torque DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 4 of 513

The

model

3N71

B

automatic

trans

mission

is

a

fully

automatic

unit

con

sisting

primarily

of

element

hydrau

lic

torque

converter

and

two

planetary

gear

sets

Two

multiple

disc

clutches

a

muItiple

disc

brake

a

band

brake

and

a

one

way

sprag

clutch

provide

the

friction

elements

required

to

obtain

the

desired

function

of

the

two

plane

tary

gear

sets

The

two

planetary

gear

sets

give

three

forward

ratios

and

one

reverse

Changing

of

the

gear

ratios

is

fully

automatic

in

relation

to

vehicle

speed

and

engine

torque

input

Vehicle

speed

and

engine

manifold

vacuum

signals

are

constantly

fed

to

the

transmission

to

provide

the

proper

gear

ratio

for

maximum

efficieq

cy

and

performance

at

all

thrqttIe

openings

The

iMiij

l

3N7I

B

has

six

selector

position

f

P

R

N

D

2

1

k

Park

position

positively

locks

the

c

ut

put

shaft

to

the

transmission

case

RY

means

of

a

locking

pawl

to

prev

nt

the

vehicle

from

rolling

either

direction

This

position

should

be

selected

when

ever

the

driver

leaves

the

vehicle

The

engine

may

be

started

in

Park

pQlition

OR

Reverse

range

enables

the

vehicle

to

be

operated

in

a

reverse

direction

N

Neutral

posItion

enables

the

engine

to

be

started

and

run

without

driving

the

vehicle

CHASSIS

DESCRIPTION

D

Drive

range

is

used

for

all

normal

driving

conditions

Drive

range

has

three

gear

ratios

frum

the

starting

ratio

to

direct

drive

2

2

range

provides

performance

for

driving

on

slippery

surfaces

2

range

can

also

be

used

for

engine

braking

2

range

can

be

selected

at

any

vehicle

speed

and

prevents

the

trans

mission

from

shifting

out

of

second

gear

I

range

can

be

selected

at

any

vehicle

speed

and

the

transmission

will

shift

to

second

gear

and

remain

in

second

until

vehide

speed

is

reduced

to

approximately

40

to

50

kmfh

25

to

31

MPH

I

range

position

prevents

the

transmission

from

shifting

out

of

low

gear

This

is

particularly

beneficial

for

maintaining

maximum

engine

braking

when

continuous

low

gear

operation

is

desirable

The

torque

converter

assembly

is

of

welded

construction

and

can

not

be

disassemble

for

service

Fluid

recommendation

Use

having

only

in

mission

automatic

transmission

fluid

DEXRON

identifications

the

3N7I

B

automatic

trans

AT

2

IA

e

l

csr

4o

J

r

s

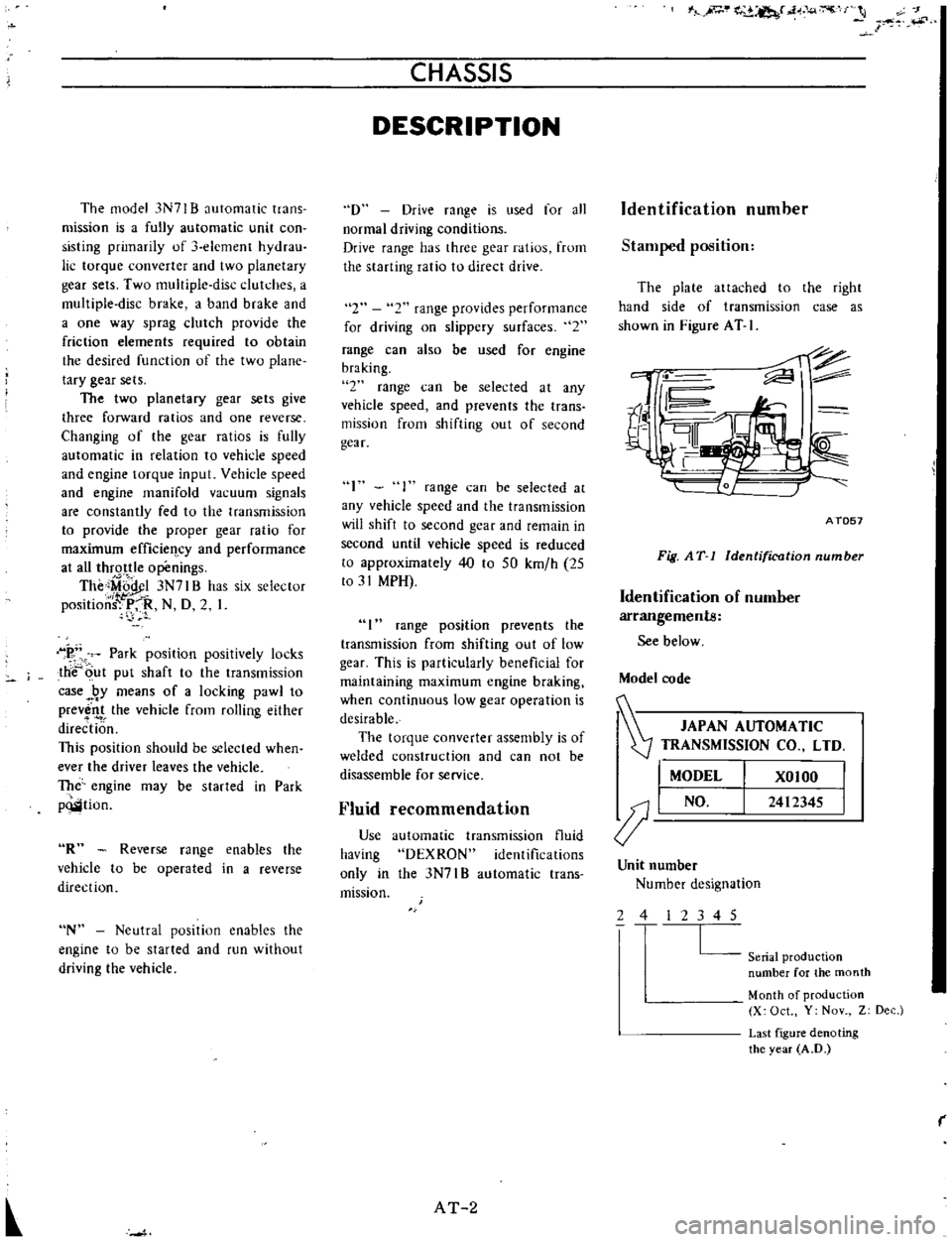

Identification

number

Stamped

position

The

plate

attached

to

the

right

hand

side

of

transmission

case

as

shown

in

Figure

AT

I

ii

II

r

4

1

r

I

to

i

AT057

Fig

AT

1

Identification

number

Identification

of

number

arrangements

See

below

Model

code

JAPAN

AUTOMATIC

Z

TRANSMISSION

CO

LTD

I

MODEL

XOIOO

J

I

NO

2412345

Unit

number

Number

designation

2

4

2

3

4

5

L

Seriat

production

number

for

the

month

Month

of

production

X

Oct

Y

Nov

Z

Dec

Last

figure

denoting

the

year

A

D

r

Page 5 of 513

AUTOMATIC

TRANSMISSION

1

1

1

I

L

@

CD

@

@

ID

@

@

h

r

H

@

@

@

@

@

@

@

4

@

@

t

I

fA

TIl70

4

t

ill

pJrP

I

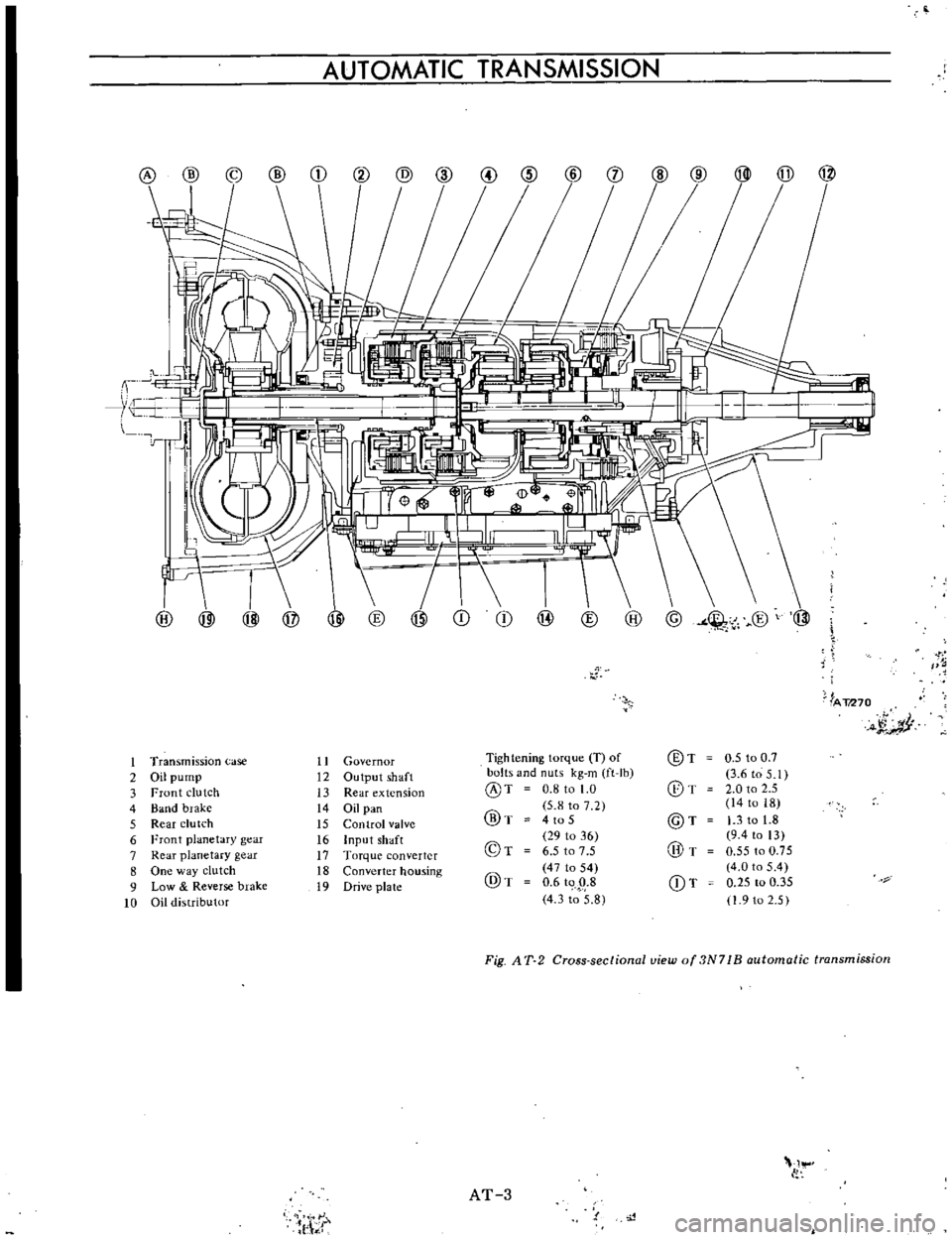

Transmission

ase

II

Governor

Tightening

torque

T

of

@T

0

5

to

0

7

2

Oil

pump

12

Output

shaft

bolts

and

nuts

kg

rn

ft

Ib

3

6

to

5

1

3

Front

clutch

13

Rear

xtcnsion

@T

0

8

to

1

0

@T

2

0

to

2

5

4

Band

brake

14

Oil

pan

@T

5

8

to

7

2

14

to

18

5

Rear

clutch

15

Control

valve

4

to

5

@T

1

3

to

1

8

6

Front

planetary

gt

ar

16

Input

shaft

@T

29

to

36

9

4

to

13

7

Rear

planetary

gear

17

Torque

converter

6

5

to

7

5

@T

0

55

to

0

75

8

One

way

clutch

18

Converter

housing

@T

47

to

54

4

0

to

5

4

9

Low

Reverse

brake

19

Drive

plate

0

6

h

Q

8

Q

T

0

25

to

0

35

10

Oil

distributor

4

3

to

5

8

1

9

to

2

5

Fig

AT

2

Cross

sectional

uiew

of

3N71

B

automatic

transmission

I

AT

3

l

t

Page 6 of 513

CHASSIS

HYDRAULIC

CONTROL

SYSTEM

l

FUNCTIONS

OF

HYDRAULIC

CONTROL

UNIT

AND

VALVES

Oil

pump

Manual

linkage

Vacuum

diaphragm

Downshift

solenoid

Governor

valve

Control

valve

assembly

HYDRAULIC

SYSTEM

AND

MECHANICAL

OPERATION

CONTENTS

P

range

Park

R

range

Reverse

N

range

Neutral

D

range

Low

gear

D2

range

2nd

gear

D3

range

Top

gear

D

range

kick

down

2

range

2nd

gear

1

range

Low

gear

12

range

2nd

gear

AT

4

AT

4

AT

5

AT

5

AT

5

AT

5

AT

7

AT13

AT

14

AT

16

AT

18

AT

20

AT

22

AT

24

AT

26

AT

28

AT

30

AT

32

FUNCTIONS

OF

HYDRAULIC

CONTROL

UNIT

AND

VALVES

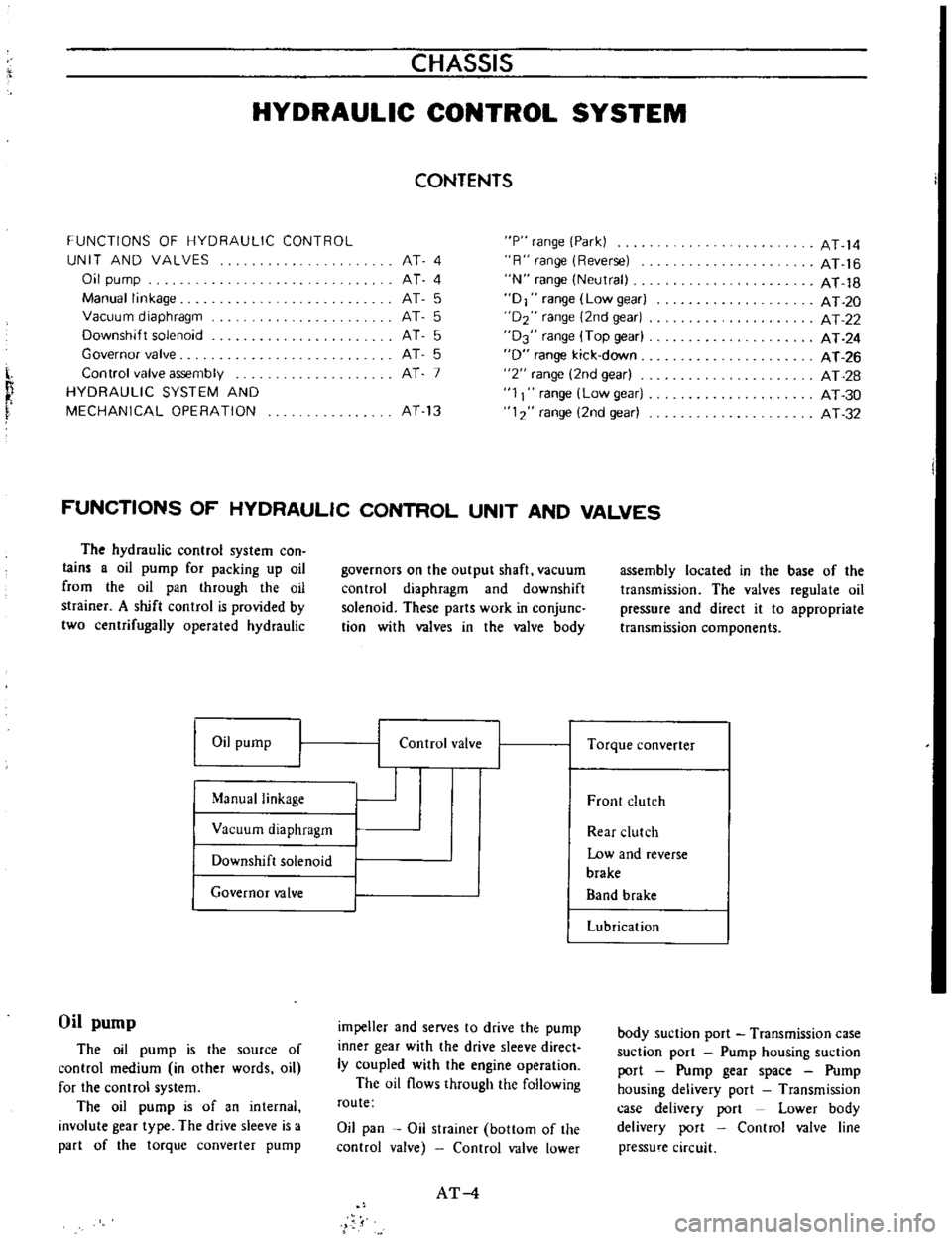

The

hydraulic

control

system

con

lain

a

oil

pump

for

packing

up

oil

from

the

oil

pan

through

the

oil

strainer

A

shift

control

is

provided

by

two

centrifugally

operated

hydraulic

Oil

pump

Manual

linkage

Vacuum

diaphragm

Downshift

solenoid

Governor

valve

Oil

pump

The

oil

pump

is

the

source

of

control

medium

in

other

words

oil

for

the

control

system

The

oil

pump

is

of

an

internal

involute

gear

type

The

drive

sleeve

is

a

part

of

the

torque

converter

pump

governors

on

the

output

shaft

vacuum

control

diaphragm

and

downshift

solenoid

These

parts

work

in

conjunc

tion

with

valves

in

the

valve

body

I

I

Control

valve

impeller

and

serves

to

drive

the

pump

inner

gear

with

the

drive

sleeve

direct

ly

coupled

with

the

engine

operation

The

oil

flows

through

the

following

route

Oil

pan

Oil

strainer

bottom

of

the

control

valve

Control

valve

lower

AT

4

assembly

located

in

the

base

of

the

transmission

The

valves

regulate

oil

pressure

and

direct

it

to

appropriate

transmission

components

I

Torque

converter

Front

clutch

Rear

clutch

Low

and

reverse

brake

Band

brake

Lubrication

body

suction

port

Transmission

case

suction

port

Pump

housing

suction

port

Pump

gear

space

Pump

housing

delivery

port

Transmission

case

delivery

port

Lower

body

delivery

port

Control

valve

line

pressure

circuit

Page 7 of 513

AUTOMATIC

TRANSMISSION

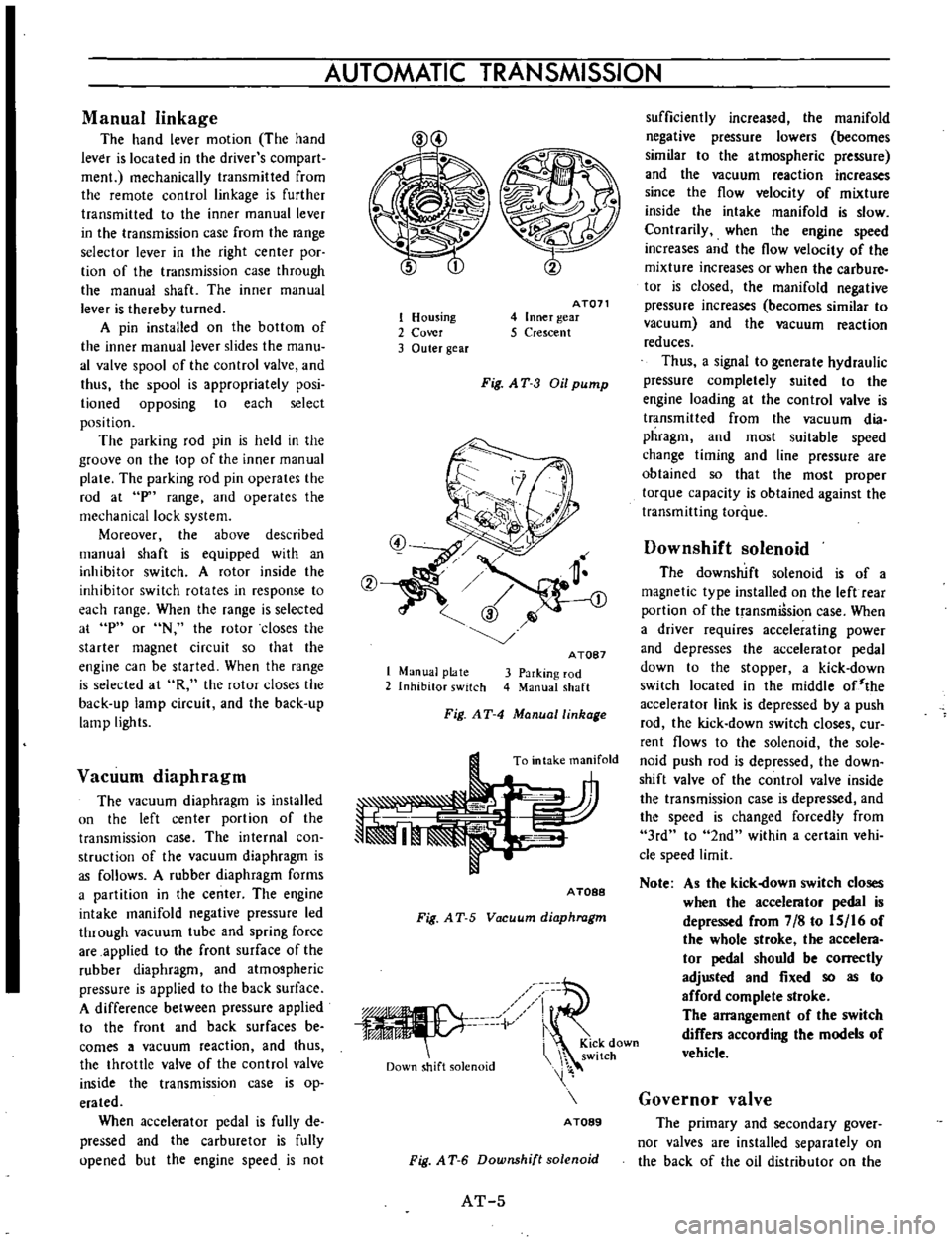

Manual

linkage

The

hand

lever

motion

The

hand

lever

is

located

in

the

driver

s

com

part

men

mechanically

transmitted

from

the

remote

control

linkage

is

further

transmitted

to

the

inner

manual

lever

in

the

transmission

case

from

the

range

selector

lever

in

the

right

center

poc

tion

of

the

transmission

case

through

the

manual

shaft

The

inner

manual

lever

is

thereby

turned

A

pin

installed

on

the

bottom

of

the

inner

manual

lever

slides

the

manu

al

valve

spool

of

the

control

valve

and

thus

the

spool

is

appropriately

posi

lioned

opposing

to

each

select

position

The

parking

rod

pin

is

held

in

the

groove

on

the

top

of

the

inner

manual

plate

The

parking

rod

pin

operates

the

rod

at

p

range

and

operates

the

mechanical

lock

system

Moreover

the

above

described

manual

shaft

is

equipped

with

an

inhibitor

switch

A

rotor

inside

the

inhibitor

switch

rotates

in

response

to

each

range

When

the

range

is

selected

at

p

or

N

the

rotor

closes

the

starter

magnet

circuit

so

that

the

engine

can

be

started

When

the

range

is

selected

at

R

the

rotor

closes

the

back

up

lamp

circuit

and

the

back

up

lamp

lights

Vacuum

diaphragm

The

vacuum

diaphragm

is

installed

un

the

left

center

portion

of

the

transmission

case

The

internal

con

struction

of

the

vacuum

diaphragm

is

as

follows

A

rubber

diaphragm

forms

a

partition

in

the

center

The

engine

intake

manifold

negative

pressure

led

through

vacuum

tube

and

spring

force

are

applied

to

the

front

surface

of

the

rubber

diaphragm

and

atmospheric

pressure

is

applied

to

the

back

surface

A

difference

between

pressure

applied

to

the

front

and

back

surfaces

be

comes

a

vacuum

reaction

and

thus

the

throttle

valve

of

the

control

valve

inside

the

transmission

case

is

op

erated

When

accelerator

pedal

is

fully

de

pressed

and

the

carburetor

is

fully

upened

but

the

engine

speed

is

not

1

Housing

2

Cover

3

Outer

gear

AT071

4

Inner

gear

5

Crescent

Fig

AT

3

Oil

pump

1

Manual

plate

2

Inhibitor

switch

A

TOB7

3

Parking

rod

4

Manual

shaft

Fig

AT

4

Manuallinhage

To

intake

manifold

A

TOBB

Fig

A

T

5

Vacuum

diaphragm

iV

Down

shift

solenoid

i

KiCk

down

switch

A

TOB9

Fig

A

T

6

Downshift

solenoid

AT

5

sufficiently

increased

the

manifold

negative

pressure

lowers

becomes

similar

to

the

atmospheric

pressure

and

the

vacuum

reaction

increases

since

the

flow

velocity

of

mixture

inside

the

intake

manifold

is

slow

Contrarily

when

the

engine

speed

increases

and

the

flow

velocity

of

the

mixture

increases

or

when

the

carbure

tor

is

closed

the

manifold

negative

pressure

increases

becomes

similar

to

vacuum

and

the

vacuum

reaction

reduces

Thus

a

signal

to

generate

hydraulic

pressure

completely

suited

to

the

engine

loading

at

the

control

valve

is

transmitted

from

the

vacuum

dia

phragm

and

most

suitable

speed

change

timing

and

line

pressure

are

obtained

so

that

the

most

proper

torque

capacity

is

obtained

against

the

transmitting

torque

Downshift

solenoid

The

downshift

solenoid

is

of

a

magnetic

type

installed

on

the

left

rear

portion

of

the

transmiSsion

case

When

a

driver

requires

accelerating

power

and

depresses

the

accelerator

pedal

down

to

the

stopper

a

kick

down

switch

located

in

the

middle

of

the

accelerator

link

is

depressed

by

a

push

rod

the

kick

down

switch

closes

cur

rent

flows

to

the

solenoid

the

sole

noid

push

rod

is

depressed

the

down

shift

valve

of

the

control

valve

inside

the

transmission

case

is

depressed

and

the

speed

is

changed

forcedly

from

3rd

to

2nd

within

a

certain

vehi

cle

speed

limit

Note

As

the

kick

own

switch

closes

when

the

accelerator

pedal

is

depressed

from

7

8

to

IS

16

of

the

whole

stroke

the

accelera

tor

pedal

should

be

correctly

adjusted

and

fixed

so

as

to

afford

complete

stroke

The

arrangement

of

the

switch

differs

according

the

models

of

vehicle

Governor

valve

The

primary

and

secondary

gover

nor

valves

are

installed

separately

on

the

back

of

the

oil

distributor

on

the

Page 11 of 513

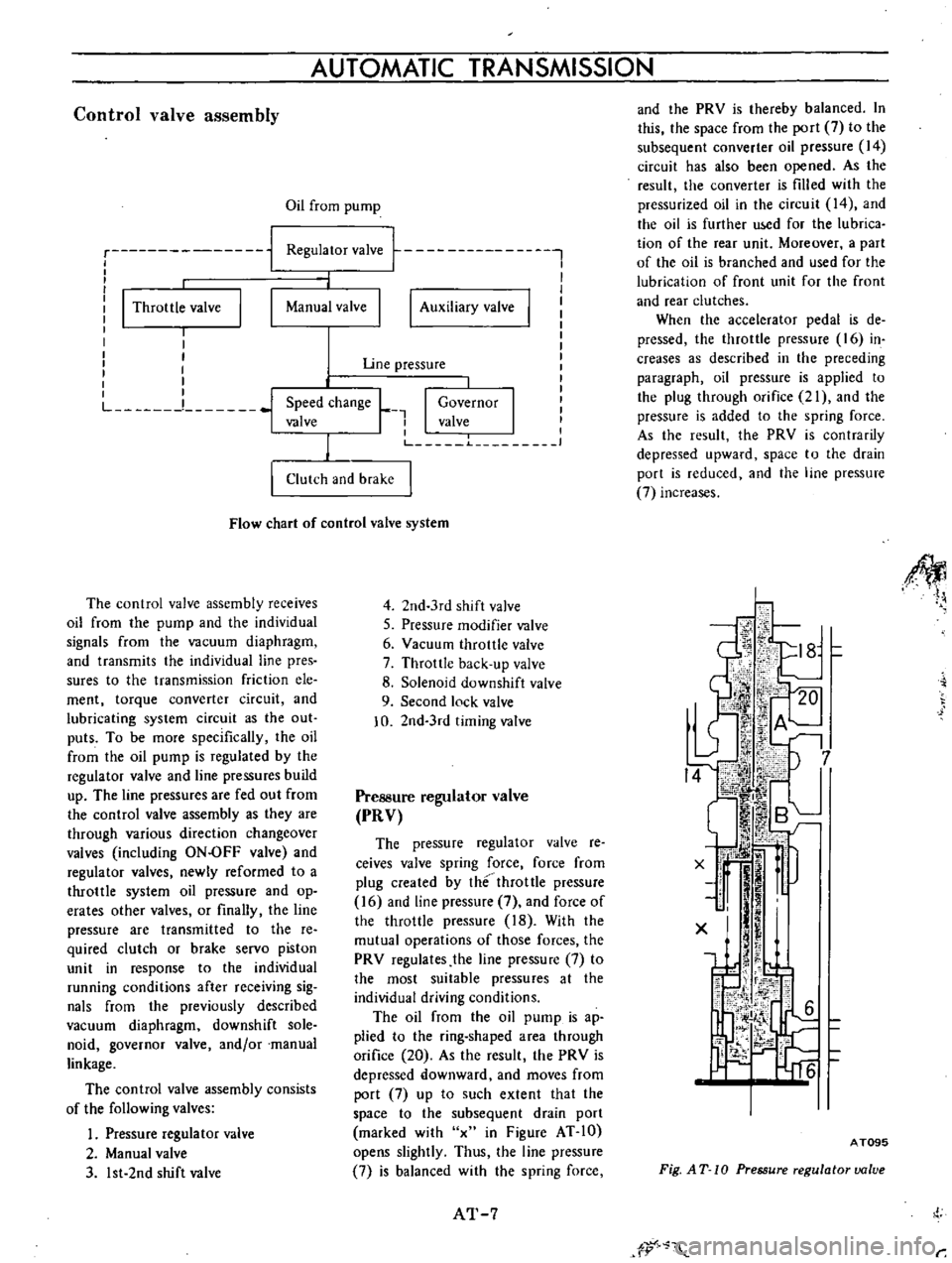

Control

valve

assembly

AUTOMATIC

TRANSMISSION

Oil

from

pump

ru

nn

i

I

I

I

Throttle

valve

I

I

1

m

nn

I

Auxiliary

valve

I

Regulator

valve

j

Manual

valve

I

Uoe

pressure

Speed

change

L

I

Governor

valve

I

I

valve

J

1

1

Clutch

and

brake

Flow

chart

of

control

valve

system

The

control

valve

assembly

receives

oil

from

the

pump

and

the

individual

signals

from

the

vacuum

diaphragm

and

transmits

the

individual

line

pres

sures

to

the

transmission

friction

ele

ment

torque

converter

circuit

and

lubricating

system

circuit

as

the

out

puts

To

be

more

specifically

the

oil

from

the

oil

pump

is

regulated

by

the

regulator

valve

and

line

pressures

build

up

The

line

pressures

are

fed

out

from

the

control

valve

assembly

as

they

are

through

various

direction

changeover

valves

including

ON

OFF

valve

and

regulator

valves

newly

reformed

to

a

throttle

system

oil

pressure

and

op

crates

other

valves

or

finally

the

line

pressure

are

transmitted

to

the

re

quired

clutch

or

brake

servo

piston

unit

in

response

to

the

individual

running

conditions

after

receiving

sig

nals

from

the

previously

described

vacuum

diaphragm

downshift

sole

noid

governor

valve

and

or

manual

linkage

The

control

valve

assembly

consists

of

the

following

valves

Pressure

regulator

valve

2

Manual

valve

3

1st

2nd

shift

valve

4

2nd

3rd

shift

valve

S

Pressure

modifier

valve

6

Yacuum

throttle

valve

7

Throttle

back

up

valve

8

Solenoid

downshift

valve

9

Second

lock

valve

0

2nd

3rd

timing

valve

Pressure

regulator

valve

PRV

The

pressure

regulator

valve

re

ceives

valve

spring

force

force

from

plug

created

by

the

throttle

pressure

16

and

line

pressure

7

and

force

of

the

throttle

pressure

18

With

the

mutual

operations

of

those

forces

the

PRY

regulates

the

line

pressure

7

to

the

most

suitable

pressures

at

the

individual

driving

conditions

The

oil

from

the

oil

pump

is

ap

plied

to

the

ring

shaped

area

through

orifice

20

As

the

result

the

PRY

is

depressed

downward

and

moves

from

port

7

up

to

such

extent

that

the

space

to

the

subsequent

drain

port

marked

with

x

in

Figure

AT

10

opens

slightly

Thus

the

line

pressure

7

is

balanced

with

the

spring

force

AT

7

and

the

PRY

is

thereby

balanced

In

this

the

space

from

the

port

7

to

the

subsequent

converter

oil

pressure

14

circuit

has

also

been

opened

As

the

result

the

converter

is

filled

with

the

pressurized

oil

in

the

circuit

14

and

the

oil

is

further

u

d

for

the

Iubrica

tion

of

the

rear

unit

Moreover

a

part

of

the

oil

is

branched

and

used

for

the

lubrication

of

front

unit

for

the

front

and

rear

clutches

When

the

accelerator

pedal

is

de

pressed

the

throttle

pressure

16

in

creases

as

described

in

the

preceding

paragraph

oil

pressure

is

applied

to

the

plug

through

orifice

21

and

the

pressure

is

added

to

the

spring

force

As

the

result

the

PRY

is

contrarily

depressed

upward

space

to

the

drain

port

is

reduced

and

the

line

pressure

7

increases

Afl

II

Jwi

06

A

J

L

I

7

I

tf

Iij

BL

i

il

J

jti

r

x

r

1

J

I

l

I

X

6

C

l

o

ii

J

f

A

T09S

Fig

AT

10

Pressure

regulator

value

tr

r

Page 14 of 513

against

the

throttle

pressure

16

When

performing

the

kick

down

the

SOV

moves

a

high

line

pressure

is

led

to

the

circuit

19

from

the

line

pressute

circuit

13

which

had

been

drained

the

plug

is

depressed

toward

the

left

and

the

circuit

19

becomes

equal

to

the

line

pressure

13

Thus

the

kick

down

is

performed

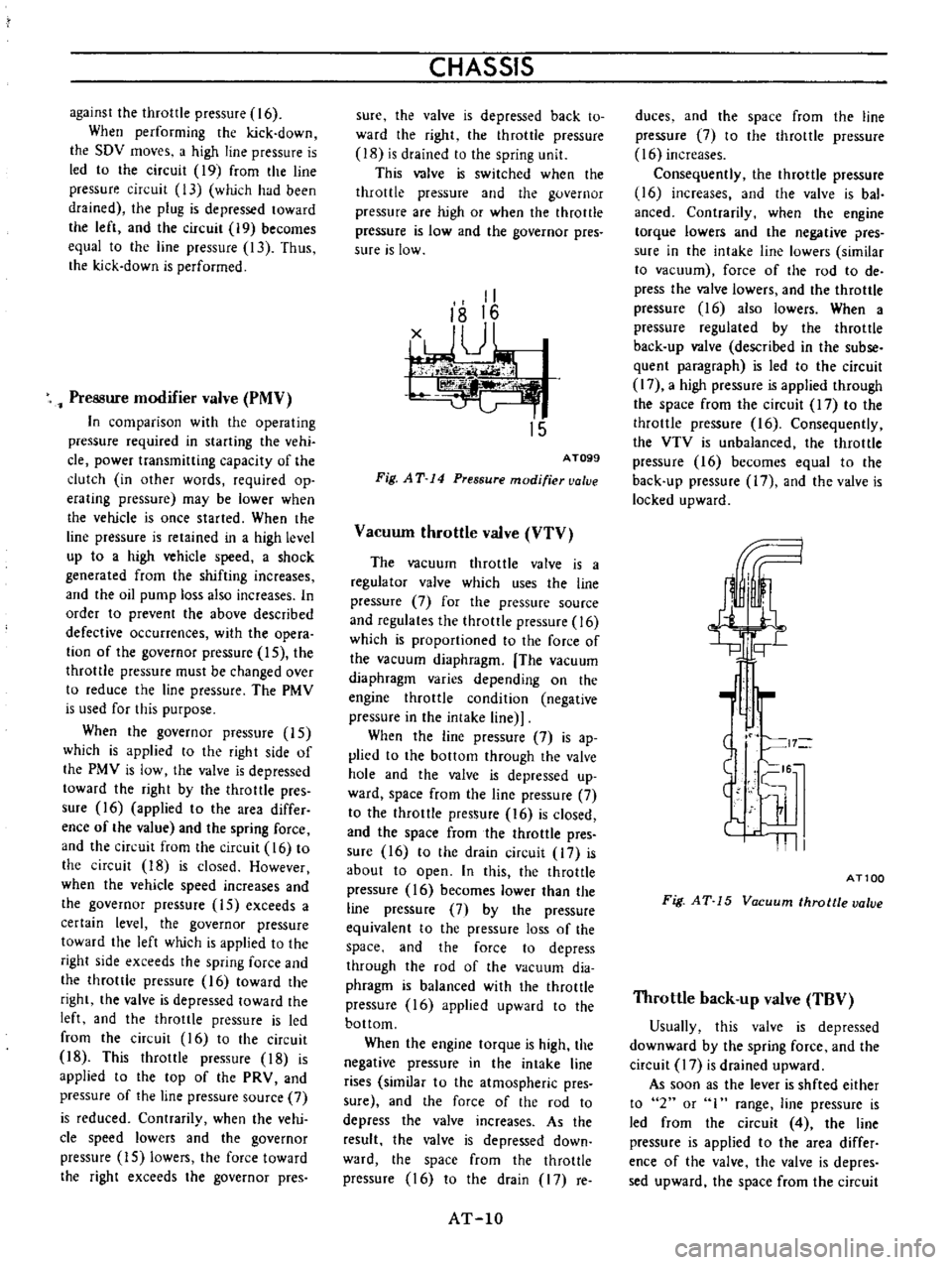

Preasure

modifier

valve

PMV

In

comparison

with

the

operating

pressure

required

in

starting

the

vehi

ele

power

transmitting

capacity

of

the

clutch

in

other

words

required

op

erating

pressure

may

be

lower

when

the

vehicle

is

once

started

When

the

line

pressure

is

retained

in

a

high

level

up

to

a

high

vehicle

speed

a

shock

generated

from

the

shifting

increases

and

the

oil

pump

loss

also

increases

In

order

to

prevent

the

above

described

defective

occurrences

with

the

opera

lion

of

the

governor

pressure

15

the

throttle

pressure

must

be

changed

over

to

reduce

the

line

pressure

The

PMV

is

used

for

this

purpose

When

the

governor

pressure

15

which

is

applied

to

the

right

side

of

the

PMV

is

low

the

valve

is

depressed

toward

the

right

by

the

throttle

pres

sure

16

applied

to

the

area

differ

ence

of

the

value

and

the

spring

force

and

the

circuit

from

the

circuit

16

to

the

circuit

18

is

closed

However

when

the

vehicle

speed

increases

and

the

governor

pressure

15

exceeds

a

certain

level

the

governor

pressure

toward

the

left

which

is

applied

to

the

right

side

exceeds

the

spring

force

and

the

throttle

pressure

16

toward

the

right

the

valve

is

depressed

toward

the

left

and

the

throttle

pressure

is

led

from

the

circuit

16

to

the

circuit

18

This

throttle

pressure

18

is

applied

to

the

top

of

the

PRY

and

pressure

of

the

line

pressure

source

7

is

reduced

Contrarily

when

the

vehi

cle

speed

lowers

and

the

governor

pressure

15

lowers

the

force

toward

the

right

exceeds

the

governor

pres

CHASSIS

sure

the

valve

is

depressed

back

to

ward

the

right

the

throttle

pressure

18

is

drained

to

the

spring

unit

This

valve

is

switched

when

the

throttle

pressure

and

the

governor

pressure

are

high

or

when

the

throttle

pressure

is

low

and

the

governor

pres

sure

is

low

II

18

16

1JU

k

I

15

AT099

Fig

AT

14

Pressure

modifier

valve

Vacuum

throttle

valve

VTV

The

vacuum

throttle

valve

is

a

regulator

valve

which

uses

the

line

pressure

7

for

the

pressure

source

and

regulates

the

throttle

pressure

16

which

is

proportioned

to

the

force

of

the

vacuum

diaphragm

The

vacuum

diaphragm

varies

depending

on

the

engine

throttle

condition

negative

pressure

in

the

intake

line

When

the

line

pressure

7

is

ap

plied

to

the

bottom

through

the

valve

hole

and

the

valve

is

depressed

up

ward

space

from

the

line

pressure

7

to

the

throttle

pressure

16

is

closed

and

the

space

from

the

throttle

pres

sure

16

to

the

drain

circuit

17

is

about

to

open

In

this

the

throttle

pressure

16

becomes

lower

than

the

line

pressure

7

by

the

pressure

equivalent

to

the

pressure

loss

of

the

space

and

the

force

to

depress

through

the

rod

of

the

vacuum

dia

phragm

is

balanced

with

the

throttle

pressure

16

applied

upward

to

the

bottom

When

the

engine

torque

is

high

the

negative

pressure

in

the

intake

line

rises

similar

to

the

atmospheric

pres

sure

and

the

force

of

the

rod

to

depress

the

valve

increases

As

the

result

the

valve

is

depressed

down

ward

the

space

from

the

throttle

pressure

16

to

the

drain

17

re

AT

lO

duces

and

the

space

from

the

line

pressure

7

to

the

throttle

pressure

16

increases

Consequently

the

throttle

pressure

16

increases

and

the

valve

is

baI

anced

Contrarily

when

the

engine

torque

lowers

and

the

negative

pres

sure

in

the

intake

line

lowers

similar

to

vacuum

force

of

the

rod

to

de

press

the

valve

lowers

and

the

throttle

pressure

16

also

lowers

When

a

pressure

regulated

by

the

throttle

back

up

valve

described

in

the

subse

quent

paragraph

is

led

to

the

circuit

17

a

high

pressure

is

applied

through

the

space

from

the

circuit

17

to

the

throttle

pressure

16

Consequently

the

VTV

is

unbalanced

the

throttle

pressure

16

becomes

equal

to

the

back

up

ptessure

17

and

the

valve

is

locked

upward

bi

II

I

ATlOa

Fig

AT

15

Vacuum

throttle

valve

Throttle

back

up

valve

TBV

Usually

this

valve

is

depressed

downward

by

the

spring

force

and

the

circuit

17

is

drained

upward

As

soon

as

the

lever

is

shfted

either

to

2

or

range

line

pressure

is

led

from

the

circuit

4

the

line

pressure

is

applied

to

the

area

differ

ence

of

the

valve

the

valve

is

depres

sed

upward

the

space

from

the

circuit

Page 17 of 513

AUTOMATIC

TRANSMISSION

HYDRAULIC

SYSTEM

AND

MECHANICAL

OPERATION

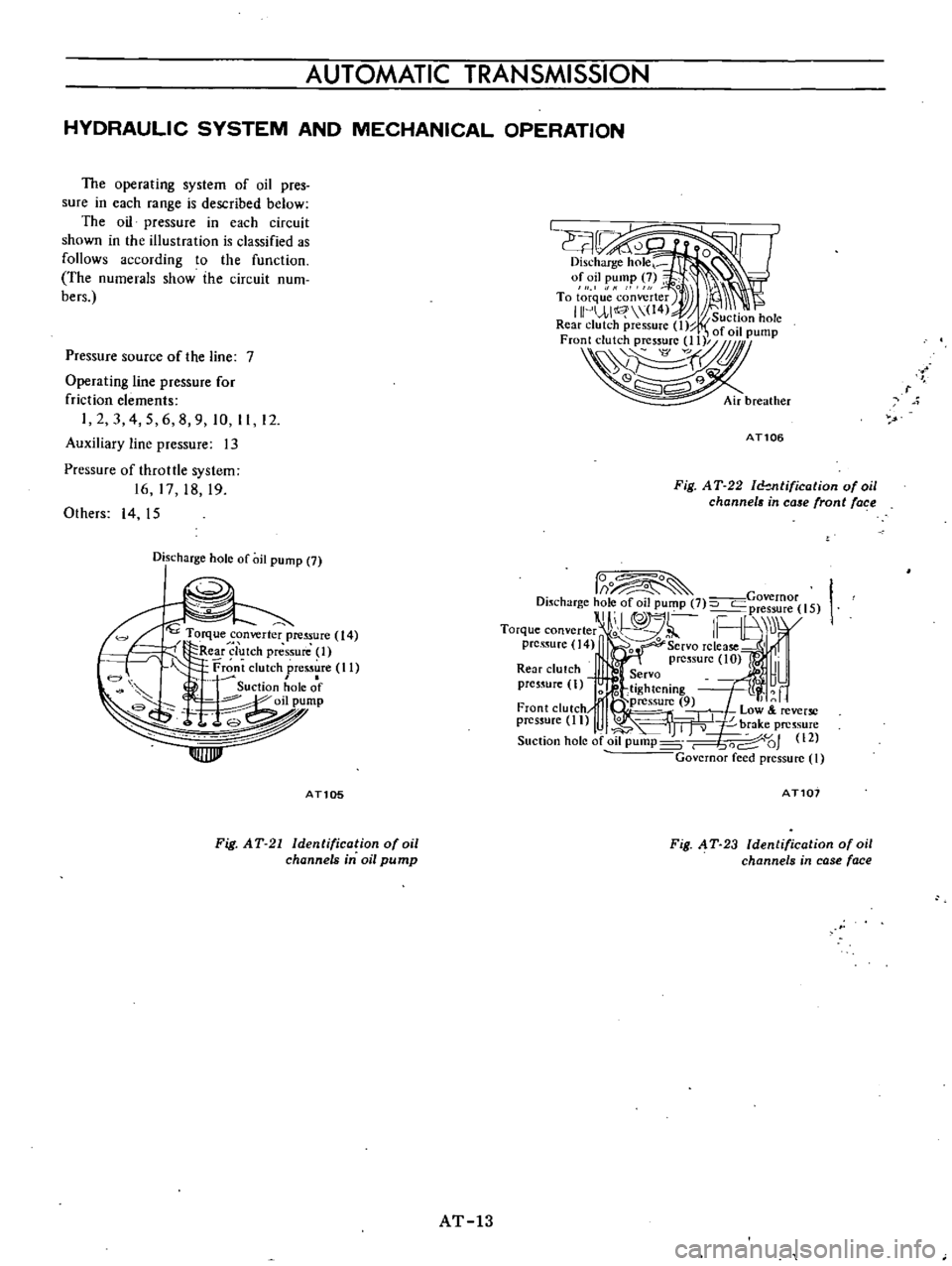

The

operating

system

of

oil

pres

sure

in

each

range

is

described

below

The

oil

pressure

in

each

circuit

shown

in

the

illustration

is

classified

as

follows

according

to

the

function

The

numerals

show

the

circuit

num

bers

Pressure

source

of

the

line

7

Operating

line

pressure

for

friction

elements

I

2

3

4

5

6

8

9

10

II

12

Auxiliary

line

pressure

13

Pressure

of

throttle

system

16

17

18

19

Others

14

15

t

AT106

Fig

AT

22

ld

Jltification

of

oil

channels

in

case

front

fac

e

Discharge

hole

of

oil

pump

7

Torque

c

nver

pre

ure

14

co

t

Re

r

lutch

pressure

l

Front

clutch

pres5ure

II

I

c

Suction

hole

of

t

o

ump

lUlJJl

0

o

f

Governor

Dl5charge

hol

of

011

pUf

lP

7

pressure

15

I

II

nl

1F

Jl

r

Torque

converter

o

L

U

pres

ure

14

It

0

Servo

release

i

I

prc

sUre

IO

Rear

clutch

Servo

L

i

pres

ure

I

0

6

tightening

19

iressu

9

01

Front

clutch

rJj

low

reverse

pressure

II

0

C

lrv

brake

pressure

Suction

hole

of

oil

pump

s

6od

OJ

12

Governor

feed

pressure

I

ATlOS

AT101

Fig

AT

21

Identification

of

oil

channels

in

oil

pu

mp

Fig

AT

23

Identification

of

oil

channels

in

case

face

AT

13

Page 19 of 513

AUTOMATIC

TRANSMISSION

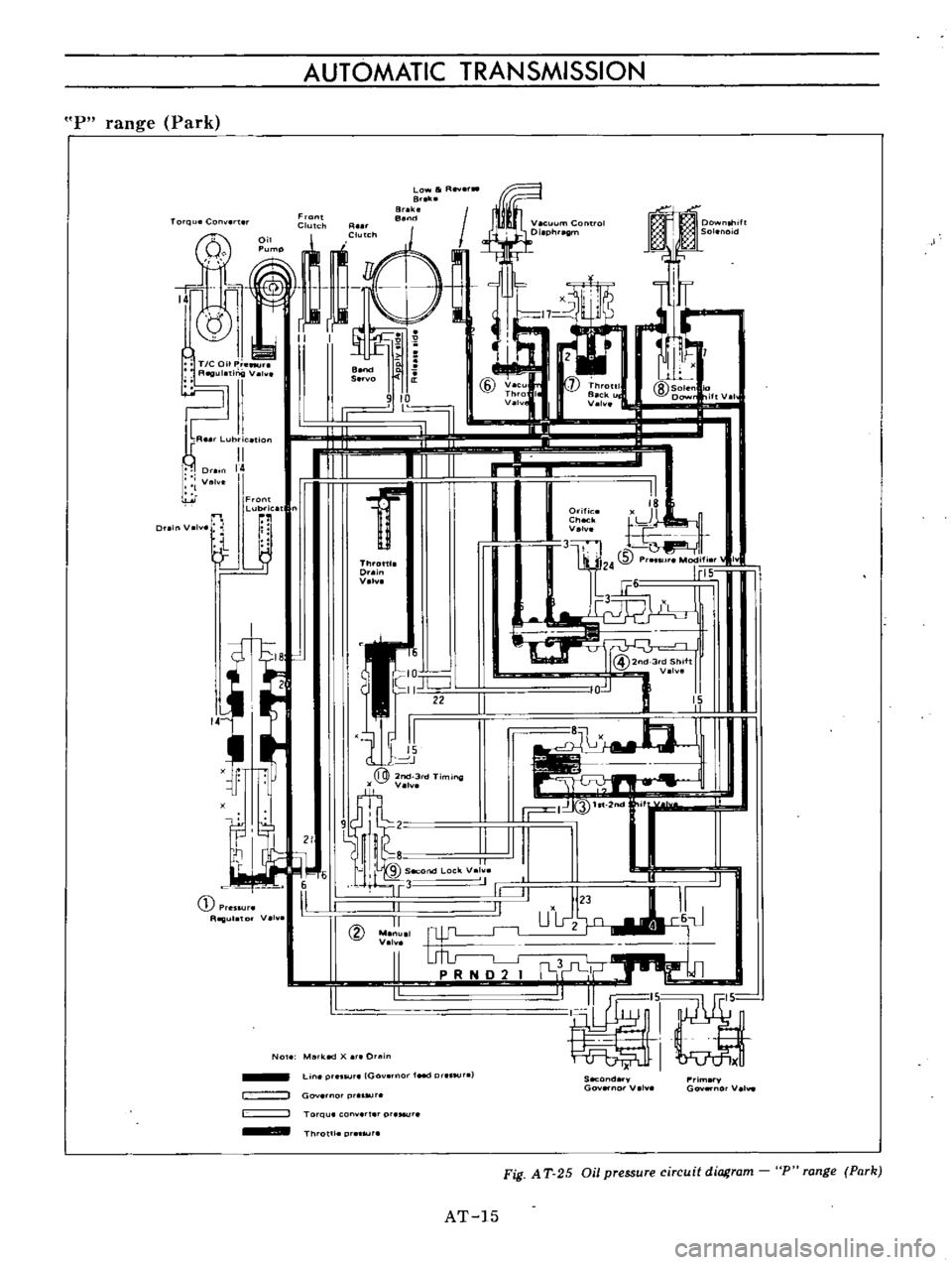

P

range

Park

Torque

Converter

Low

R

Brek

Brake

Sand

I

1

VOO

O

Solenoid

C

iT

A

q

r

CMo

I

I

U1

t5

I

j

I

T

CQ

r

C

A

uIUi

g

Velv

Bend

i

Servo

1f

a

riealion

11

11111

J

I

2

CID

v

f

0

1

J

fI

I

I

1

O

II

II

CID

Solen

iO

Cow

lift

I

J

II

I

Front

Lubrical

n

v

n

1

j

III

r

I

1

II

Orifice

18

C

tt

J

v

2

5

Mod

I

I

1

1

I

J

5JJ

if

1

@

2nd

3rd

Timing

I

1l

If

m

t

I

r

I

m

II

I

I

I

II

R

vuletor

Valve

II

U

L

J

l2

23

6

@

Menuel

Vel

P

R

N

D

2

I

fl31

i

I

I

I

I

l

I

Throttl

Dr

n

Valy

T

o

u

g

Il

I

d

Not

Jhorklld

Cu

in

lsur

Go

ernor

1

1

litHe

OICondery

Gov

norVelYe

Primary

Gov

no

1

Governor

ur

T

eMU

H

Fig

A

T

25

Oil

pressure

circuit

diagram

P

range

Park

AT

15

Page 20 of 513

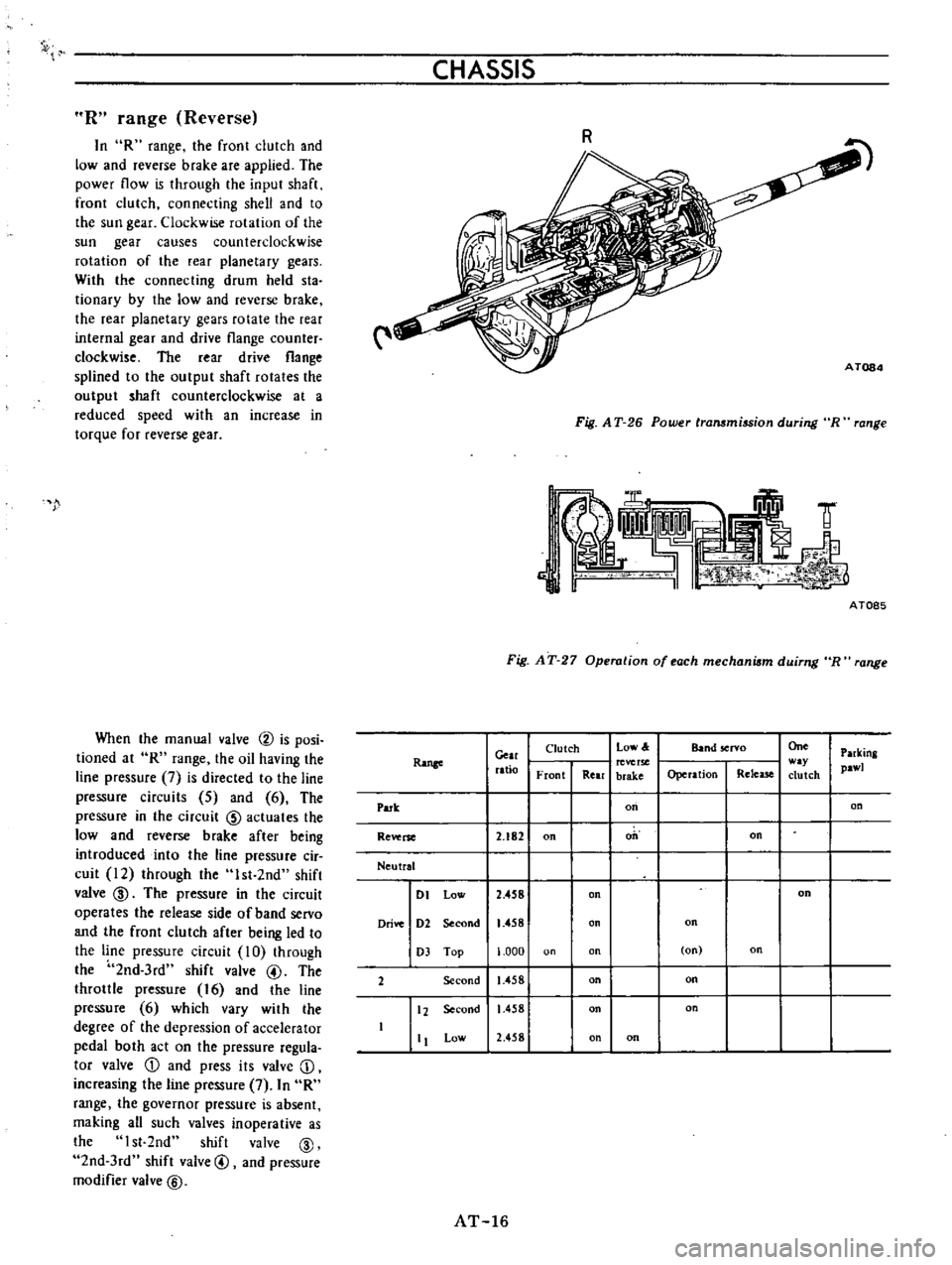

R

range

Reverse

In

R

range

the

front

clutch

and

low

and

reverse

brake

are

applied

The

power

flow

is

through

the

input

shaft

front

clutch

connecting

sheU

and

to

the

sun

gear

Clockwise

rotatiun

of

the

sun

gear

causes

counterclockwise

rotation

of

the

rear

planetary

gears

With

the

connecting

drum

held

sta

tionary

by

the

low

and

reverse

brake

the

rear

planetary

gears

rotate

the

rear

internal

gear

and

drive

flange

counter

clockwise

The

rear

drive

flange

splined

to

the

output

shaft

rotates

the

output

shaft

counterclockwise

at

a

reduced

speed

with

an

increase

in

torque

for

reverse

gear

J

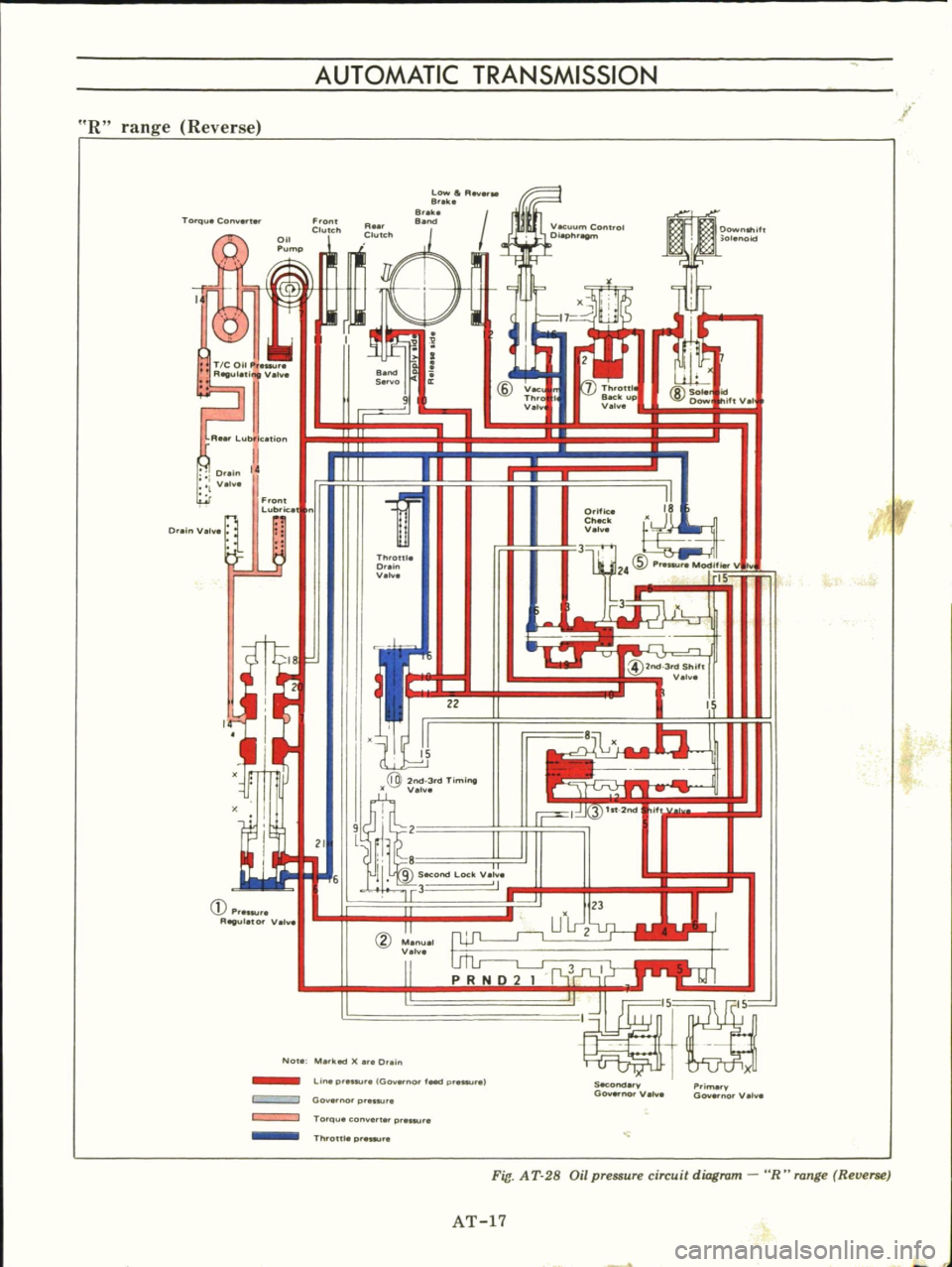

When

the

manual

valve

V

is

posi

tioned

at

R

range

the

oil

having

the

line

pressure

7

is

directed

to

the

line

pressure

circuits

5

and

6

The

pressure

in

the

circuit

ID

actuates

the

low

and

reverse

brake

after

being

introduced

into

the

line

pressure

cir

cuit

I2

through

the

lst

2nd

shift

valve

ID

The

pressure

in

the

circuit

operates

the

release

side

ofband

servo

and

the

front

clutch

after

being

led

to

the

line

pressure

circuit

10

through

the

2nd

3rd

shift

valve

@

The

throttle

pressure

16

and

the

line

pressure

6

which

vary

with

the

degree

of

the

depression

of

accelerator

pedal

both

act

on

the

pressure

regula

tor

valve

CD

and

press

its

valve

CD

increasing

the

line

pressure

7

In

R

range

the

governor

pressure

is

absent

making

all

sllch

valves

inoperative

as

the

lst

2nd

shift

valve

@

2nd

3rd

shift

valve

and

pressure

modifier

valve

@

CHASSIS

R

C

Fig

AT

26

Power

transmission

during

R

range

lI

a

Go

I

w

L

AT085

Fig

AT

27

Operation

of

each

mechani6m

duirng

OR

range

Clutch

low

Band

servo

One

Parking

Ran

Gear

ratio

reverse

way

pawl

Front

Rear

brake

Operation

Release

clutch

Park

on

on

Reverse

2

182

on

on

on

Neutral

01

low

2

458

nn

on

Drive

D2

Second

458

nn

on

OJ

Top

1

000

on

on

2

Second

458

nn

t2

Second

458

on

tt

low

2

458

on

on

AT

16

Page 21 of 513

AUTOMATIC

TRANSMISSION

R

range

Reverse

o

fro

Clutch

R

Clutch

Low

0

R

8

B

e

Torque

Con

14

Q

T

CO

fI

I

9

ID

v

Th

Vel

r

j

Orei

1

Ve

Front

Lubdce

O

IfQ

Cheek

Vah

OJ

iJ

Thronle

D

ein

V

D

i

V

l

x

21

CDp

R

Iulato

Velv

@

Not

M

k

r

D

ein

Unep

n

IGover

o

t

t

praaur

1

G

l

Gov

r

o

pr

Torque

CO

rler

p

ThrOU

epr

s

cOnclMV

Gov

nOt

V

P

i

V

Gov

nor

Velv

Fie

A

T

28

Oil

pressure

circuit

diagram

R

range

RelJerse

AT

17