lock DATSUN B110 1973 Service Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 96 of 513

CHASSIS

Reinstallation

Reinstall

the

wheel

bearing

in

reverse

sequence

of

removal

2

Install

the

bearing

outer

race

by

the

use

of

a

froot

wheel

bearing

drift

special

tool

ST353

10000

Fig

FA

22

Installing

bearing

outer

race

3

Fill

the

wheel

hub

and

hub

cap

with

multi

purpose

grease

MIL

G2108

or

10924

up

to

the

portion

indicated

by

asterisk

in

Figure

F

A

23

l

I

L

I

I

P

p

r

Fig

FA

23

Greasing

points

of

hub

assembly

4

Fill

the

spaces

between

wheel

bearing

rollers

and

grease

seal

lip

pocket

with

multi

purpose

grease

suf

ficiently

FA

10

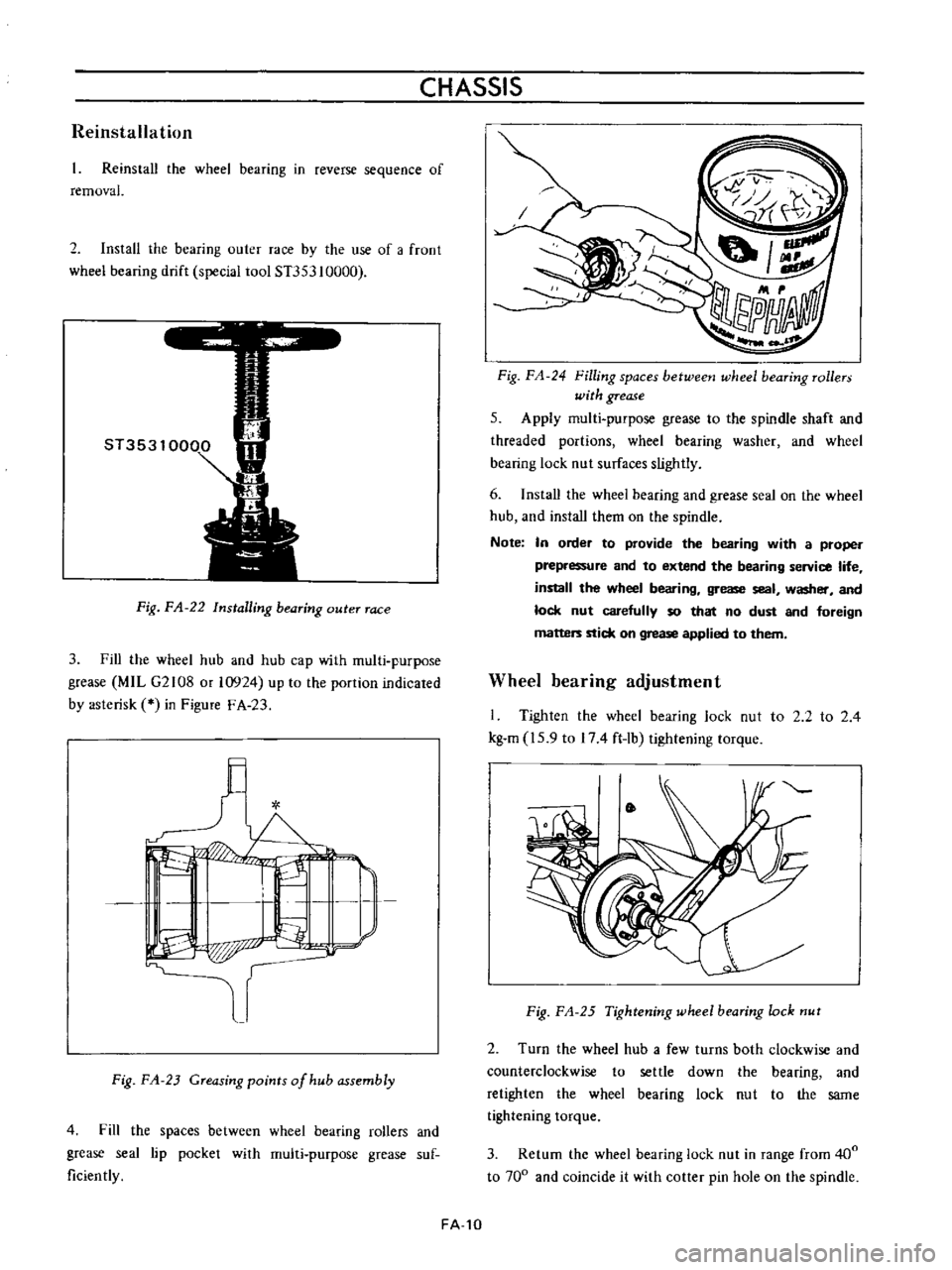

Fig

FA

24

Filling

spaces

betweetJ

wheel

bearing

rollers

with

grease

5

Apply

multi

purpose

grease

to

the

spindle

shaft

and

threaded

portions

wheel

bearing

washer

and

wheel

bearing

lock

nut

surfaces

slightly

6

Install

the

wheei

bearing

and

grease

seal

on

the

wheel

hub

and

install

them

on

the

spindle

Note

In

order

to

provide

the

bearing

with

a

proper

prepressure

and

to

extend

the

bearing

service

life

install

the

wheel

bearing

grease

seal

washer

and

lock

nut

carefully

so

that

no

dust

and

foreign

matters

stick

on

grease

applied

to

them

Wheel

bearing

adjustment

I

Tighten

the

wheel

bearing

lock

nut

to

2

2

to

2

4

kg

m

15

9

to

174

ft

lb

tightening

torque

Fig

FA

25

Tightening

wheel

bearing

lock

nut

2

Turn

the

wheel

hub

a

few

turns

both

clockwise

and

counterclockwise

to

settle

down

the

bearing

and

retighten

the

wheel

bearing

lock

nut

to

the

same

tightening

torque

3

Return

the

wheel

bearing

lock

nut

in

range

from

400

to

700

and

coincide

it

with

cotter

pin

hole

on

the

spindle

Page 97 of 513

FRONT

AXLE

FRONT

SUSPENSION

t

t

Fig

FA

26

Returning

wheel

bearing

lock

nut

4

Turn

the

wheel

hub

a

few

turns

both

clockwise

and

counterclockwise

again

to

allow

the

bearing

breaking

in

measure

bearing

rotation

starting

torque

apply

a

cotter

pin

to

secure

the

nut

if

the

measured

starting

torque

is

within

the

rated

value

and

install

the

hub

cap

hub

cap

Wheel

bearing

rotation

starting

torque

9

0

kg

cm

7

8

in

1b

4

0

kg

cm

3

4

7

in

1b

At

the

hub

bolt

1

57

kg

3

461b

New

bearing

0

7

kg

1

54lb

Used

bearing

No

slackness

should

exist

toward

the

axis

direction

New

bearing

Used

bearing

J

o

i

@

j

Be

sure

to

remove

the

brake

pad

Disc

type

brake

Correctly

measure

starting

force

toward

tangential

direction

against

the

hub

bolt

Fig

FA

27

Measuring

wheel

bearing

ro

ation

starting

torque

STRUT

ASSEMBLY

The

strut

assembly

consisting

of

a

strut

outer

casing

with

spindle

forms

a

cylinder

between

the

piston

rod

guide

and

bottom

valve

The

inner

components

are

precisely

assembled

and

no

dirt

and

foreign

matter

intrusions

are

permitted

The

components

such

as

piston

rod

piston

rod

guide

cylinder

and

bottom

valve

are

handled

together

as

an

assembly

When

replacing

them

be

sure

to

replace

the

inner

components

as

an

assembly

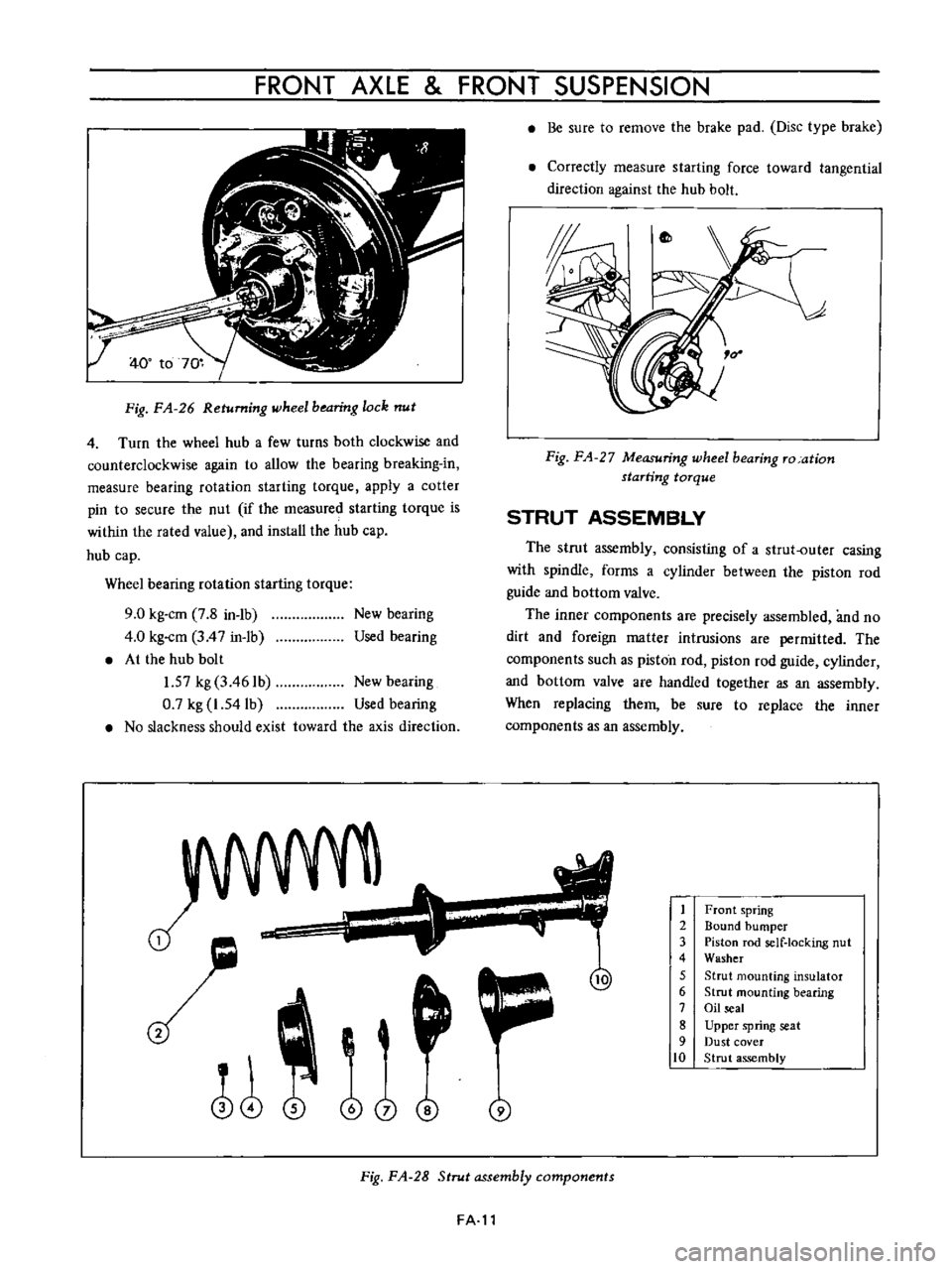

1

2

3

4

5

6

7

8

9

10

Front

spring

Bound

bumper

Piston

rod

self

locking

nut

Washer

Strut

mounting

insulator

Strut

mounting

bearing

Oil

seal

Upper

spring

seat

Dust

cover

Strut

assembly

Fig

FA

28

Strut

assembly

components

FA

l1

Page 98 of 513

fl

i

i

I

1

I

I

i

2

4

L

thi7

lrr

I

1

1

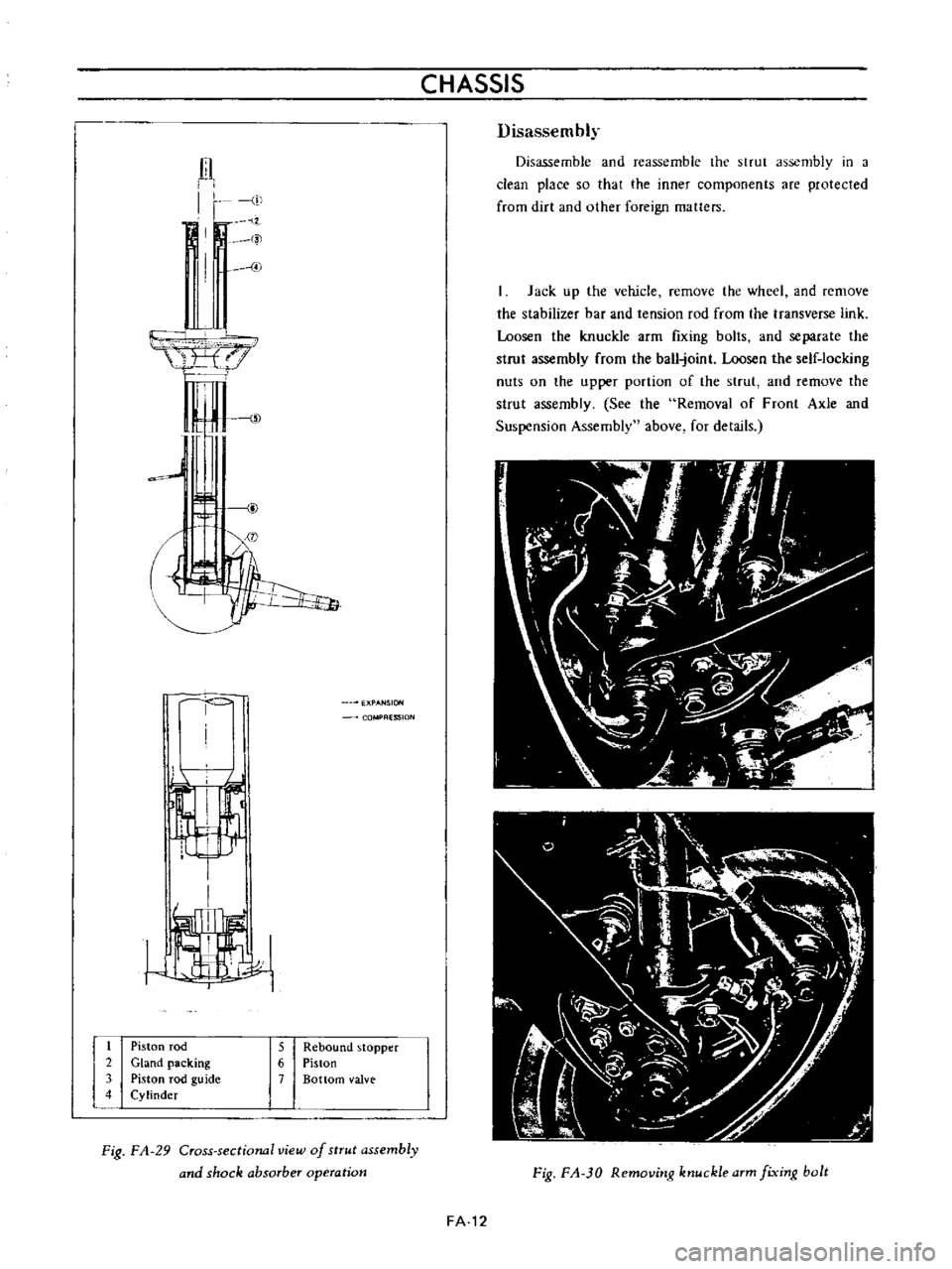

Piston

rod

2

Gland

packing

3

Piston

rod

guide

4

Cylinder

CHASSIS

ESSION

5

Rebound

stopper

6

Piston

7

Bottom

valve

Fig

FA

29

Cross

sectional

view

of

strut

assembly

and

shock

absorber

operation

Disassembly

Disassemble

and

reassemble

the

strut

assembly

in

a

clean

place

so

that

the

inner

components

are

protected

from

dirt

and

other

foreign

matters

Jack

up

the

vehicle

remove

the

wheel

and

remove

the

stabilizer

bar

and

tension

rod

from

the

transverse

link

Loosen

the

knuckle

arm

fIxing

bolts

and

separate

the

strut

assembly

from

the

ball

joint

Loosen

the

self

locking

nuts

on

the

upper

portion

of

the

strut

and

remove

the

strut

assembly

See

the

Removal

of

Front

Axle

and

Suspension

Assembly

above

for

details

Fig

FA

JO

Removitlg

ktluckle

arm

fixitlg

bolt

FA

12

Page 99 of 513

FRONT

AXLE

FRONT

SUSPENSION

Fig

FA

31

Removing

front

strut

assembly

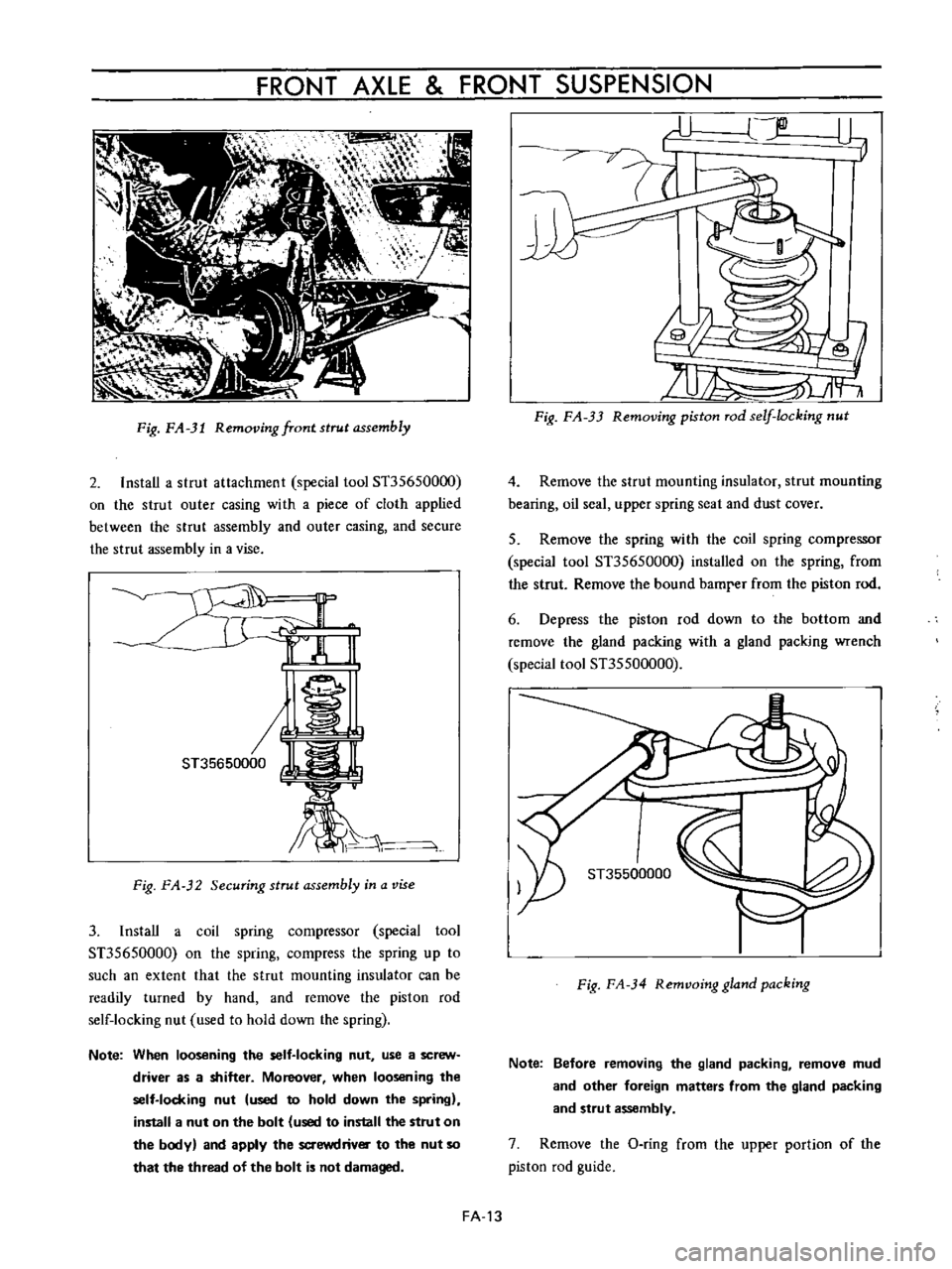

2

InstaU

a

strut

attachment

special

tool

ST35650000

00

the

strut

outer

casing

with

a

piece

of

cloth

applied

between

the

strut

assembly

and

outer

casing

and

secure

the

strut

assembly

in

a

vise

J

1

i

kj

ST35650000

W

lL

bi

Fig

FA

32

Securing

strut

assembly

in

a

vise

3

1nstaU

a

coil

spring

compressor

special

tool

ST35650000

on

the

spring

compress

the

spring

up

to

such

an

extent

that

the

strut

mounting

insulator

can

be

readily

turned

by

hand

and

remove

the

piston

rod

self

locking

nut

used

to

hold

down

the

spring

Note

When

loosening

the

self

locking

nut

use

a

screw

driver

as

a

shitter

Moreover

when

loosening

the

self

locking

nut

used

to

hold

down

the

spring

install

a

nut

on

the

bolt

used

to

install

the

strut

on

the

body

and

apply

the

saewdrivOI

to

the

nut

so

that

the

thread

of

the

bolt

is

not

damaged

r

U

jlD

L1

19

71

it

fr

Fig

FA

33

Removing

piston

rod

self

locking

nut

4

Remove

the

strut

mounting

insulator

strut

mounting

bearing

oil

seal

upper

spring

seat

and

dust

cover

5

Remove

the

spring

with

the

coil

spring

compressor

special

tool

ST35650000

installed

on

the

spring

from

the

strut

Remove

the

bound

bamrer

from

the

piston

rod

6

Depress

the

piston

rod

down

to

the

bottom

and

remove

the

gland

packing

with

a

gland

packing

wrench

special

tool

ST35500000

I

ST35500000

Fig

FA

34

Remvoing

gland

packing

Note

Before

removing

the

gland

packing

remove

mud

and

other

foreign

matters

from

the

gland

packing

and

strut

assembly

7

Remove

the

O

ring

from

the

upper

portion

of

the

piston

rod

guide

FA

13

Page 103 of 513

FRONT

AXLE

FRONT

SUSPENSION

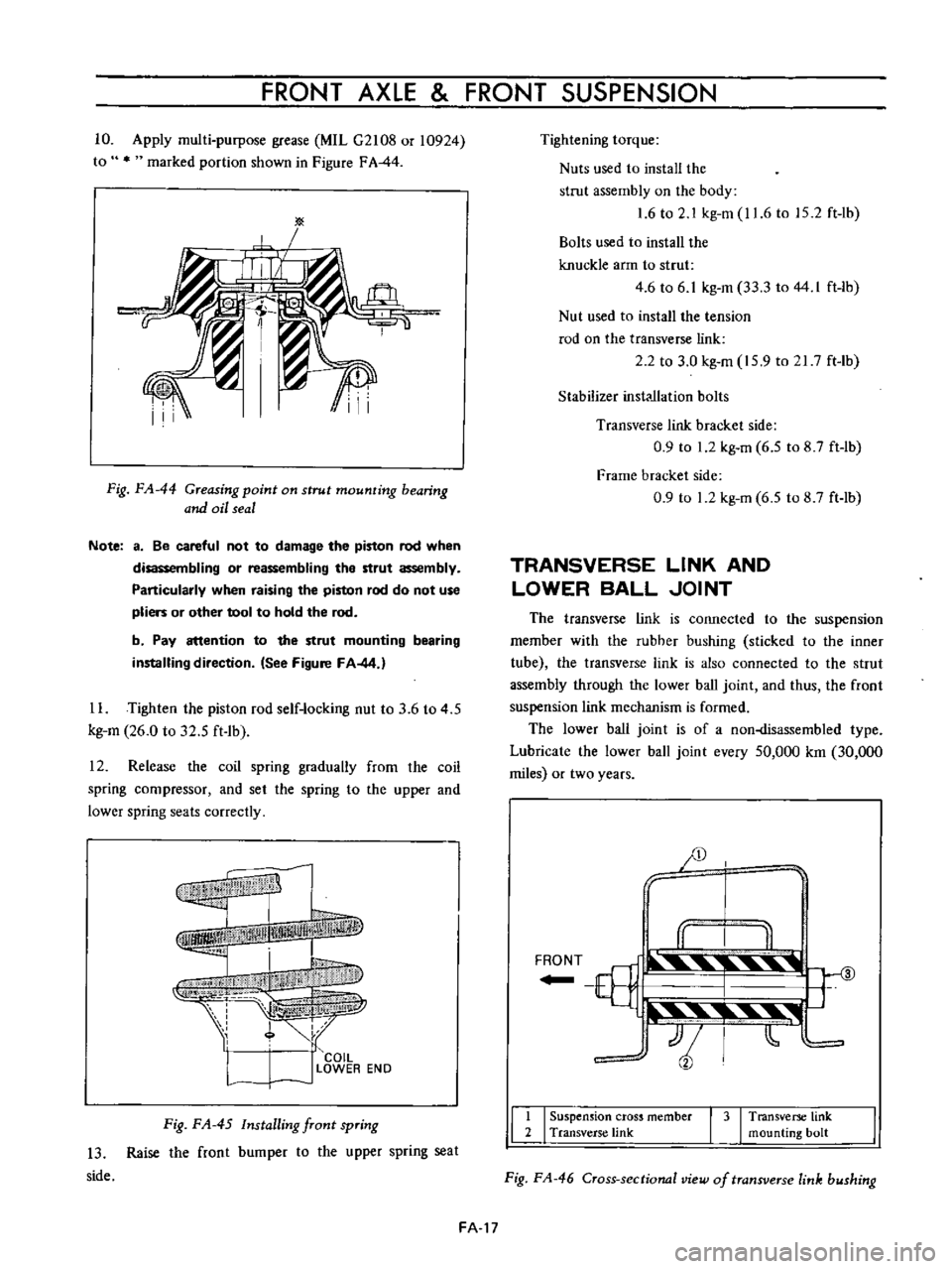

10

Apply

multi

purpose

grease

MIL

G2108

or

10924

to

marked

portion

shown

in

Figure

FA

44

Fig

FA

44

Greasing

point

on

strut

mounting

bearing

and

oil

seal

Note

a

Be

careful

not

to

damage

the

piston

rod

when

disassembling

or

reassembling

the

strut

assembly

Particularly

when

raising

the

piston

rod

do

not

use

pliers

or

other

tool

to

hold

the

rod

b

Pay

attention

to

the

strut

mounting

bearing

installing

direction

See

Figure

FA

44

1

L

Tighten

the

piston

rod

self

locking

nut

to

3

6

to

4

5

kg

m

26

0

to

32

5

ft

1b

12

Release

the

coil

spring

gradually

from

lhe

coil

spring

compressor

and

set

the

spring

to

the

upper

and

lower

spring

seats

correctly

f

I

I

COIL

l

J

LOWER

EN

D

Fig

FA

45

Installing

front

spring

13

Raise

the

front

bumper

to

the

upper

spring

seat

side

Tightening

torque

Nuts

used

to

install

the

strut

assembly

on

the

body

1

6

to

2

1

kg

m

11

6

to

15

2

ft

lb

Bolts

used

to

install

the

knuckle

arm

to

strut

4

6

to

6

1

kg

m

33

3

to

44

I

ft

lb

Nut

used

to

install

the

tension

rod

on

the

transverse

link

2

2

to

3

0

kg

m

15

9

to

21

7

ft

Ib

Stabilizer

inst

llation

bolts

Transverse

link

bracket

side

0

9

to

1

2

kg

m

6

5

to

8

7

ft

lb

Frame

bracket

side

0

9

to

1

2

kg

m

6

5

to

8

7

ft

lb

TRANSVERSE

LINK

AND

LOWER

BALL

JOINT

The

transverse

link

is

connected

to

the

suspension

member

with

the

rubher

bushing

sticked

to

the

inner

tube

the

transverse

link

is

also

connected

to

the

strut

assembly

through

the

lower

ball

joint

and

thus

the

front

suspension

link

mechanism

is

formed

The

lower

ball

joint

is

of

a

non

lisassembled

type

Lubricate

the

lower

ball

joint

every

50

000

km

30

000

miles

or

two

years

JD

y

I

II

I

II

F

T

ill

3

YJ

t

tjli

t

11

I

Suspension

cross

member

I

3

I

Transverse

link

2

Transverse

link

mounting

bolt

Fig

FA

46

Cross

sectional

view

of

transverse

link

bushing

FA

17

Page 108 of 513

CHASSIS

For

high

speed

Over

100

km

h

or

60

MPH

ADJUSTMENT

OF

WHEEL

ALIGNMENT

Use

a

turning

radius

gauge

and

alignment

gauge

for

the

measurement

2

Carry

out

wheel

alignment

on

a

flat

surface

with

tire

air

pressure

adjusted

to

the

normal

pressure

ADJUSTMENT

OF

VEHICLE

LEVEL

Vehicle

level

is

adjusted

by

changing

springs

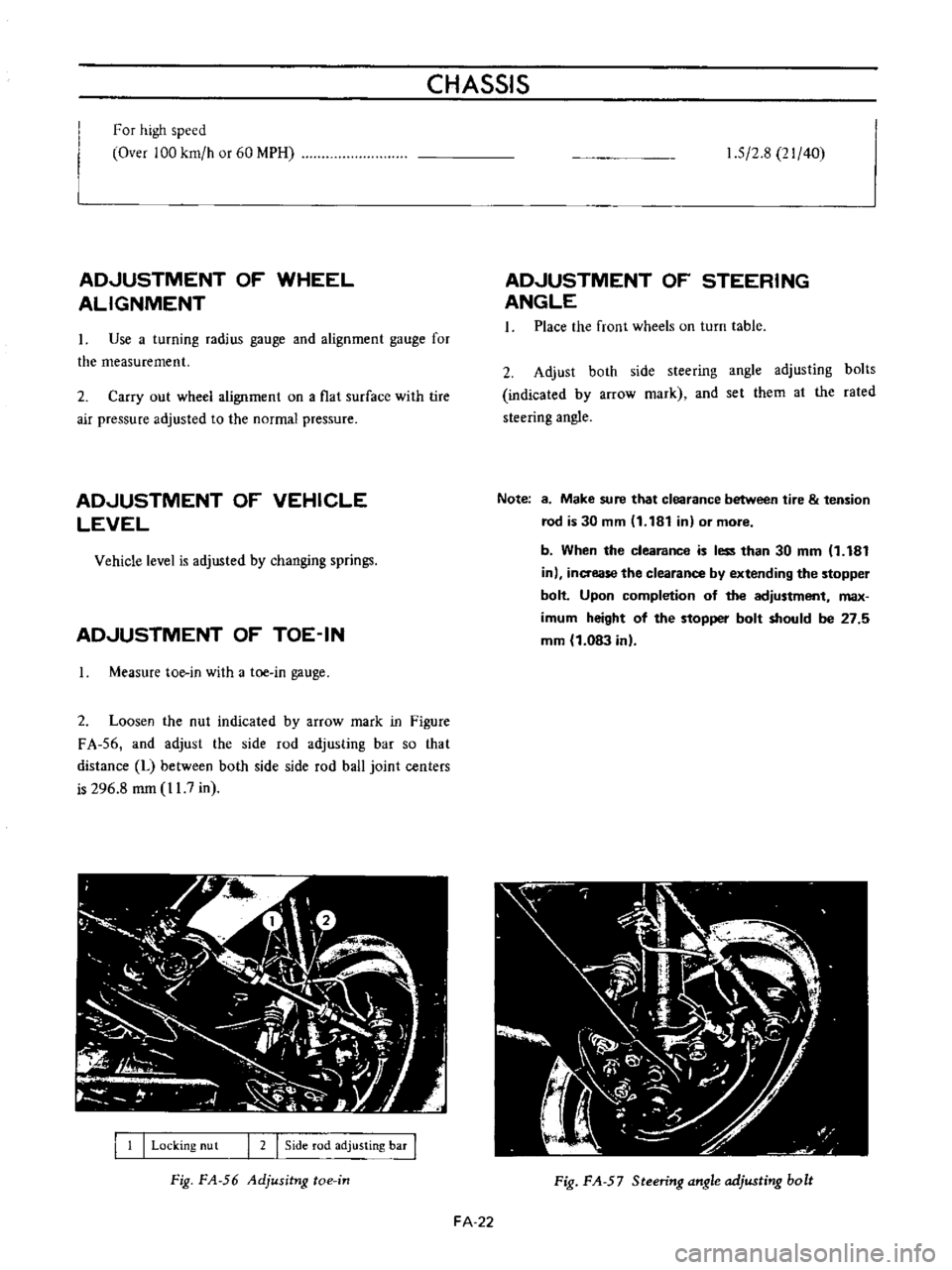

ADJUSTMENT

OF

TOE

IN

Measure

toe

in

with

a

toe

in

gauge

2

Loosen

the

nut

indicated

by

arrow

mark

in

Figure

FA

56

and

adjust

the

side

rod

adjusting

bar

so

that

distance

L

between

both

side

side

rod

ball

joint

centers

is

296

8

mm

11

7

in

I

1

I

Locking

nu

t

I

2

I

Side

rod

adjusting

bar

I

Fig

FA

56

Adjusitng

toe

in

1

5

2

8

21

40

ADJUSTMENT

OF

STEERING

ANGLE

1

Place

the

front

wheels

on

turn

table

2

Adjust

both

side

steering

angle

adjusting

bolts

indicated

by

arrow

mark

and

set

them

al

the

rated

steering

angle

Note

8

Make

sure

that

clearance

between

tire

tension

rod

is

30

mm

11

181

in

or

more

b

When

the

clearance

is

less

than

30

mm

1

181

in

inaease

the

clearance

by

extending

the

stopper

bolt

Upon

completion

of

the

adjustment

max

imum

height

of

the

stopper

bolt

should

be

27

5

mm

1

083

in

Fig

FA

57

Steering

angle

adjusting

bolt

FA

22

Page 110 of 513

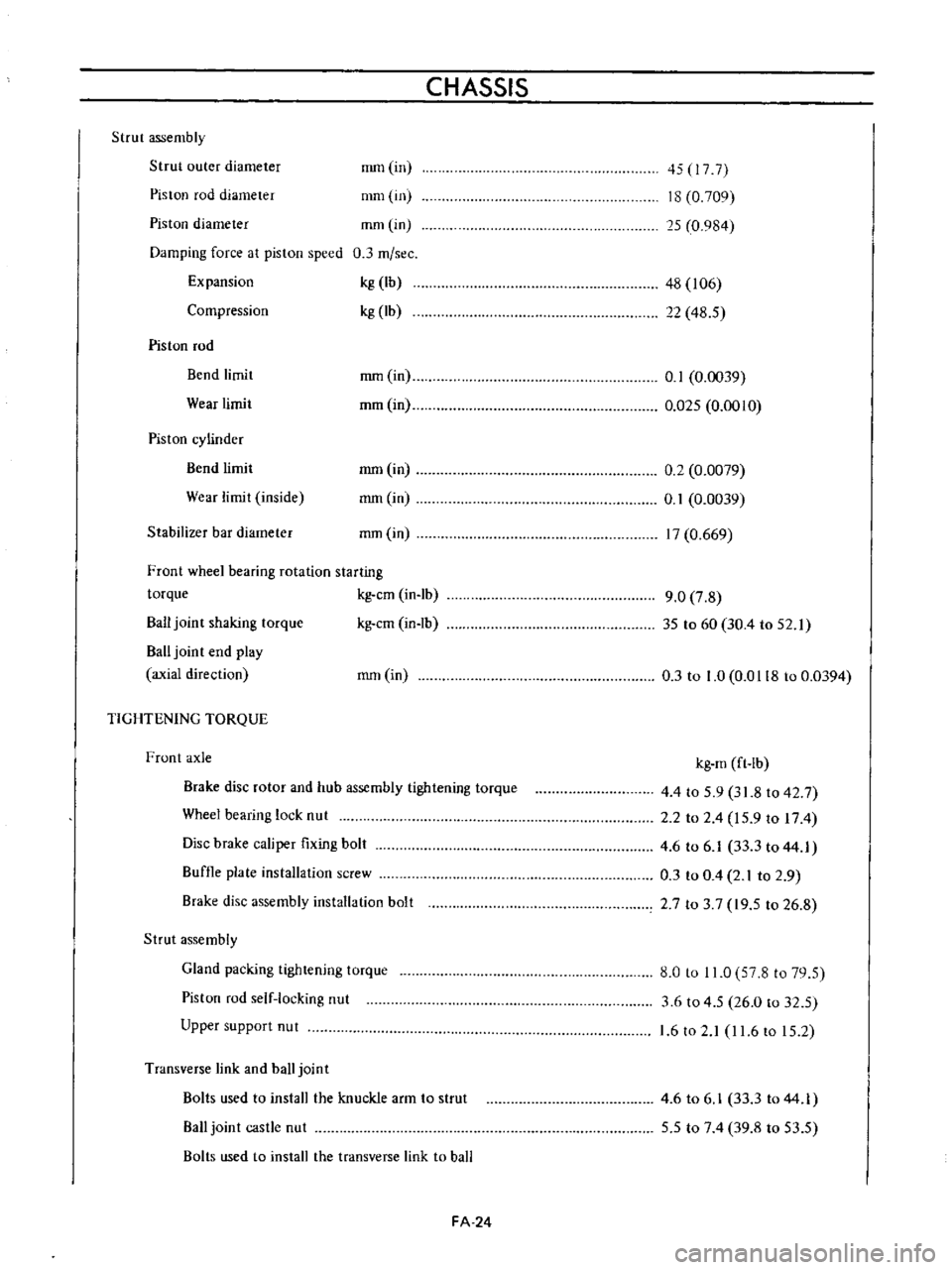

CHASSIS

Strut

assembly

Strut

outer

diameter

Piston

rod

diameter

mmlin

nml

in

45

17

7

18

0

709

15

0

984

Piston

diameter

mmlin

Damping

force

at

piston

speed

0

3

m

sec

Expansion

kg

Ib

Compression

kg

lb

48

106

22

48

5

Piston

rod

Bend

limit

Wear

limit

mm

in

0

1

0

0039

mm

in

0

025

0

0010

Piston

cylinder

Bend

limit

Wear

limit

inside

mm

in

mm

in

0

2

0

0079

0

1

0

0039

17

0

669

Stabilizer

bar

diameter

mm

in

Front

wheel

bearing

rotation

starting

torque

kg

cm

in

lb

Ball

joint

shaking

torque

kg

cm

in

lb

Ball

joint

end

play

axial

direction

mm

in

9

0

7

8

35

to

60

30

4

to

52

1

0

3

to

1

0

0

0118

to

0

0394

TIGHTENING

TORQUE

Front

axle

Brake

disc

rotor

and

hub

assembly

tightening

torque

Wheel

bearing

lock

nut

Disc

brake

caliper

fixing

bolt

Buffle

plate

installation

screw

Brake

disc

assembly

installation

bolt

kg

m

ft

lb

4

4

to

5

9

31

8

to

42

7

2

2

to

2

4

15

9

to

174

4

6

to

6

1

33

3

to

44

1

0

3

to

0

4

2

1

to

2

9

2

7

to

3

7

19

5

to

26

8

Strut

assembly

Gland

packing

tightening

torque

Piston

rod

self

locking

nut

Upper

support

nut

8

0

to

11

0

57

8

to

79

5

3

6

to

4

5

26

0

to

32

5

1

6

to

2

1

I

1

6

to

15

2

Transverse

link

and

ball

joint

Bolts

used

to

install

the

knuckle

arm

to

strut

Ball

joint

castle

nut

Bolts

used

to

install

the

transverse

link

to

ball

4

6

to

6

1

33

3

to

44

1

5

5

to

7

4

39

8

to

53

5

FA

24

Page 117 of 513

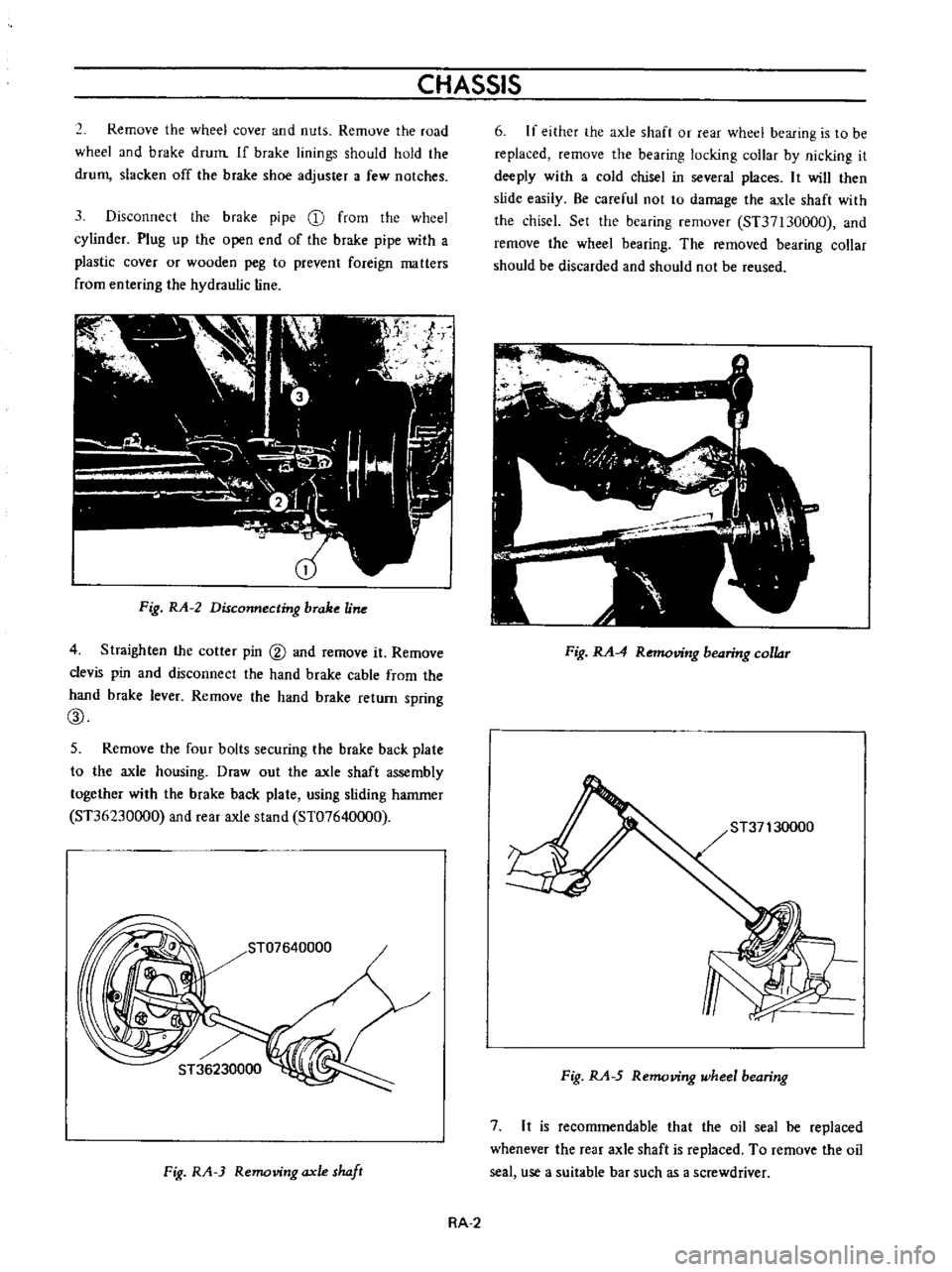

CHASSIS

2

Remove

the

wheel

cover

and

nuts

Remove

the

road

wheel

and

b

rake

drum

If

brake

linings

should

hold

the

drum

slacken

off

the

brake

shoe

adjuster

a

few

notches

3

Disconnect

the

brake

pipe

CD

from

the

wheel

cylinder

Plug

up

the

open

end

of

the

brake

pipe

with

a

plastic

cover

or

wooden

peg

to

prevent

foreign

matters

from

entering

the

hydraulic

line

Fig

RA

2

Disconnecting

brake

Une

4

Straighten

the

cotler

pin

@

and

remove

it

Remove

clevis

pin

and

disconnect

the

hand

brake

cable

from

the

hand

brake

lever

Remove

the

hand

brake

return

spring

CID

5

Remove

the

four

bolts

securing

the

brake

back

plate

to

the

axle

housing

Draw

out

the

axle

shaft

assembly

together

with

the

brake

back

plate

using

sliding

hammer

ST36230000

and

rear

axle

stand

ST07640000

ST07640000

I

Fig

RA

3

Removing

axle

shaft

6

If

either

the

axle

shaft

or

rear

wheel

bearing

is

to

be

replaced

remove

the

bearing

locking

collar

by

nicking

it

deeply

with

a

cold

chisel

in

several

places

It

will

then

slide

easily

Be

careful

not

to

damage

the

axle

shaft

with

the

chiscl

Set

the

bearing

remover

ST37130000

and

remove

the

wheel

bearing

The

removed

bearing

collar

should

be

discarded

and

should

not

be

reused

Fig

RA

4

Removing

bearing

collar

Fig

RA

5

Removing

wheel

bearing

7

It

is

recommendable

that

the

oil

seal

be

replaced

whenever

the

rear

axle

shaft

is

replaced

To

remove

the

oil

seal

use

a

suitable

bar

such

as

a

screwdriver

RA

2

Page 120 of 513

REAR

AXLE

REAR

SUSPENSION

DESCRIPTION

Rear

suspension

consists

of

semi

elliptic

leaf

springs

telescopic

hydraulic

shock

absorbers

and

rubber

bumpers

The

rear

spring

center

pin

is

off

set

110

mm

4

33

in

toward

the

front

from

the

center

of

the

spring

This

is

done

to

reduce

spring

wind

up

and

to

decrease

the

arc

while

the

rear

wheel

swings

through

Thereby

minimizing

the

possibility

of

the

rear

suspension

effecting

vehicle

stability

Iso

clamp

devices

are

used

for

attaching

the

axle

housing

to

the

spring

The

leaf

springs

shock

absorbers

and

rear

axle

housing

are

mounted

on

rubber

bushings

at

each

end

to

minimize

noise

and

vibration

of

the

transmission

to

the

car

body

and

passenger

compartment

REAR

SPRING

Removal

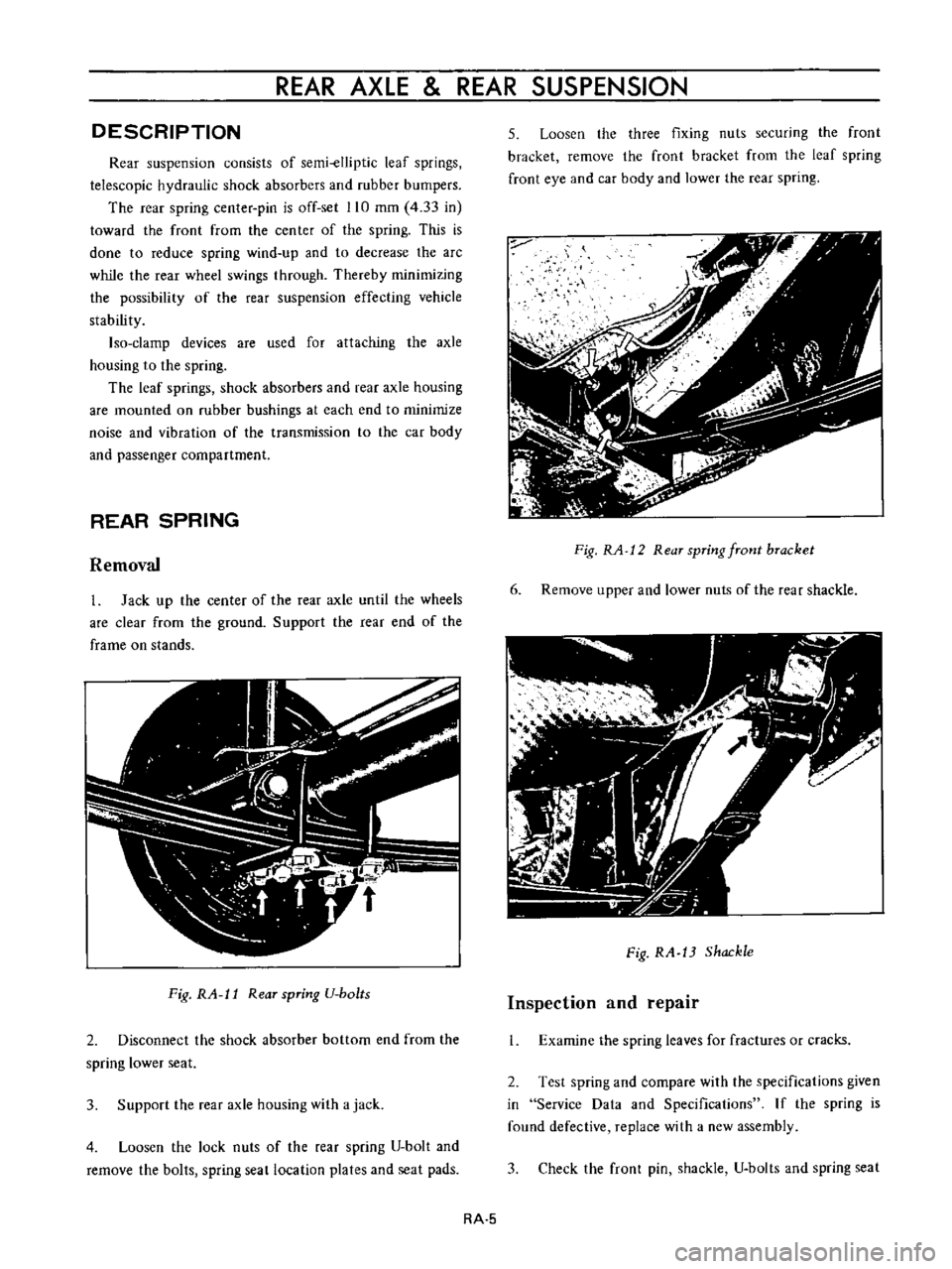

1

Jack

up

the

center

of

the

rear

axle

until

the

wheels

are

clear

from

the

ground

Support

the

rear

end

of

the

frame

on

stands

Fig

RA

l1

Rear

spring

U

bo

ts

2

Disconnect

the

shock

absorber

bottom

end

from

the

spring

lower

seat

3

Support

the

rear

axle

housing

with

a

jack

4

Loosen

the

lock

nuts

of

the

rear

spring

U

bolt

and

remove

the

bolts

spring

seat

location

plates

and

seat

pads

5

Loosen

the

three

fixing

nuts

securing

the

front

bracket

remove

the

front

bracket

from

the

leaf

spring

front

eye

and

car

body

and

lower

the

rear

spring

Fig

RA

12

Rear

spring

front

bracket

6

Remove

upper

and

lower

nuts

of

the

rear

shackle

Fig

RA

13

Shackle

Inspection

and

repair

1

Examine

the

spring

leaves

for

fractures

or

cracks

2

Test

spring

and

compare

with

the

specifications

given

in

Service

Data

and

Specifications

If

the

spring

is

found

defective

replace

with

a

new

assembly

3

Check

the

front

pin

shackle

U

bolts

and

spring

seat

RA

5

Page 134 of 513

CHASSIS

Fig

BR

19

Greasing

points

on

brake

disc

3

Tighten

the

brake

disc

installation

bolt

to

2

7

to

3

7

kg

m

19

5

to

26

7

ft

lb

4

Adjust

brake

shoe

clearance

and

perform

air

bleeding

on

the

hydraulic

system

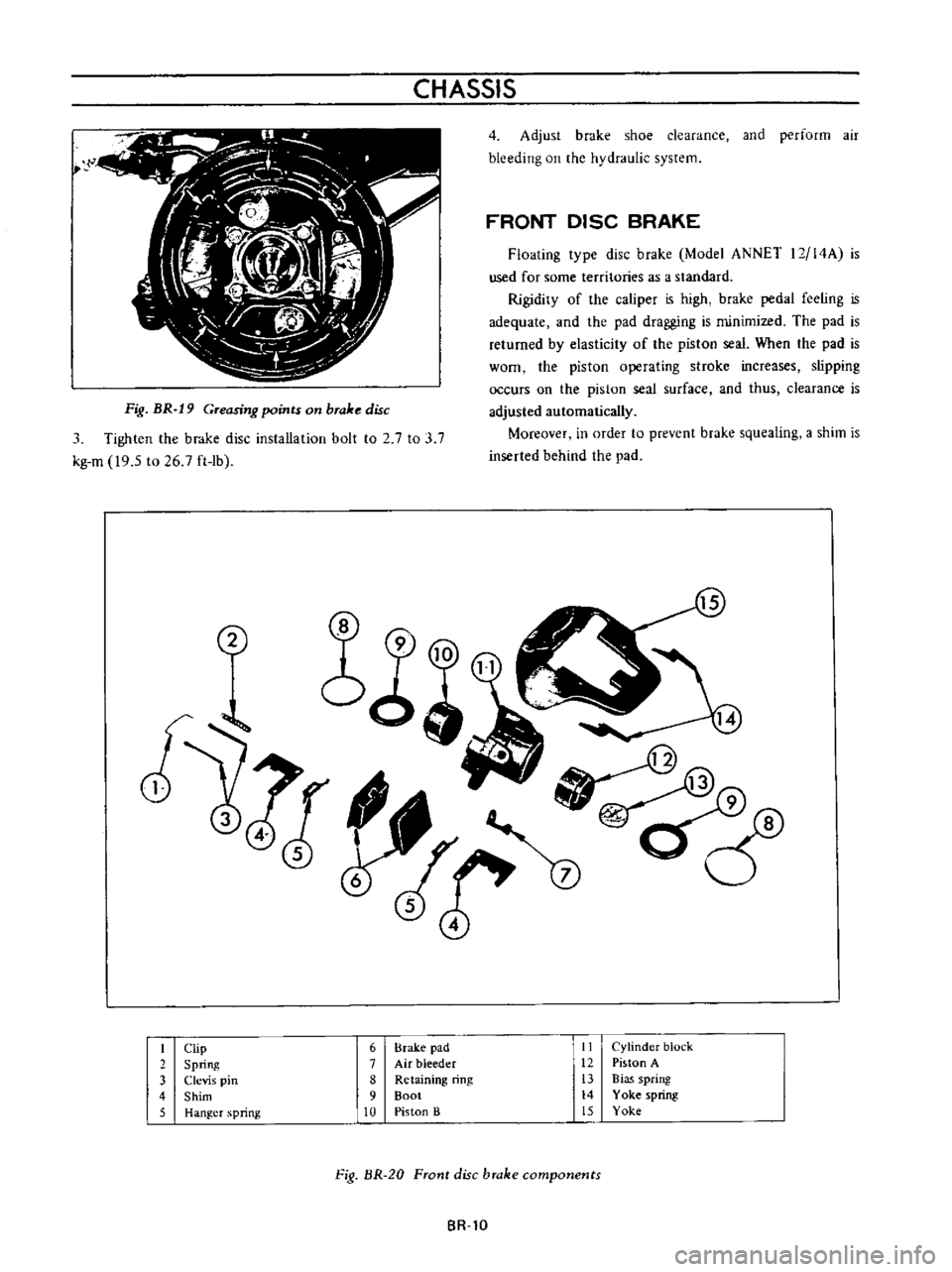

FRONT

DISC

BRAKE

Floating

type

disc

brake

Model

ANNET

12

14A

is

used

for

some

territories

as

a

standard

Rigidity

of

the

caliper

is

high

brake

pedal

feeling

is

adequate

and

the

pad

dragging

is

minimized

The

pad

is

returned

by

elasticity

of

the

piston

seal

When

the

pad

is

worn

the

piston

operating

stroke

increases

slipping

occurs

on

the

piston

seal

surface

and

thus

clearance

is

adjusted

automatically

Moreover

in

order

to

prevent

brake

squealing

a

shim

is

inserted

behind

the

pad

2

I

Clip

6

Brake

pad

II

Cylinder

block

2

Spring

7

Air

bleeder

12

Piston

A

3

Clevis

pin

8

Retaining

ring

13

Bias

spring

4

Shim

9

Boot

14

Yoke

spring

5

Hanger

spring

10

Piston

B

15

Yoke

Fig

BR

20

Front

disc

brake

components

BR

lO