lock DATSUN B110 1973 Service Owners Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 313 of 513

ENGINE

Adjusting

carburetor

idle

rpm

mixture

ratio

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

and

calibrated

Warm

up

the

engine

sufficiently

2

Continue

engine

operation

for

one

minute

under

idling

speed

3

Adjust

throttle

adjusting

screw

so

that

engine

speed

is

800

rpm

in

NO

position

for

automatic

transmission

4

Check

ignition

timing

if

necessary

adjust

it

to

the

specifications

Ignition

timing

SO

800

rpm

S

Adjust

idle

adjusting

screw

so

that

CO

percentage

is

1

5

t

O

S

6

Repeat

the

adjustments

as

described

in

steps

3

and

S

above

so

that

CO

percentage

is

I

i

t

O

S

at

800

rpm

Cautions

a

On

automatic

transmission

equipped

model

check

must

be

done

in

the

0

position

Be

sure

to

apply

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Hold

brake

pedal

while

stepping

down

on

accelerator

pedal

Otherwise

car

will

rush

out

dangerously

7

On

automatic

transmission

equipped

model

make

sure

that

the

adjustment

has

been

made

with

the

selector

lever

in

N

position

And

then

check

the

specifications

with

the

lever

in

D

position

Insure

that

CO

percent

and

idle

speed

are

as

follows

Idle

rpm

CO

percentage

with

lever

in

D

position

6S0

I

S

t

O

S

If

necessary

adjust

by

progressively

turning

throttle

adjusting

screw

and

idle

adjusting

screw

until

correct

adjustments

are

made

Notes

a

Do

not

attempt

to

screw

down

the

idle

adjusting

screw

completely

to

avoid

damage

to

the

tip

which

will

tend

to

cause

malfunctions

b

After

idle

adjustment

has

been

made

shift

the

lever

to

N

or

p

position

for

automatic

transmission

c

Remove

wheel

chocks

before

starting

the

car

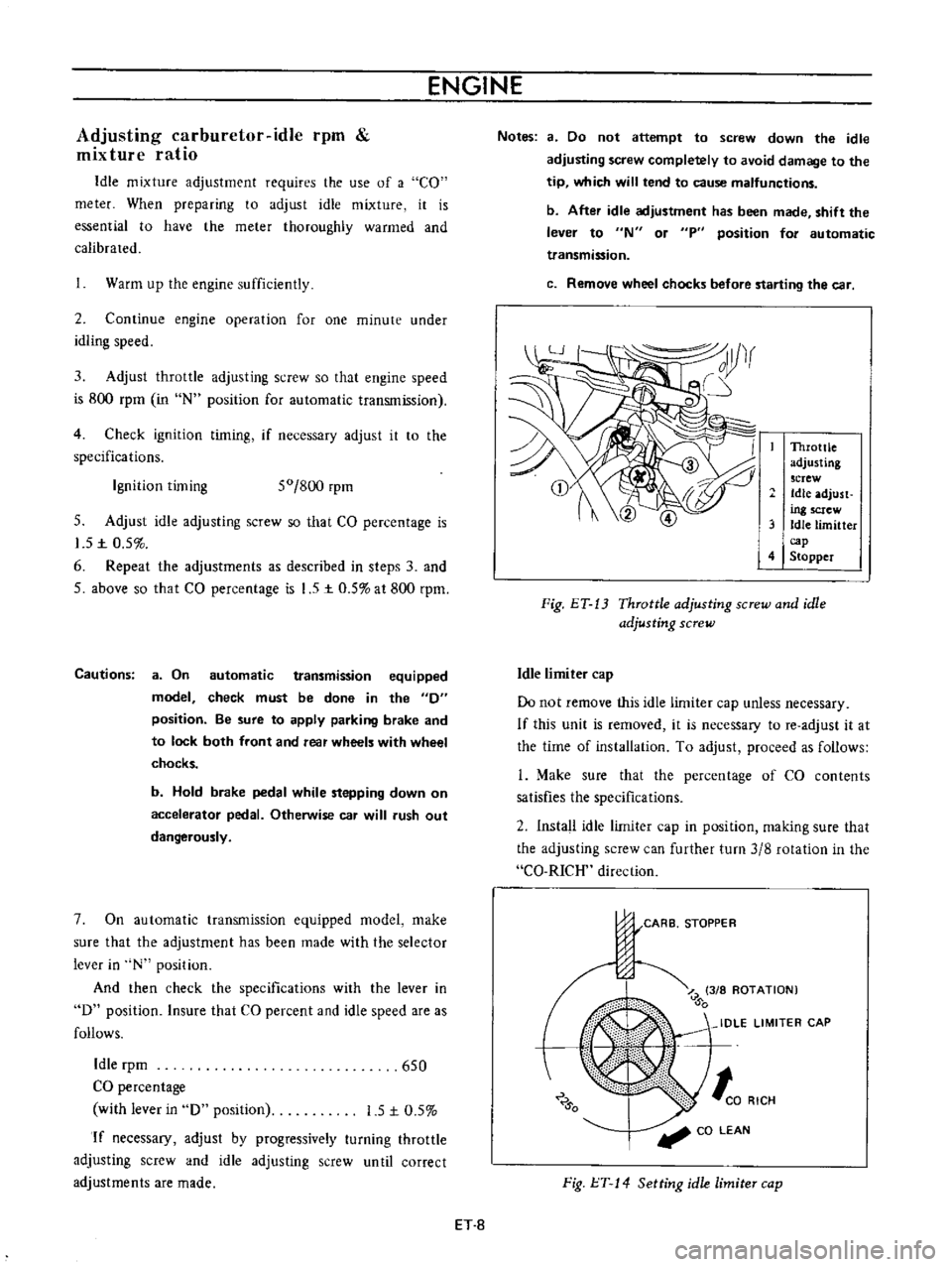

Throttle

adjusting

screw

Idle

adjust

ing

screw

3

Idle

limitter

cap

4

Stopper

Fig

ET

13

Throttle

adjusting

screw

and

idle

adjusting

screw

Idle

limiter

cap

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

removed

it

is

necessary

to

re

adjust

it

at

the

time

of

installation

To

adjust

proceed

as

follows

L

Make

sure

that

the

percentage

of

CO

contents

satisfies

the

specifications

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

can

further

turn

3

8

rotation

in

the

CO

RICH

direction

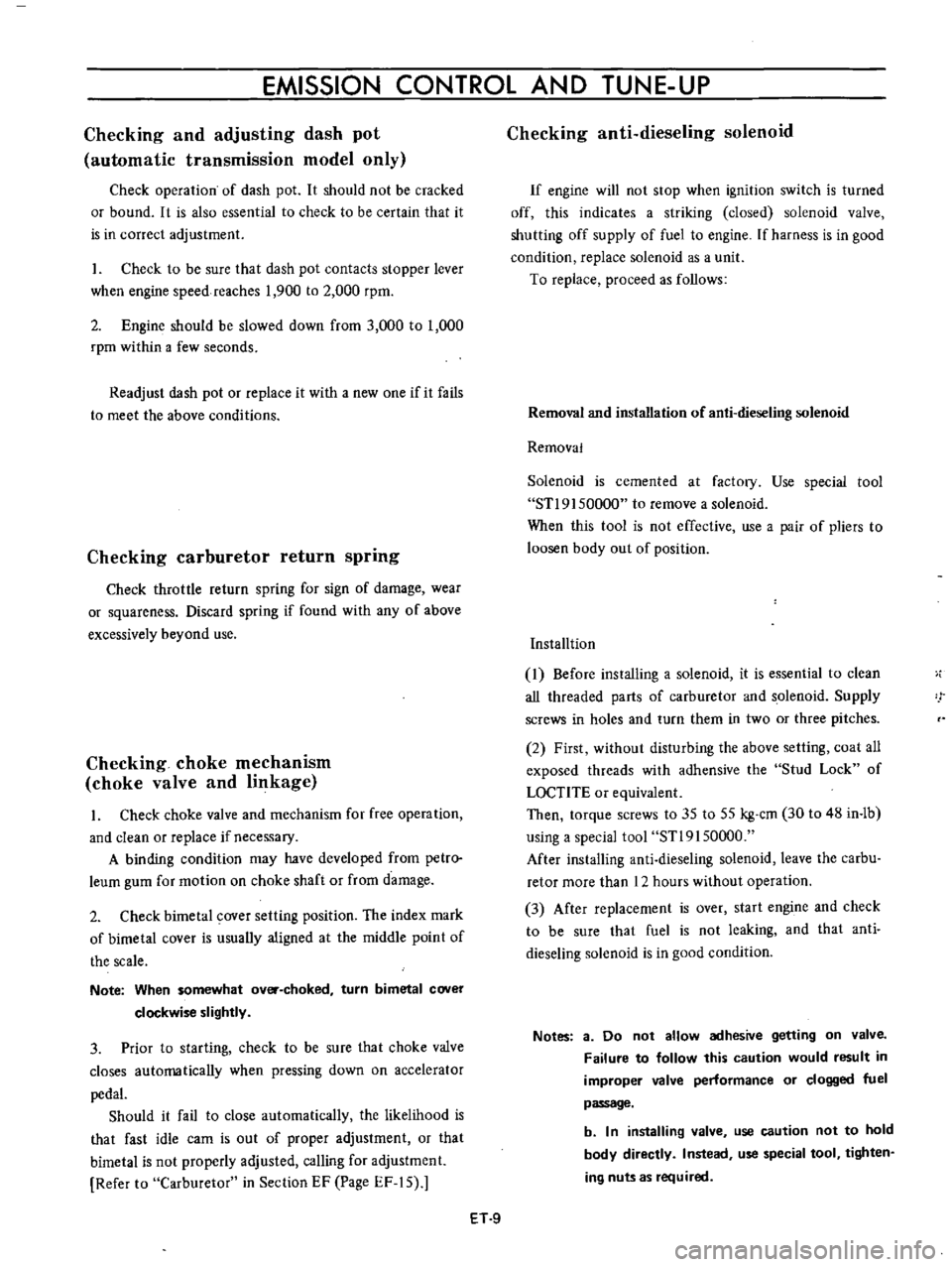

CARB

STOPPER

J

Z

3

8

ROTATION

0

IDLE

LIMITER

CAP

0

to

RICH

CO

LEAN

Fig

l

T

14

Setting

idle

limiter

cap

ET

8

Page 314 of 513

EMISSION

CONTROL

AND

TUNE

UP

Checking

and

adjusting

dash

pot

automatic

transmission

model

only

Check

operation

of

dash

pot

It

should

not

be

cracked

or

bound

It

is

also

essential

to

check

to

be

certain

that

it

is

in

correct

adjustment

L

Check

to

be

sure

that

dash

pot

contacts

stopper

lever

when

engine

speed

reaches

1

900

to

2

000

rpm

2

Engine

should

be

slowed

down

from

3

000

to

1

000

rpm

within

a

few

seconds

Readjust

dash

pot

or

replace

it

with

a

new

one

if

it

fails

to

meet

the

above

conditions

Checking

carburetor

return

spring

Check

throttle

return

spring

for

sign

of

damage

wear

or

squareness

Discard

spring

if

found

with

any

of

above

excessively

beyond

use

Checking

choke

mechanism

choke

valve

and

linkage

1

Check

choke

valve

and

mechanism

for

free

operation

and

clean

or

replace

if

necessary

A

binding

condition

may

have

developed

from

petro

leum

gum

for

motion

on

choke

shaft

or

from

damage

2

Check

bimetal

cover

setting

position

The

index

mark

of

bimetal

cover

is

usually

aligned

at

the

middle

point

of

the

scale

Note

When

somewhat

over

choked

turn

bimetal

caver

clockwise

slightly

3

Prior

to

starting

check

to

be

sure

that

choke

valve

closes

automatically

when

pressing

down

on

accelerator

pedal

Should

it

fail

to

close

automatically

the

likelihood

is

that

fast

idle

cam

is

out

of

proper

adjustment

or

that

bimetal

is

not

properly

adjusted

calling

for

adjustment

Refer

to

Carburetor

in

Section

EF

Page

EF

15

Checking

anti

dieseling

solenoid

If

engine

will

not

stop

when

ignition

switch

is

turned

off

this

indicates

a

striking

closed

solenoid

valve

shutting

off

supply

of

fuel

to

engine

If

harness

is

in

good

condition

replace

solenoid

as

a

unit

To

replace

proceed

as

follows

Removal

and

installation

of

anti

dieseling

solenoid

Removal

Solenoid

is

cemented

at

factory

Use

special

tool

STl

91

50000

to

remove

a

solenoid

When

this

tool

is

not

effective

use

a

pair

of

pliers

to

loosen

body

out

of

position

lnstalltion

I

Before

installing

a

solenoid

it

is

essential

to

clean

all

threaded

parts

of

carburetor

and

solenoid

Supply

screws

in

holes

and

turn

them

in

two

or

three

pitches

2

First

without

disturbing

the

above

setting

coat

all

exposed

threads

with

adhensive

the

Stud

Lock

of

LOCTlTE

or

equivalent

Then

torque

screws

to

35

to

55

kg

cm

30

to

48

in

lb

using

a

special

tool

STl9150000

After

installing

anti

dieseling

solenoid

leave

the

carbu

retor

more

than

12

hours

without

operation

3

After

replacement

is

over

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

solenoid

is

in

good

condition

Notes

a

Do

not

allow

adhesive

getting

on

valve

Failure

to

follow

this

caution

would

result

in

improper

valve

performance

or

clogged

fuel

passage

b

I

n

installing

valve

use

caution

not

to

hold

body

directly

Instead

use

special

tool

tighten

ing

nuts

as

required

ET

9

Page 319 of 513

ENGINE

Adjusting

throttle

opener

setting

engine

speed

1

Connect

servo

diaphragm

vacuum

hose

directly

to

intake

manifold

connector

without

laying

through

vacuum

control

valve

2

With

negative

pressure

vacuum

in

intake

manifold

servo

diaphragm

operates

and

thus

the

primary

throttle

valve

is

opened

When

servo

diaphragm

nor

mally

operates

engine

speed

rises

reaching

1

650

to

1

850

rpm

When

engine

speed

is

not

within

this

range

turn

adjusting

screw

as

necessary

See

Figure

ET

20

l

When

engine

speed

is

lower

than

the

prescribed

range

turn

adjusting

screw

clockwise

2

When

engine

speed

is

higher

than

the

prescribed

range

turn

adjusting

screw

counterclockwise

Upon

completion

of

the

adjustment

set

adjusting

screw

lock

nut

secwely

making

sure

that

engine

speed

is

in

the

prescribed

range

@

II

I

AdJustmg

screw

2

Lock

nut

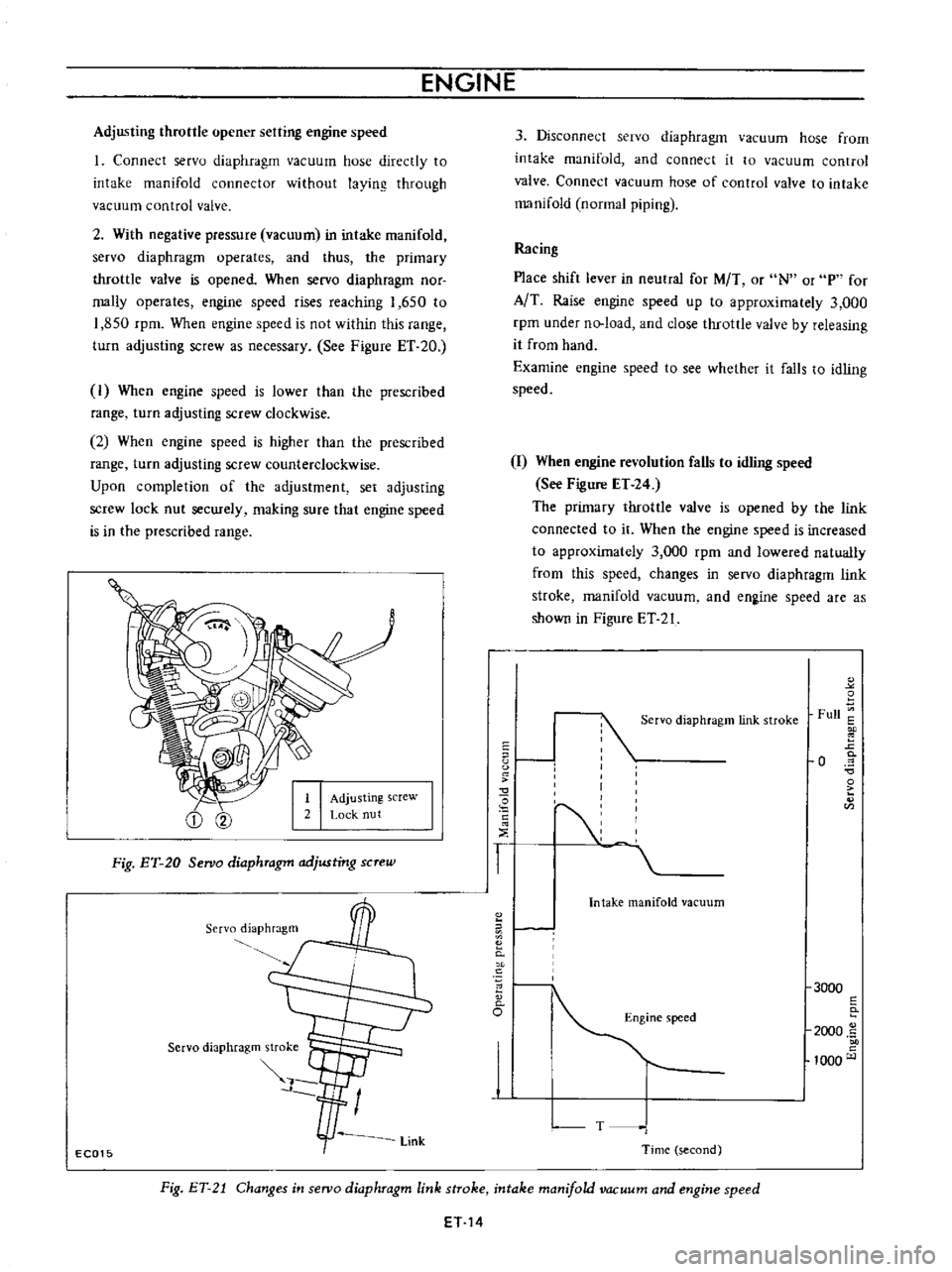

Fig

ET

20

Servo

diaphragm

adjusting

screw

Servo

diaphragm

Servo

diaphragm

stroke

Link

EC015

3

Disconnect

servo

diaphragm

vacuum

hose

from

intake

manifold

and

connect

it

to

vacuum

control

valve

Connect

vacuum

hose

of

control

valve

to

intake

manifold

normal

piping

Racing

Place

shift

lever

in

neutral

for

MfT

or

N

or

p

for

AlT

Raise

engine

speed

up

to

approximately

3

000

rpm

under

no

load

and

close

throttle

valve

by

releasing

it

from

hand

Examine

engine

speed

to

see

whether

it

falls

to

idling

speed

I

When

engine

revolution

rails

to

idling

speed

See

Figure

ET

24

The

primary

throttle

valve

is

opened

by

the

link

connected

to

it

When

the

engine

speed

is

increased

to

approximately

3

000

rpm

and

lowered

natually

from

this

speed

changes

in

servo

diaphragm

link

stroke

manifold

vacuum

and

en

ine

speed

are

as

shown

in

Figure

ET

21

o

u

u

0

2

Se

o

diaphragm

link

stroke

I

u

2

Full

0

o

Intake

manifold

vacuum

u

c

E

c

O

3000

c

e

Engine

speed

2000

g

i

c

1000

T

j

Time

second

Fig

ET

21

Changes

in

servo

diaphragm

link

stroke

intake

manifold

vacuum

and

engine

speed

ET

14

Page 321 of 513

ENGINE

How

to

read

Figure

ET

22

Determining

operating

pressure

and

adjustment

of

vacuum

control

valve

1

When

atmospheric

pressure

is

known

operating

pressure

is

found

by

following

the

arrow

line

A

When

altitude

is

known

operating

pressure

is

found

by

following

the

arroW

line

B

2

Turn

the

adjusting

screw

of

the

vacuum

control

valve

See

Figure

ET

23

and

adjsut

the

vacuum

control

valve

so

that

negative

pressure

in

the

intake

manifold

is

suspended

for

a

few

seconds

at

the

value

of

operating

pressure

found

as

described

in

I

above

while

the

engine

speed

decreases

from

3

000

to

1

000

rpm

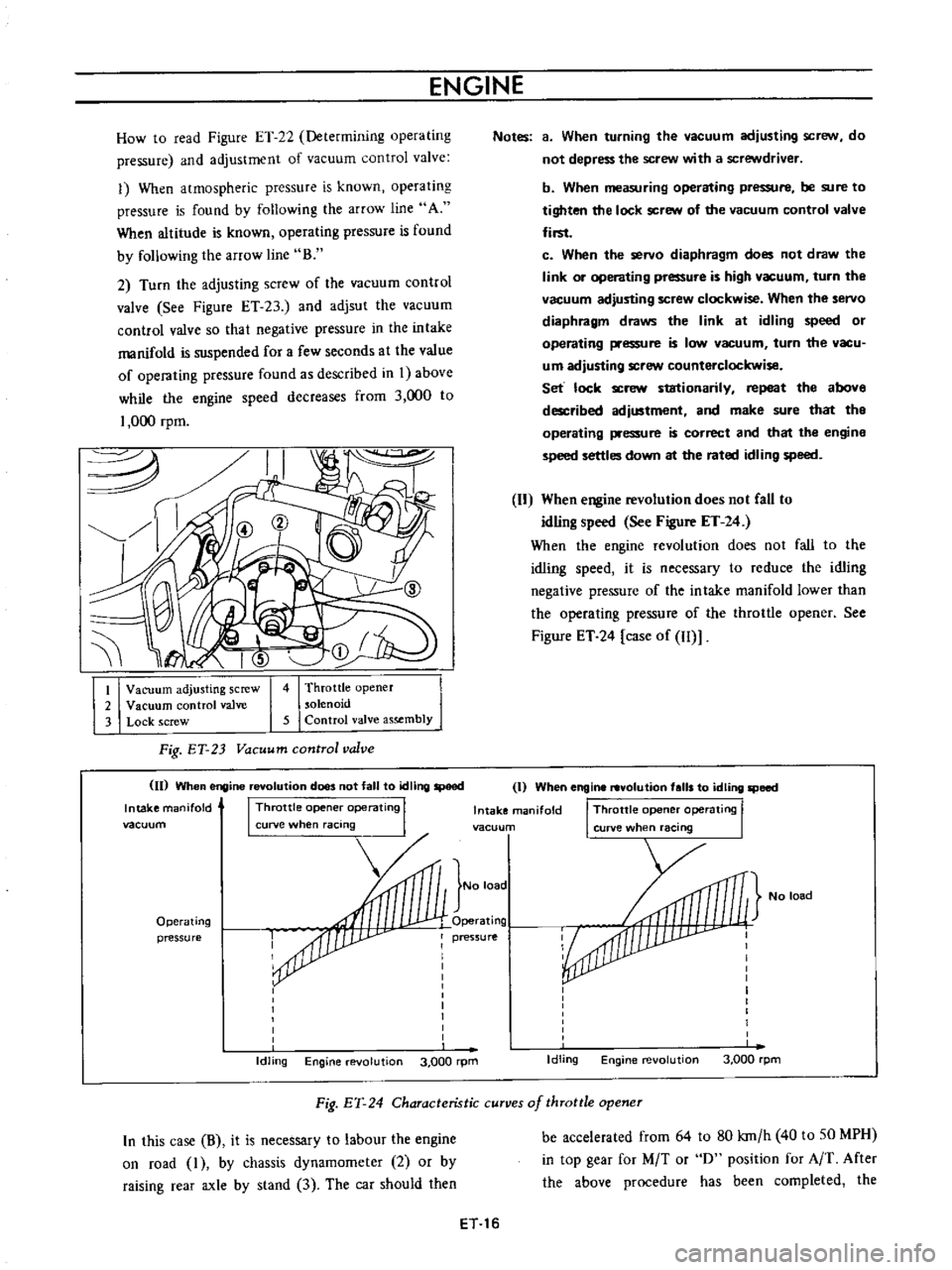

I

Vacuum

adjusting

screw

2

Vacuum

control

valve

3

Lock

screw

4

Throttle

opener

solenoid

5

Control

valve

assembly

Fig

ET

23

Vacuum

control

valve

II

When

engine

revolution

does

not

fall

to

tdling

speed

Intake

manifold

I

Throttle

opene

operating

I

vacuum

curve

when

racing

Operating

pressure

Idling

Engine

evolution

3

000

rpm

Notes

a

When

turning

the

vacuum

adjusting

scre

N

do

not

depress

the

screw

with

a

screwdriver

b

When

measuring

operating

pressure

be

sure

to

tighten

the

lock

screw

of

the

vacuum

control

valve

first

c

When

the

servo

diaphragm

does

not

draw

the

link

or

operating

pressure

is

high

vacuum

turn

the

vacuum

adjusting

screw

clockwise

When

the

servo

diaphragm

draws

the

link

at

idling

speed

or

operating

pressure

is

low

vacuum

turn

the

vacu

um

adjusting

screw

counterclockwise

Set

lock

screw

stationarily

repeat

the

above

described

adjustment

and

make

sure

that

tho

operating

pressure

is

correct

and

that

the

engine

speed

settles

down

at

the

rated

idling

speed

When

engine

revolution

does

not

CaU

to

idling

speed

See

Figure

ET

24

When

the

engine

revolution

does

not

fall

to

the

idling

speed

it

is

necessary

to

reduce

the

idling

negative

pressure

of

the

intake

manifold

lower

than

the

operating

pressure

of

the

throttle

opener

See

Figure

ET

24

case

of

Il

Il

I

When

engine

revolution

falls

to

idling

speed

Intake

manifold

I

Throttle

opene

operating

I

vacuun

curve

when

racing

No

load

No

load

Operating

pressure

I

I

I

I

I

I

I

I

I

Idling

Engine

revolution

3

000

rpm

Fig

EY

24

Characteristic

curves

of

throttle

opener

In

this

case

B

it

is

necessary

to

labour

the

engine

on

road

I

by

chassis

dynamometer

2

or

by

raising

rear

axle

by

stand

3

The

car

should

then

be

accelerated

from

64

to

80

kro

h

40

to

SO

MPH

in

top

gear

for

M

T

or

0

position

for

A

T

After

the

above

procedure

has

been

completed

the

ET

16

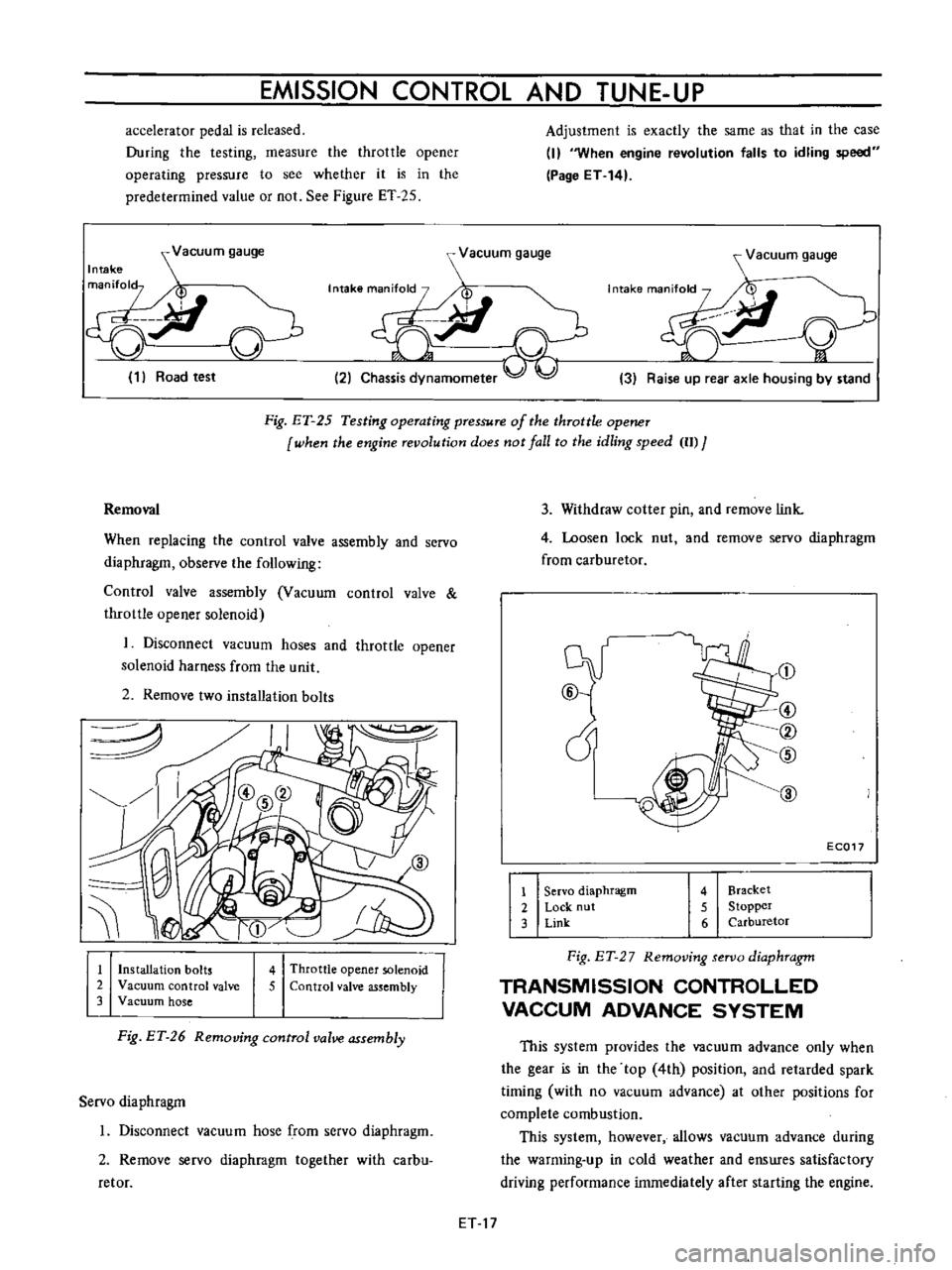

Page 322 of 513

EMISSION

CONTROL

AND

TUNE

UP

accelerator

pedal

is

released

During

the

testing

measure

the

throttle

opener

operating

pressure

to

see

whether

it

is

in

the

predetermined

value

or

not

See

Figure

ET

25

Adjustment

is

exactly

the

same

as

that

in

the

case

I

When

engine

revolution

falls

to

idling

speed

Page

ET

14

Vacuum

gauge

Intake

man

fol

p

ci

J

v

1

Road

test

r

Vacuum

gauge

7I

t

i

2

Chassis

dynamometer

Vacuum

gauge

y

3

Raise

up

rear

axle

housing

by

stand

Fig

ET

25

Testing

operating

pressure

of

the

throttle

opener

when

fhe

engine

revolufion

does

not

lall

fo

fhe

idling

speed

II

J

3

Withdraw

cotter

pin

and

remove

link

4

Loosen

lock

nut

and

remove

servo

diaphragm

from

carburetor

Removal

When

replacing

the

control

valve

assembly

and

servo

diaphragm

observe

the

following

Control

valve

assembly

Vacuum

control

valve

throttle

opener

solenoid

1

Disconnect

vacuum

hoses

and

throttle

opener

solenoid

harness

from

the

unit

2

Remove

two

installation

bolts

J

@

cY

@

1

Servo

diaphragm

2

Lock

nut

3

Link

@

CV

@

EC017

4

Bracket

5

Stopper

6

Carburetor

1

Installation

bolts

2

Vacuum

control

valve

3

Vacuum

hose

4

Throttle

opener

solenoid

5

Control

valve

assembly

Fig

ET

2

7

Removing

servo

diaphragm

TRANSMISSION

CONTROLLED

VACCUM

ADVANCE

SYSTEM

Fig

ET

26

Removing

control

valve

assembly

This

system

provides

the

vacuum

advance

only

when

the

gear

is

in

the

top

4th

position

and

retarded

spark

timing

with

no

vacuum

advance

at

other

positions

for

complete

combustion

This

system

however

allows

vacuum

advance

during

the

warming

up

in

cold

weather

and

enswes

satisfactory

driving

performance

immediately

after

starting

the

engine

Servo

diaphragm

1

Disconnect

vacuum

hose

from

servo

diaphragm

2

Remove

servo

diaphragm

together

with

carbu

retor

ET

17

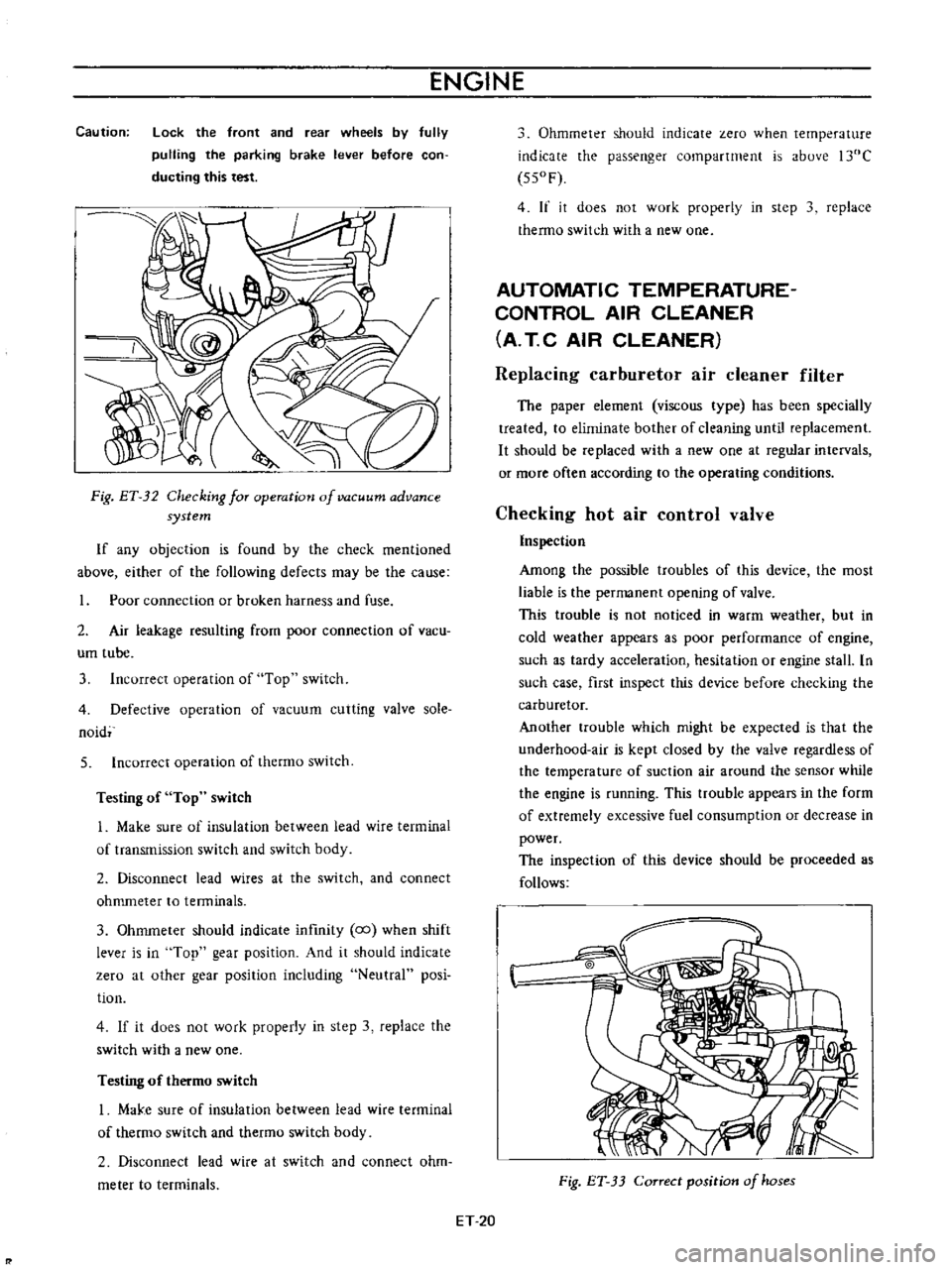

Page 325 of 513

ENGINE

Caution

lock

the

front

and

rear

wheels

by

fully

pulling

the

parking

brake

lever

before

con

ducting

this

test

Fig

ET

32

Checking

for

operation

of

vacuum

advance

system

If

any

objection

is

found

by

the

check

mentioned

above

either

of

the

following

defects

may

be

the

cause

Poor

connection

or

broken

harness

and

fuse

2

Air

leakage

resulting

from

poor

connection

of

vacu

um

tube

3

Incorrect

operation

of

Top

switch

4

Defective

operation

of

vacuum

cutting

valve

sole

naid

5

Incorrect

operation

of

thermo

switch

Testing

of

Top

switch

1

Make

sure

of

insulation

between

lead

wire

terminal

of

transmission

switch

and

switch

body

2

Disconnect

lead

wires

at

the

switch

and

connect

ohmmeter

to

tenninals

3

Ohmmeter

should

indicate

infmity

co

when

shift

lever

is

in

Top

gear

position

And

it

should

indicate

zero

at

other

gear

position

including

Neutral

posi

tion

4

If

it

does

not

work

properly

in

step

3

replace

the

switch

with

a

new

one

Testing

of

thermo

switch

I

MaJ

e

sure

of

insulation

between

lead

wire

terminal

of

thermo

switch

and

thetmo

switch

body

2

Disconnect

lead

wire

at

switch

and

connect

ohm

meter

to

terminals

Ohmmeter

should

indicate

zero

when

temperature

indicate

the

passenger

compartment

is

above

l30C

550F

4

If

it

does

not

work

properly

in

step

3

replace

thermo

switch

with

a

new

one

AUTOMATIC

TEMPERATURE

CONTROL

AIR

CLEANER

A

T

C

AIR

CLEANER

Replacing

carburetor

air

cleaner

filter

The

paper

element

viscous

type

has

been

specially

treated

to

eliminate

bother

of

cleaning

until

replacement

It

should

be

replaced

with

a

new

one

at

regular

intervals

or

more

often

according

to

the

operating

conditions

Checking

hot

air

control

valve

Inspection

Among

the

possible

troubles

of

this

device

the

most

liable

is

the

permanent

opening

of

valve

This

trouble

is

not

noticed

in

warm

weather

but

in

cold

weather

appears

as

poor

performance

of

engine

such

as

tardy

acceleration

hesitation

or

engine

stall

In

such

case

first

inspect

this

device

before

checking

the

carburetor

Another

trouble

which

might

be

expected

is

that

the

underhood

air

is

kept

closed

by

the

valve

regardless

of

the

temperature

of

suction

air

around

the

sensor

while

the

engine

is

running

This

ttOuble

appears

in

the

form

of

extremely

excessive

fuel

consumption

or

decrease

in

power

The

inspection

of

this

device

should

be

proceeded

as

follows

Fig

ET

33

Correct

position

of

hoses

ET

20

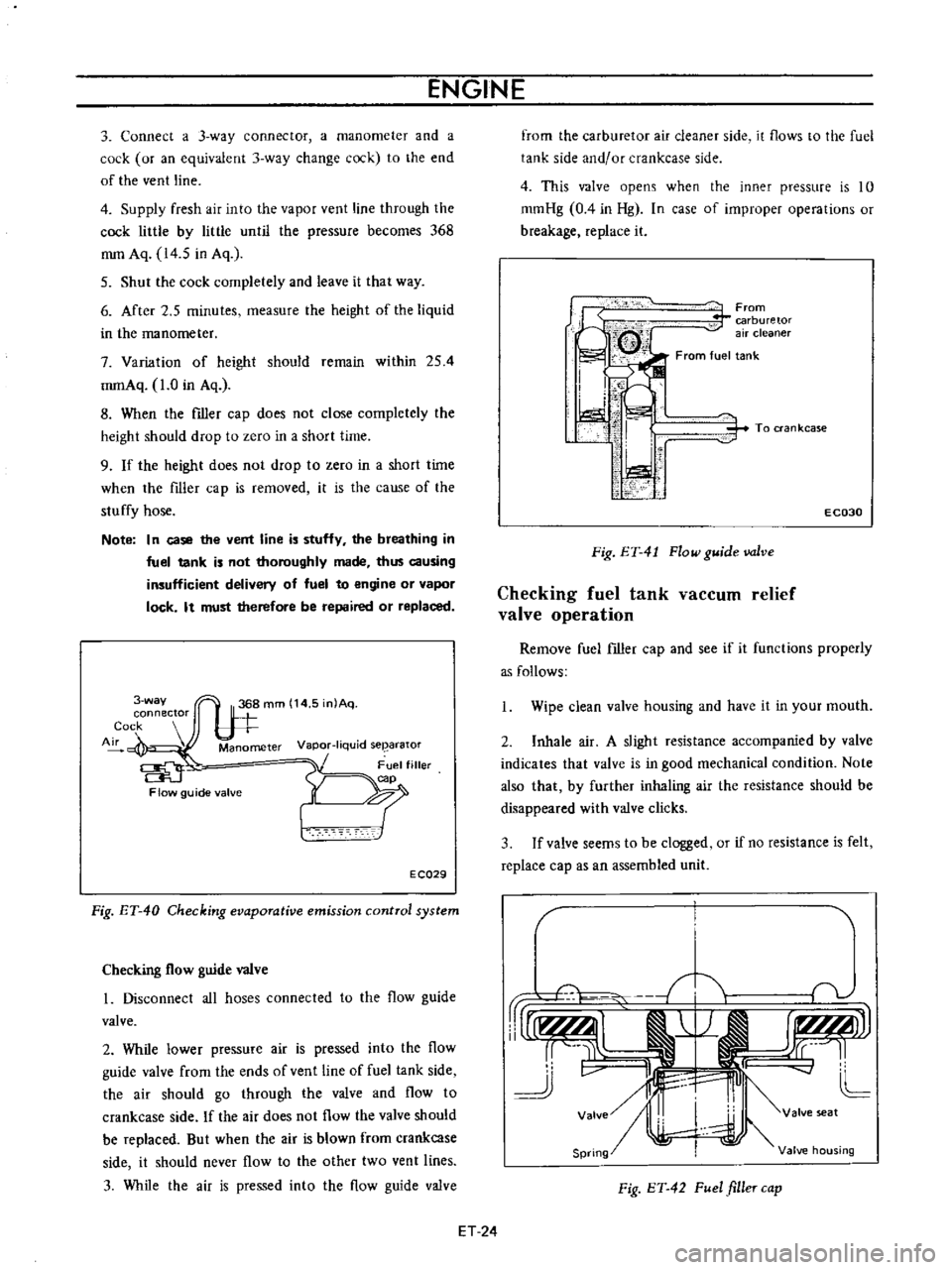

Page 329 of 513

ENGINE

3

Connect

a

3

way

connector

a

manometer

and

a

cock

or

an

equivalent

3

way

change

cock

to

the

end

of

the

vent

line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

the

pressure

becomes

368

mm

Aq

14

5

in

Aq

5

Shut

the

cock

completely

and

leave

it

that

way

6

After

2

5

minutes

measure

the

height

of

the

liquid

in

the

manometer

7

Variation

of

height

should

remain

within

254

mmAq

1

0

in

Aq

8

When

the

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

If

the

height

does

not

drop

to

zero

in

a

short

time

when

the

filler

cap

is

removed

it

is

the

cause

of

the

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

made

thus

causing

insufficient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

therefore

be

repaired

or

replaced

3

way

connector

Cock

Air

Manometer

Vapor

liquid

seearator

Flow

guide

valve

E

CQ29

Fig

ET

40

Checking

evaporative

emission

control

system

Checking

flow

guide

valve

I

Disconnect

all

hoses

connected

to

the

flow

guide

valve

2

While

lower

pressure

air

is

pressed

into

the

flow

guide

valve

from

the

ends

of

vent

line

of

fuel

tank

side

the

air

should

go

through

the

valve

and

flow

to

crankcase

side

If

the

air

does

not

flow

the

valve

should

be

replaced

But

when

the

air

is

blown

from

crankcase

side

it

should

never

flow

to

the

other

two

vent

lines

3

While

the

air

is

pressed

into

the

flow

guide

valve

from

the

carburetor

air

cleaner

side

it

flows

to

the

fuel

tank

side

and

or

crankcase

side

4

This

valve

opens

when

the

inner

pressure

is

10

mmHg

0

4

in

Hg

In

case

of

improper

operations

or

breakage

replace

it

From

carburetor

air

cleaner

From

fuel

tank

i

I

I

ti

i

i

1

1

i

To

ran

kcase

E

C030

Fig

ET

41

Flow

guide

valve

Checking

fuel

tank

vaCCUID

relief

valve

operation

Remove

fuel

filler

cap

and

see

if

it

functions

properly

as

follows

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

accompanied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

clicks

3

If

valve

seems

to

be

clogged

or

if

no

resistance

is

felt

replace

cap

as

an

assembled

unit

T

1i

v

rUr1f

AlI

j

r

I

r

tLMJJl

rr

L

cc

11

J

v

II

4J

L

Valve

I

valve

seat

Spring

Valve

housing

Fig

ET

42

Fuel

filler

cap

ET

24

Page 337 of 513

ABNORMAL

COMBUSTION

backfire

afterflfe

run

on

etc

Improper

ignition

timing

Fuel

system

in

trouble

Defective

cylinder

head

etc

EXCESSIVE

OIL

CONSUMPTION

Oil

leakage

Excessive

oil

consumption

ENGINE

Improper

ignition

timing

Improper

heat

range

of

the

spark

plugs

Damaged

carburetor

or

manifold

gasket

backfire

afterflre

Defective

carburetor

jet

Improper

function

of

the

float

Uneven

idling

Improperly

adjusted

valve

clearance

Excess

carbon

in

the

combustion

chamber

Damaged

valve

spring

backfire

afterure

Loose

oil

drain

plug

Loose

or

damaged

oil

pan

gasket

Loose

or

damaged

chain

cover

gasket

Defective

oil

seals

in

front

and

rear

of

the

crankshaft

Loose

or

damaged

locker

cover

gasket

Improper

tightening

of

oil

filter

Loose

or

damaged

oil

pressure

switch

Worn

cylinder

and

piston

Improper

location

of

the

ring

split

or

reo

versed

assembly

ET

32

Adjust

the

ignition

timing

Use

specified

spark

plugs

Replace

them

with

new

ones

Disassemble

the

carburetor

and

check

it

Adjust

the

level

and

check

the

needle

valve

Adjust

Readjust

Remove

the

cylinder

head

and

remove

carbon

Replace

it

with

a

new

one

Tighten

it

Renew

the

gasket

or

tighten

it

Renew

the

gasket

or

tighten

it

Renew

the

oil

seals

Renew

the

gasket

or

tighten

it

Do

not

tighten

excessively

Renew

the

gasket

and

tighten

it

cor

rectly

Retighten

or

renew

the

oil

pressure

switch

Overhaul

the

cylinder

and

renew

the

piston

Reassemble

the

piston

rings

correctly

Page 338 of 513

EMISSION

CONTROL

AND

TUNE

UP

Othm

POOR

FUEL

CONSUMPTION

See

the

explanation

of

the

power

decrease

Othe

TROUBLE

IN

OTHER

FUNCfIONS

Decreased

oil

pressure

Excessive

wear

on

the

sliding

parts

Damaged

or

seized

piston

rings

Worn

piston

ring

groove

and

rings

Fatigue

ofvalve

oil

seal

lip

Worn

valve

stem

Inadequate

quality

of

engine

oiL

Engine

overheat

Exceeding

idling

revolution

Defective

acceleration

recovery

Fuel

leakage

Inadequa

Ie

oil

quality

Overheat

Defective

function

of

oil

pump

regulator

valve

Functional

deterioration

of

oil

pump

Blocked

oil

ftIter

nerased

clearance

in

various

sliding

parts

Blocked

oil

strainer

Troubles

in

the

oil

gauge

pressure

switch

Oil

pressure

decrease

Defective

quality

or

contamination

of

oil

Defective

air

cleaner

Overheat

or

overcoal

ET

33

Renew

the

rings

Repair

or

renew

the

piston

and

cyl

inder

Renew

the

piston

and

piston

ring

Replace

the

seal

lip

with

a

new

one

Renew

the

valve

or

the

guide

Use

the

designated

oiL

Previously

mentioned

Adjust

it

to

the

designated

rpm

Adjust

it

Repair

or

tighten

the

connection

of

fuel

pipes

Use

the

designated

oil

Previously

mentioned

Disassemble

the

oil

pump

and

repair

or

renew

it

Repair

or

replace

it

with

a

new

one

Renew

it

Disassemble

and

replace

the

worn

parts

with

new

ones

Clean

it

Replace

it

with

a

new

one

Previously

mentioned

Replace

the

oil

with

proper

one

and

change

the

ftIter

elemerit

Replace

the

air

cleaner

element

Previously

mentioned

Page 341 of 513

ENGINE

MECHANICAL

GENERAL

DESCRIPTION

CONTENTS

ENGINE

CYLINDER

BLOCK

CRAN

KSHAFT

PISTON

AND

CONNECTING

ROD

CYLINDER

HEAD

EM

EM

2

EM

2

EM

2

EM

2

CAMSHAFT

VALVE

MECHANISM

CAMSHAFT

DRIVE

MANIFOLD

EM

3

EM

3

EM

3

EM

3

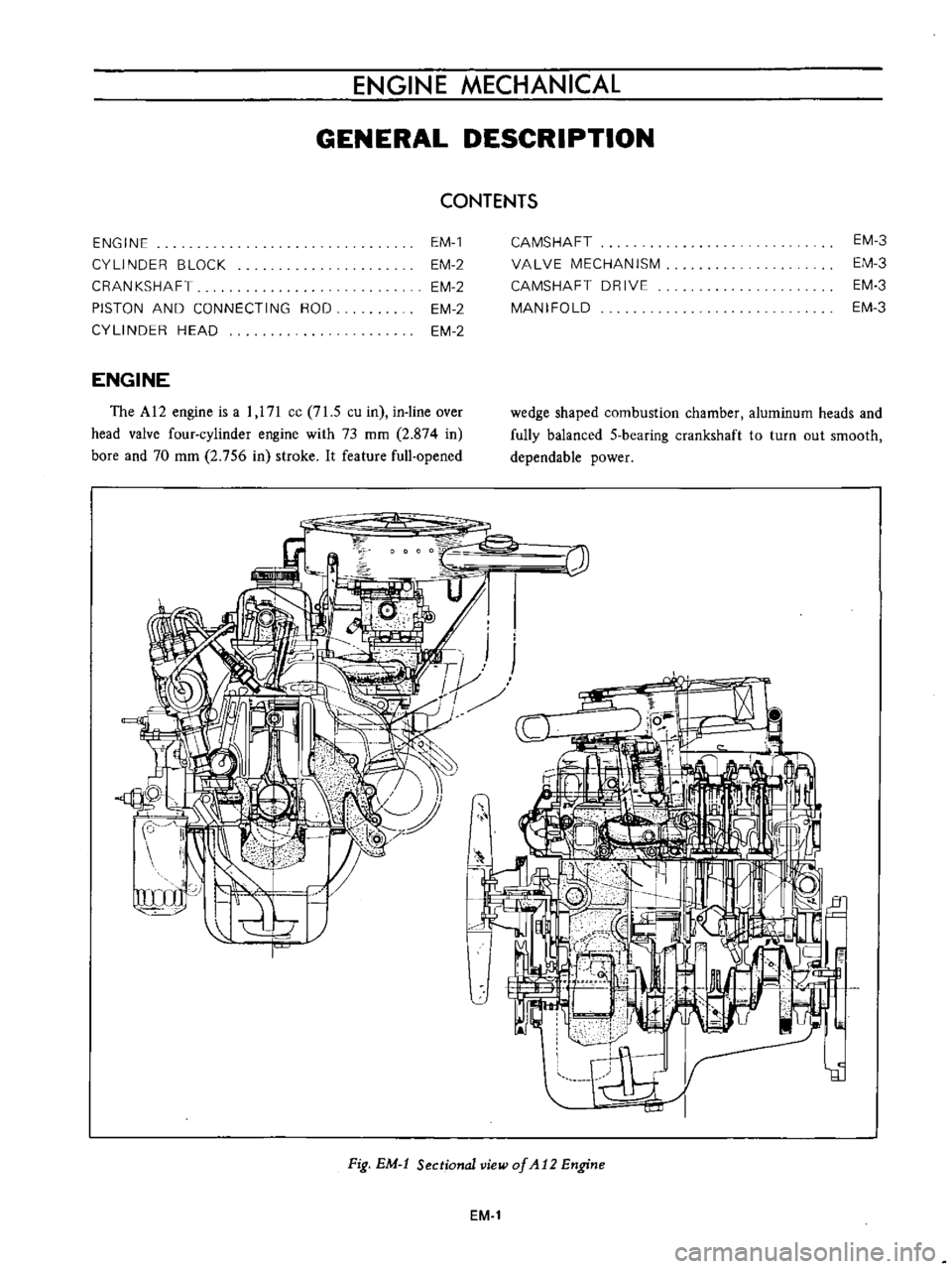

ENGINE

The

AI2

engine

is

a

1

171

cc

71

5

cu

in

in

line

over

head

valve

four

cylinder

engine

with

73

mm

2

874

in

bore

and

70

mm

2

756

in

stroke

It

feature

full

opened

wedge

shaped

combustion

chamber

aluminum

heads

and

fully

balanced

5

bearing

crankshaft

to

turn

out

smooth

dependable

power

c

Ii

I

l

1

nun

y

r

r

Fig

EM

t

Sectional

view

of

At2

Engine

EM

1