lock DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 362 of 513

ENGINE

Pig

EM

62

Bearing

clearance

check

Measuring

connecting

rod

bearing

clearance

Measure

connecting

rod

bearing

clearance

in

the

same

manner

Tightening

torque

3

2

to

3

8

kg

m

23

to

28

ft

Ib

Bearing

oil

clearance

Standard

Wear

limit

Main

bearing

clearance

rom

in

0

020

to

0

062

0

0008

to

0

0024

0

1

0

0039

Connecting

rod

bearing

clearance

mm

in

0

020

to

0

050

0

0008

to

0

0020

0

1

0

0039

2

If

clearance

exceeds

the

specified

value

replace

bearing

with

an

undersize

bearing

and

grind

out

the

crankshaft

journal

adequately

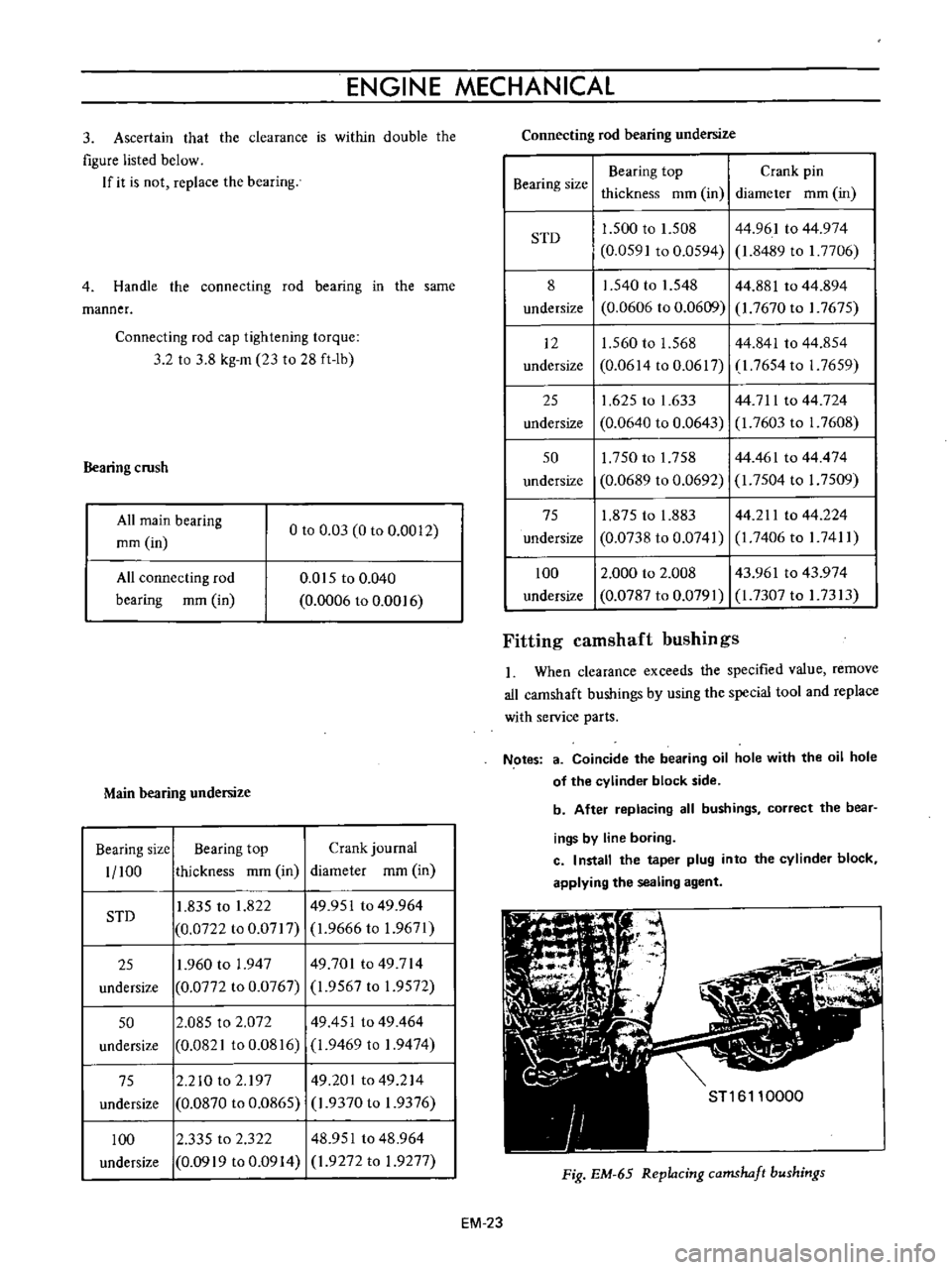

Fig

EM

63

Bearing

clearance

check

Fitting

crankshaft

bearings

I

Set

the

bushings

on

the

main

bearing

cap

and

the

cylinder

block

bearing

recess

and

tighten

the

cap

bolts

to

the

specified

torque

Tightening

torque

5

0

to

5

3

kg

m

36

to

38

ft

lb

2

Loosen

the

cap

bolt

on

one

side

and

measure

clearance

between

the

cap

and

cylinder

block

side

n

n

u

ii

Bearing

6

Weight

EM143

Fig

EM

64

Bearing

crush

check

EM

22

Page 363 of 513

ENGINE

MECHANICAL

3

Ascertain

that

the

clearance

is

within

double

the

figure

listed

below

If

it

is

not

replace

the

bearing

4

Handle

the

connecting

rod

bearing

in

the

same

manner

Connecting

rod

cap

tightening

torque

3

2

to

3

8

kg

m

23

to

28

ft

lb

Bearing

crush

All

main

bearing

mm

in

o

to

0

03

0

to

0

0012

All

connecting

rod

bearing

mm

in

0

Ql5

to

0

040

0

0006

to

0

0016

Main

bearing

undersize

Bearing

size

Bearing

top

Crank

journal

1

100

thickness

mm

in

diameter

mm

in

STD

1

835

to

1

822

49

951

to

49

964

0

0722

to

0

0717

1

9666

to

1

9671

25

1

960

to

1

947

49701

to

49

714

undersize

0

0772

to

0

0767

1

9567

to

1

9572

50

2

085

to

2

072

49451

to

49

464

undersize

0

0821

to

0

0816

1

9469

to

1

9474

75

2

210

to

2

197

49

201

to

49

214

undersize

0

0870

to

0

0865

1

9370

to

1

9376

100

2

335

to

2

322

48

951

to

48

964

undersize

0

0919

to

0

0914

1

9272

to

1

9277

Connecting

rod

bearing

undersize

Bearing

top

Crank

pin

Bearing

size

thickness

mm

in

diameter

mm

in

1

500

to

1

508

44

961

to

44

974

0

0591

to

0

0594

1

8489

to

I

7706

8

1

540

to

1

548

44

881

to

44

894

undersize

0

0606

to

0

0609

1

7670

to

I

7675

STD

12

1

560

to

1

568

44

841

to

44

854

undersize

0

0614

to

0

0617

I

7654

to

I

7659

25

1

625

to

1

633

44

711

to

44

724

undersize

0

0640

to

0

0643

1

7603

to

I

7608

50

I

750

to

1

758

44

461

to

44

474

undersize

0

0689

to

0

0692

1

7504

to

I

7509

75

1

875

to

1

883

44

211

to

44

224

undersize

0

0738

to

0

0741

1

7406

to

I

7411

100

2

000

to

2

008

43

961

to

43

974

undersize

0

0787

to

0

0791

1

7307

to

I

7313

Fitting

camshaft

bushings

When

clearance

exceeds

the

specified

value

remove

all

camshaft

bushings

by

using

the

special

tool

and

replace

with

service

parts

Notes

3

Coincide

the

bearing

oil

hole

with

the

oil

hole

of

the

cylinder

block

side

b

After

replacing

all

bushings

correct

the

bear

ings

by

line

boring

c

I

nstall

the

taper

plug

into

the

cylinder

block

applying

the

sealing

agent

Fig

EM

65

Replacing

camshaft

bushings

EM

23

Page 366 of 513

ENGINE

ST130300

1

EM156

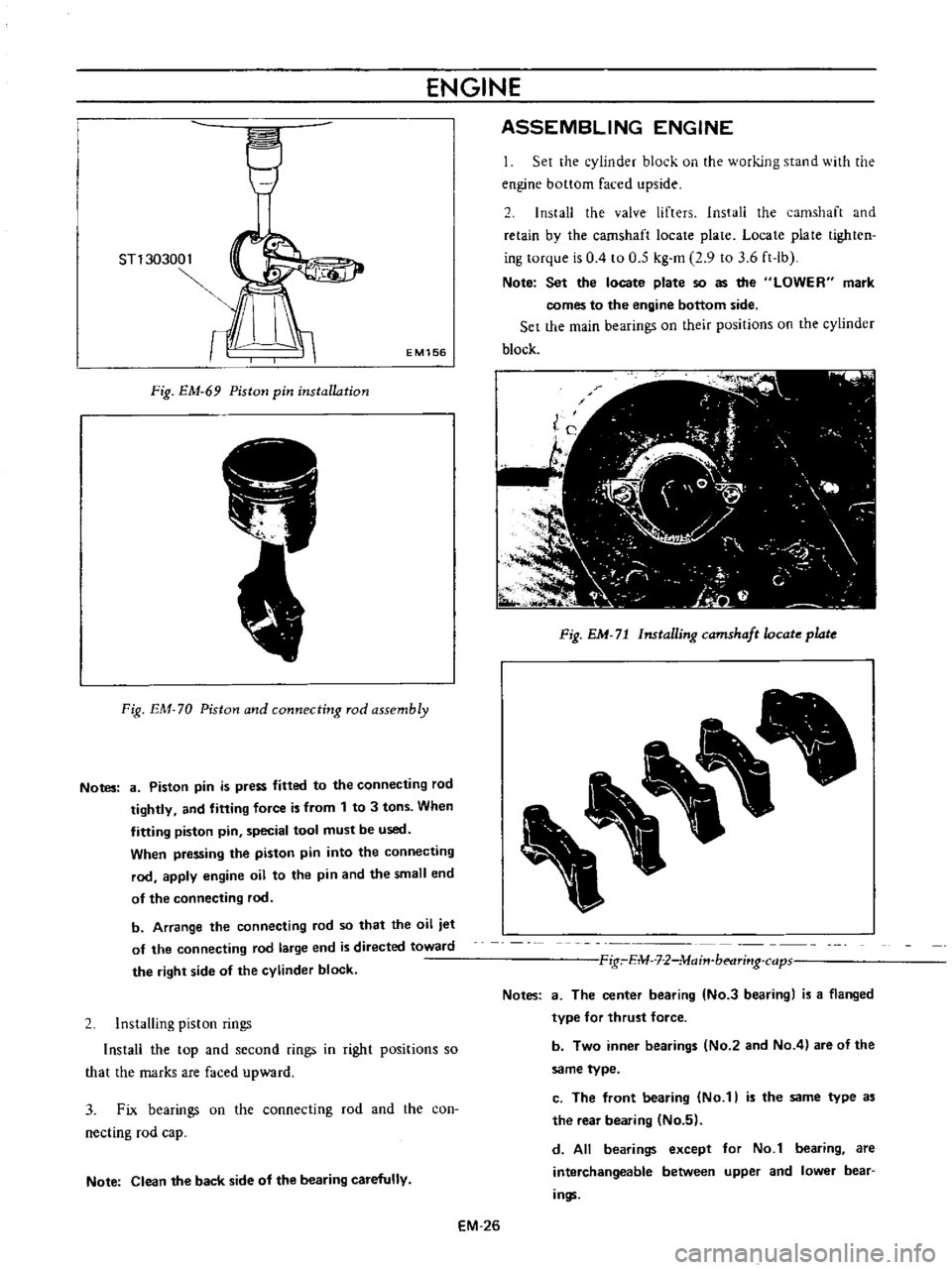

Fig

EM

69

Piston

pin

installation

Fig

EM

70

Piston

and

connecting

rod

assembly

Notes

8

Piston

pin

is

press

fitted

to

the

connecting

rod

tightly

and

fitting

force

is

from

1

to

3

tons

When

fitting

piston

pin

special

tool

must

be

used

When

pressing

the

piston

pin

into

the

connecting

rod

apply

engine

oil

to

the

pin

and

the

small

end

of

the

connecting

rod

b

Arrange

the

connecting

rod

so

that

the

oil

jet

of

the

connecting

rod

large

end

is

directed

toward

the

right

side

of

the

cylinder

block

2

Installing

piston

rings

Install

the

top

and

second

fings

in

right

positions

so

that

the

marks

are

faced

upward

3

Fix

bearings

on

the

connecting

rod

and

the

con

necting

rod

cap

Note

Clean

the

back

side

of

the

bearing

carefully

ASSEMBLING

ENGINE

Set

the

cylinder

block

on

the

working

stand

with

the

engine

bottom

faced

upside

2

Install

the

valve

lifters

Install

the

camshaft

and

retain

by

the

camshaft

locate

plate

Locate

plate

tighten

ing

torque

is

0

4

to

0

5

kg

m

2

9

to

3

6

ft

lb

Note

Set

the

locate

plate

so

as

the

LOWER

mark

comes

to

the

engine

bottom

side

Set

the

main

bearings

on

their

positions

on

the

cylinder

block

Fig

EM

71

Installing

camshaft

ocate

plate

Fig

E1U

7

2

lvlajn

betlrj

lg

cap

Notes

a

The

center

bearing

No

3

bearing

is

a

flanged

type

for

thrust

force

b

Two

inner

bearings

No

2

and

No

4

are

of

the

same

type

c

The

front

bearing

No

1

is

the

same

type

a

the

rear

bearing

No

5

d

All

bearings

except

for

No

1

bearing

are

interchangeable

between

upper

and

lower

bear

ings

EM

26

Page 367 of 513

ENGINE

MECHANICAL

3

Apply

engine

oil

to

the

main

bearing

surfaces

on

both

sides

of

the

cylinder

block

and

cap

Install

the

crankshaft

4

Install

the

main

bearing

cap

and

tighten

the

bolts

with

specified

torque

Tightening

torque

5

0

to

6

0

kg

m

36

to

43

ft

lb

Notes

a

Arrange

the

parts

so

that

the

arrow

mark

on

the

bearing

cap

is

faced

toward

the

front

of

the

engine

b

Prior

to

tightening

the

bearing

cap

bolts

place

the

bearing

cap

at

a

proper

position

by

shifting

the

crankshaft

in

the

axial

direction

c

Tighten

the

bearing

cap

bolts

gradually

in

separating

two

to

three

stages

and

outwardly

from

the

center

beari

ng

d

After

securing

the

bearing

cap

bolts

ascertain

that

the

crankshaft

can

be

easily

rotated

5

Make

sure

that

the

crankshaft

end

play

is

correct

Crankshaft

end

play

0

05

to

0

15

rom

0

0020

to

0

0059

in

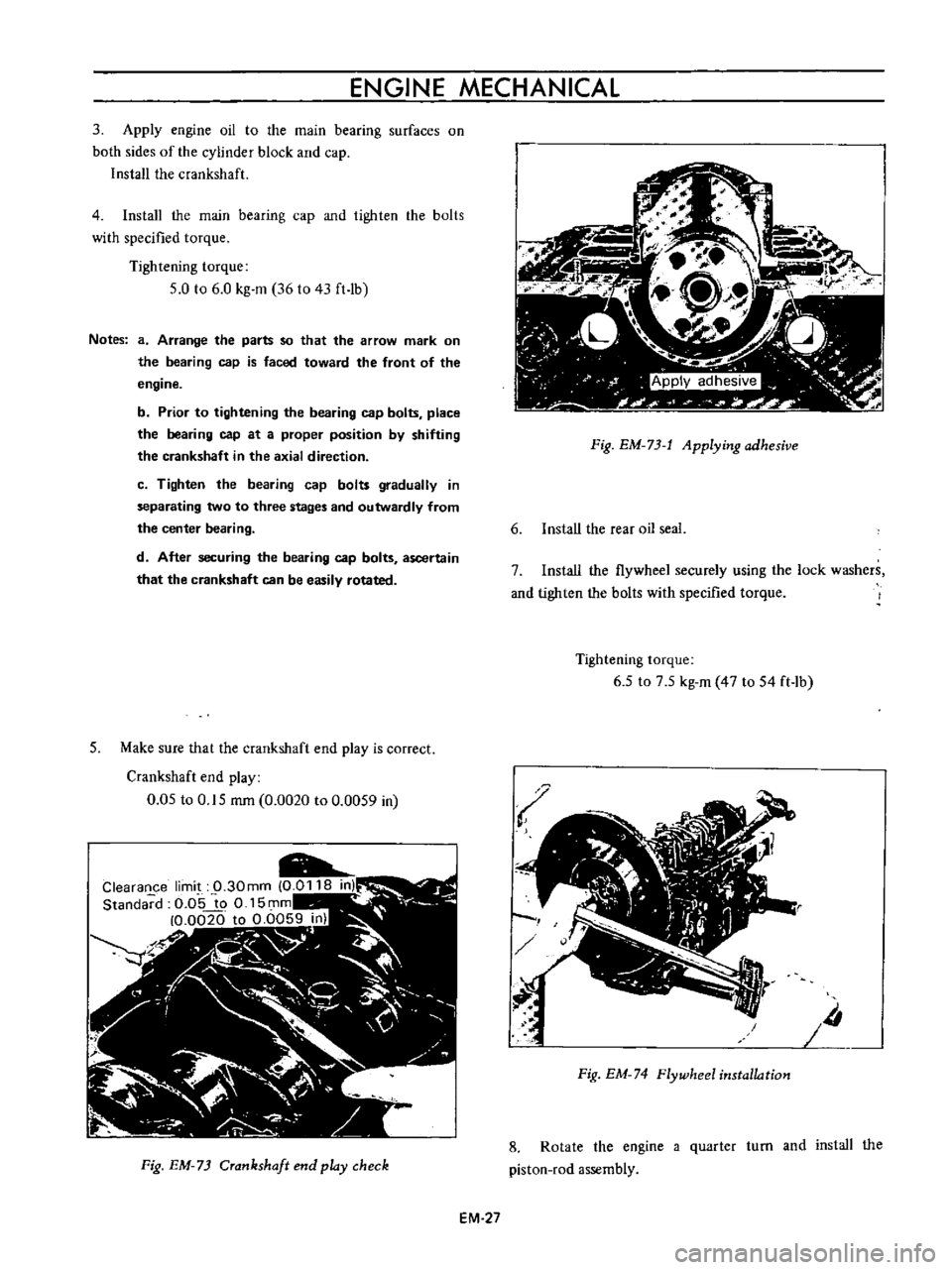

Fig

EM

73

Crankshaft

end

play

check

EM

27

Fig

EM

73

t

Applying

adhesive

6

Install

the

rear

oil

seal

7

Install

the

flywheel

securely

using

the

lock

washers

and

tighten

the

bolts

with

specified

torque

Tightening

torque

6

5

to

7

5

kg

m

47

to

54

ft

lb

Iii

Fig

EM

74

Flywheel

installation

8

Rotate

the

engine

a

quarter

turn

and

install

the

piston

rod

assembly

Page 370 of 513

ENGINE

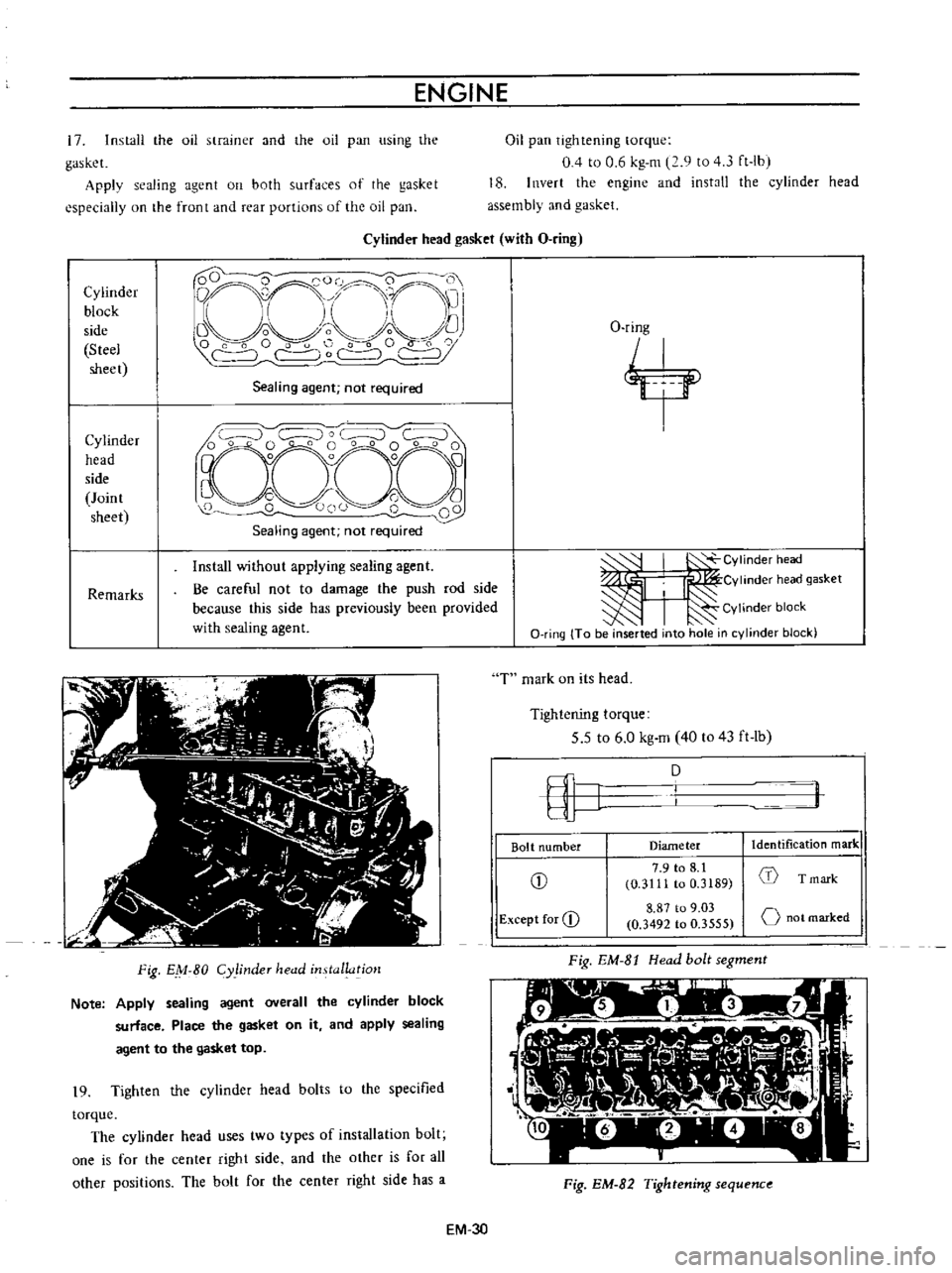

17

Install

the

oil

strainer

and

the

oil

pan

using

the

gasket

Apply

sealing

agent

on

hath

surfaces

of

the

gasket

especially

on

the

front

and

rear

portions

of

the

oil

pan

Oil

pan

tightening

torque

0

4

to

0

6

kg

m

I

9

to

4

3

ft

lbJ

I

R

I

nvcrt

the

engine

and

install

the

cylinder

head

assembly

and

gasket

Cylinder

head

gasket

with

O

ring

Cylinder

block

side

Steel

sheet

D

QCO

0

0

i

O

1

nrr

11

I

Li

I

I

Vo

o

f

C

C

r

c

Sealing

agent

not

required

Cylinder

head

side

Joint

sheet

Remarks

Install

without

applying

sealing

agent

Be

careful

not

to

damage

the

push

rod

side

because

this

side

has

previously

been

provided

with

sealing

agent

Fig

EM

80

Cy

linder

head

installatjo

1

Note

Apply

sealing

agent

overall

the

cylinder

block

surface

Place

the

gasket

on

it

and

apply

sealing

agent

to

the

gasket

top

19

Tighten

the

cylinder

head

bolts

to

the

specified

torque

The

cylinder

head

uses

two

types

of

installation

bolt

one

is

for

the

center

right

side

and

the

other

is

for

all

other

positions

The

bolt

for

the

center

right

side

has

a

O

ring

j

I

Y

J

CYlinder

head

I

I

Cvlinderheadgasket

I

Cylinder

block

O

ring

To

be

inserted

into

hole

in

cylinder

block

T

mark

on

its

head

Tightening

torque

5

5

to

6

0

kg

m

40

to

43

ft

lb

fI

J

D

Bolt

number

Diameter

Identification

mark

CD

7

9

to

8

1

1

0

3111

to

0

3189

T

mark

Except

for

CD

8

87

to

9

03

o

not

marked

0

3492

to

0

3555

Fig

EM

8t

Head

bolt

segment

l

Fig

EM

82

Tightening

sequenc

EM

3D

Page 383 of 513

LUBRICATION

CIRCUIT

Oil

drawn

from

the

oil

pan

through

the

inlet

screen

and

tube

to

the

inlet

side

of

the

oil

pump

is

delivered

by

th

oil

pump

through

the

outlet

portion

of

the

oil

pump

and

the

oil

gallery

to

the

inlet

side

of

the

full

flow

oil

filter

and

to

the

main

oil

gallery

The

main

oil

gallery

supplies

oil

to

the

crankshaft

main

bearings

and

drilled

passages

in

the

crankshaft

and

thus

oil

is

fed

directly

from

the

main

bearings

to

the

connecting

rod

bearings

Oil

injected

from

jet

holes

on

connecting

rods

lubri

cates

the

cylinder

walls

and

pistion

pins

The

oil

distributed

from

the

main

gallery

enters

the

chain

teosioner

and

the

pad

is

held

against

the

chain

by

oil

pressure

and

spring

The

oil

also

lubricates

the

timing

chain

through

the

jet

hole

located

near

the

chain

Furthermore

lubricant

is

supplied

to

each

camshaft

bearing

through

each

crankshaft

main

bearing

and

finally

to

the

011

gallery

in

the

rocker

shaft

through

the

center

camshaft

bearing

The

rocker

arm

and

valve

are

lubricated

by

the

oil

through

the

oil

gallery

in

the

rockershaft

To

this

oil

gallery

lubricant

is

supplied

through

the

center

camshaft

bearing

as

shown

in

Figure

EL

I

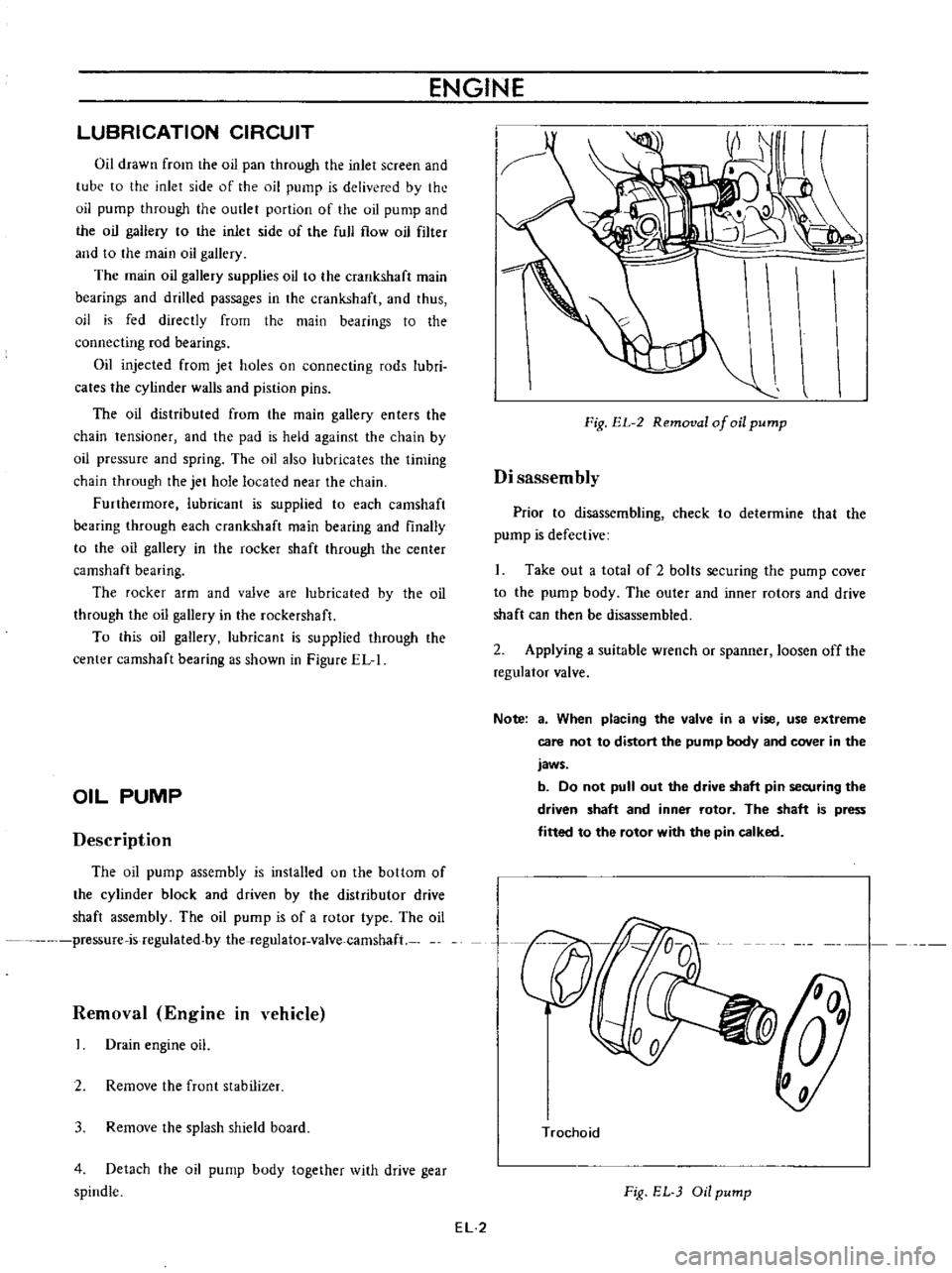

OIL

PUMP

Description

The

oil

pump

assembly

is

installed

on

the

bottom

of

the

cylinder

block

and

driven

by

the

distributor

drive

shaft

assembly

The

oil

pump

is

of

a

rotor

type

The

oil

pressure

is

regulated

by

the

regulator

valve

camshaft

Removal

Engine

in

vehicle

Drain

engine

oil

2

Remove

the

frunt

stabilizer

3

Remove

the

splash

shield

board

4

Detach

the

oil

pump

body

together

with

drive

gear

spindle

ENGINE

Fig

EL

2

Removal

of

oil

pump

Disassembly

Prior

to

disassembling

check

to

determine

that

the

pump

is

defective

Take

out

a

total

of

2

bolts

securing

the

pump

cover

to

the

pump

body

The

outer

and

inner

rotors

and

drive

shaft

can

then

be

disassembled

2

Applying

a

suitable

wrench

or

spanner

loosen

off

the

regulator

valve

Note

a

When

placing

the

valve

in

a

vise

use

extreme

care

not

to

distort

the

pump

body

and

cover

in

the

jaws

b

Do

not

pull

out

the

drive

shaft

pin

securing

the

driven

shaft

and

inner

rotor

The

shaft

is

press

fitted

to

the

rotor

with

the

pin

calked

n

Trochoid

Fig

EL

Oil

pump

EL

2

Page 387 of 513

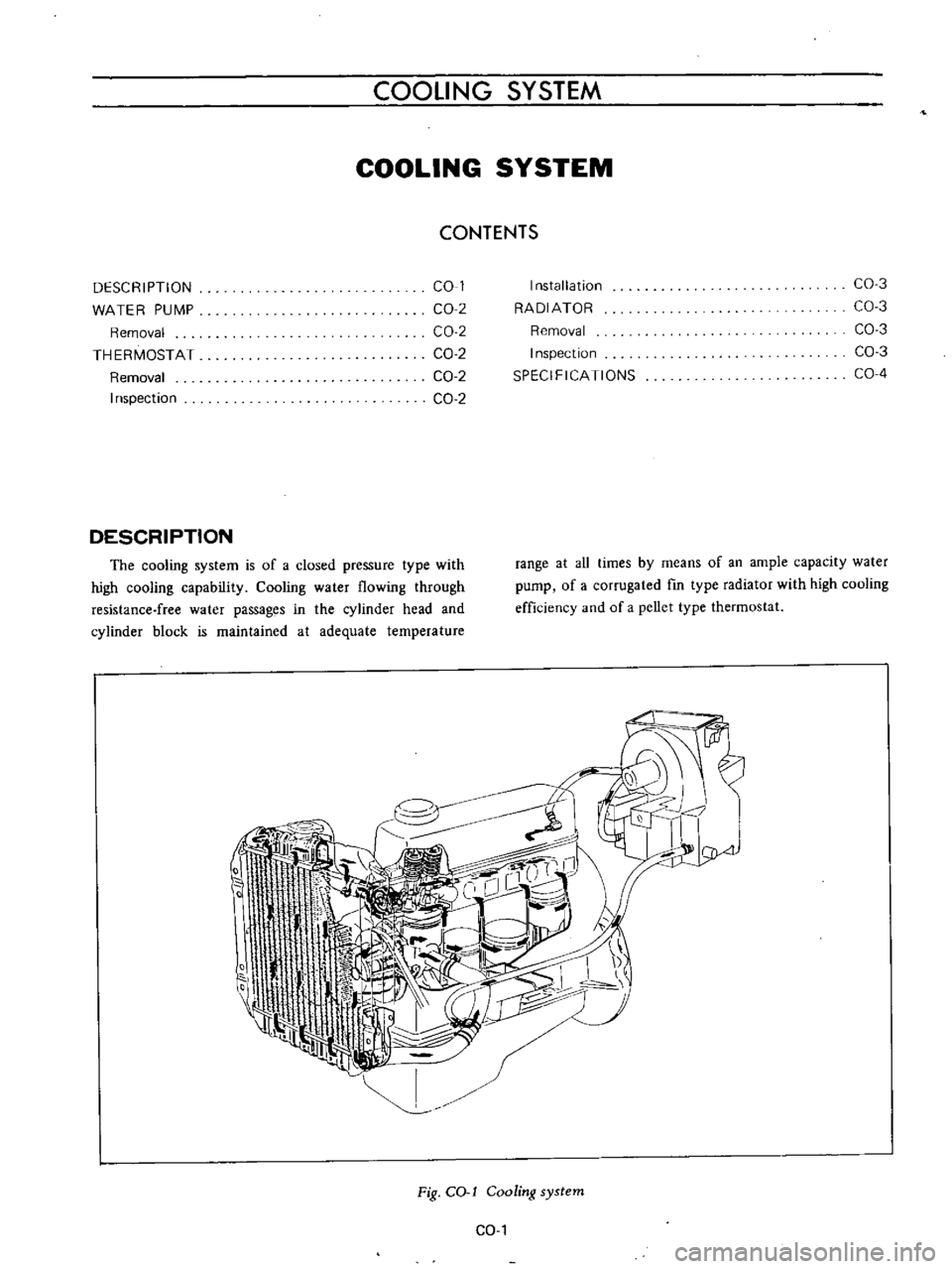

COOLING

SYSTEM

COOLING

SYSTEM

CONTENTS

DESCRIPTION

WATER

PUMP

Removal

THERMOSTAT

Removal

Inspection

CO

1

CO

2

CO

2

CO

2

CO

2

CO

2

DESCRIPTION

The

cooling

system

is

of

a

closed

pressure

type

with

high

cooling

capability

Cooling

water

flowing

through

resistance

free

water

passages

in

the

cylinder

head

and

cylinder

block

is

maintained

at

adequate

temperature

Installation

RADIATOR

Removal

Inspection

SPECIFICATIONS

CO

3

CO

3

CO

3

CO

3

CO

4

range

at

aU

times

by

means

of

an

ample

capacity

water

pump

of

a

corrugated

fm

type

radiator

with

high

cooling

efficiency

and

of

a

pellet

type

thermostat

I

I

I

0

Jrl

oA

Fig

COol

Cooling

system

CO

I

Page 399 of 513

ENGINE

INSPECTION

Check

the

upper

and

lower

bodies

for

cracks

2

Check

the

valve

assembly

for

wear

of

the

valve

and

valve

spring

Blow

the

valve

assembly

by

breath

to

examine

its

function

3

Check

the

diaphragm

for

small

holes

cracks

and

wear

4

Check

the

rocker

arm

for

wear

at

the

portion

in

contact

with

the

camshaft

5

Check

the

rocker

arm

pin

for

wear

since

a

worn

pin

may

cause

oil

leakage

6

Check

all

other

components

for

any

abnormalities

and

replace

with

new

parts

as

required

ASSEMBLY

Assembly

is

done

in

reverse

order

of

disassembly

For

reassembly

and

reinstallation

the

following

matters

should

be

noted

Use

new

gasket

2

Lubricate

the

rocker

arm

link

rocker

arm

pin

and

lever

pin

before

installation

3

To

test

the

function

position

the

fuel

pump

assem

bly

about

I

meter

3

3

ft

above

fuel

level

with

a

pipe

connecting

the

fuel

pump

and

the

fuel

strainer

and

operate

the

rocker

afm

by

hand

If

fuel

is

drawn

up

soon

after

the

rocker

arm

is

released

the

function

of

the

pump

is

satisfactory

CARBURETOR

CONTENTS

DESCRIPTION

STRUCTURE

AND

OPERATION

EF

8

EF

9

EF

10

EF

11

EF

12

EF

12

EF

12

EF

14

EF

14

EF

15

EF

15

EF

16

EF

16

Primary

system

Secondary

system

Anti

dieseling

solenoid

valve

Float

system

Electric

automatic

choke

ADJUSTMENT

Idling

adjustment

Fuel

level

adjustment

Fast

idle

adjustment

Vacuum

break

adjustment

Choke

un

loader

adjustment

DESCRIPTION

The

carburetors

are

of

a

downdraft

type

which

is

designed

and

built

to

increase

power

and

fuel

economy

as

Bi

metal

setting

Adjustment

of

interlock

opening

of

primary

and

secondary

throttle

valves

Dash

pot

adjustment

MAJOR

SERVICE

OPERATIONS

Removal

Disassembly

Cleaning

and

inspection

Assembly

and

installation

JETS

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EF

17

EF

18

EF

18

EF

19

EF

19

EF

19

EF

21

EF

22

EF

22

EF

22

EF

22

well

as

to

reduce

the

emission

of

exhaust

gases

These

carburetors

present

several

distinct

features

of

importance

to

the

car

owners

A

summary

of

features

is

as

follows

EF

8

Page 403 of 513

ENGINE

Step

system

The

construction

of

this

system

corresponds

to

the

idling

and

slow

system

of

the

primary

system

This

system

aims

at

the

power

filling

up

of

the

gap

when

fuel

supply

is

transferred

from

the

primary

system

to

the

secondary

system

The

step

port

is

located

near

the

auxiliary

valve

in

its

fully

closed

state

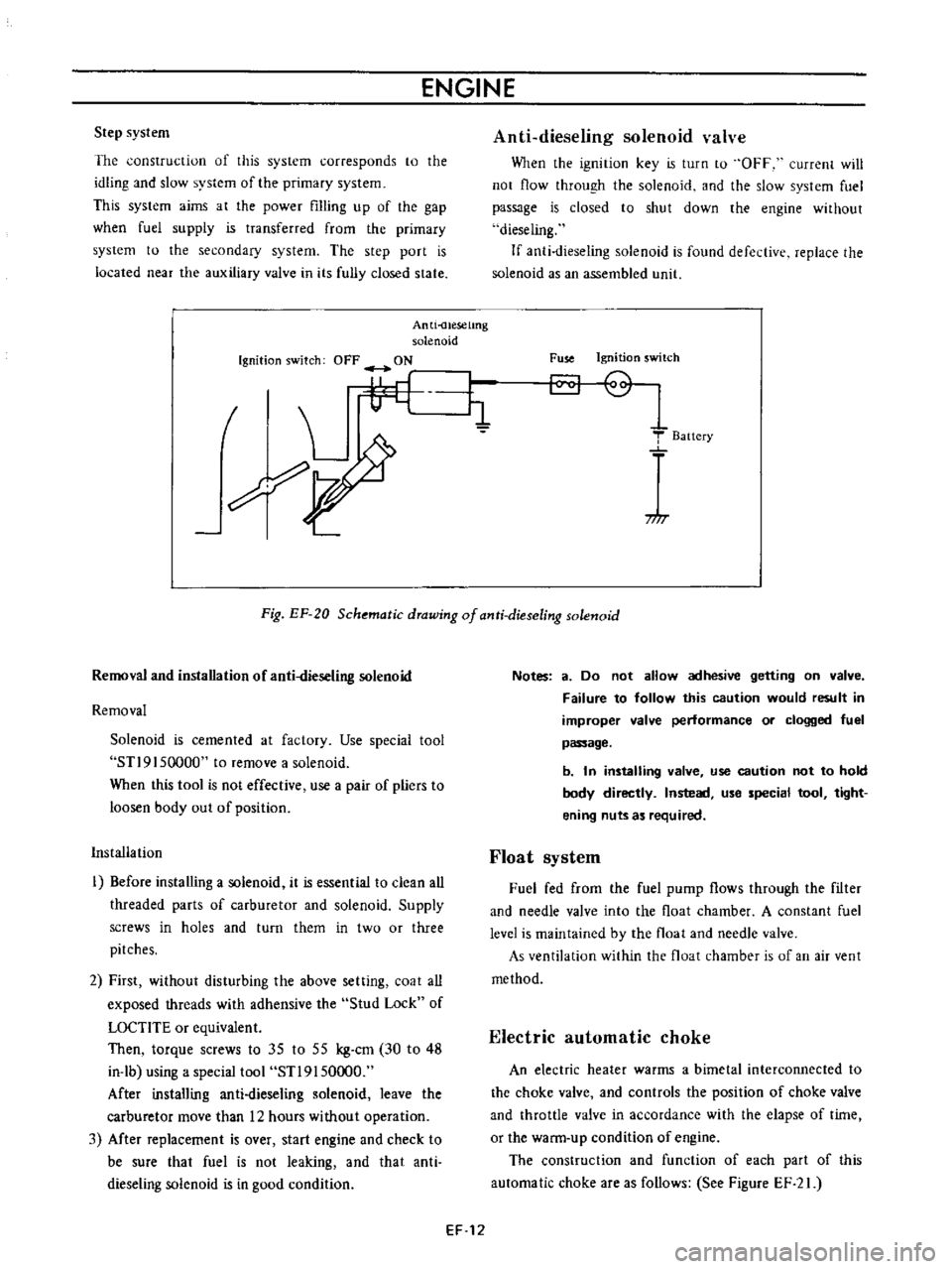

Anti

uesetmg

solenoid

Ignition

switch

OFF

ON

I

L

i1

7

I

Anti

dieseling

solenoid

valve

When

the

ignition

key

is

turn

to

OFF

current

will

not

flow

through

the

solenoid

and

the

slow

system

fuel

passage

is

closed

to

shut

down

the

engine

without

dieseling

If

anti

dieseling

solenoid

is

found

defective

replace

the

solenoid

as

an

assembled

llnit

Fuse

Ignition

switch

T

Baitery

717

Fig

EF

20

Schematic

drawing

of

anti

dieseling

solenoid

Removal

and

installation

of

anti

dieseling

solenoid

Removal

Solenoid

is

cemented

at

factory

Use

special

tool

STl9

I

50000

to

remove

a

solenoid

When

this

tool

is

not

effective

use

a

pair

of

pliers

to

loosen

body

out

of

position

Installation

I

Before

installing

a

solenoid

it

is

essential

to

clean

all

threaded

parts

of

carburetor

and

solenoid

Supply

screws

in

holes

and

turn

them

in

two

or

three

pitches

2

First

without

disturbing

the

above

setting

coat

all

exposed

threads

with

adhensive

the

Stud

Lock

of

LOCTlTE

or

equivalent

Then

torque

screws

to

35

to

55

kg

cm

30

to

48

in

lb

using

a

special

tool

STl9150000

After

installing

anti

dieseling

solenoid

leave

the

carburetor

move

than

12

hours

without

operation

3

Mter

replacement

is

over

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

solenoid

is

in

good

condition

Notes

a

Do

not

allow

adhesive

getting

on

valve

Failure

to

follow

this

caution

would

result

in

improper

valve

performance

or

clogged

fuel

passage

b

In

installing

valve

use

caution

not

to

hold

body

directly

Instead

use

special

tool

tight

ening

nuts

as

required

Float

system

Fuel

fed

from

the

fuel

pump

flows

through

the

filter

and

needle

valve

into

the

float

chamber

A

constant

fuel

level

is

maintained

by

the

float

and

needle

valve

As

ventilation

within

the

float

chamber

is

of

an

air

vent

method

Electric

automatic

choke

An

electric

heater

warms

a

bimetal

interconnected

to

the

choke

valve

and

controls

the

position

of

choke

valve

and

throttle

valve

in

accordance

with

the

elapse

of

time

or

the

warm

up

condition

of

engine

The

construction

and

function

of

each

part

of

this

automatic

choke

are

as

follows

See

Figure

EF

21

EF

12

Page 405 of 513

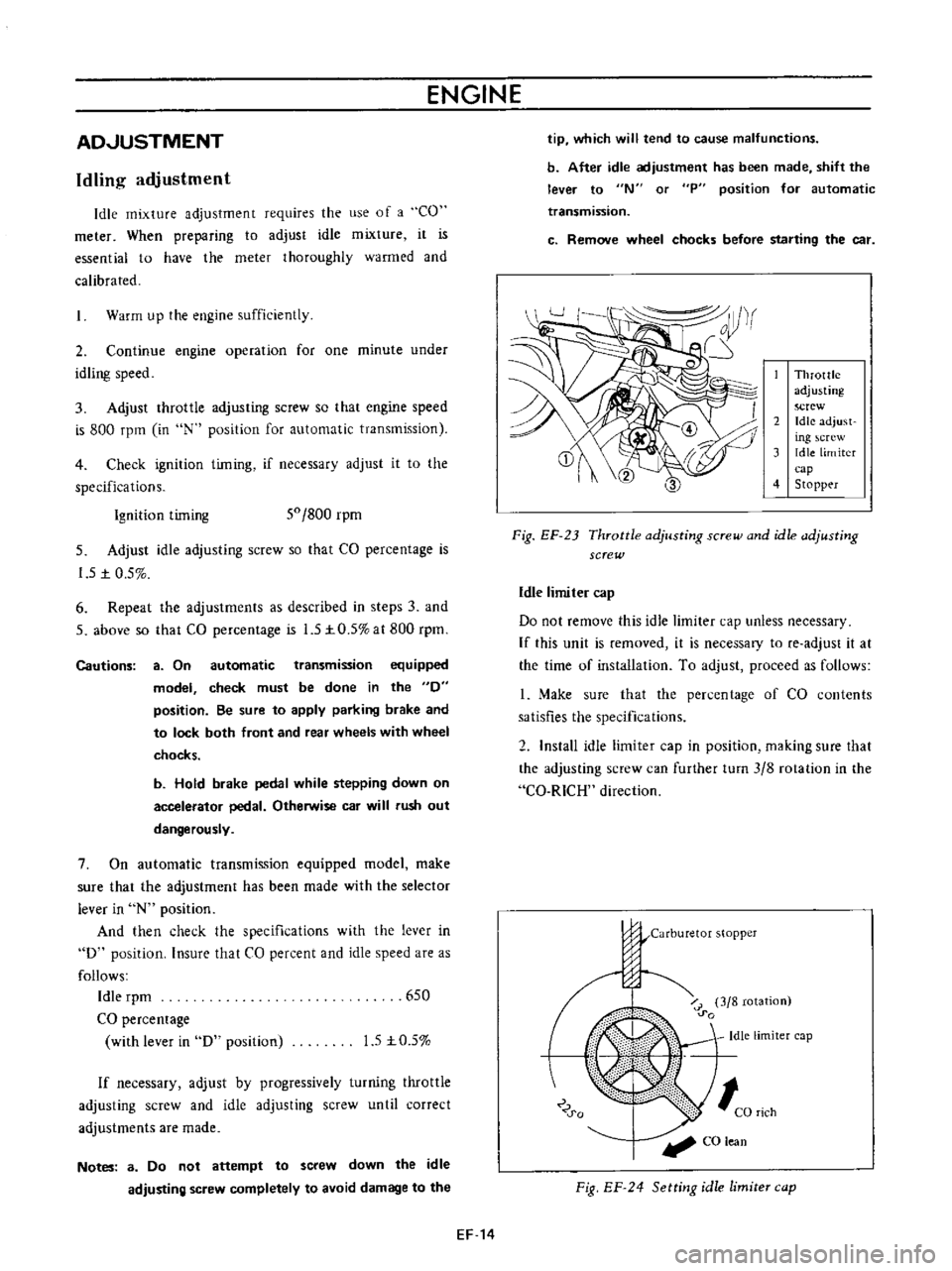

ENGINE

AD

JUSTMENT

Idling

adjustment

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

and

calibrated

Warm

up

the

engine

sufficiently

2

Continue

engine

operation

for

one

minute

under

idling

speed

3

Adjust

throttle

adjusting

screw

so

that

engine

speed

is

800

rpm

in

N

position

for

automatic

transmission

4

Check

ignition

timing

if

necessary

adjust

it

to

the

specifications

Ignition

timing

50

800

rpm

5

Adjust

idle

adjusting

screw

so

that

ca

percentage

is

1

5

t

0

5

6

Repeat

the

adjustments

as

described

in

steps

3

and

5

above

so

that

ca

percentage

is

1

5

to

5

at

800

rpm

Cautions

a

On

automatic

transmission

equipped

model

check

must

be

done

in

the

0

position

Be

sure

to

apply

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Hold

brake

pedal

while

stepping

down

on

accelerator

pedal

Otherwise

car

will

rush

out

dangerously

7

On

automatic

transmission

equipped

model

make

sure

that

the

adjustment

has

been

made

with

the

selector

lever

in

N

position

And

then

check

the

specifications

with

the

lever

in

D

position

Insure

that

CO

percent

and

idle

speed

are

as

follows

Idle

rpm

650

ca

percentage

with

lever

in

D

position

15

to

5

If

necessary

adjust

by

progressively

turning

throttle

adjusting

screw

and

idle

adjusting

screw

until

correct

adjustments

are

made

Notes

a

Do

not

attempt

to

screw

down

the

id

Ie

adjusting

screw

completely

to

avoid

damage

to

the

EF

14

tip

which

will

tend

to

cause

malfunctions

b

After

idle

adjustment

has

been

made

shift

the

lever

to

N

or

p

position

for

automatic

transmission

c

Remove

wheel

chocks

before

starting

the

car

Throttle

adjusting

screw

2

Idle

adjust

ing

crew

3

Idle

limiter

cap

4

Stopp

r

Fig

EF

23

Throttle

adjusting

screw

and

idle

adjusting

screw

Idle

limiter

cap

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

removed

it

is

necessary

to

fe

adjust

it

at

the

time

of

installation

To

adjust

proceed

as

follows

1

Make

sure

that

the

percentage

of

CO

contents

satisfies

the

specifications

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

can

further

turn

3

8

rotation

in

the

Ca

RICH

direction

j

j

Carburetor

stopper

o

u

o

i

r

3

8

rotation

0

0

Idle

limiter

cap

0

0

CO

lean

Fig

EF

24

Setting

idle

limite

cap