engine DATSUN B110 1973 Service Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 64 of 513

CHASSIS

SERVICE

DATA

AND

SPECIFICATIONS

General

specifications

Torque

converter

Type

Stall

torque

ratio

Transmission

Type

Control

elements

Gear

ratio

Selector

positions

Oil

pump

Type

Number

of

pump

Oil

Capacity

Hydraulic

control

system

Lubrication

system

Cooling

system

Multiple

disc

clutch

Band

brake

Multiple

disc

brake

One

way

clutch

1st

lnd

3rd

Reverse

P

Park

R

Reverse

N

Neutral

D

Drive

1

lnd

lock

I

Lock

up

AT

60

Symmetrical3

element

I

stage

l

phase

torque

converter

coupling

2

0

I

3

speed

forward

and

one

speed

reverse

with

planetary

gear

train

1

I

I

I

2

458

1

458

1

000

2

182

The

transmission

is

placed

in

neutral

The

output

shaft

is

fixed

The

engine

can

be

started

Backward

running

The

transmission

is

in

neutral

The

engine

can

be

started

Up

or

downshifts

automatically

to

and

from

1st

lnd

and

top

Fixed

at

2nd

Fixed

at

low

or

downshifts

from

2nd

Internally

intermeslting

involute

gear

pump

Automatic

transmission

fluid

Dexron

type

5

5

liters

57

8

U

S

qts

47

8

Imp

qts

Approximately

1

7

liters

27

8

U

S

qts

2

3

8

Imp

qts

in

torque

converter

Controlled

by

detecting

the

negative

pressure

of

intake

manifold

and

the

revolution

speed

of

output

shaft

Forced

lubrication

by

an

oil

pwnp

Air

cooled

Page 66 of 513

CHASSIS

Engine

idling

and

stall

revolution

Engine

with

emission

control

device

Idling

revolution

rpm

650

at

0

position

800

at

N

position

1

750

to

2

000

Stall

revolution

rpm

Tightening

torque

kg

m

ft

Ib

Test

plug

oil

pressure

inspection

hole

Support

actuator

parking

rod

inserting

position

to

rear

extension

Oil

charging

pipe

to

case

Dust

cover

to

converter

housing

Selector

range

lever

to

manual

shaft

Lower

shift

rod

lock

nut

6

5

t07

5

47

to

54

0

8

to

1

0

5

8

to

7

2

4

0

to

5

0

30

to

36

4

0

to

5

0

30

to

36

2

0

to

2

5

15

to

18

0

5

to

0

7

3

6

to

5

1

0

5

to

0

7

3

6toS

I

1

2

to

1

5

8

7

to

10

8

1

5

to

4

0

II

to

29

1

3

to

1

8

9

4

to

13

0

55

to

0

75

4

0

to

5

4

0

25

to

0

35

1

9

to

2

5

0

25

to

0

35

1

9

to

2

5

0

5

to

0

7

3

6

to

5

I

0

25

to

0

35

1

9

to

2

5

0

5

to

0

7

3

6

to

5

1

0

6

to

0

8

4

4

to

5

8

0

5

to

0

7

3

6

to

5

1

3

0

to

4

0

22

to

29

3

0

to

5

0

22

to

36

14

to

2

1

10

to

15

0

8

to

l

l

5

8

to

7

9

0

55

to

0

75

4

0

to

5

4

0

55

to

0

75

4

0

to

5

4

3

0

to

4

0

22

to

29

2

0

to

2

9

15

to

21

Drive

plate

to

crankshaft

Drive

plate

to

torque

converter

Converter

housing

to

engine

Transmission

case

to

converter

housing

Transmission

case

to

rear

extension

Oil

pan

to

transmission

case

Servo

piston

retainer

to

transmission

case

Piston

stem

when

adjuting

band

brake

Piston

stem

lock

nut

One

way

clutch

inner

race

to

transmission

case

Control

valve

body

to

transmission

case

Lower

valve

body

to

upper

valve

body

Side

plate

to

control

valve

body

Nut

for

control

valve

reamer

bolt

Oil

strainer

to

lower

valve

body

Governor

valve

body

to

oil

distributor

Oil

pump

housing

to

oil

pump

cover

Inhibitor

switch

to

transmh

sion

case

Manual

shaft

lock

nut

Oil

tube

to

transmission

case

Turn

back

two

turns

after

tightening

AT

62

Page 90 of 513

CHASSIS

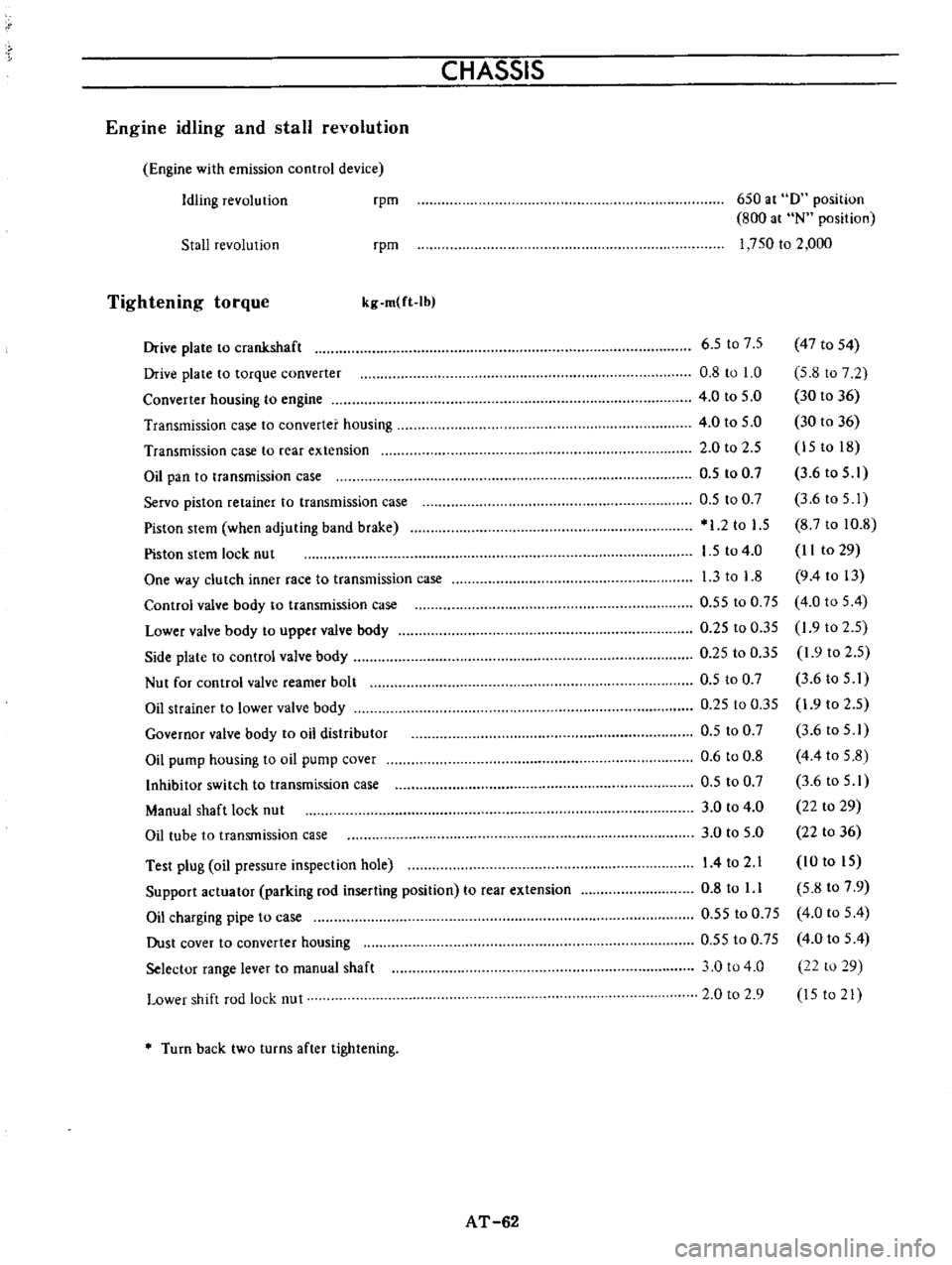

8

Support

the

engine

remove

the

engine

mounting

bolts

indicated

by

arrow

mark

and

separate

the

sus

pension

cross

member

from

the

engine

assembly

Ij

i

1

C

w

ii

lJ

c

l

I

N

r

1

a

n

h

JI

Fig

FA

7

Supporting

engine

I

IV

U

II

G

11J

r

j

F

l

I

IV

I

iL

I

0

I

l

tt

I

i

L

I

It

v

i

1

0

b

c

Ii

irti

J

I

I

1

1

Zi

J

l

ll

c

h

f

J

f

C

Fig

FA

8

Removing

engine

mounting

bolts

9

Apply

a

jack

to

the

patch

unit

in

the

center

of

the

suspension

cross

member

to

support

the

member

loosen

the

bolts

indicated

by

arrow

marks

and

separate

the

suspension

cross

member

from

the

body

Fig

FA

9

Jack

up

point

of

suspension

cross

member

Fig

FA

10

Removing

suspension

cross

member

10

Loosen

the

self

locking

nut

on

the

strut

assembly

and

holding

the

strut

assembly

dismount

the

front

suspension

assembly

Fig

F

1

11

Removing

s

flocking

nut

Fig

F

A

12

Removing

front

axle

and

suspension

assembly

FAA

Page 131 of 513

Tightening

torque

3

way

connector

1

5

to

1

8

kg

m

10

8

to

13

0

ft

lh

1

5

to

1

8

kg

m

10

8

to

13

0

ft

lh

1

5

to

1

8

kg

m

10

8

to

13

0

ft

lb

0

7

to

0

9

kg

m

5

1

to

6

5

ft

1b

Master

cylinder

Brake

hose

Air

bleeder

5

Fill

the

master

cylinder

brake

fluid

reservoir

with

brake

fluid

and

perform

air

bleeding

complele1y

Note

a

Do

not

use

brake

fluid

other

than

specified

b

The

specified

brake

fluid

is

used

for

both

single

and

tandem

type

master

cylinders

6

Upon

completion

of

air

bleeding

make

sure

that

the

brake

operates

correctly

and

check

the

brake

tube

and

hose

connectors

for

fluid

leaking

Fully

depress

the

brake

pedal

continue

to

depress

the

brake

pedal

for

several

seconds

and

make

sure

that

no

brake

fluid

leaks

from

any

part

of

the

brake

line

Replace

defective

part

if

required

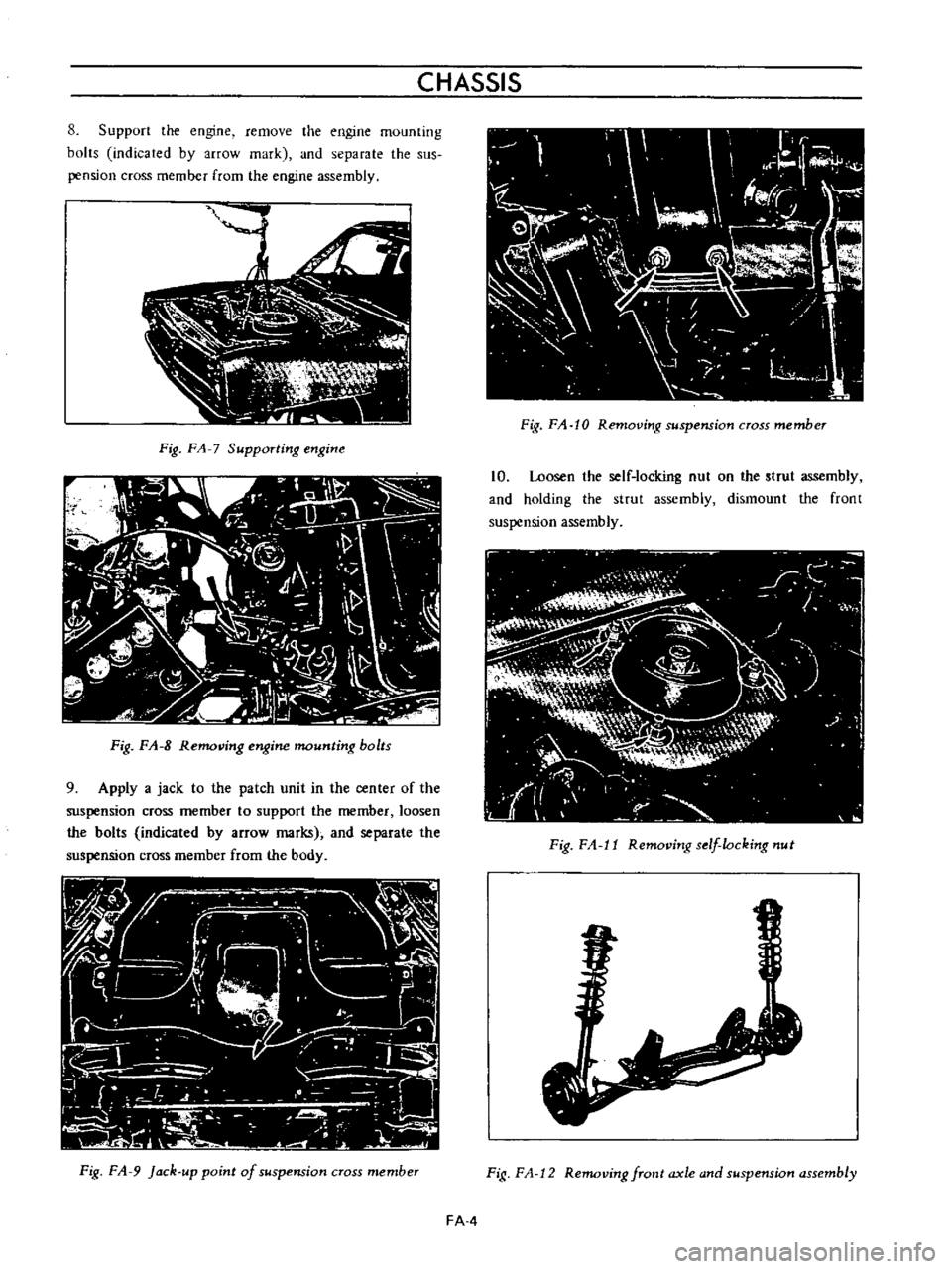

Brake

line

pressure

differential

warning

light

switch

A

warning

light

is

located

on

the

instrument

panel

to

warn

the

driver

when

a

pressure

difference

of

13

to

17

kg

cm2

185

to

2421bJsq

in

exists

between

the

front

and

rear

b

rake

systems

A

hydraulically

actuated

warning

light

switch

is

located

in

the

engine

compartment

Both

front

and

rear

brake

systems

are

connected

to

this

switch

assembly

When

a

pressure

difference

of

13

to

17

kgJcm2

185

to

242

lbJsq

in

occurs

between

the

front

and

rear

brake

systems

the

valves

will

shuttle

toward

the

side

with

the

low

pressure

The

valve

contacts

with

the

switch

terminal

BRAKE

the

ground

circuit

for

the

warning

light

is

completed

and

thus

the

warning

light

lights

In

this

case

correct

the

hydraulic

brake

problem

and

bleed

the

brakes

Check

the

warning

light

switch

assembly

for

a

proper

operation

Check

the

switch

assembly

for

fluid

leakage

Note

Do

not

attempt

to

repair

switch

for

any

reason

replace

switch

assembly

completely

1

To

front

brake

L

H

2

From

master

cylinder

F

3

From

master

cylinder

R

4

To

rear

brake

L

B

R

M

5

To

front

brake

R

H

Fig

BR

12

Warning

light

switch

r

I

@

I

I

3

I

Valve

assembly

4

Piston

load

spring

Wire

terminal

Brake

tube

Fig

BR

13

Sectional

view

of

warning

light

switch

BR

7

Page 163 of 513

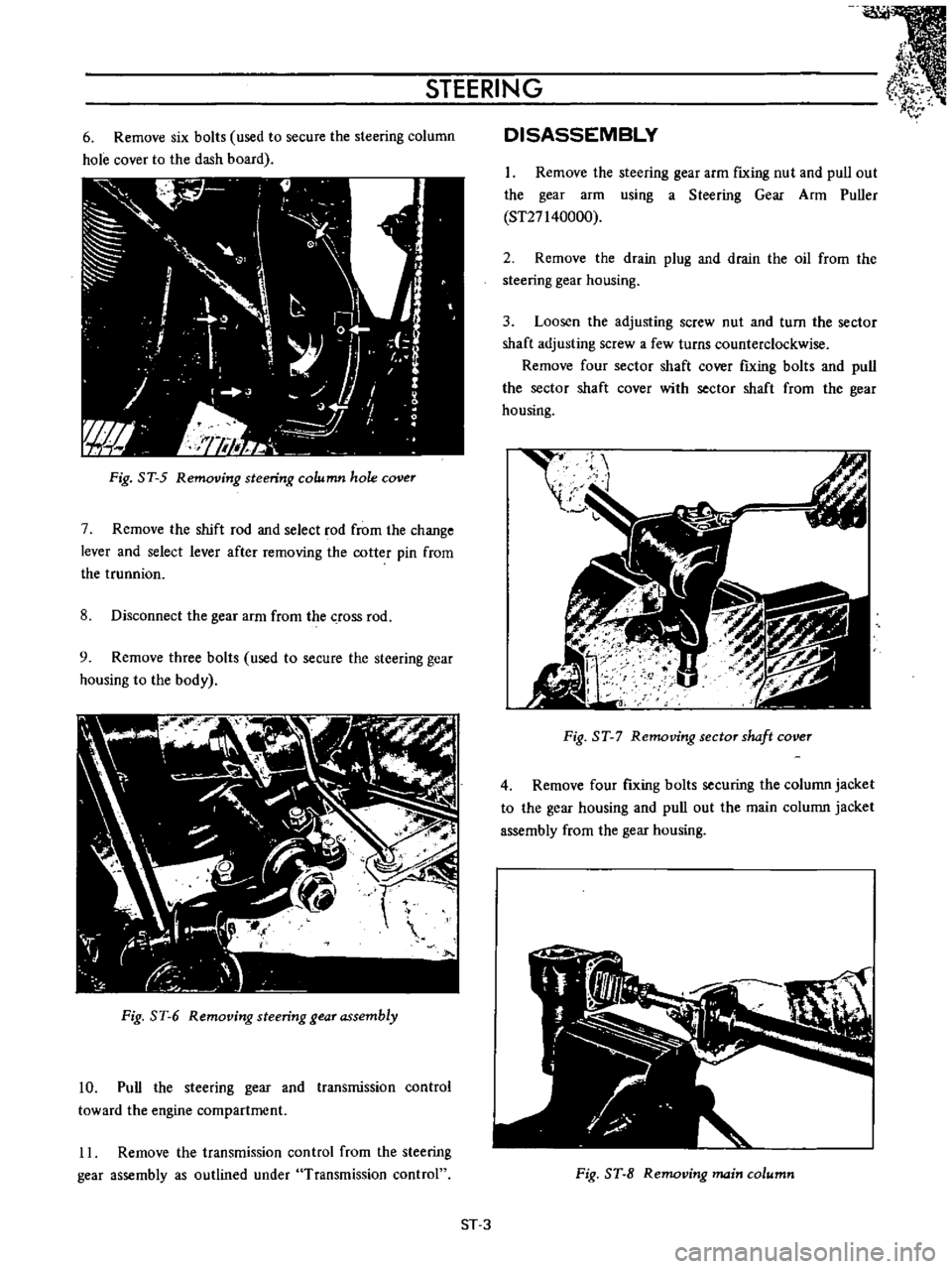

STEERING

6

Remove

six

bolts

used

to

secure

the

steering

column

hole

cover

to

the

dash

board

Fig

ST

5

Removing

steering

column

hole

cover

7

Remove

the

shift

rod

and

select

rod

from

the

change

lever

and

select

lever

after

removing

the

cotter

pin

from

the

trunnion

8

Disconnect

the

gear

arm

from

the

crOSS

rod

9

Remove

three

bolts

used

to

secure

the

steering

gear

housing

to

the

body

Fig

ST

6

Removing

steering

gear

assembly

10

Pull

the

steering

gear

and

transmission

control

toward

the

engine

compartment

11

Remove

the

transmission

control

from

the

steering

gear

assembly

as

outlined

under

Transmission

control

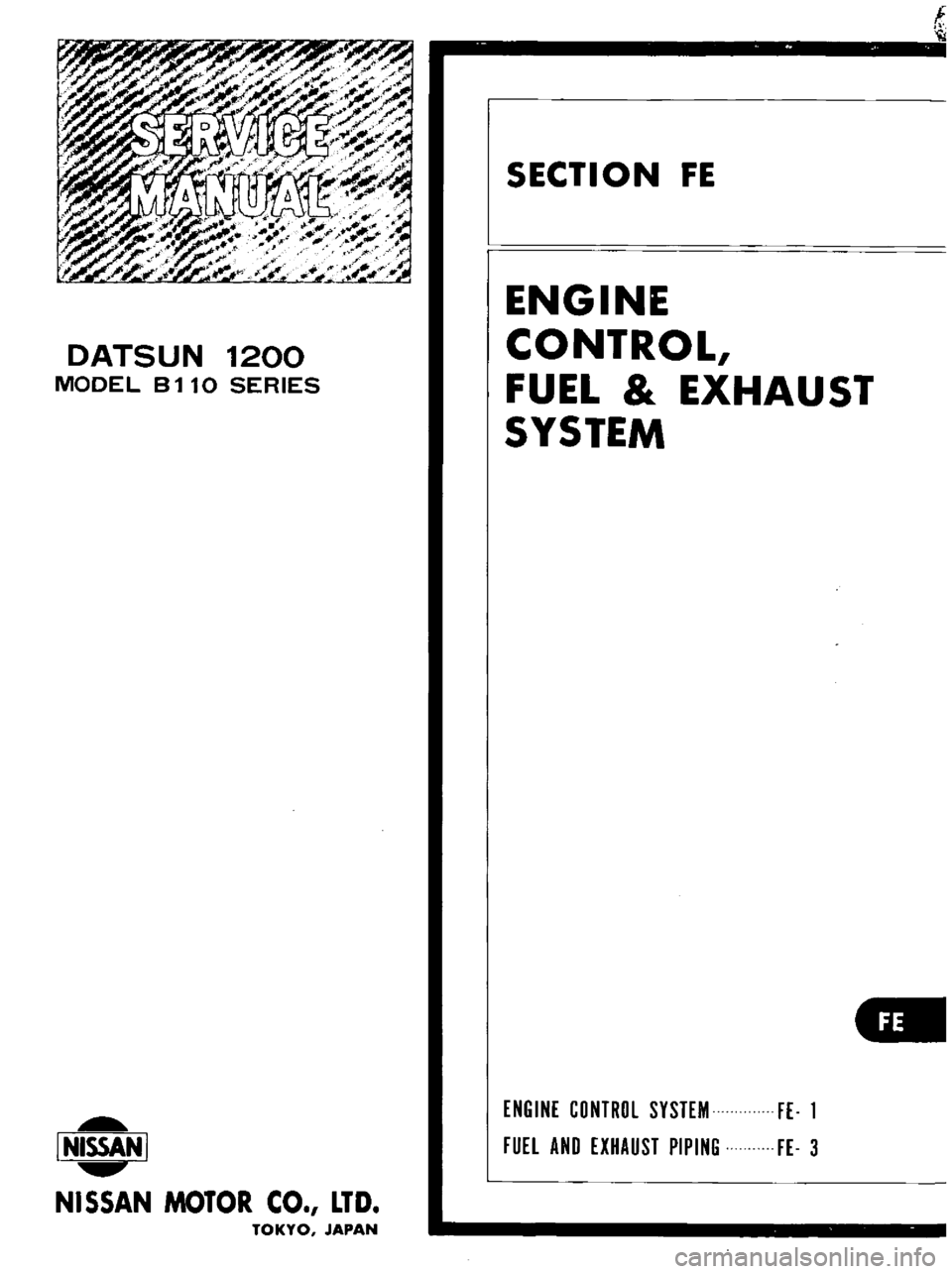

DISASSEMBLY

1

Remove

the

steering

gear

arm

fIxing

nut

and

pull

out

the

gear

arm

using

a

Steering

Gear

Arm

Puller

ST27140000

2

Remove

the

drain

plug

and

drain

the

oil

from

the

steering

gear

housing

3

Loosen

the

adjusting

screw

nut

and

turn

the

sector

shaft

adjusting

screw

a

few

turns

counterclockwise

Remove

four

sector

shaft

cover

fIxing

bolts

and

pull

the

sector

shaft

cover

with

sector

shaft

from

the

gear

housing

t

I

gJ

I

I

Fig

ST

7

Removing

sector

shaft

cover

4

Remove

four

fIxing

bolts

securing

the

column

jacket

to

the

gear

housing

and

pull

out

the

main

column

jacket

assembly

from

the

gear

housing

Fig

ST

8

Removing

main

column

ST

3

Page 179 of 513

DATSUN

1200

MODEL

8110

SERIES

L

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

t

SECTION

FE

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEM

ENGINE

CONTROL

SYSTEM

FE

1

FUEl

AND

EXHAUST

PIPING

FE

3

Page 180 of 513

ENGINE

CONTROL

FUEl

EXHAUST

SYSTEM

ENGINE

CONTROL

SYSTEM

CONTENTS

Description

ACCELERATOR

CONTROL

FE

1

FE

2

ACCELERATOR

CONTROL

I

I

I

I

Accelerator

pedal

Accelerator

arm

I

31

Wire

outer

case

4

Inner

wire

Adjustment

Et3

I

FE

2

I

JIJ

rl

bid

I

I

51

Pedal

stopper

6

Return

spring

Fig

FE

1

Accelerator

control

system

for

R

H

drive

r

7

i

ID

E

Accelerator

pedal

Accelerator

arm

I

31

Wire

outcr

case

4

Inner

wire

L

AJ

I

51

Pedal

stopper

6

Return

spring

Fig

FE

2

Accelerator

control

system

for

L

R

drive

FE

1

Page 181 of 513

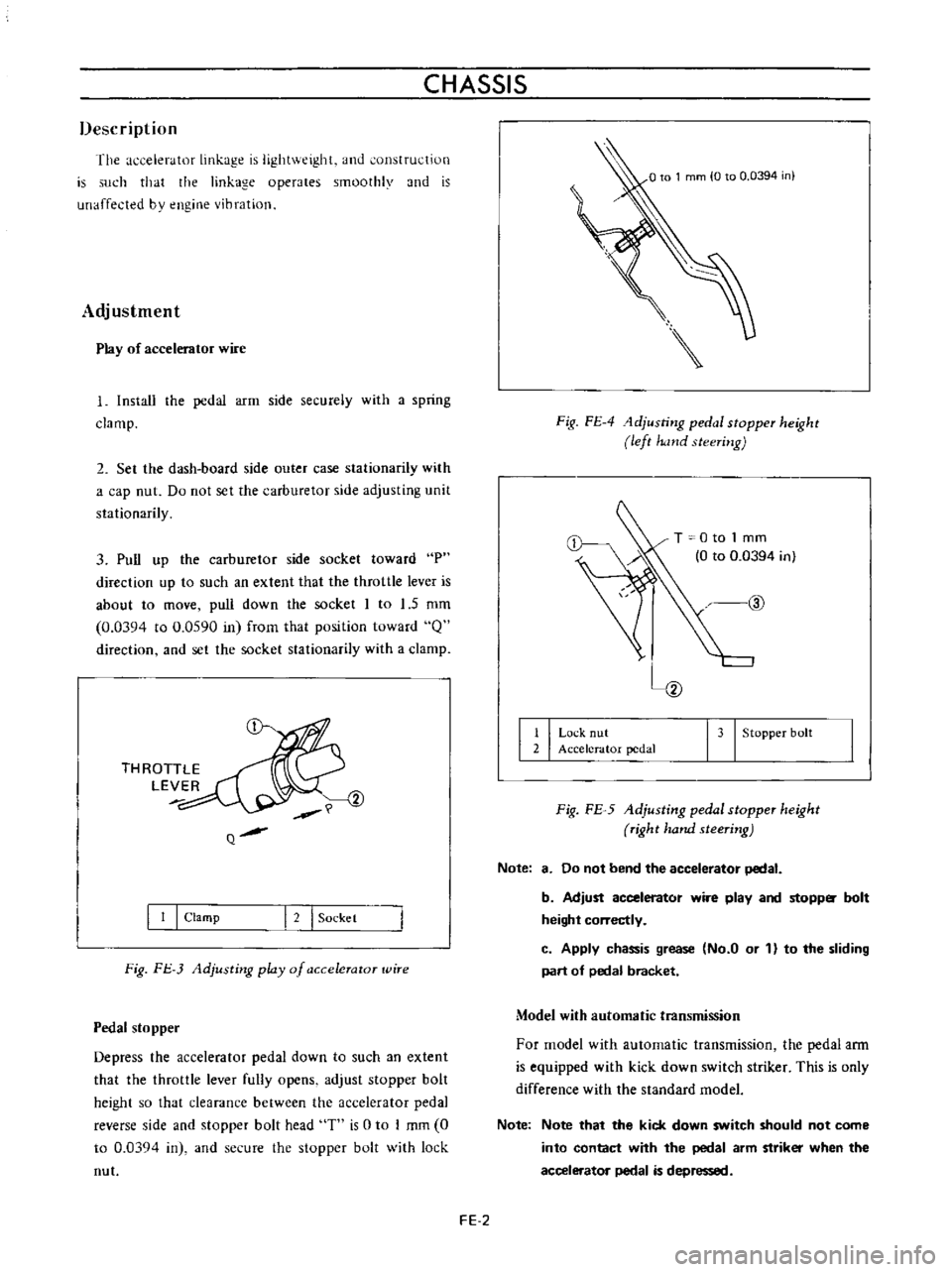

CHASSIS

Description

The

accelerator

linkage

is

lightv

eighL

and

onstfuction

is

such

that

the

linkage

operates

smoothly

and

is

unaffected

bv

engine

vibration

Adjustment

Play

of

accelerator

wire

I

Install

the

pedal

arm

side

securely

with

a

spring

clamp

2

Set

the

dash

board

side

Quter

case

stationarily

with

a

cap

nut

Do

not

set

the

carburetor

side

adjusting

unit

stationarily

3

Pull

up

the

carburetor

side

socket

toward

P

direction

up

to

such

an

extent

that

the

throttle

lever

is

about

to

move

pull

down

the

socket

I

to

1

5

mm

0

0394

to

0

0590

in

frorn

that

position

toward

Q

direction

and

set

the

socket

stationarily

with

a

clamp

THROTTLE

LEVER

Q

I

I

I

Clamp

I

2

I

Sockel

Fig

FJ

3

Adjusting

play

of

a

ccelerator

wire

Pedal

stopper

Depress

the

accelerator

pedal

down

to

such

an

extent

that

the

throttle

lever

fully

opens

adjust

stopper

bolt

height

so

that

clearance

between

the

accelerator

pedal

reverse

side

and

stopper

bolt

head

T

is

0

to

I

mm

0

to

0

03Q4

in

and

secure

the

stopper

bolt

with

lock

nut

Fig

FE

4

1djusting

pedal

stopper

height

left

hand

steering

T

0

to

1

mm

0

to

0

0394

in

@

I

I

Lo

k

nut

2

Accelerator

pedal

I

3

I

Stopper

bolt

Fig

FE

5

Adjusting

pedal

stopper

height

right

hand

steering

Note

8

Do

not

bend

the

accelerator

pedal

b

Adjust

accelerator

wire

play

and

stopp

bolt

height

correctly

c

Apply

chassis

grease

No

a

or

1

to

the

sliding

part

of

pedal

bracket

Model

with

automatic

transmission

For

model

with

automatic

transmission

the

pedal

ann

is

equipped

with

kick

down

switch

striker

This

is

only

difference

with

the

standard

model

Note

Note

that

the

kick

down

switch

should

not

come

into

contact

with

the

pedal

arm

striker

when

the

accelerator

pedal

is

depressed

FE

2

Page 182 of 513

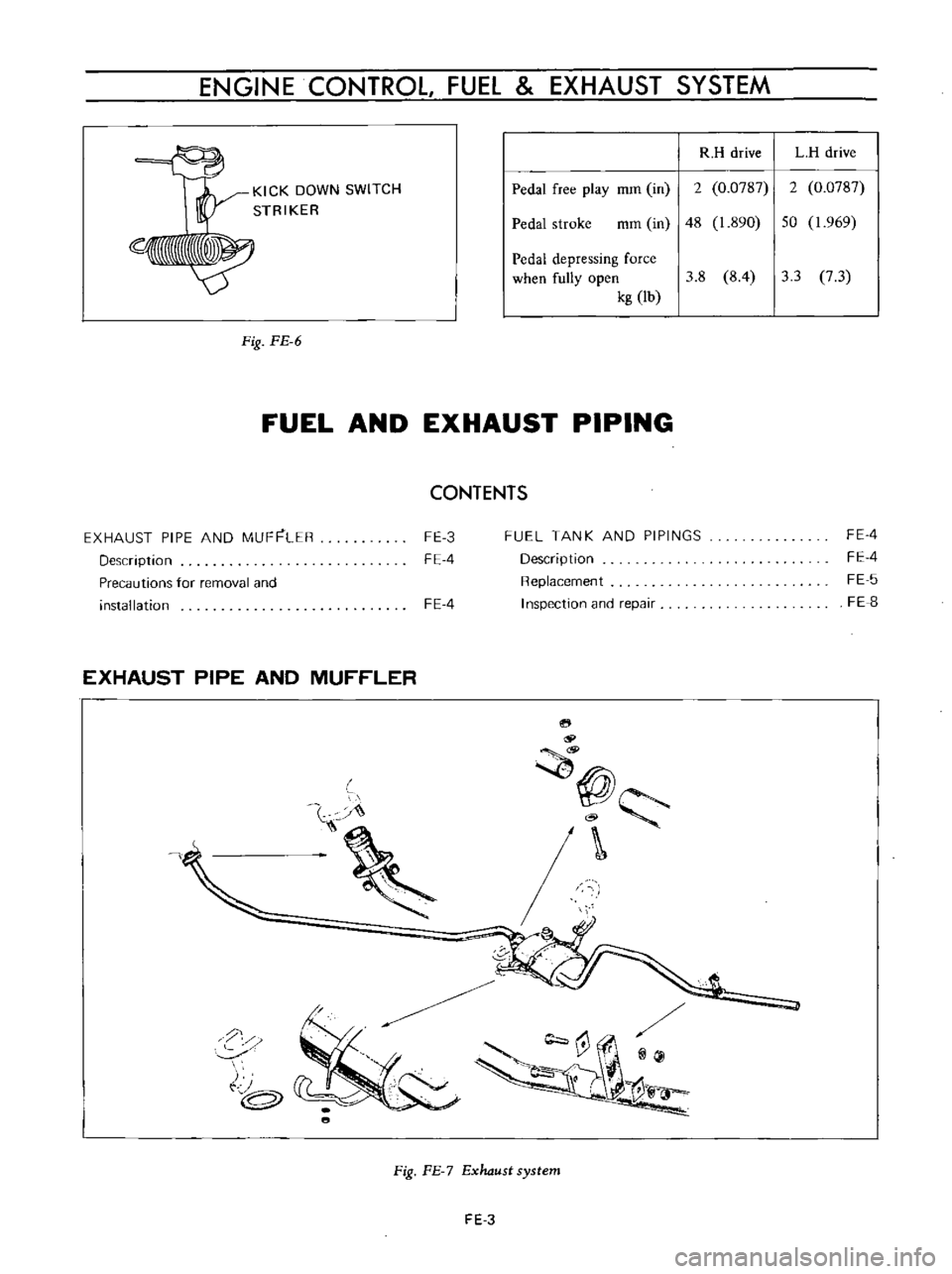

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEM

R

H

drive

L

H

drive

KICK

DOWN

SWITCH

STRIKER

Pedal

free

play

mrn

in

2

0

0787

2

0

0787

Pedal

stroke

mm

in

48

1

890

50

1

969

Pedal

depressing

force

when

fully

open

3

8

8

4

3

3

7

3

kg

lb

Fig

FE

6

FUEL

AND

EXHAUST

PIPING

CONTENTS

EXHAUST

PIPE

AND

MUF

LER

Description

Precautions

for

removal

and

installation

FE

3

FE

4

FUEL

TANK

AND

PIPINGS

Description

Replacement

I

nspection

and

repair

FE

4

FE

4

FE

5

FE

S

FE

4

EXHAUST

PIPE

AND

MUFFLER

i

@

@

@

Fig

FE

Exhaust

system

FE

3

Page 184 of 513

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEM

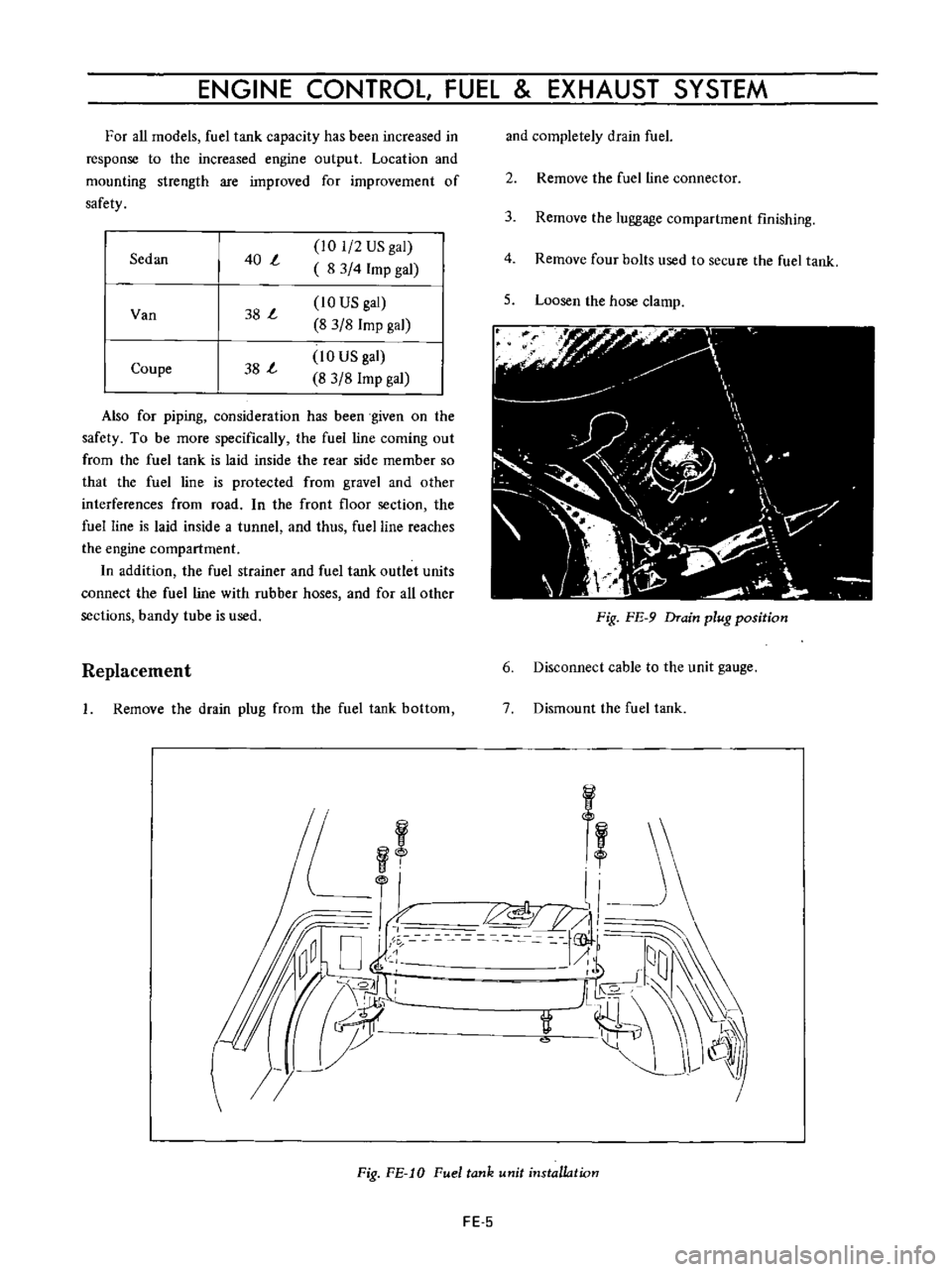

For

all

models

fuel

tank

capacity

has

been

increased

in

response

to

the

increased

engine

output

Location

and

mounting

strength

are

improved

for

improvement

of

safety

Sedan

40

l

101

2

US

gal

8

3

4

Imp

gal

Van

38

l

10

US

gal

8

3

8

Imp

gal

Coupe

38

l

10

US

gal

8

3

8

Imp

gal

and

completely

drain

fuel

2

Remove

the

fuel

line

connector

3

Remove

the

luggage

compartment

finishing

4

Remove

four

bolts

used

to

secure

the

fuel

tank

5

Loosen

the

hose

clamp

f

r

II

J

y

I

0

I

V

Ii

i

iJb

Also

for

piping

consideration

has

been

given

on

the

safety

To

be

more

specifically

the

fuel

line

coming

out

from

the

fuel

tank

is

laid

inside

the

rear

side

member

so

that

the

fuel

line

is

protected

from

gravel

and

other

interferences

from

road

In

the

front

floor

section

the

fuel

line

is

laid

inside

a

tunnel

and

thus

fuel

line

reaches

the

engine

compartment

In

addition

the

fuel

strainer

and

fuel

tank

outlet

units

connect

the

fuel

line

with

rubber

hoses

and

for

aU

other

sections

bandy

tube

is

used

Fig

FE

9

Drain

plug

position

Replacement

Remove

the

drain

plug

from

the

fuel

tank

bottom

6

Disconnect

cable

to

the

unit

gauge

7

Dismount

the

fuel

tank

f

I

Y

L

ll

C

jjhrr

@

Fig

FE

10

Fuel

tank

14nit

installation

FE

5