DATSUN B110 1973 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 341 of 513

ENGINE

MECHANICAL

GENERAL

DESCRIPTION

CONTENTS

ENGINE

CYLINDER

BLOCK

CRAN

KSHAFT

PISTON

AND

CONNECTING

ROD

CYLINDER

HEAD

EM

EM

2

EM

2

EM

2

EM

2

CAMSHAFT

VALVE

MECHANISM

CAMSHAFT

DRIVE

MANIFOLD

EM

3

EM

3

EM

3

EM

3

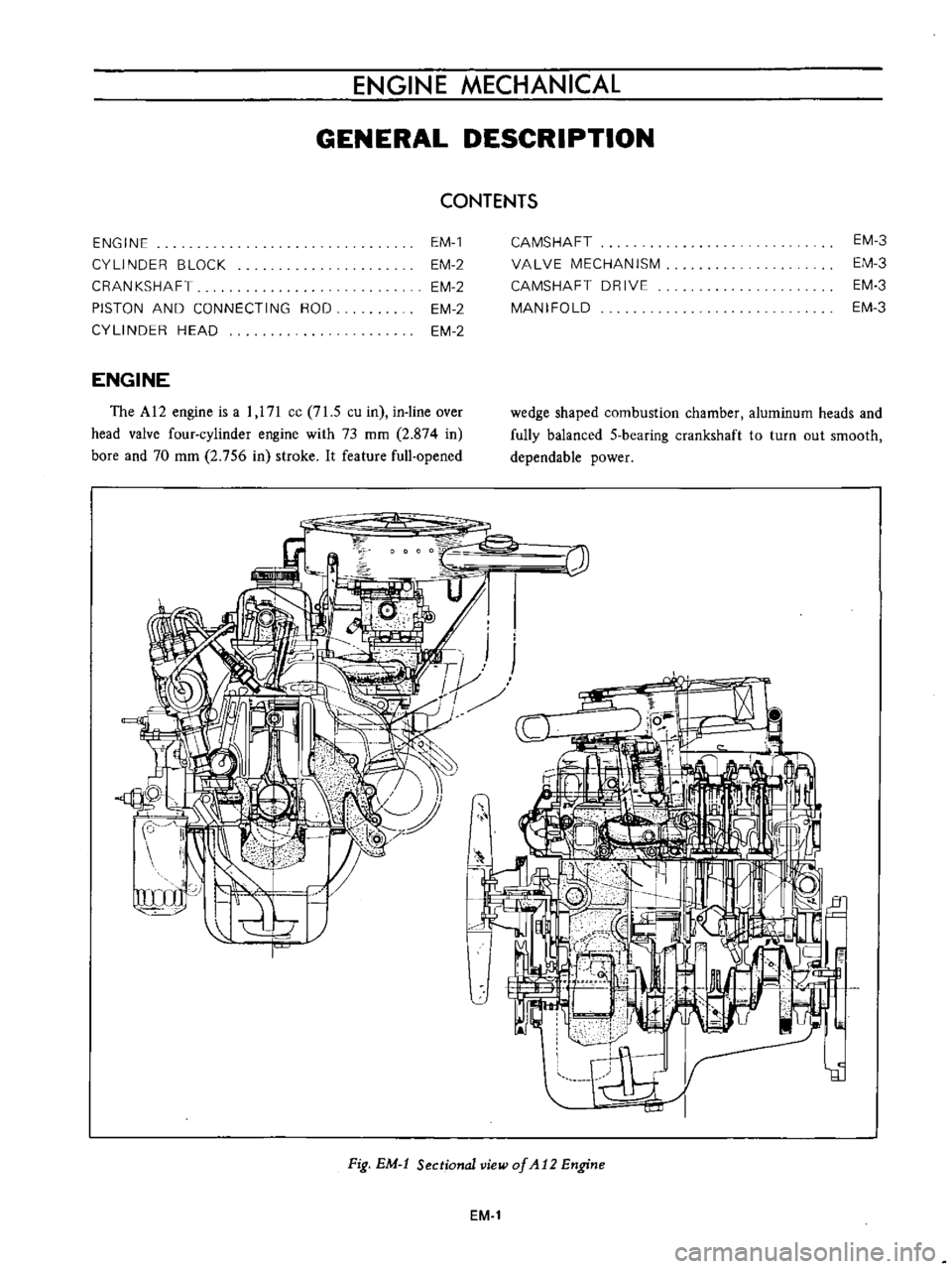

ENGINE

The

AI2

engine

is

a

1

171

cc

71

5

cu

in

in

line

over

head

valve

four

cylinder

engine

with

73

mm

2

874

in

bore

and

70

mm

2

756

in

stroke

It

feature

full

opened

wedge

shaped

combustion

chamber

aluminum

heads

and

fully

balanced

5

bearing

crankshaft

to

turn

out

smooth

dependable

power

c

Ii

I

l

1

nun

y

r

r

Fig

EM

t

Sectional

view

of

At2

Engine

EM

1

Page 342 of 513

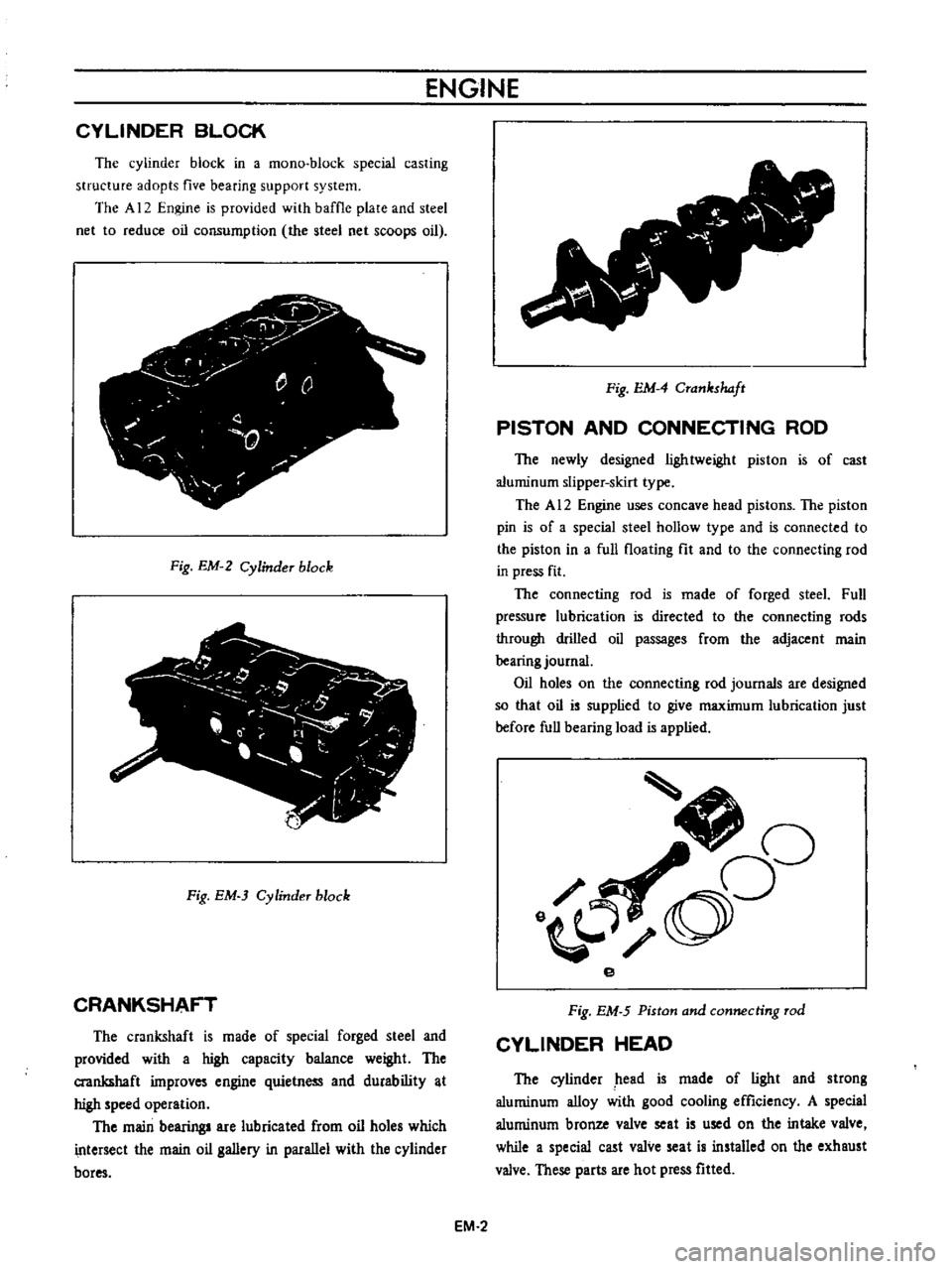

ENGINE

CYLINDER

BLOCK

The

cylinder

block

in

a

mono

block

special

casting

structure

adopts

five

bearing

support

system

The

A

12

Engine

is

provided

with

baffle

plate

and

steel

net

to

reduce

oil

consumption

the

steel

net

scoops

oil

j

y

r

0

Q

0

T

Fig

EM

2

Cylinder

block

Fig

EM

3

Cylinder

block

CRANKSHAFT

The

crankshaft

is

made

of

special

forged

steel

and

provided

with

a

high

capacity

balance

weight

The

crankshaft

improves

engine

quietness

and

durability

t

high

speed

operation

The

main

bearing

are

lubricated

from

oil

holes

which

intersect

the

main

oil

gallery

in

parallel

with

the

cylinder

bores

v

Fig

EM

4

Crankshaft

PISTON

AND

CONNECTING

ROD

The

newly

designed

lightweight

piston

is

of

cast

aluminum

slipper

skirt

type

The

A

12

Engine

uses

concave

head

pistons

The

piston

pin

is

of

a

special

steel

hollow

type

and

is

connected

to

the

piston

in

a

full

floating

fit

and

to

the

connecting

rod

in

press

fit

The

connecting

rod

is

made

of

forged

steeL

Full

pressure

lubrication

is

directed

to

the

connecting

rods

through

drilled

oil

passages

from

the

adjacent

main

bearing

journal

Oil

holes

on

the

connecting

rod

journals

are

designed

so

that

oil

is

supplied

to

give

maximum

lubrication

just

before

full

bearing

load

is

applied

J

oO

o

e

Fig

EM

5

Piston

and

connecting

rod

CYLINDER

HEAD

The

cylinder

head

is

made

of

light

and

strong

aluminum

alloy

with

good

cooling

efficiency

A

special

aluminum

bronze

valve

seat

is

used

on

the

intake

valve

while

a

special

cast

valve

seat

is

installed

on

the

exhaust

valve

These

parts

are

hot

press

fitted

EM

2

Page 343 of 513

ENGINE

MECHANICAL

Fig

EM

6

Cylinder

head

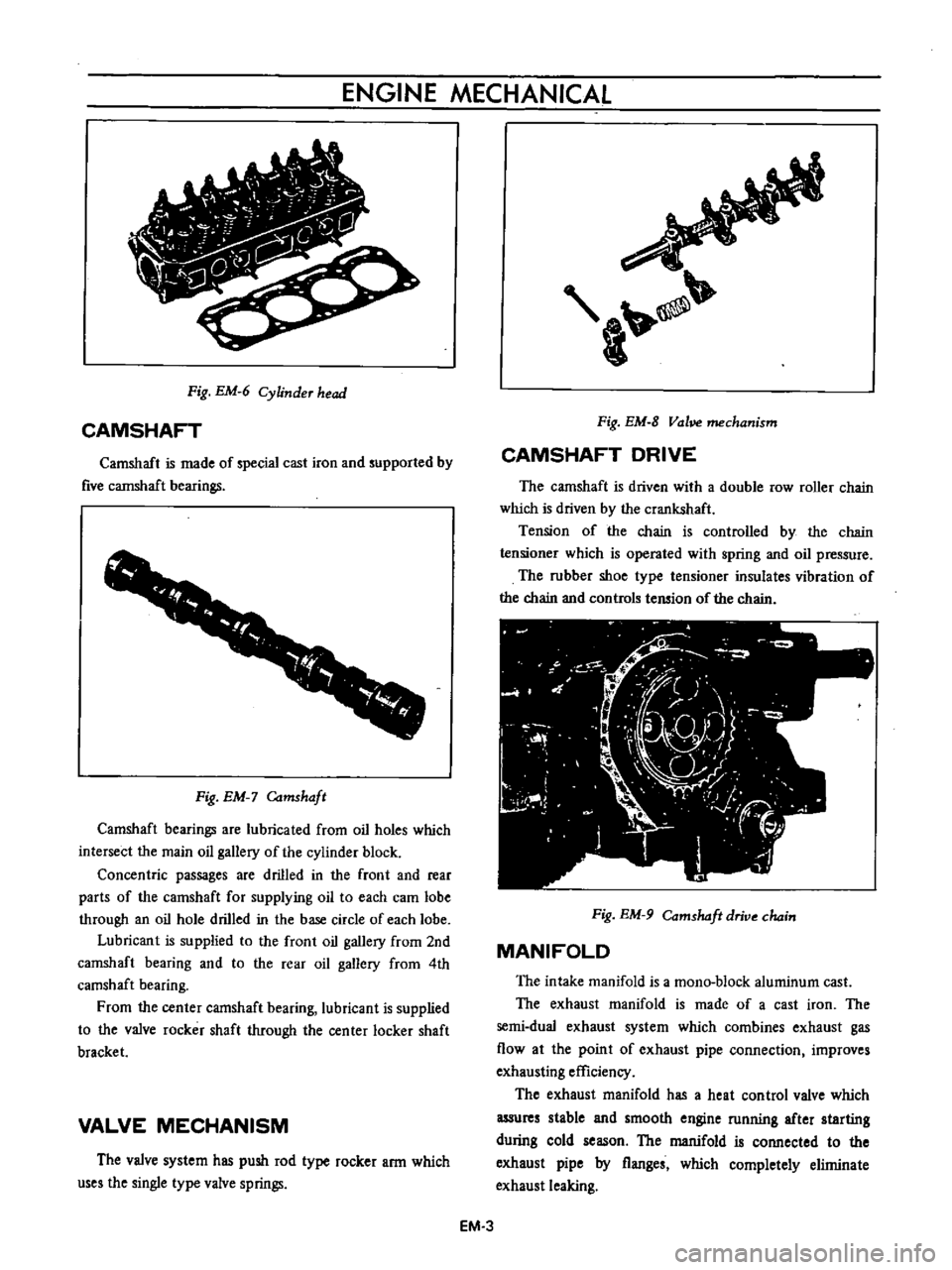

CAMSHAFT

Camshaft

is

made

of

special

cast

iron

and

supported

by

five

cannshaft

bearings

1

1

f

r

f

r

I

Fig

EM

Camshaft

Camshaft

bearings

are

lubricated

from

oil

holes

which

intersect

the

main

oil

gallery

of

the

cylinder

block

Concentric

passages

are

drilled

in

the

front

and

rear

parts

of

the

camshaft

for

supplying

oil

to

each

cam

lobe

through

an

oil

hole

drilled

in

the

base

circle

of

each

lobe

Lubricant

is

supplied

to

the

front

oil

gallery

from

2nd

camshaft

bearing

and

to

the

rear

oil

gallery

from

4th

camshaft

bearing

From

the

center

camshaft

bearing

lubricant

is

supplied

to

the

valve

rocker

shaft

through

the

center

locker

shaft

bracket

VALVE

MECHANISM

The

valve

system

has

push

rod

type

rocker

arm

which

uses

the

single

type

valve

springs

a

Fig

EM

8

Vol

mechanism

CAMSHAFT

DRIVE

The

camshaft

is

driven

with

a

double

row

roller

chain

which

is

driven

by

the

crankshaft

Tension

of

the

chain

is

controlled

by

the

chain

tensioner

which

is

operated

with

spring

and

oil

pressure

The

rubber

shoe

type

tensioner

insulates

vibration

of

the

chain

and

controls

tension

of

the

chain

Fig

EM

9

Comshdft

drive

chain

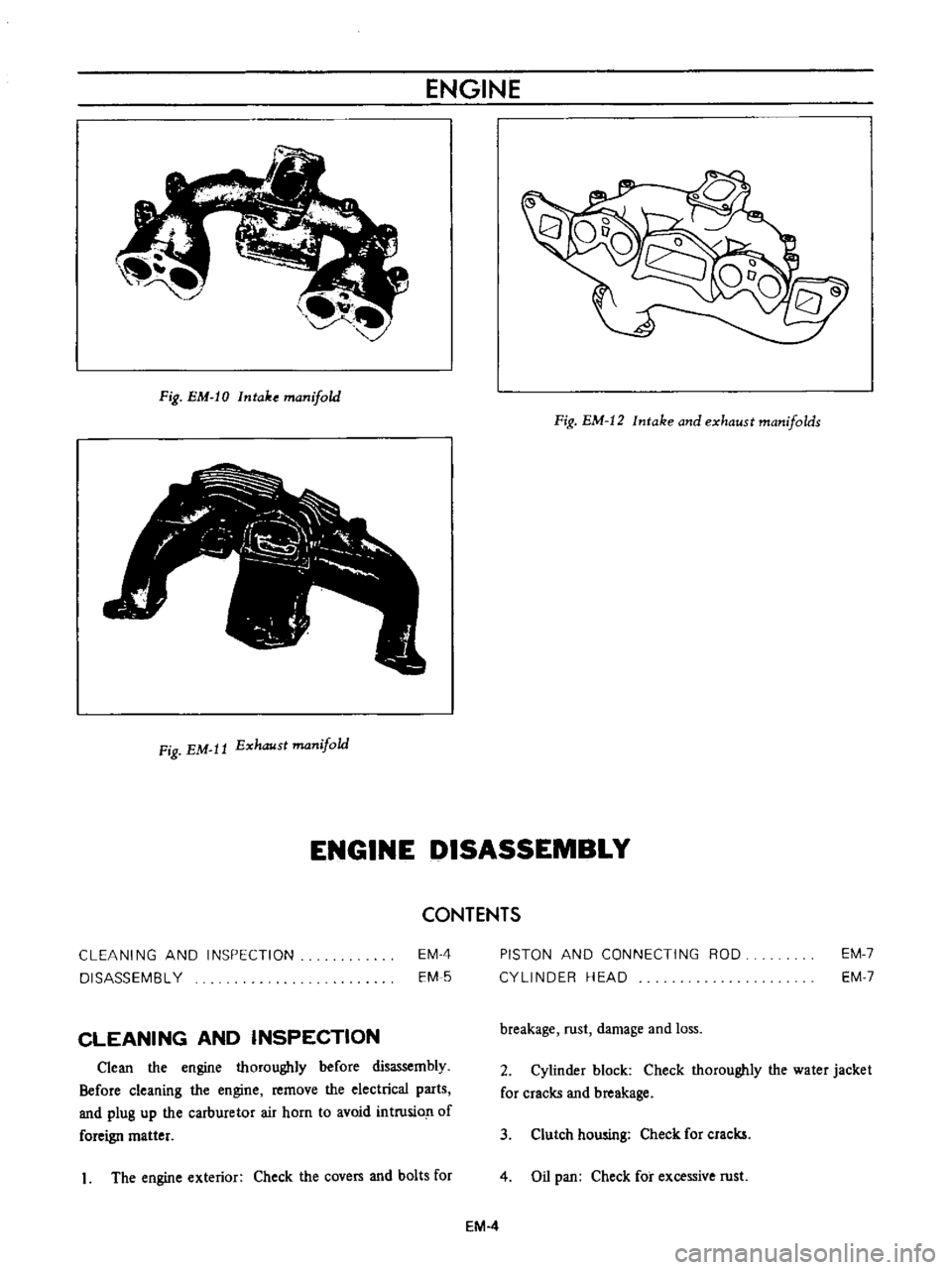

MANIFOLD

The

intake

manifold

is

a

mono

block

aluminum

cast

The

exhaust

manifold

is

made

of

a

cast

iron

The

semi

dual

exhaust

system

which

combines

exhaust

gas

flow

at

the

point

of

exhaust

pipe

connection

improves

exhausting

efficiency

The

exhaust

manifold

has

a

heat

control

valve

which

assures

stable

and

smooth

engine

running

after

starting

during

cold

season

The

manifold

is

connected

to

the

exhaust

pipe

by

flanges

which

completely

eliminate

exhaust

leaking

EM

3

Page 344 of 513

ENGINE

Fig

EM

IO

Intake

manifold

Fig

EM

12

Intake

and

exhaust

manifolds

Fig

EM

It

Exhaust

manifold

ENGINE

DISASSEMBLY

CONTENTS

CLEANING

AND

INSPECTION

DISASSEMBL

Y

EM

4

EM

5

PISTON

AND

CONNECTING

ROD

CYLINDER

HEAD

EM

7

EM

7

CLEANING

AND

INSPECTION

breakage

rust

damage

and

loss

Clean

the

engine

thoroughly

before

disassembly

Before

cleaning

the

engine

remove

the

electrical

parts

and

plug

up

the

carburetor

air

horn

to

avoid

intrusio

n

of

foreign

matter

2

Cylinder

block

Check

thoroughly

the

water

jacket

for

cracks

and

breakage

3

Clutch

howing

Check

for

cracks

1

The

engine

exterior

Check

the

covers

and

bolts

for

4

Oil

pan

Check

for

excessive

rust

EM

4

Page 345 of 513

ENGINE

MECHANICAL

I

I

J

I

v

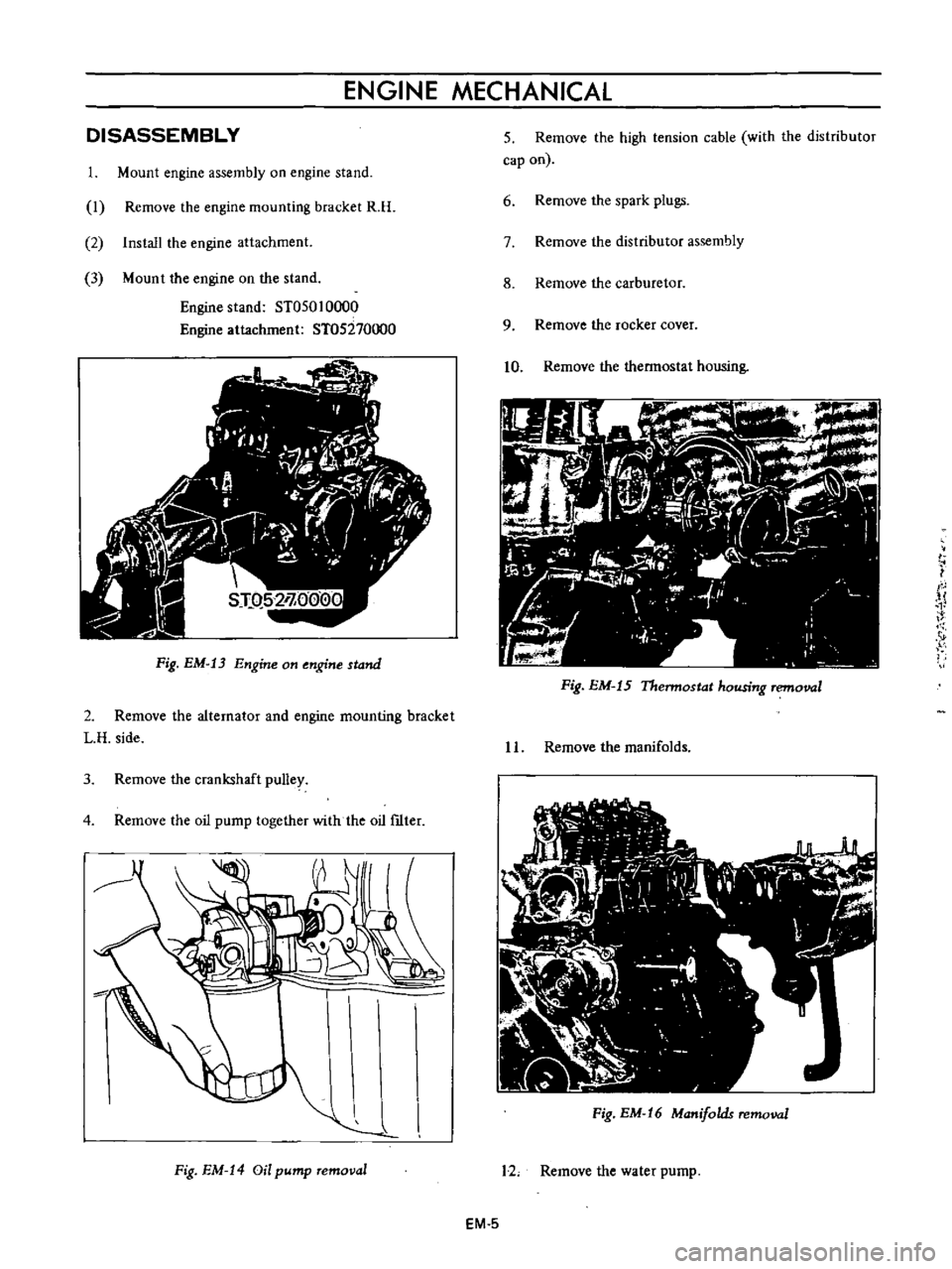

Fig

EM

13

Engine

on

engine

stand

DISASSEMBLY

1

Mount

engine

assembly

on

engine

stand

I

Remove

the

engine

mounting

bracket

R

H

2

Install

the

engine

attachment

3

Mount

the

engine

on

the

stand

Engine

stand

ST050

10000

Engine

attachment

ST05270000

2

Remove

the

alternator

and

engine

mounting

bracket

L

H

side

3

Remove

the

crankshaft

pulley

4

Remove

the

oil

pump

together

with

the

oil

ftIter

Fig

EM

14

Oil

pump

removal

5

Remove

the

high

tension

cable

with

the

distributor

cap

on

6

Remove

the

spark

plugs

7

Remove

the

distributor

assembly

8

Remove

the

carburetor

9

Remove

the

rocker

cover

10

Remove

the

thermostat

housing

Fig

EM

15

Thermostat

housing

removal

I

L

Remove

the

manifolds

Fig

EM

16

Manifolds

removal

12

Remove

the

water

pump

EM

5

Page 346 of 513

ENGINE

l

JJ

l

Ii

Fig

EM

t7

Water

pump

r

1

13

Remove

the

fuel

pump

14

Remove

the

rocker

shaft

assembly

and

push

rods

Fig

EM

18

Rocker

shaft

assembly

removal

IS

Remove

the

cylinder

head

assembly

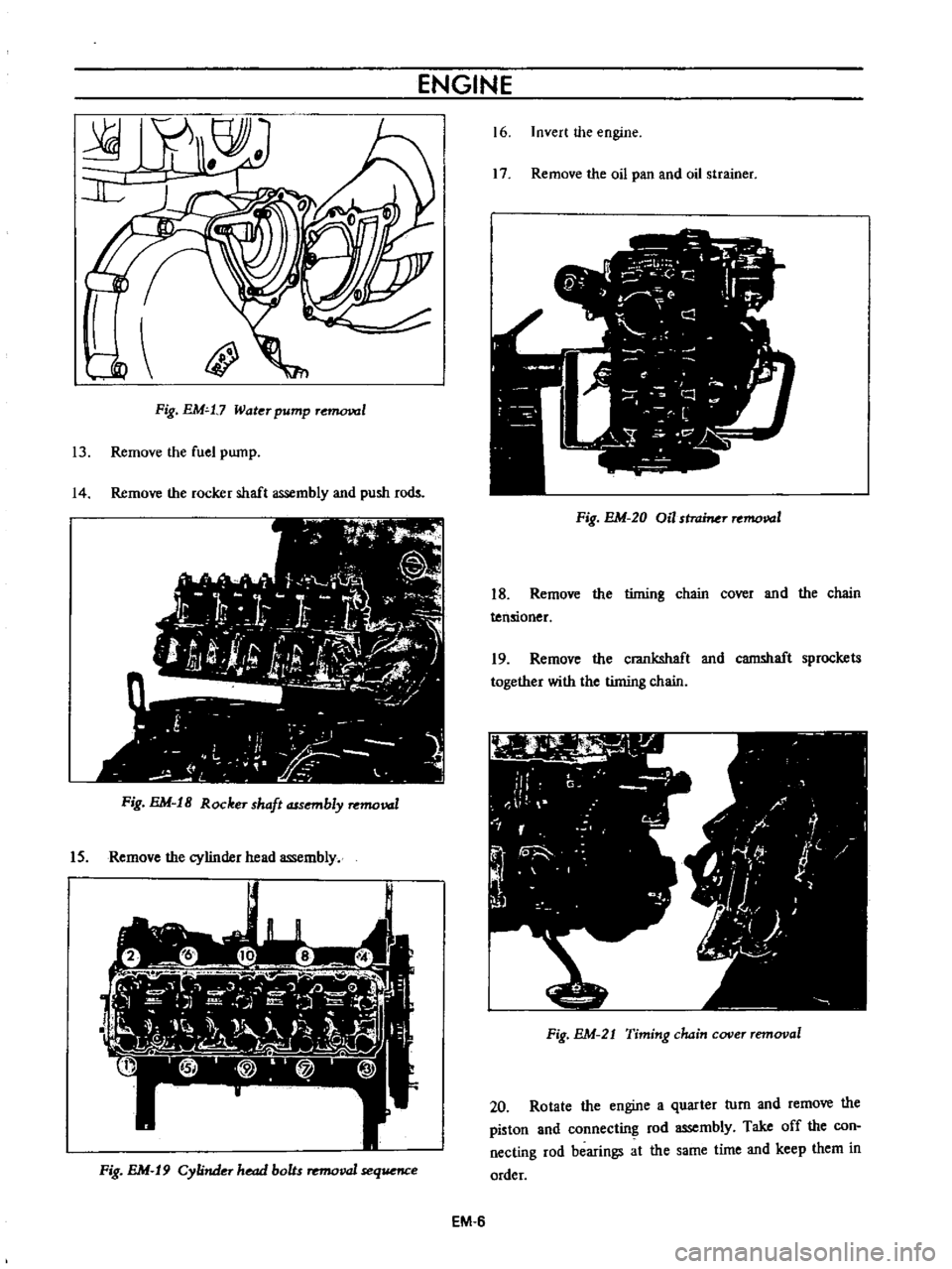

Fig

EM

19

Cylinder

head

bolts

removal

sequence

16

Invert

the

engine

17

Remove

the

oil

pan

and

oil

strainer

Fig

EM

20

Oil

stromer

removal

18

Remove

the

timing

chain

cover

and

the

chain

tensioner

19

Remove

the

crankshaft

and

camshaft

sprockets

together

with

the

timing

chain

Fig

EM

21

Timing

chain

cover

removal

20

Rotate

the

engine

a

quarter

turn

and

remove

the

piston

and

connecting

rod

assembly

Take

off

the

con

necting

rod

bearings

at

the

same

time

and

keep

them

in

order

EM

6

Page 347 of 513

ENGINE

MECHANICAL

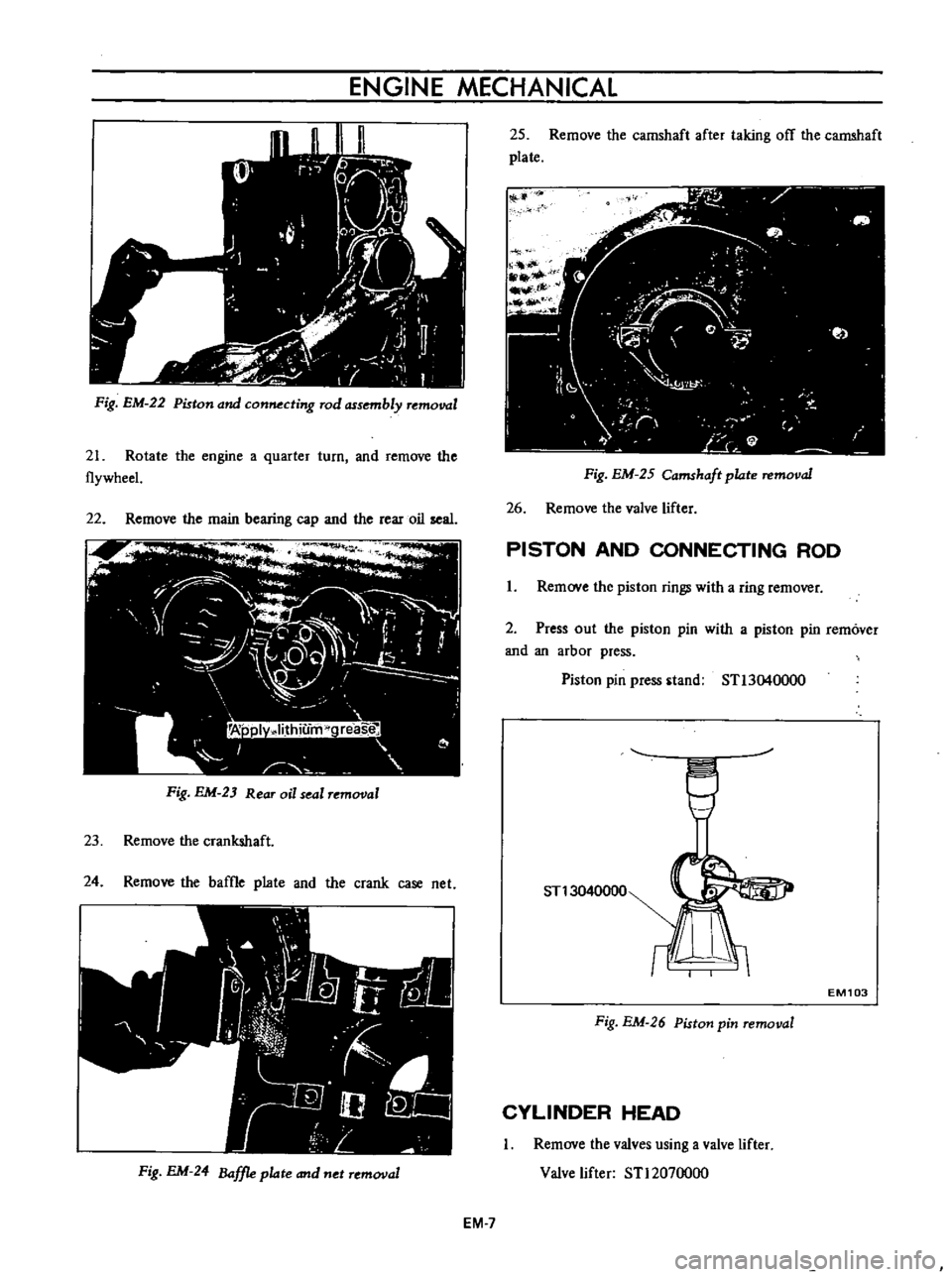

Fig

EM

22

Piston

and

conMcting

rod

assembly

removal

21

Rotate

the

engine

a

quarter

turn

and

remove

the

flywheeL

22

Remove

the

main

bearing

cap

and

the

rear

oil

seal

Fig

EM

2J

Rear

oil

seal

removal

23

Remove

the

crankshaft

24

Remove

the

baffie

plate

and

the

crank

case

net

Fig

EM

24

Baffle

plate

and

net

removal

25

Remove

the

camshaft

after

taking

ofT

the

camshaft

plate

Fig

EM

25

Camshaft

plate

removal

26

Remove

the

valve

lifter

PISTON

AND

CONNECTING

ROD

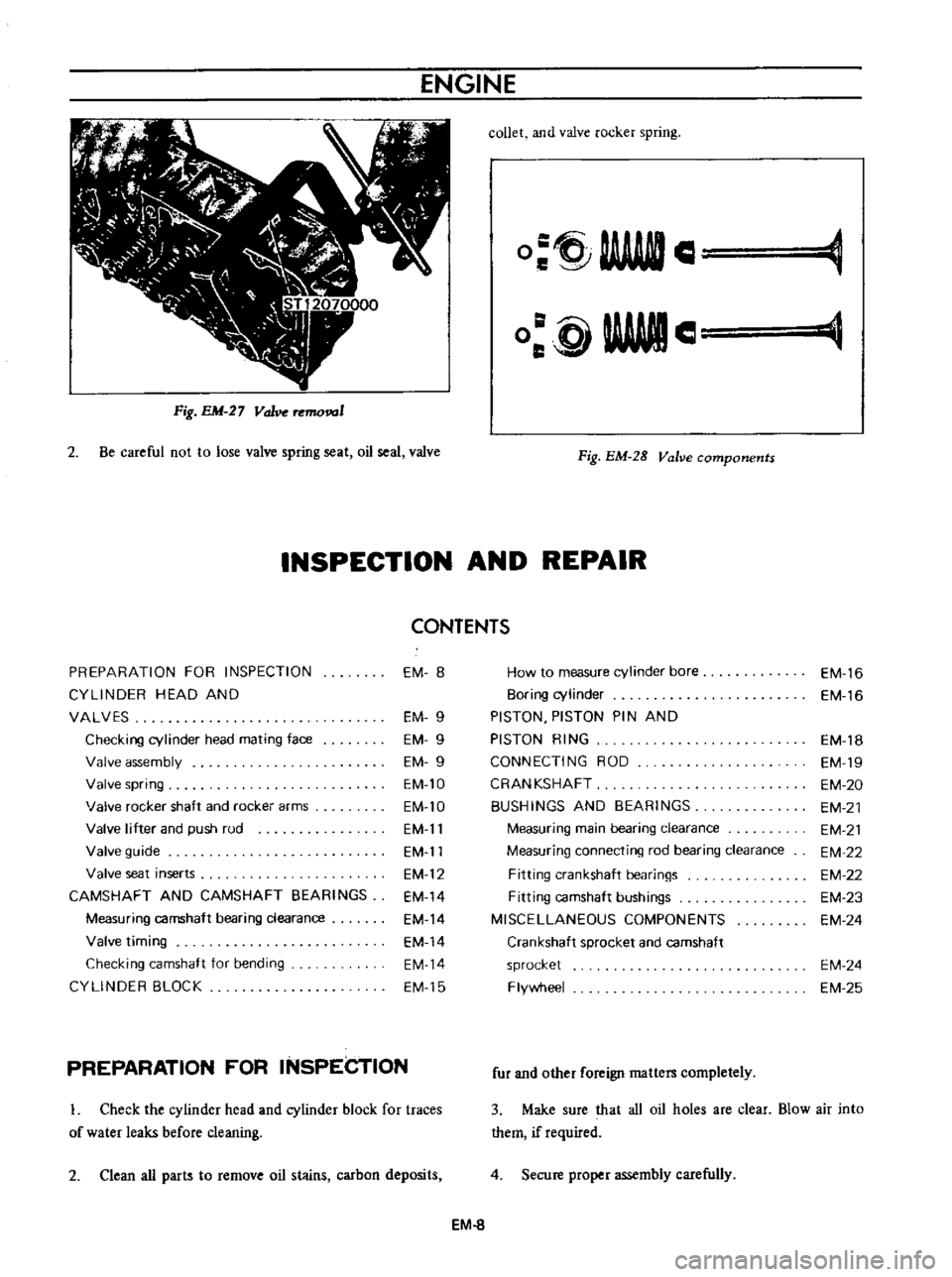

1

Remove

the

piston

rings

with

a

ring

remover

2

Press

out

the

piston

pin

with

a

piston

pin

remover

and

an

arbor

press

Piston

pin

press

oland

STl3040000

ST13040000

EM103

Fig

EM

26

Piston

pin

removal

CYLINDER

HEAD

Remove

the

valves

using

a

valve

lifter

Valve

lifter

STl2070000

EM

Page 348 of 513

ENGINE

J

I

r

I

I

J

fj

7

L

j

8

if

d1

I

ilfi

3

c

7

I

t

j

v

1

Ji

Fig

EM

27

Valve

mo

1

2

Be

careful

not

to

lose

valve

spring

seat

oil

seal

valve

collet

and

valve

rocker

spring

O

tj

AAAftIl

C

e

WWII

o

glAWle

Fig

EM

28

Valve

components

INSPECTION

AND

REPAIR

CONTENTS

PREPARATION

FOR

INSPECTION

EM

8

How

to

measure

cylinder

bore

EM

16

CYLlNOER

HEAD

AND

80ring

cylinder

EM

16

VALVES

EM

9

PISTON

PISTON

PIN

AND

Checking

cylinder

head

mating

face

EM

9

PISTON

RING

EM

18

Valve

assembly

EM

9

CONNECTING

ROD

EM

19

Valve

spring

EM

10

CRANKSHAFT

EM

20

Valve

rocker

shaft

and

rockei

arms

EM

lO

BUSHINGS

AND

BEARINGS

EM

21

Valve

lifter

and

push

rud

EM

11

Measuring

main

bearing

clearance

EM

21

Valve

guide

EM

11

Measuring

connecting

rod

bearing

clearance

EM

22

Valve

seat

inserts

EM

12

Fitting

crankshaft

bearings

EM

22

CAMSHAFT

AND

CAMSHAFT

BEARINGS

EM

14

Fitting

camshaft

bushings

EM

23

Measuring

camshaft

bearing

clearance

EM

14

MISCELLANEOUS

COMPONENTS

EM

24

Valve

timing

EM

14

Crankshaft

sprocket

and

camshaft

Checking

camshaft

for

bending

EM

14

sprocket

EM

24

CYLlNOER

BLOCK

EM

15

Flywheel

EM

25

PREPARATION

FOR

INSPECTION

L

Check

the

cylinder

head

and

cylinder

block

for

traces

of

water

leaks

before

cleaning

2

Clean

all

parts

to

remove

oil

stains

carbon

deposits

fur

and

other

foreign

matters

completely

3

Make

sure

that

all

oil

holes

are

clear

Blow

air

into

them

if

required

4

Secure

proper

assembly

carefully

EM

8

Page 349 of 513

ENGINE

MECHANICAL

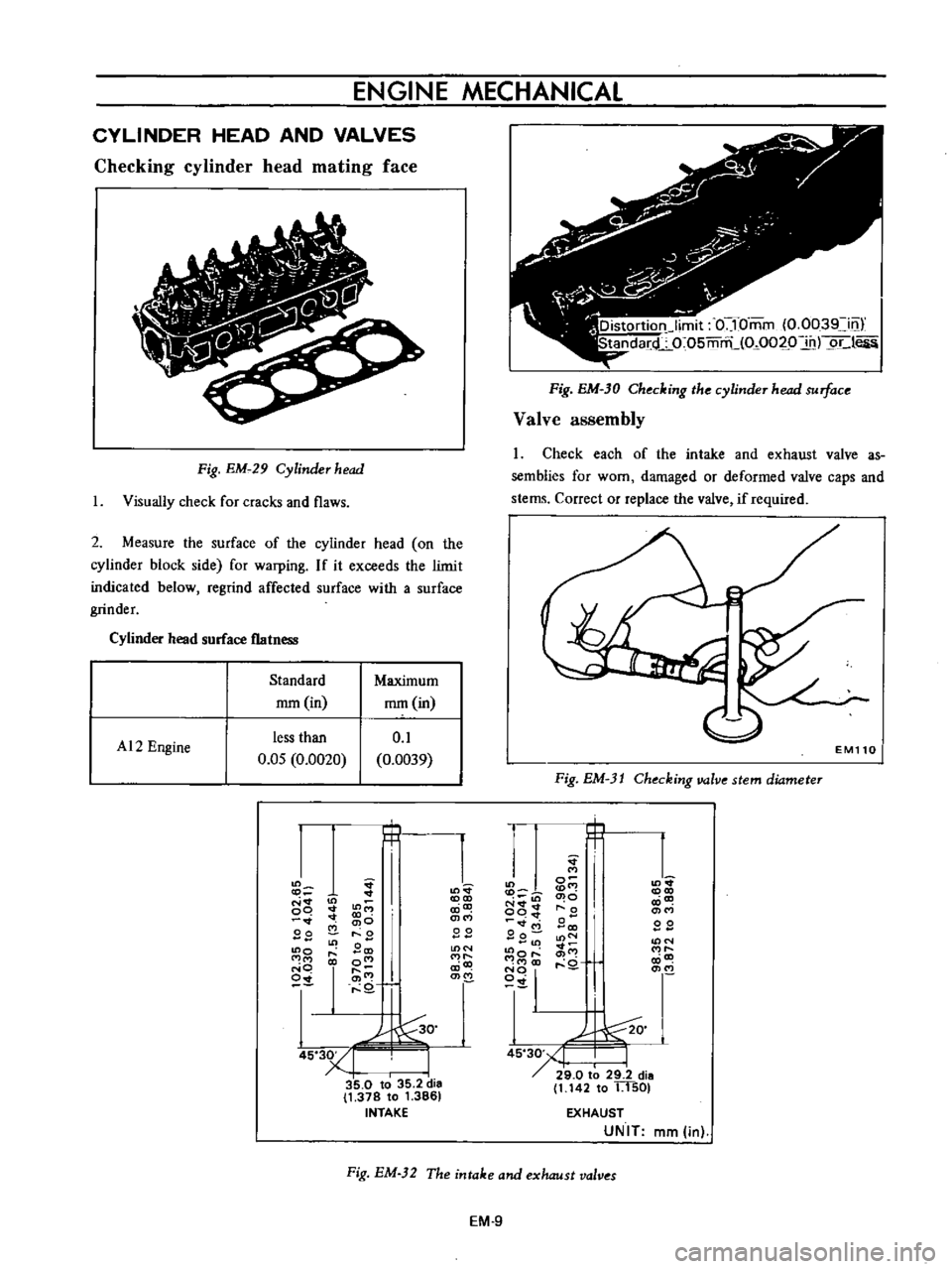

CYLINDER

HEAD

AND

VALVES

Checking

cylinder

head

mating

face

Fig

EMc29

Cylinder

head

I

Visually

check

for

cracks

and

flaws

2

Measure

the

surface

of

the

cylinder

head

on

the

cylinder

block

side

for

warping

If

it

exceeds

the

limit

indicated

below

regrind

affected

surface

with

a

surface

grinder

Cylinder

head

surface

flatness

Standard

Maximum

rom

in

mm

in

AI2

Engine

less

than

0

1

O

OS

0

0020

0

0039

t

C

in

00

co

0

00

2

0

Sco

co

0

0

i

Q

coco

a

ilt

BE

mIX

2

00

5

3YI

I

35

0

to

35

2

dia

1

378

to

1

3861

INTAKE

Fig

EM

30

Checking

the

cylinder

head

surface

Valve

a88embly

I

Check

each

of

the

intake

and

exhaust

valve

asc

semblies

for

wom

damaged

or

deformed

valve

caps

and

stems

Correct

or

replace

the

valve

if

required

l

EM110

Fig

EM

31

Chuking

valve

stem

diameter

t

L

coco

CO

co

BE

Ln

oq

q

od

M

2

g

tOo

18co1

O

c

0

DO

o

0

0

co

o

CO

co

J00

45

30

1

I

I

2

9

0

t

29

2

dia

1

142

to

1

l501

EXHAUST

UNIT

mm

in

Fig

EM

32

The

intake

and

exhaust

valves

EM

9

Page 350 of 513

ENGINE

2

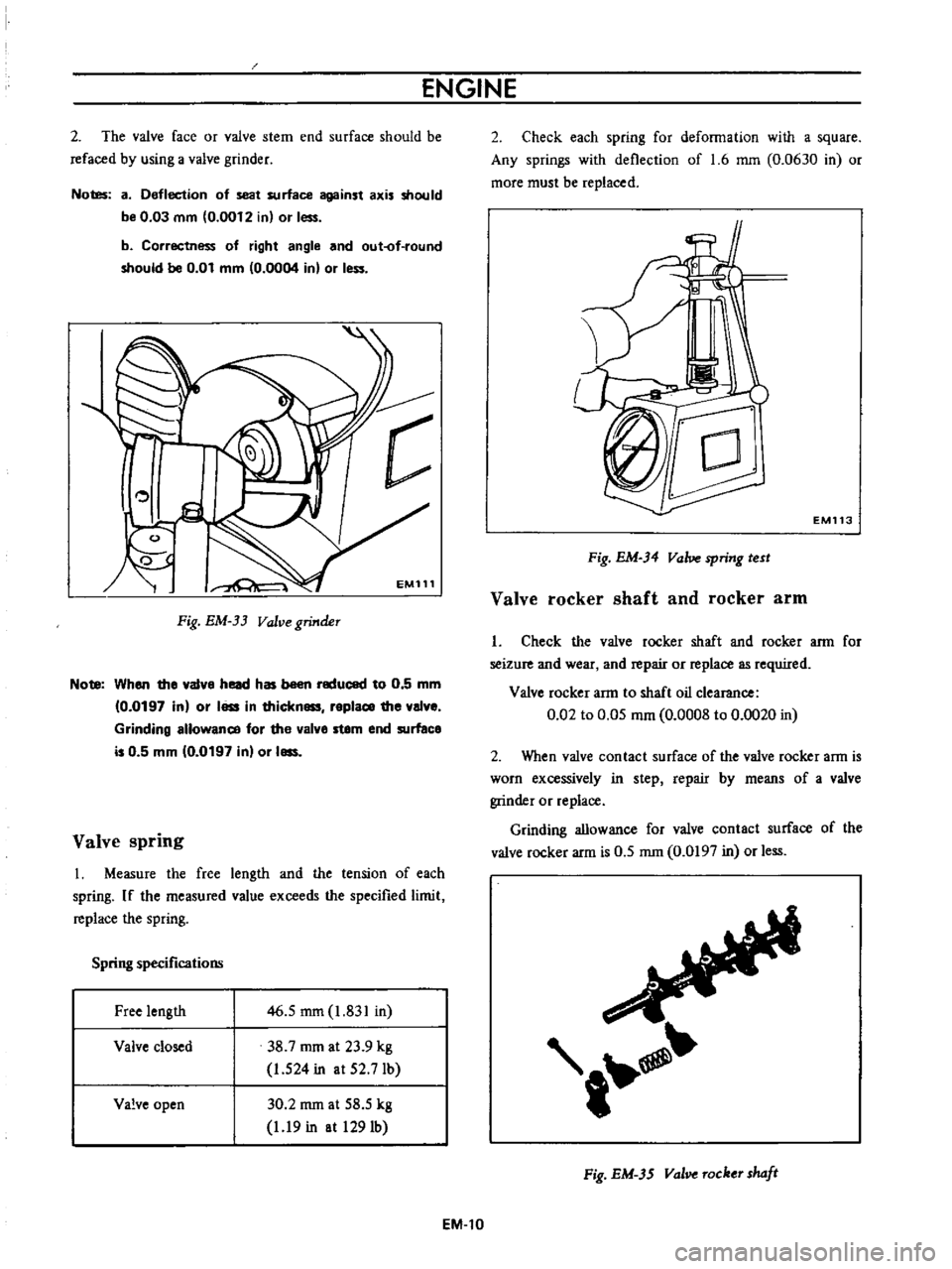

The

valve

face

or

valve

stem

end

surface

should

be

refaced

by

using

a

valve

grinder

Notes

a

Deflection

of

seat

surface

against

axis

should

be

0

03

mm

0

0012

in

or

less

b

Correctness

of

right

angle

and

out

of

round

should

be

0

01

mm

0

0004

in

or

I

c

EM111

Fig

EM

33

Valve

grinder

Note

When

the

a1ve

head

has

been

reduced

to

0

5

mm

0

0197

in

or

I

in

thickn

replace

the

al

e

Grinding

allowance

for

the

alve

stem

end

surface

is

0

5

mm

10

0197

in

or

I

Valve

spring

I

Measure

the

free

length

and

the

tension

of

each

spring

If

the

measured

value

exceeds

the

specified

limit

replace

the

spring

Spring

specifications

Free

length

46

5

mm

1

831

in

38

7

rom

at

23

9

kg

1

524

in

at

52

7Ib

Valve

closed

Valve

open

30

2

rom

at

58

5

kg

1

19

in

at

1291b

EM

l0

2

Check

each

spring

for

deformation

with

a

square

Any

springs

with

deflection

of

1

6

mm

0

0630

in

or

more

must

be

replaced

EM113

Fig

EM

34

Valve

spring

test

Valve

rocker

shaft

and

rocker

arm

I

Check

the

valve

rocker

shaft

and

rocker

arm

for

seizure

and

wear

and

repair

or

replace

as

required

Valve

rocker

arm

to

shaft

oil

clearance

0

02

to

0

05

mm

0

0008

to

0

0020

in

2

When

valve

contact

surface

of

the

valve

rocker

arm

is

worn

excessively

in

step

repair

by

means

of

a

valve

grinder

or

replace

Grinding

allowance

for

valve

contact

surface

of

the

valve

rocker

arm

is

0

5

rom

0

0197

in

or

less

t

Fig

EM

3S

val

Tocker

shaft