lock DATSUN B110 1973 Service Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 64 of 513

CHASSIS

SERVICE

DATA

AND

SPECIFICATIONS

General

specifications

Torque

converter

Type

Stall

torque

ratio

Transmission

Type

Control

elements

Gear

ratio

Selector

positions

Oil

pump

Type

Number

of

pump

Oil

Capacity

Hydraulic

control

system

Lubrication

system

Cooling

system

Multiple

disc

clutch

Band

brake

Multiple

disc

brake

One

way

clutch

1st

lnd

3rd

Reverse

P

Park

R

Reverse

N

Neutral

D

Drive

1

lnd

lock

I

Lock

up

AT

60

Symmetrical3

element

I

stage

l

phase

torque

converter

coupling

2

0

I

3

speed

forward

and

one

speed

reverse

with

planetary

gear

train

1

I

I

I

2

458

1

458

1

000

2

182

The

transmission

is

placed

in

neutral

The

output

shaft

is

fixed

The

engine

can

be

started

Backward

running

The

transmission

is

in

neutral

The

engine

can

be

started

Up

or

downshifts

automatically

to

and

from

1st

lnd

and

top

Fixed

at

2nd

Fixed

at

low

or

downshifts

from

2nd

Internally

intermeslting

involute

gear

pump

Automatic

transmission

fluid

Dexron

type

5

5

liters

57

8

U

S

qts

47

8

Imp

qts

Approximately

1

7

liters

27

8

U

S

qts

2

3

8

Imp

qts

in

torque

converter

Controlled

by

detecting

the

negative

pressure

of

intake

manifold

and

the

revolution

speed

of

output

shaft

Forced

lubrication

by

an

oil

pwnp

Air

cooled

Page 66 of 513

CHASSIS

Engine

idling

and

stall

revolution

Engine

with

emission

control

device

Idling

revolution

rpm

650

at

0

position

800

at

N

position

1

750

to

2

000

Stall

revolution

rpm

Tightening

torque

kg

m

ft

Ib

Test

plug

oil

pressure

inspection

hole

Support

actuator

parking

rod

inserting

position

to

rear

extension

Oil

charging

pipe

to

case

Dust

cover

to

converter

housing

Selector

range

lever

to

manual

shaft

Lower

shift

rod

lock

nut

6

5

t07

5

47

to

54

0

8

to

1

0

5

8

to

7

2

4

0

to

5

0

30

to

36

4

0

to

5

0

30

to

36

2

0

to

2

5

15

to

18

0

5

to

0

7

3

6

to

5

1

0

5

to

0

7

3

6toS

I

1

2

to

1

5

8

7

to

10

8

1

5

to

4

0

II

to

29

1

3

to

1

8

9

4

to

13

0

55

to

0

75

4

0

to

5

4

0

25

to

0

35

1

9

to

2

5

0

25

to

0

35

1

9

to

2

5

0

5

to

0

7

3

6

to

5

I

0

25

to

0

35

1

9

to

2

5

0

5

to

0

7

3

6

to

5

1

0

6

to

0

8

4

4

to

5

8

0

5

to

0

7

3

6

to

5

1

3

0

to

4

0

22

to

29

3

0

to

5

0

22

to

36

14

to

2

1

10

to

15

0

8

to

l

l

5

8

to

7

9

0

55

to

0

75

4

0

to

5

4

0

55

to

0

75

4

0

to

5

4

3

0

to

4

0

22

to

29

2

0

to

2

9

15

to

21

Drive

plate

to

crankshaft

Drive

plate

to

torque

converter

Converter

housing

to

engine

Transmission

case

to

converter

housing

Transmission

case

to

rear

extension

Oil

pan

to

transmission

case

Servo

piston

retainer

to

transmission

case

Piston

stem

when

adjuting

band

brake

Piston

stem

lock

nut

One

way

clutch

inner

race

to

transmission

case

Control

valve

body

to

transmission

case

Lower

valve

body

to

upper

valve

body

Side

plate

to

control

valve

body

Nut

for

control

valve

reamer

bolt

Oil

strainer

to

lower

valve

body

Governor

valve

body

to

oil

distributor

Oil

pump

housing

to

oil

pump

cover

Inhibitor

switch

to

transmh

sion

case

Manual

shaft

lock

nut

Oil

tube

to

transmission

case

Turn

back

two

turns

after

tightening

AT

62

Page 68 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

PROPELLER

SHAFT

AND

UNIVERSAL

JOINT

CONTENTS

DESC

R

I

PTI

ON

REMOVAL

DISASSEMBL

Y

INSPECTION

ASSEMBL

Y

PD

PD

2

PD

2

PD

2

PD

2

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

PD

3

PD

3

j

j

lI

ID

1

Assembly

yoke

sleeve

2

As

mbly

journal

with

lever

3

Ring

snap

bearing

race

4

Assembly

race

bearing

5

Assembly

journal

with

bearing

6

Yoke

flange

7

Ring

snap

bearing

race

8

Assembly

race

bearing

9

Bolt

10

Washer

lock

11

Nut

Fig

PD

l

Propeller

shaft

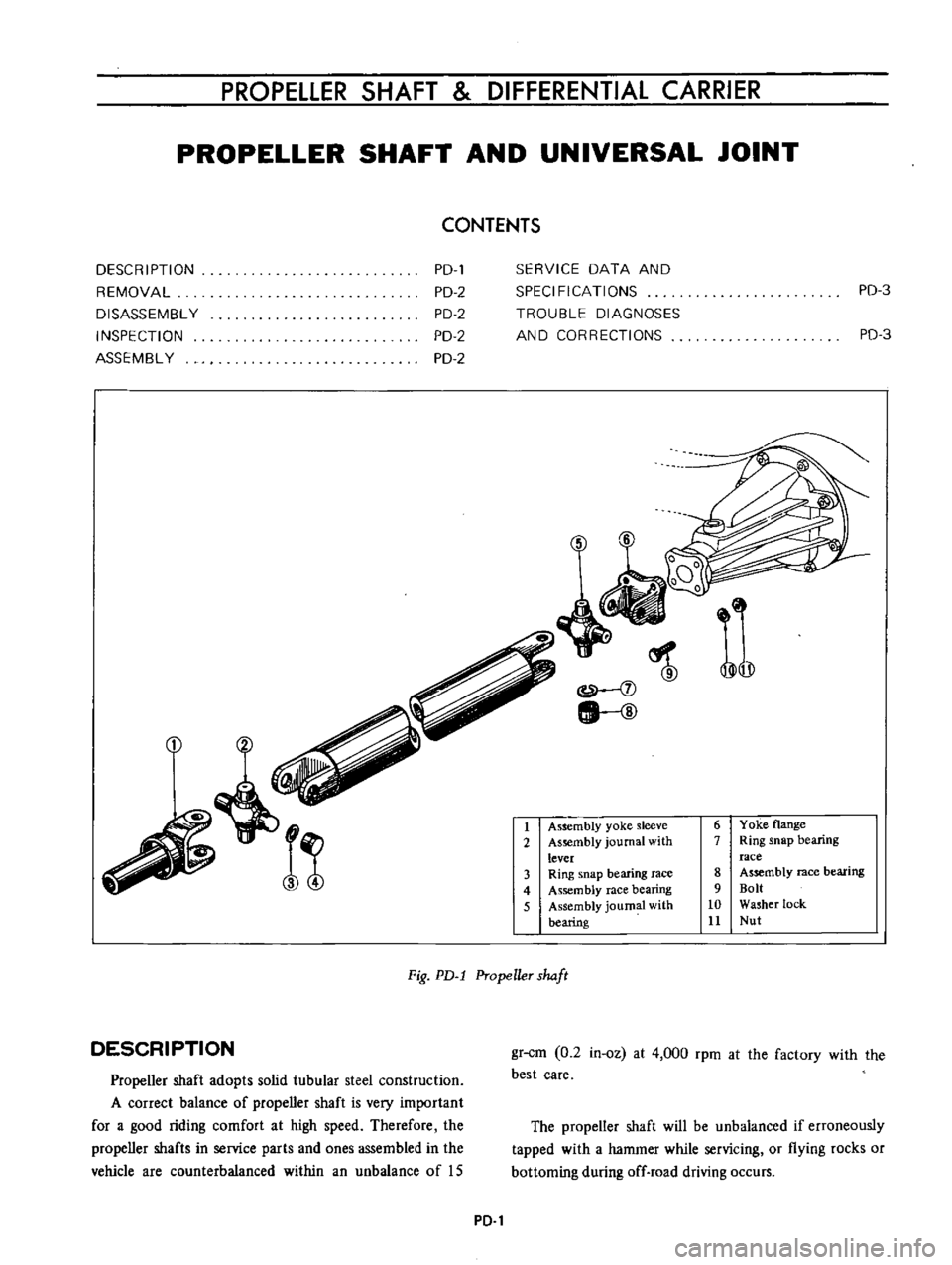

DESCRIPTION

Propeller

shaft

adopts

solid

tubular

steel

construction

A

correct

balance

of

propeller

shaft

is

very

important

for

a

good

riding

comfort

at

high

speed

Therefore

the

propeller

shafts

in

service

parts

and

ones

assembled

in

the

vehicle

are

counterbalanced

within

an

unbalance

of

IS

gr

cm

0

2

in

oz

at

4

000

rpm

at

the

factory

with

the

best

care

The

propeller

shaft

will

be

unbalanced

if

erroneously

tapped

with

a

hammer

while

servicing

or

flying

rocks

or

bottoming

during

off

road

driving

occurs

PD

1

Page 73 of 513

CHASSIS

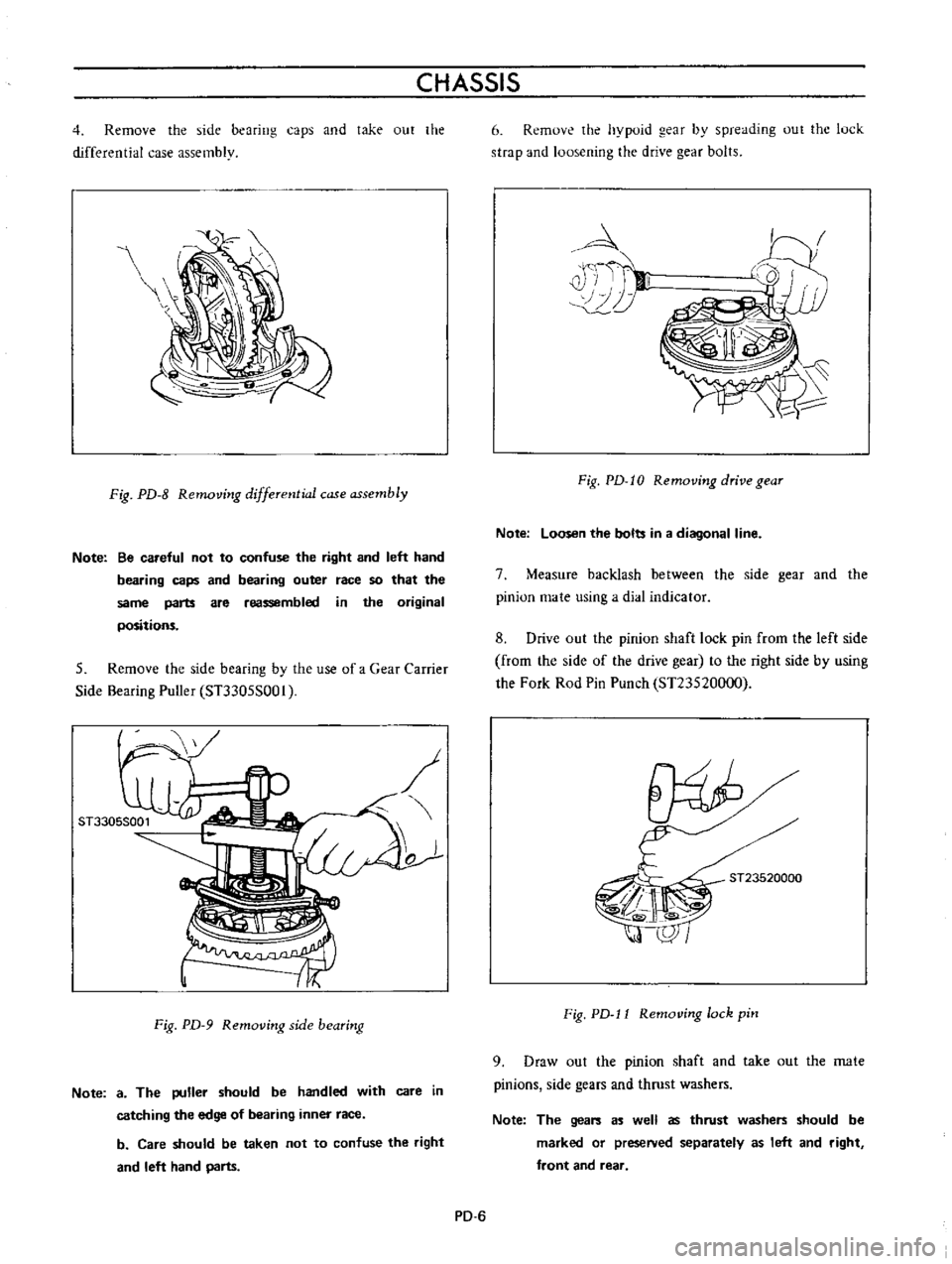

4

Remove

the

side

bearing

caps

and

take

out

the

differential

case

assembly

Fig

PD

8

Removing

differential

case

assembly

Note

Be

careful

not

to

confuse

the

right

and

left

hand

bearing

caps

and

bearing

outer

race

so

that

the

same

parts

are

reassembled

in

the

original

positions

5

Remove

the

side

bearing

by

the

use

of

a

Gear

Carrier

Side

Bearing

Puller

ST3305S001

o

Fig

PD

9

Removing

side

bearing

Note

a

The

puller

should

be

handled

with

care

in

catching

the

edge

of

bearing

inner

race

b

Care

should

be

taken

not

to

confuse

the

right

and

left

hand

parts

6

Remove

the

hypoid

gear

by

spreading

out

the

luck

strap

and

loosening

the

drive

gear

bolts

4

i

T

II

10

Fig

PD

I0

Removing

drive

gear

Note

Loosen

the

bolts

in

a

diagonal

line

7

Measure

backlash

between

the

side

gear

and

the

pinion

mate

using

a

dial

indicator

8

Drive

out

the

pinion

shaft

lock

pin

from

the

left

side

from

the

side

of

the

drive

gear

to

the

right

side

by

using

the

Fork

Rod

Pin

Punch

ST23520000

ST23520000

Fig

PD

l1

Removing

lock

pin

9

Draw

out

the

pinion

shaft

and

take

out

the

mate

pinions

side

gears

and

thrust

washers

Note

The

gears

as

well

as

thrust

washers

should

be

marked

or

preseNed

separately

as

left

and

right

front

and

rear

PD

6

Page 74 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

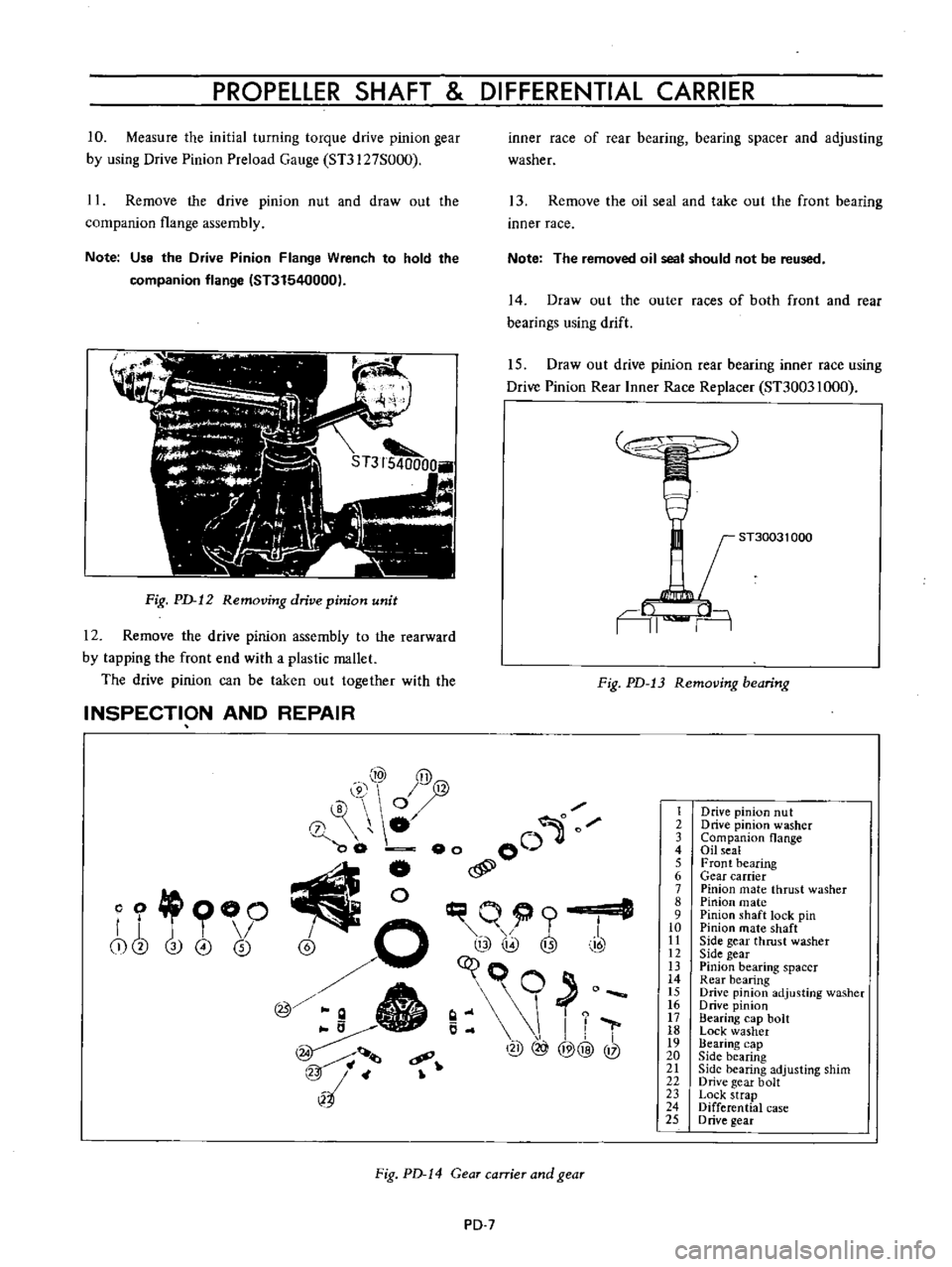

10

Measure

the

initial

turning

torque

drive

pinion

gear

by

using

Drive

Pinion

Preload

Gauge

Sn127S000

11

Remove

the

drive

pinion

nut

and

draw

out

the

companion

flange

assembly

Note

Use

the

Drive

Pinion

Flange

Wrench

to

hold

the

companion

flange

IST31540000

Fig

PD

12

Removing

drive

pinion

unit

12

Remove

the

drive

pinion

assembly

to

the

rearward

by

tapping

the

front

end

with

a

plastic

mallet

The

drive

pinion

can

be

taken

out

together

with

the

INSPECTION

AND

REPAIR

inner

race

of

rear

bearing

bearing

spacer

and

adjusting

washer

13

Remove

the

oil

seal

and

take

out

the

front

bearing

inner

race

Note

The

removed

oil

seal

should

not

be

reused

14

Draw

out

the

outer

races

of

both

front

and

rear

bearings

using

drift

15

Draw

out

drive

pinion

rear

bearing

inner

race

using

Drive

Pinion

Rear

Inner

Race

Replacer

ST30031000

ST30031

000

AI

n

Fig

PD

13

Removing

bearing

10

y@

@

0

0

0

00

eo

00

j

l

I

@

o

q@

@

t

I

7

c9

@

@@

@

l2

4

o

OO

r

j

T

I

i

cb

3

0

0

Fig

PD

14

Gear

carrier

and

gear

PD

7

1

2

3

4

S

6

7

8

9

10

II

12

IJ

14

IS

16

17

18

19

20

21

22

23

24

25

Drive

pinion

nut

Drive

pinion

washer

Companion

flange

Oil

seal

Front

bearing

Gear

carrier

Pinion

mate

thrust

washer

Pinion

mate

Pinion

shaft

lock

pin

Pinion

mate

shaft

Side

gear

thrust

washer

Side

gear

Pinion

bearing

spacer

Rear

bearing

Drive

pinion

adjusting

washer

o

rive

pinion

Bearing

cap

bolt

Lock

washer

Bearing

cap

Side

bearing

Side

bearing

adjusting

shim

Drive

gear

bolt

Lock

strap

Differential

case

D

rive

gear

Page 76 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

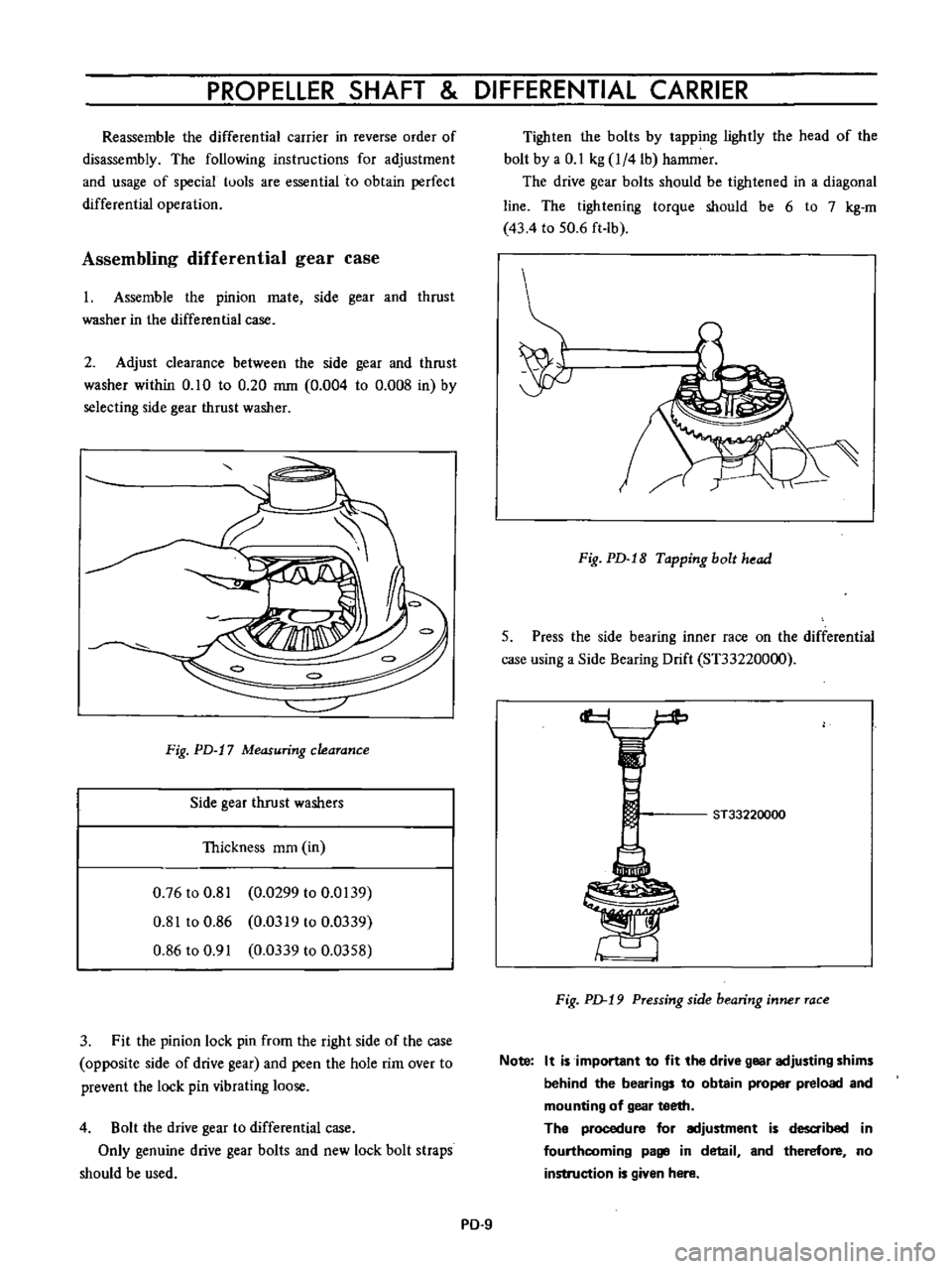

Reassemble

the

differential

carrier

in

reverse

order

of

disassembly

The

following

instructions

for

adjustment

and

usage

of

special

tuols

are

essential

to

obtain

perfect

differential

operation

Assembling

differential

gear

case

1

Assemble

the

pinion

mate

side

gear

and

thrust

washer

in

the

differential

case

2

Adjust

clearance

between

the

side

gear

and

thrust

washer

within

0

10

to

0

20

mm

0

004

to

0

008

in

by

selecting

side

gear

thrust

washer

Fig

PD

17

Measuring

clearance

Side

gear

thrust

washers

Thickness

mm

in

0

76

to

0

81

0

0299

to

0

0139

0

81

to

0

86

0

0319

to

0

0339

0

86

to

0

91

0

0339

to

0

0358

3

Fit

the

pinion

lock

pin

from

the

right

side

of

the

case

opposite

side

of

drive

gear

and

peen

the

hole

rim

over

to

prevent

the

lock

pin

vibrating

loose

4

Bolt

the

drive

gear

to

differential

case

Only

genuine

drive

gear

bolts

and

new

lock

bolt

straps

should

be

used

Tighten

the

bolts

by

tapping

lightly

the

head

of

the

bolt

by

a

0

1

kg

l

4lb

hammer

The

drive

gear

bolts

should

be

tightened

in

a

diagonal

line

The

tightening

torque

should

be

6

to

7

kg

m

43

4

to

50

6

ft

lb

Fig

PD

18

Tapping

bolt

head

5

Press

the

side

bearing

inner

race

on

the

differential

case

using

a

Side

Bearing

Drift

ST33220000

cf

ST33220000

F

ig

p

19

Pressing

side

bearing

inner

race

Note

It

is

important

to

fit

the

drive

gear

adjusting

shims

behind

the

bearings

to

obtain

proper

preload

and

mounting

of

gear

teeth

The

procedure

for

adjustment

is

d

ibed

in

fourthcoming

page

in

detail

and

therefore

no

instruction

is

given

here

PD

9

Page 77 of 513

CHASSIS

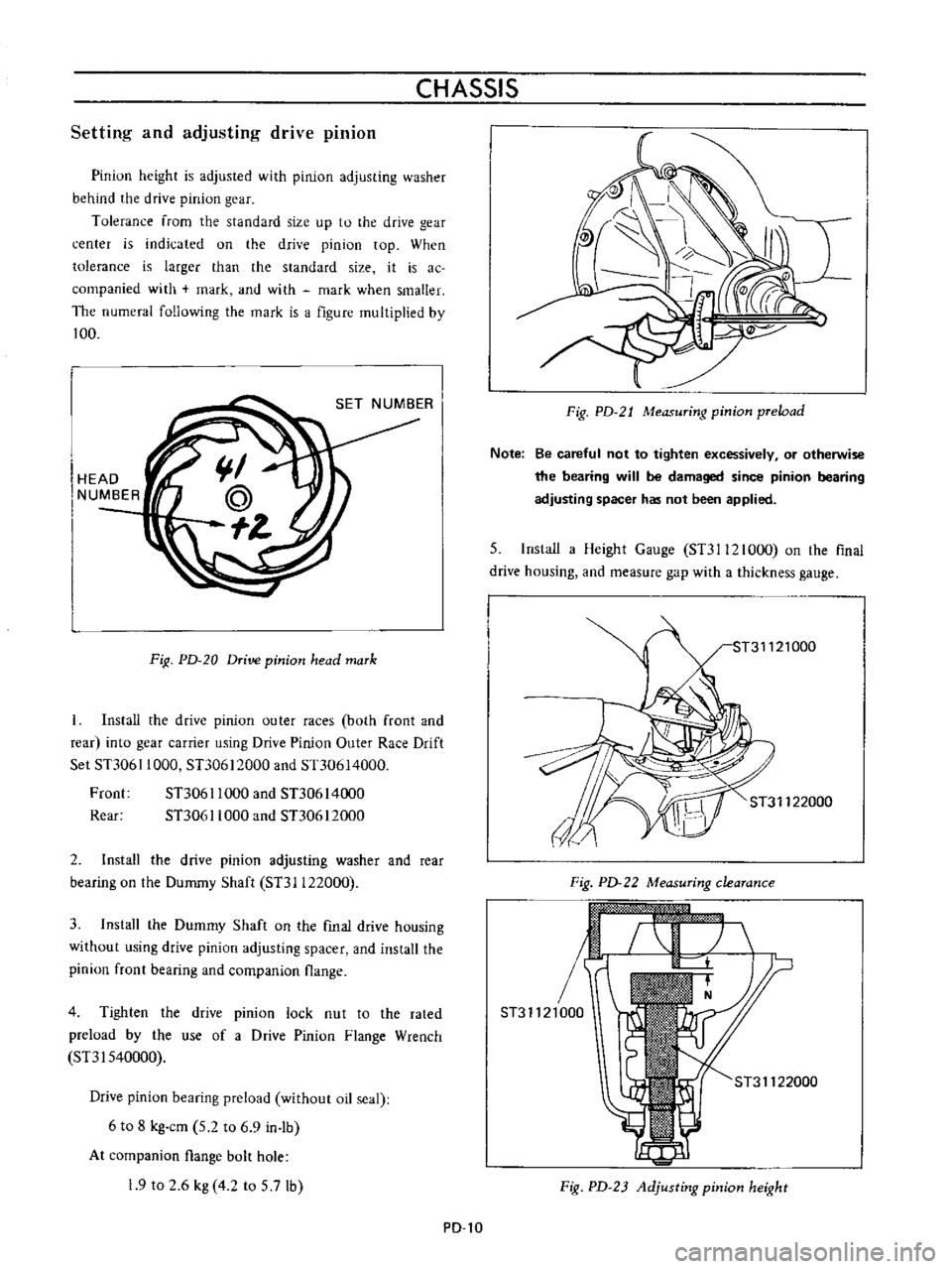

Setting

and

adjusting

drive

pinion

Pinion

height

is

adjusted

with

pinion

adjusting

washer

behind

the

drive

pinion

gear

Tolerance

from

the

standard

size

up

to

the

drive

gear

center

is

indicated

on

the

drive

pinion

top

When

tolerance

is

larger

than

the

standard

size

it

is

ac

companied

with

mark

and

with

mark

when

smaller

The

numeral

following

the

mark

is

a

figure

multiplied

by

100

HEAD

NUMBER

FiR

PD

20

Drive

pinion

head

mark

Install

the

drive

pinion

outer

races

both

front

and

rear

into

gear

carrier

using

Drive

Pinion

Outer

Race

Drift

Set

STJ061

1000

STJ0612000

and

Sn0614000

Froot

STJ061

1000

and

STJ0614000

Rear

STJ061

1000

and

STJ0612000

2

Install

the

drive

pinion

adjusting

washer

and

rear

bearing

on

the

Dummy

Shaft

STJI122000

3

Install

the

Dummy

Shaft

on

the

fmal

drive

housing

without

using

drive

pinion

adjusting

spacer

and

install

the

pinion

front

bearing

and

companion

flange

4

Tighten

the

drive

pinion

lock

nut

to

the

rated

preload

by

the

use

of

a

Drive

Pinion

Flange

Wrench

SnI540000

Drive

pinion

bearing

preload

without

oil

seal

6

to

8

kg

cm

5

2

to

6

9

in

lb

At

companion

flange

bolt

hole

19

to

2

6

kg

4

2

to

5

7lb

PD

l0

Fig

PD

21

Measuring

pinion

preload

Note

Be

careful

not

to

tighten

excessively

or

otherwise

the

bearing

will

be

damaged

since

pinion

bearing

adjusting

spacer

has

not

been

applied

5

Install

a

Height

Gauge

STJI12l000

on

the

flnal

drive

housing

and

measure

gap

with

a

thickness

gauge

ST31122000

Fig

PD

22

Measuring

clearance

r

ST31121000

ST31122000

Fig

PD

23

Adjusting

pinion

height

Page 89 of 513

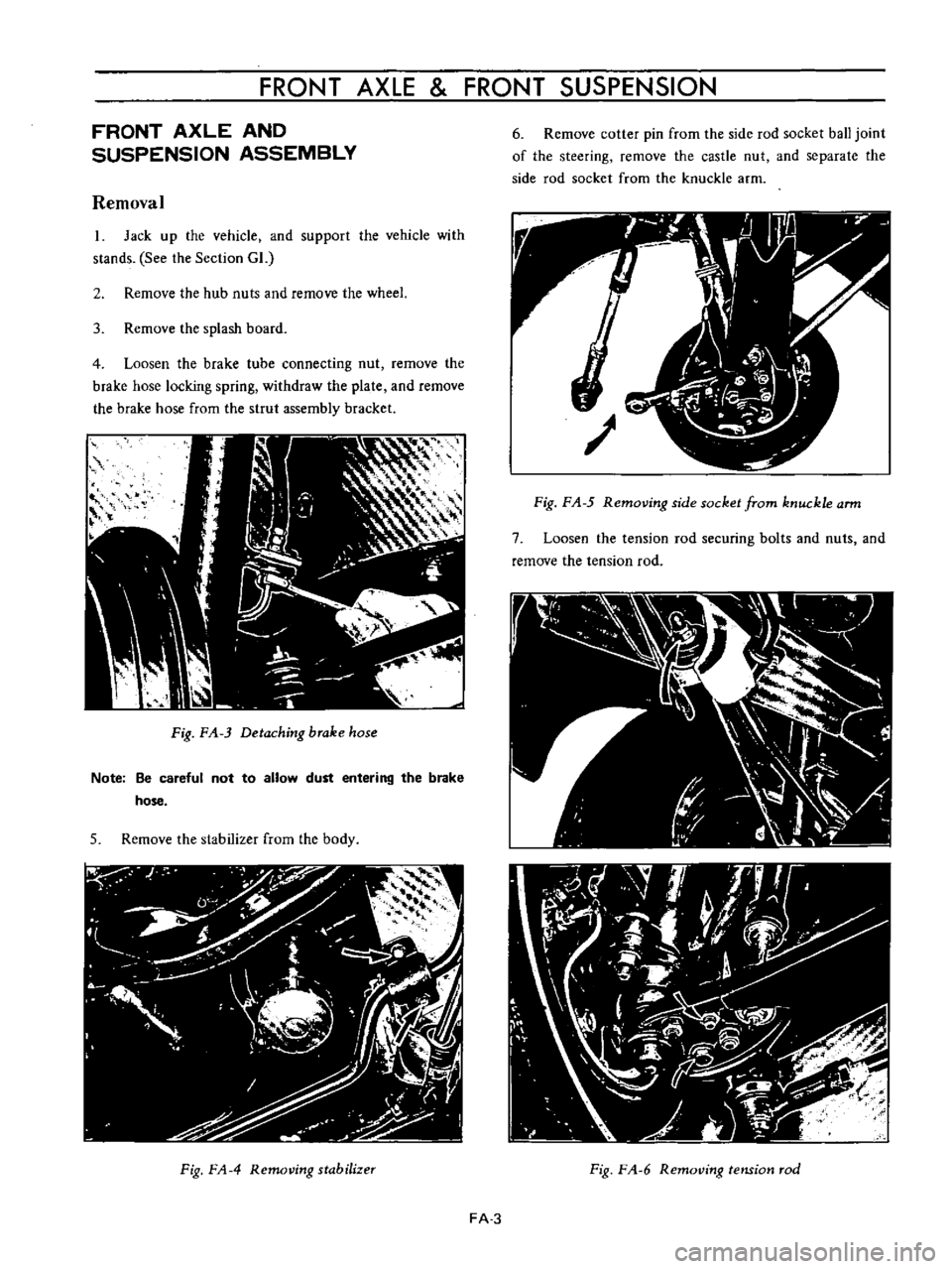

FRONT

AXLE

FRONT

SUSPENSION

FRONT

AXLE

AND

SUSPENSION

ASSEMBLY

Removal

1

Jack

up

the

vehicle

and

support

the

vehicle

with

stands

See

the

Section

GL

2

Remove

the

hub

nuts

and

remOve

the

wheel

3

Remove

the

splash

board

4

Loosen

the

brake

tube

connecting

nut

remove

the

brake

hose

locking

spring

withdraw

the

plate

and

remOve

the

brake

hose

from

the

strul

assembly

bracket

Fig

FA

3

Detaching

brake

hose

Note

Be

careful

not

to

allow

dust

entering

the

brake

hose

5

Remove

the

stabilizer

from

the

body

Fig

FA

4

Removing

stabilizer

6

Remove

cotter

pin

from

the

side

rod

socket

ball

joint

of

the

steering

remove

the

castle

nut

and

separate

the

side

rod

socket

from

the

knuckle

arm

Fig

F

A

5

Removing

side

socket

from

knuckle

arm

7

Loosen

the

tension

rod

securing

bolts

and

nuts

and

remove

the

tension

rod

Fig

F

A

6

RemotJing

tension

rod

FA

3

Page 90 of 513

CHASSIS

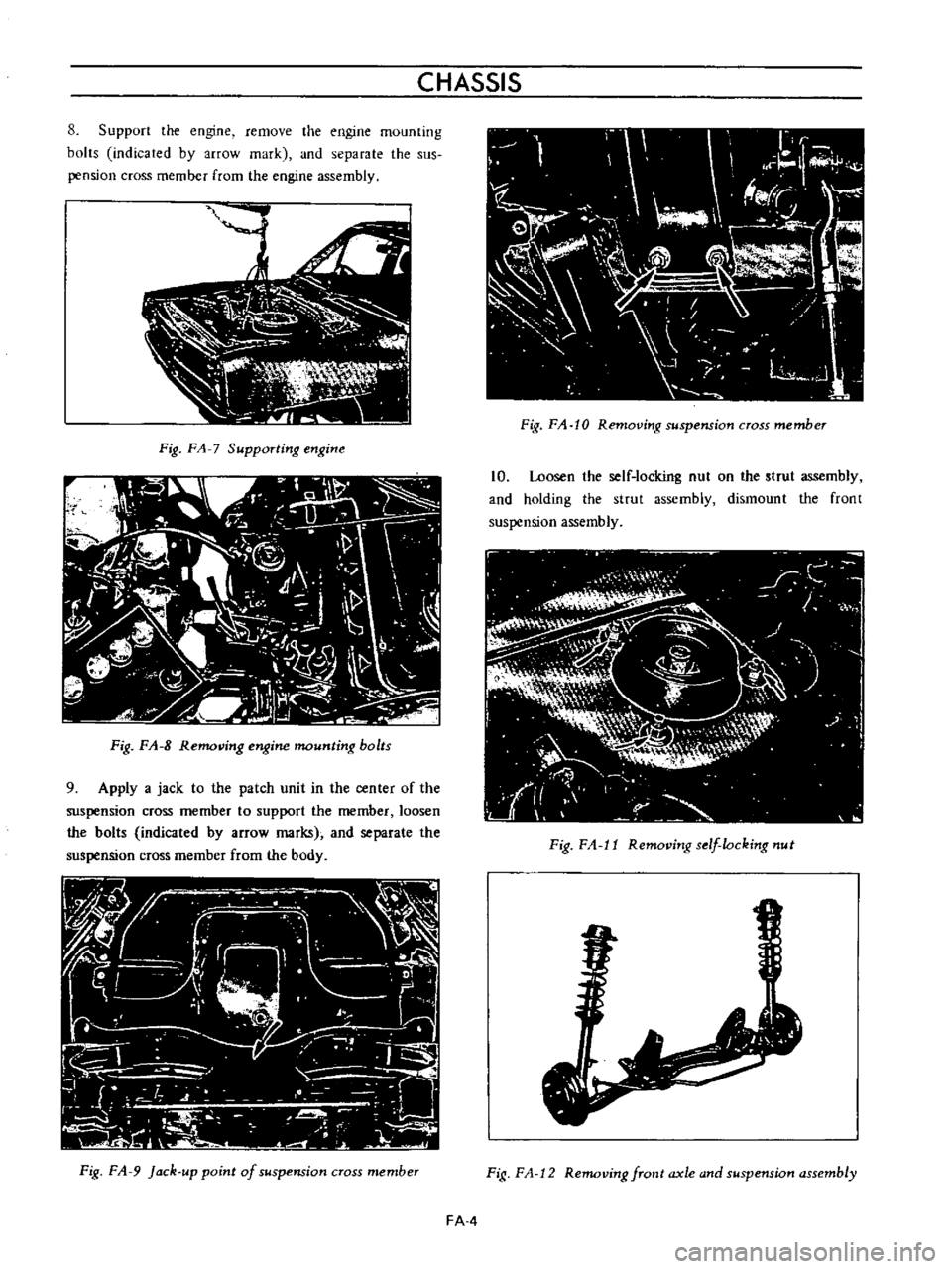

8

Support

the

engine

remove

the

engine

mounting

bolts

indicated

by

arrow

mark

and

separate

the

sus

pension

cross

member

from

the

engine

assembly

Ij

i

1

C

w

ii

lJ

c

l

I

N

r

1

a

n

h

JI

Fig

FA

7

Supporting

engine

I

IV

U

II

G

11J

r

j

F

l

I

IV

I

iL

I

0

I

l

tt

I

i

L

I

It

v

i

1

0

b

c

Ii

irti

J

I

I

1

1

Zi

J

l

ll

c

h

f

J

f

C

Fig

FA

8

Removing

engine

mounting

bolts

9

Apply

a

jack

to

the

patch

unit

in

the

center

of

the

suspension

cross

member

to

support

the

member

loosen

the

bolts

indicated

by

arrow

marks

and

separate

the

suspension

cross

member

from

the

body

Fig

FA

9

Jack

up

point

of

suspension

cross

member

Fig

FA

10

Removing

suspension

cross

member

10

Loosen

the

self

locking

nut

on

the

strut

assembly

and

holding

the

strut

assembly

dismount

the

front

suspension

assembly

Fig

F

1

11

Removing

s

flocking

nut

Fig

F

A

12

Removing

front

axle

and

suspension

assembly

FAA

Page 92 of 513

CHASSIS

Tightening

torque

of

front

suspension

cross

member

and

body

is

3

2

to

4

0

kg

m

23

1

to

28

9

ft

Ib

5

Tightening

torque

of

bolt

used

to

secure

the

upper

portion

of

the

strut

assembly

on

the

body

is

1

6

to

2

1

kg

m

11

6

to

15

2ft

lb

FRONT

AXLE

Removal

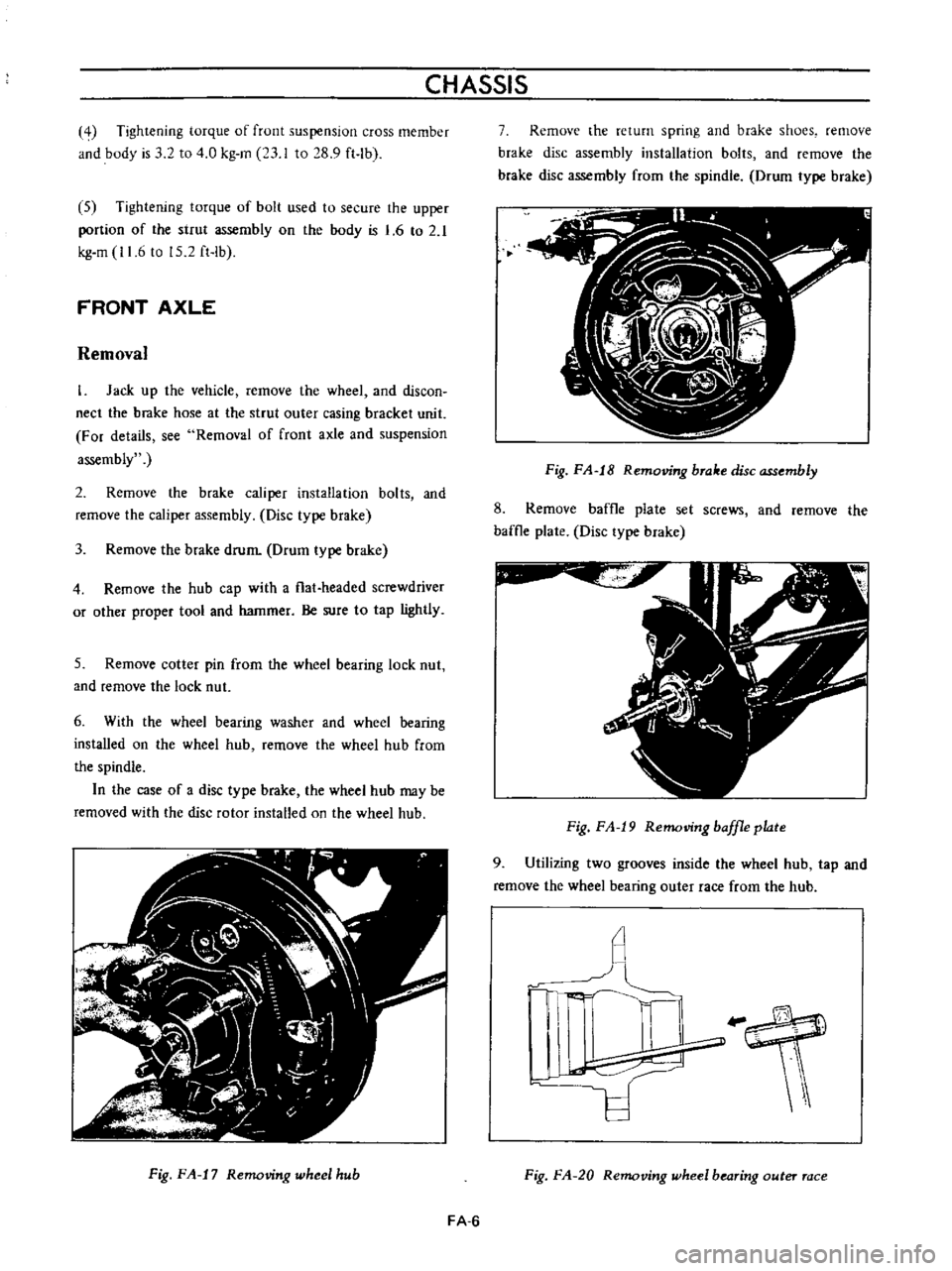

I

Jack

up

the

vehicle

remove

the

wheel

and

discon

nect

the

brake

hose

at

the

strut

outer

casing

bracket

unit

For

details

see

Removal

of

front

axle

and

suspension

assembly

2

Remove

the

brake

caliper

installation

bolts

and

remove

the

caliper

assembly

Disc

type

brake

3

Remove

the

brake

druOL

Drum

type

brake

4

Remove

the

hub

cap

with

a

flal

headed

screwdriver

or

other

proper

tool

and

hammer

Be

sure

to

tap

lightly

5

Remove

cotter

pin

from

the

wheel

bearing

lock

nut

and

remove

the

lock

nut

6

With

the

wheel

bearing

washer

and

wheel

bearing

installed

on

the

wheel

hub

remove

the

wheel

hub

from

the

spindle

In

the

case

of

a

disc

type

brake

the

wheel

hub

may

be

removed

with

the

disc

rotor

installed

on

the

wheel

hub

Fig

FA

17

Removing

wheel

hub

7

Remove

the

return

spring

and

brake

shoes

remove

brake

disc

assembly

installation

bolts

and

remove

the

brake

disc

assembly

from

the

spindle

Drum

type

brake

Fig

FA

IS

Removing

brake

disc

a

ssembly

8

Remove

baffle

plate

set

screws

and

remove

the

baffle

plate

Disc

type

brake

Fig

FA

19

Removingbaffleplate

9

Utilizing

two

grooves

inside

the

wheel

hub

tap

and

remove

the

wheel

bearing

outer

race

from

the

hub

Fig

FA

20

Removing

wheel

bearing

outer

race

FA

6