DATSUN B110 1969 Service Owner's Manual

Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 21 of 136

ted

compare

valve

ttmmg

data

wIth

the

valve

I

ttmmg

diagram

to

ensure

that

begmmng

and

endmg

of

stroke

for

all

cylmders

are

com

plymg

with

specified

advance

and

retard

figures

Cylinder

Block

Check

the

cyhnder

head

v1sually

for

defects

such

as

cracks

and

flaws

Measure

the

top

of

the

cyhnder

block

cyhn

der

head

matmg

face

for

warpmg

If

the

warp

exceeds

the

hmlt

correct

1t

Measure

the

cyhnder

bore

for

out

of

round

and

wear

WIth

a

bore

gauge

If

wear

or

out

of

round

IS

exceSS1ve

rebore

the

cyhnder

walls

by

means

of

a

bormg

machme

Umt

degree

a

b

d

f

c

e

248

248

14

54

12

56

Standard

MaxImum

tolerance

Surface

flatness

less

than

o

0020

o

0039

m

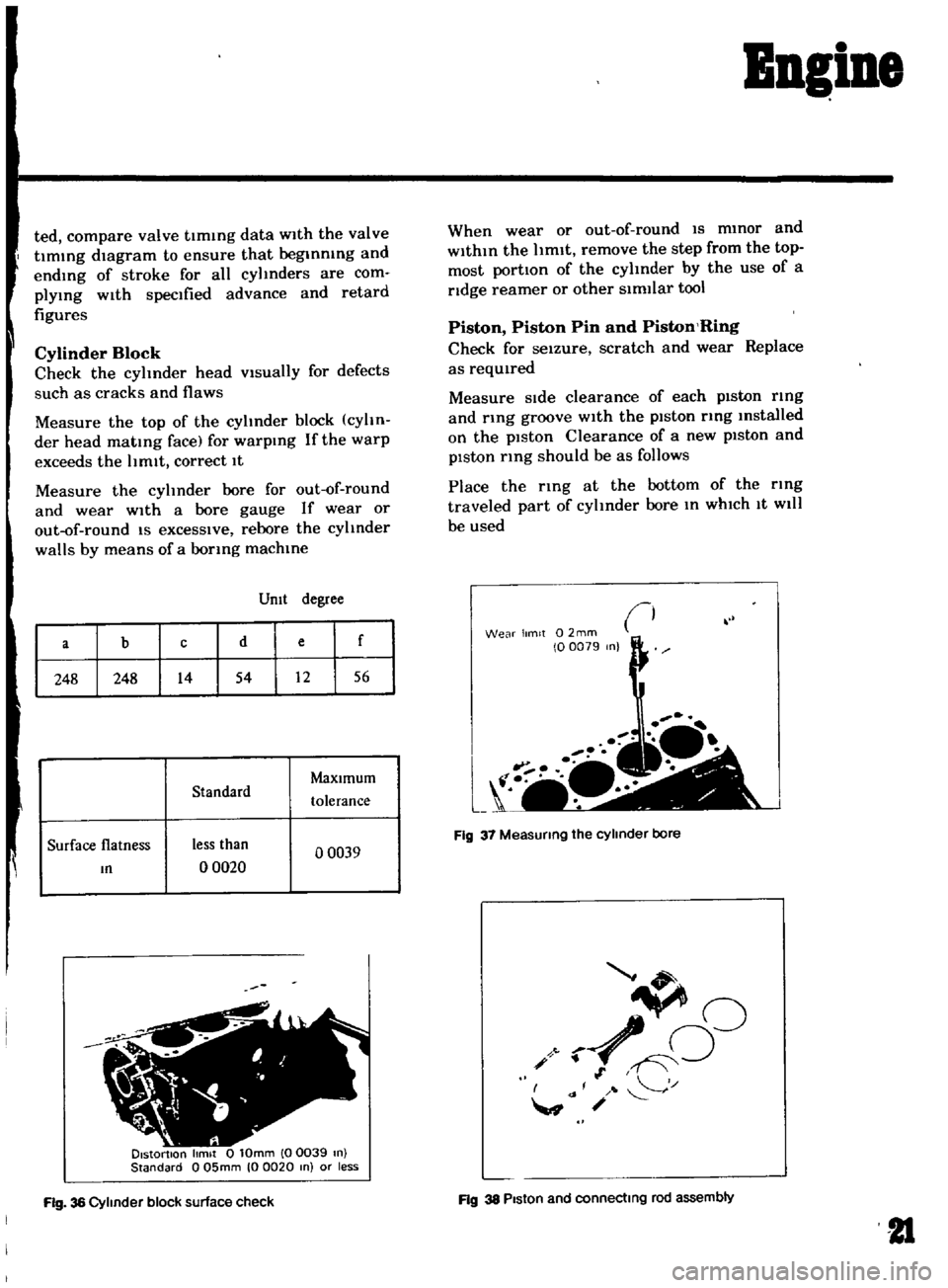

Distortion

limIt

0

101010

00039

In

Standard

0051010

100020

In

or

less

Fig

36

Cylinder

block

surface

check

Bogioe

When

wear

or

out

of

round

1S

mmor

and

wlthm

the

hmlt

remove

the

step

from

the

top

most

portIOn

of

the

cyhnder

by

the

use

of

a

ridge

reamer

or

other

slm11ar

tool

Piston

Piston

Pin

and

Piston

Ring

Check

for

seIzure

scratch

and

wear

Replace

as

reqUIred

Measure

Side

clearance

of

each

piston

rmg

and

ring

groove

WIth

the

piston

rmg

mstalled

on

the

piston

Clearance

of

a

new

pIston

and

p1ston

rmg

should

be

as

follows

Place

the

rmg

at

the

bottom

of

the

rmg

traveled

part

of

cyhnder

bore

m

wh1ch

It

wlll

be

used

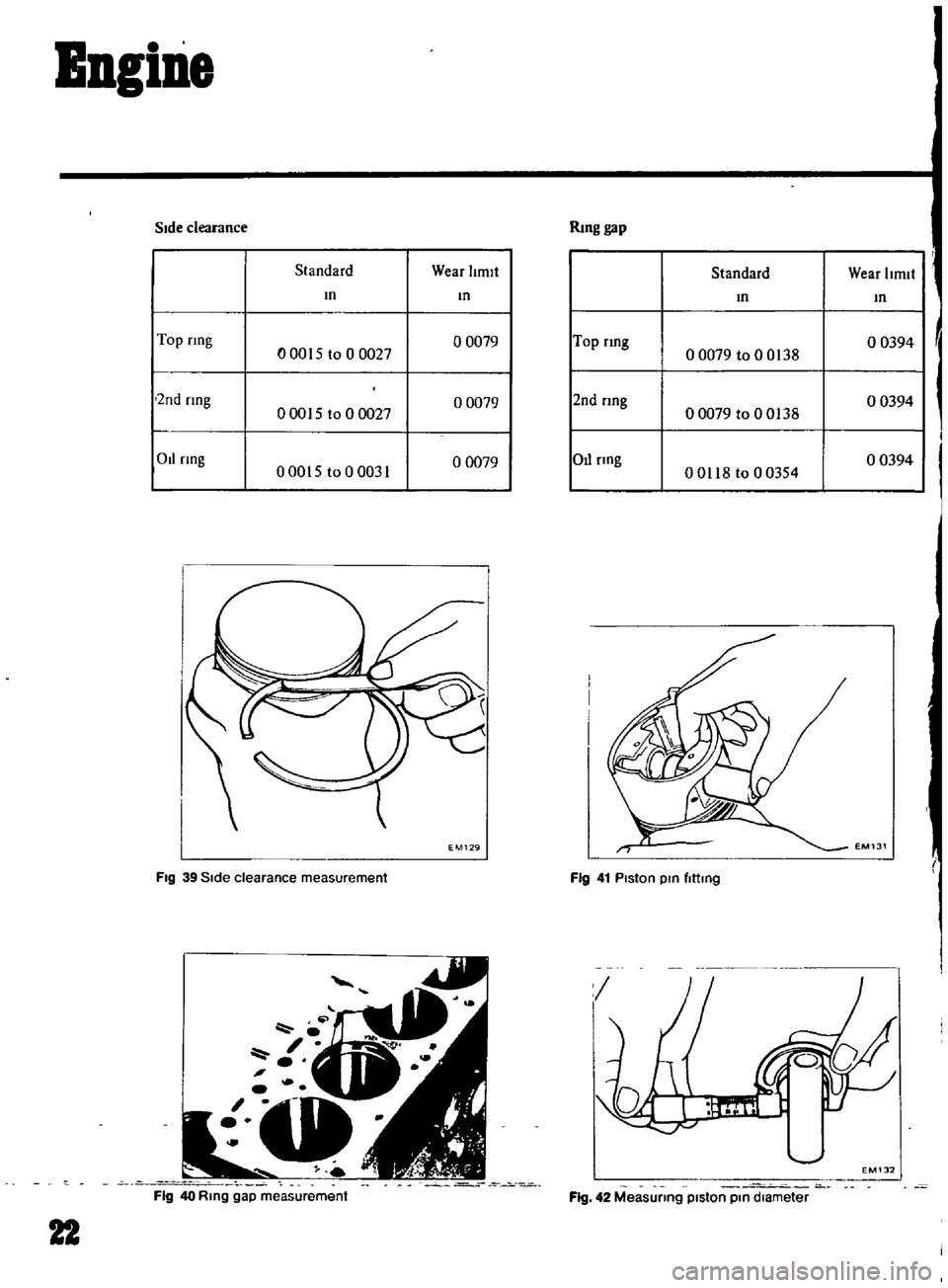

Wear

limIt

02mm

0

0079

In

I

Fig

37

MeaSUring

the

cylinder

bore

SAO

I

O

I

f

Fig

38

Piston

and

connecting

rod

assembly

II

Page 22 of 136

BogiDe

SIde

clearance

Standard

Wear

limIt

m

m

Top

rIng

o

0079

0015

to

0

0027

2nd

rIng

00015

to

0

0027

o

0079

Ot

rIng

00015

to

0

0031

o

0079

EM129

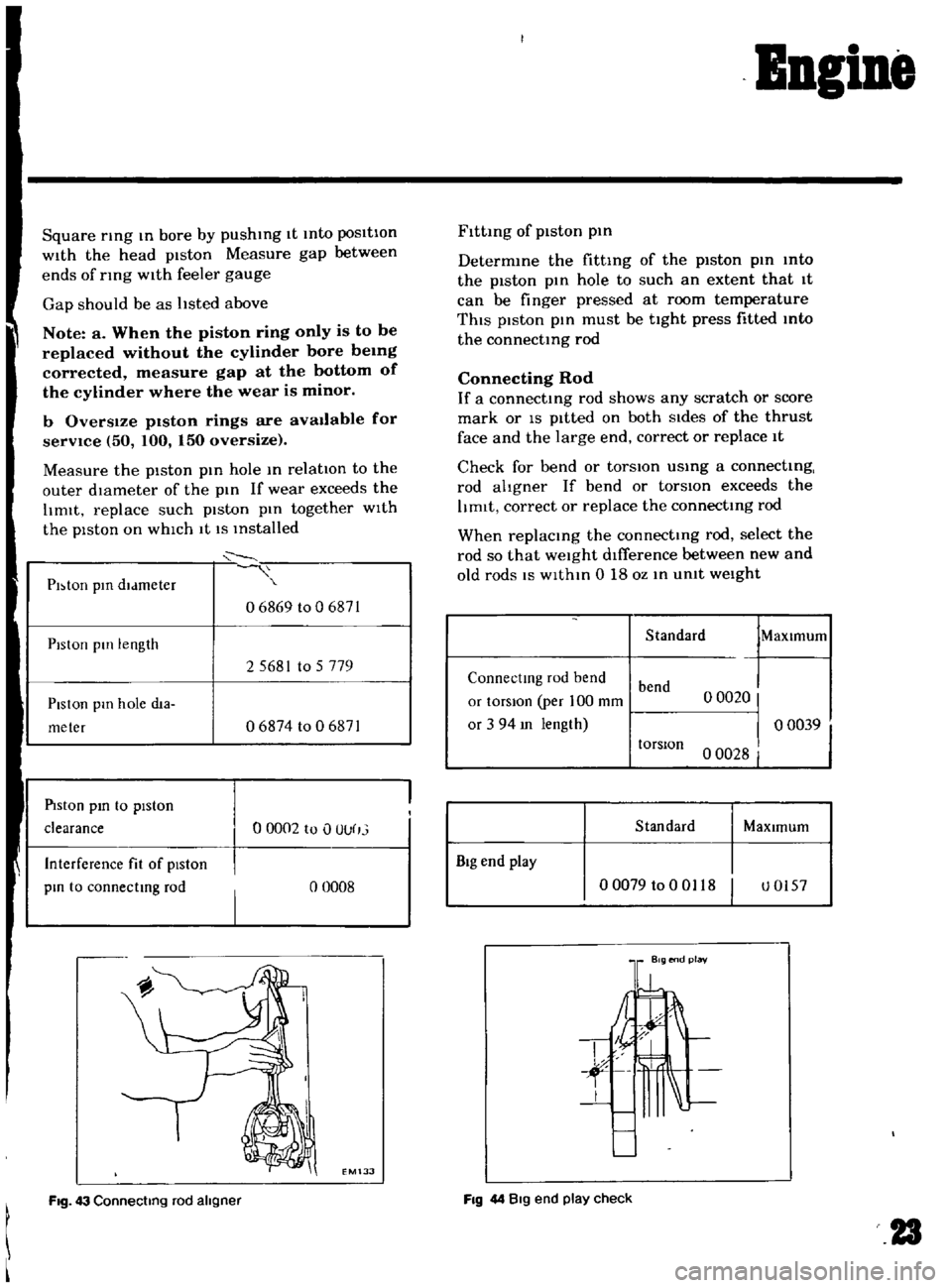

Fig

39

Side

clearance

measurement

Fig

40

Ring

gap

measurement

22

Rmg

gap

Standard

Wear

limIt

m

m

Top

rmg

o

0394

00079

to

0

0138

2nd

rIng

o

0394

00079

to

00138

OtlrIng

o

0394

00118

to

00354

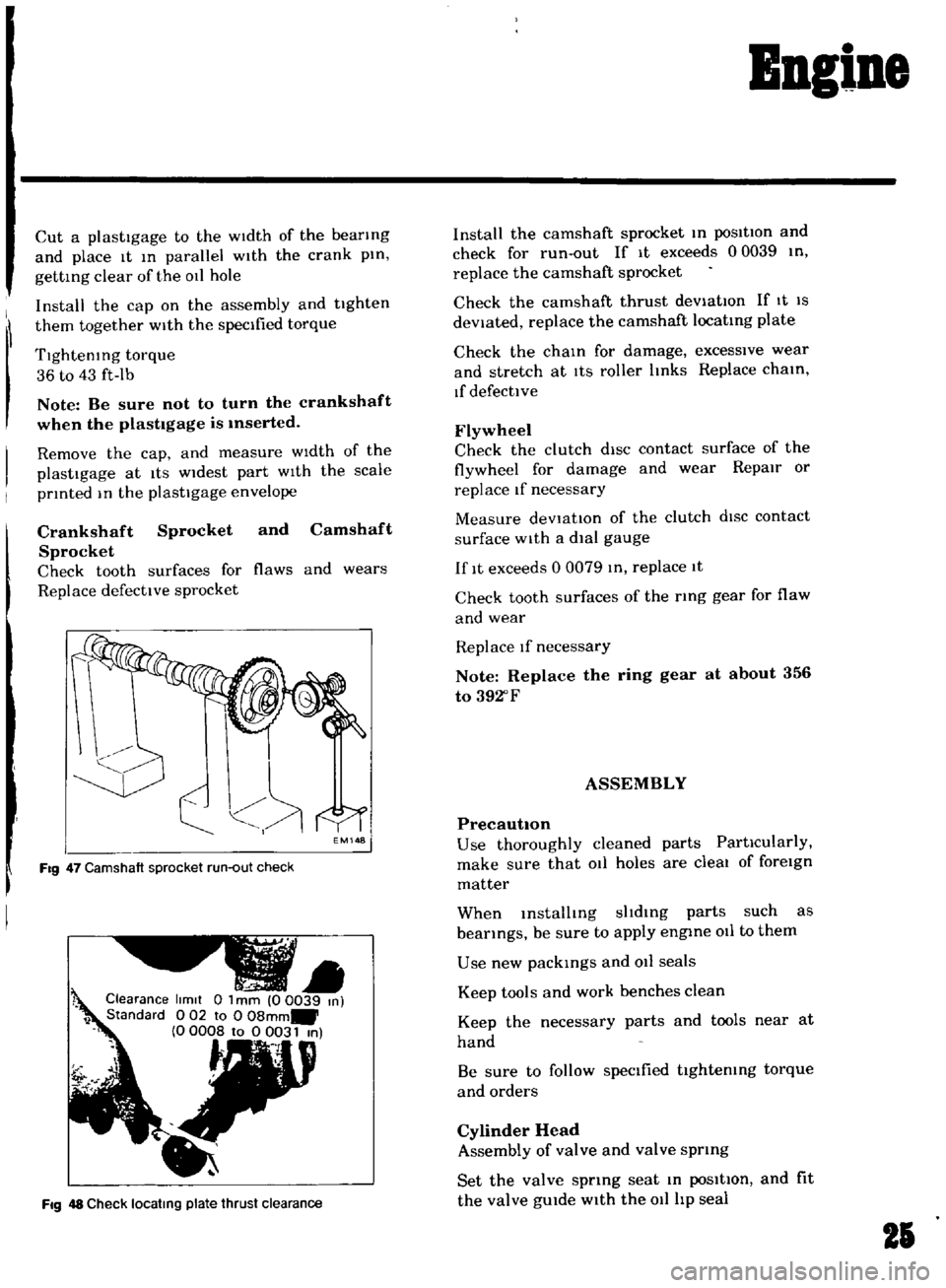

Fig

41

Piston

pin

fitting

EM131

Fig

42

Measunng

piston

pin

diameter

Page 23 of 136

Square

rmg

m

bore

by

pushing

It

mto

pos1t1on

wIth

the

head

piston

Measure

gap

between

ends

of

rmg

with

feeler

gauge

Gap

should

be

as

hsted

above

Note

a

When

the

piston

ring

only

is

to

be

replaced

without

the

cylinder

bore

bemg

corrected

measure

gap

at

the

bottom

of

the

cylinder

where

the

wear

is

minor

b

Overs1ze

piston

rings

are

avaIlable

for

service

50

100

150

oversize

Measure

the

piston

pm

hole

m

relation

to

the

outer

dIameter

of

the

pm

If

wear

exceeds

the

hmlt

replace

such

piston

pm

together

with

the

pIston

on

whIch

It

IS

mstalled

PI

ton

pill

dldmeter

06869

to

06871

PIston

pill

length

25681

to

5779

Piston

pm

hole

dta

meter

06874

to

0

6871

PIston

pm

to

piston

clearance

00002

to

OOUr

j

Interference

fit

of

piston

pm

to

connectmg

rod

o

0008

EM133

FIg

43

Connecting

rod

ahgner

Bngine

Flttmg

of

piston

pm

Determme

the

fittmg

of

the

piston

pm

mto

the

piston

pm

hole

to

such

an

extent

that

1t

can

be

finger

pressed

at

room

temperature

ThIS

piston

pm

rnust

be

tight

press

fitted

mto

the

connectmg

rod

Connecting

Rod

If

a

connectmg

rod

shows

any

scratch

or

score

mark

or

IS

pitted

on

both

Sides

of

the

thrust

face

and

the

large

end

correct

or

replace

It

Check

for

bend

or

torsIOn

usmg

a

connectmg

rod

ahgner

If

bend

or

torsIOn

exceeds

the

hmlt

correct

or

replace

the

connectmg

rod

When

replacing

the

connectmg

rod

select

the

rod

so

that

weight

difference

between

new

and

old

rods

IS

wlthm

0

18

oz

m

umt

weIght

Standard

MaXimum

Connectmg

rod

bend

bend

or

tOrsIon

per

100

mm

o

0020

or

3

94

m

length

o

00391

torsIOn

o

0028

I

Standard

MaXImum

BIg

end

play

00079

to

0

0118

I

U0157

FIg

44

Big

end

play

check

23

Page 24 of 136

BogiDe

27

00

to

27

05

1063

to

1

0651

1910

to

1940

1910

to

19

40

0752

to

07641

0752

to

0

7641

49951

to

49

964

dl

11

9666

to

1

9671

ALL

MAIN

BEARING

JOURNALS

34

97

to

35

03

1

377

to

1

3791

44

961

to

44

974

dl

1

7701

to

1

7706

ALL

CRANK

PINS

UNIT

mm

m

Fig

45

Crankshaft

S

tanddrd

MaXimum

Taper

out

of

round

of

uank

Journal

and

o

0004

00012

crank

pm

Standard

MaxJmum

Crankshaft

bend

m

o

0006

o

0020

Install

connecting

rods

wIth

bearings

on

to

the

corresponding

crank

pinS

and

measure

the

thrust

clearance

If

the

measured

value

ex

ceeds

the

hmlt

replace

such

connecting

rod

Crankshaft

Check

the

crankshaft

Journal

and

crank

pin

for

scars

biased

wear

and

cracks

Repair

or

replace

as

reqUired

Check

the

crankshaft

for

bend

If

the

bend

ex

ceeds

the

hmlt

replace

the

crankshaft

Note

When

me

8

sJlring

jJ

nc

ldtSe

dial

gauge

14

Standard

Llmtl

Crankshaft

free

end

play

m

o

0020

to

0

0059

00118

EM141

Fig

46

Plasllgage

Bend

value

is

a

half

of

the

readmg

ob

tamed

when

the

crankshaft

is

turned

once

with

the

dial

gauge

applied

to

Its

center

journal

After

regrInding

the

crankshaft

fimsh

It

to

the

necessary

size

by

uSing

an

adequate

un

derSize

bearing

according

to

the

extent

of

reqUIred

repair

Install

the

crankshaft

In

the

cyhnder

block

and

measure

th

the

thruht

clearance

Check

the

main

drIve

shaft

pilot

beating

at

the

rear

end

of

the

crankshaft

for

wear

and

damage

Replace

It

1f

any

defects

are

detected

Bushing

and

Bearing

Check

all

bearIngs

and

bushings

for

seIzure

melt

scar

and

burr

Rgj

Jlace

bushings

If

any

defects

are

detected

Wipe

off

011

and

dust

especially

the

rear

of

the

bushing

Set

the

main

bearing

on

the

cap

block

Page 25 of 136

Ingine

1

Cut

a

plastIgage

to

the

wIdth

of

the

bearing

and

place

It

m

parallel

with

the

crank

pm

gettmg

clear

of

the

011

hole

Install

the

cap

on

the

assembly

and

tighten

them

together

with

the

specified

torque

Tlghtentng

torque

36

to

43

ft

lb

Note

Be

sure

not

to

turn

the

crankshaft

when

the

plastIgage

is

Inserted

Remove

the

cap

and

measure

wIdth

of

the

plastlgage

at

Its

widest

part

wIth

the

scale

printed

tn

the

plastIgage

envelope

Crankshaft

Sprocket

and

Camshaft

Sprocket

Check

tooth

surfaces

for

flaws

and

wears

Replace

defective

sprocket

EM148

Fig

47

Camshaft

sprocket

run

out

check

Clearance

limit

0

1

mm

00039

m

1

Standard

0

02

to

0

08mm

0

0008

to

0

0031

m

t

Fig

48

Check

locatmg

plate

thrust

clearance

Install

the

camshaft

sprocket

m

posItion

and

check

for

run

out

If

It

exceeds

00039

tn

replace

the

camshaft

sprocket

Check

the

camshaft

thrust

deViatIOn

If

It

IS

deViated

replace

the

camshaft

locatmg

plate

Check

the

cham

for

damage

excessive

wear

and

stretch

at

ItS

roller

Imks

Replace

cham

If

defective

Flywheel

Check

the

clutch

diSC

contact

surface

of

the

flywheel

for

damage

and

wear

Repair

or

replace

If

necessary

Measure

deVtat10n

of

the

clutch

dISC

contact

surface

with

a

dial

gauge

If

It

exceeds

0

0079

m

replace

1t

Check

tooth

surfaces

of

the

ring

gear

for

flaw

and

wear

Replace

If

necessary

Note

Replace

the

ring

gear

at

about

356

to

392

F

ASSEMBLY

PrecautIOn

Use

thoroughly

cleaned

parts

PartIcularly

make

sure

that

011

holes

are

cleal

of

foreign

matter

When

mstalltng

sltdmg

parts

such

as

bearings

be

sure

to

apply

engme

011

to

them

Use

new

packmgs

and

011

seals

Keep

tools

and

work

benches

clean

Keep

the

necessary

parts

and

tools

near

at

hand

Be

sure

to

follow

specified

tIghtemng

torque

and

orders

Cylinder

Head

Assembly

of

valve

and

valve

sprmg

Set

the

valve

sprmg

seat

m

poSItIon

and

fit

the

valve

gUIde

with

the

011

hp

seal

21

Page 26 of 136

BDgiDe

Fig

49

Valve

installatIon

STl

303001

EM156

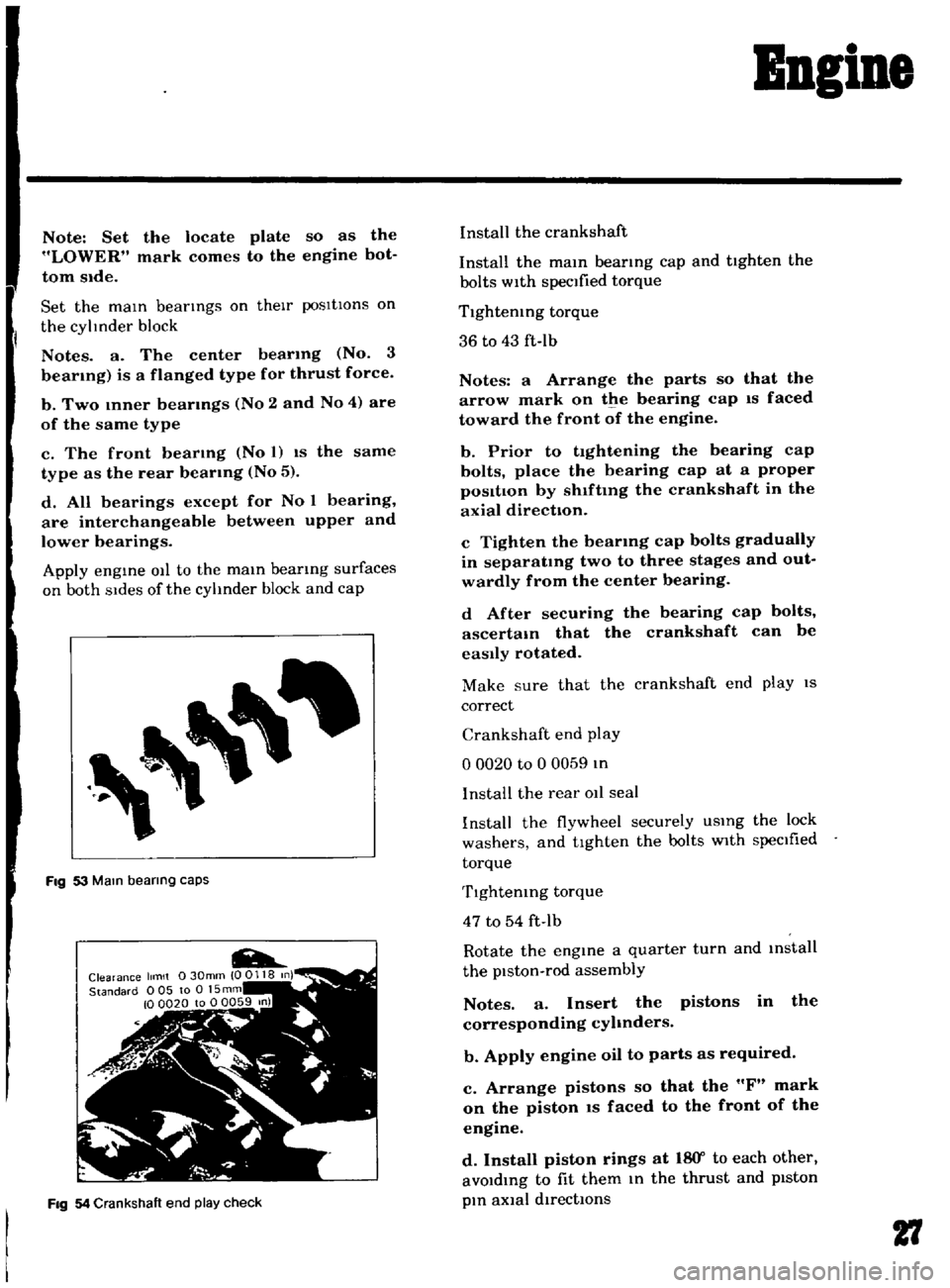

Fig

50

Piston

pin

installation

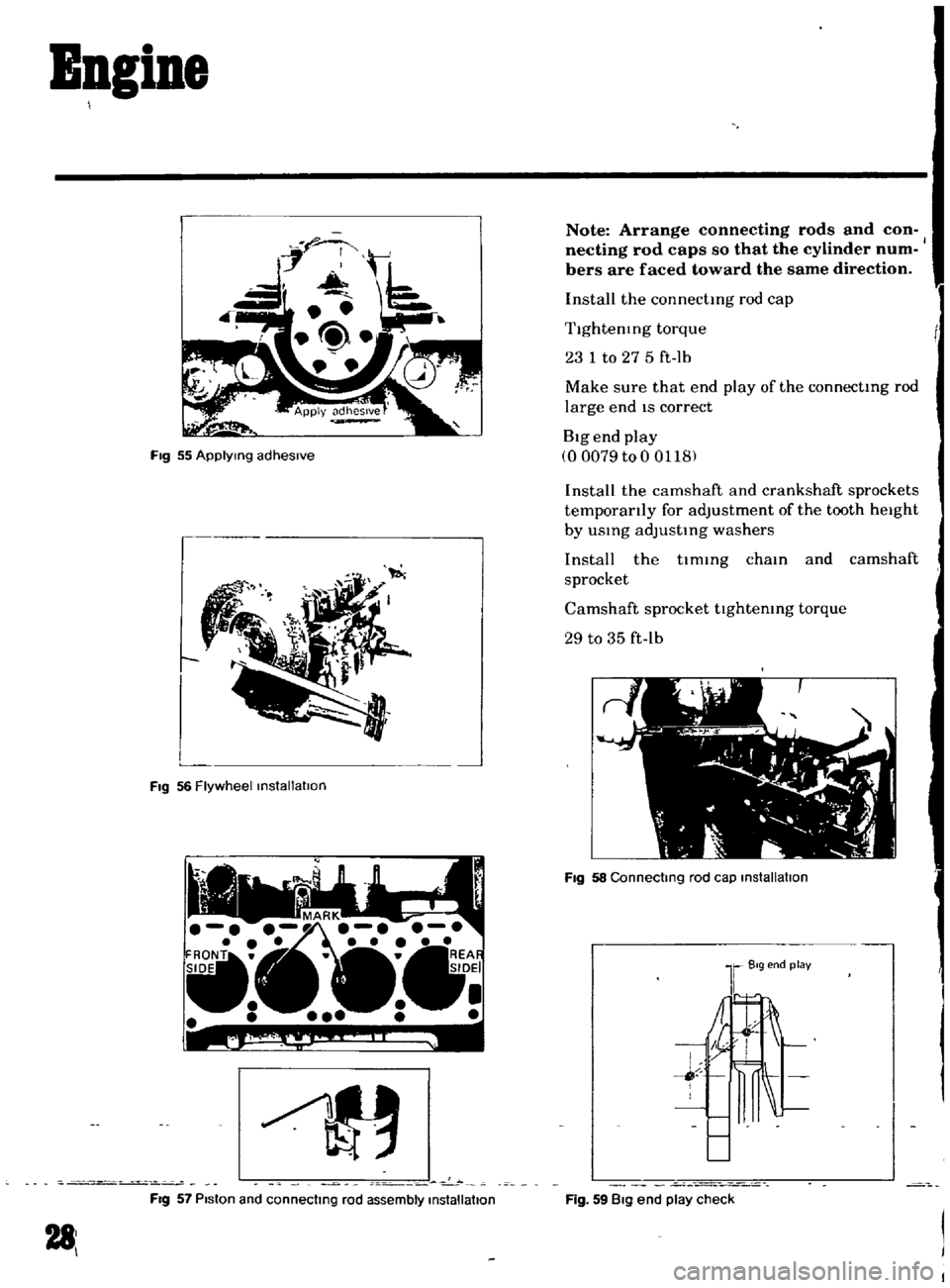

FIg

51

Piston

and

connecting

rod

assembly

Assemble

the

parts

In

order

valve

sprmg

spnng

retamer

valve

collet

and

val

ve

rocker

gUIde

28

Note

Make

sure

that

the

valve

face

is

clear

from

foreign

matters

Piston

and

Connecting

Rod

Assemble

pIston

piston

pm

and

connecting

rod

assorted

accordmg

to

cyhnder

number

for

every

cylInder

Notes

a

P1ston

pin

is

press

fitted

to

the

connectmg

rod

tightly

and

fitting

force

is

from

1

to

3

tons

When

fitting

piston

pin

speCIal

tool

must

be

used

When

pressmg

the

piston

pin

into

the

con

necting

rod

apply

engine

oil

to

the

pin

and

the

small

end

of

the

connecting

rod

b

Arrange

the

connecting

rod

so

that

the

oil

Jet

of

the

connecting

rod

large

end

is

directed

toward

the

right

side

of

the

cylinder

block

InstallIng

piston

rmgs

Install

the

top

and

second

rings

In

nght

pOSItIOns

so

that

the

marks

are

faced

upward

FIX

bearings

on

the

connecting

rod

and

the

connecting

rod

cap

Note

Clean

the

back

side

of

the

bearmg

carefully

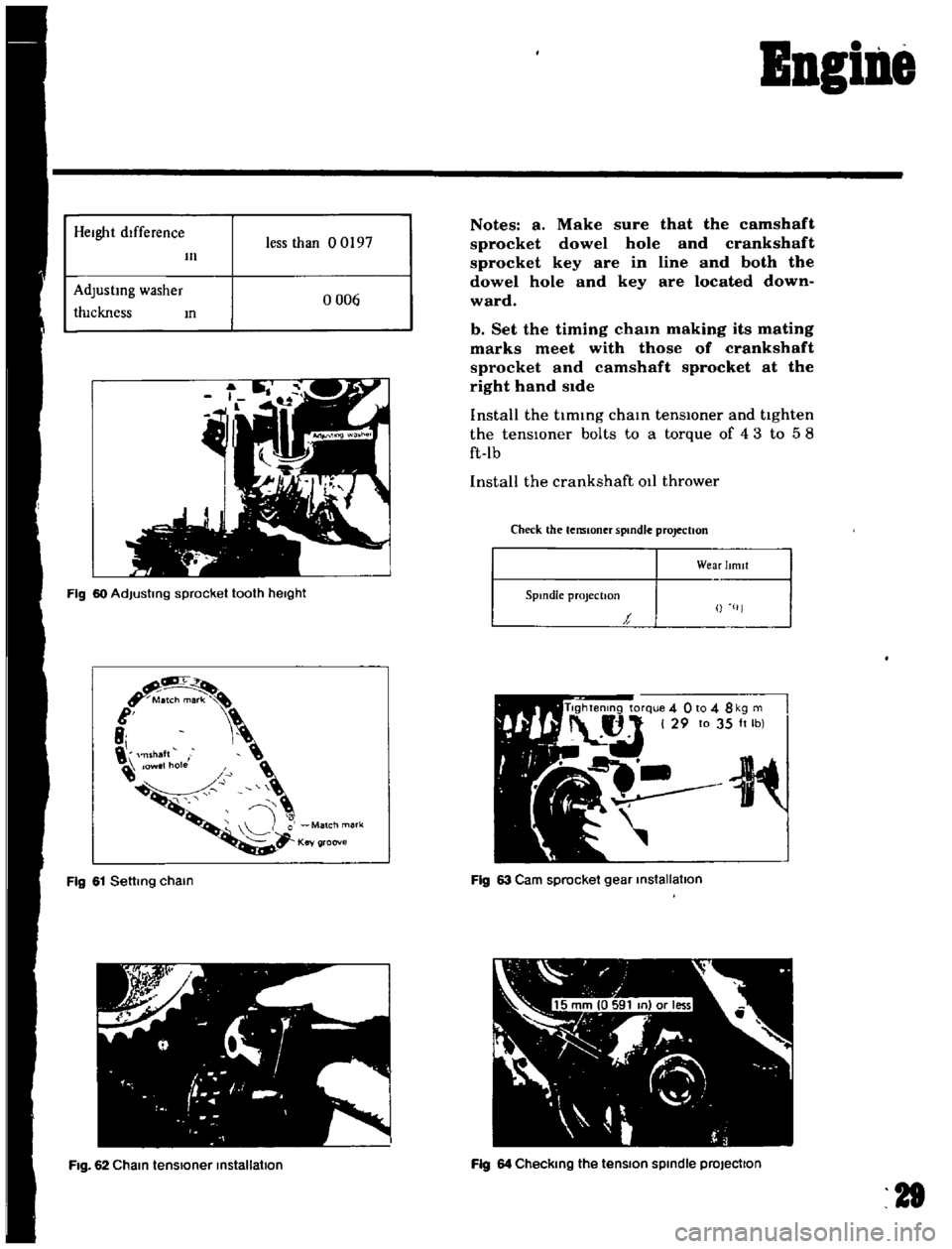

Engine

Set

the

cyhnder

block

on

the

workmg

stand

WIth

the

engine

bottom

faced

upSIde

Install

the

valve

hfters

Install

the

camshaft

and

retain

by

the

camshaft

locate

plate

Locate

plate

tightemng

torque

IS

2

9

to

3

6

ft

lb

Fig

52

Installing

camshaft

locate

plate

Page 27 of 136

Bogine

Note

Set

the

locate

plate

so

as

the

LOWER

mark

comes

to

the

engine

bot

tom

side

Set

the

maIn

bearIngR

on

theIr

posItIOns

on

the

cylinder

block

Notes

a

The

center

bearmg

No

3

bearmg

is

a

flanged

type

for

thrust

force

b

Two

lOner

bearmgs

No

2

and

No

4

are

of

the

same

type

c

The

front

bearmg

No

1

IS

the

same

type

as

the

rear

bearmg

No

5

d

All

bearings

except

for

No

I

bearing

are

interchangeable

between

upper

and

lower

bearings

Apply

engIne

OIl

to

the

mam

bearIng

surfaces

on

both

sIdes

of

the

cyltnder

block

and

cap

Fig

53

Mam

bearing

caps

Fig

54

Crankshaft

end

play

check

Install

the

crankshaft

Install

the

mam

bearmg

cap

and

tighten

the

bolts

with

specified

torque

Tlghtemng

torque

36

to

43

ft

Ib

Notes

a

Arrange

the

parts

so

that

the

arrow

mark

on

the

bearing

cap

IS

faced

toward

the

front

of

the

engine

b

Prior

to

tightening

the

bearing

cap

bolts

place

the

bearing

cap

at

a

proper

posItIon

by

shlftmg

the

crankshaft

in

the

axial

direction

c

Tighten

the

bearmg

cap

bolts

gradually

in

separatmg

two

to

three

stages

and

out

wardly

from

the

center

bearing

d

After

securing

the

bearing

cap

bolts

ascertam

that

the

crankshaft

can

be

easily

rotated

Make

sure

that

the

crankshaft

end

play

IS

correct

Crankshaft

end

play

o

0020

to

0

0059

In

I

nstalI

the

rear

011

seal

Install

the

flywheel

securely

USIng

the

lock

washers

and

tighten

the

bolts

with

specIfied

torque

Tlghtemng

torque

47

to

54

ft

Ib

Rotate

the

engine

a

quarter

turn

and

mstall

the

piston

rod

assembly

Notes

a

Insert

the

pistons

in

the

corresponding

cyhnders

b

Apply

engine

oil

to

parts

as

required

c

Arrange

pistons

so

that

the

F

mark

on

the

piston

IS

faced

to

the

front

of

the

engine

d

Install

piston

rings

at

18

Y

to

each

other

avoIdIng

to

fit

them

In

the

thrust

and

pIston

pIn

aXial

directIOns

27

Page 28 of 136

Bagine

Fig

55

ApplYing

adhesive

L

FIg

56

Flywheel

installation

c

0

FIg

57

Piston

and

connecting

rod

assembly

installation

281

Note

Arrange

connecting

rods

and

con

necting

rod

caps

so

that

the

cylinder

num

bers

are

faced

toward

the

same

direction

Install

the

connectmg

rod

cap

Tlghtenmg

torque

23

1

to

27

5

ft

lb

Make

sure

that

end

play

of

the

connectmg

rod

large

end

IS

correct

Big

end

play

00079

to

0

0118

Install

the

camshaft

and

crankshaft

sprockets

temporarily

for

adjustment

of

the

tooth

height

by

usmg

adJustmg

washers

Install

the

tlmmg

cham

and

camshaft

sprocket

Camshaft

sprocket

tlghtemng

torque

29

to

35

ft

lb

FIg

58

Connecting

rod

cap

installation

Fig

59

Big

end

play

check

Page 29 of 136

Bogine

HeIght

dIfference

less

than

0

0197

III

AdJustmg

washer

0006

tluckness

m

Fig

60

AdJustmg

sprocket

tooth

heIght

a

IT

Match

mark

e

8

Tlsnaft

0w

1

hol

0

0

0

Matohma

k

Key

groove

Fig

61

Settmg

cham

r

f

r

0

tt

I

I

l

f

I

4

Fig

62

Cham

tensloner

Installation

Notes

a

Make

sure

that

the

camshaft

sprocket

dowel

hole

and

crankshaft

sprocket

key

are

in

line

and

both

the

dowel

hole

and

key

are

located

down

ward

b

Set

the

timing

cham

making

its

mating

marks

meet

with

those

of

crankshaft

sprocket

and

camshaft

sprocket

at

the

right

hand

side

Install

the

tlmmg

cham

tenslOner

and

tighten

the

tenslOner

bolts

to

a

torque

of

43

to

58

ft

Ib

Install

the

crankshaft

011

thrower

Check

the

temloner

spondle

projection

Wear

limit

Spindle

projection

t

Fig

63

Carn

sprocket

gear

mstallatlon

Fig

64

Checkmg

the

tension

spindle

projection

21

Page 30 of 136

BDgiDe

Install

the

new

011

seal

to

the

front

cover

The

front

cover

011

seal

should

be

replaced

when

the

front

cover

IS

disassembled

Install

the

front

cover

applYing

the

seahng

agent

to

both

surfaces

of

the

gasket

Tlghtemng

torque

36

to

5

1

ft

lb

Install

the

ot

strainer

and

the

011

pan

uSing

the

gasket

Apply

seahng

agent

on

both

surfaces

of

the

gasket

especIally

on

the

front

and

rear

por

tlOns

of

the

011

pan

011

pan

tlghtemng

torque

2

9

to

4

3

ft

lb

Invert

the

engine

and

Install

the

cyhnder

head

assembly

and

gasket

Note

Apply

sealing

agent

overall

the

cylinder

block

surface

Place

the

gasket

on

It

and

apply

sealing

agent

to

the

gasket

top

Tighten

the

cylinder

head

bolts

to

the

peclfied

torque

Cylmder

bloLk

Side

Stecl

heet

Sealmg

agent

not

required

Cylinder

head

Side

Jomt

sheet

Remarks

Install

WIthout

applymg

sealing

agent

Be

careful

not

to

damage

the

push

rod

Side

because

thIS

SIde

has

prevIOusly

been

provIded

WIth

sealing

agent

J

30

v

o

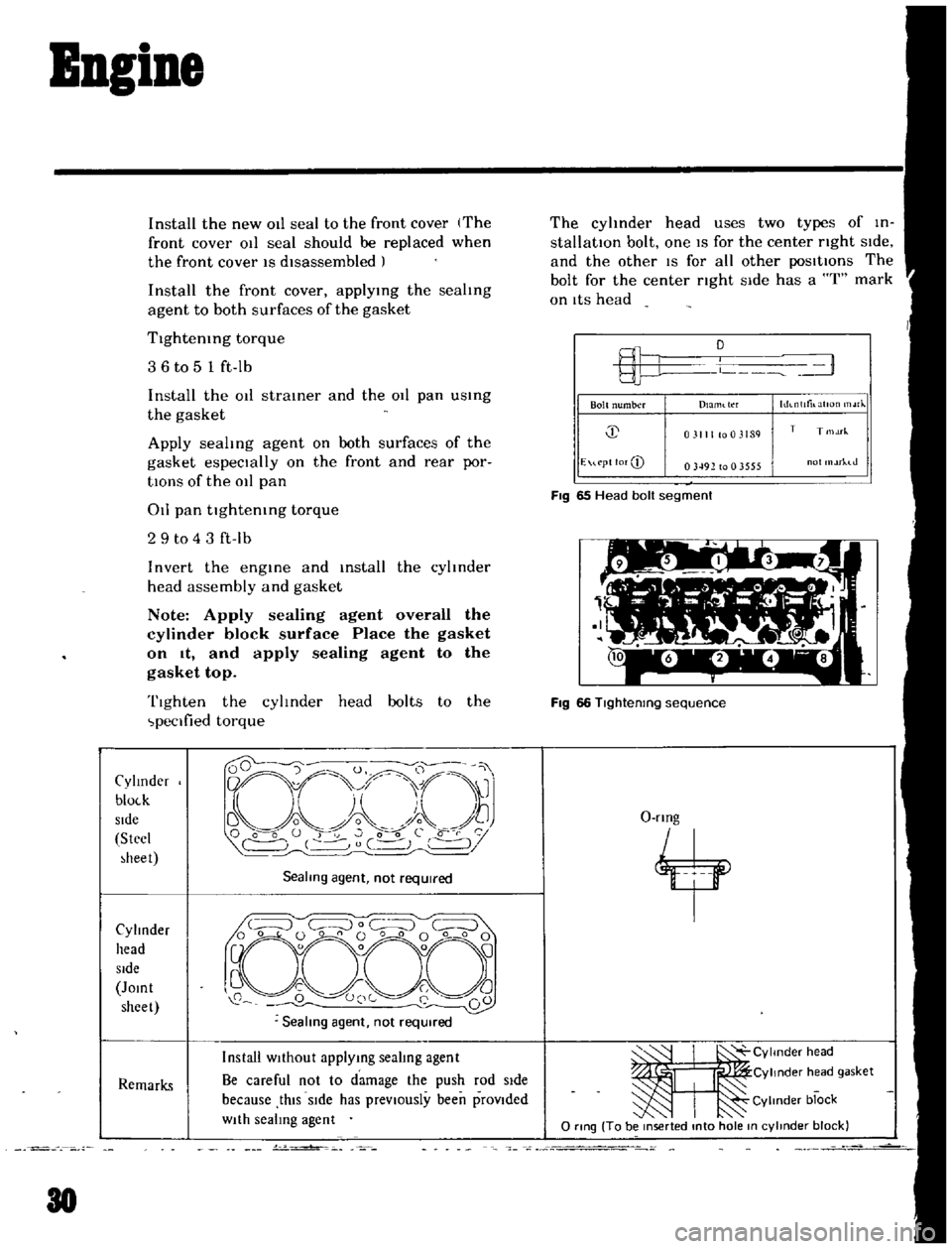

The

cyhnder

head

uses

two

types

of

in

stallatIOn

bolt

one

IS

for

the

center

nght

SIde

and

the

other

IS

for

all

other

posItIOns

The

bolt

for

the

center

nght

Side

has

a

I

mark

on

ItS

head

L

1

Bolt

number

hh

nlltilatlOn

rJ

Dlaml

tl

f

j

031111003189

T

T

1M

E

u

pt

lor

CD

03492

to

0

3555

ot

rhJ

FIg

65

Head

bolt

segment

Fig

66

Tlghtenmg

sequence

O

rmg

4

ItI

CYlmder

head

Cylinder

h

ad

gasket

Cylinder

block

o

rtng

To

be

mserted

mto

hole

m

cylmder

block