lock DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 33 of 513

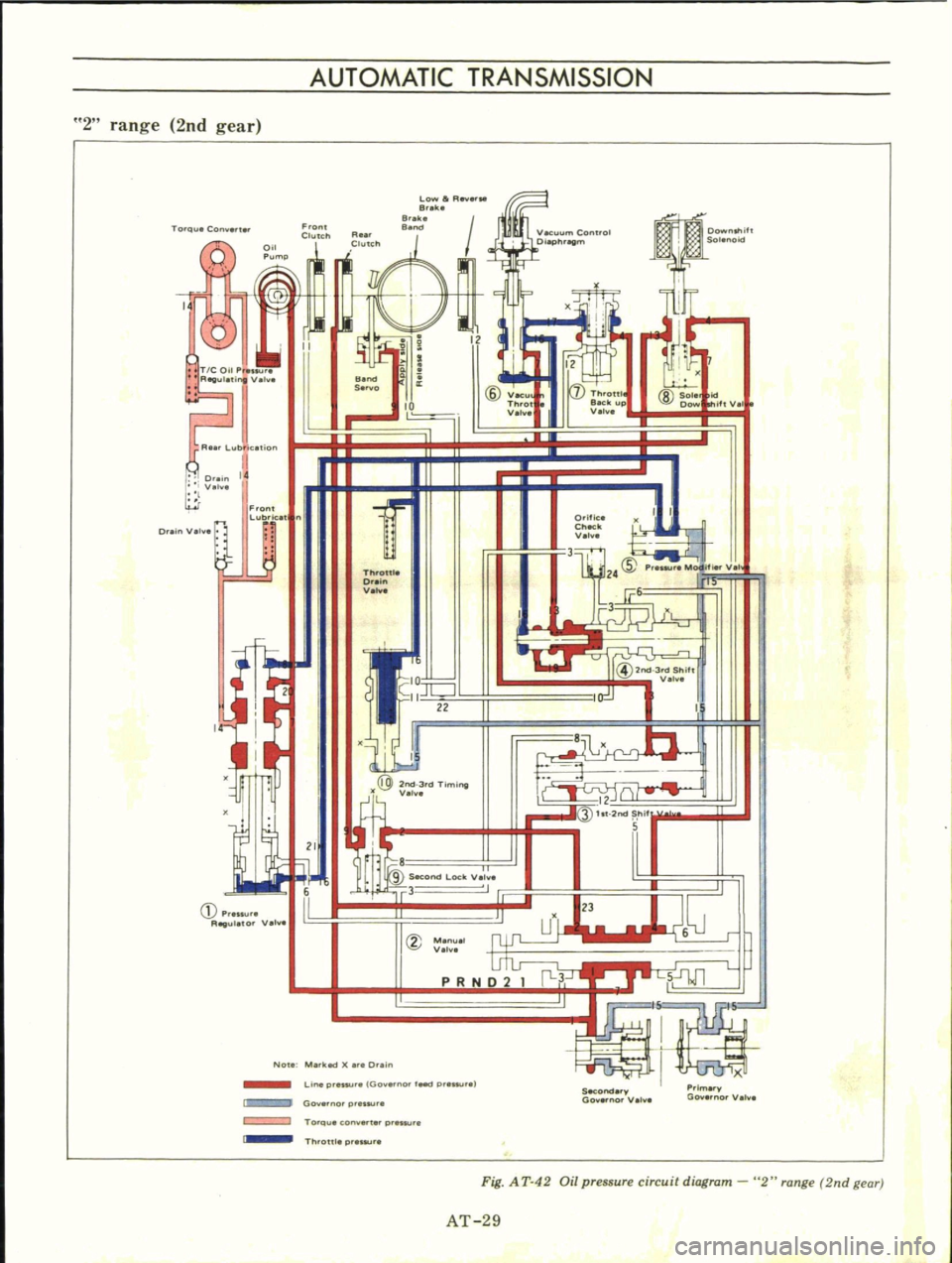

AUTOMATIC

TRANSMISSION

2

range

2nd

gear

To

queCo

Low

a

R

8

ka

8

ke

Oownltlift

Solenoid

14

12

@

VK

Throt

V

I

7

Throttl

Sack

up

V

lv

@SOl

o

if

V

I

Front

Lubrk

n

Orltlc

Ch

k

V

l

Dr

n

V

1

ThroW

Drain

V

Ye

Pt

Mod

fier

V

I

IS

8Rt

@2

3rdTimi

Sl

It

V

12

3

ht

2nd

Sf

ll

5

Secor

d

Lock

V

I

3

I

@

M

nu

l

V

I

5

I1Jl

ill

Pr

ur

R

vulatO

V

I

Note

M

keel

r

D

in

a

P

imary

Go

no

V

h

Line

pr

IGo

no

teed

p

luure

Go

no

p

E2I

B

Ii

iiiIJ

To

c

U

con

t

p

Th

oUl

prn

SecOnda

y

00

0

V

lv

Fig

AT

42

Oil

pressure

circuit

diagram

2

range

2nd

gear

AT

29

Page 34 of 513

CHASSIS

1

range

Low

gear

When

starting

in

I

range

the

driving

gear

is

locked

to

the

low

gear

ratIO

In

1

range

the

reaT

dutch

is

applied

and

the

low

and

reverse

brake

holds

the

connecting

drum

and

rear

planet

carrier

from

rotating

The

power

flow

takes

place

through

the

input

shaft

and

into

the

rear

dutch

Rotation

of

the

rear

clutch

drives

the

rear

clutch

hub

and

front

internal

gear

The

front

internal

gear

rotates

the

front

planetary

gears

clockwise

to

cause

the

sun

gear

to

rotate

counter

clockwise

Counterclockwise

rotation

of

the

sun

gear

turns

the

rear

planetary

gear

clockwise

The

rear

planet

carrier

splined

to

the

connecting

drum

is

held

from

rotating

by

the

low

and

reverse

brake

The

clockwise

rotation

of

the

rear

planetary

gears

therefore

rotates

the

rear

internal

gear

and

internal

drive

tlange

The

internal

drive

tlange

is

splined

to

the

output

shaft

and

rotates

the

output

shaft

clockwise

However

the

output

shaft

rotates

at

a

lower

speed

compared

with

that

of

the

input

shaft

This

is

caused

by

the

fact

that

the

front

planet

carrier

rotates

at

the

same

speed

as

the

output

shaft

in

the

same

direction

since

the

carrier

is

splined

to

the

output

shaft

The

front

internal

gear

and

planetary

gear

as

sembly

are

rotating

in

the

same

direc

tion

but

the

planet

carrier

is

rotating

at

a

speed

slower

than

the

ring

gear

So

the

gear

ratio

of

this

speed

range

is

a

combination

of

the

ratios

provided

by

the

front

and

rear

planetary

gear

a

semblies

When

the

manual

valve

CV

is

posi

tioned

at

I

the

line

pressure

7

is

applied

into

the

line

pressure

circuits

I

4

and

5

The

oil

pressure

in

5

actuates

the

low

and

reverse

brake

after

being

introduced

into

the

circuit

12

through

the

lst

2nd

shift

valve

@

and

the

line

pressure

I

acts

on

i

C

AT076

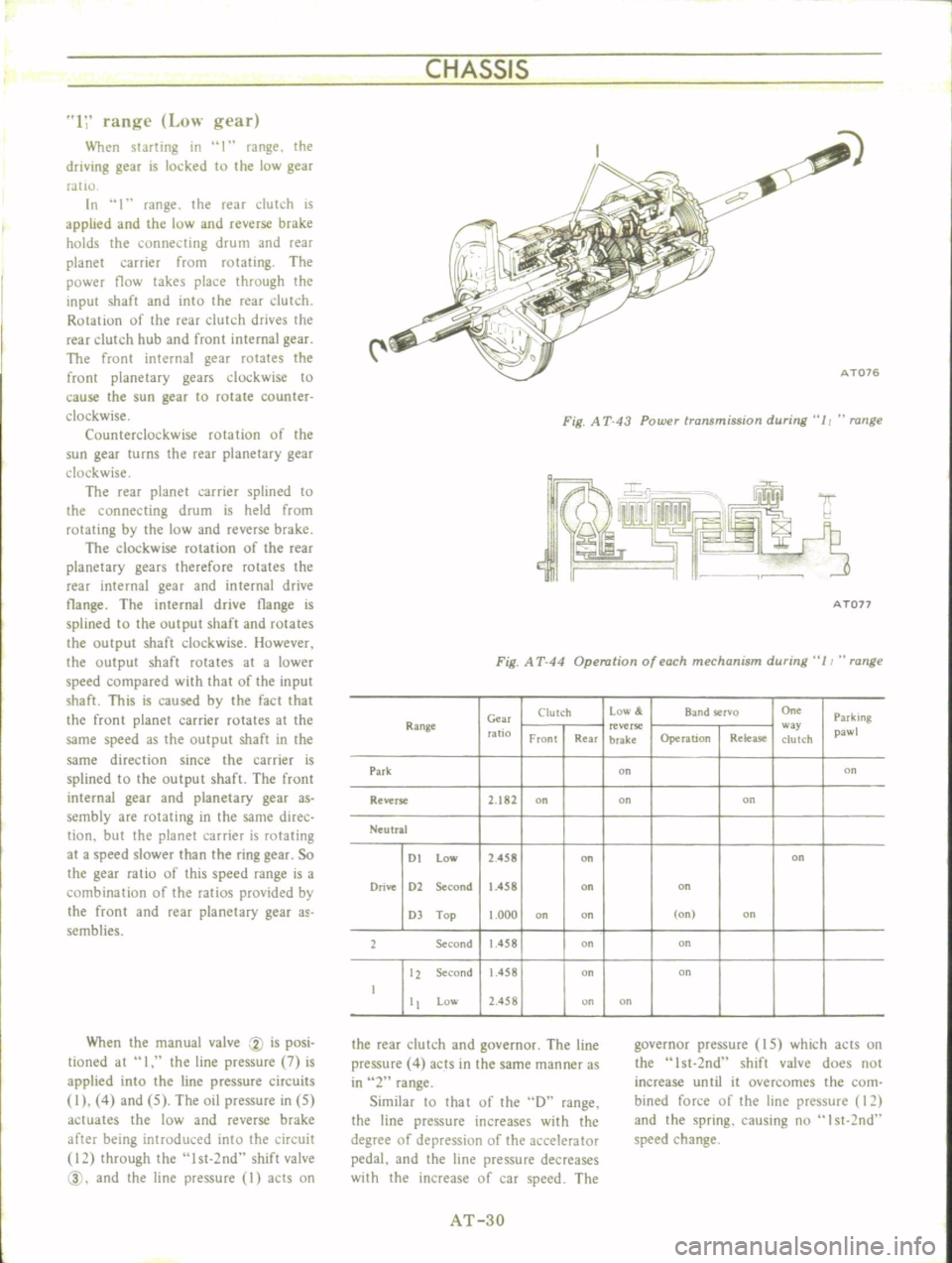

Fig

A

T

43

Power

transmission

during

11

range

A

Ton

Fig

A

T

44

Operation

of

each

mechanism

during

11

range

Clutch

Low

Band

rvo

On

Parking

Range

Gm

ratio

reverse

w

pawl

Front

Rear

brake

Operation

Release

clutch

Park

on

on

Reverse

2

182

on

on

on

Neutral

DI

low

2

458

on

on

Drive

D2

Second

1

458

on

on

D

Top

1

000

on

on

on

on

2

Second

1

458

on

on

12

Second

1

458

on

on

I

Low

2

458

on

on

the

rear

clutch

and

governor

The

line

pressure

4

acts

in

the

same

manner

as

in

2

range

Similar

10

that

of

the

D

range

the

line

pressure

increases

with

the

degree

of

depressiun

of

the

accelerator

pedal

and

the

line

pressure

decreases

with

the

increase

of

car

speed

The

governor

pressure

IS

which

acts

on

the

Ist

2nd

shift

valve

does

not

increase

until

it

overcomes

the

com

bined

force

of

the

line

pressure

12

and

the

spring

causing

nu

I

st

2nd

speed

change

AT

3D

Page 37 of 513

AUTOMATIC

TRANSMISSION

REMOVAL

AND

INSTAllATION

TRANSMISSION

ASSEMBLY

Removal

Installation

TRANSMISSION

ASSEMBLY

When

dismounting

the

automatic

transmission

from

a

vehicle

pay

at

tention

to

the

following

points

1

Before

dismounting

the

trans

mission

rigidly

inspect

it

by

aid

of

the

Troubleshooting

Chart

and

dis

mount

it

only

when

considered

to

be

necessary

2

Dismount

the

transmission

with

utmost

care

and

when

mounting

observe

the

tightening

torque

indi

cated

on

another

table

not

to

exert

excessive

force

Removal

In

dismounting

automatic

transmis

sion

from

vehicle

proceed

as

follows

i

Disconnect

battery

ground

cable

from

terminal

2

Jack

up

car

and

support

its

weight

on

safety

stands

Recommend

a

hydraulic

hoist

or

open

pit

be

utilized

if

available

Make

sure

that

safety

is

insured

3

Remove

propeller

shaft

Note

Plug

up

the

opening

in

the

rear

extension

to

prevent

oil

from

flowing

out

4

Disconnect

front

exhaust

tube

5

Disconnect

selector

range

lever

from

manual

shaft

6

Disconnect

wire

connections

at

inhibitor

switch

CONTENTS

AT

33

AT

33

AT

33

TRANSMISSION

CONTROL

LINKAGE

Removal

and

installation

Adjustment

AT

35

AT

36

AT

36

7

Disconnect

vacuum

tube

from

vacuum

diaphragm

and

wire

connec

tions

at

downshift

solenoid

8

Disconnect

speedometer

cable

from

rear

extension

9

Disconnect

oil

charging

pipe

10

Support

engine

by

locating

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

Support

transmission

by

means

of

3

transmission

jack

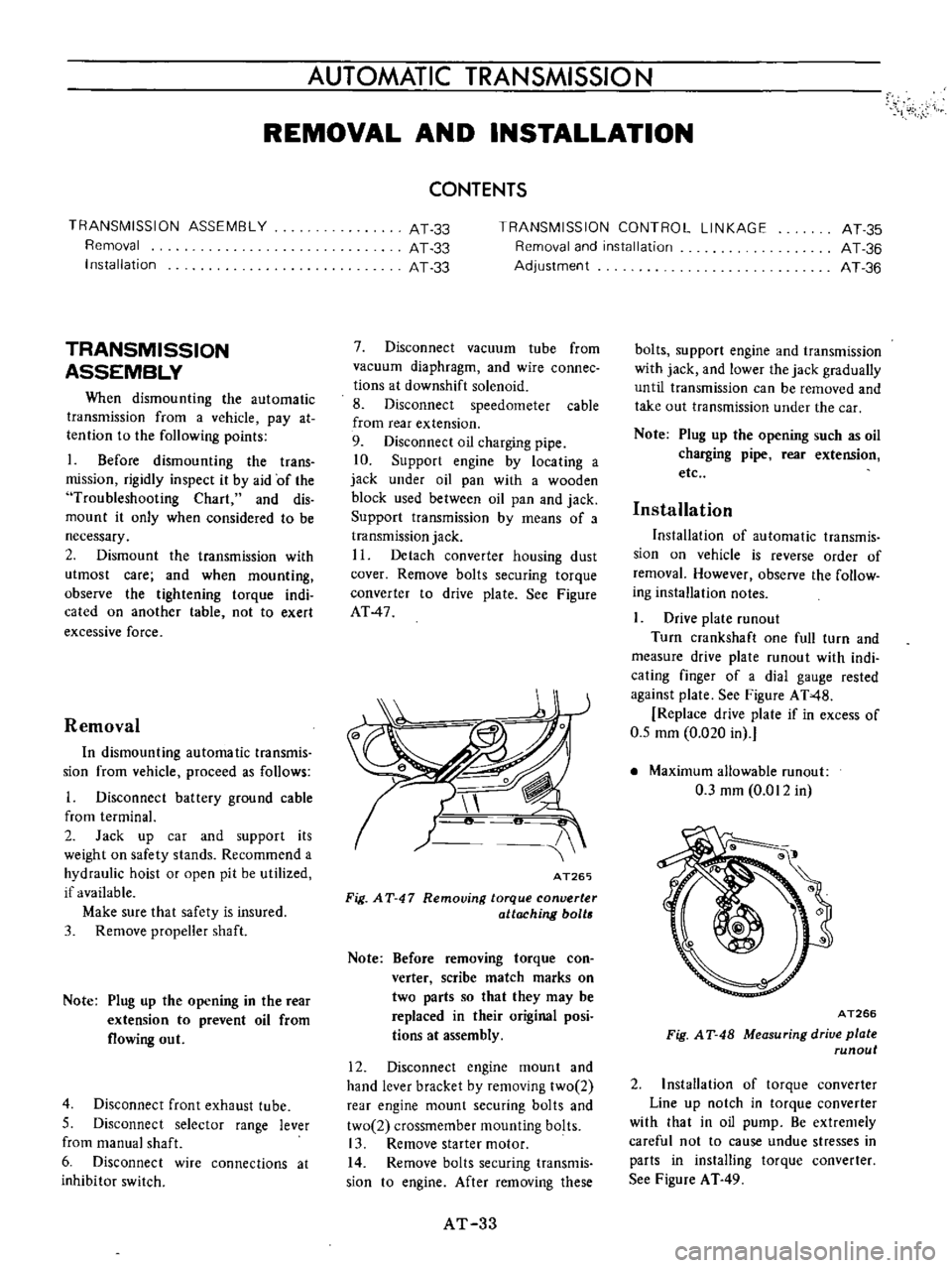

11

Detach

converter

housing

dust

cover

Remove

bolts

securing

torque

converter

to

drive

plate

See

Figure

AT

47

AT265

Fig

AT

47

Removing

torque

converter

attaching

bolt

Note

Before

removing

torque

con

verter

scribe

match

marks

on

two

parts

so

that

they

may

be

replaced

in

their

original

posi

tions

at

assembly

12

Disconnect

engine

moun

t

and

hand

lever

bracket

by

removing

two

2

rear

engine

mount

securing

bolts

and

two

2

crossmember

mounting

bolts

13

Remove

starter

motor

14

Remove

bolts

securing

transmis

sion

to

engine

After

removing

these

AT

33

bolts

support

engine

and

transmission

with

jack

and

lower

the

jack

gradually

until

transmission

can

be

removed

and

take

out

transmission

under

the

car

Note

Plug

up

the

opening

such

as

oil

charging

pipe

rear

extension

etc

Installation

Installation

of

automatic

transmis

sion

on

vehicle

is

reverse

order

of

removal

However

observe

the

follow

ing

installation

notes

Drive

plate

mnout

Turn

crankshaft

one

full

turn

and

measure

drive

plate

mnou

t

with

indi

cating

finger

of

a

dial

gauge

rested

against

plate

See

Figure

AT48

Replace

drive

plate

if

in

excess

of

0

5

mm

0

020

in

Maximum

allowable

mnout

0

3

mm

0

012

in

A

T266

Fig

A

T

48

Measuring

drive

plate

runout

2

Installation

of

torque

converter

Line

up

notch

in

torque

converter

with

that

in

oil

pump

Be

extremely

careful

not

to

cause

undue

stresses

in

parts

in

installing

torque

converter

See

Figure

A

T

49

Page 42 of 513

I

J

It

r

I

x

f

Fig

AT

54

Remouing

valve

body

tt

l

v

AT121

Fig

A

T

55

Loosening

band

en

a

Fig

AT

56

Removing

oil

pump

AT123

Fig

A

T

5

7

Removing

band

strut

Fig

A

T

SS

Removing

connecting

shell

CHASSIS

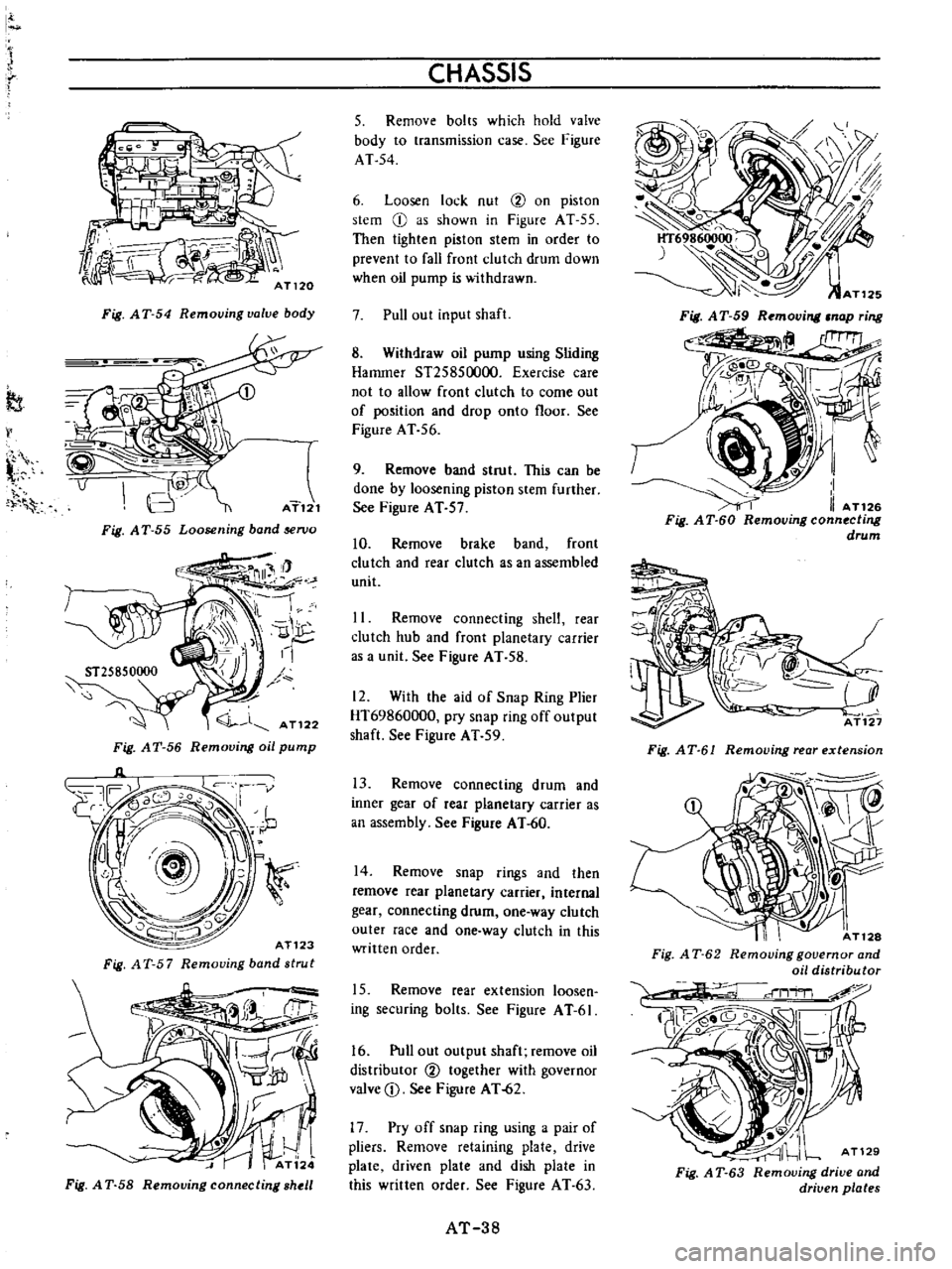

5

Remove

bolts

which

hold

valve

body

to

transmission

case

See

Figure

AT

54

6

Loosen

lock

nut

2

on

piston

stem

CI

as

shown

in

Figure

AT

55

Then

tighten

piston

stem

in

order

to

prevent

to

fall

front

clutch

drum

down

when

oil

pump

is

withdrawn

7

Pull

out

input

shaft

8

Withdraw

oil

pump

using

Sliding

Hammer

S125850000

Exercise

care

not

to

allow

front

clutch

to

come

out

of

position

and

drop

onto

floor

See

Figure

AT

56

9

Remove

band

strut

This

can

be

done

by

loosening

piston

stem

further

See

Figure

AT

57

10

Remove

brake

band

front

clutch

and

rear

clutch

as

an

assembled

unit

11

Remove

connecting

shelt

rear

clutch

hub

and

front

planetary

carrier

as

a

unit

See

Figure

AT

58

12

With

the

aid

of

Snap

Ring

Plier

HT69860000

pry

snap

ring

off

output

shaft

See

Figure

AT

59

13

Remove

connecting

drum

and

inner

gear

of

rear

planetary

carrier

as

an

assembly

See

Figure

AT

60

14

Remove

snap

rings

and

then

remove

rear

planetary

carrier

internal

gear

connecting

drum

one

way

clutch

outer

race

and

one

way

clutch

in

this

written

order

15

Remove

rear

extension

loosen

ing

securing

bolts

See

Figure

A

T

6I

16

Pull

out

output

shaft

remove

oil

distriburor

2

together

with

governor

valve

D

See

Figure

AT

62

17

Pry

off

snap

ring

using

a

pair

of

pliers

Remove

retaining

plate

drive

plate

driven

plate

and

dish

plate

in

this

written

order

See

Figure

AT

63

AT

38

Fig

AT

61

Removing

rear

extension

I

AT128

Fig

A

T

62

Removing

governor

and

oil

distributor

AT129

Fig

A

T

63

Removing

drive

and

driven

plates

Page 43 of 513

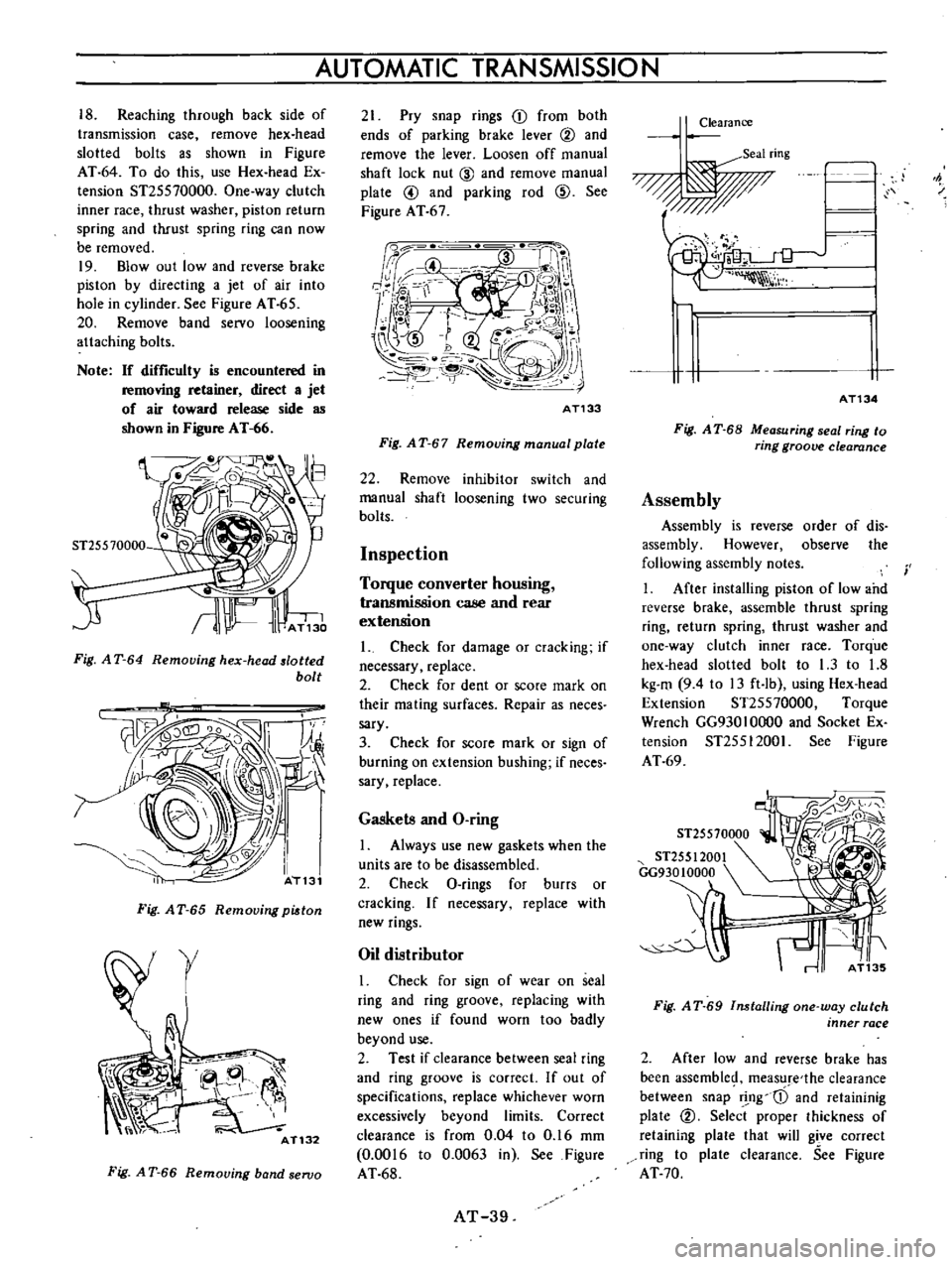

18

Reaching

through

back

side

of

transmission

case

remove

hex

head

slotted

bolts

as

shown

in

Figure

AT

64

To

do

this

use

Hex

head

Ex

tension

ST25570000

One

way

clutch

inner

race

thrust

washer

piston

return

spring

and

thrust

spring

ring

can

now

be

removed

19

Blowout

low

and

reverse

brake

piston

by

directing

a

jet

of

air

into

hole

in

cylinder

See

Figure

A

T

65

20

Remove

band

servo

loosening

attaching

bolts

Note

If

difficulty

is

encountered

in

removIng

retainer

direct

a

jet

of

air

toward

release

side

as

shown

in

Figure

AT

66

ST25570000

Fig

A

T

64

Removing

hex

head

lotted

bolt

Fig

A

T

65

Removing

pi

ton

r

AT132

Fig

A

T

66

Removing

band

seroo

AUTOMATIC

TRANSMISSION

21

Pry

snap

rings

CD

from

both

ends

of

parking

brake

lever

@

and

remove

the

lever

Loosen

off

manual

shaft

lock

nut

CID

and

remove

manual

plate

@

and

parking

rod

@

See

Figure

AT

67

Qd

i

f

W

II

4

i

n

n

r

1

K

j

e

0

H

o

i

j

j

I

j

l

m

r

JlII

2

U

r

K

F

J

r

0

f

1

r

AT133

Fig

A

T

67

Removing

manual

plate

22

Remove

inhibitor

switch

and

manual

shaft

loosening

two

securing

bolts

Inspection

Torque

converter

housing

transmission

case

and

rear

extension

1

Check

for

damage

or

cracking

if

necessary

replace

2

Check

for

dent

or

score

mark

on

their

mating

surfaces

Repair

as

neees

sary

3

Check

for

score

mark

or

sign

of

burning

on

extension

bushing

if

neces

sary

replace

Gaskets

and

O

ring

1

Always

use

new

gaskets

when

the

units

are

to

be

disassembled

2

Check

O

rings

for

burrs

or

cracking

If

necessary

replace

with

new

rings

Oil

distributor

I

Check

for

sign

of

wear

on

seal

ring

and

ring

groove

replacing

with

new

ones

if

found

worn

too

badly

beyond

use

2

Test

if

clearance

between

seal

ring

and

ring

groove

is

correct

If

out

of

specifications

replace

whichever

worn

excessively

beyond

limits

Correct

clearance

is

from

0

04

to

0

16

mm

0

0016

to

0

0063

in

See

Figure

AT

68

AT

39

Clearance

Seal

ring

F

1

I

i

h

AT134

Fig

A

T

68

Measuring

seal

ring

to

ring

groove

clearance

Assembly

Assembly

is

reverse

order

of

dis

assembly

However

observe

the

following

assembly

notes

1

After

installing

piston

of

low

and

reverse

brake

assemble

thrust

spring

ring

return

spring

thrust

washer

and

one

way

clutch

inner

race

Torque

hex

head

slotted

bolt

to

1

3

to

1

8

kg

m

94

to

13

ft

Ib

using

Hex

head

Extension

ST25570000

Torque

Wrench

GG930

1

0000

and

Socket

Ex

tension

ST25512001

See

Figure

AT

69

i

ST25570000

ST255

1

2001

GG93010000

0

rr

l

f

r

Fig

A

T

69

Installing

one

way

clutch

inner

race

2

After

low

and

reverse

brake

has

been

assemble

measure

the

clearance

between

snap

r

ng

cD

and

retaininig

plate

@

Select

proper

thickness

of

retaining

plate

that

will

gi

ve

correct

ring

to

plate

clearance

See

Figure

AT

70

Page 44 of 513

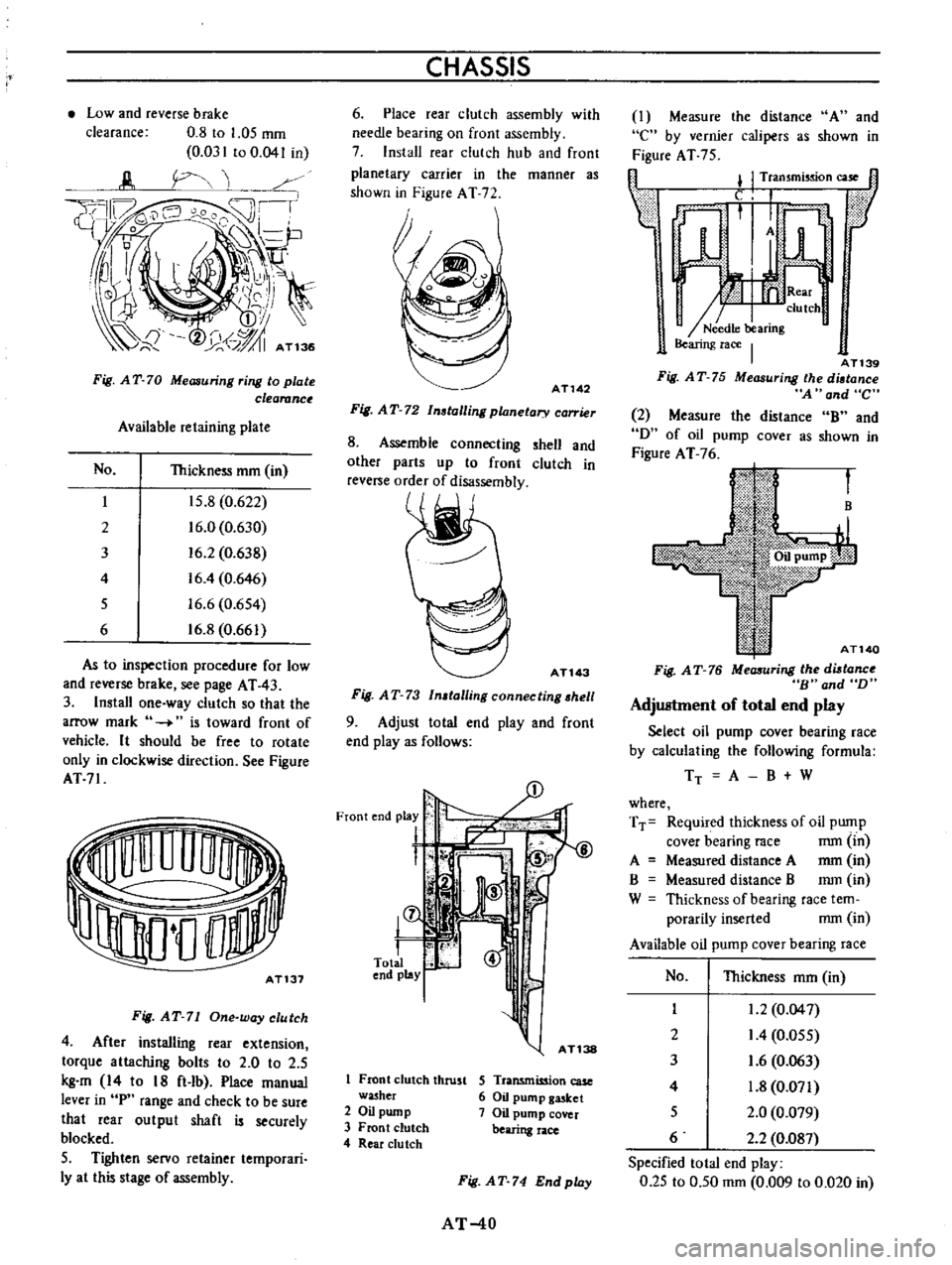

Low

and

reverse

brake

clearance

0

8

to

1

05

mm

0

031

to

0

041

in

Fig

AT

70

Measuring

ring

to

plate

clearanc

Available

retaining

plate

No

Thickness

mm

in

I

15

8

0

622

2

16

0

0

630

3

16

2

0

638

4

16

4

0

646

5

16

6

0

654

6

16

8

0

661

As

to

inspection

procedure

for

low

and

reverse

brake

see

page

AT

43

3

Install

one

way

clutch

so

that

the

arrow

mark

is

toward

front

of

vehicle

It

should

be

free

to

rotate

only

in

clockwise

direction

See

Figure

AT71

AT131

Fig

AT

71

One

way

clutch

4

After

installing

rear

extension

torque

attaching

bolts

to

2

0

to

2

5

kg

m

14

to

18

ft

lb

Place

manual

lever

in

P

range

and

check

to

be

sure

that

rear

output

shaft

is

securely

blocked

5

Tighten

servo

retainer

temporari

Iy

at

this

stage

of

assembly

CHASSIS

6

Place

rear

clutch

assembly

with

needle

bearing

on

front

assembly

7

Install

rear

clutch

hub

and

front

planetary

carrier

in

the

manner

as

shown

in

Figure

AT

72

AT142

Fig

AT

72

Installing

planetary

carrier

8

Assemble

connecting

shell

and

other

parts

up

to

front

clutch

in

reve

e

order

of

disassembly

ATl43

Fig

AT

73

In

talling

connecting

hell

9

Adjust

total

end

play

and

front

end

playas

follows

L

@

8

S

I

fT

15

l

r

1

Front

clutch

thrust

washer

2

Oil

pump

3

Front

clutch

4

Rear

du

tch

S

Transmission

case

6

Oil

pump

gasket

7

Oil

pump

cover

bearing

race

Fig

AT

74

Endplay

AT

40

I

Measure

the

distance

A

and

e

by

vernier

calipers

as

shown

in

Figure

AT

75

fl

l

I

Transmission

case

1l

Lf

ar

n

h

AT139

Fig

AT

75

Measuring

the

diltance

A

and

C

2

Measure

the

distance

B

and

D

of

oil

pump

COVer

as

shown

in

Figure

AT

76

B

AT140

Fig

AT

76

MeaJIuring

the

diltanc

B

and

D

Adjustment

of

total

end

play

Select

oil

pump

cover

bearing

race

by

calculating

the

following

formula

TT

A

B

W

where

TT

Required

thickness

of

oil

pump

cover

bearing

race

mm

in

A

Measured

distance

A

mm

in

B

Measured

distance

B

mm

in

W

Thickness

of

bearing

race

tem

porarily

inserted

mm

in

Available

oil

pump

cover

bearing

race

No

Thickness

mm

in

I

1

2

0

04

7

2

I

4

0

055

3

1

6

0

063

4

1

8

0

071

5

2

0

0

079

6

2

2

0

087

Specified

total

end

play

0

25

to

0

50

mm

0

009

to

0

020

in

Page 45 of 513

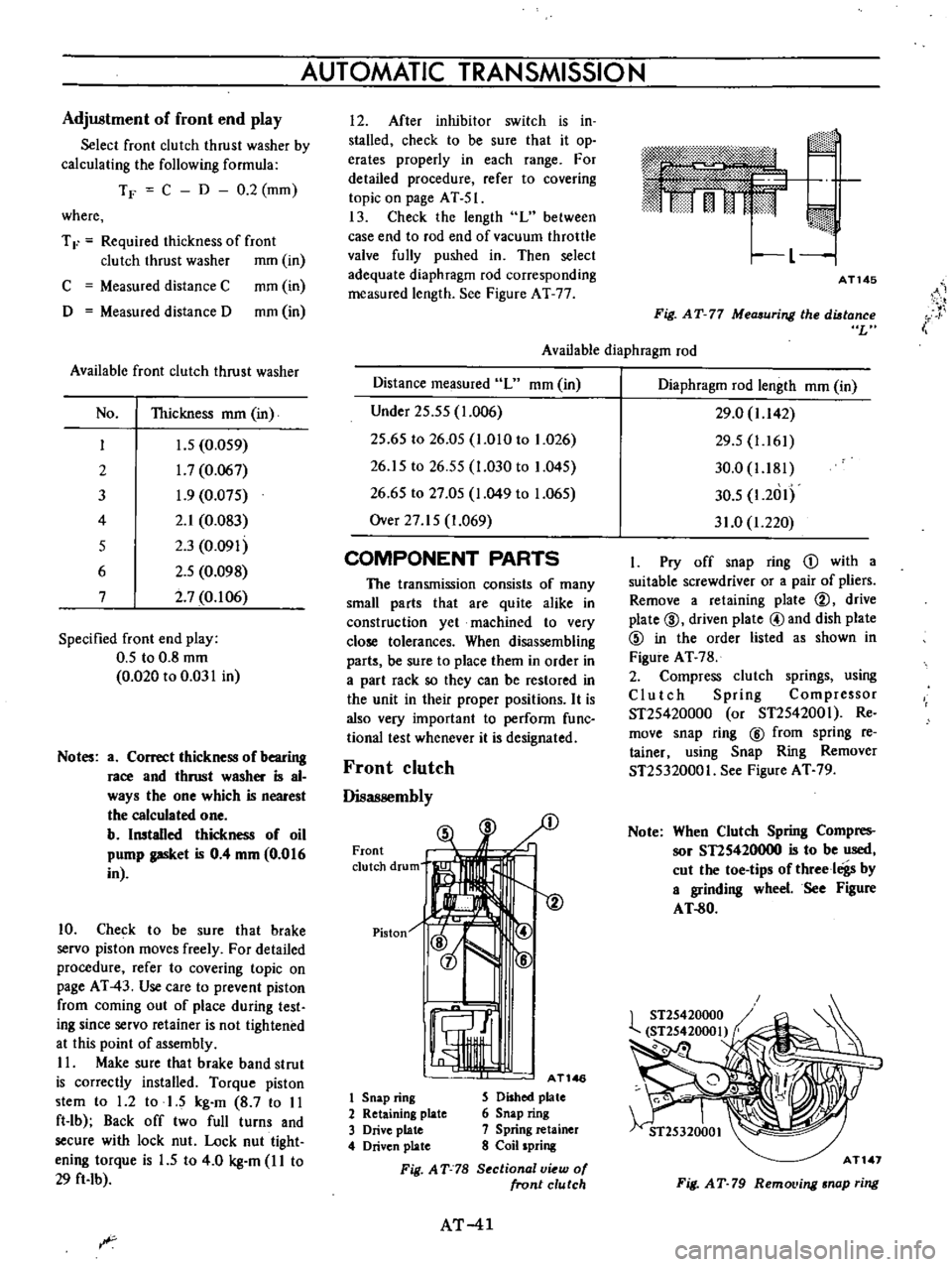

Adjustment

of

front

end

play

Select

front

clutch

thrust

washer

by

calculating

the

following

formula

TF

C

D

0

2

mm

where

T

F

Required

thickness

of

front

clutch

thrust

washer

mm

in

C

Measured

distance

C

mm

in

D

Measured

distance

D

mm

in

Available

front

clutch

thrust

washer

No

Thickness

mm

in

I

J

5

0

059

2

1

7

0

067

3

1

9

0

075

4

2

1

0

083

5

2

3

0

091

6

2

5

0

098

7

2

7

0

106

Specified

front

end

play

0

5

to

0

8

mm

0

020

to

0

031

in

Notes

a

Correct

thickness

of

bearing

race

and

thrust

washer

is

al

ways

the

one

which

is

nearest

the

calculated

one

b

Installed

thickness

of

oil

pump

gasket

is

0

4

mm

0

016

in

10

Check

to

be

sure

that

brake

servo

piston

moves

freely

For

detailed

procedure

refer

to

covering

topic

on

page

AT

43

Use

care

to

prevent

piston

from

coming

out

of

place

during

test

ing

since

servo

retainer

is

not

tightened

at

this

point

of

assembly

II

Make

sure

that

brake

band

strut

is

correctly

installed

Torque

piston

stem

to

1

2

to

1

5

kg

m

8

7

to

II

ft

lb

Back

off

two

full

turns

and

secure

with

lock

nut

Lock

nut

tight

ening

torque

is

1

5

to

4

0

kg

m

I

I

to

29

ft

Ib

AUTOMATIC

TRANSMISSION

I

2

After

inhibitor

switch

is

in

stalled

check

to

be

sure

that

it

op

erates

properly

in

each

range

For

detailed

procedure

refer

to

covering

topic

on

page

AT

51

13

Check

the

length

L

between

case

end

to

rod

end

of

vacuum

throttle

valve

fully

pushed

in

Then

select

adequate

diaphragm

rod

corresponding

measured

length

See

Figure

AT

77

m

rj

I

L

1

AT145

i

Fig

AT

77

Measuring

the

distance

L

Available

diaphragm

rod

Distance

measured

L

mm

in

Under

25

55

1

006

25

65

to

26

05

1

010

to

1

026

26

15

to

26

55

1

030

to

1

045

26

65

to

27

05

1

049

to

1

065

Over

27

15

1

069

COMPONENT

PARTS

The

transmission

consists

of

many

small

parts

that

are

quite

alike

in

construction

yet

machined

to

very

close

tolerances

When

disassembling

parts

be

sure

to

place

them

in

order

in

a

part

rack

so

they

can

be

restored

in

the

unit

in

their

proper

positions

It

is

also

very

important

to

perform

func

tional

test

whenever

it

is

designated

Front

clutch

Disassembly

Front

clutch

drum

Piston

1

AT146

1

Snap

ring

S

Dished

plate

2

Retaining

plate

6

Snap

ring

3

Drive

plate

7

Spring

retainer

4

Driven

plate

8

Coil

spring

Fig

AT

78

S

ctional

v

w

of

front

clutch

AT

41

Diaphragm

rod

length

mm

in

29

0

1

142

29

5

1

161

30

0

1

181

30

5

1

2

1I

31

0

1

220

I

Pry

off

snap

ring

D

with

a

suitable

screwdriver

or

a

pair

of

pliers

Remove

a

retaining

plate

@

drive

plate

@

driven

plate

@and

dish

plate

@

in

the

order

listed

as

shown

in

Figure

AT

78

2

Compress

clutch

springs

using

Clutch

Spring

Compressor

ST25420000

or

ST2542001

Re

move

snap

ring

@

from

spring

re

tainer

using

Snap

Ring

Remover

ST25320001

See

Figure

AT

79

Note

When

Clutch

Spring

Compres

sor

STIS420000

is

to

be

used

cut

the

toe

tips

of

threeloigs

by

a

grinding

wheel

See

Figure

AT

80

AT

1

Fig

AT

79

RemoL

ing

snap

ring

Page 50 of 513

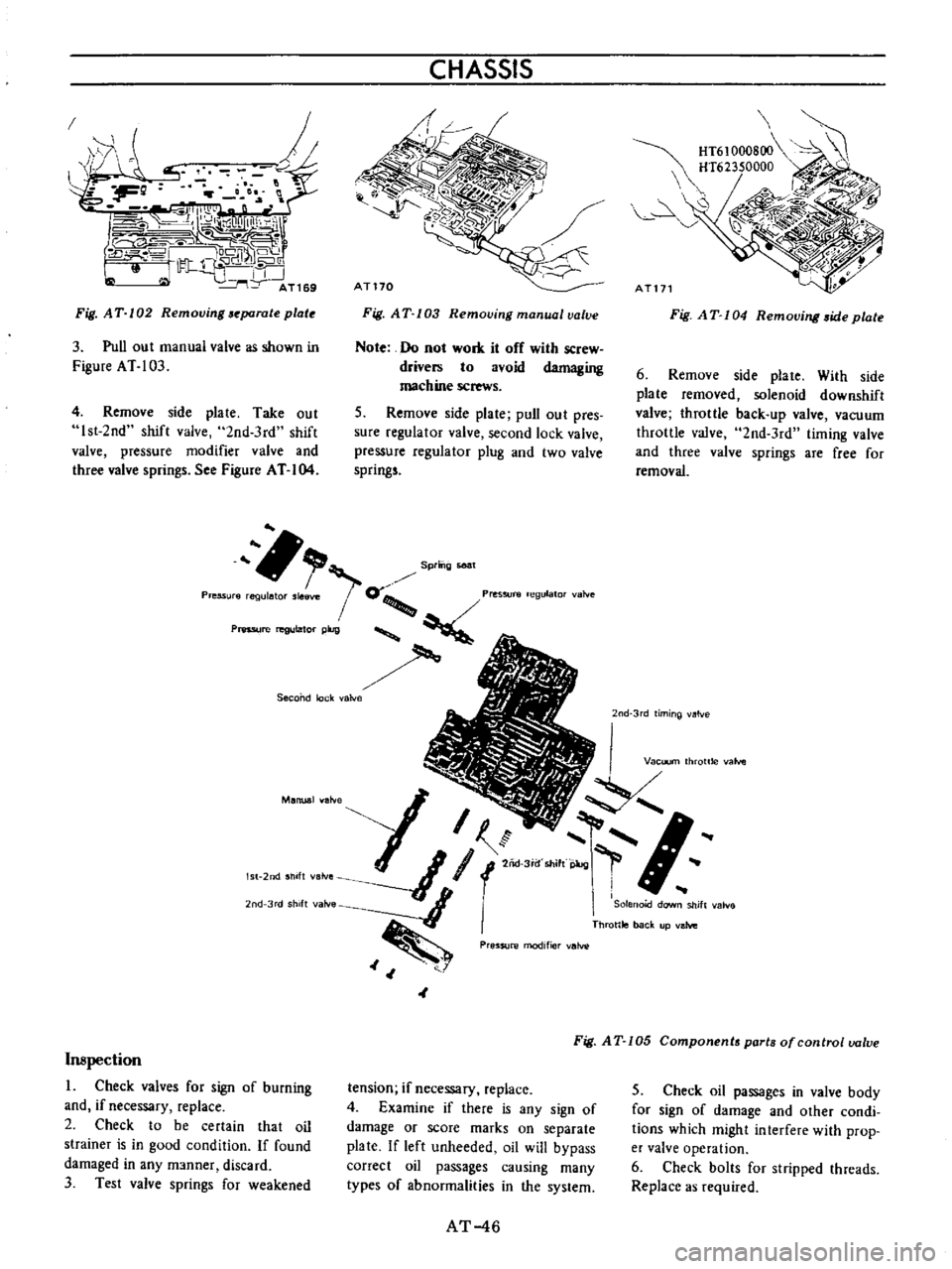

I

Fig

AT

102

Removing

5

parote

plate

3

Pull

out

manual

valve

as

shown

in

Figure

AT

103

4

Remove

side

plate

Take

out

1st

2nd

shift

valve

2nd

3rd

shift

valve

pressure

modifier

valve

and

three

valve

springs

See

Figure

AT

I04

CHASSIS

AT170

Fig

AT

103

Removing

manual

valve

Note

Do

not

work

it

off

with

screw

drivers

to

avoid

damaging

machine

screws

5

Remove

side

plate

pull

out

pres

sure

regulator

valve

second

lock

valve

pressure

regulator

plug

and

two

valve

springs

sp

m

Pressure

regutlltor

sleeve

C

Prt

ssure

P

elato

piug

IZt

1

2iid3

d

h

1

alve

7

I

Solenoid

down

skutt

Throttle

back

up

alw

p

u

modif

Second

lock

alve

MllllU81

1st

2nd

shift

2nd

3rd

shift

Inspection

I

Check

valves

for

sign

of

burning

and

if

necessary

replace

2

Check

to

be

certain

that

oil

strainer

is

in

good

condition

If

found

damaged

in

any

ffi3nner

discard

3

Test

valve

springs

for

weakened

egulator

alve

3

1

ott

jj

r

of

U

d

4

t

i

i

J

j

r

r

lC

i

i

4

i

I

5

j

AT171

Fig

A

T

l

04

Removing

8ide

plate

6

Remove

side

plate

With

side

plate

removed

solenoid

downshift

valve

throttle

back

up

valve

vacuum

throttle

valve

2nd

3rd

timing

valve

and

three

valve

springs

are

free

for

removal

2nd

3rd

timing

3

ve

i

Vacuum

Ihrotlle

alve

aive

Fig

AT

L05

Components

parts

of

control

value

tension

if

necessary

replace

4

Examine

if

there

is

any

sign

of

damage

or

score

marks

on

separate

plate

If

left

unheeded

oil

will

bypass

correct

oil

passages

causing

many

types

of

abnormalities

in

the

system

AT

46

5

Check

oil

passages

in

valve

body

for

sign

of

damage

and

other

condi

tions

which

might

interfere

with

prop

er

valve

operation

6

Check

bolts

for

stripped

threads

Replace

as

required

Page 51 of 513

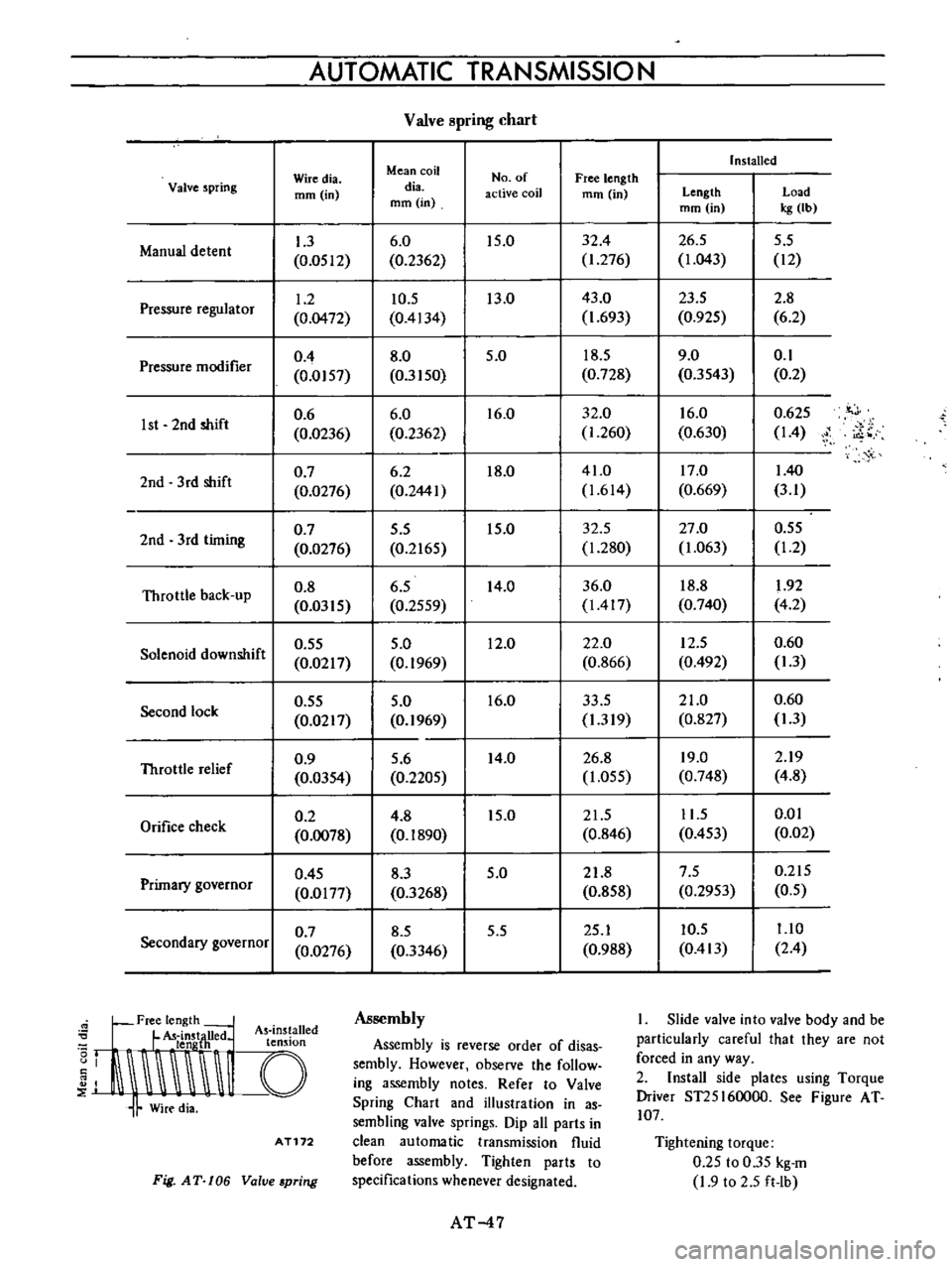

AUTOMATIC

TRANSMISSIO

N

Valve

pring

chart

Installed

Wiredia

Mean

coil

No

of

Free

length

Valve

spring

mm

in

dia

active

coil

mm

in

Length

Load

mm

in

mm

in

kg

Ib

1

3

6

0

15

0

32

4

26

5

5

5

Manual

detent

0

0512

0

2362

1

276

1

043

12

1

2

10

5

13

0

43

0

23

5

2

8

Pressure

regulator

0

0472

0

4134

1

693

0

925

6

2

0

4

8

0

5

0

18

5

9

0

0

1

Pressure

modifier

0

0157

0

3150

0

728

0

3543

0

2

0

6

6

0

16

0

32

0

16

0

0

625

it

J

1st

2nd

shift

0

0236

0

2362

1

260

0

630

14

i

o

0

7

6

2

18

0

41

0

17

0

140

2nd

3

rd

shift

0

0276

0

2441

1

614

0

669

3

1

0

7

5

5

15

0

32

5

27

0

0

55

2nd

3rd

timing

0

0276

0

2165

1

280

1

063

1

2

Throttle

back

up

0

8

6

5

14

0

36

0

18

8

1

92

0

0315

0

2559

1417

0

740

4

2

0

55

5

0

12

0

22

0

12

5

0

60

Solenoid

downshift

0

0217

0

1969

0

866

0

492

1

3

0

55

5

0

16

0

33

5

21

0

0

60

Second

lock

0

0217

0

1969

1

319

0

827

1

3

0

9

5

6

14

0

26

8

19

0

2

19

Throttle

relief

0

0354

0

2205

1

055

0

748

4

8

0

2

4

8

15

0

21

5

11

5

0

01

Orifice

check

0

0078

0

1890

0

846

0

453

0

02

0

45

8

3

5

0

21

8

7

5

0

215

Primary

governor

0

0177

0

3268

0

858

0

2953

0

5

0

7

8

5

5

5

25

1

10

5

1

10

Secondary

governor

0

0276

0

3346

0

988

0

413

2

4

Free

length

L

U

d

As

ins

alled

I

t

LldnstjH

e

t

n

Ion

J

I

I

Assembly

Assembly

is

reverse

order

of

disas

sembly

However

observe

the

follow

ing

assembly

notes

Refer

to

Valve

Spring

Chart

and

illustration

in

as

sembling

valve

springs

Dip

all

parts

in

clean

automatic

transmission

fluid

before

assembly

Tighten

parts

to

specifications

whenever

designated

AT172

Fig

AT

106

Value

pring

AT

47

I

Slide

valve

into

valve

body

and

be

particularly

careful

that

they

are

not

forced

in

any

way

2

Install

side

plates

using

Torque

Driver

ST25I60000

See

Figure

AT

107

Tightening

torque

0

25

to

0

35

kg

m

1

9

to

2

5

ft

Ib

Page 63 of 513

Order

Others

AUTOMATIC

TRANSMISSION

Test

item

4

Shift

down

Dr4D2

DI

5

Shift

down

DJ

I2

l

6

Shift

down

DJ

2

7

Shift

up

I

12

8

Shift

up

or

down

when

start

ing

in

2

range

9

Parking

Abnormal

shock

oil

leakage

Procedure

Check

vehicle

speeds

and

engine

rpm

in

shifting

down

3rd

2nd

I

st

continued

while

coasting

with

acceleraling

pedal

released

in

0

range

and

engine

vacuum

pressure

of

about

450

mmHg

Check

for

shifting

down

DJ

12

and

engine

braking

and

further

for

shifting

down

12

11

and

engine

braking

after

shifting

the

lever

into

I

range

with

the

accelerator

pedal

released

and

the

engine

vacuum

pressure

of

0

mmHg

while

driving

at

about

SO

km

h

31

MPH

in

DJ

range

Check

for

quick

shifting

down

DJ

2

and

engine

braking

after

shifting

the

lever

into

2

range

while

driving

at

about

50

km

h

31

MPH

in

DJ

range

Further

check

the

transmission

for

being

locked

to

the

2nd

gear

ratio

regardless

of

vehicle

speed

Check

for

the

transmission

not

shifting

up

during

acceIera

tion

when

starting

in

1

t

nge

It

Check

the

transmission

for

not

shifting

up

or

down

durih

t

acceleration

or

deceleration

when

starting

in

2

range

Confirm

that

vehicle

will

not

move

on

grade

when

shifting

to

P

range

Put

on

record

of

observed

conditions

during

these

tests

such

as

gear

noise

abnormal

noise

of

clutches

and

acceleration

performance

AT

59