engine DATSUN B110 1973 Service Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 281 of 513

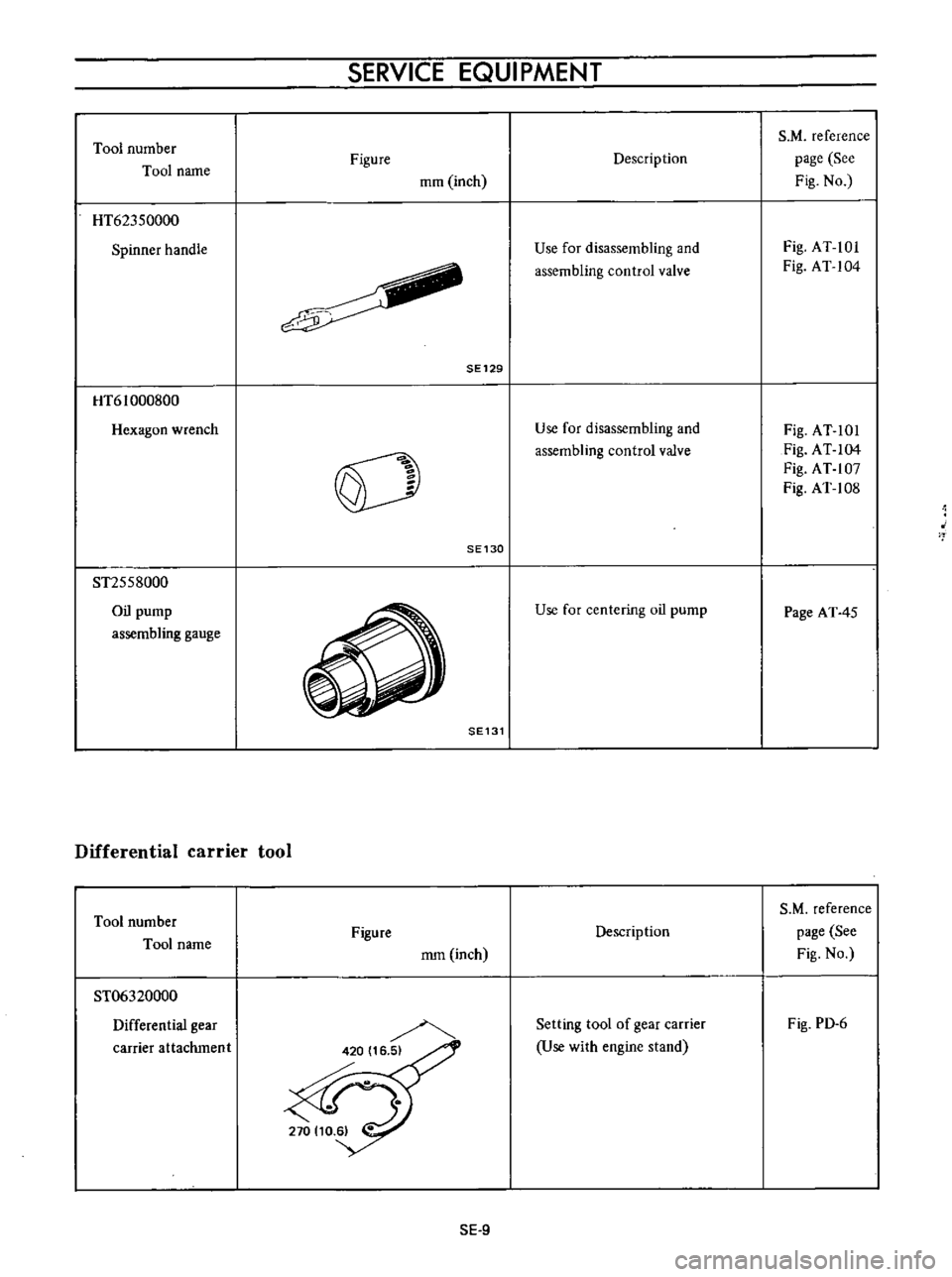

SERVICE

EQUIPMENT

Tool

number

S

M

reference

Tool

name

Figure

Description

page

See

mm

inch

Fig

No

HT62350000

Spinner

handle

Use

for

disassembling

and

Fig

AT

101

assembling

control

valve

Fig

AT

104

SE129

HT61000800

Hexagon

wrench

Use

for

disassembling

and

Fig

AT

101

0

assembling

control

valve

Fig

AT

104

Fig

AT

107

Fig

AT

108

SE130

sT2558000

Oil

pump

Use

for

centering

oil

pump

Page

AT

45

assembling

gauge

SE131

Differential

carrier

tool

Tool

number

Tool

name

Figure

Description

S

M

reference

page

See

Fig

No

rom

inch

sT06320000

Differential

gear

carrier

attachment

Setting

tool

of

gear

carrier

Use

with

engine

stand

Fig

PD

6

sE

9

Page 291 of 513

ti

r

f

o

1

b

4

AI

I

W

n

t

i

i

1

i

f

f

7i

ii

y

0

r

1

J

1

t

I

r

I

DATSUN

1200

SERVICE

MANUAL

MODEL

8110

SERIES

N

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

j

QUICK

REFERENCE

INDEX

GENERAL

INfORMATION

GI

EMISSION

CONTROL

AND

TUNE

UP

ET

ENGINE

MECHANICAL

EM

REAR

AXlE

8

REAR

SUSPENSiON

BRAKE

WHEEL

AND

TIRE

STEERING

ENGINE

CONTROL

fUEL

8

EXHAUST

BODY

BODY

ElECTRICAL

SERVICE

EQUIPMENT

Page 297 of 513

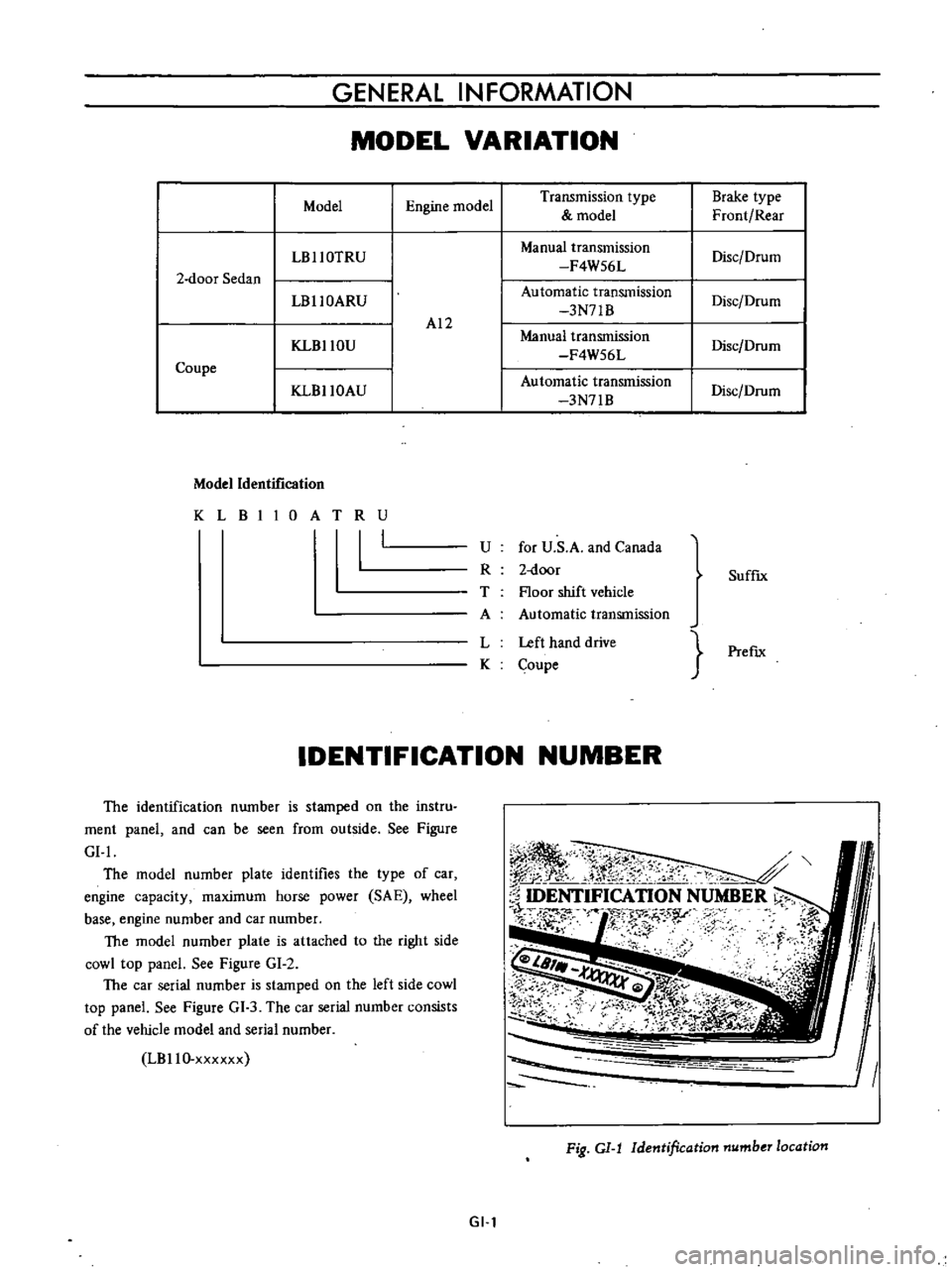

GENERAL

INFORMATION

MODEL

VARIATION

Model

Engine

model

Transmission

type

Brake

type

model

Front

Rear

LBllOTRU

Manual

transmission

Disc

Drum

F4W56L

2

door

Sedan

LBllOARU

Automatic

transmission

Disc

Drum

3N71B

AI2

KLBllOU

Manual

transmission

Disc

Drum

F4W56L

Coupe

Automatic

transmission

KLBllOAU

3N71B

Disc

Drum

Model

Identification

KLBIIOATRU

I

U

for

U

S

A

and

Canada

R

2

door

T

Floor

shift

vehicle

A

Automatic

transmission

L

Left

hand

drive

K

Coupe

SuffIx

PrefIx

IDENTIFICATION

NUMBER

The

identification

number

is

stamped

on

the

instru

ment

panel

and

can

be

seen

from

outside

See

Figure

GI

I

The

model

number

plate

identifles

the

type

of

car

engine

capacity

maximum

horse

power

SA

E

wheel

base

engine

number

and

car

number

The

model

number

plate

is

attached

to

the

right

side

cowl

top

panel

See

Figure

GI

2

The

car

serial

number

is

stamped

on

the

left

side

cowl

top

panel

See

Figure

GI

3

The

car

serial

number

consists

of

the

vehicle

model

and

serial

number

LBllO

xxxxxx

I

ll

r

N

t

0

S

k

j

c

ftr

o

l

l

r

2

0

IDENTIFICATION

NUMBER

l

r

f

N

s

r

F

i

u

I

Fig

GI

J

Identification

number

location

GI

l

Page 298 of 513

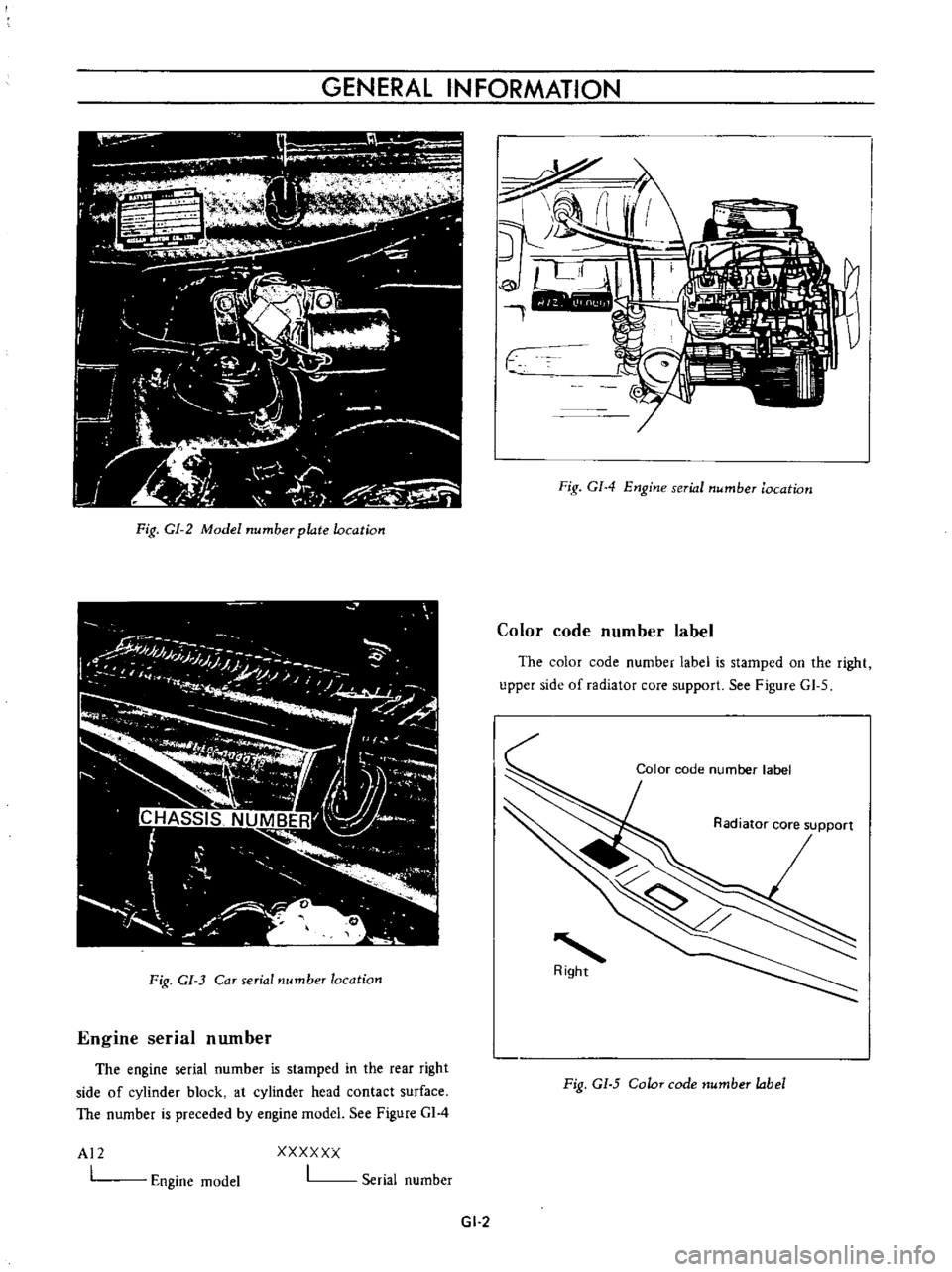

GENERAL

INFORMATION

Fig

GI

2

Model

number

plate

location

Fig

GI

3

Car

serial

number

location

Engine

serial

number

The

engine

serial

number

is

stamped

in

the

rear

right

side

of

cylinder

block

at

cylinder

head

contact

surface

The

number

is

preceded

by

engine

model

See

Figure

GI

4

AI2

I

xxxxxx

I

Serial

number

Engine

model

c

Fig

G

44

Engine

serial

number

ioeation

Color

code

number

label

The

color

code

number

label

is

stamped

on

the

right

upper

side

of

radiator

core

support

See

Figure

GI

5

Color

code

number

label

Radiator

core

support

Fig

GI

5

Color

code

number

label

GI

2

Page 302 of 513

GENERAL

INFORMATION

RECOMMENDED

LUBRICANT

SPECI

FICATIONS

Item

Gasoline

engine

oil

o

Transmission

and

steering

Differential

Automatic

TIM

fluid

Multipurpose

grease

Brake

and

clutch

fluid

Antifreeze

coolant

i

Specifications

SAE

Classification

SO

or

SE

API

G

L

4

API

GL

5

Type

DEXRON

NLGI2

DOT

3

Long

Life

Coolant

GI

6

Remarks

Furthermore

refer

to

SAE

recommended

viscosity

table

See

Page

GI

5

Lithium

soap

base

Page 303 of 513

GENERAL

INFORMATION

NISSAN

LONG

LIFE

COOLANT

L

L

C

The

cooling

system

has

been

filled

at

factory

with

the

Long

Life

Coolant

L

L

C

and

water

for

aU

season

protection

This

coolant

provides

freezing

protection

to

150C

50F

in

a

30

Long

Life

Coolant

ratio

and

also

protects

the

engine

against

corrosion

If

outside

tempera

ture

falls

down

to

350C

3IOF

fill

a

50

50

mixture

of

the

Long

Life

Coolant

and

water

The

Long

Life

Coolant

is

an

ethylene

glycol

base

product

containing

any

glyc

erine

ethyl

or

methyl

alcohoL

The

Long

Life

Coolant

must

not

be

mixed

with

any

other

product

scale

nor

sediment

accumulated

in

water

jacket

or

radiator

adverse

ly

affects

heat

radiation

efficiency

When

the

coolant

is

changed

the

system

should

be

thoroughly

flushed

out

by

opening

the

two

drain

plugs

one

at

the

bottom

of

the

radiator

and

the

other

at

the

left

side

of

the

cylinder

block

until

clean

water

comes

out

Always

use

clean

soft

water

in

the

radiator

for

filling

the

radiator

DC

OF

01321

30

1

221

I

I

I

I

1

I

I

I

10

20

30

40

50

10

14

20

1

4

40

1

401

50

581

Fig

GI

13

Protection

concentration

Boiling

point

Percent

0

9

kg

cm2

Freeze

coneen

Sea

level

cooling

sys

protection

tratioo

tern

pressure

30

1060C

1240C

15OC

2210

F

2550

F

5OF

50

1090C

1270C

350C

2280

F

26IOF

3IOF

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

GI

7

Page 305 of 513

SERV

I

CE

0

M

ANUttlJ

j

f

l

DATSUN

1200

MODEL

B

110

SERIES

rNlSSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

J

f

p

l

SECTION

ET

GII

EMISSION

CONTROL

AND

TUNE

UP

EMISSION

CONTROL

SYSTEM

AND

ENGINE

TUNE

UP

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Ell

El

25

El

26

Page 306 of 513

EMISSION

CONTROL

AND

TUNE

UP

EMISSION

CONTROL

SYSTEM

AN

D

ENGINE

TUNE

UP

CONTENTS

BASIC

MECHANICAL

SYSTEM

ET

Checking

and

adjusting

dash

pot

Adjusting

intake

and

exhaust

valve

automatic

transmission

model

only

ET

9

clearances

ET

1

Checking

carburetor

return

spring

ET

9

Checking

and

adjustin9

drive

belt

ET

2

Checking

choke

mechanism

choke

valve

Retightening

cylinder

head

bolts

manifold

and

linkagel

ET

9

nuts

and

carburetor

securing

nuts

ET

2

Checking

anti

dieseling

solenoid

ET

9

Checking

engine

oil

ET

2

Replacing

fuel

filter

ET

10

Replacing

oil

filter

ET

3

Checking

fuel

lines

hoses

pipings

Changing

engine

coolant

L

L

C

ET

3

connections

etc

ET10

Checking

cooling

system

hoses

and

THROTTLE

OPENER

CONTROL

SYSTEM

ET

10

connections

ET

4

Checking

and

adjusting

throttle

opener

ET

13

Checking

vacuum

fittings

hoses

and

TRANSMISSION

CONTROLLED

VACUUM

connections

ET

4

ADVANCE

SYSTEM

ET

17

Checking

engine

compression

ET

4

Checking

electrical

advance

control

system

ET

19

Checking

exhaust

manifold

heat

control

AUTOMATIC

TEMPERATURE

CONTROL

AIR

valve

ET

5

CLEANER

A

T

C

AIR

CLEANER

ET

20

IGNITION

AND

FUEL

SYSTEM

ET

5

Replacing

carburetor

air

cleaner

filter

ET

20

Checking

battery

ET

5

Checking

hot

air

control

valve

ET

20

Checking

and

adjusting

ignition

timing

ET

5

CRANKCASE

EMISSION

CONTROL

Checking

or

replacing

distributor

breaker

SYSTEM

ET

22

point

condenser

and

spark

plugs

ET

6

Checking

or

replacing

PCV

valve

ET

23

Checking

distributor

ignition

wiring

and

Checking

ventilation

hoses

ET

23

ignition

coil

ET

7

EVAPORATIVE

EMISSION

CONTROL

Checking

distributor

cap

and

rotor

ET

7

SYSTEM

ET

23

Adjusting

carburetor

id

Ie

rpm

and

Checking

engine

compartment

hose

mixture

ratio

ET

8

connections

and

fuel

vapor

control

valves

ET

23

Checking

fuel

tank

vacuum

relief

valve

operation

ET

24

BASIC

MECHANICAL

SYSTEM

1

Start

engine

and

run

it

until

it

is

heated

to

operating

temperature

or

at

least

more

than

800C

I760F

of

engine

oil

temperature

then

stop

engine

Adjusting

intake

and

exhaust

valve

clearances

Valve

clearance

adjustment

should

be

made

while

engine

is

stationary

To

adjust

proceed

as

follows

2

Rotate

crankshaft

to

bring

No

1

cylinder

in

top

dead

center

on

its

compression

stroke

3

Remove

valve

rocker

cover

to

gain

access

to

valve

ET

1

Page 307 of 513

ENGINE

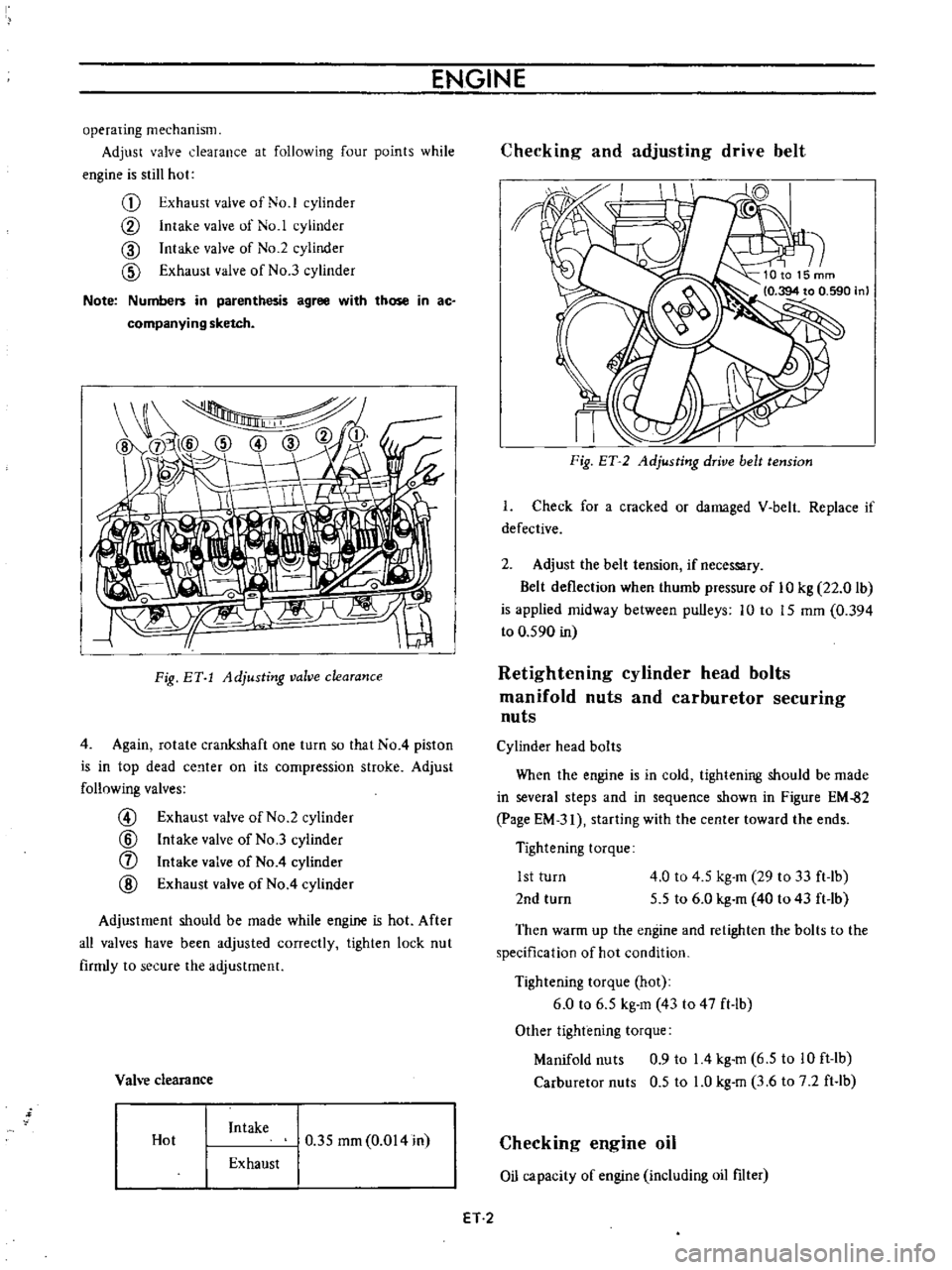

operating

mechanism

Adjust

valve

clearance

at

following

four

points

while

engine

is

still

hot

G

Exhaust

valve

of

No

1

cylinder

CV

Intake

valve

of

No

1

cylinder

CID

Intake

valve

of

No

2

cylinder

CID

Exhaust

valve

of

No

3

cylinder

Note

Numbers

in

parenthesis

agree

with

those

in

ac

companying

sketch

I

Fig

BY

1

Adjusting

valve

clearance

4

Again

rotate

crankshaft

one

turn

so

that

No

4

piston

is

in

top

dead

ce

lter

on

its

compression

stroke

Adjust

follnwing

valves

@

Exhaust

valve

of

No

2

cylinder

@

Intake

valve

of

No

3

cylinder

f

Intake

valve

of

No

4

cylinder

@

Exhaust

valve

of

No

4

cylinder

Adjustment

should

be

made

while

engine

is

hot

After

all

valves

have

been

adjusted

correctly

tighten

lock

nut

firmly

to

secure

the

adjustment

Vah

e

clearance

Hot

Intake

0

35

mm

0

014

in

Exhaust

Checking

and

adjusting

drive

belt

II

I

Fig

ET

2

Adjusting

drive

belt

tension

I

Check

for

a

cracked

or

damaged

V

belt

Replace

if

defective

2

Adjust

the

belt

tension

if

necessary

Belt

deflection

when

thumb

pressure

of

10

kg

22

0

lb

is

applied

midway

between

pulleys

10

to

15

mm

0

394

to

0

590

in

Retightening

cylinder

head

bolts

manifold

nuts

and

carburetor

securing

nuts

Cylinder

head

bolts

When

the

engine

is

in

cold

tightening

should

be

made

in

several

steps

and

in

sequence

shown

in

Figure

EM

82

page

EM

31

starting

with

the

center

toward

the

ends

Tightening

torque

1st

turn

2nd

turn

4

0

to

4

5

kg

m

29

to

33

ft

lb

5

5

to

6

0

kg

m

40

to

43

ft

lb

Then

warm

up

the

engine

and

retighten

the

bolts

to

the

specification

of

hot

condition

Tightening

torque

hot

6

0

to

6

5

kg

m

43

to

47

ft

lb

Other

tightening

torque

Manifold

nuts

0

9

to

14

kg

m

6

5

to

10

ft

lb

Carburetor

nuts

0

5

to

LO

kg

m

3

6

to

7

2

ft

lb

Checking

engine

oil

Oil

capacity

of

engine

including

oil

filter

ET

2

Page 308 of 513

EMISSION

CONTROL

AND

TUNE

UP

Capacity

Maximum

3

3

L

X

US

gal

y

Imp

gal

2

3

L

US

gal

f

Imp

gal

Minimum

Make

sure

that

engine

oil

is

not

deteriorated

with

cooling

water

or

gasoline

Drain

and

refill

the

oil

if

necessary

Notes

a

A

milky

oil

indicates

the

presence

of

cooling

water

Find

the

cause

for

necessary

corrective

action

b

Oil

with

extremely

low

viscosity

indicates

dilution

with

gasoline

2

Check

oil

level

If

found

below

L

mark

refill

to

H

mark

on

gauge

Fig

ET

3

Checking

engine

oil

level

Replacing

oil

filter

The

oil

ftIter

is

of

a

cartridge

type

The

oil

filter

can

be

removed

using

oil

ftIter

wrench

STl9320000

Check

for

oil

leaks

through

gasketed

flange

If

any

leakage

is

found

retighten

slightly

If

necessary

replace

filter

as

an

assembly

2

When

installing

an

oil

filter

tighten

by

hand

Note

Do

not

overtighten

oil

filter

or

oil

leakage

way

result

Changing

engine

coolant

L

L

C

Nissan

long

life

coolant

LLC

is

an

ethylene

glycol

base

product

containing

chemical

inhibitors

to

protect

the

cooling

system

from

rusting

and

corrosion

The

L

L

C

does

not

contain

any

glycerine

ethyl

or

methyl

alcohol

It

will

not

evaporate

or

boil

away

and

can

be

used

with

either

high

or

low

temperature

thermostat

It

flows

freely

transfers

heat

efficiently

and

will

not

clog

the

passages

in

the

cooling

system

The

LL

C

must

not

be

mixed

with

other

products

This

coolant

can

be

used

throughout

tlie

seasons

of

the

year

Whenever

any

coolant

is

changed

the

cooling

system

should

be

flushed

and

refilled

with

a

new

coolant

Check

the

level

J

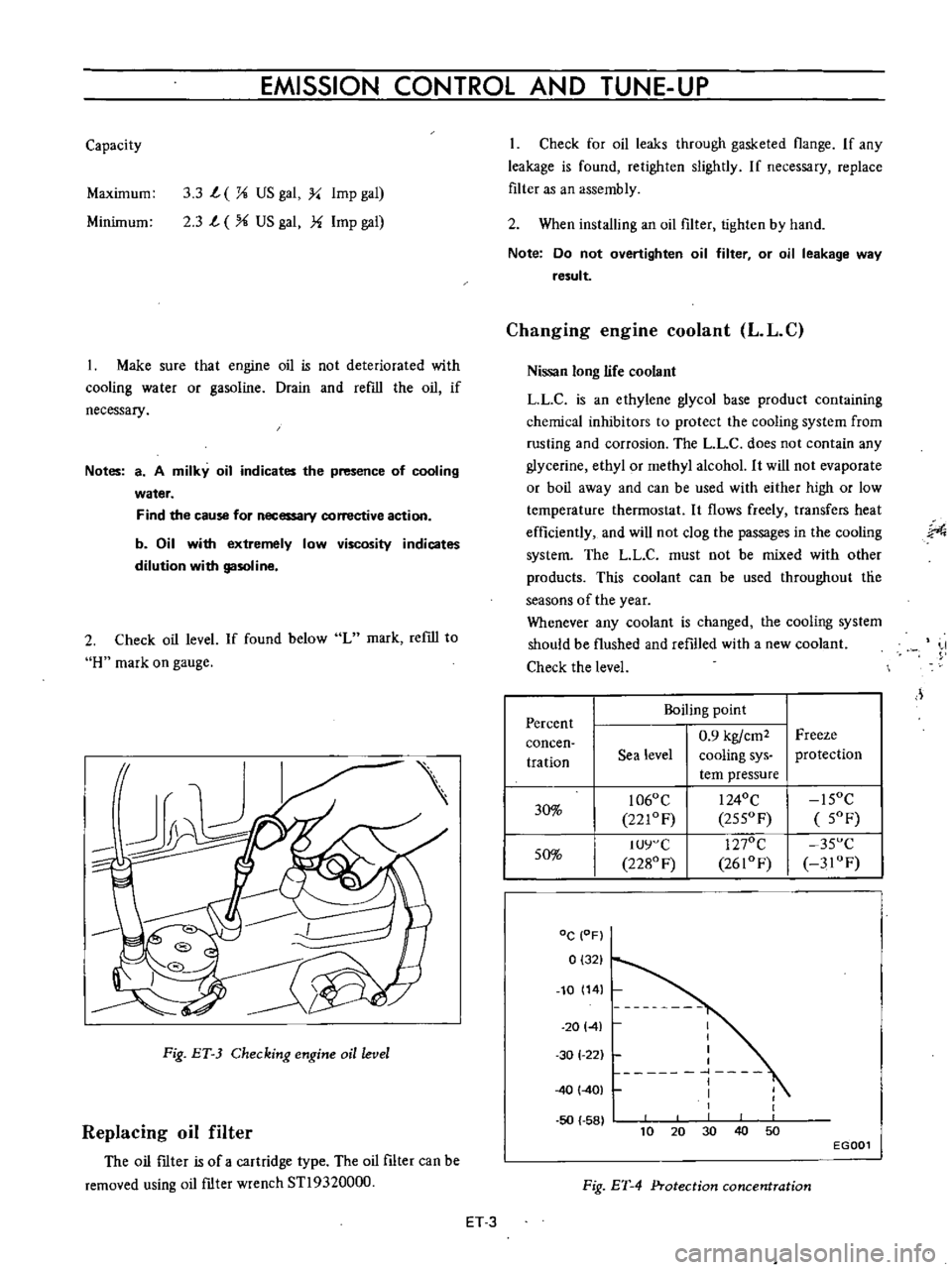

Percent

Boiling

point

0

9

kgfcm2

Freeze

concen

tration

Sea

level

cooling

sys

protection

tern

pressure

30

1060

C

I

240C

15OC

221OF

255OF

5OF

50

IUY

C

1270C

35

C

2280

F

2610F

3IOF

DC

OF

0

321

10

14

20141

50

58

I

I

I

I

1

I

I

1

30

1

22

40

401

40

10

30

50

20

EGOOl

Fig

ET

4

Protection

concentration

ET

3