DATSUN B110 1973 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 221 of 513

Installation

Install

the

door

glass

and

regulator

in

reverse

sequence

of

removal

Reinstall

the

seal

screen

after

correctly

adjusting

door

window

closing

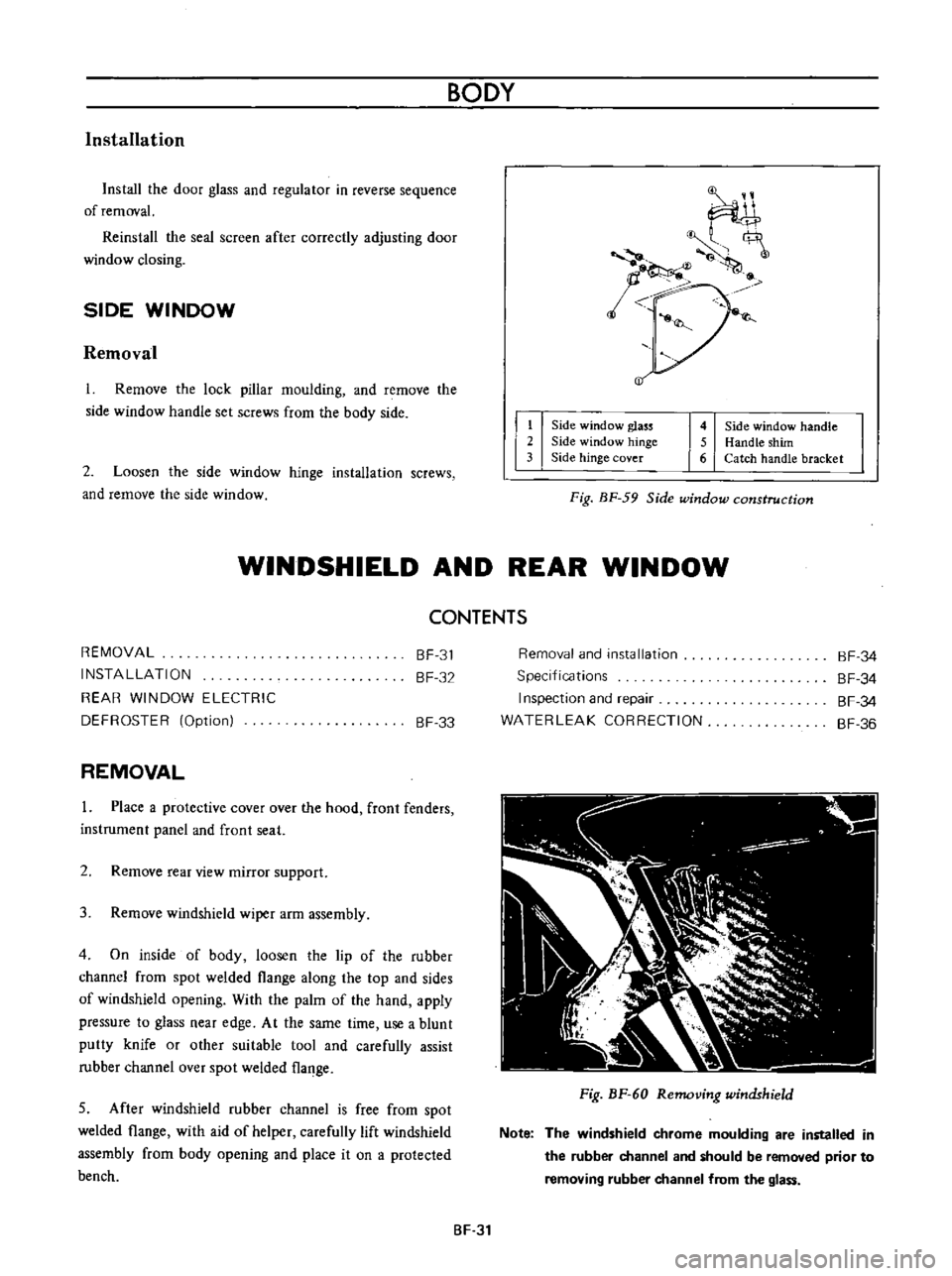

SIDE

WINDOW

Removal

I

Remove

the

lock

pillar

moulding

and

remove

the

side

window

handle

set

screws

from

the

body

side

2

Loosen

the

side

window

hinge

installation

screws

and

remove

the

side

window

BODY

7

I

I

I

c

t

2

3

Side

window

glass

Side

window

hinge

Side

hinge

cover

4

Side

window

handle

5

Handle

shim

6

Catch

handle

bracket

Fig

BF

59

Side

window

construction

WINDSHIELD

AND

REAR

WINDOW

CONTENTS

REMOVAL

INSTAllATION

REAR

WINDOW

ELECTRIC

DEFROSTER

Option

SF

31

SF

32

SF

33

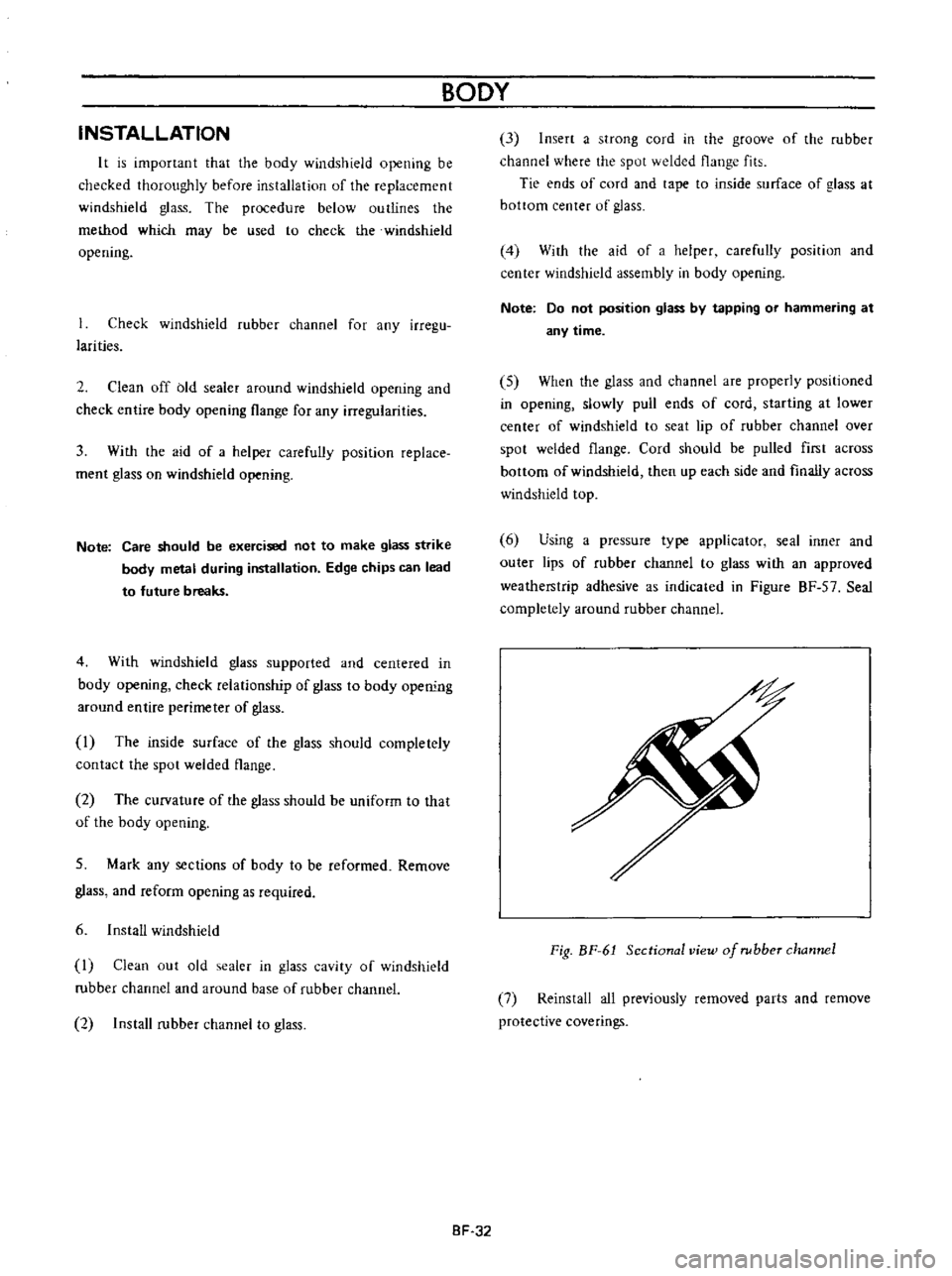

REMOVAL

1

Place

a

protective

cover

over

the

hood

front

fenders

instrument

panel

and

front

seat

2

Remove

rear

view

mirror

support

3

Remove

windshield

wiper

arm

assembly

4

On

inside

of

body

loosen

the

lip

of

the

rubber

channel

from

spot

welded

flange

along

the

top

and

sides

of

windshield

opening

With

the

palm

of

the

hand

apply

pressure

to

glass

near

edge

At

the

same

time

use

a

blunt

putty

knife

or

other

suitable

tool

and

carefully

assist

rubber

channel

over

spot

welded

flange

5

After

windshield

rubber

channel

is

free

from

spot

welded

flange

with

aid

of

helper

carefully

lift

windshield

assembly

frorn

body

opening

and

place

it

on

a

protected

bench

Removal

and

installation

Specifications

I

nspection

and

repair

WATERlEAK

CORRECTION

BF

34

SF

34

SF

34

SF

36

Fig

BF

60

Removing

windshield

Note

The

windshield

chrome

moulding

are

installed

in

the

rubber

channel

and

should

be

removed

prior

to

removing

rubber

channel

from

the

gla55

SF

31

Page 222 of 513

INSTALLATION

It

is

important

that

the

body

windshield

opening

be

checked

thoroughly

before

installation

of

the

replacement

windshield

glass

The

procedure

below

outlines

the

method

which

may

be

used

to

check

the

windshield

opening

Check

windshield

rubber

channel

for

any

irregu

larities

2

Clean

off

bid

sealer

around

windshield

opening

and

check

entire

body

opening

flange

for

any

irregularities

3

With

the

aid

of

a

helper

carefully

position

replace

ment

glass

on

windshield

opening

Note

Care

should

be

exercised

not

to

make

glass

strike

body

metal

during

installation

Edge

chips

can

lead

to

future

breaks

4

With

windshield

glass

supported

and

centered

in

body

opening

check

relationship

of

glass

to

body

ope

rung

around

entire

perimeter

of

glass

I

The

inside

surface

of

the

glass

should

completely

contact

the

spot

welded

flange

2

The

curvature

of

the

glass

should

be

uniform

to

that

of

the

body

opening

5

Mark

any

sections

of

body

to

be

reformed

Remove

glass

and

reform

opening

as

required

6

Install

windshield

I

Clean

out

old

sealer

in

glass

cavity

of

windshield

rubber

channel

and

around

base

of

rubber

channel

2

Install

rubber

channel

to

glass

BODY

8F

32

3

Insert

a

strong

cord

in

the

groove

of

the

rubber

channel

where

the

spot

welded

flange

fits

Tie

ends

of

cord

and

tape

to

inside

surface

of

glass

at

bottom

center

of

glass

4

With

the

aid

of

a

helper

carefully

position

and

center

windshield

assembly

in

body

opening

Note

Do

not

position

glass

by

tapping

or

hammering

at

any

time

5

When

the

glass

and

channel

are

properiy

positioned

in

opening

slowly

pull

ends

of

cord

starting

at

lower

center

of

windshield

to

seat

lip

of

rubber

channel

over

spot

welded

flange

Cord

should

be

pulled

first

across

bottom

of

windshield

then

up

each

side

and

finally

across

windshield

top

6

Using

a

pressure

type

applicator

seal

inner

and

outer

lips

of

rubber

channel

to

glass

with

an

approved

weatherstrip

adhesive

as

indicated

in

Figure

BF

57

Seal

completely

around

rubber

channel

Fig

BF

61

Sectional

view

of

rubber

channel

7

Reinstall

all

previously

removed

parts

and

remove

protective

coverings

Page 223 of 513

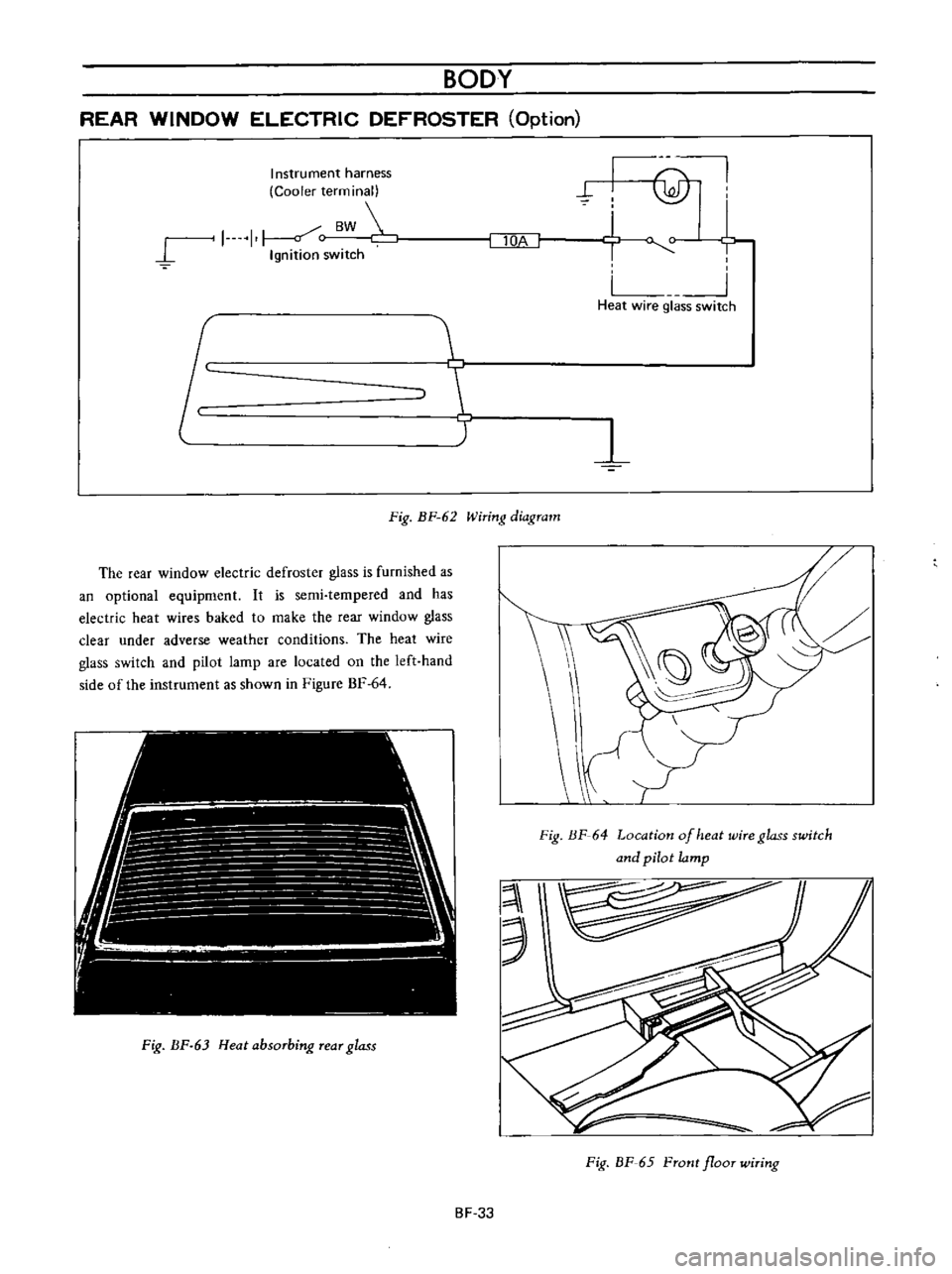

BODY

REAR

WINDOW

ELECTRIC

DEFROSTER

Option

J

Instrument

harness

Cooler

terminal

J

1

1

c

BW

Ignition

switch

I

lOA

@

hi

u

Heat

wire

glass

switch

T

Fig

BF

62

Wiring

diagram

The

rear

window

electric

defroster

glass

is

furnished

as

an

optional

equipment

It

is

semi

tempered

and

has

electric

heat

wires

baked

to

make

the

rear

window

glass

clear

under

adverse

weather

conditions

The

heat

wire

glass

switch

and

pilot

larnp

are

located

on

the

left

hand

side

of

the

instrument

as

shown

in

Figure

BF

64

Fig

BF

63

Heat

absorbing

rear

glass

Fig

HF

64

Location

of

heat

wire

glass

switch

and

pilot

lamp

3

Fig

BF

65

Front

floor

wiring

BF

33

Page 224 of 513

BODY

Removal

and

installation

The

rear

window

electric

defroster

glass

is

removed

from

or

installed

on

its

position

in

the

same

manner

as

that

for

the

standard

rear

window

glass

Heat

wire

harness

1

Fig

BF

66

Rear

floor

wiring

Note

a

Use

care

not

to

give

scratches

and

wiring

b

Remove

weather

strip

whenever

glass

is

to

be

replaced

After

glass

is

installed

in

place

apply

sealant

between

panel

and

weather

strip

1

Connection

Specifications

Glass

Semi

tempered

heat

absorbing

type

Power

consumption

75W

l2V

Heating

wire

Baked

on

rear

window

Interior

side

Heating

wire

coverage

Horizontal

Vertical

Full

width

390

mm

15

35

in

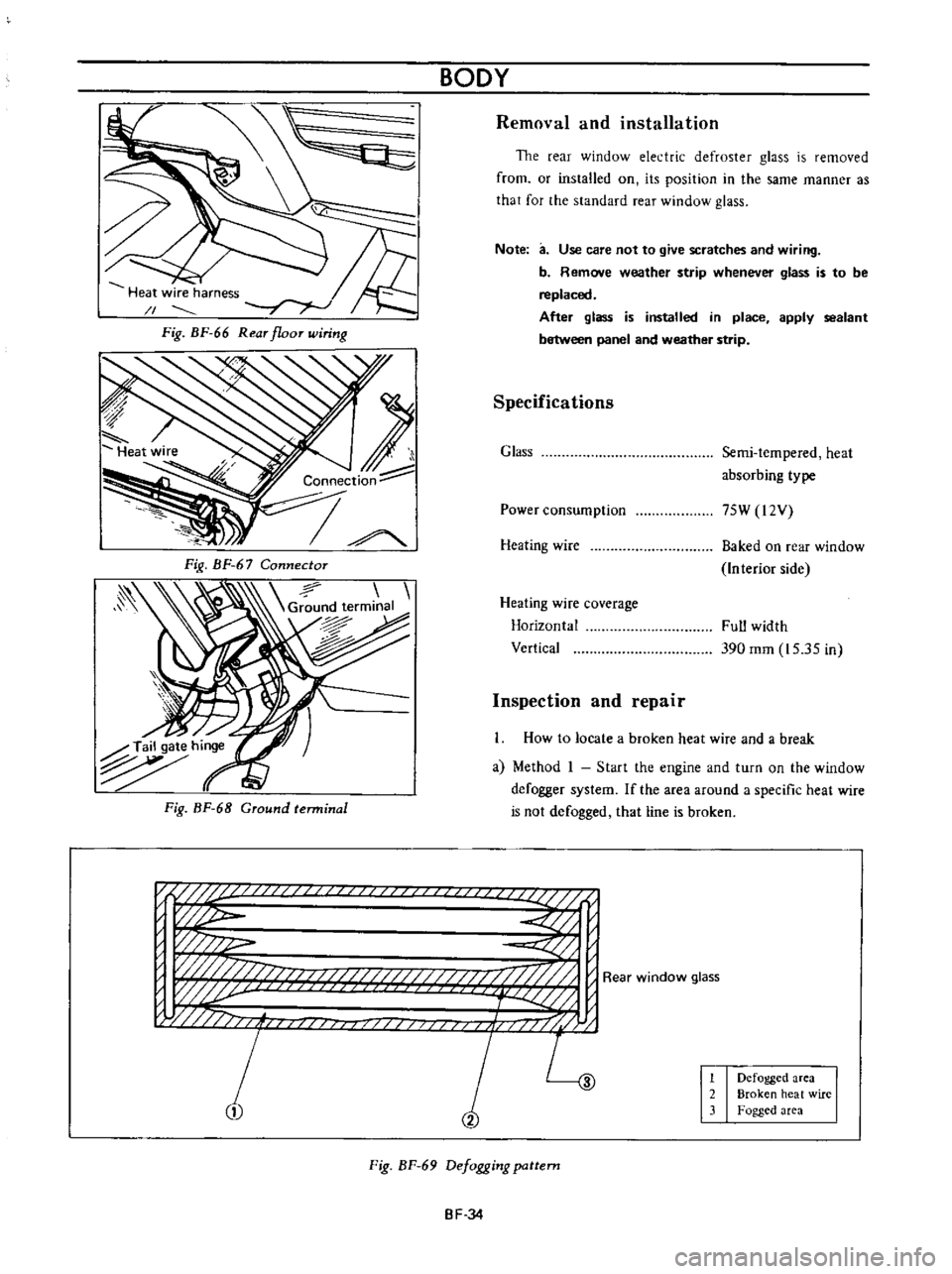

Inspection

and

repair

Ground

terminal

How

to

locate

a

broken

heat

wire

and

a

break

a

Method

I

Start

the

engine

and

turn

on

the

window

defogger

system

If

the

area

around

a

specific

heat

wire

is

not

defogged

that

line

is

broken

n

if

U

i

p

w

w

j

w

j

fj

f

i

j

L

1

2

Defogged

area

Broken

heat

wire

Fogged

area

Fig

BF

69

Defogging

pattern

BF

34

Page 225 of 513

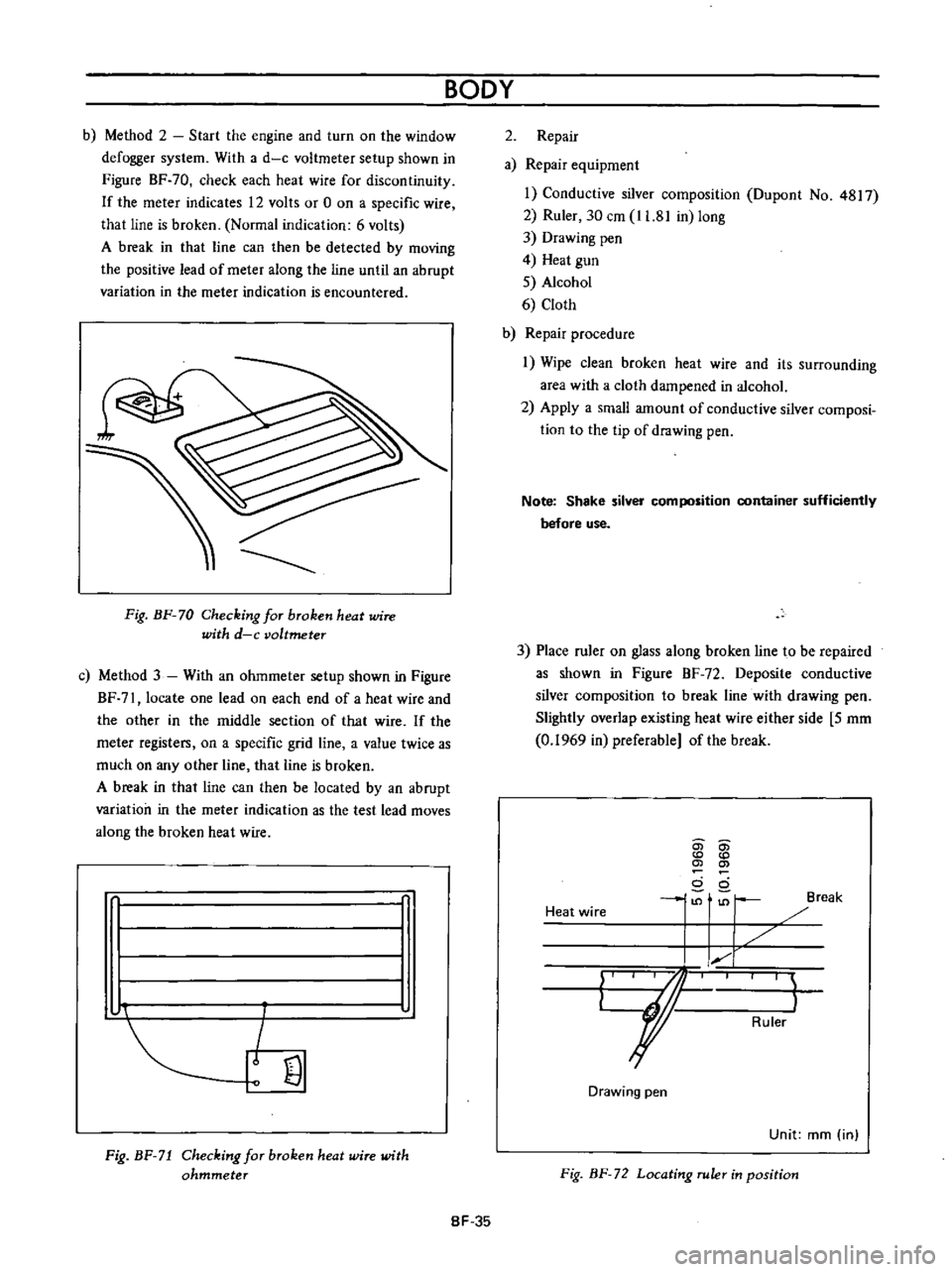

BODY

b

Method

2

Start

the

engine

and

turn

on

the

window

defogger

system

With

a

d

c

voltmeter

setup

shown

in

Figure

BF

70

check

each

heat

wire

for

discontinuity

If

the

meter

indicates

12

volts

or

0

on

a

specific

wire

that

line

is

broken

Normal

indication

6

volts

A

break

in

that

line

can

then

be

detected

by

moving

the

positive

lead

of

meter

along

the

line

until

an

abrupt

variation

in

the

meter

indication

is

encountered

Fig

BF

70

Checking

for

broken

heat

wire

with

d

c

voltmeter

c

Method

3

With

an

ohmmeter

setup

shown

in

Figure

BF

7l

locate

one

lead

on

each

end

of

a

heat

wire

and

the

other

in

the

rniddle

section

of

that

wire

If

the

meter

registers

on

a

specific

grid

line

a

value

twice

as

much

on

any

other

line

that

line

is

broken

A

break

in

that

line

can

then

be

located

by

an

abrupt

variation

in

the

meter

indication

as

the

test

lead

moves

along

the

broken

heat

wire

r

I

I

I

J

I

I

v

Ejl

Fig

BF

71

Checking

for

broken

heat

wire

with

ohmmeter

2

Repair

a

Repair

equipment

1

Conductive

silver

composition

Dupont

No

4817

2

Ruler

30

em

11

81

in

long

3

Drawing

pen

4

Heat

gun

5

Alcohol

6

Cloth

b

Repair

procedure

1

Wipe

clean

broken

heat

wire

and

its

surrounding

area

with

a

cloth

dampened

in

alcohol

2

Apply

a

small

amount

of

conductive

silver

composi

tion

to

the

tip

of

drawing

pen

Note

Shake

silver

composition

container

sufficiently

before

use

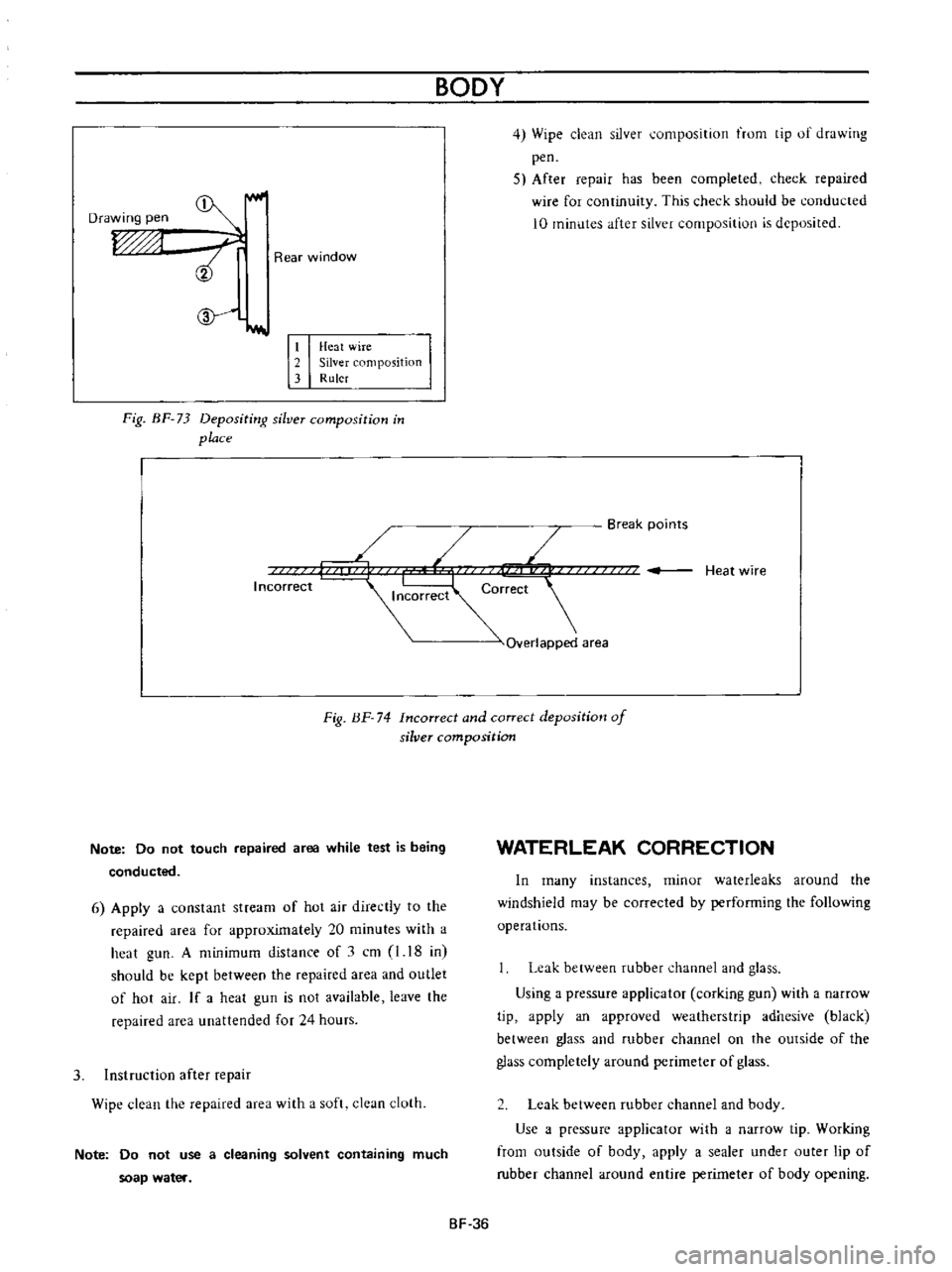

3

Place

ruler

on

glass

along

broken

line

to

be

repaired

as

shown

in

Figure

BF

72

Deposite

conductive

silver

composition

to

break

line

with

drawing

pen

Slightly

overlap

existing

heat

wire

either

side

5

mm

0

1969

in

preferable

of

the

break

Heat

wire

0

en

0

0

d

ci

1

I

Break

I

1

I

kr

I

I

Ruler

Drawing

pen

Unit

mm

in

Fig

BF

72

Locating

ruler

in

position

8F

35

Page 226 of 513

Drawing

pen

ri

Rear

window

L

Ii

r

Heat

wire

2

Silver

Imposition

3

Ruler

Fig

BF

73

Depositi

rg

silver

composition

in

place

BODY

4

Wipe

clean

silver

umposition

trom

tip

of

drawing

pen

5

After

repair

has

been

completed

check

repaired

wire

for

continuity

This

check

shuuld

be

conducted

10

minutes

after

silver

composition

is

deposited

Break

points

L

Heat

wire

orrect

r

Overlapped

area

Incorrect

Fig

BF

74

Incorrect

and

correct

deposition

of

silver

composition

Note

Do

not

touch

repaired

area

while

test

is

being

conducted

6

Apply

a

constant

stream

of

hot

air

directly

to

the

repaired

area

for

approximately

20

minutes

with

a

heat

gun

A

minimum

distance

of

1

cm

l

18

in

should

be

kept

between

the

repaired

area

and

outlet

of

hot

air

If

a

heat

gun

is

not

available

leave

the

repaired

area

unattended

for

24

hours

3

Instruction

after

repair

Wipe

clean

the

repaired

area

with

a

soft

clean

cloth

Note

Do

not

use

a

cleaning

solvent

containing

much

soap

water

WATERLEAK

CORRECTION

In

many

instances

minor

waterleaks

around

the

windshield

may

be

corrected

by

performing

the

following

operations

Leak

between

rubber

channel

and

glass

Using

a

pressure

applicator

corking

gun

with

a

narrow

tip

apply

an

approved

weatherstrip

adhesive

black

between

glass

and

rubber

channel

on

the

outside

of

the

glass

completely

around

perimeter

of

glass

Leak

between

rubber

channel

and

body

Use

a

pressure

applicator

with

a

narrow

tip

Working

from

outside

of

body

apply

a

sealer

under

outer

lip

of

rubber

channel

around

entire

perimeter

of

body

opening

SF

36

Page 227 of 513

BODY

VENTILATOR

CONTENTS

DESCRIPTION

BF

37

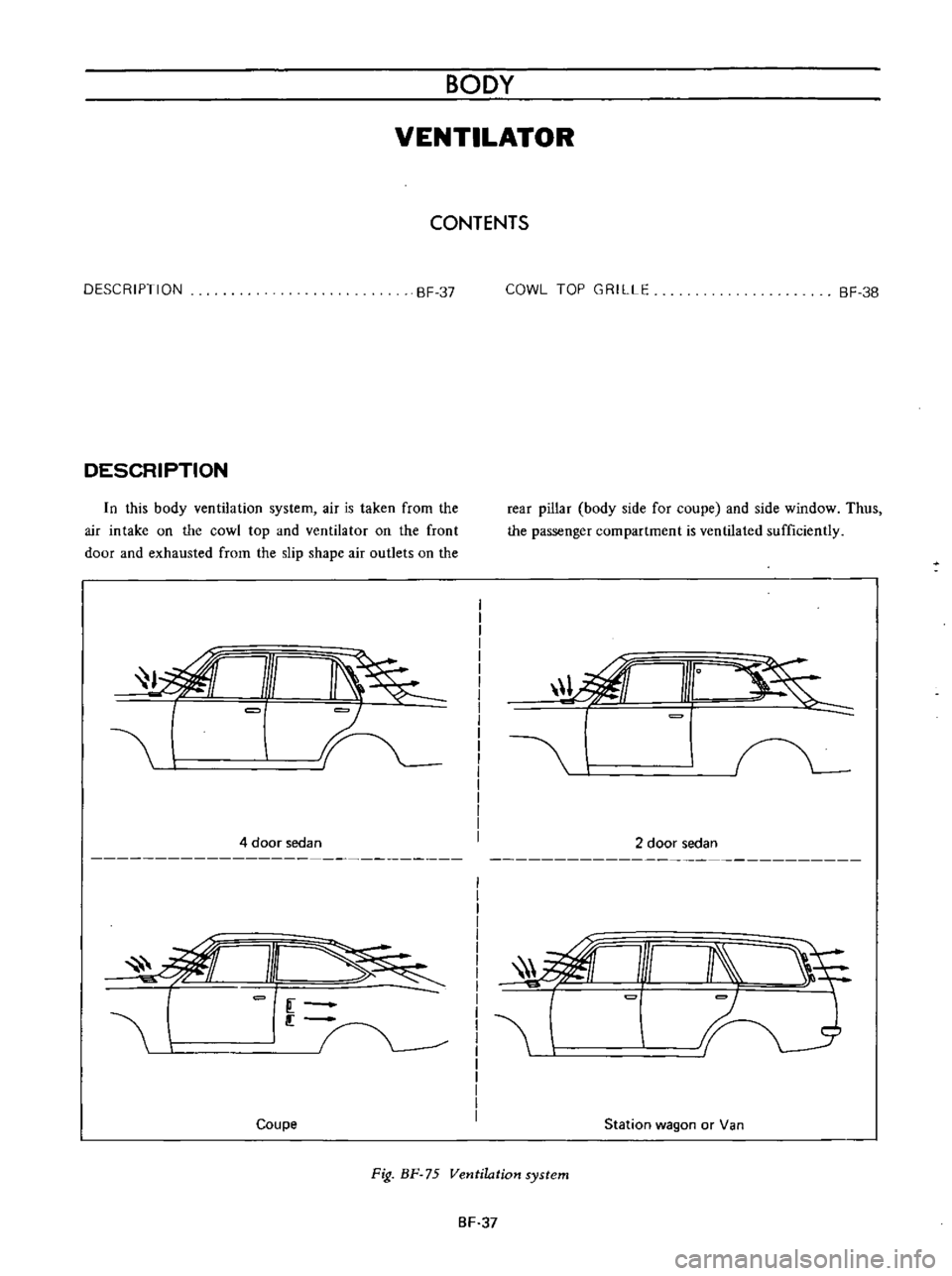

DESCRIPTION

In

this

body

ventilation

system

air

is

taken

from

the

air

intake

on

the

cowl

top

and

ventilator

on

the

front

door

and

exhausted

from

the

slip

shape

air

outlets

on

the

4

1

4

door

sedan

I

Coupe

COWL

TOP

GRILLE

BF

38

rear

pillar

body

side

for

coupe

and

side

window

Thus

the

passenger

compartment

is

ventilated

sufficiently

L

2

door

sedan

I

I

1

Station

wagon

or

Van

Fig

BF

75

Ventilation

system

BF

37

Page 228 of 513

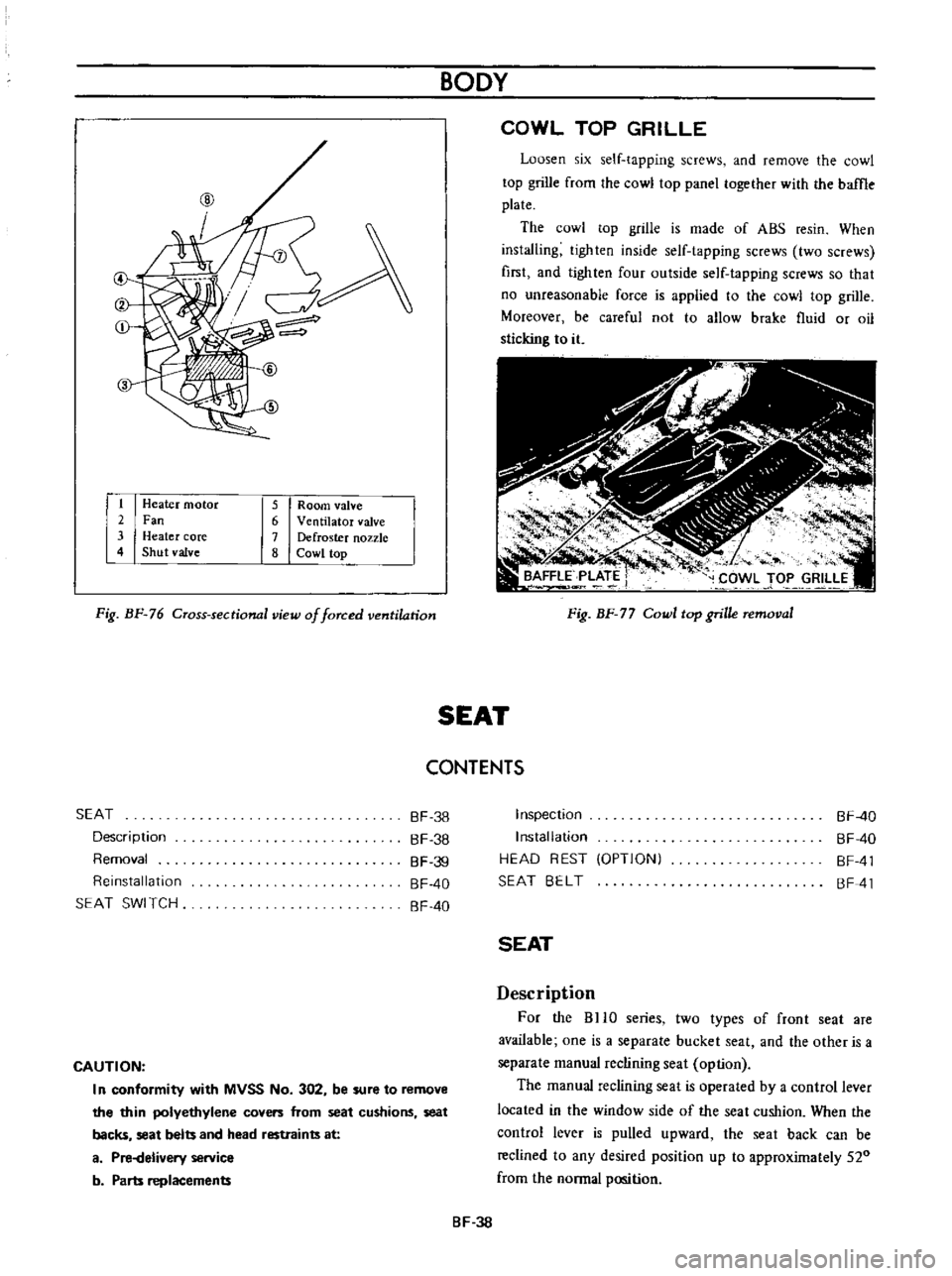

@

c

@

CD

w

1

Heater

motor

2

Fan

3

Heater

core

4

Shut

valve

5

Room

valve

6

Ventilator

valve

7

Defroster

nozzle

8

Cowl

top

Fig

BF

76

Cross

sectional

view

of

forced

ventilation

BODY

COWL

TOP

GRILLE

Loosen

six

self

tapping

screws

and

remove

the

cowl

top

grille

from

the

cowl

top

panel

together

with

the

baffle

plate

The

cowl

top

grille

is

made

of

ABS

resin

When

installing

tighten

inside

self

tapping

screws

two

screws

first

and

lighten

four

outside

self

tapping

screws

so

that

no

unreasonable

force

is

applied

to

the

cowl

top

grille

Moreover

be

careful

not

to

allow

brake

fluid

or

oil

sticking

to

it

Fig

BF

77

Cowl

top

grille

removal

SEAT

CONTENTS

SEAT

Description

Removal

Reinstallation

SEAT

SWI

TCH

BF

38

BF

38

BF

39

BF

40

BF

40

CAUTION

I

n

conformity

with

MVSS

No

302

be

sure

to

remove

the

thin

polyethylene

covers

from

seat

cushions

seat

backs

seat

belts

and

head

restraints

at

a

Pi

Helivery

service

b

Parts

replacements

Inspection

Installation

HEAD

REST

OPTIONI

SEAT

BELT

BF

40

BF

40

BF

41

BF

41

SEAT

Description

For

the

BHO

series

two

types

of

front

seat

are

available

one

is

a

separate

bucket

seat

and

the

other

is

a

separate

manual

reclining

seat

option

The

manual

reclining

seat

is

operated

by

a

control

lever

located

in

the

window

side

of

the

seat

cushion

When

the

control

lever

is

pulled

upward

the

seat

back

can

be

reclined

to

any

desired

position

up

to

approximately

520

from

the

normal

position

BF

38

Page 229 of 513

Fig

BF

78

Front

seat

Removal

Slide

rail

of

front

seat

I

Slide

the

lower

rail

toward

rear

side

of

the

seat

and

remove

the

seat

frame

connecting

bolts

2

Remove

return

spring

3

Slide

the

lower

rail

forward

and

remove

the

fIxing

bolts

from

the

rear

side

Rear

seat

sedan

1

Remove

two

screws

from

both

sides

of

the

seat

cushion

2

Raising

front

side

of

the

seat

cushion

pull

it

out

3

Remove

the

seat

back

attaching

screws

Fig

BF

79

Removing

seat

cushion

fixing

screws

BODY

Fig

BF

80

Removing

seat

back

installation

screws

4

Unhook

the

seat

back

at

the

rear

bulk

head

upper

portion

Rear

seat

coupe

Raising

rear

side

of

the

seat

cushion

pull

out

the

cushion

stopper

and

remove

the

seat

cushion

Fig

BF

81

Removing

Tear

seat

cushion

2

Loosen

installation

screws

and

remove

the

seat

back

Rear

seat

Van

I

Turn

down

the

seat

cushion

forward

remove

four

screws

and

remove

the

seat

cushion

as

shown

in

Figure

BF

82

8F

39

Page 230 of 513

Fig

BF

82

Removing

rear

seat

cushion

2

With

the

seat

back

turned

down

remove

two

screws

from

the

wheel

house

and

remove

the

seat

back

111

I

V

RH

0

1

lr

Fig

BF

83

Removing

rear

seat

back

Reinstallation

Reinstall

the

seat

cushions

and

seat

backs

in

reverse

sequence

of

removal

SEAT

SWITCH

Inspection

Seat

switch

should

operate

accurately

Prior

to

inspecting

seat

switch

disconnect

harness

I

Place

standard

weight

on

the

illustrated

position

of

assistant

seat

Note

Put

weight

on

shadowed

area

See

Figure

BF

84

BODY

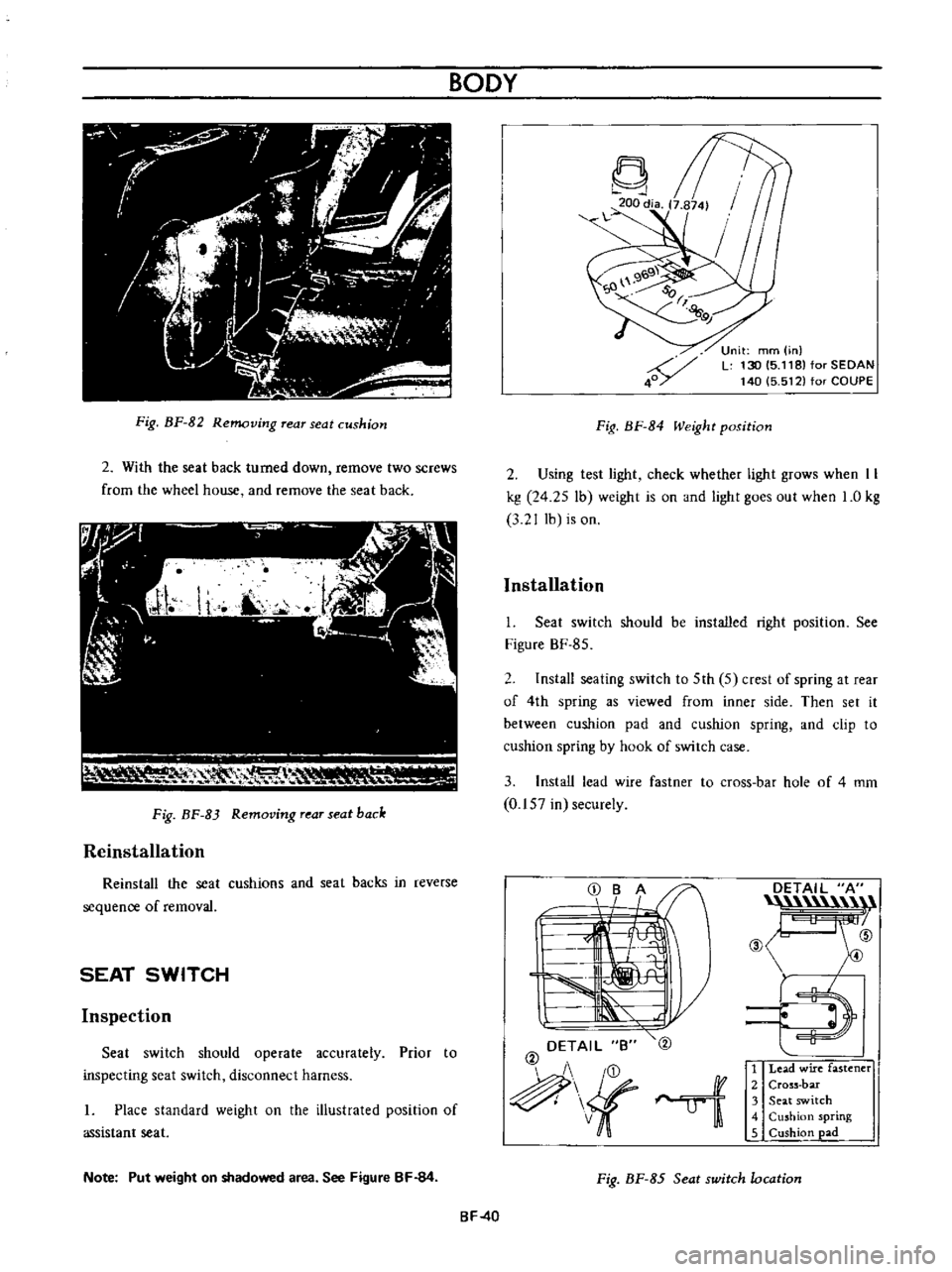

Fig

BF

84

Weight

position

Unit

mm

in

L

130

15

118

for

SEDAN

140

5

512

for

COUPE

2

Using

test

light

check

whether

light

grows

when

II

kg

24

25

lb

weight

is

on

and

light

goes

out

when

1

0

kg

3

2

J

lb

is

on

Installation

I

Seat

switch

should

be

installed

right

position

See

Figure

BF

85

2

Install

seating

switch

to

5th

5

crest

of

spring

at

rear

of

4th

spring

as

viewed

from

inner

side

Then

set

it

between

cushion

pad

and

cushion

spring

and

clip

to

cushion

spring

by

hook

of

switch

case

3

Install

lead

wire

fastner

to

cross

bar

hole

of

4

mm

0

157

in

securely

DETAIL

B

@

ui

DETAIL

A

n

@

ID

E

l

1

Lead

wire

fastener

2

Cross

bar

3

Seat

switch

4

Cushion

spring

5

Cushion

pad

Fig

BF

85

Seat

switch

location

BF

40