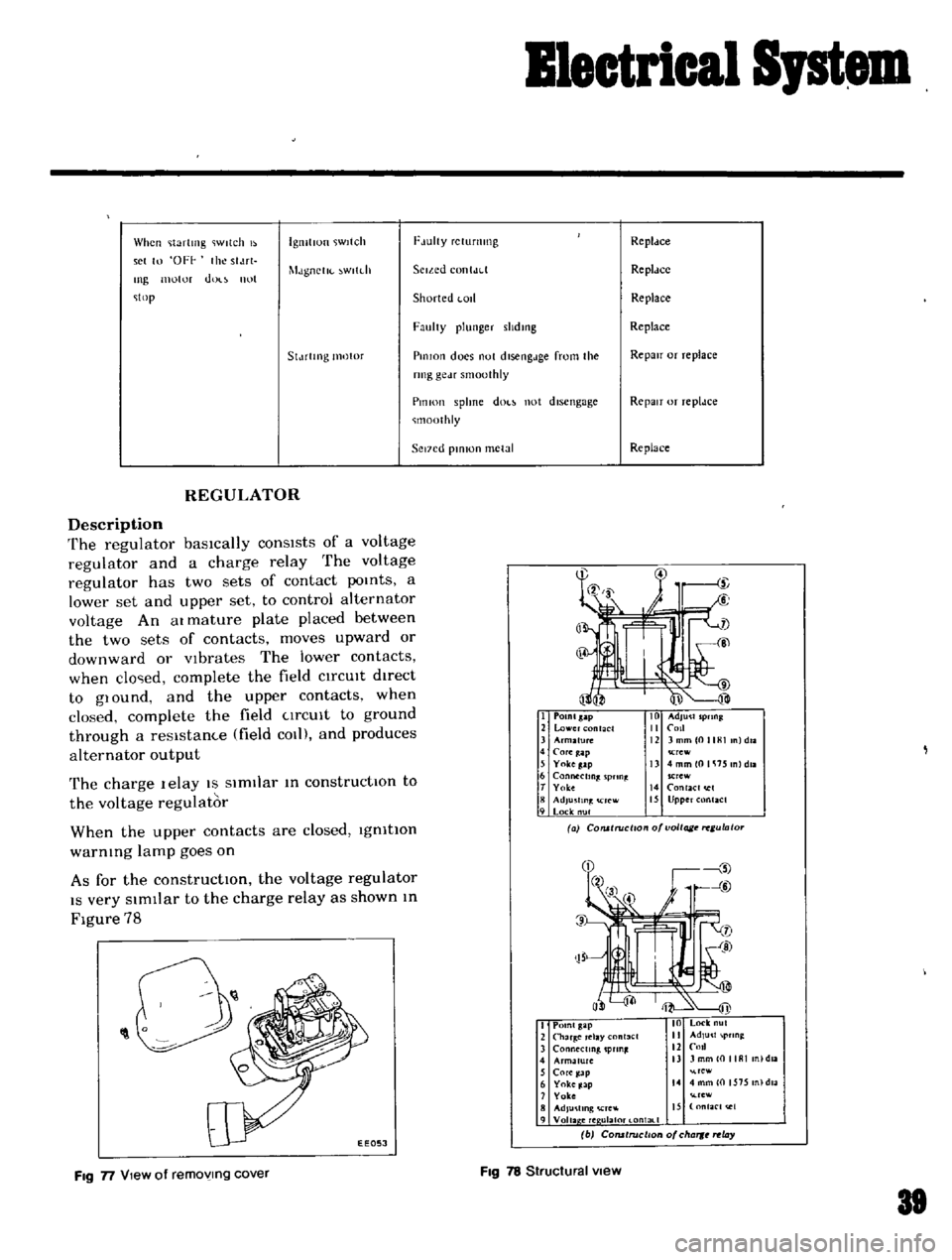

REGULATOR

Description

The

regulator

basically

consists

of

a

voltage

regulator

and

a

charge

relay

The

voltage

regulator

has

two

sets

of

contact

poInts

a

lower

set

and

upper

set

to

control

alternator

voltage

An

at

mature

plate

placed

between

the

two

sets

of

contacts

moves

upward

or

downward

or

Vibrates

The

lower

contacts

when

clo

ed

complete

the

field

CIrCUIt

dIrect

to

glOund

and

the

upper

contacts

when

closed

complete

the

field

CIrCUIt

to

ground

through

a

resIstam

e

field

COl

and

produces

alternator

output

The

charge

lelay

IS

SimIlar

In

constructIOn

to

the

voltage

regulator

When

the

upper

contacts

are

closed

IgnitIOn

warnIng

lamp

goes

on

As

for

the

constructIOn

the

voltage

regulator

IS

very

SImIlar

to

the

charge

relay

as

shown

In

Figure

78

I

POlnlsap

2

lower

nt

CI

3

Arm2fu1C

4

COfe

ap

5

Yokeg

lp

6

Connecting

pnn

t

T

Yolce

8

AdJu

fln

rcw

9

Lock

nul

Crew

13

4mmlOlli15

nldll

SCrew

14

RlaCI

I

15

Upper

Rlact

a

COlUlruci

o

o

voltage

ulato

O

0

1

EEOSJ

I

Point

gap

2

Char

Clay

nl3el

3

ConMctmg

pun

4

Armature

nl

daa

5

Core

ap

re

6

Yoke

Jap

14

4

mm

0

1575

n

dla

7

Yoke

rew

8

AdJu

llng

Cre

IS

nfaC

t

e1

9

Voila

ere

ulal0t

l

ontal

1

b

COfUtruclton

of

cha

rt

ay

FIg

n

View

of

removing

cover

FIg

78

Structural

view

81

Page 39 of 136

Blectrical

Sptem

Troubles

Trouble

locatIon

Not

output

Alternator

Regulator

WIring

Low

output

Alterndtor

Regulator

Wifing

TROUBLE

SHOOTING

Causes

Sl1ckmg

brushes

Duty

brushes

and

slIp

nngs

Loose

connections

or

broken

leads

Open

stator

coLI

Open

rotor

cotl

DefectIVe

dJodes

Shorted

rotor

Shorted

stator

Grounded

A

ternunal

Broken

fan

belt

FJulty

voltage

regulator

pomt

con

tact

Broken

cable

or

disconnectIOn

of

chargIng

CIH

UIt

StIcking

brushes

Low

brush

spring

tenSion

Duty

slIp

nngs

Partially

shorted

ground

or

open

stator

cod

Partially

shorted

or

grounded

rotor

c01l

DefectIVe

dIOde

Loose

or

worn

fan

belt

Improper

voltage

regulator

adlust

Pl

n

I

Faulty

voltage

regulator

pomt

con

t

ct

Defective

operation

Faulty

chargmg

CUI

Ult

lead

WIn

connection

Remedies

Correct

or

replace

brush

and

brush

spnng

aean

RetIghten

or

solder

connection

Replace

leads

If

necessary

6

RepaIr

or

replace

the

stator

coLi

Replace

the

rotor

Replace

the

dIOde

assembly

Replace

the

rotor

RepaIr

or

replace

the

stator

Replace

the

Insulator

Replace

the

belt

RepdU

01

replace

the

regulator

Repdtr

or

replace

Correct

or

replace

brushes

If

neces

sary

Correct

or

replace

brush

Clean

Replace

the

stator

Replace

the

rotor

Replace

the

dIode

assembly

Rettghlen

or

replace

the

belt

Check

the

voltage

regulalor

op

eratIOn

no

rep

Jr

r

J

j

required

Repair

or

replace

the

regulator

Re

olf

or

rpla

e

t

J

Loose

baltery

leririmaJ

Rettghten

1

Page 40 of 136

i

J

t

1

p

3

t

t

i

I

EXCCS

lVe

output

Alterndlor

P

Short

l

lfculted

or

broken

neutral

Replace

the

wife

Wife

Reguldtor

Impro

er

voltdge

regulator

adJust

ment

Defective

operatIon

9i

reg

ator

oP

P

lor

replace

as

rw

t

Check

the

charge

relay

operation

and

repair

or

replace

as

requIred

Check

the

voltage

t

fa

hon

and

ep

lf

required

Improper

charge

relay

adjustment

detecttve

operatIOn

and

or

faulty

pomt

contact

t

f

J

r

p

i

lC

I

1

1

r

i

r

A

1

A

f

l

1

1

S

1

P

1