DATSUN B110 1973 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 251 of 513

9HORN

r

I

01

8ATTERY

HI

IGI

s

ILl

C

iORN

BODY

FUSE

H

S

HORN

BUTTON

BGI

J

H

B

S

Il

I

n6lm

I

L

J

L

HORN

RELAY

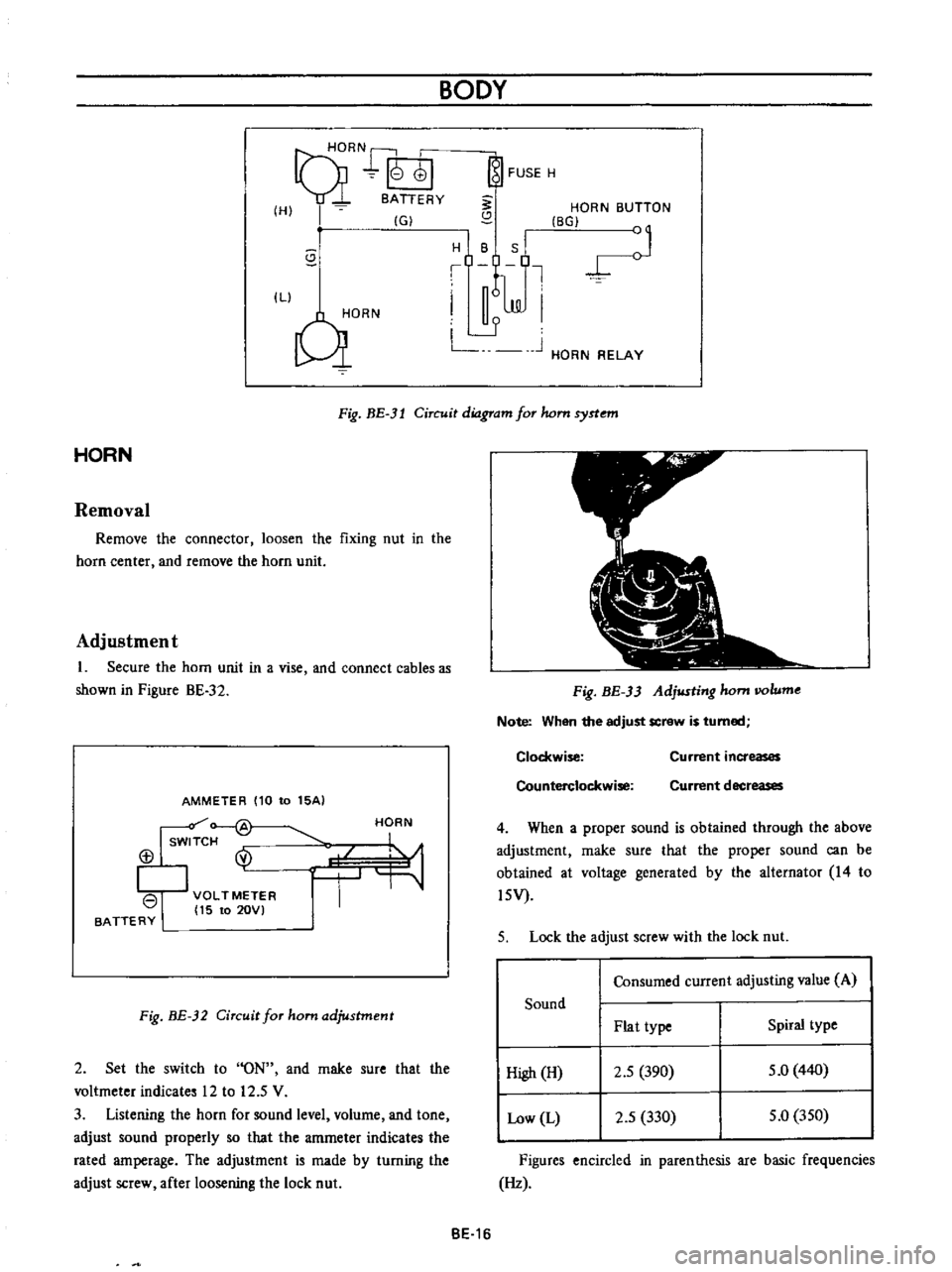

Fig

BE

3l

Circuit

diagram

for

hom

syrtem

HORN

Removal

Remove

the

connector

loosen

the

fixing

nut

in

the

horn

center

and

remove

the

horn

unit

Adjustment

1

Secure

the

horn

unit

in

a

vise

and

connect

cables

as

shown

in

Pigure

BE

32

AMMETER

110

to

15AI

Isw

f

@

113

I

VOLTMETER

I

15

to

20VI

BATTERY

HORN

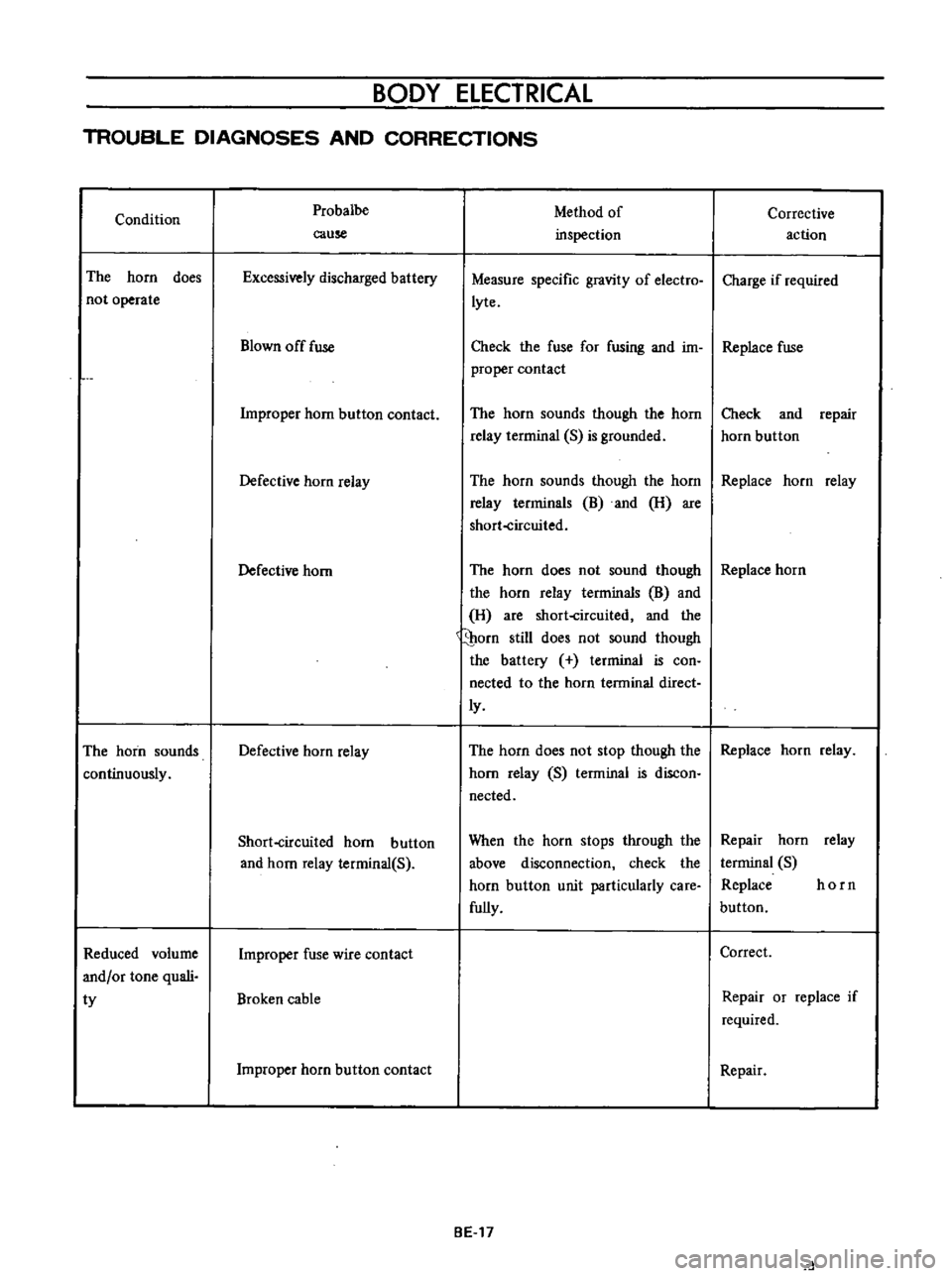

Fig

BE

32

Circuit

for

ham

adjustment

2

Set

the

switch

to

ON

and

rnake

sure

that

the

voltmeter

indicates

12

to

12

5

V

3

Listening

the

horn

for

sound

level

volurne

and

tone

adjust

sound

properly

so

that

the

amrneter

indicates

the

rated

amperage

The

adjustment

is

made

by

turning

the

adjust

screw

after

loosening

the

lock

nut

Fig

BE

33

Adjusting

hom

IIOlume

Note

When

the

adjust

screw

is

turned

Clockwise

Counterclockwise

Current

increases

Current

decreases

4

When

a

proper

sound

is

obtained

through

the

above

adjustment

rnake

sure

that

the

proper

sound

can

be

obtained

at

voltage

generated

by

the

alternator

14

to

l5V

5

Lock

the

adjust

screw

with

the

lock

nut

Consumed

current

adjusting

value

A

Sound

Plat

type

Spiral

type

High

H

2

5

390

5

0

440

Low

L

2

5

330

5

0

350

Figures

encircled

in

parenthesis

are

basic

frequencies

Hz

BE

16

Page 252 of 513

BODY

ELECTRICAL

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

The

horn

does

not

operate

The

horn

sounds

continuously

Reduced

volume

and

or

tone

quali

ty

Probalbe

cause

Excessively

discharged

battery

Blown

off

fuse

Improper

horn

button

contact

Defective

horn

relay

Defective

horn

Defective

horn

relay

Short

circuited

horn

button

and

horn

relay

terminal

S

Improper

fuse

wire

contact

Broken

cable

Improper

horn

button

contact

Method

of

inspection

Measure

specific

gravity

of

electro

lyte

Corrective

action

Charge

if

required

Check

the

fuse

for

fusing

and

im

Replace

fuse

proper

contact

The

horn

sounds

though

the

horn

relay

terrninal

S

is

grounded

Check

and

repair

horn

button

The

horn

sounds

though

the

horn

Replace

horn

relay

relay

terrninals

B

and

H

are

short

circuited

The

horn

does

not

sound

though

Replace

horn

the

horn

relay

terminals

B

and

H

are

short

circuited

and

the

porn

still

does

not

sound

though

the

battery

terminal

is

con

nected

to

the

horn

terminal

direct

ly

The

horn

does

not

stop

though

the

Replace

horn

relay

horn

relay

S

terminal

is

discon

nected

When

the

horn

stops

through

the

above

disconnection

check

the

horn

button

unit

particularly

care

fully

BE

17

Repair

horn

relay

terminal

S

Replace

horn

button

Correct

Repair

or

replace

if

required

Repair

d

Page 253 of 513

BODY

METERS

AND

GAUGES

CONTENTS

CLUSTER

LID

Oescri

ption

Removal

SPEEDOMETER

Replacement

FUEL

GAUGE

AND

TEMPERATURE

GAUGE

Description

Replacement

BE

1B

BE

18

BE

18

BE

19

BE

19

BE

19

BE

19

BE

20

CLUSTER

LID

Description

The

cluster

lid

holds

various

rneters

indicators

and

clock

located

around

the

speedorneter

Printed

circuit

board

is

used

at

the

back

of

the

meter

as

shown

in

Figure

BE

38

and

the

printed

circuit

board

is

connected

with

multiple

connectors

Thus

the

meters

Can

be

inspected

and

serviced

extremely

easily

Except

for

the

speed

ometer

all

rneters

are

operated

electrically

The

fuel

gauge

and

therrnometer

are

very

reliable

and

they

are

equipped

with

bimetal

devices

F

a

o

ill

I

1

a

a

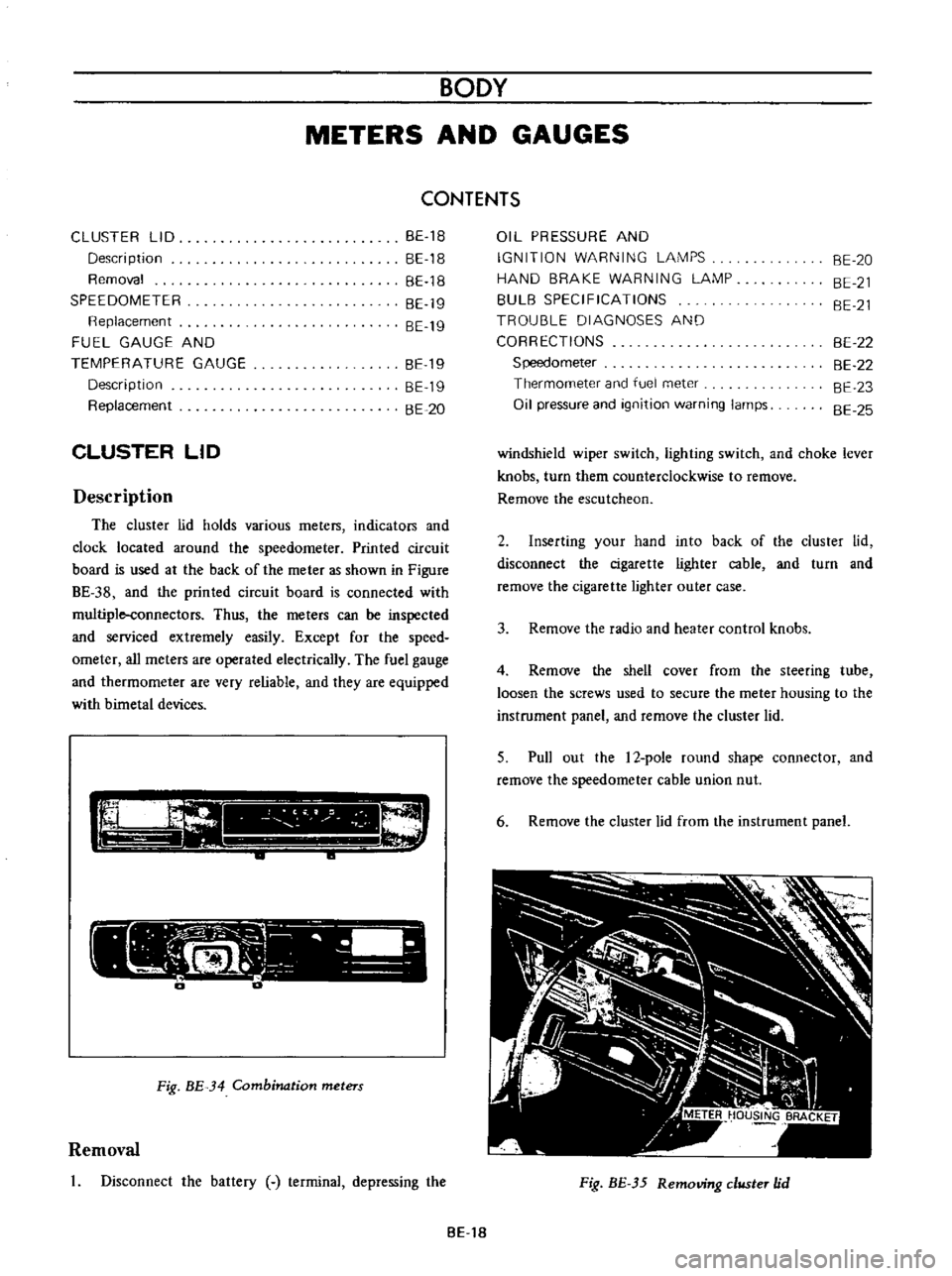

Fig

BE

34

Combination

meters

Removal

Disconnect

the

battery

terminal

depressing

the

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

HAND

BRAKE

WARNING

LAMP

BULB

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Speedometer

Thermometer

and

fuel

meter

Oil

pressure

and

ignition

warning

lamps

BE

20

BE

21

BE

21

BE

22

BE

22

BE

23

BE

25

windshield

wiper

switch

lighting

switch

and

choke

lever

knobs

turn

them

counterclockwise

to

remove

Remove

the

escutcheon

2

Inserting

your

hand

into

back

of

the

cluster

lid

disconnect

the

cigarette

lighter

cable

and

turn

and

remove

the

cigarette

lighter

outer

case

3

Remove

the

radio

and

heater

control

knobs

4

Remove

the

shell

cover

from

the

steering

tube

loosen

the

screws

used

to

secure

the

meter

housing

to

the

instrument

panel

and

remove

the

cluster

lid

5

Pull

out

the

l2

pole

round

shape

connector

and

remove

the

speedometer

cable

union

nut

6

Remove

the

cluster

lid

from

the

instrument

panel

Fig

BE

35

Removing

clllSter

jd

BE

18

Page 254 of 513

BODY

ELECTRICAL

SPEEDOMETER

The

speedometer

is

equipped

with

a

total

odometer

which

records

travelled

distance

Replacement

1

When

removing

the

speedometer

remove

the

cluster

lid

first

Separate

the

combination

meter

housing

from

the

cluster

lid

after

removing

four

screws

and

remove

the

trip

recorder

reset

knob

if

any

2

Unscrew

two

screws

and

remove

the

speedometer

from

the

combination

meter

housing

3

Reinstall

a

new

speedometer

in

reverse

sequence

of

removal

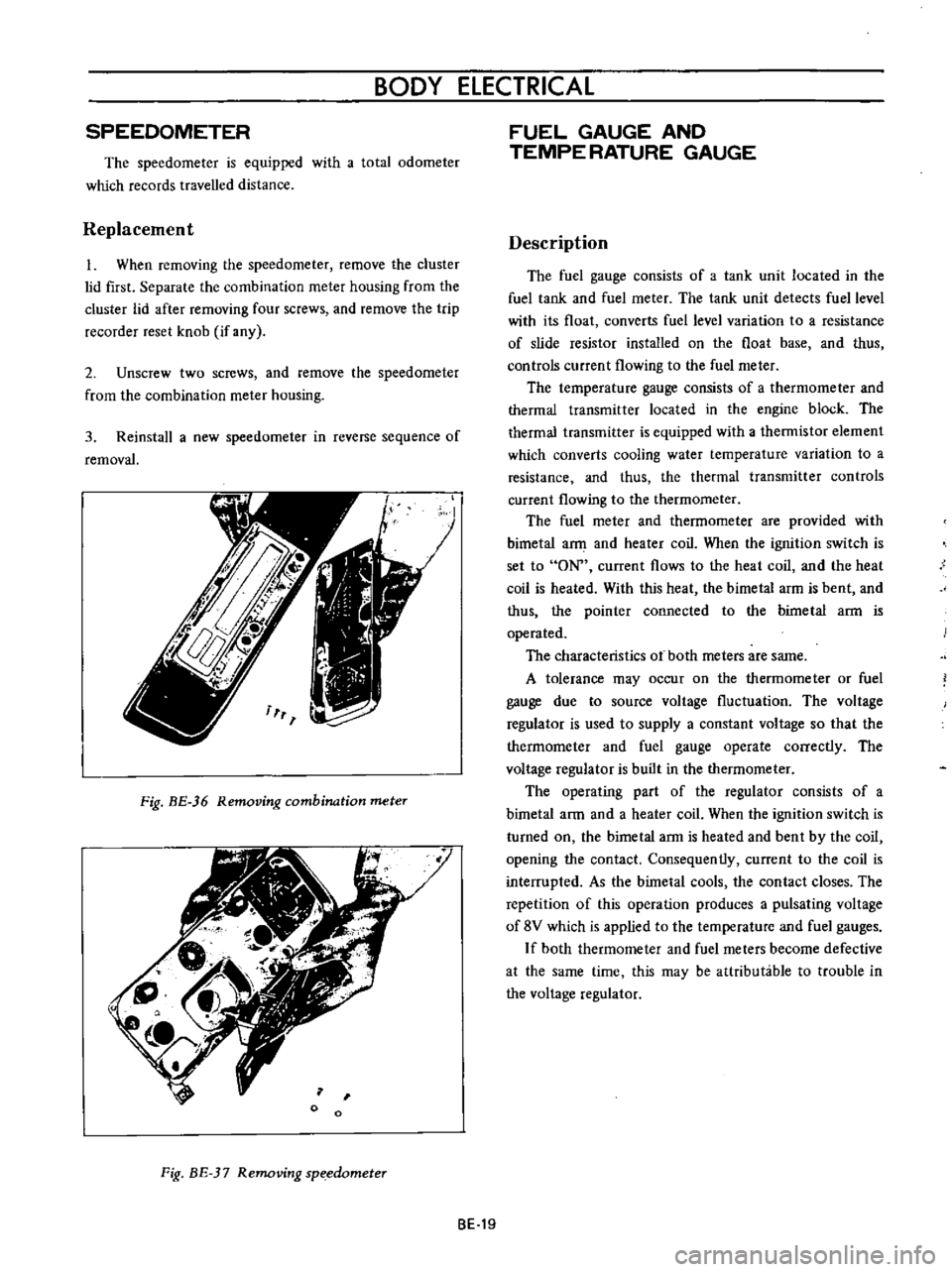

Fig

BE

36

Removing

combination

meter

o

Fig

BE

37

Removing

sp

edometer

FUEL

GAUGE

AND

TEMPE

RATURE

GAUGE

Description

The

fuel

gauge

consists

of

a

tank

unit

located

in

the

fuel

tank

and

fuel

meter

The

tank

unit

detects

fuel

level

with

its

float

converts

fuel

level

variation

to

a

resistance

of

slide

resistor

installed

on

the

float

base

and

thus

controls

current

flowing

to

the

fuel

meter

The

temperature

gauge

consists

of

a

thermorneter

and

thermal

transmitter

located

in

the

engine

block

The

thermal

transmitter

is

equipped

with

a

thermistor

element

which

converts

cooling

water

temperature

variation

to

a

resistance

and

thus

the

thermal

transmitter

controls

current

flowing

to

the

thermometer

The

fuel

rneter

and

thermometer

are

provided

with

bimetal

a

and

heater

coil

When

the

ignition

switch

is

set

to

ON

current

flows

to

the

heat

coil

and

the

heat

coil

is

heated

With

this

heat

the

bimetal

arm

is

bent

and

thus

the

pointer

connected

to

the

bimetal

ann

is

operated

The

characteristics

ot

both

meters

are

same

A

tolerance

may

occur

on

the

thermometer

or

fuel

gauge

due

to

source

voltage

fluctuation

The

voltage

regulator

is

used

to

supply

a

constant

voltage

so

that

the

therrnorneter

and

fuel

gauge

operate

correctly

The

voltage

regulator

is

built

in

the

thermometer

The

operating

part

of

the

regulator

consists

of

a

bimetal

arm

and

a

heater

coil

When

the

ignition

switch

is

turned

on

the

birnetal

arm

is

heated

and

bent

by

the

coil

opening

the

contact

Consequently

current

to

the

coil

is

interrupted

As

the

bimetal

cools

the

contact

closes

The

repetition

of

this

operation

produces

a

pulsating

voltage

of

8V

which

is

applied

to

the

ternperature

and

fuel

gauges

If

both

thermometer

and

fuel

meters

become

defective

at

the

same

time

this

may

be

attributable

to

trouble

in

the

voltage

regulator

BE

19

Page 255 of 513

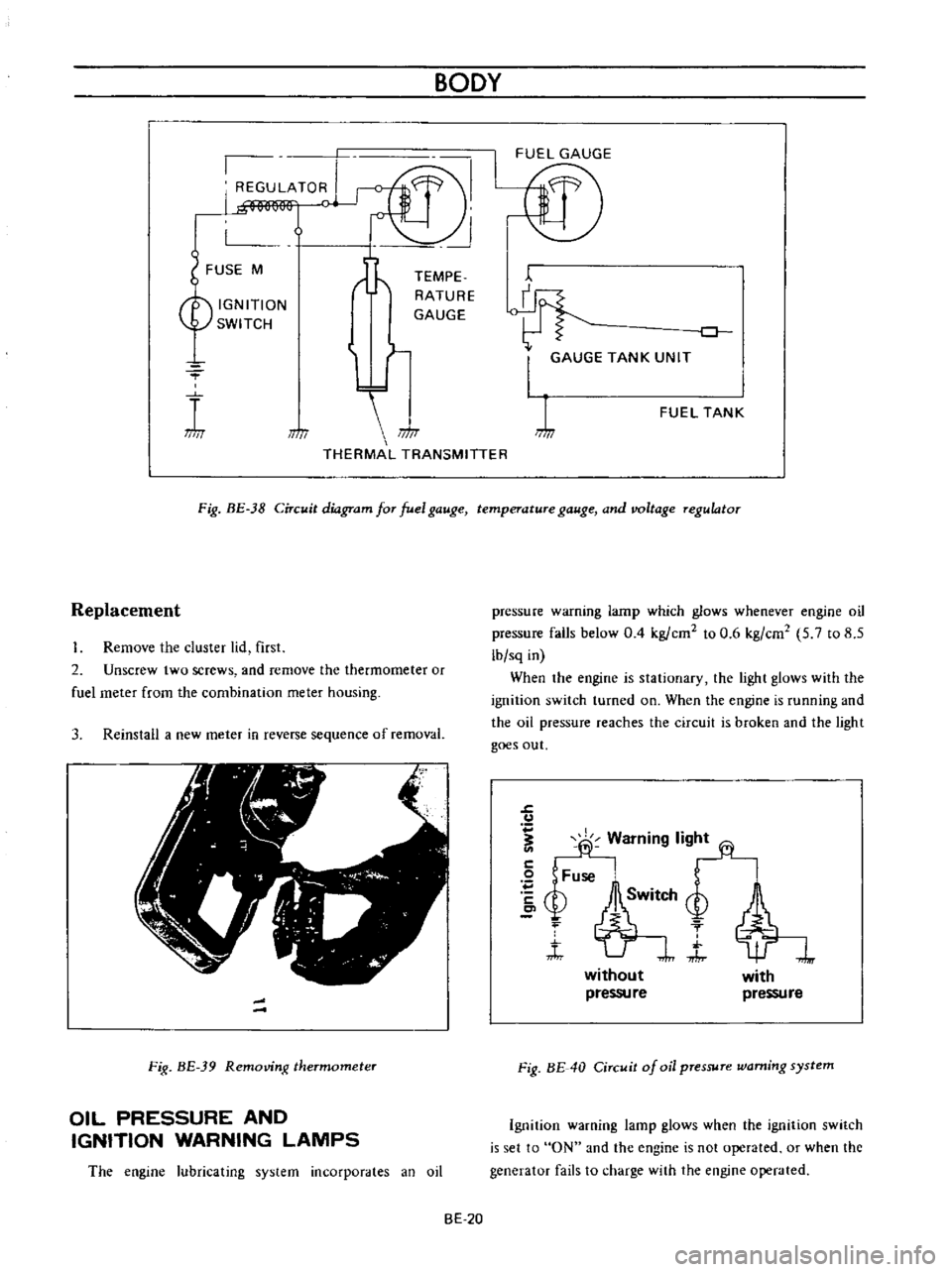

BODY

REGULATOR

FUSE

M

TEMPE

RATURE

GAUGE

IGNITION

SWITCH

Lf

I

iT

Ji

1M

THERMAL

TRANSMITTER

I

J

0

I

GAUGE

TANK

UNIT

FUEL

TANK

Fig

BE

38

Circuit

diagram

for

fuel

gauge

temperature

gauge

and

voltage

regulator

Replacement

Remove

the

cluster

lid

first

2

Unscrew

two

screws

and

remove

the

thermometer

or

fuel

meter

from

the

combination

meter

housing

3

Reinstall

a

new

meter

in

reverse

sequence

of

removal

Fig

BE

39

Removing

thermometer

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

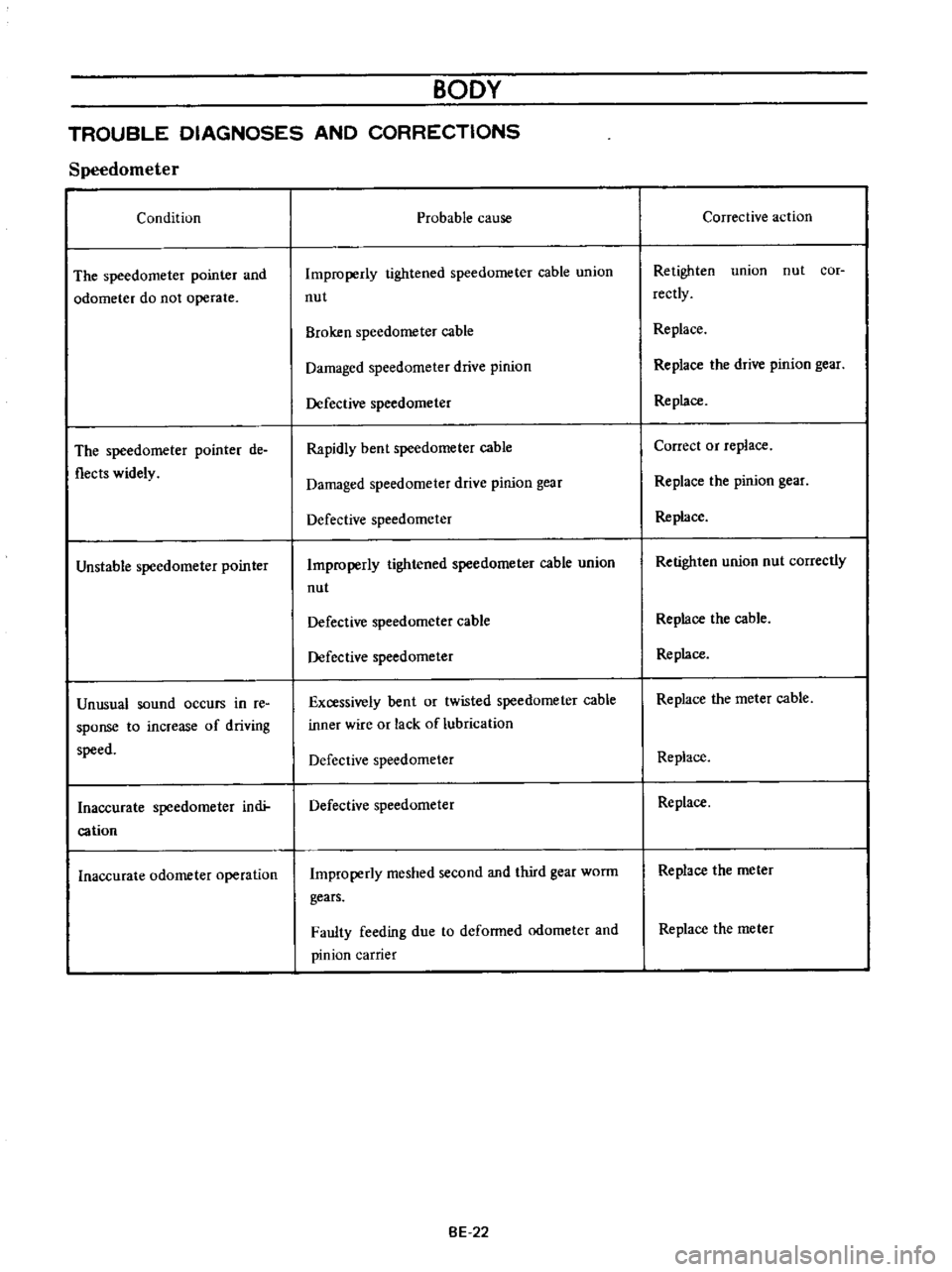

The

engine

lubricating

system

incorporates

an

oil

pressure

warning

lamp

which

glows

whenever

engine

oil

pressure

falls

below

0

4

kg

ern

to

0

6

kg

em

5

7

to

8

5

lb

sq

in

When

the

engine

is

stationary

the

light

glows

with

the

ignition

switch

turned

on

When

the

engine

is

running

and

the

oil

pressure

reaches

the

circuit

is

broken

and

the

light

goes

out

J

u

fj

Warning

lig

2

Fuse

bSM

Q

f

t

J

without

pressu

re

with

pressure

Fig

BE

40

Circuit

of

oil

pressure

warning

system

Ignition

warning

lamp

glows

when

the

ignition

switch

is

set

to

ON

and

the

engine

is

not

operated

or

when

the

generator

fails

to

charge

with

the

engine

operated

BE

20

Page 256 of 513

BODY

ElECTRICAL

When

the

ignition

switch

is

set

to

ON

the

ignition

wa

rning

circuit

is

closed

and

current

flows

flows

from

the

ignition

switch

to

the

warning

lamp

bulb

and

ground

through

the

regulator

When

the

engine

is

started

and

the

generator

comes

into

operation

the

generator

output

current

opposes

the

current

flowing

from

the

warning

lamp

in

effect

it

breaks

the

warning

circuit

ground

connection

and

the

lamp

goes

out

l

r

hffi

u

z

Ignition

switch

I

Q

6

I

0

c

M

1

E

8

ca

i

L

g

PI

lot

c

P

I

j

co

rt

0

relay

E

0

5

y

y

1

N

N

3

Alternator

Regulator

Fig

BE

41

Circuit

of

ignition

warning

system

HAND

BRAKE

WARNING

LAMP

This

lamp

functions

both

hand

brake

warning

larnp

and

BULB

SPECIFICATIONS

service

brake

line

pressure

differential

warning

lamp

When

a

difference

between

front

and

rear

brake

line

pressures

reaches

the

rated

range

13

to

17

kgfcm2

185

to

242

lb

sq

in

the

ground

circuit

for

the

warning

lamp

is

closed

and

the

warning

lamp

lights

IGNITION

SWITCH

WARNING

LAMP

L

E

WARNING

SWITCH

1

SERVICE

BRAKE

LINE

PRESSU

R

E

DIFFERENTIAL

WARNING

J

SWITCH

Fig

BE

42

Circuit

diagram

for

brake

warning

system

tern

Specifications

Square

type

meter

Round

type

meter

Meter

illumination

larnp

VoW

12

3

4

2

12

1

7

3

Turn

signal

pilot

lamp

VoW

12

3

4

2

12

1

7

2

Head

lamp

main

high

beam

VoW

12

3

4

I

12

17

1

pilot

lamp

Ignition

warning

lamp

VoW

123

4

I

12

17

1

Oil

pressure

warning

lamp

VoW

12

3

4

1

12

1

7

1

Hand

brake

warning

lamp

VoW

12

1

7

1

for

U

S

A

CANADA

Clock

illumination

lamp

VoW

123

4

I

12

17

2

Figure

encircled

in

parentheses

indicates

number

of

bulbs

used

BE

21

Page 257 of 513

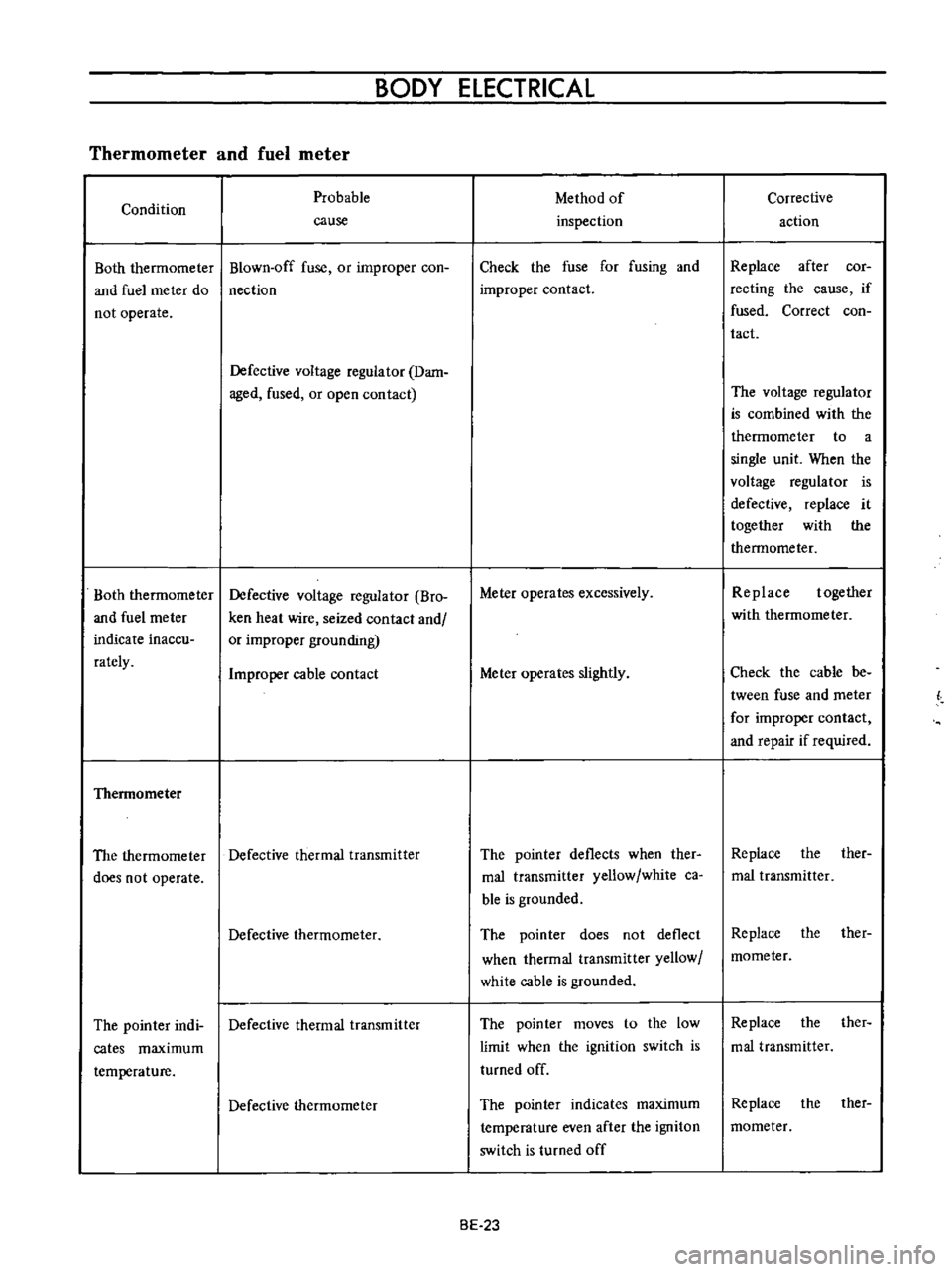

BODY

Speedometer

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

The

speedorneter

pointer

and

odometer

do

not

operate

The

speedorneter

pointer

de

flects

widely

Unstable

speedometer

pointer

Unusual

sound

occurs

in

re

sponse

to

increase

of

driving

speed

Inaccurate

speedometer

indi

cation

Inaccurate

odometer

operation

Probable

cause

Improperly

tightened

speedometer

cable

union

nut

Broken

speedometer

cable

Damaged

speedorneter

drive

pinion

Defective

speedorneter

Rapidly

bent

speedometer

cable

Damaged

speedometer

drive

pinion

gear

Defective

speedometer

Irnproperly

tightened

speedometer

cable

union

nut

Defective

speedometer

cable

Defective

speedorneter

Excessively

bent

or

twisted

speedometer

cable

inner

wire

or

lack

of

lubrication

Defective

speedorneter

Defective

speedorneter

Irnproperly

meshed

second

and

third

gear

worm

gears

Faulty

feeding

due

to

deformed

odometer

and

pinion

carrier

BE

22

Corrective

action

Retighten

union

nut

cor

rectly

Replace

Replace

the

drive

pinion

gear

Replace

Correct

or

replace

Replace

the

pinion

gear

Replace

Retighten

union

nut

correctly

Replace

the

cable

Replace

Replace

the

meter

cable

Replace

Replace

Replace

the

meter

Replace

the

meter

Page 258 of 513

BODY

ELECTRICAL

Thermometer

and

fuel

meter

Condition

Both

therrnorneter

and

fuel

rneter

do

not

operate

Both

thermorneter

and

fuel

rneter

indicate

inaccu

rately

Thennometer

Probable

cause

Blown

off

fuse

or

improper

coo

nection

Defective

voltage

regulator

Dam

aged

fused

or

open

contact

Defective

voltage

regulator

Bro

ken

heat

wire

seized

contact

and

or

improper

grounding

Improper

cable

contact

The

thermometer

Defective

thermal

transmitter

does

not

operate

Defective

thermometer

The

pointer

indi

Defective

thermal

transmitter

cates

maximum

temperature

Defective

thermometer

Method

of

inspection

Check

the

fuse

for

fusing

and

improper

contact

Meter

operates

excessively

Meter

operates

slightly

The

pointer

deflects

when

ther

mal

transrnitter

yellow

white

ca

ble

is

grounded

The

pointer

does

not

deflect

when

thermal

transmitter

yellow

white

cable

is

grounded

The

pointer

moves

to

the

low

limit

when

the

ignition

switch

is

turned

off

The

pointer

indicates

maximum

temperature

even

after

the

ignitoD

switch

is

turned

off

BE

23

Corrective

action

Replace

after

cor

recting

the

cause

if

fused

Correct

coo

tact

The

voltage

regulator

is

combined

with

the

thermometer

to

a

single

unit

When

the

voltage

regulator

is

defective

replace

it

together

with

the

thermometer

Replace

together

with

thermometer

Check

the

cable

be

tween

fuse

and

meter

for

improper

contact

and

repair

if

required

Replace

the

ther

mal

transmitter

Replace

the

ther

mometer

Replace

the

ther

mal

transmitter

Replace

the

ther

mometer

Page 259 of 513

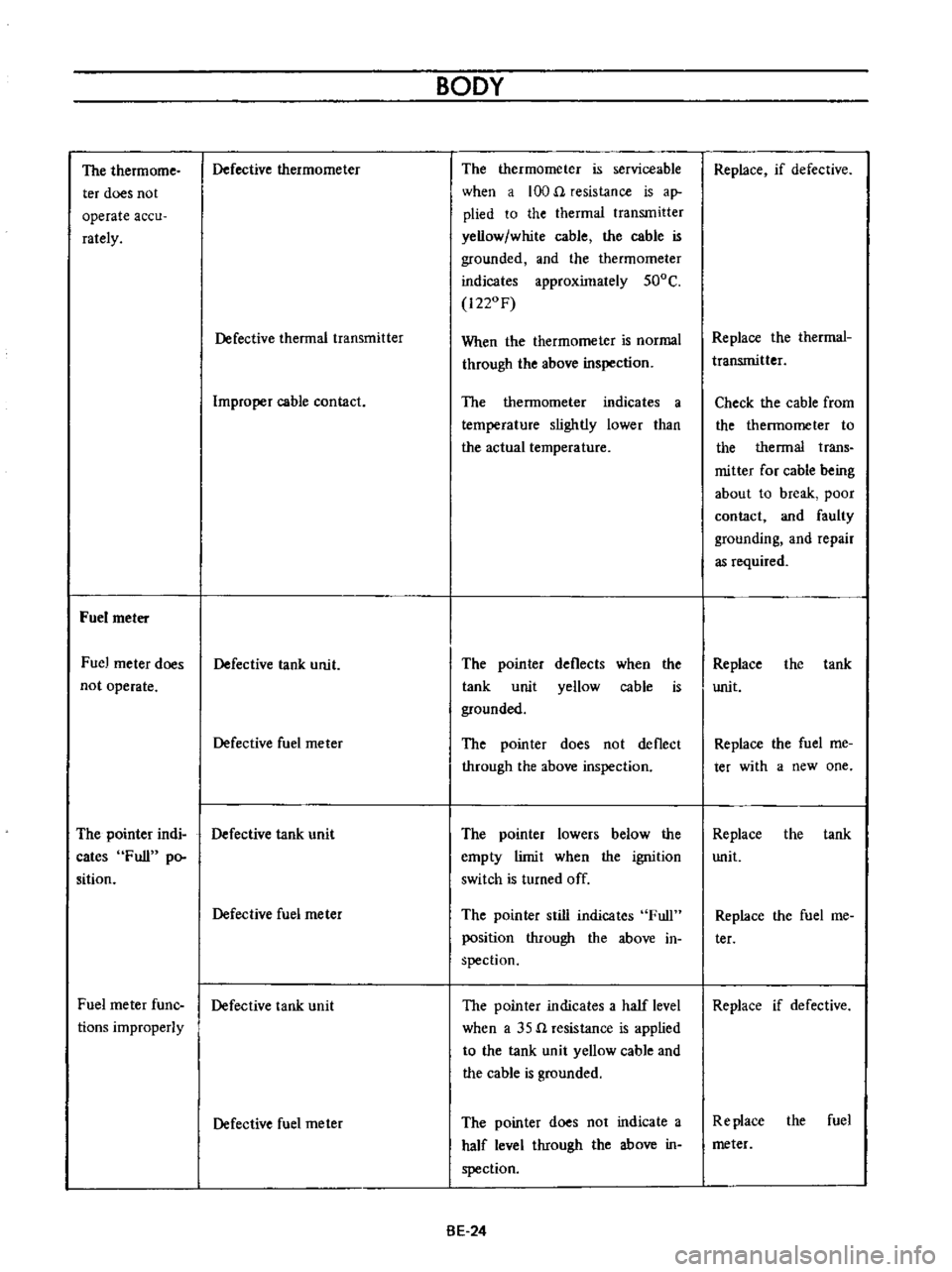

The

thermome

ter

does

not

operate

accu

rately

Fuel

meter

Fuel

meter

does

not

operate

Defective

thermometer

Defective

thermal

transmitter

Improper

cable

contact

Defective

tank

unit

Defective

fuel

meter

The

pointer

indi

Defective

tank

unit

cates

Full

po

sition

Fuel

meter

fune

tions

improperly

Defective

fuel

rneter

Defective

tank

unit

Defective

fuel

rneter

BODY

The

thermometer

is

serviceable

when

a

100

n

resistance

is

ap

plied

to

the

thermal

transmitter

yellow

white

cable

the

cable

is

grounded

and

the

thermorneter

indicates

approximately

500C

1220F

When

the

thermometer

is

normal

through

the

above

inspection

The

thermometer

indicates

a

temperature

slightly

lower

than

the

actual

temperature

The

poin

ter

tank

unit

grounded

deflects

yellow

when

the

cable

is

The

pointer

does

not

deflect

through

the

above

inspection

The

pointer

lowers

below

the

ernpty

limit

when

the

ignition

switch

is

turned

off

The

pointer

still

indicates

Full

position

through

the

above

in

spection

The

pointer

indicates

a

half

level

when

a

35

n

resistance

is

applied

to

the

tank

unit

yellow

cable

and

the

cable

is

grounded

The

pointer

does

not

indicate

a

half

level

through

the

above

in

spection

BE

24

Replace

if

defective

Replace

the

therrnal

transmitter

Check

the

cable

from

the

thermometer

to

the

thermal

trans

mitter

for

cable

being

about

to

break

poor

contact

and

faulty

grounding

and

repair

as

required

Replace

unit

the

tank

Replace

the

fuel

me

tee

with

a

new

one

Replace

the

tank

unit

Replace

the

fuel

me

ter

Replace

if

defective

Replace

the

fuel

meter

Page 260 of 513

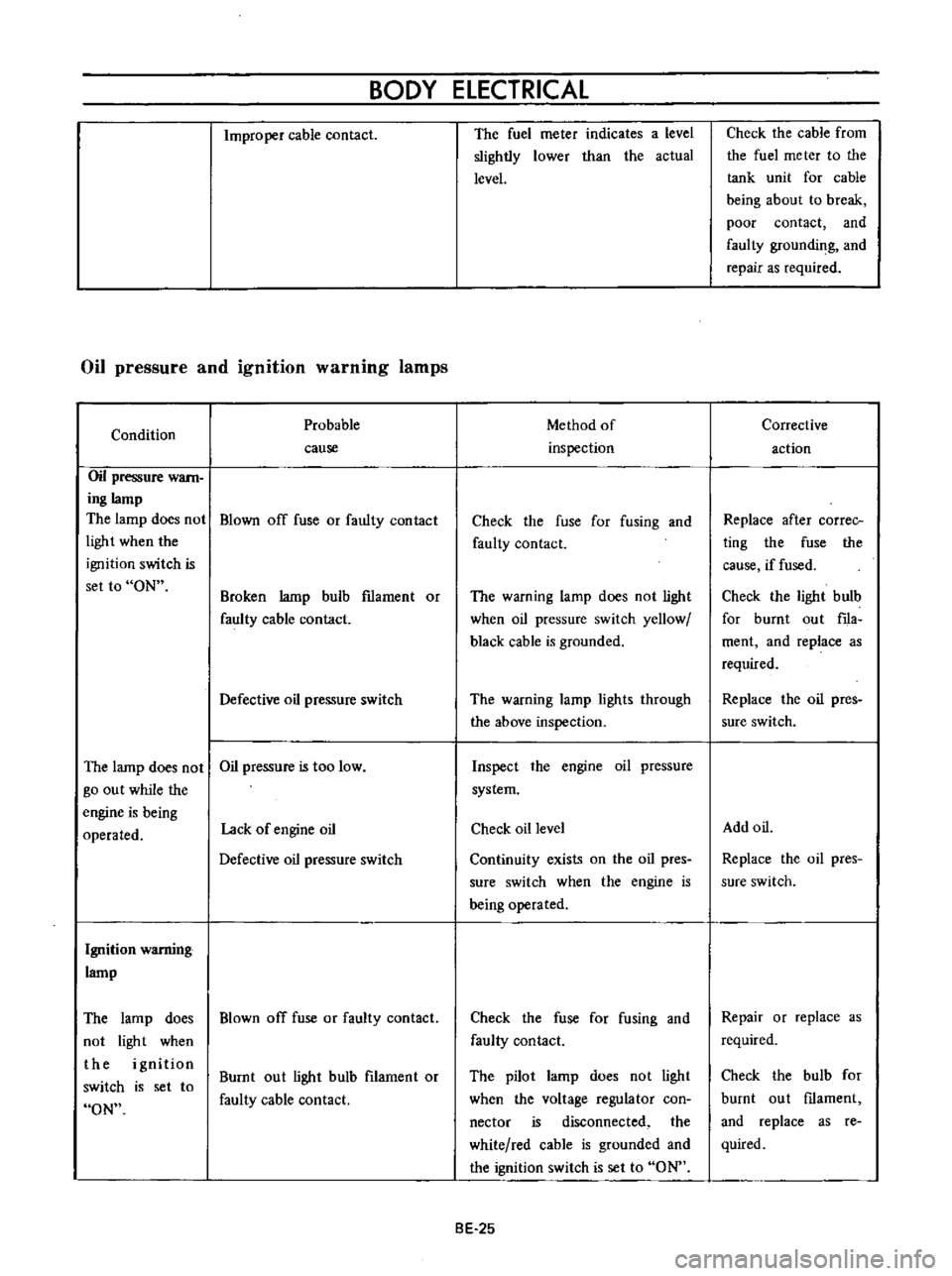

BODY

ELECTRICAL

Improper

cable

contact

Oil

pressure

and

ignition

warning

lamps

Condition

Oil

pressure

Want

ing

lamp

The

lamp

does

not

ligh

t

when

the

ignition

switch

is

set

to

ON

Probable

cause

Blown

off

fuse

or

faulty

contact

Broken

lamp

bulb

fIlarnent

or

faulty

cable

contact

Defective

oil

pressure

switch

The

lamp

does

not

Oil

pressure

is

too

low

go

out

while

the

engine

is

being

operated

Lack

of

engine

oil

Defective

oil

pressure

switch

Ignition

warning

lamp

The

lamp

does

not

light

when

the

ignition

switch

is

set

to

ON

Blown

off

fuse

or

faulty

contact

Burnt

out

light

bulb

filarnent

or

faulty

cable

contact

The

fuel

rneter

indicates

a

level

slightly

lower

than

the

actual

level

Method

of

inspection

Check

the

fuse

for

fusing

and

faulty

contact

The

warning

lamp

does

not

light

when

oil

pressure

switch

yellow

black

cable

is

grounded

The

warning

lamp

lights

through

the

above

inspection

Inspect

the

engine

oil

pressure

system

Check

oil

level

Continuity

exists

on

the

oil

pres

sure

switch

when

the

engine

is

being

operated

Check

the

fuse

for

fusing

and

faulty

contact

The

pilot

lamp

does

not

light

when

the

voltage

regulator

con

nector

is

disconnected

the

white

red

cable

is

grounded

and

the

ignition

switch

is

set

to

ON

BE

25

Check

the

cable

from

the

fuel

meter

to

the

tank

unit

for

cable

being

about

to

break

poor

contact

and

faulty

grounding

and

repair

as

required

Corrective

action

Replace

after

corree

ting

the

fuse

the

cause

if

fused

Check

the

light

bulb

for

burnt

out

fIla

ment

and

replace

as

required

Replace

the

oil

pres

sure

switch

Add

oil

Replace

the

oil

pres

sure

switch

Repair

or

replace

as

required

Check

the

bulb

for

burnt

out

fIlament

and

replace

as

re

quired