lock DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 468 of 513

ENGINE

REMOVAL

INSTAllATION

5

Disconnecting

clutch

wire

on

right

hand

drive

model

On

left

hand

drive

model

disconnect

hydraulic

line

from

the

clutch

slave

cylinder

Disconnect

the

clutch

wire

at

the

portion

of

the

withdrawal

lever

See

the

section

covering

the

clutch

6

Remove

the

exhaust

front

tube

ij

f

I

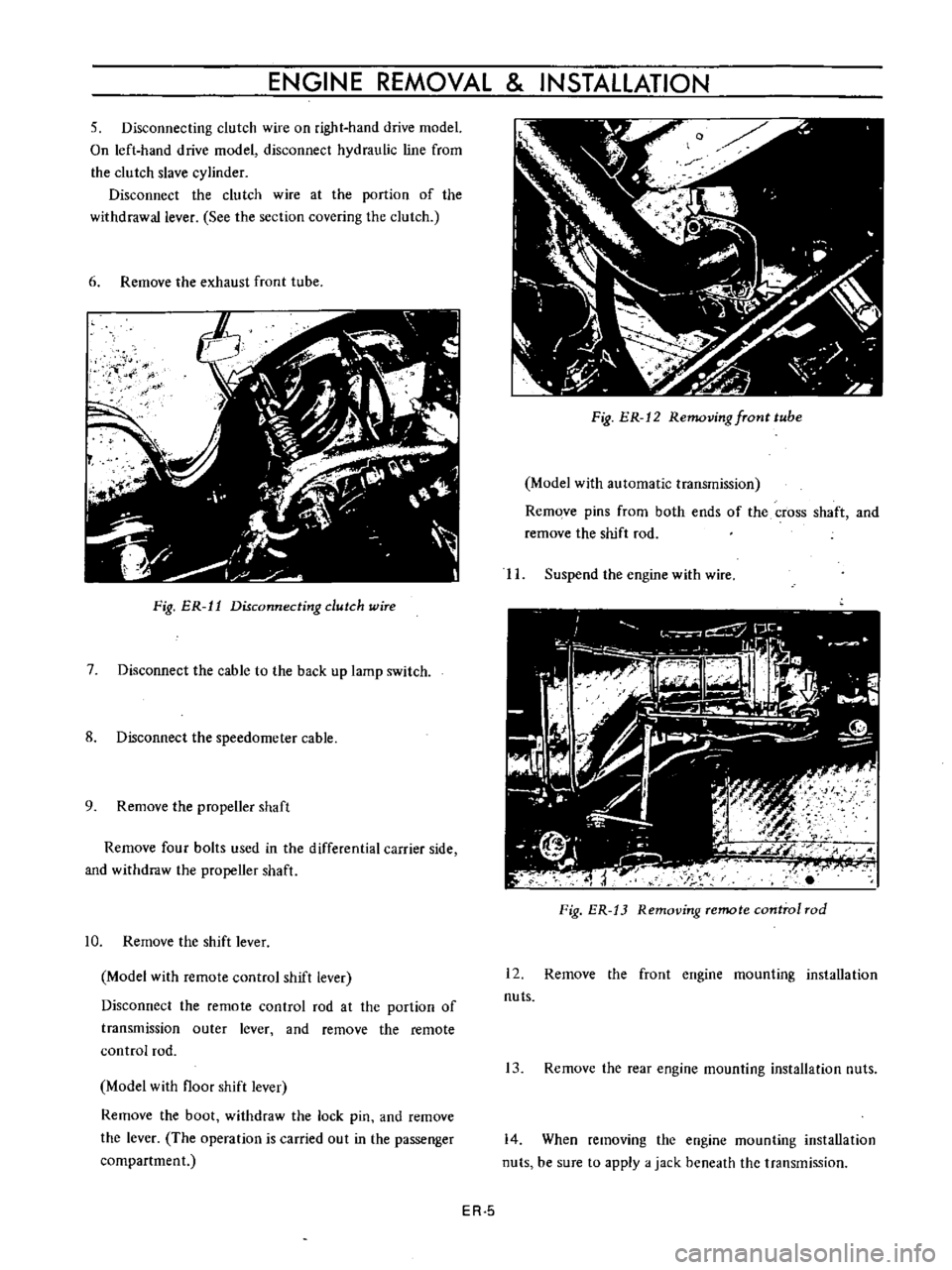

Fig

ER

11

Disconnecting

dutch

wire

7

Disconnect

the

cable

to

the

back

up

lamp

switch

8

Disconnect

the

speedometer

cable

9

Remove

the

propeller

shaft

Remove

four

bolts

used

in

the

differential

carrier

side

and

withdraw

the

propeller

shaft

10

Remove

the

shift

lever

Model

with

remote

control

shift

lever

Disconnect

the

remote

control

rod

at

the

portion

of

transmission

outer

lever

and

remove

the

remote

control

rod

Model

with

floor

shift

lever

Remove

the

boot

withdraw

the

lock

pin

and

remove

the

lever

The

operation

is

carried

out

in

the

passenger

compartment

Fig

ER

12

Removing

fTont

tube

Model

with

automatic

transmission

Remove

pins

from

both

ends

of

the

cross

shaft

and

remove

the

shift

rod

II

Suspend

the

engine

with

wire

Fig

ER

13

Removing

remote

control

rod

12

Remove

the

front

engine

mounting

installation

nuts

13

Remove

the

rear

engine

mounting

installation

nuts

14

When

removing

the

engine

mounting

installation

nuts

be

sure

to

apply

a

jack

beneath

the

transmission

ER

5

Page 476 of 513

CHASSIS

fulcrum

type

The

mechanical

type

clutch

control

system

consists

of

pendent

clutch

pedal

clutch

control

cable

and

with

drawallever

The

withdrawal

lever

is

of

an

outer

fulcrum

type

which

provides

a

great

lever

ratio

and

thus

force

required

in

depressing

clutch

pedal

is

reduced

CLUTCH

PEDAL

Hydraulic

clutch

Removal

Remove

the

return

spring

2

Loosen

the

lock

nut

of

the

master

cylinder

push

rod

and

disconnect

the

push

rod

end

3

Remove

the

lock

nut

and

washer

of

the

pedal

shaft

and

remove

the

pedal

lever

Inspection

Thoroughly

clean

all

disassembled

parts

indicated

below

and

carefully

check

them

for

wear

damage

and

other

abnormal

conditions

Repair

or

replace

them

with

new

ones

if

required

f

fS

C5

J

dJ

YII

10

1

@

c

i

@

j

1

4

K

Clutch

pedal

free

trrlel

30

mm

1

181

nl

00

@

P

IO

Pedal

head

rubber

2

Return

spring

3

Pedal

lever

bush

4

Fulcrum

pedal

pin

etc

Reinstallation

Reinstall

the

clutch

pedal

in

reverse

sequence

of

removal

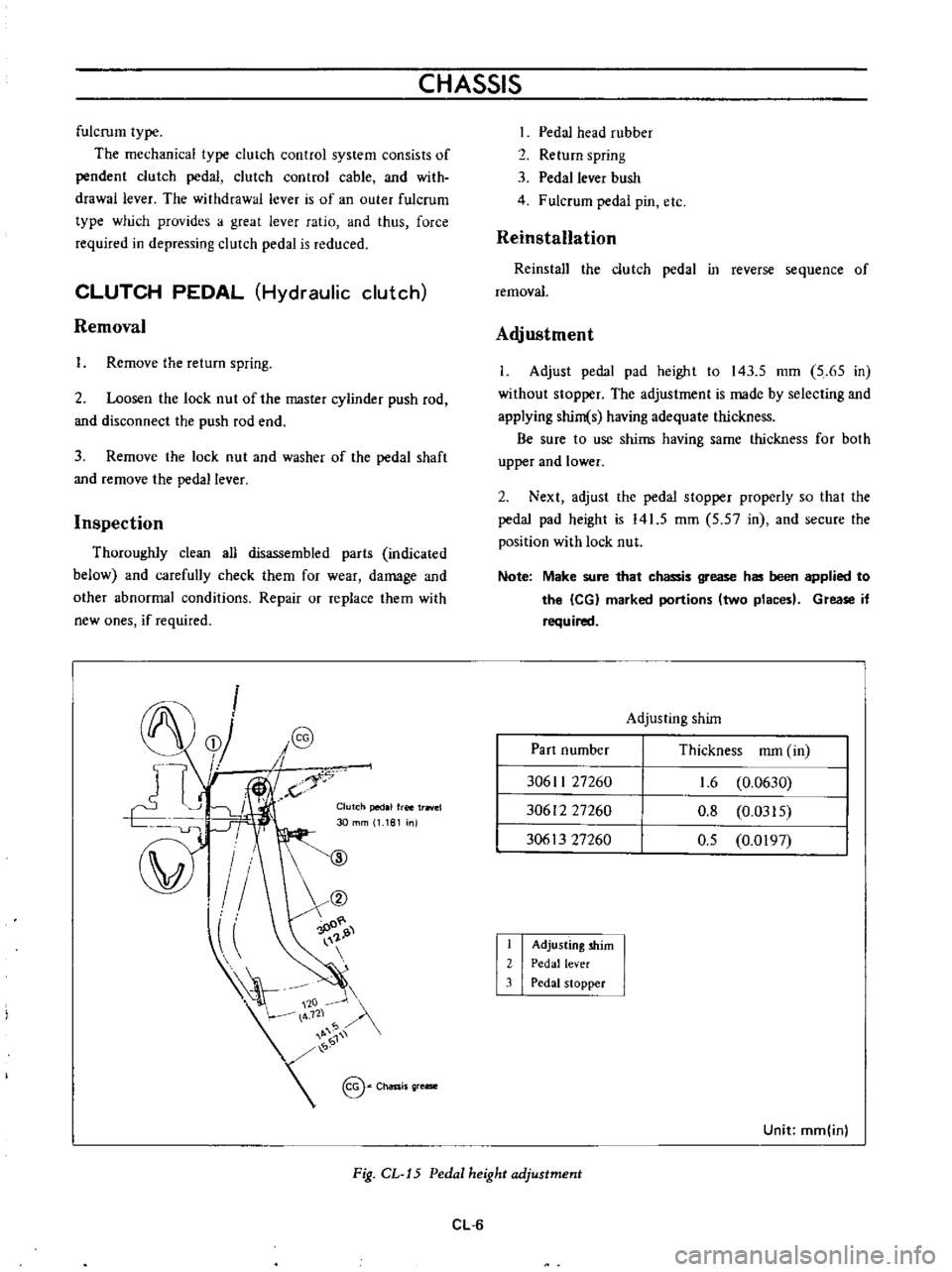

Adjustment

I

Adjust

pedal

pad

height

to

143

5

mm

5

65

in

without

stopper

The

adjustment

is

made

by

selecting

and

applying

shim

s

having

adequate

thickness

Be

sure

to

use

shims

having

same

thickness

for

both

upper

and

lower

2

Next

adjust

the

pedal

stopper

properly

so

that

the

pedal

pad

height

is

141

5

mm

5

57

in

and

secure

the

position

with

lock

nut

Note

Make

sure

that

chassis

grease

has

been

applied

to

the

leG

marked

portions

two

places

Grease

if

required

Adjusting

shim

Part

number

Thickness

mm

in

30611

27260

30612

27260

30613

27260

1

6

0

0630

0

8

0

0315

0

5

0

0197

I

2

3

Adjusting

shim

Pedal

lever

Pedal

stopper

Unit

mm

inl

Fig

CL

J5

Pedal

height

adjustment

CL

6

Page 477 of 513

CLUTCH

CLUTCH

PEDAL

AND

CLUTCH

CONTROL

CABLE

Mechanical

clutch

Removal

Loosen

the

control

cable

adjusting

nut

and

discon

nect

the

control

cable

from

the

withdrawal

lever

III

Adjusting

nut

2

I

Lock

nut

Fig

CL

16

Clutch

cunITol

cable

11

I

Withdrawal

lever

I

2

I

Clutch

control

cable

Fig

CL

17

Disconnecting

clutch

control

cable

2

Unhook

the

clutch

pedal

return

spring

3

Remove

the

clutch

brake

Pedal

installation

bolts

and

remove

the

clutch

pedal

and

control

cable

1

I

Return

spring

31

au

tch

pedal

2

Fulcrum

pedal

pin

Fig

CL

I8

Removing

pedal

installation

bolt

Inspection

Thoroughly

clean

all

disassembled

parts

indicated

below

and

carefully

check

them

for

wear

damage

and

other

abnormal

conditions

Repair

or

replace

as

required

Control

cable

2

Pedal

head

rubber

3

Pedal

lever

bush

4

Fulcrum

pedal

pin

5

Others

Reinstallation

Reinstall

the

clutch

pedal

and

clutch

control

cable

in

reverse

sequence

of

removal

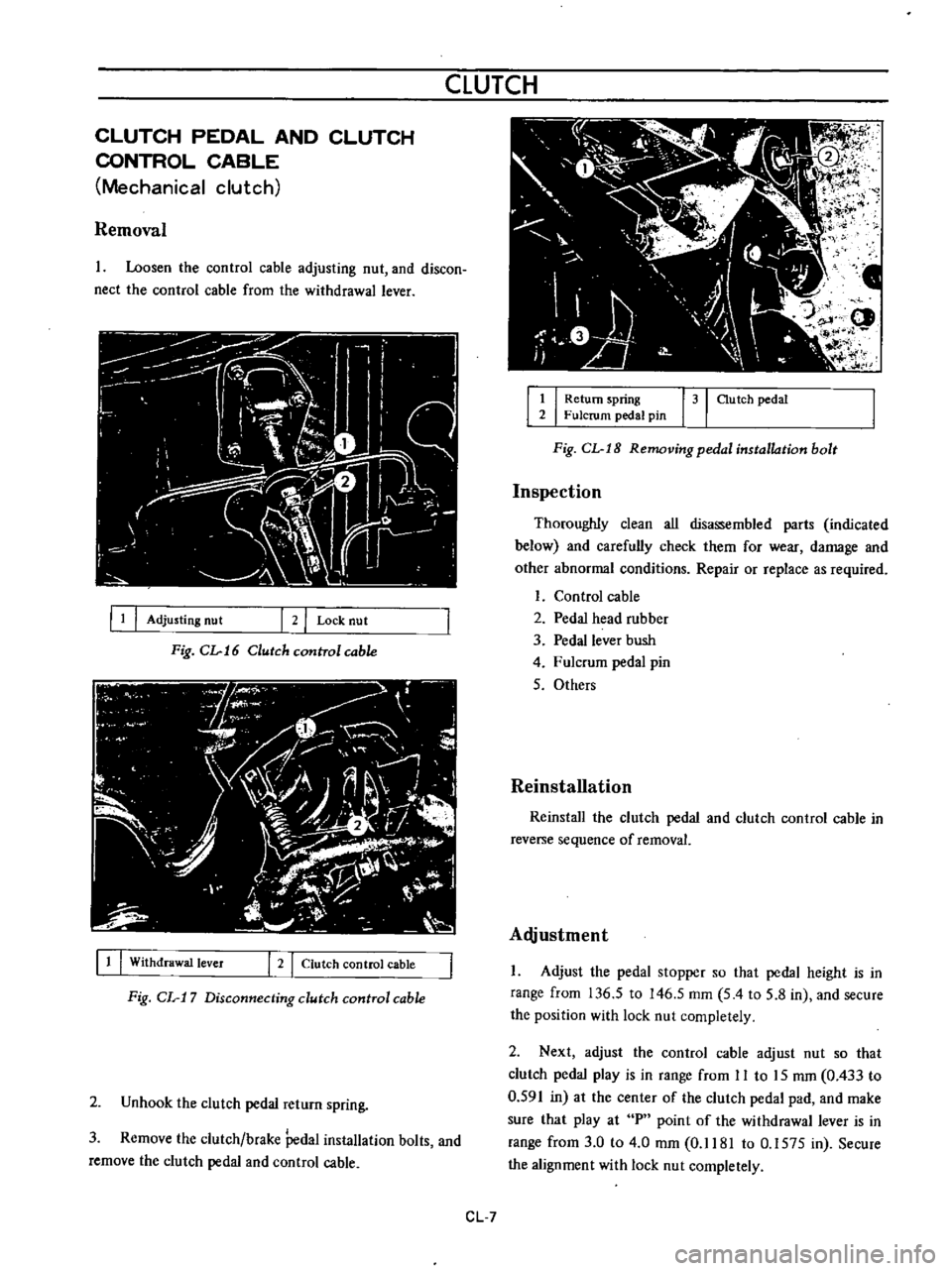

Alljustment

Adjust

the

pedal

stopper

so

that

pedal

height

is

in

range

from

136

5

to

146

5

mm

5

4

to

5

8

in

and

secure

the

position

with

lock

nut

completely

2

Next

adjust

the

control

cable

adjust

nut

so

that

clutch

pedal

play

is

in

range

from

II

to

15

mm

0

433

to

0

591

in

at

the

center

of

the

clutch

pedal

pad

and

make

sure

that

play

at

P

point

of

the

withdrawal

lever

is

in

range

from

3

0

to

4

0

mm

0

1181

to

0

1575

in

Secure

the

alignment

with

lock

nut

completely

CL

7

Page 478 of 513

CHASSIS

i

I

I

I

II

I

I

J

u

IlllrP

Zll

I

ff

Pedal

play

11

to

15

I

0

433

to

0

591

I

W

p

da

stfO

l

e

1

P

point

end

play

l

e

A

1

C

3

0

to

A

O

Chassis

grease

20

0

1181

to

0

1575

I

Y

136

5

to

lA6

5

I

5

A

to

5

81

0

Note

Connect

the

control

cable

correctly

so

that

mark

cap

is

faced

upward

as

shown

in

the

following

figure

Make

sure

that

chassis

grease

has

been

I

2

3

Lock

nu

t

Adjusting

nut

Pedal

stopper

applied

to

the

CG

marked

positions

three

places

Apply

grease

if

required

@

300R

t2

8J

Unit

mm

in

Fig

CL

19

Pedal

height

adjustment

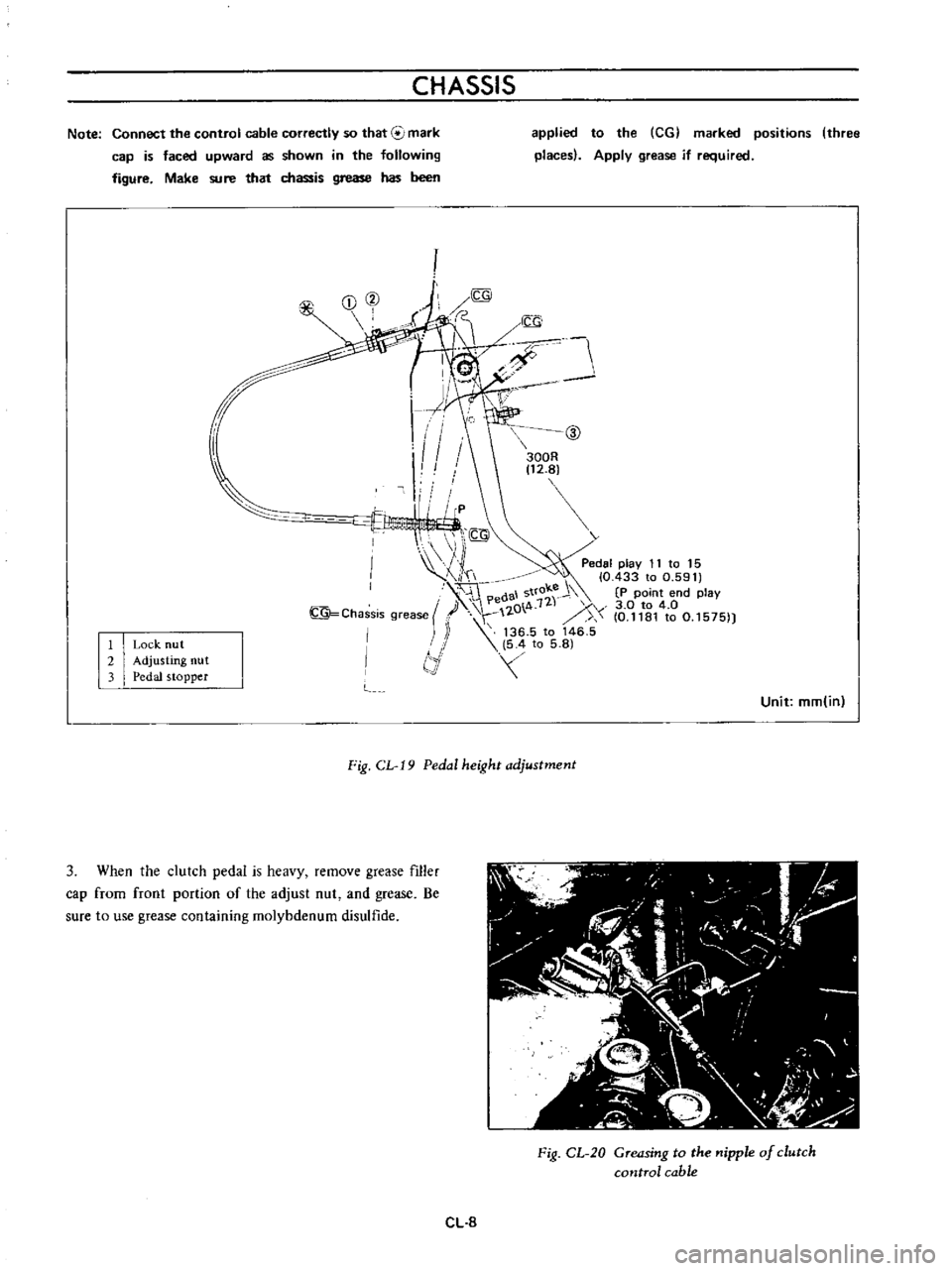

3

When

the

clutch

pedal

is

heavy

remove

grease

filler

cap

from

front

portion

of

the

adjust

nut

and

grease

Be

sure

to

use

grease

containing

molybdenum

disulfide

Fig

CL

20

Greasing

to

the

nipple

of

clutch

control

cable

CL

8

Page 480 of 513

CHASSIS

2

Apply

brake

fluid

sufficiently

to

the

cylinder

and

piston

and

assemble

them

Reinstallation

Reinstall

the

master

cylinder

assembly

in

reverse

sequence

of

removal

and

adjust

as

follows

I

Adjust

the

pedal

height

by

changing

the

push

rod

length

2

B

eed

air

out

of

the

hydraulic

system

OPERATING

CYLINDER

Hydraulic

clutch

Removal

Remove

the

return

spring

2

Disconnect

the

clutch

line

from

the

operating

cyl

inder

3

Disconnect

the

push

rod

from

the

withdrawal

lever

4

Release

two

bolts

used

to

mount

the

operating

cylinder

to

the

clutch

housing

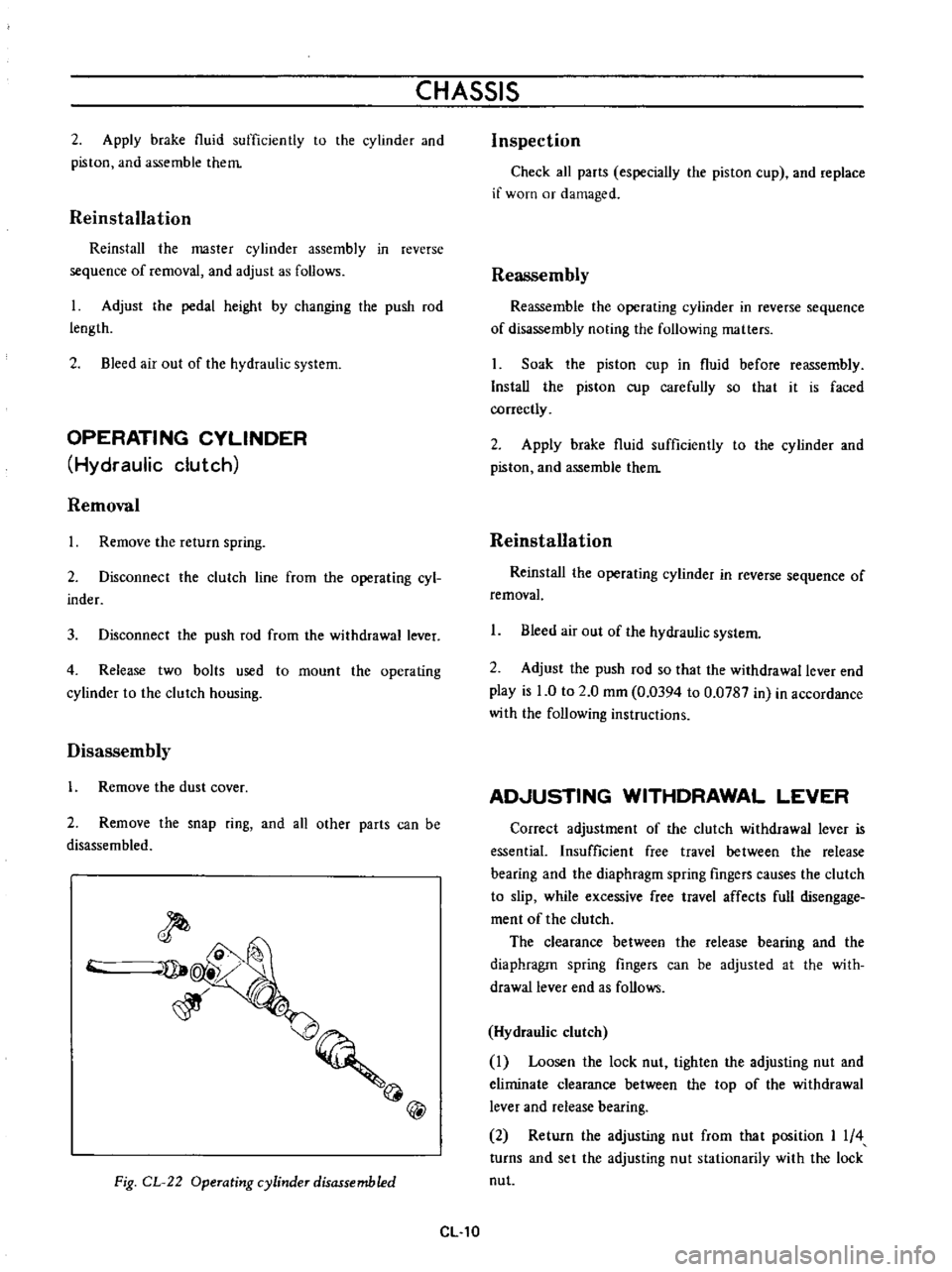

Disassembly

1

Remove

the

dust

cover

2

Remove

the

snap

ring

and

all

other

parts

can

be

disassembled

@

Fig

CL

22

Operating

cylinder

disassembled

CL

10

Inspection

Check

all

parts

especially

the

piston

cup

and

replace

if

worn

or

damaged

Reassembly

Reassemble

the

operating

cylinder

in

reverse

sequence

of

disassembly

noting

the

following

matters

Soak

the

piston

cup

in

fluid

before

reassembly

Install

the

piston

cup

carefully

so

that

it

is

faced

correctly

2

Apply

brake

fluid

sufficiently

to

the

cylinder

and

piston

and

assemble

them

Reinstallation

Reinstal

the

operating

cylinder

in

reverse

sequence

of

removal

1

Bleed

air

out

of

the

hydraulic

system

2

Adjust

the

push

rod

so

that

the

withdrawal

lever

end

play

is

0

to

2

0

mm

0

0394

to

0

0787

in

in

accordance

with

the

following

instructions

AD

USTING

WITHDRAWAL

LEVER

Correct

adjustment

of

the

clutch

withdrawal

lever

is

essential

Insufficient

free

travel

between

the

release

bearing

and

the

diaphragm

spring

fingers

causes

the

clutch

to

slip

while

excessive

free

travel

affects

full

disengage

ment

of

the

clutch

The

clearance

between

the

release

bearing

and

the

diaphragm

spring

fingers

can

be

adjusted

at

the

with

drawallever

end

as

follows

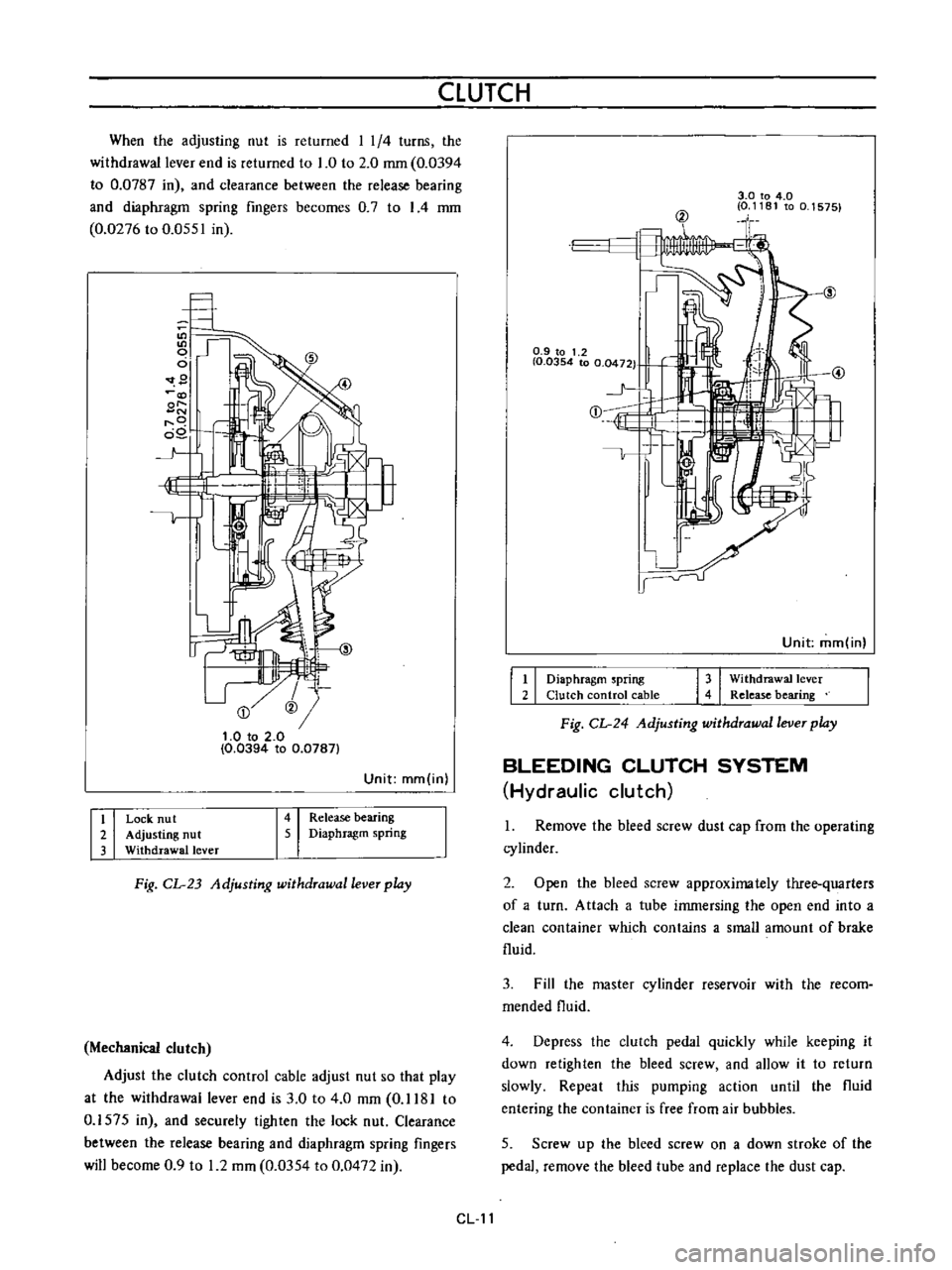

Hydraulic

clutch

Loosen

the

lock

nut

tighten

the

adjusting

nut

and

eliminate

clearance

between

the

top

of

the

withdrawal

lever

and

release

bearing

2

Return

the

adjusting

nut

from

that

position

I

4

turns

and

set

the

adjusting

nut

stationarily

with

the

lock

nut

Page 481 of 513

CLUTCH

When

the

adjusting

nut

is

returned

I

1

4

turns

the

withdrawal

lever

end

is

returned

to

1

0

to

2

0

mm

0

0394

to

0

0787

in

and

clearance

between

the

release

bearing

and

diaphragm

spring

fingers

becomes

0

7

to

I

4

mm

0

0276

to

0

0551

in

9

@

t

O

to

2

0

0

0394

to

0

0787

Unit

mm

in

I

i

I

I

I

Release

bearing

Diaphragm

spring

Lock

nu

t

Adjusting

nut

Withdrawal

lever

Fig

CL

23

Adjusting

withdrawal

lever

play

Mechanical

clutch

Adjust

the

clutch

control

cable

adjust

nut

so

that

play

at

the

withdrawal

lever

end

is

3

0

to

4

0

mm

0

1181

to

0

1575

in

and

securely

tighten

the

lock

nut

Clearance

between

the

release

bearing

and

diaphragm

spring

fingers

will

become

0

9

to

1

2

mm

0

0354

to

0

0472

in

3

0

to

4

0

0

1181

to

0

1575

@

0

9

to

1

2

I

0

0354

to

0

0472

1

j

E

1

Unit

mm

in

I

I

I

I

Diaphragm

spring

Clutch

control

cable

Withdrawal

lever

Release

bearing

Fig

CL

24

Adjusting

withdrawal

lever

play

BLEEDING

CLUTCH

SYSTEM

Hydraulic

clutch

1

Remove

the

bleed

screw

dust

cap

from

the

operating

cylinder

2

Open

the

bleed

screw

approximately

three

quarters

of

a

turn

Attach

a

tube

immersing

the

open

end

into

a

clean

container

which

contains

a

small

amount

of

brake

fluid

3

Fill

the

master

cylinder

reservoir

with

the

recom

mended

fluid

4

Depress

the

clutch

pedal

quickly

while

keeping

it

down

retighten

the

bleed

screw

and

allow

it

to

return

slowly

Repeat

this

pumping

action

until

the

fluid

entering

the

container

is

free

from

air

bubbles

5

Screw

up

the

bleed

screw

on

a

down

stroke

of

the

pedal

remove

the

bleed

tube

and

replace

the

dust

cap

CL

11

Page 491 of 513

CHASSIS

To

prevent

the

oil

pan

from

damaging

insert

a

wooden

block

between

the

pan

and

jack

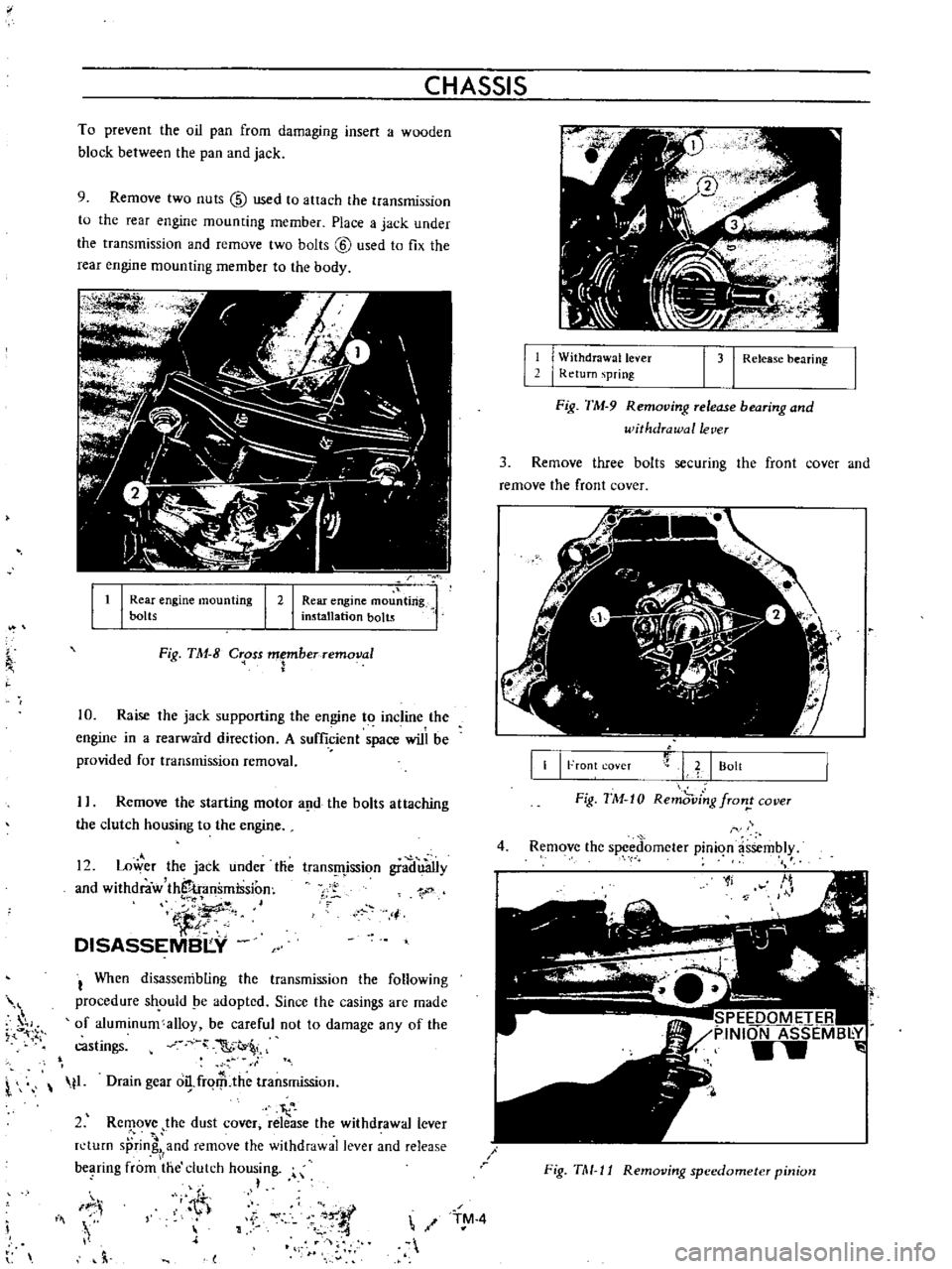

9

Remove

two

nuts

@

used

to

attach

the

transmission

to

the

rear

engine

mounting

member

Place

a

jack

under

the

transmission

and

remove

two

bolts

@

used

to

fix

the

rear

engine

mounting

member

to

the

body

It

I

Rear

engine

mou

ting

installation

bolts

I

Rear

engine

mounting

bolts

I

2

Fig

TM

8

C

oss

Fberremoval

10

Raise

the

jack

supporting

the

engine

to

incline

the

engine

in

a

rearward

direction

A

sufficient

space

will

be

provided

for

transmission

removal

I

Remove

the

starting

motor

a

d

the

bolts

attaching

the

clutch

housing

to

the

engine

12

Lower

the

jack

under

tlie

and

withdraw

thS

transmission

iJ

DISASSEMBI

Y

trans

fljssion

gradu3Ily

1

j

I

When

disassembling

the

transmission

the

following

procedure

sh

ould

pe

adopted

Since

the

casings

are

made

of

aluminum

alloy

be

careful

not

to

damage

any

of

the

castings

C

t

l

t1

Drain

gear

o

frqrP

the

transmission

I

2

Rc

ove

the

dust

cover

release

the

withdrawal

lever

n

turn

sprin

and

remove

the

withdrawal

lever

and

release

bC

lring

from

the

clutch

housing

h

IF

i

Iii

h

l

11

I

W

ithdrawallever

I

Return

spring

1

31

Release

bearing

Fig

TM

9

Removing

release

bearing

and

withdrawal

lever

3

Remove

three

bolts

securing

the

front

cover

and

remove

the

front

cover

II

I

Front

coveT

L

I

Bolt

Fig

TM

10

Remd

ving

fron

cover

4

Remove

the

spced

omcter

pinion

assembly

1f

SPEEDOMETER

PINION

ASSEMB

Y

w

Fig

TM

11

Removing

speedometer

pinion

TM

4

Page 500 of 513

j

TRANSMISSION

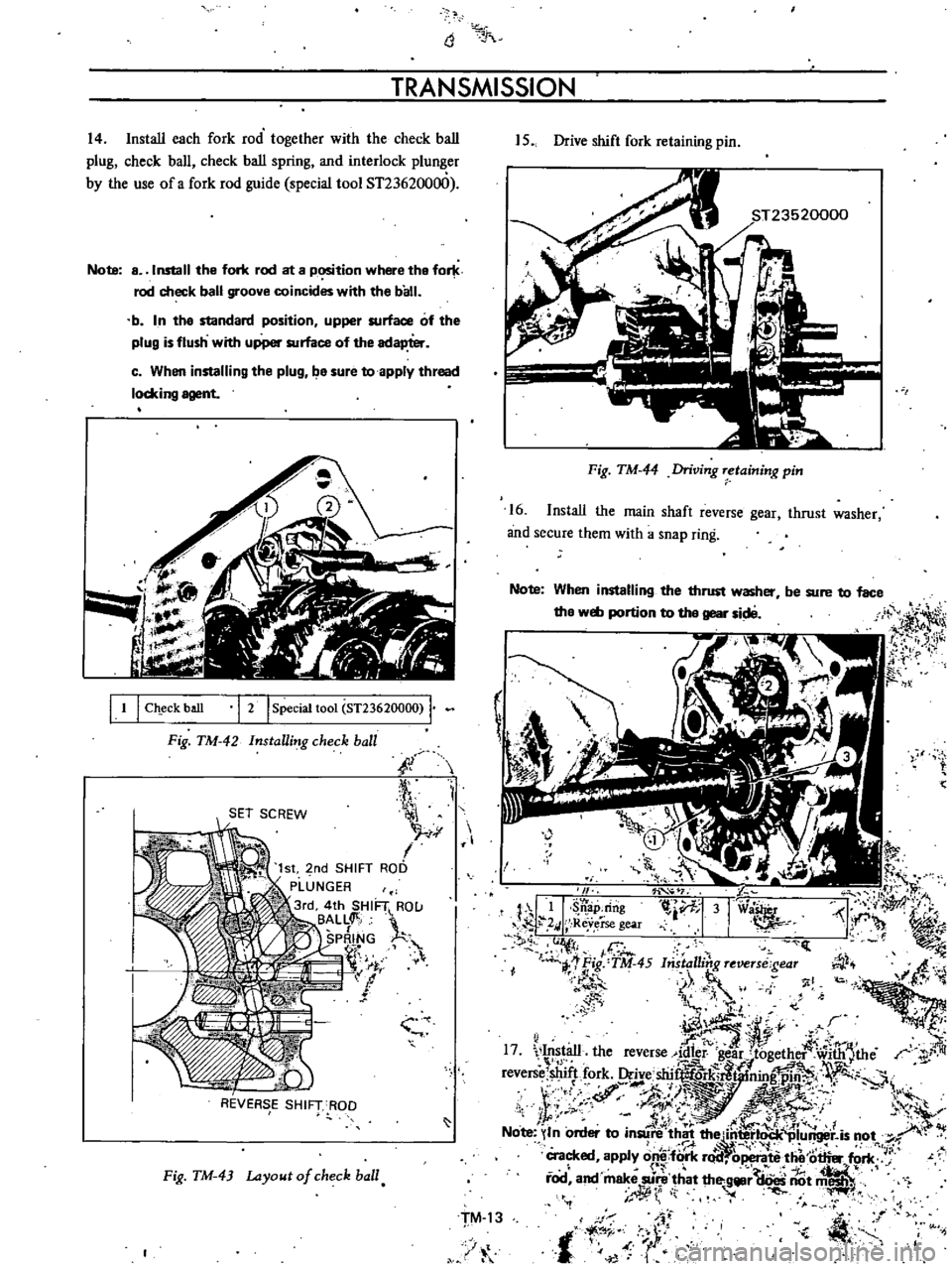

14

Install

each

fork

rod

together

with

the

check

ball

plug

check

ball

check

ball

spring

and

interlock

plu

er

by

the

use

of

a

fork

rod

guide

special

tool

ST236200

0

Note

a

Install

the

fori

rod

at

a

p

tion

where

tha

for

rod

check

ball

groove

coincides

with

the

ball

b

In

tha

standard

position

upper

surface

of

the

plug

is

flush

with

upper

surface

of

the

adapter

c

When

installing

the

plug

ba

sure

to

apply

thread

locking

agent

I

1

I

Ch

eck

ball

I

2

I

Special

toot

ST23620000

Fig

TM

42

InstaUing

check

ball

i

l

SET

SCREW

J

r

r

I

1st

2nd

SHIFT

ROD

PLUNGER

3rd

4th

SHIF1

RO

U

BALL

lt

SPRING

r

if

If

f

J

REVERSE

SHIFT

ROD

Fig

TM

43

Layout

of

check

ball

15

Drive

shift

fork

retaining

pin

Fig

TM

44

Driving

retaining

pin

16

Install

the

main

shaft

reverse

gear

thrust

washer

and

secure

them

with

a

snap

ring

Note

When

installing

the

thrust

washer

tha

web

portion

to

the

gear

sid8

be

sure

to

face

I

J

ll

it

ij

I

r

7

I

t

Lt

l

i

JI

h

l

p

II

Si

ap

dng

l

iVf

31

via

I

i

i

2

I

Reverse

gear

rll

f

F

O

1

Ii

ct

I

C

I

jf

1

Fig

TM

45

bista

ling

reveTS

gear

fJ

i

tJ

i

J

I

1

i

4

1

a

ot

j

l

i1i

o

f

tJ

r

w

i6

J

t

F

I

f

1

it

IV

I

17

1

t

1

the

reverse

@Isr

e

r

tilgether

wi1

tJthe

r

shift

k

Oc

shi

k

7i

fN

revers

lO

r

r

1

mg

1

1

f

i

J

4t

z

1

if

f

St

J

f

l

p

t

A

J

t

M

ff

J

1

A

Note

In

order

to

in

re

t

1h

f

t

li

u

r

is

O

cracked

apply

onl

fo

rk

r

id

ope

te

thet6t1ier

fori

J

t

i

fod

an

make

sU

r

e

that

th

gljllr

aoes

nOt

miiSli

J

o

I

t

J

t

if

z

TM

13

1

t

Page 509 of 513

CHASSIS

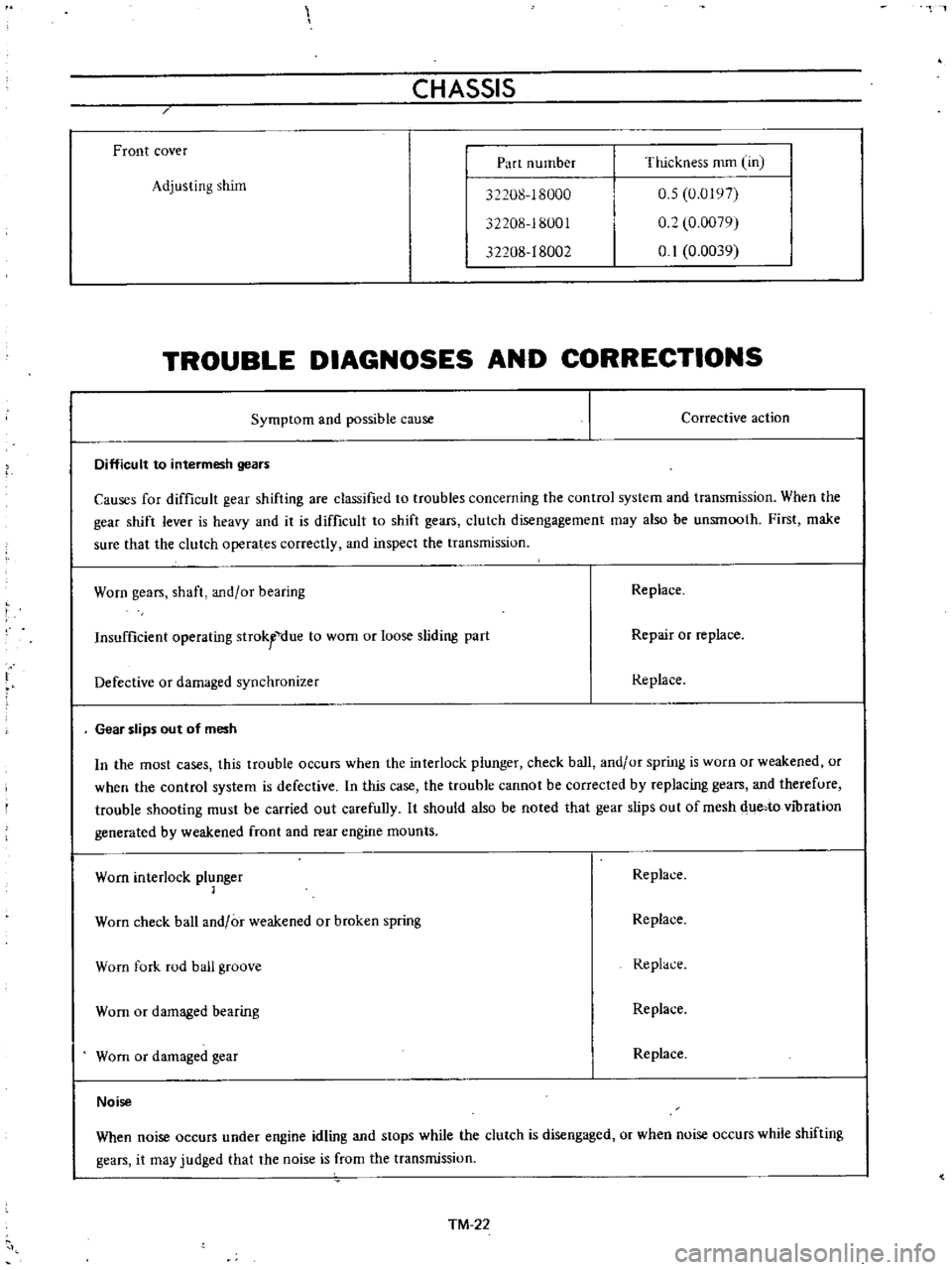

Front

cover

Part

number

Thickness

mm

Un

Adjusting

shim

32208

18000

32208

18001

32208

18002

0

5

0

0197

0

2

0

0079

0

1

0

0039

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Symptom

and

possible

cause

Corrective

action

Difficult

to

intermesh

gears

Causes

for

difficult

gear

shifting

are

classified

to

troubles

concerning

the

control

system

and

transmission

When

the

gear

shift

lever

is

heavy

and

it

is

difficult

to

shift

gears

clutch

disengagement

may

also

be

unsmooth

First

make

sure

that

the

clutch

operates

correctly

and

inspect

the

transmission

Worn

gears

shaft

and

or

bearing

Replace

Insufficient

operating

strokfdue

to

wom

or

loose

sliding

part

Repair

or

replace

Defective

or

damaged

synchronizer

Replace

Gear

slips

out

of

mesh

In

the

most

cases

this

trouble

occurs

when

the

interlock

plunger

check

ball

and

or

spring

is

wuro

or

weakened

or

when

the

control

system

is

defective

In

this

case

the

trouble

cannot

be

corrected

by

replacing

gears

and

therefure

trouble

shooting

must

be

carried

out

carefully

It

should

also

be

noted

that

gear

slips

out

of

mesh

due

to

vibration

generated

by

weakened

front

and

rear

engine

mounts

Worn

interlock

plunger

1

Replace

Worn

check

ball

and

or

weakened

or

broken

spring

Replace

Worn

fork

rod

ball

groove

Replace

Worn

or

damaged

bearing

Replace

Worn

or

damaged

gear

Replace

Noise

When

noise

occurs

under

engine

idling

and

stops

while

the

clutch

is

disengaged

or

when

noise

occurs

while

shifting

gears

it

may

judged

that

the

noise

is

from

the

transmissiun

TM

22