DATSUN B110 1973 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1973,

Model line: B110,

Model: DATSUN B110 1973

Pages: 513, PDF Size: 28.74 MB

DATSUN B110 1973 Service Repair Manual

B110 1973

DATSUN

DATSUN

https://www.carmanualsonline.info/img/56/56904/w960_56904-0.png

DATSUN B110 1973 Service Repair Manual

Trending: window, check oil, fuel, sensor, AUX, automatic transmission fluid, Charging system

Page 181 of 513

CHASSIS

Description

The

accelerator

linkage

is

lightv

eighL

and

onstfuction

is

such

that

the

linkage

operates

smoothly

and

is

unaffected

bv

engine

vibration

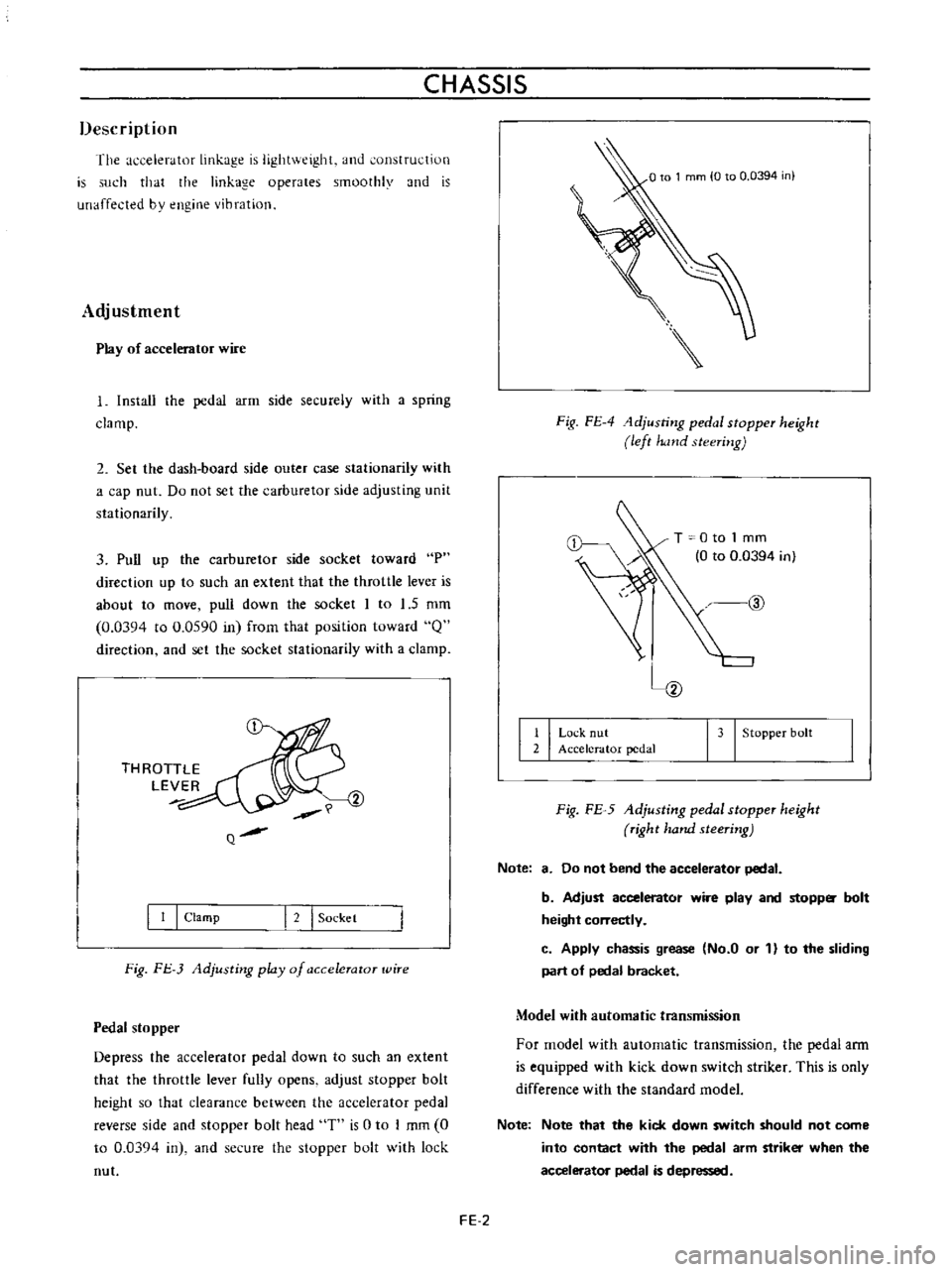

Adjustment

Play

of

accelerator

wire

I

Install

the

pedal

arm

side

securely

with

a

spring

clamp

2

Set

the

dash

board

side

Quter

case

stationarily

with

a

cap

nut

Do

not

set

the

carburetor

side

adjusting

unit

stationarily

3

Pull

up

the

carburetor

side

socket

toward

P

direction

up

to

such

an

extent

that

the

throttle

lever

is

about

to

move

pull

down

the

socket

I

to

1

5

mm

0

0394

to

0

0590

in

frorn

that

position

toward

Q

direction

and

set

the

socket

stationarily

with

a

clamp

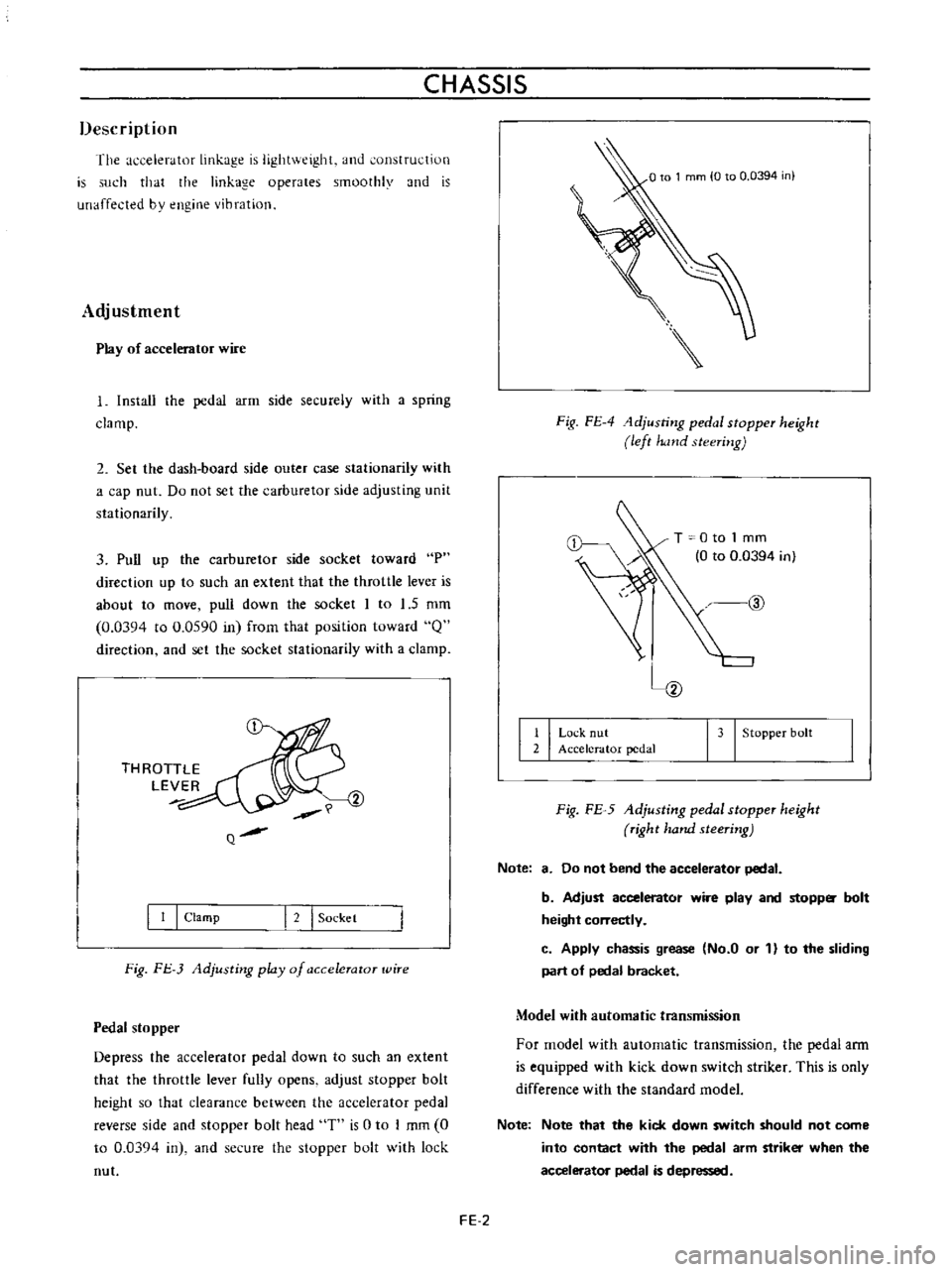

THROTTLE

LEVER

Q

I

I

I

Clamp

I

2

I

Sockel

Fig

FJ

3

Adjusting

play

of

a

ccelerator

wire

Pedal

stopper

Depress

the

accelerator

pedal

down

to

such

an

extent

that

the

throttle

lever

fully

opens

adjust

stopper

bolt

height

so

that

clearance

between

the

accelerator

pedal

reverse

side

and

stopper

bolt

head

T

is

0

to

I

mm

0

to

0

03Q4

in

and

secure

the

stopper

bolt

with

lock

nut

Fig

FE

4

1djusting

pedal

stopper

height

left

hand

steering

T

0

to

1

mm

0

to

0

0394

in

@

I

I

Lo

k

nut

2

Accelerator

pedal

I

3

I

Stopper

bolt

Fig

FE

5

Adjusting

pedal

stopper

height

right

hand

steering

Note

8

Do

not

bend

the

accelerator

pedal

b

Adjust

accelerator

wire

play

and

stopp

bolt

height

correctly

c

Apply

chassis

grease

No

a

or

1

to

the

sliding

part

of

pedal

bracket

Model

with

automatic

transmission

For

model

with

automatic

transmission

the

pedal

ann

is

equipped

with

kick

down

switch

striker

This

is

only

difference

with

the

standard

model

Note

Note

that

the

kick

down

switch

should

not

come

into

contact

with

the

pedal

arm

striker

when

the

accelerator

pedal

is

depressed

FE

2

Page 182 of 513

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEM

R

H

drive

L

H

drive

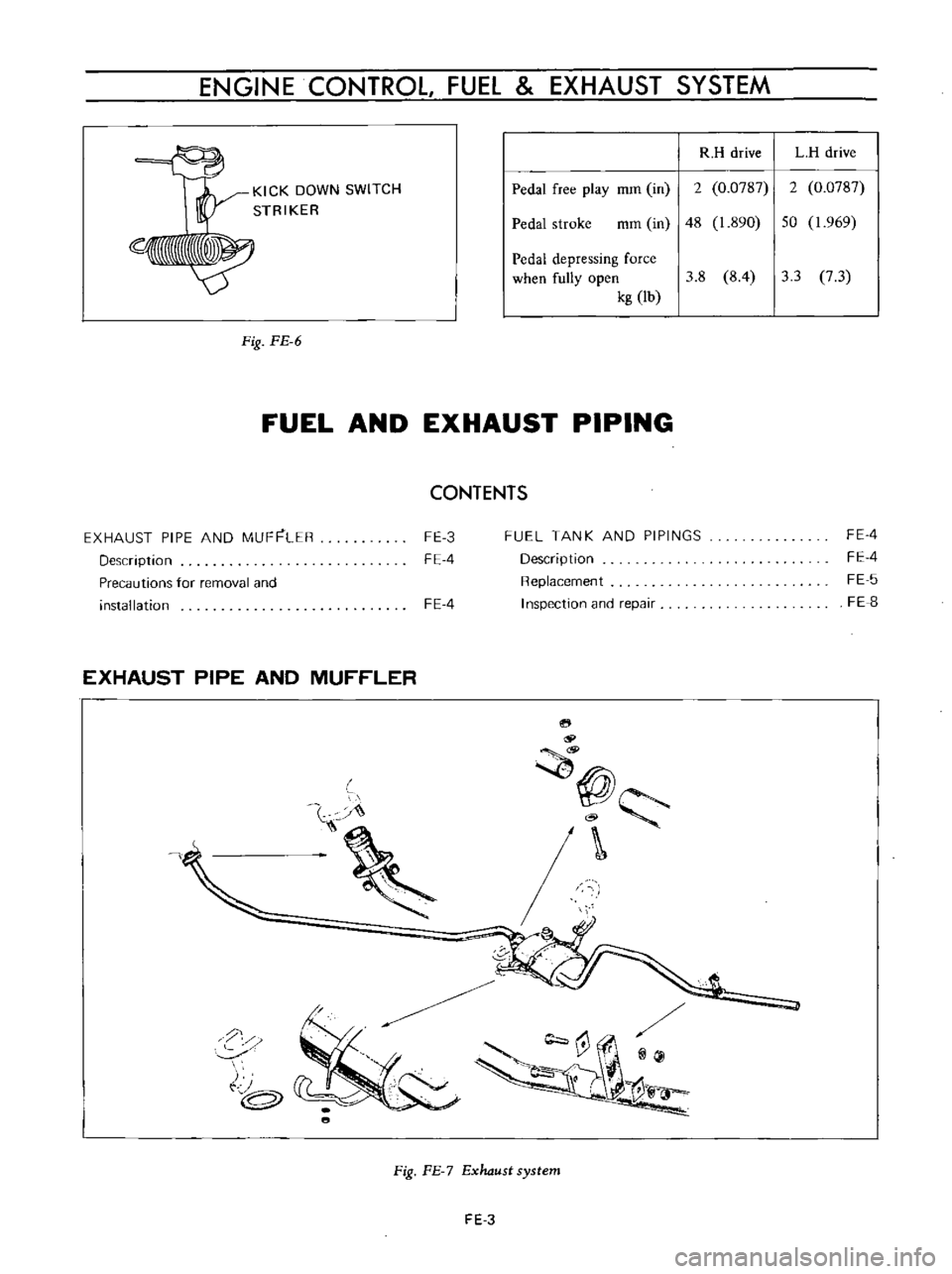

KICK

DOWN

SWITCH

STRIKER

Pedal

free

play

mrn

in

2

0

0787

2

0

0787

Pedal

stroke

mm

in

48

1

890

50

1

969

Pedal

depressing

force

when

fully

open

3

8

8

4

3

3

7

3

kg

lb

Fig

FE

6

FUEL

AND

EXHAUST

PIPING

CONTENTS

EXHAUST

PIPE

AND

MUF

LER

Description

Precautions

for

removal

and

installation

FE

3

FE

4

FUEL

TANK

AND

PIPINGS

Description

Replacement

I

nspection

and

repair

FE

4

FE

4

FE

5

FE

S

FE

4

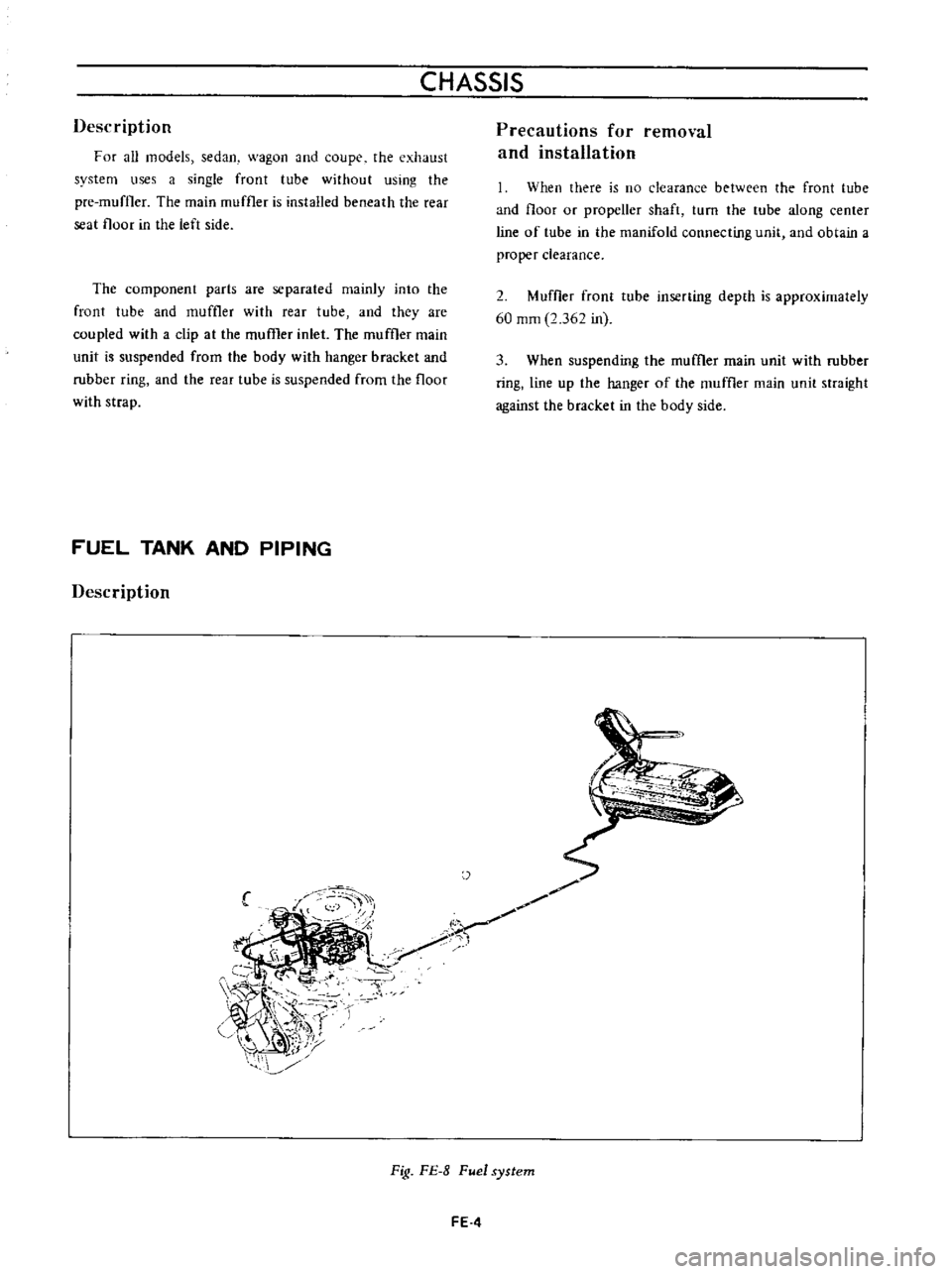

EXHAUST

PIPE

AND

MUFFLER

i

@

@

@

Fig

FE

Exhaust

system

FE

3

Page 183 of 513

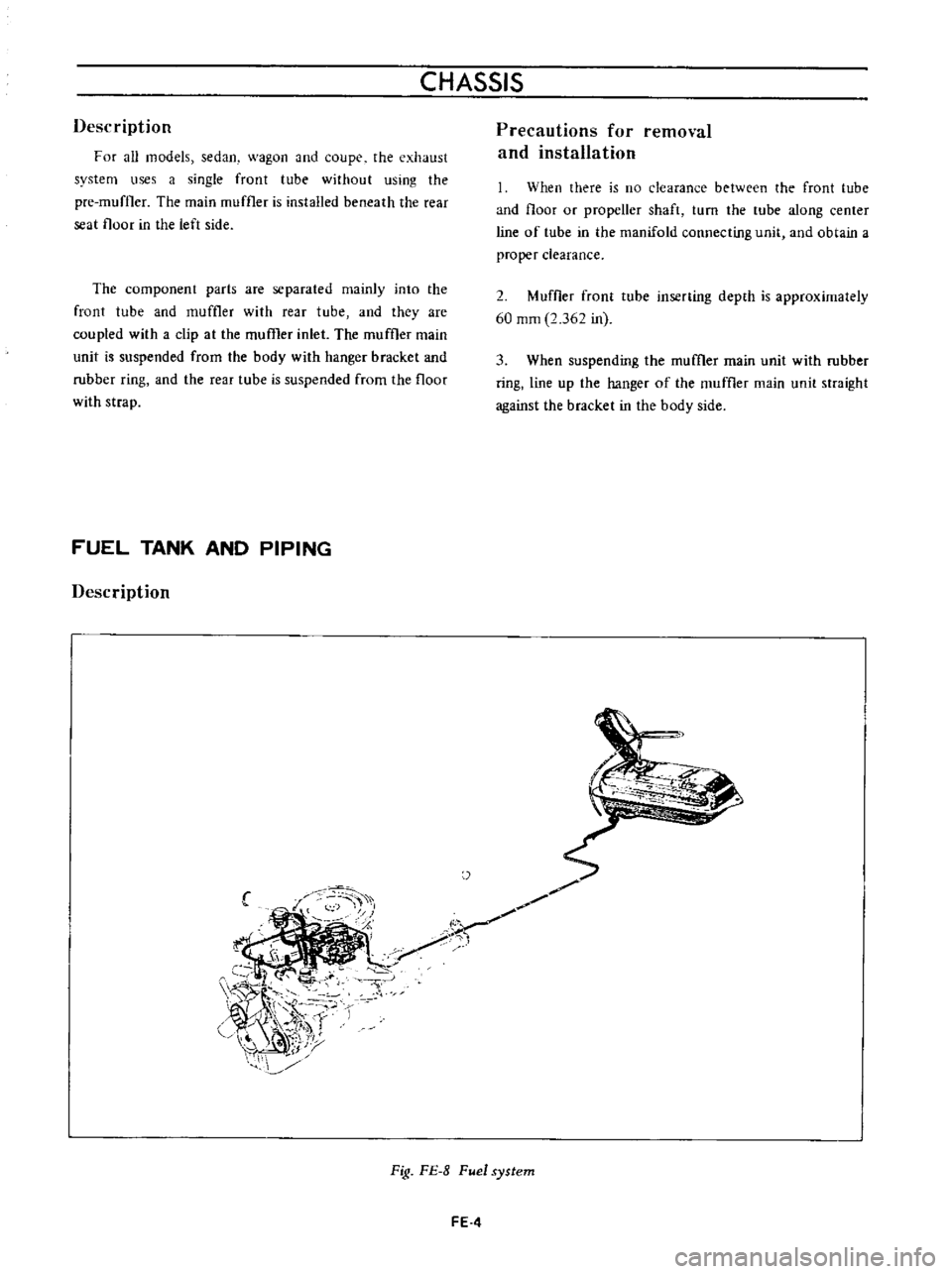

CHASSIS

Description

F

Of

aU

models

sedan

wagon

and

coupe

the

exhaust

system

uses

a

single

front

tube

without

using

the

pre

muffler

The

main

muffler

is

installed

beneath

the

rear

seat

floor

in

the

left

side

The

component

parts

are

separated

mainly

into

the

front

tube

and

muffler

with

rear

tube

and

they

are

coupled

with

a

dip

at

the

muffler

inlet

The

rnuffler

main

unit

is

suspended

from

the

body

with

hanger

bracket

and

rubber

ring

and

the

rear

tube

is

suspended

from

the

floor

with

strap

FUEL

TANK

AND

PIPING

Description

Precautions

for

removal

and

installation

When

there

is

no

clearance

between

the

front

tube

and

floor

or

propeller

shaft

turn

the

tube

along

center

line

of

tube

in

the

manifold

connecting

unil

and

obtain

a

proper

clearance

2

Muffler

front

tube

inserting

depth

is

approximately

60

mm

2

362

in

3

When

suspending

the

muffler

rnain

unit

with

rubber

ring

line

up

the

hanger

of

the

muffler

main

unit

straight

against

the

bracket

in

the

body

side

OJ

f

r

ii

7

0

i

i

c

5t

r

t5j

n

jJ

I

L

Fig

FE

8

Fuel

system

FE

4

Page 184 of 513

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEM

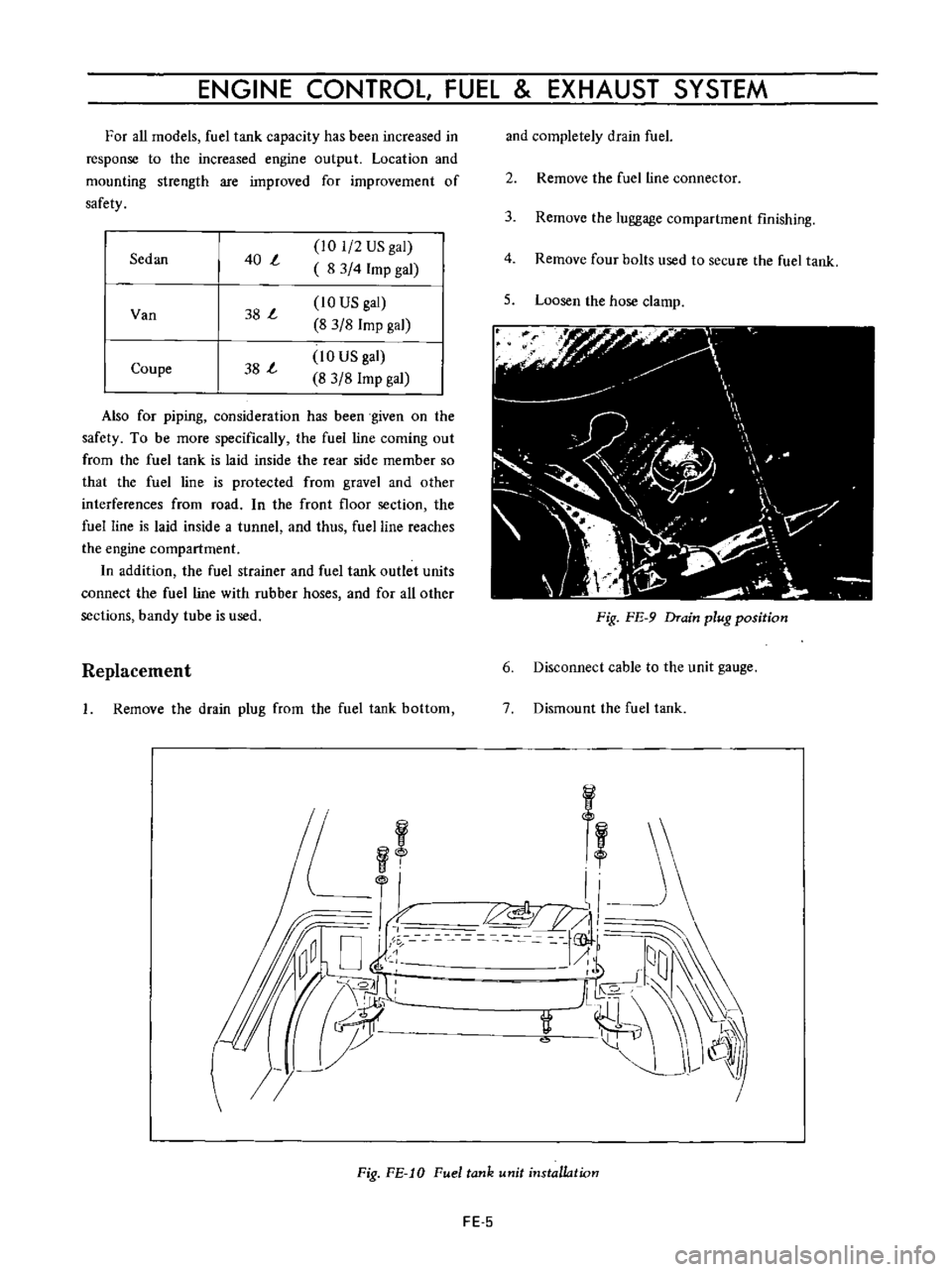

For

all

models

fuel

tank

capacity

has

been

increased

in

response

to

the

increased

engine

output

Location

and

mounting

strength

are

improved

for

improvement

of

safety

Sedan

40

l

101

2

US

gal

8

3

4

Imp

gal

Van

38

l

10

US

gal

8

3

8

Imp

gal

Coupe

38

l

10

US

gal

8

3

8

Imp

gal

and

completely

drain

fuel

2

Remove

the

fuel

line

connector

3

Remove

the

luggage

compartment

finishing

4

Remove

four

bolts

used

to

secure

the

fuel

tank

5

Loosen

the

hose

clamp

f

r

II

J

y

I

0

I

V

Ii

i

iJb

Also

for

piping

consideration

has

been

given

on

the

safety

To

be

more

specifically

the

fuel

line

coming

out

from

the

fuel

tank

is

laid

inside

the

rear

side

member

so

that

the

fuel

line

is

protected

from

gravel

and

other

interferences

from

road

In

the

front

floor

section

the

fuel

line

is

laid

inside

a

tunnel

and

thus

fuel

line

reaches

the

engine

compartment

In

addition

the

fuel

strainer

and

fuel

tank

outlet

units

connect

the

fuel

line

with

rubber

hoses

and

for

aU

other

sections

bandy

tube

is

used

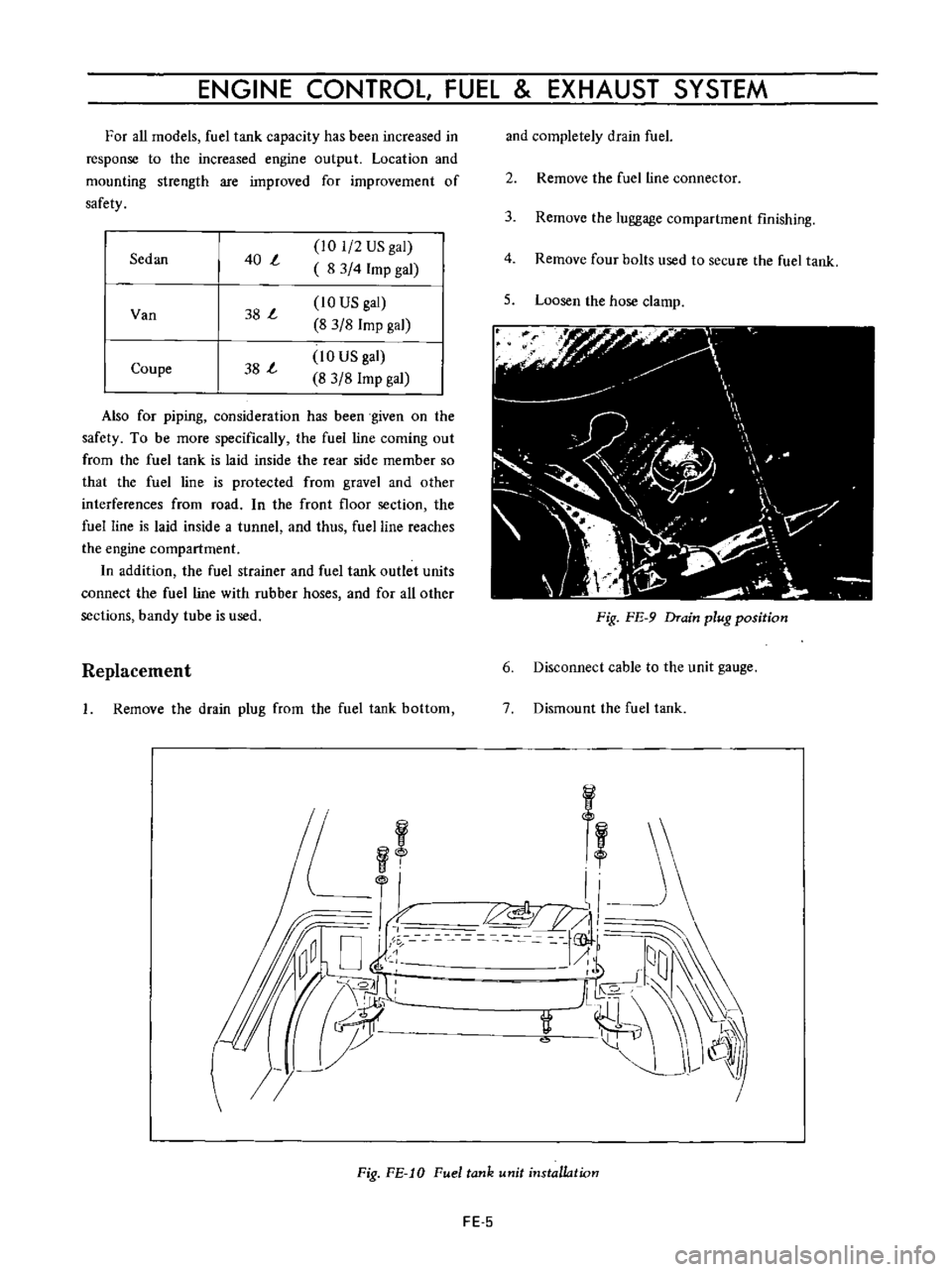

Fig

FE

9

Drain

plug

position

Replacement

Remove

the

drain

plug

from

the

fuel

tank

bottom

6

Disconnect

cable

to

the

unit

gauge

7

Dismount

the

fuel

tank

f

I

Y

L

ll

C

jjhrr

@

Fig

FE

10

Fuel

tank

14nit

installation

FE

5

Page 185 of 513

CHASSIS

I

I

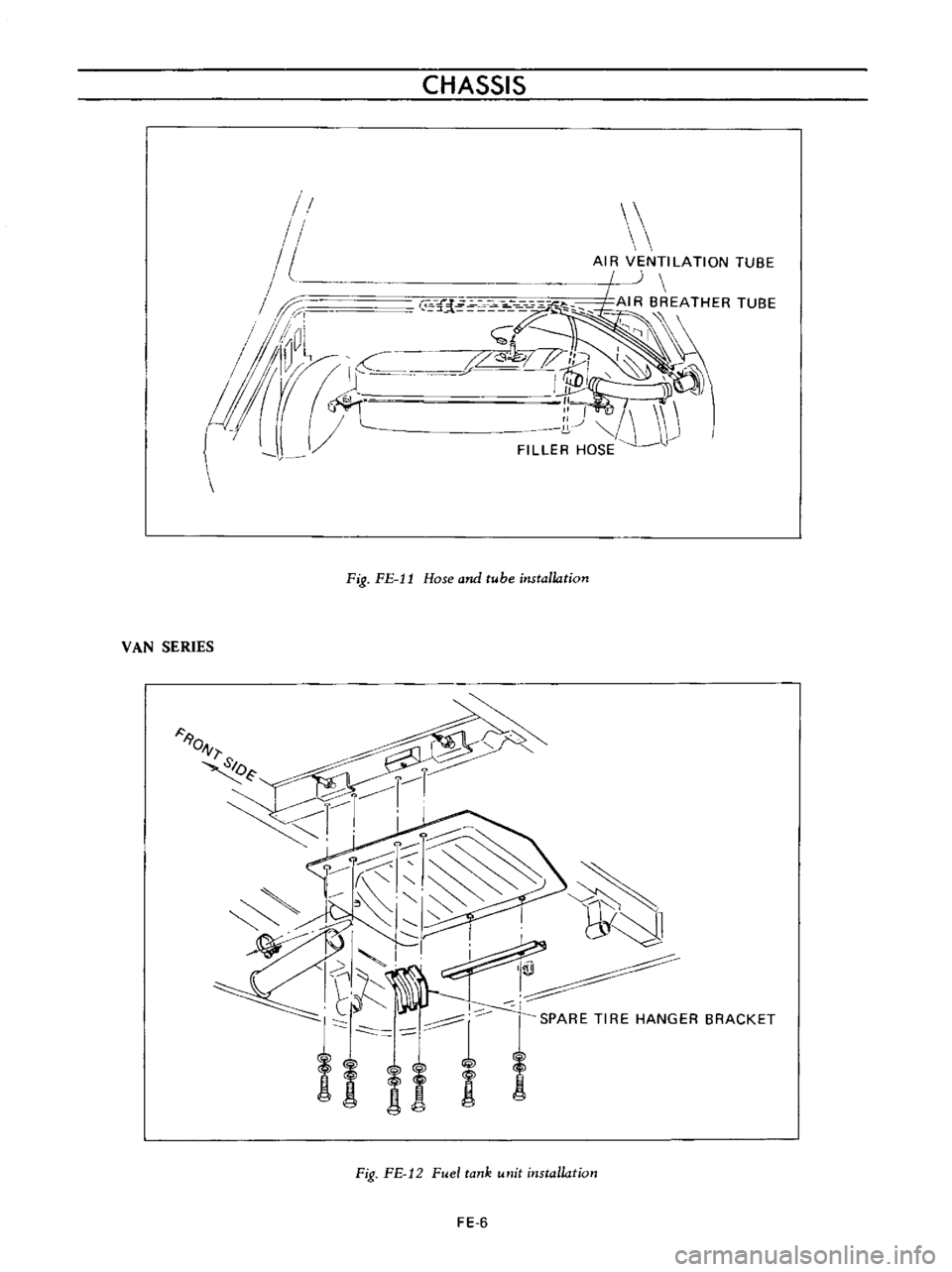

AIR

VENTILATION

TUBE

I

l

i

f

I

REtTHER

TUBE

1110

l

1

j

7

7

I

ji

lf

ff

h

j

Ij

I

1

L

J

1

I

FILL

HO

l

Fig

FE

11

Hose

and

tube

installation

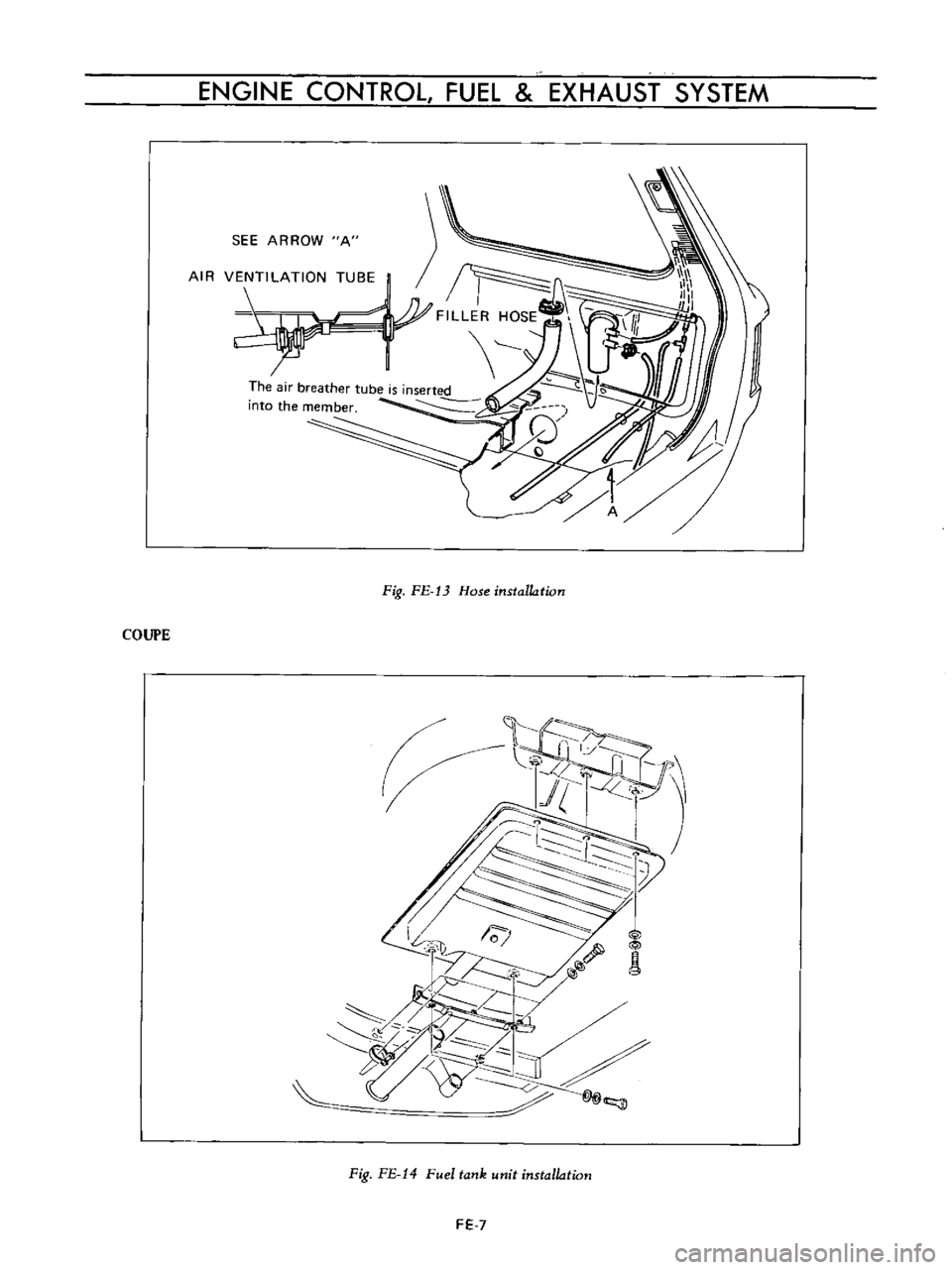

VAN

SERIES

90

1

SID

o

I

I

I

I

n

2

G

l

1

I

rl

b

IJ

I

if

I

f

f

f

Aun

AO

Fig

FE

12

Fuel

tank

unit

installation

FE

6

Page 186 of 513

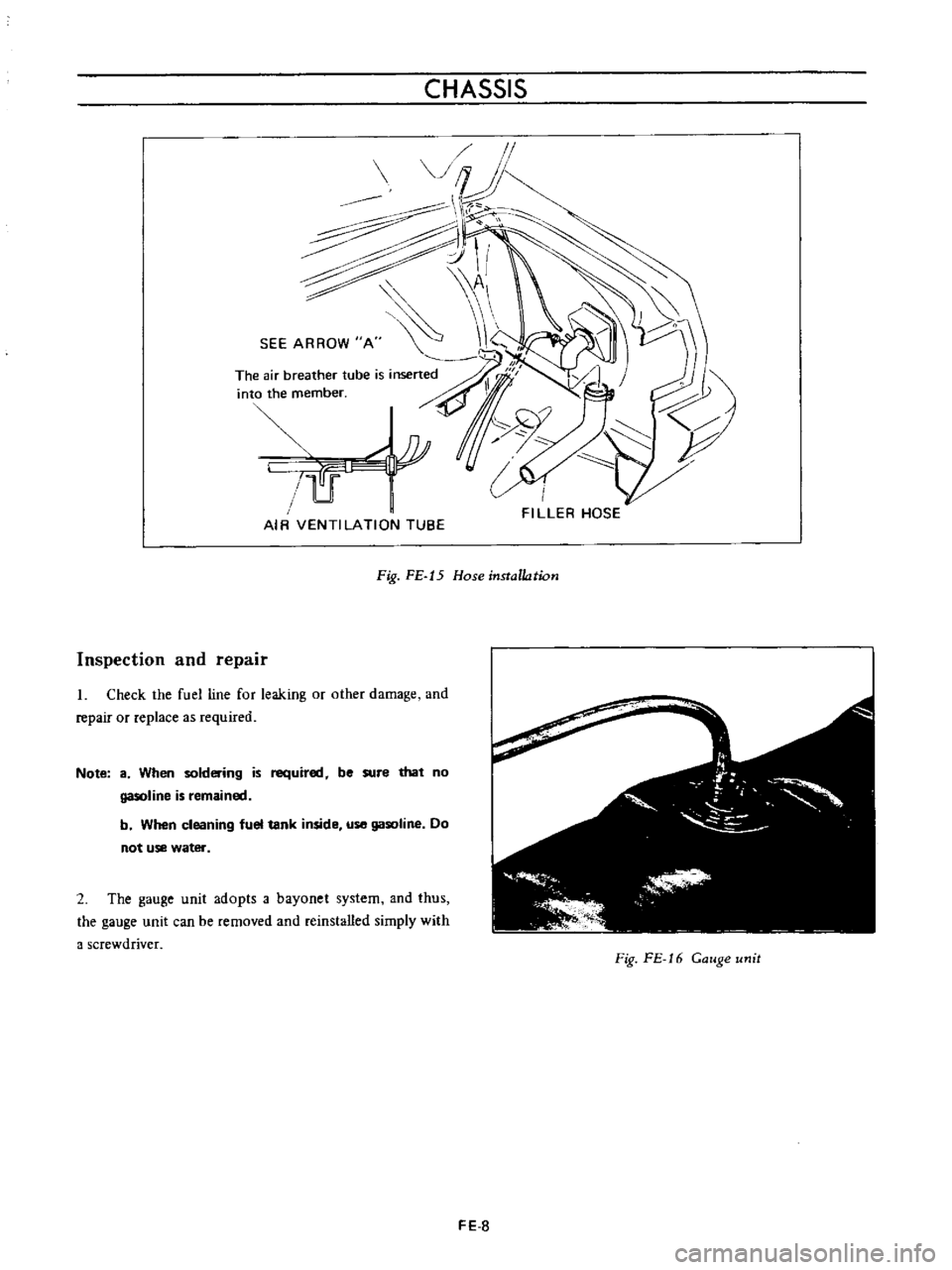

COUPE

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEM

SEE

ARROW

A

Fig

FE

13

Hose

installation

Fig

FE

14

Fuel

tank

unit

installation

FE

7

Page 187 of 513

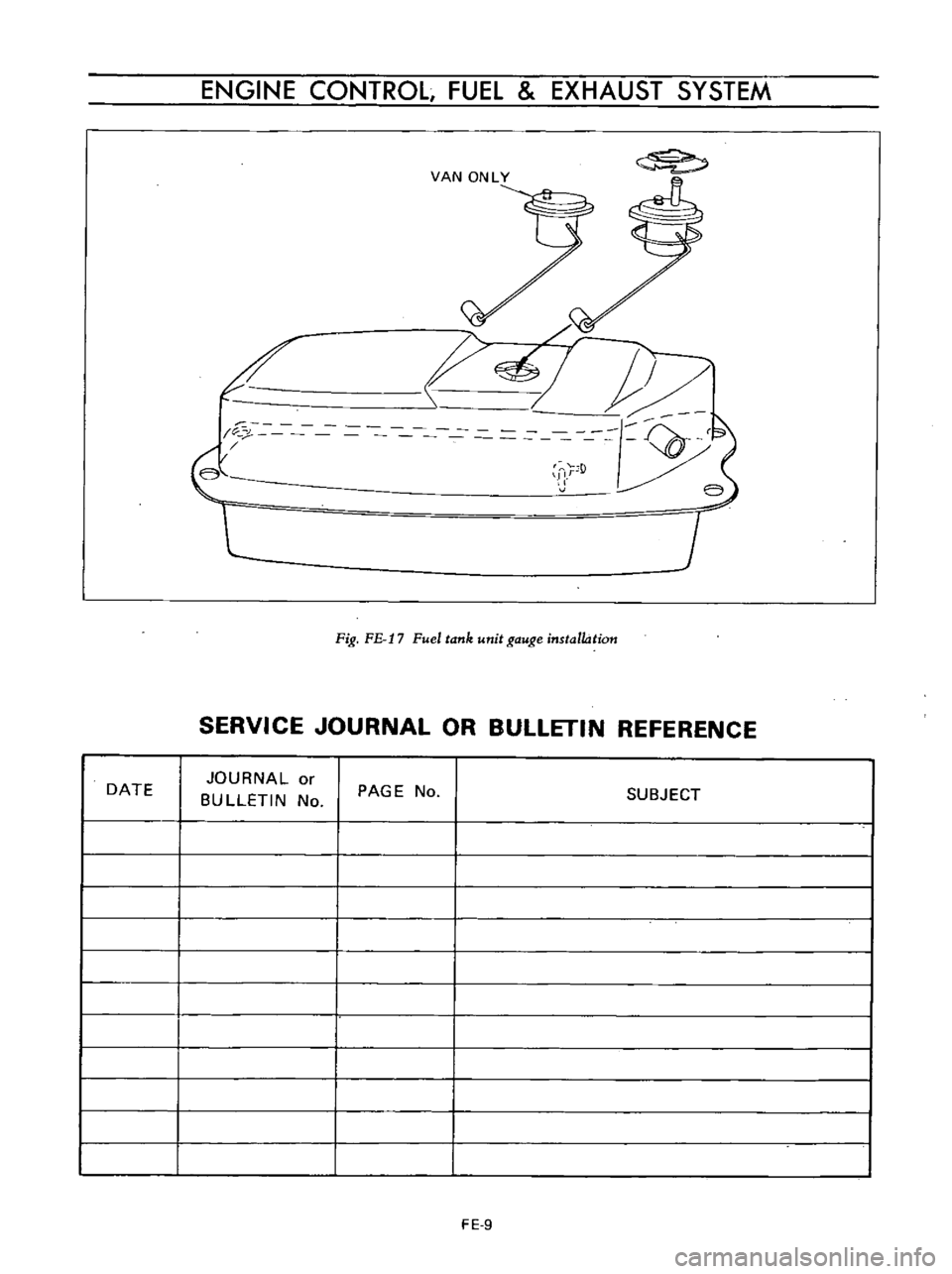

CHASSIS

II

IJ

II

t

Ii

A1

SEE

ARROW

A

r

r

I

7JJ

TI

r

i

FI

LLER

HOSE

AIR

VENTILATION

TUBE

Fig

FE

15

Hose

installation

Inspection

and

repair

I

Check

the

fuel

line

for

leaking

or

other

damage

and

repair

or

replace

as

required

Note

8

When

soldering

is

required

be

sure

that

no

gasoline

is

remained

b

When

cleaning

fuel

tank

inside

use

gasoline

Do

not

use

water

2

The

gauge

unit

adopts

a

bayonet

system

and

thus

the

gauge

unit

can

be

removed

and

reinstalled

simply

with

a

screwdriver

Fig

FE

16

Gauge

unit

FE

S

Page 188 of 513

DATE

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEM

VAN

ONLY

r

j

f

Qo

I

e

nr

e

Fig

FE

17

Fuel

tank

unit

gauge

installation

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

FE

9

Page 189 of 513

DATE

CHASSIS

SERVICE

JOURNAL

OR

BUllETIN

REFERENCE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

FE

10

Page 190 of 513

SERVI

oE

NuA

r

DATSUN

1200

MODEL

B

1

10

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

BF

BODY

GENERAL

DESCRIPTION

UNDERBODY

ALIGNMENT

HOOD

FRONT

FENDER

AND

FRONT

END

TRUNK

LID

AND

REAR

BUMPER

DOORS

WINDSHIELD

AND

REAR

WINDOW

VENTILATOR

SEAT

INSTRUMENT

PANEL

ROOM

TRIM

BF

1

BF

9

BF

14

BF

17

BF

19

BF

24

BF

31

BF

37

BF38

BF

42

BF

43

Trending: battery replacement, fuse box diagram, tow, cooling, washer fluid, maintenance, fuel type