DATSUN B110 1973 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 261 of 513

The

lamp

does

not

go

out

when

the

engine

is

started

Faulty

charging

system

BODY

Inspect

the

charging

system

WINDSHIELD

WIPER

AND

WASHER

Description

Wiper

motor

replacement

Wiper

blade

operating

range

CONTENTS

BE

26

BE

27

BE

27

Description

The

windshield

wipers

consist

of

wiper

motor

link

mechanism

wiper

arms

and

blades

The

wiper

motor

unit

consists

of

a

motor

and

auto

stop

mechanism

The

wiper

rnotor

is

of

a

2

speed

type

When

the

wiper

switch

knob

is

pulled

to

the

I

st

step

the

windshield

wipers

operate

at

low

speed

and

when

pulled

to

the

2nd

step

operate

at

high

speed

The

wiper

motor

unit

is

located

on

the

cowl

dash

in

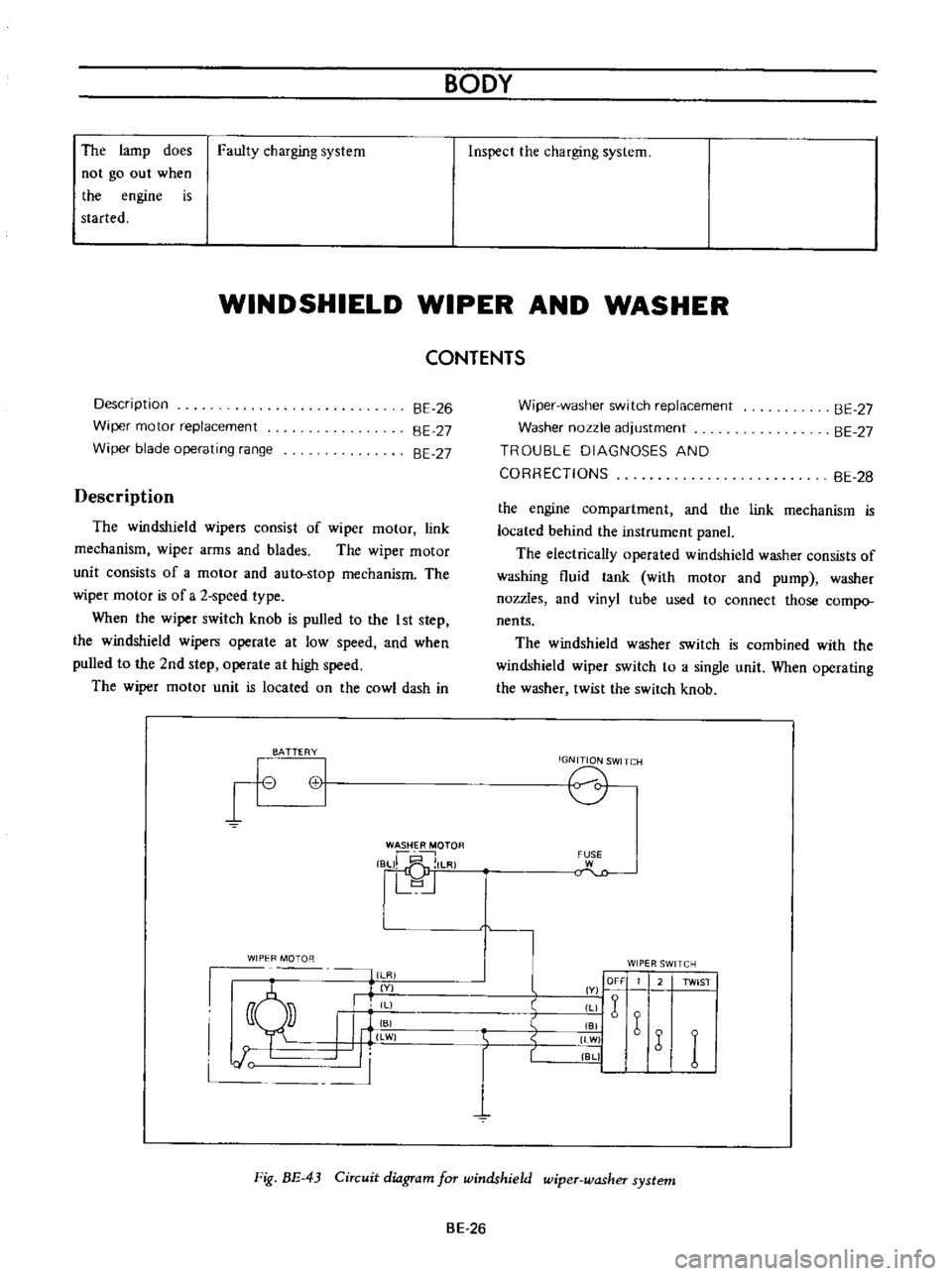

BATTERY

Cl

WIPER

MOTOR

rrQ

J

WASHER

MOTOR

IB

ILRI

L

CJ

LA

t

Y

I

Ll

j

IBI

1

f

I

LW

I

Wiper

washer

switch

replacement

Washer

nozzle

adjustment

TROUBLE

OIAGNOSES

ANO

CORRECTIONS

BE

27

BE

27

BE

28

the

engine

compartment

and

the

link

mechanism

is

located

behind

the

instrument

panel

The

electrically

operated

windshield

washer

consists

of

washing

fluid

lank

with

rnotor

and

pump

washer

nozzles

and

vinyl

tube

used

to

connect

those

compo

nents

The

windshield

washer

switch

is

combined

with

the

windshield

wiper

switch

to

a

single

unit

When

operating

the

washer

twist

the

switch

knob

IG

FUSE

W

v

l

i

f

WIPER

SWITCH

10FFI

I

2

I

TWIST

I

y

ILl

I

b

I

J

6

I

BLII

Fig

BE

43

Circuit

diagram

for

windshield

wiper

washer

system

BE

26

Page 262 of 513

BODY

ELECTRICAL

Wiper

motor

replacement

First

of

all

remove

the

connector

plug

from

the

wiper

motoI

2

Remove

a

nut

used

to

connect

wiper

motor

worm

wheel

shaft

to

the

connecting

rod

from

passenger

compartment

side

dash

panel

3

Loosen

three

bolts

used

to

install

the

wiper

motor

on

the

cowl

dash

remove

the

wiper

motor

4

Reinstall

a

new

wiper

motor

in

reverse

sequence

of

removal

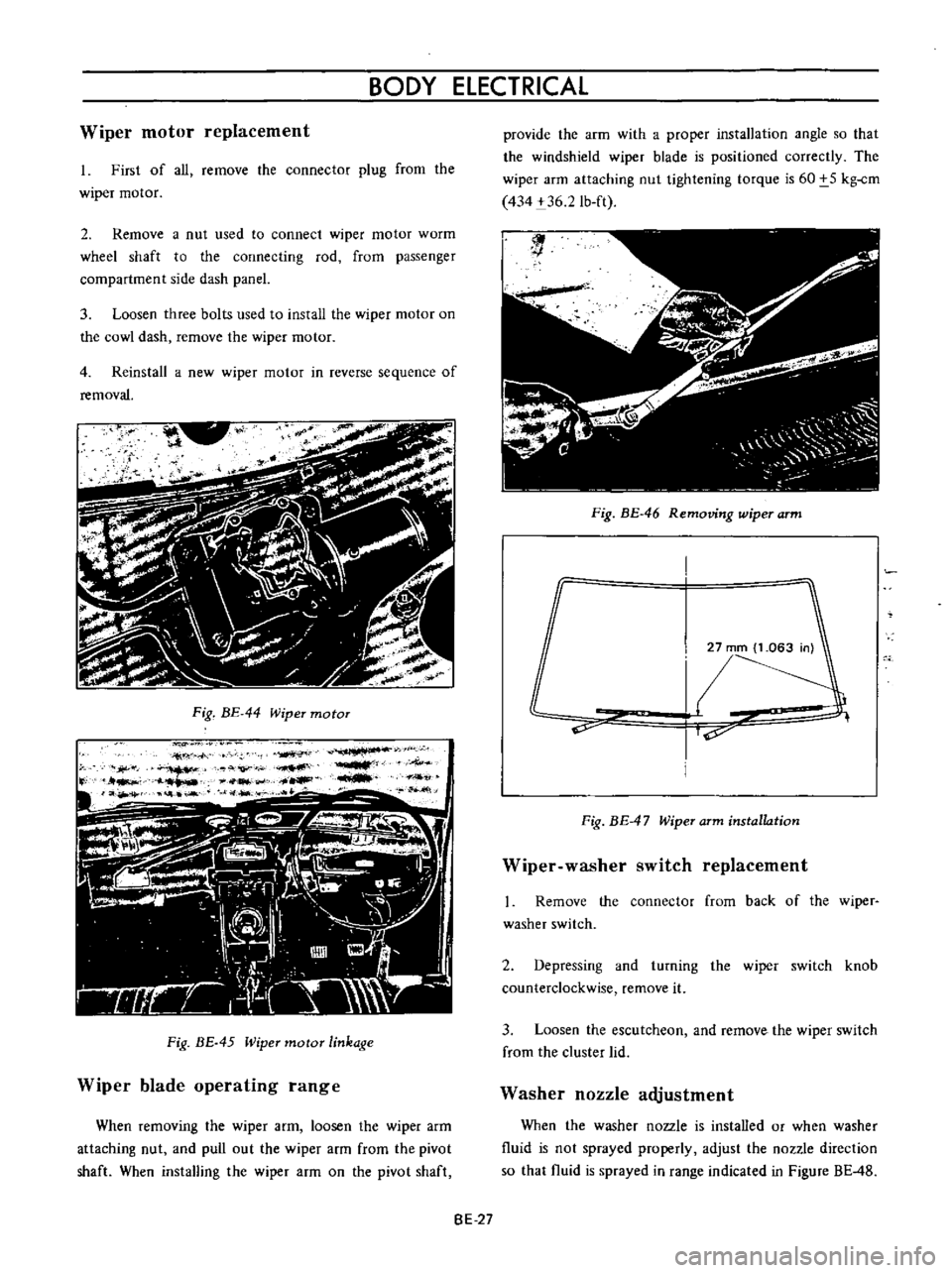

Fig

BE

44

Wiper

motor

Q

V

rt

ir

o

y

At

Jllif

Fig

BE

45

Wiper

motor

linkage

Wiper

blade

operating

range

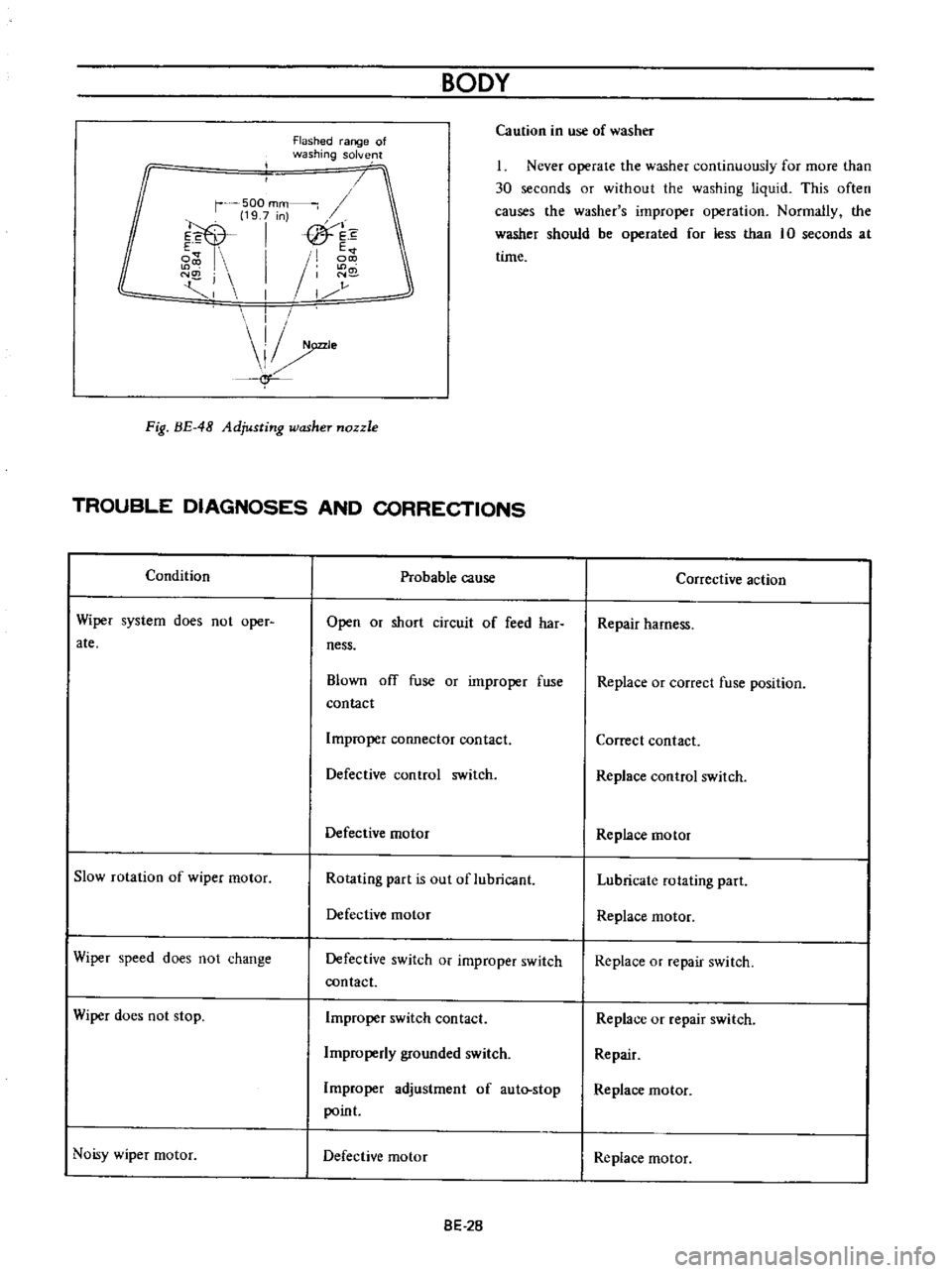

When

removing

the

wiper

arm

loosen

the

wiper

arm

attaching

nut

and

pull

out

the

wiper

arm

from

the

pivot

shaft

When

installing

the

wiper

arm

on

the

pivot

shaft

provide

the

arm

with

a

proper

installation

angle

so

that

the

windshield

wiper

blade

is

positioned

correctly

The

wiper

arm

attaching

nut

tightening

torque

is

60

5

kg

m

434

36

2lb

ft

Fig

BE

46

Removing

wiper

arm

00

I

i

Fig

BE

47

Wiper

arm

installation

Wiper

washer

switch

replacement

Remove

the

connector

from

back

of

the

wiper

washer

switch

2

Depressing

and

turning

the

wiper

switch

knob

counterclockwise

remove

it

3

Loosen

the

escutcheon

and

remove

the

wiper

switch

from

the

cluster

lid

Washer

nozzle

adjustment

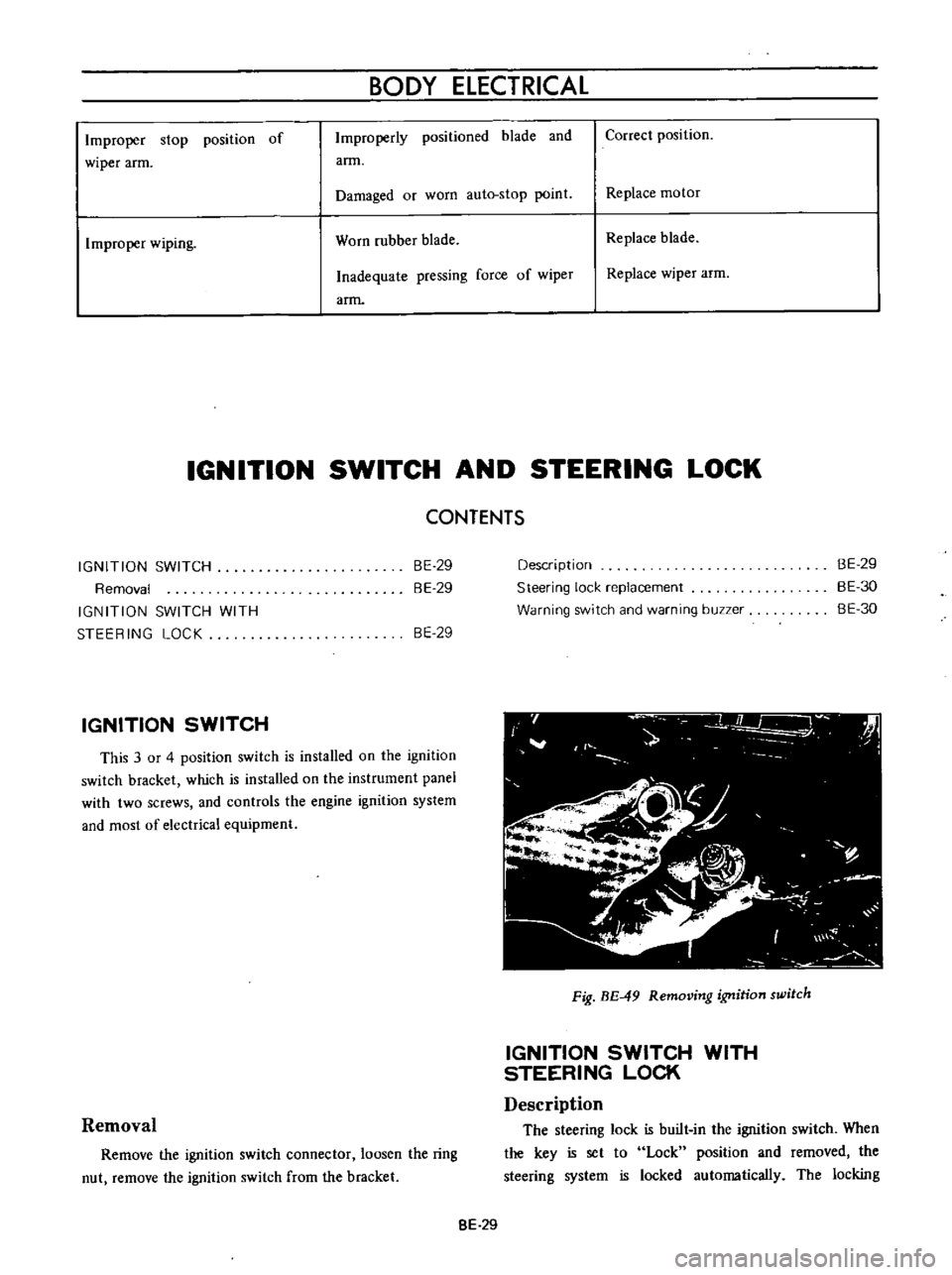

When

the

washer

nozzle

is

installed

or

when

washer

fluid

is

not

sprayed

properly

adjust

the

nozzle

direction

so

that

fluid

is

sprayed

in

range

indicated

in

Figure

BE

48

BE

27

Page 263 of 513

BODY

Flashed

range

of

washing

solve

lt

Ca

ution

in

use

of

washer

r

500

mm

19

7

n

E

I

fTh

e

i

E

I

I

N

j

1

N

I

1

r

j

I

I

e

f

1

Never

operate

the

washer

continuously

for

more

than

30

seconds

or

without

the

washing

liquid

This

often

causes

the

washer

s

improper

operation

Normally

the

washer

should

be

operated

for

less

than

10

seconds

at

time

Fig

BE

48

Adjusting

washer

nozzle

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Corrective

action

Wiper

system

does

not

oper

ate

Open

or

short

circuit

of

feed

har

ness

Repair

harness

Blown

ofT

fuse

or

improper

fuse

contact

Replace

or

correct

fuse

position

Improper

connector

contact

Correct

contact

Defective

control

switch

Replace

control

switch

Defective

motor

Replace

motor

Slow

rotation

of

wiper

motor

Rotating

part

is

out

of

lubricant

Lubricate

rotating

part

Defective

motor

Replace

rnotor

Wiper

speed

does

not

change

Defective

switch

or

improper

switch

contact

Replace

or

repair

switch

Wiper

does

not

stop

Improper

switch

contact

Replace

or

repair

switch

Irnproperly

grounded

switch

Repair

Improper

adjustment

of

aut

stop

point

Replace

motor

Noisy

wiper

motor

Defective

motor

Replace

motor

8E

2B

Page 264 of 513

BODY

ELECTRICAL

Improper

stop

position

of

wiper

arm

Improperly

positioned

blade

and

arm

Correct

position

Damaged

or

worn

auto

stop

point

Replace

motor

Improper

wiping

Worn

rubber

blade

Replace

blade

Inadequate

pressing

force

of

wiper

arm

Replace

wiper

arm

IGNITION

SWITCH

AND

STEERING

LOCK

CONTENTS

IGNITION

SWITCH

Removal

IGNITION

SWITCH

WITH

STEER

ING

LOCK

BE

29

BE

29

BE

29

IGNITION

SWITCH

This

3

or

4

position

switch

is

installed

on

the

ignition

switch

bracket

which

is

installed

on

the

instrument

panel

with

two

screws

and

controls

the

engine

ignition

system

and

most

of

electrical

equipment

Removal

Remove

the

ignition

switch

connector

loosen

the

ring

nut

remove

the

ignition

switch

from

the

bracket

Description

Steering

lock

replacement

Warning

switch

and

warning

buzzer

BE

29

BE

30

BE

30

Fig

BE

49

Removing

ignition

switch

IGNITION

SWITCH

WITH

STEERING

LOCK

Description

The

steering

lock

is

built

in

the

ignition

switch

When

the

key

is

set

to

Lock

position

and

rernoved

the

steering

system

is

locked

automatically

The

locking

8E

29

Page 265 of 513

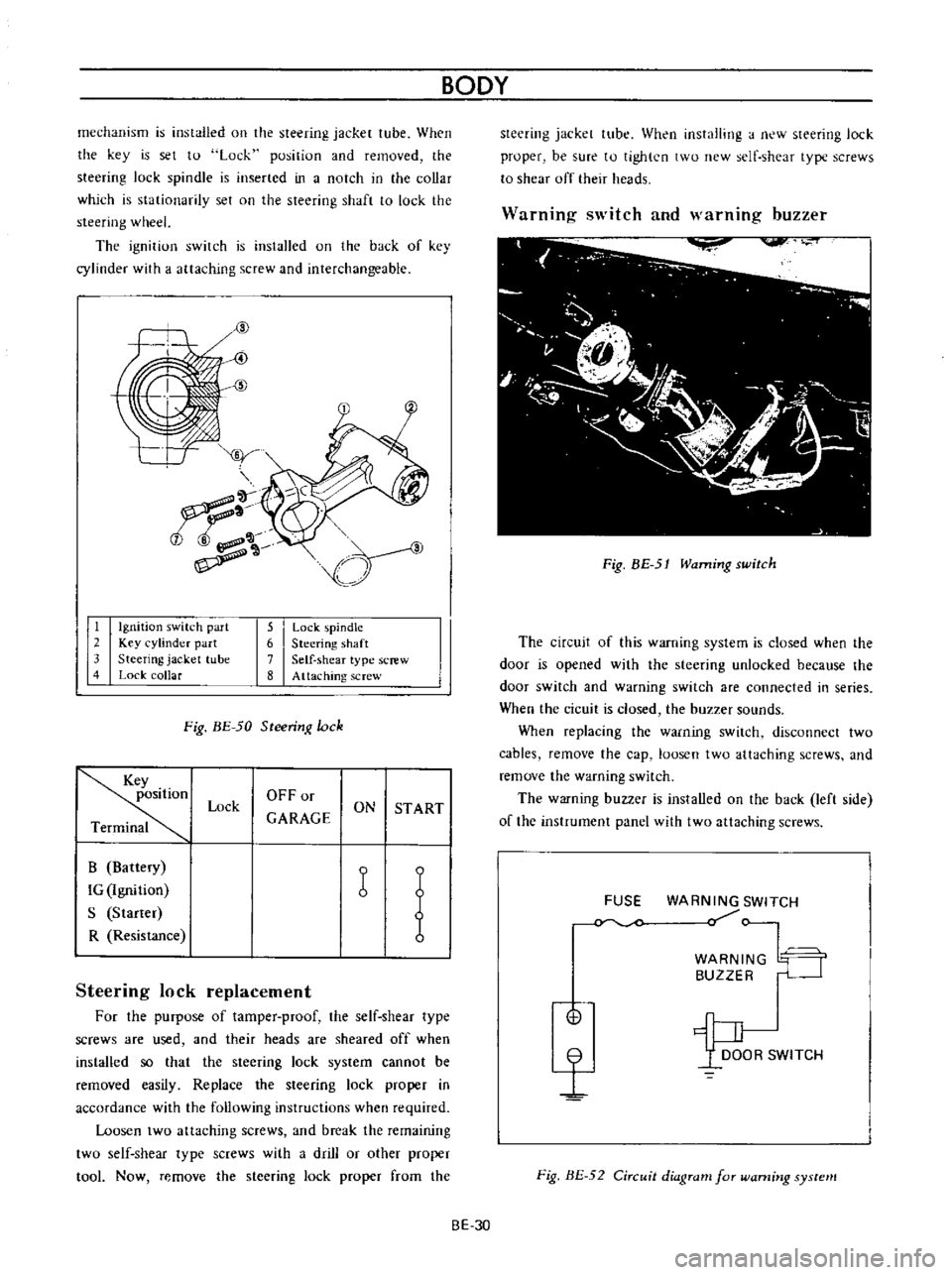

mechanism

is

installed

on

the

steering

jacket

tube

When

the

key

is

set

to

Lock

position

and

removed

the

steering

lock

spindle

is

inserted

in

a

notch

in

the

collar

which

is

stationarity

set

on

the

steering

shaft

to

lock

the

steering

wheel

The

ignitiun

switch

is

installed

on

the

back

of

key

cylinder

with

a

attaching

screw

and

interchangeable

tf

iY

t

7

a

1

Ignition

switch

part

2

Key

cylinder

part

3

Steering

jacket

tube

4

Lock

collar

5

Lock

pindle

6

Steering

shaft

7

Self

shear

type

screw

8

Attaching

screw

Fig

BE

50

Steering

lock

Key

position

Terminal

OFFor

GARAGE

Lock

ON

ST

ART

B

Battery

IG

Ignition

S

Starter

R

Resistance

b

1

Steering

lock

replacement

For

the

purpuse

of

tamper

proof

the

self

shear

type

screws

are

used

and

their

heads

are

sheared

off

when

installed

so

that

the

steering

lock

system

cannot

be

removed

easily

Replace

the

steering

lock

proper

in

accordance

with

the

following

instructions

when

required

Loosen

two

attaching

screws

and

break

the

remaining

twu

self

shear

type

screws

with

a

drill

or

other

proper

tool

Now

remove

the

steering

lock

proper

from

the

BODY

BE

30

steering

jacket

tube

When

installing

a

new

steering

lock

proper

be

sure

tu

tighten

two

new

self

shear

type

screws

to

shear

off

their

heads

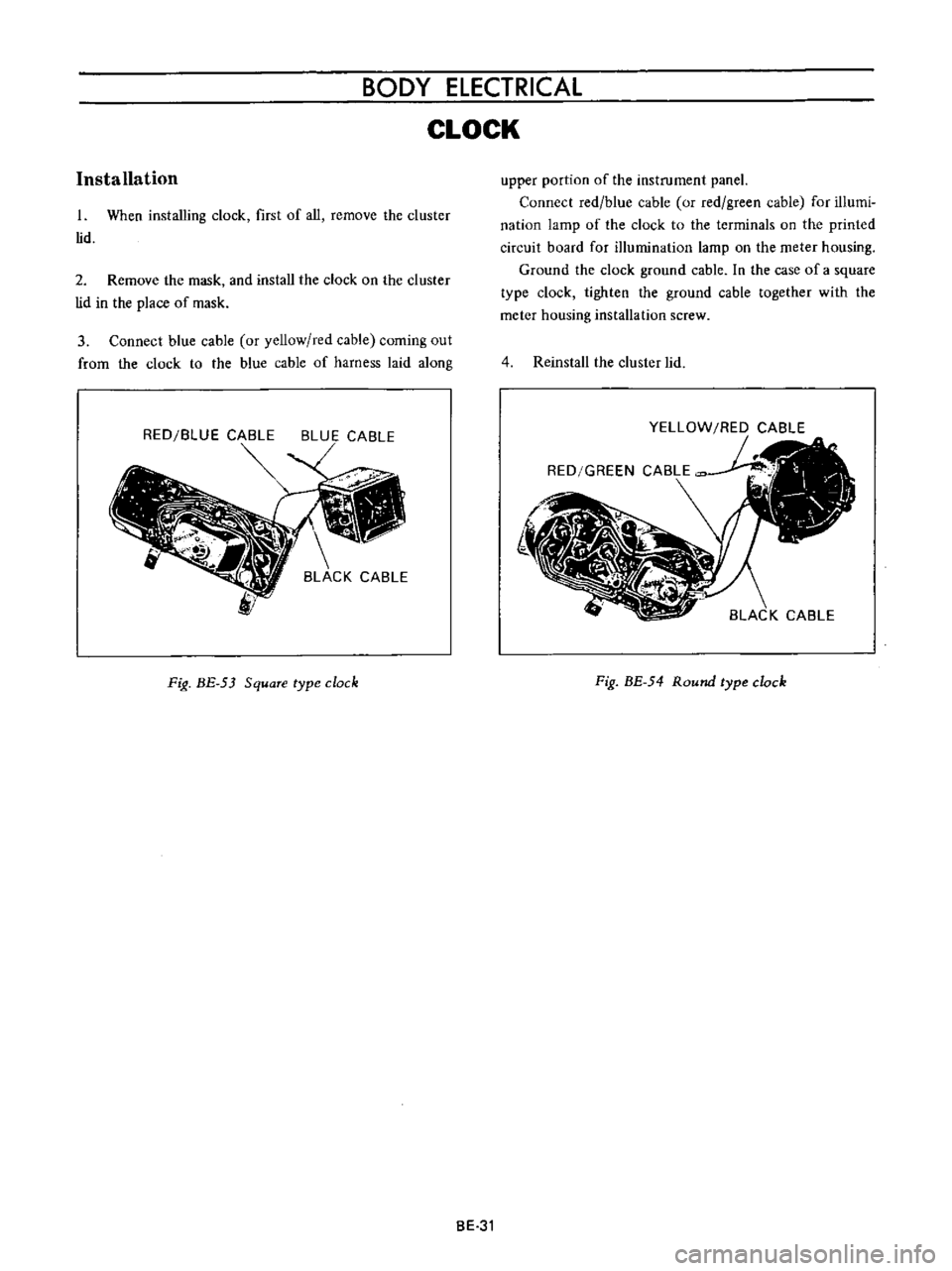

Warning

switch

and

warnmg

buzzer

Fig

BE

51

Warning

switch

The

circuit

of

this

warning

system

is

closed

when

the

door

is

opened

with

the

steering

unlocked

because

the

door

switch

and

warning

switch

are

connected

in

series

When

the

cicuit

is

closed

the

buzzer

sounds

When

replacing

the

warning

switch

disconnect

two

cables

remove

the

cap

loosen

two

attaching

screws

and

remove

the

warning

switch

The

warning

buzzer

is

installed

on

the

back

left

side

of

the

instrument

panel

with

two

attaching

screws

FUSE

WARNING

SWITCH

WARN

BUZZ

G

n

WITCH

t

Fig

BE

52

Circuit

diagram

for

warning

system

Page 266 of 513

BODY

ELECTRICAL

CLOCK

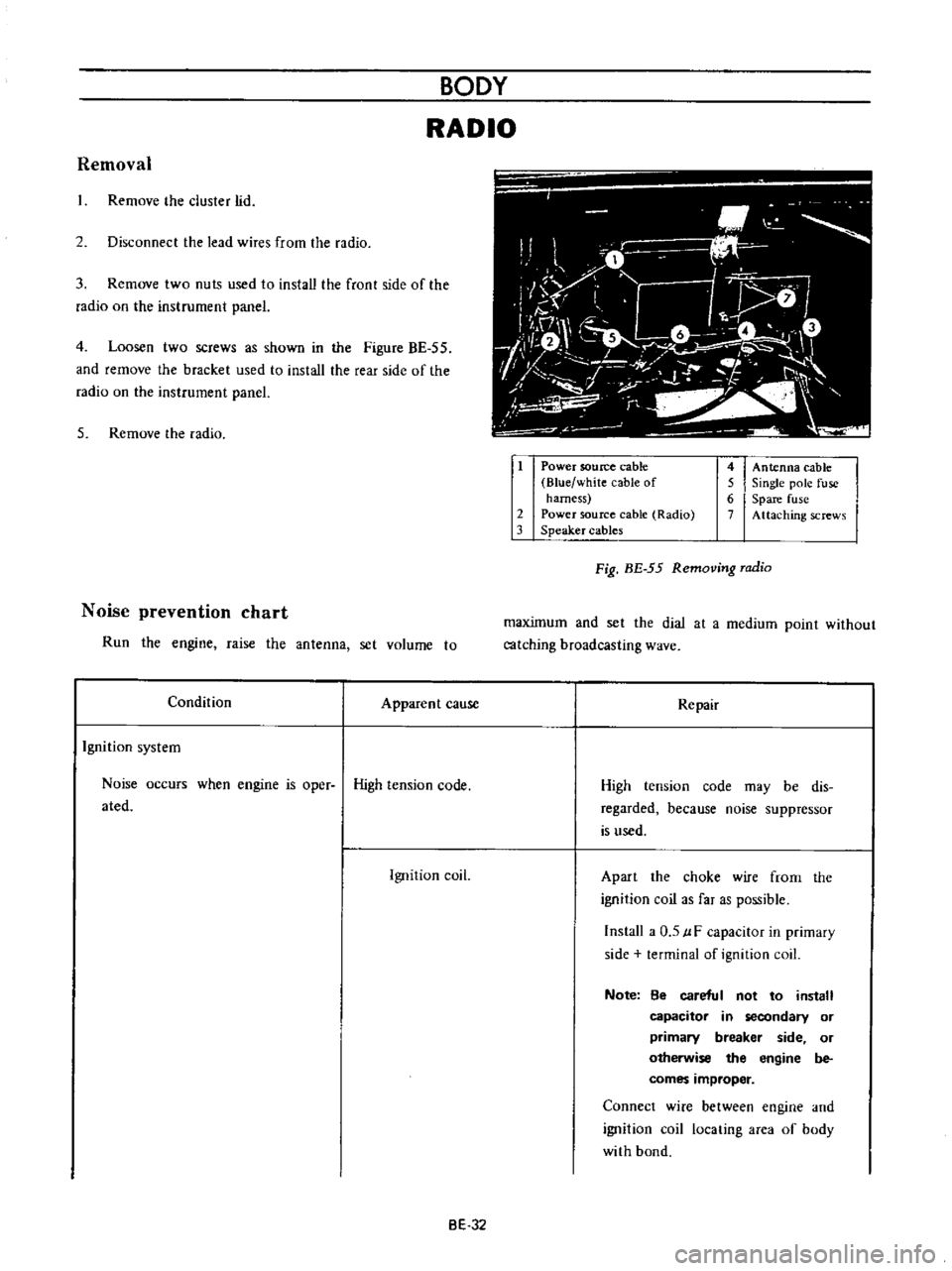

Installation

upper

portion

of

the

instrument

panel

Connect

red

blue

cable

or

red

green

cable

for

illumi

nation

lamp

of

the

clock

to

the

terminals

on

the

printed

circuit

board

for

illumination

lamp

on

the

meter

housing

Ground

the

clock

ground

cable

In

the

case

of

a

square

type

clock

tighten

the

ground

cable

together

with

the

meter

housing

installation

screw

1

When

installing

clock

first

of

all

remove

the

cluster

lid

2

Remove

the

mask

and

install

the

clock

on

the

cluster

lid

in

the

place

of

mask

3

Connect

blue

cable

or

yellow

red

cable

coming

out

from

the

clock

to

the

blue

cable

of

harness

laid

along

4

Reinstall

the

cluster

lid

RED

BLUE

CABLE

BLUE

CABLE

Fig

BE

53

Square

type

clock

Fig

BE

54

Round

type

clock

BE

31

Page 267 of 513

BODY

RADIO

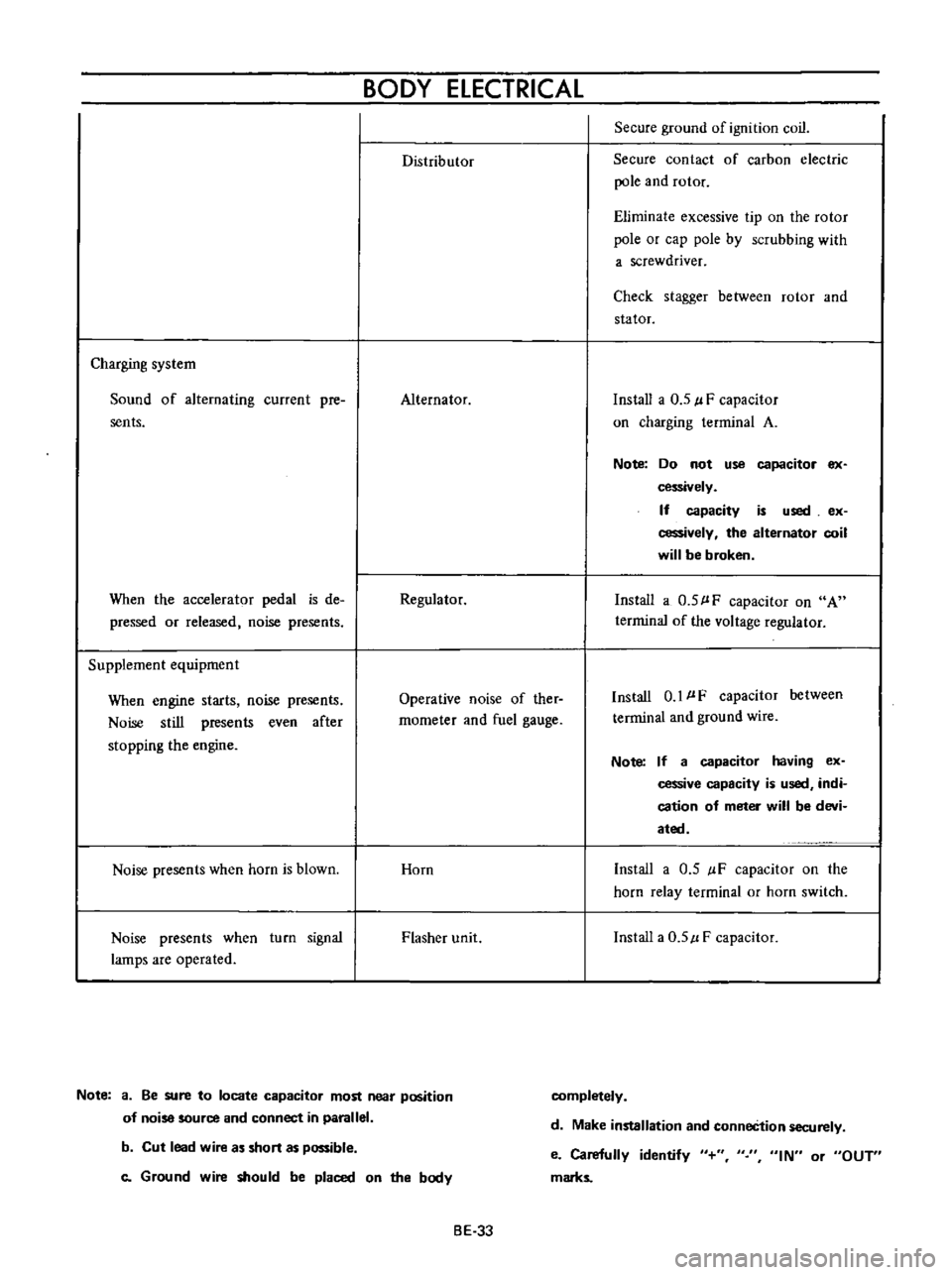

Removal

Remove

he

cluster

lid

2

Disconnect

the

lead

wires

from

the

radio

3

Remove

two

nuts

used

to

install

the

front

side

of

the

radio

on

the

instrument

panel

4

Loosen

two

screws

as

shown

in

the

Figure

BE

55

and

remove

the

bracket

used

to

install

the

rear

side

of

the

radio

on

the

instrument

panel

5

Remove

the

radio

Noise

prevention

chart

Run

the

engine

raise

the

antenna

set

volume

to

Condition

Apparent

cause

Ignition

system

Noise

occurs

when

engine

is

oper

High

tension

code

ated

Ignition

coil

i

O

i

M

1

iiJ

1

7

L

l

o

f

I

ft

V

r

1

1

v

I

I

t

i

J

iL

1

Power

soutee

cable

Blue

white

cable

of

harness

2

Power

source

cable

Radio

3

Speaker

cables

4

Antenna

cable

5

Single

pole

fuse

6

Spare

fuse

7

Attaching

screws

Fig

BE

55

Removing

radio

maximum

and

set

the

dial

at

a

medium

point

without

catching

broadcasting

wave

Repair

High

tension

code

may

be

dis

regarded

because

noise

suppressor

is

used

Apart

the

choke

wire

frorn

the

ignition

coil

as

far

as

possible

Install

a

0

5

uF

capacitor

in

primary

side

terminal

of

ignition

coil

Note

8e

careful

not

to

install

capacitor

in

secondary

or

primary

breaker

side

or

otherwise

the

engine

be

comes

improper

Connect

wire

between

engine

and

ignition

coil

locating

area

of

body

with

bond

BE

32

Page 268 of 513

BODY

ELECTRICAL

Distributor

Secure

ground

of

ignition

coil

Secure

contact

of

carbon

electric

pole

and

rotor

Eliminate

excessive

tip

on

the

rotor

pole

or

cap

pole

by

scrubbing

with

a

screwdriver

Check

stagger

between

rotor

and

stator

Charging

system

Sound

of

alternating

current

pre

sents

Alternator

Install

a

0

5

l

F

capacitor

on

charging

terminal

A

Note

Do

not

use

capacitor

ex

cessively

If

capacity

is

used

ex

cessively

the

alternator

coil

will

be

broken

When

the

accelerator

pedal

is

de

pressed

or

released

noise

presents

Regulator

Install

a

0

5

l

F

capacitor

on

A

terrninal

of

the

voltage

regulator

Supplement

equipment

When

engine

starts

noise

presents

Noise

still

presents

even

after

stopping

the

engine

Operative

noise

of

ther

rnometer

and

fuel

gauge

Install

0

1

l

F

capacitor

between

terminal

and

ground

wire

Note

If

a

capacitor

having

ex

cessive

capacity

is

used

indi

cation

of

meter

will

be

devi

ated

Noise

presents

when

horn

is

blown

Horn

Install

a

0

5

IF

capacitor

on

the

horn

relay

terminal

or

horn

switch

Noise

presents

when

turn

signal

lamps

are

operated

Flasher

unit

Install

a

0

5

l

F

capacitor

Note

a

Be

sure

to

locate

capacitor

most

near

position

of

noise

source

and

connect

in

parallel

completely

d

Make

installation

and

conneCtion

securely

b

Cut

lead

wire

as

short

as

possible

c

Ground

wire

should

be

placed

on

the

body

e

Carefully

identify

marks

IN

or

OUT

BE

33

Page 269 of 513

Removal

and

installation

A

I

I

I

@

I

Removal

and

installation

BODY

HEATER

CONTENTS

BE

34

TROUBLE

DIAGNOSES

AND

CORRECTIONS

BE

35

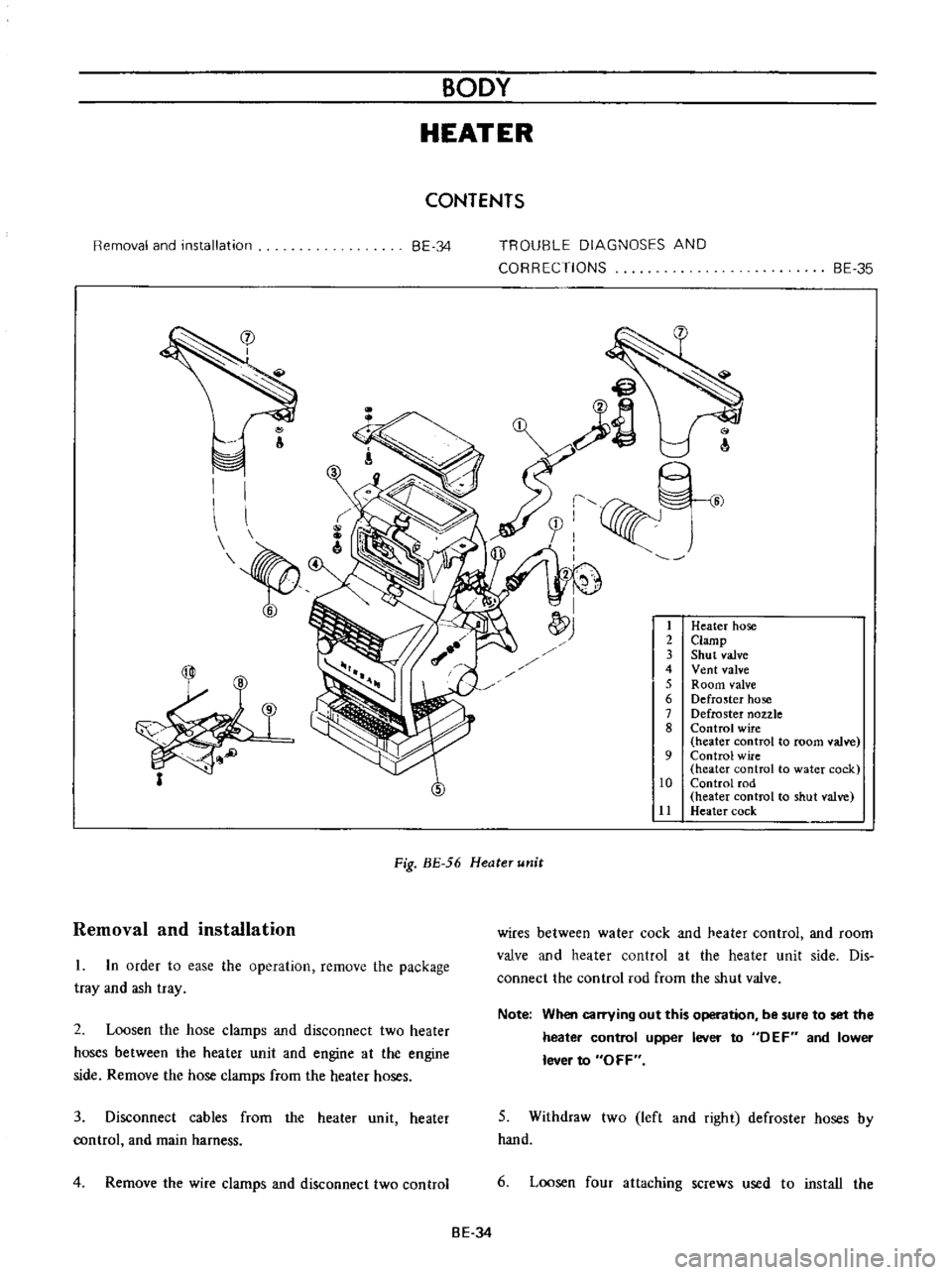

Fig

BE

56

Heater

unit

6

1

Heater

hose

2

Clamp

3

Shut

valve

4

Vent

valve

5

Room

valve

6

Defroster

hose

7

Defroster

nozzle

8

Control

wire

heater

control

to

room

valve

9

Control

wire

heater

control

to

water

cock

10

Control

rod

heater

control

to

shut

valve

11

Heater

cock

1

In

order

to

ease

the

operation

remove

the

package

tray

and

ash

tray

wires

between

water

cock

and

peater

control

and

room

valve

and

heater

control

at

the

heater

unit

side

Dis

connect

the

control

rod

from

the

shut

valve

2

Loosen

the

hose

clamps

and

disconnect

two

heater

hoses

between

the

heater

unit

and

engine

at

the

engine

side

Remove

the

hose

clamps

from

the

heater

hoses

Note

When

carrying

out

this

operation

be

sure

to

set

the

heater

control

upper

lever

to

OEF

and

lower

lever

to

OFF

3

Disconnect

cables

from

the

heater

unit

heater

control

and

main

harness

5

Withdraw

two

left

and

right

defroster

hoses

by

hand

4

Remove

the

wire

clamps

and

disconnect

two

control

6

Loosen

four

attaching

screws

used

to

install

the

BE

34

Page 270 of 513

BODY

ELECTRICAL

heater

unit

on

the

dash

board

and

remove

the

heater

unit

carefully

panel

8

Rernove

two

self

tapping

screws

from

back

of

the

instrument

panel

and

remove

the

defroster

nozzle

7

When

removing

the

heater

control

from

the

instru

ment

panel

remove

the

control

knob

and

loosen

two

screws

used

to

install

the

heater

control

on

the

instrument

9

The

heater

unit

is

installed

in

reverse

sequence

of

removal

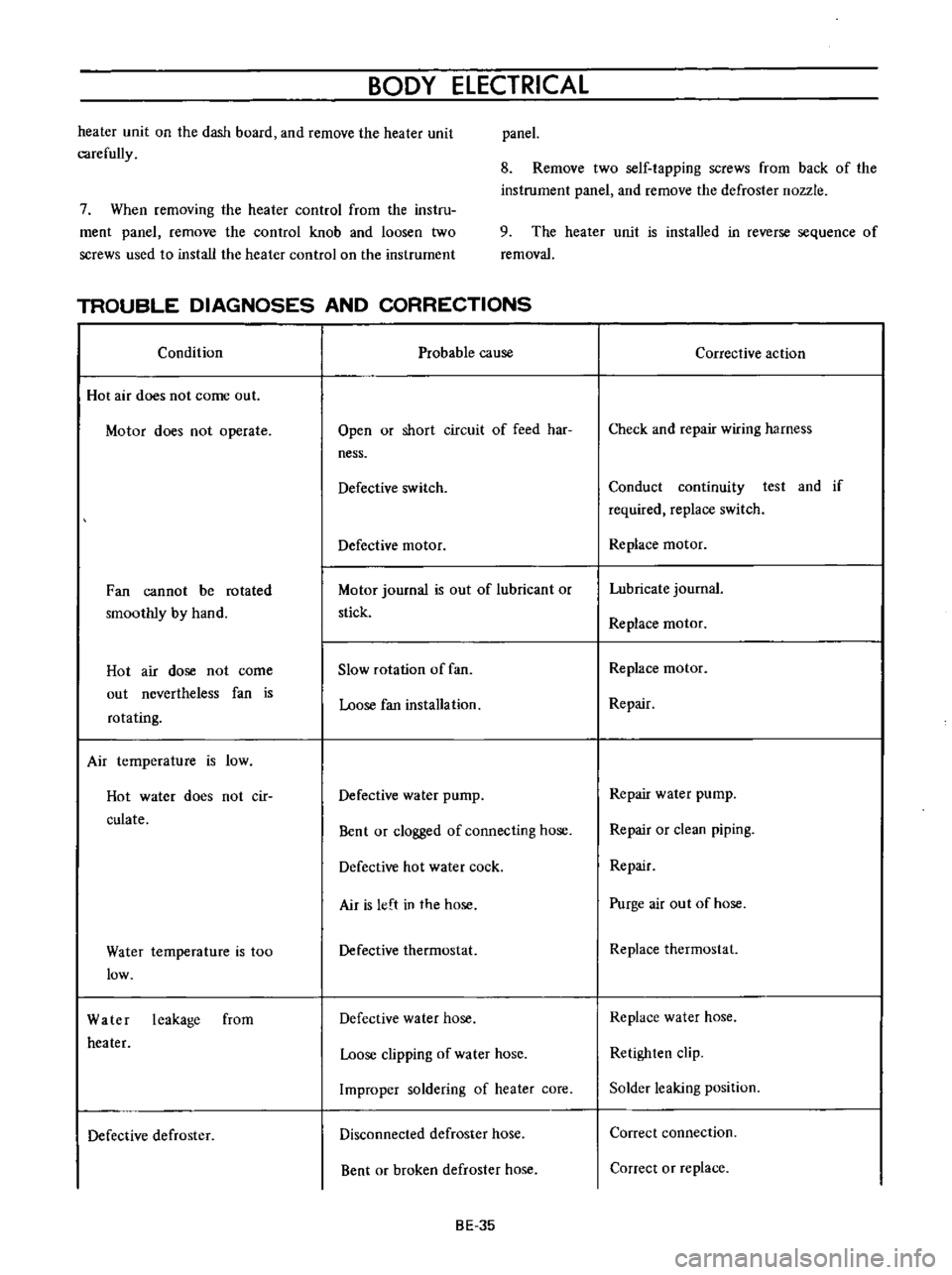

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Hot

air

does

not

come

out

Motor

does

not

operate

Open

or

short

circuit

of

feed

har

ness

Defective

switch

Defective

motor

Fan

cannot

be

rotated

smoothly

by

hand

Motor

journal

is

out

of

lubricant

or

stick

Hot

air

dose

not

come

out

nevertheless

fan

is

rotating

Slow

rotation

of

fan

Loose

fan

installation

Air

temperature

is

low

Hot

water

does

not

cir

culate

Defective

water

pump

Bent

or

clogged

of

connecting

hose

Defective

hot

water

cock

Air

is

left

in

the

hose

Water

temperature

is

too

low

Defective

thermostat

Water

leakage

from

heater

Defective

water

hose

Loose

clipping

of

water

hose

Improper

soldering

of

heater

core

Defective

defroster

Disconnected

defroster

hose

Bent

or

broken

defroster

hose

BE

35

Corrective

action

Check

and

repair

wiring

harness

Conduct

continuity

test

and

if

required

replace

switch

Replace

motor

Lubricate

journal

Replace

motor

Replace

motor

Repair

Repair

water

pump

Repair

or

clean

piping

Repair

Purge

air

out

of

hose

Replace

thermostat

Replace

water

hose

Retighten

clip

Solder

leaking

position

Correct

connection

Correct

or

replace