DATSUN B110 1973 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 381 of 513

y

1

S

E

R

V

E

z

t

i

A

l

r

i

r

z

0

X

j

r

I

X

M

A

N

IJ

I

Ii

r

II

J

r

f

vli

jI

J

I

r

Jt

DATSUN

1200

MODEL

8110

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

EL

ENGINE

LUBRICATION

SYSTEM

LUBRICATION

SYSTEM

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Ell

El

4

Page 382 of 513

ENGINE

lUBRICATION

SYSTEM

LUBRICATION

SYSTEM

CONTENTS

DESCRIPTION

LUBRICATION

CIRCUIT

OIL

PUMP

Description

Removal

EL

1

EL

2

EL

2

EL

2

EL

2

Disassembly

I

nspection

and

repair

OIL

PRESSURE

REGULATOR

VALVE

OIL

FILTER

EL

2

EL

3

EL

3

EL

3

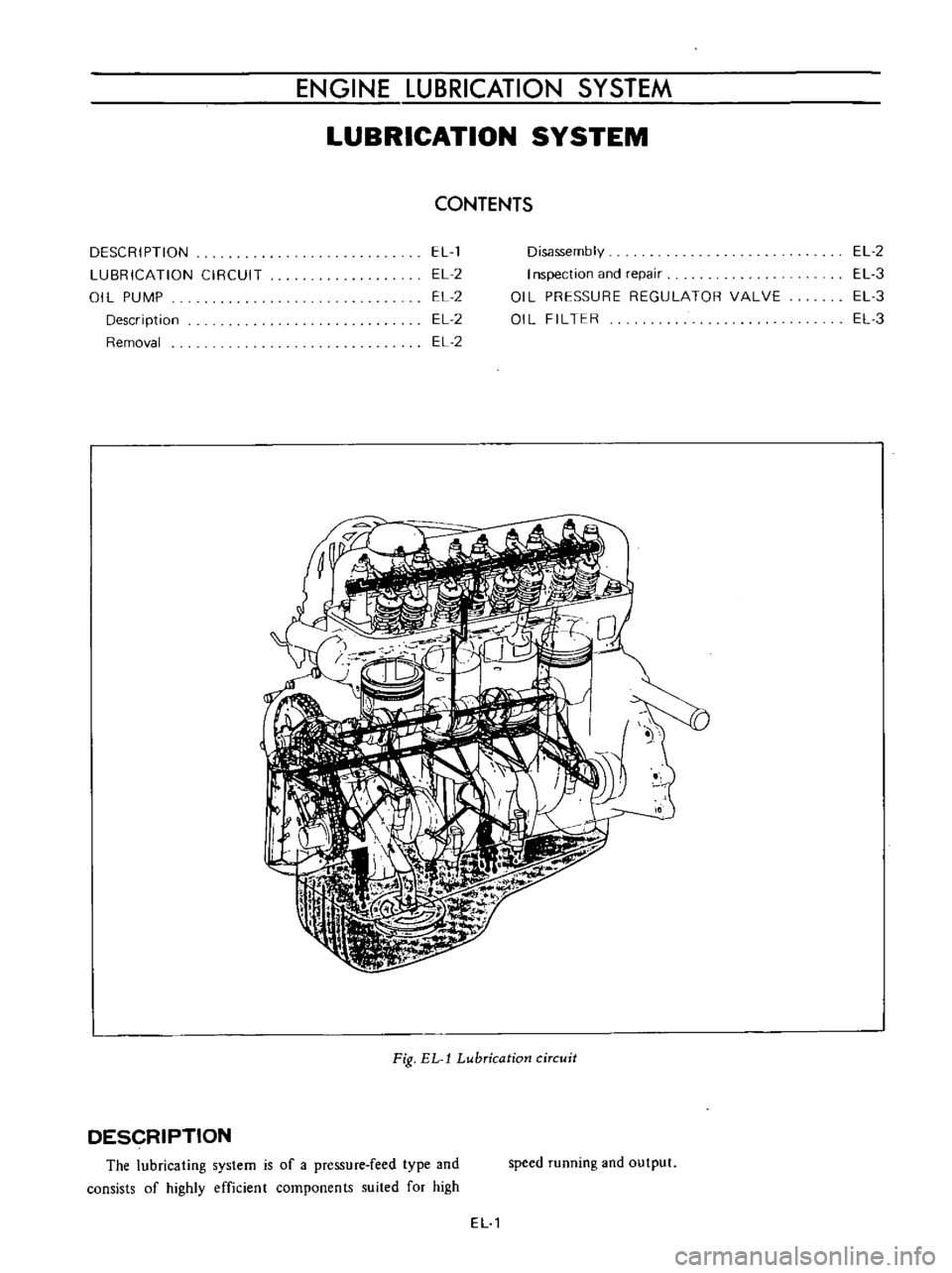

Fig

EL

l

Lubrication

circuit

DESCRIPTION

The

lubricating

system

is

of

a

pressure

feed

type

and

consists

of

highly

efficient

components

suited

for

high

speed

running

and

output

EL

1

Page 383 of 513

LUBRICATION

CIRCUIT

Oil

drawn

from

the

oil

pan

through

the

inlet

screen

and

tube

to

the

inlet

side

of

the

oil

pump

is

delivered

by

th

oil

pump

through

the

outlet

portion

of

the

oil

pump

and

the

oil

gallery

to

the

inlet

side

of

the

full

flow

oil

filter

and

to

the

main

oil

gallery

The

main

oil

gallery

supplies

oil

to

the

crankshaft

main

bearings

and

drilled

passages

in

the

crankshaft

and

thus

oil

is

fed

directly

from

the

main

bearings

to

the

connecting

rod

bearings

Oil

injected

from

jet

holes

on

connecting

rods

lubri

cates

the

cylinder

walls

and

pistion

pins

The

oil

distributed

from

the

main

gallery

enters

the

chain

teosioner

and

the

pad

is

held

against

the

chain

by

oil

pressure

and

spring

The

oil

also

lubricates

the

timing

chain

through

the

jet

hole

located

near

the

chain

Furthermore

lubricant

is

supplied

to

each

camshaft

bearing

through

each

crankshaft

main

bearing

and

finally

to

the

011

gallery

in

the

rocker

shaft

through

the

center

camshaft

bearing

The

rocker

arm

and

valve

are

lubricated

by

the

oil

through

the

oil

gallery

in

the

rockershaft

To

this

oil

gallery

lubricant

is

supplied

through

the

center

camshaft

bearing

as

shown

in

Figure

EL

I

OIL

PUMP

Description

The

oil

pump

assembly

is

installed

on

the

bottom

of

the

cylinder

block

and

driven

by

the

distributor

drive

shaft

assembly

The

oil

pump

is

of

a

rotor

type

The

oil

pressure

is

regulated

by

the

regulator

valve

camshaft

Removal

Engine

in

vehicle

Drain

engine

oil

2

Remove

the

frunt

stabilizer

3

Remove

the

splash

shield

board

4

Detach

the

oil

pump

body

together

with

drive

gear

spindle

ENGINE

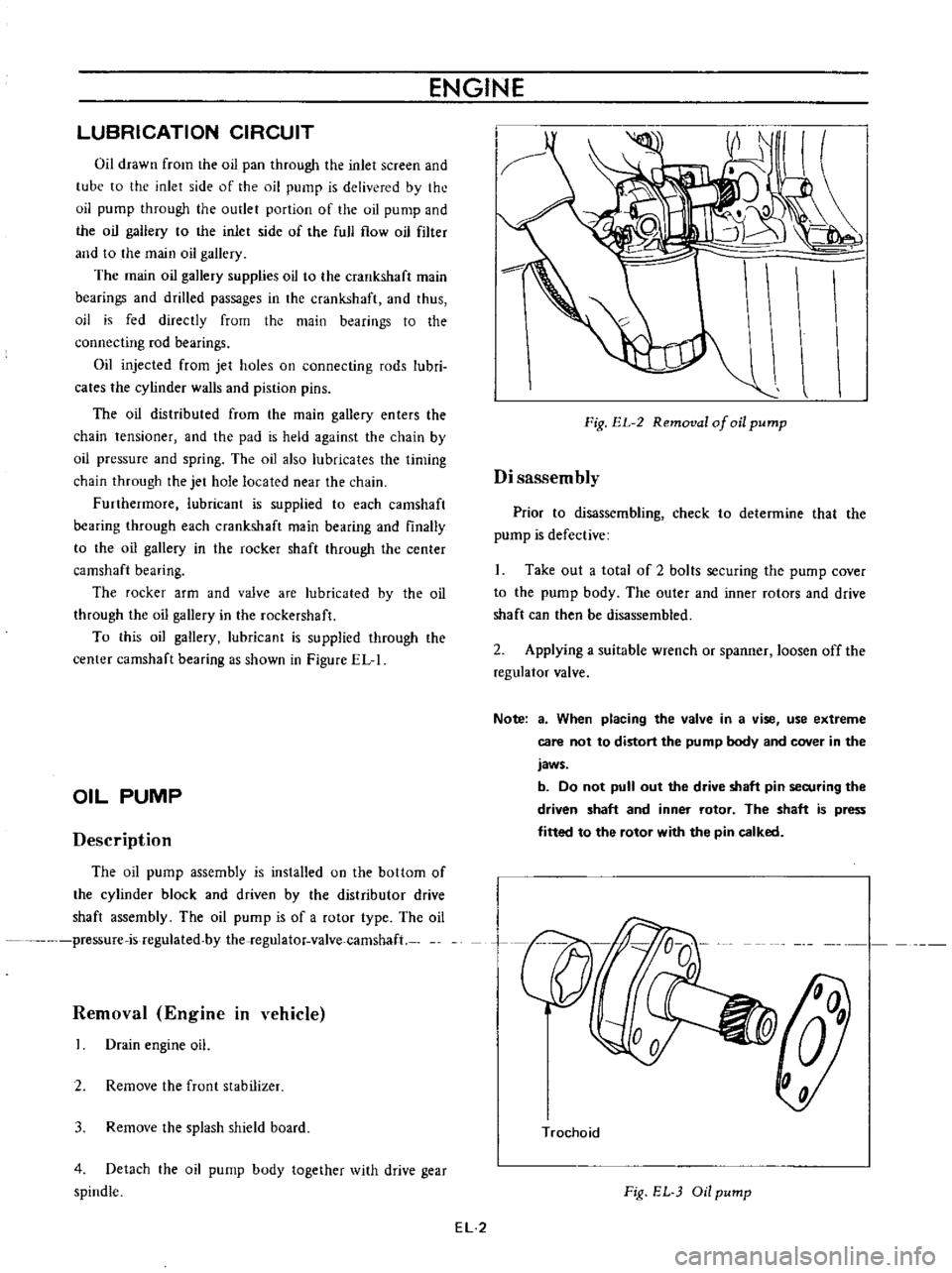

Fig

EL

2

Removal

of

oil

pump

Disassembly

Prior

to

disassembling

check

to

determine

that

the

pump

is

defective

Take

out

a

total

of

2

bolts

securing

the

pump

cover

to

the

pump

body

The

outer

and

inner

rotors

and

drive

shaft

can

then

be

disassembled

2

Applying

a

suitable

wrench

or

spanner

loosen

off

the

regulator

valve

Note

a

When

placing

the

valve

in

a

vise

use

extreme

care

not

to

distort

the

pump

body

and

cover

in

the

jaws

b

Do

not

pull

out

the

drive

shaft

pin

securing

the

driven

shaft

and

inner

rotor

The

shaft

is

press

fitted

to

the

rotor

with

the

pin

calked

n

Trochoid

Fig

EL

Oil

pump

EL

2

Page 384 of 513

ENGINE

LUBRICATION

SYSTEM

Inspection

and

repair

Clean

the

disassembled

parts

with

cleaning

solvent

and

inspect

for

defects

Inspect

the

drive

rotor

shaft

for

excessive

wear

and

scores

and

check

the

following

clearances

Side

clearance

between

Quter

and

inner

rotors

0

12

mm

0

0047

in

or

below

Tip

clearance

0

04

to

0

I2mm

0

0016

to

0

0047

in

Clearance

between

outer

rotor

and

body

0

15

to

0

21

rom

0

0059

to

0

0083

in

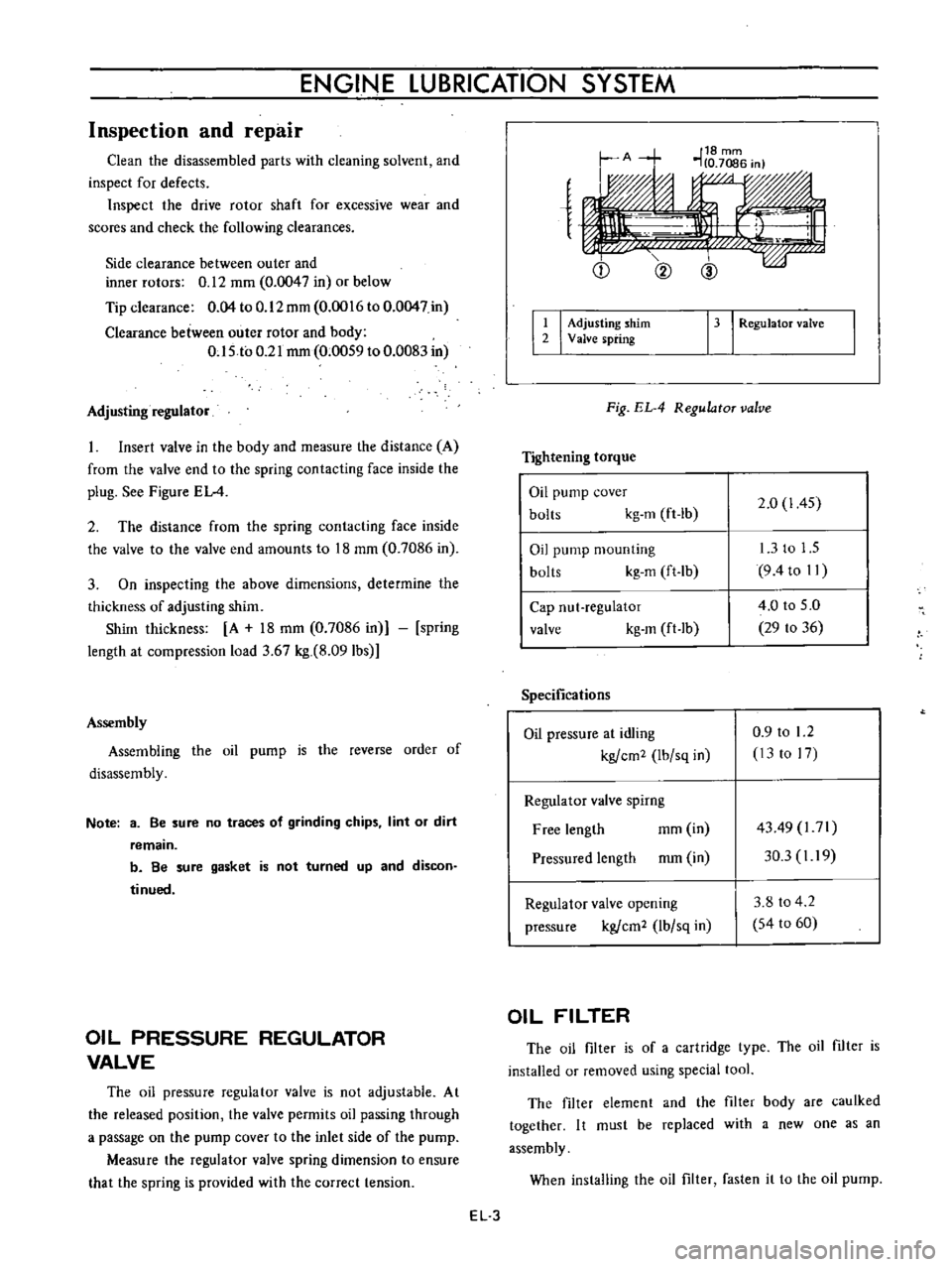

Adjusting

regulator

Insert

valve

in

the

body

and

measure

the

distance

A

from

the

valve

end

to

the

spring

contacting

face

inside

the

plug

See

Figure

EL

4

2

The

distance

from

the

spring

contacting

face

inside

the

valve

to

the

valve

end

amounts

to

18

mm

0

7086

in

3

On

inspecting

the

above

dimensions

determine

the

thickness

of

adjusting

shim

Shim

thickness

A

18

mm

0

7086

in

spring

length

at

compression

load

3

67

kg

8

091bs

Assembly

Assembling

the

oil

pump

is

the

reverse

order

of

disassembly

Note

3

Be

sure

no

traces

of

grinding

chips

lint

or

dirt

remain

b

Be

sure

gasket

is

not

turned

up

and

discon

tinued

OIL

PRESSURE

REGULATOR

VALVE

The

oil

pressure

regulator

valve

is

not

adjustable

At

the

released

position

the

valve

permits

oil

passing

through

a

passage

on

the

pump

cover

to

the

inlet

side

of

the

pump

Measure

the

regulator

valve

spring

dimension

to

ensure

that

the

spring

is

provided

with

the

correct

tension

e

Q

@

I

I

Adjusting

shim

2

Valve

spring

13

I

RegulatoT

valve

Fig

EL

4

RegulatoT

valve

Tightening

torque

Oil

pump

cover

bolts

kg

m

ft

lb

2

0

1

45

Oil

pump

mounting

bolts

kg

m

ft

lb

13

to

1

5

9

4to

II

Cap

nut

regulator

valve

kg

m

ft

lb

4

0

to

5

0

29

to

36

Specifications

Oil

pressure

at

idling

kgfcm2

Ibfsq

in

0

9

to

1

2

13

to

17

Regulator

valve

spirng

Free

length

mm

in

Pressured

length

mm

in

4349

l71

30

3

I

19

Regulator

valve

opening

pressure

kgfcm2

lbfsq

in

3

8

to

4

2

54

to

60

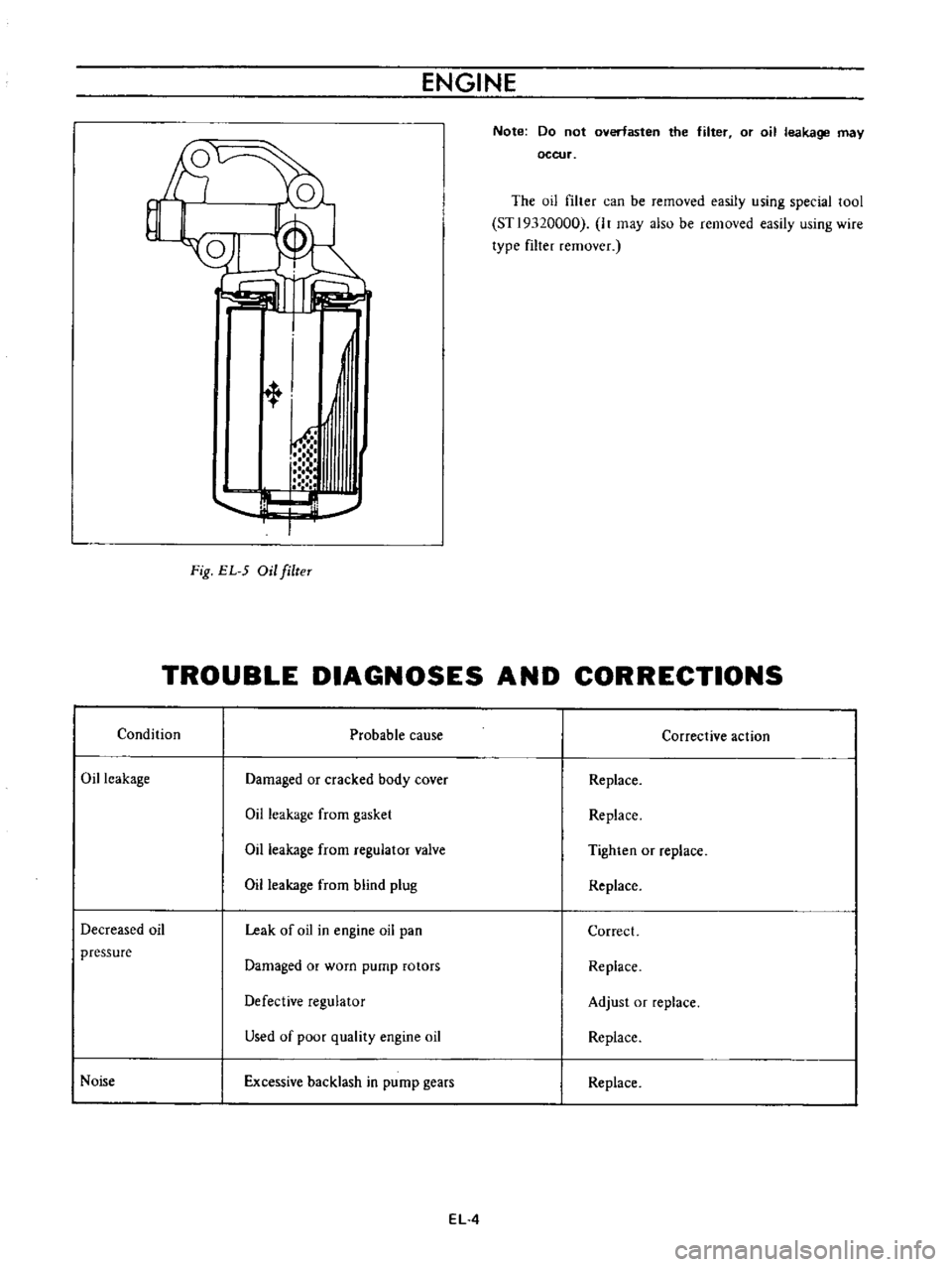

OIL

FILTER

The

oil

filter

is

of

a

cartridge

type

The

oil

filter

is

installed

or

removed

using

special

tool

The

filter

element

and

the

filter

body

are

caulked

together

I

t

must

be

replaced

with

a

new

one

as

an

assembly

When

installing

the

oil

filter

fasten

it

to

the

oil

pump

EL

3

Page 385 of 513

ENGINE

Note

Do

not

oyerlasten

the

filter

or

oil

leakage

may

occur

The

oil

filter

can

be

removed

easily

using

special

tool

STl9320000

It

may

also

be

removed

easily

using

wire

type

filter

remover

l

t

1

h

T

Fig

EL

5

Oil

filteT

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Corrective

action

Oil

leakage

Damaged

or

cracked

body

cover

Replace

Oil

leakage

from

gasket

Replace

Oil

leakage

from

regulator

valve

Tighten

or

replace

Oil

leakage

from

blind

plug

Replace

Decreased

oil

Leak

of

oil

in

engine

oil

pan

Correct

pressure

Damaged

or

worn

pump

rotors

Replace

Defective

regulator

Adjust

or

replace

Used

of

poor

quality

engine

oil

Replace

Noise

Excessive

backlash

in

pump

gears

Replace

EL

4

Page 386 of 513

r

r

J

j

r

I

1

Bi

l

it

1

J

f

J

f

f

r

c

i

I

i

f

4

Y

fj

r

i

SER

V

E

o

r

irJ

fl

i

rt

r

f

c

V

A

M

I

I

U

I

L

WI

F

or

i

7

v

I

1II

i

r

JIt

l

W

1

pI

r

r

1

r

0

j

j

j

t

r

7

f

of

JI

p

Xjlf

ii

i

t

oI

c

J

SECTION

CO

DATSUN

1200

MODEL

8110

SERIES

COOLING

SYSTEM

LNISSAN

I

NI55AN

MOTOR

CO

LTD

TOKYO

JAPAN

COOLING

SYSTEM

co

1

Page 387 of 513

COOLING

SYSTEM

COOLING

SYSTEM

CONTENTS

DESCRIPTION

WATER

PUMP

Removal

THERMOSTAT

Removal

Inspection

CO

1

CO

2

CO

2

CO

2

CO

2

CO

2

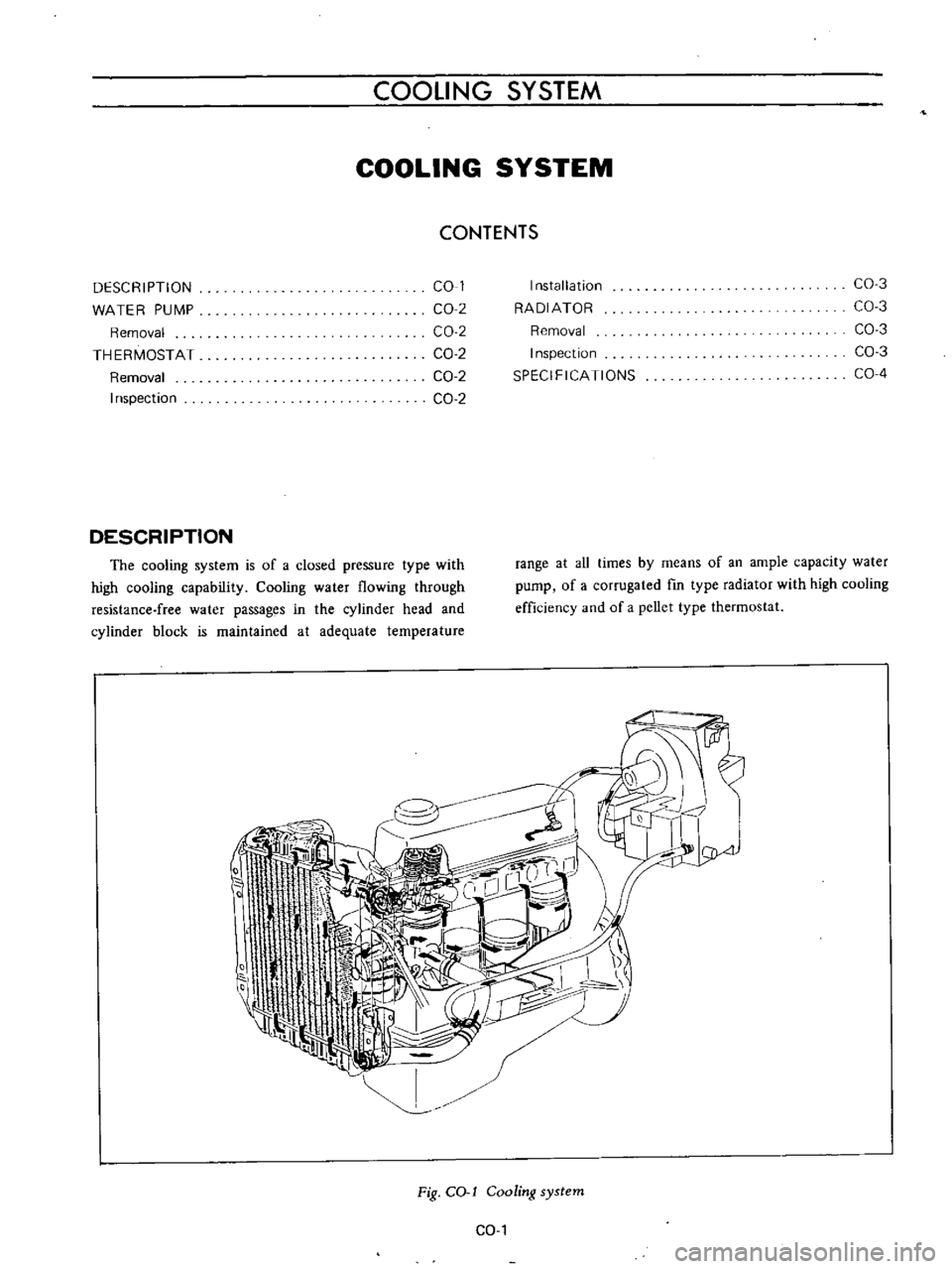

DESCRIPTION

The

cooling

system

is

of

a

closed

pressure

type

with

high

cooling

capability

Cooling

water

flowing

through

resistance

free

water

passages

in

the

cylinder

head

and

cylinder

block

is

maintained

at

adequate

temperature

Installation

RADIATOR

Removal

Inspection

SPECIFICATIONS

CO

3

CO

3

CO

3

CO

3

CO

4

range

at

aU

times

by

means

of

an

ample

capacity

water

pump

of

a

corrugated

fm

type

radiator

with

high

cooling

efficiency

and

of

a

pellet

type

thermostat

I

I

I

0

Jrl

oA

Fig

COol

Cooling

system

CO

I

Page 388 of 513

ENGINE

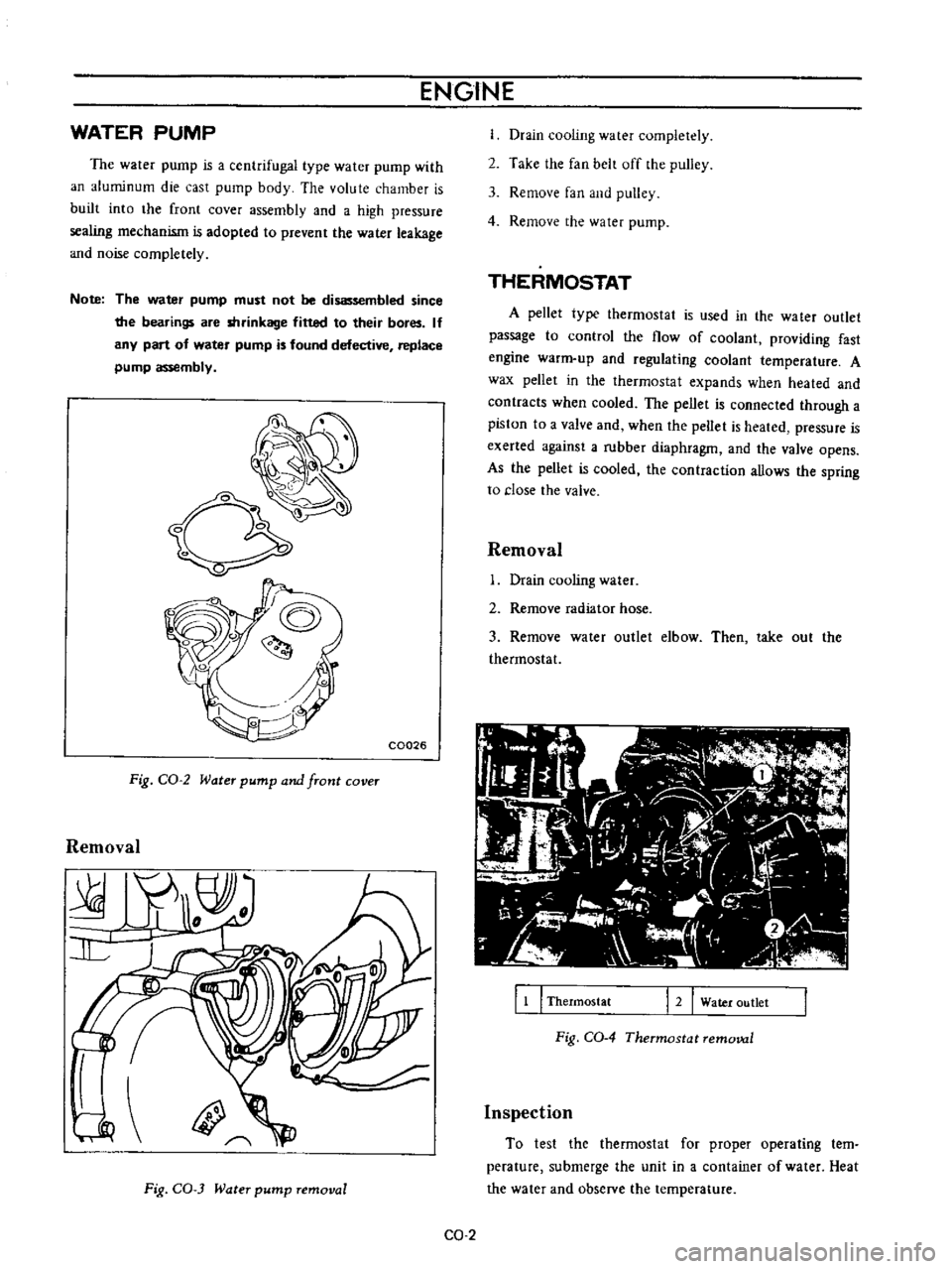

WATER

PUMP

The

water

pump

is

a

centrifugal

type

water

pump

with

an

aluminum

die

cast

pump

body

The

volute

chamber

is

built

into

the

front

cover

assembly

and

a

high

pressure

sealing

mechanism

is

adopted

to

prevent

the

water

leakage

and

noise

completely

Note

The

water

pump

must

not

be

disassembled

since

the

bearings

are

shrinkage

fitted

to

their

bores

If

any

part

of

water

pump

is

found

defective

replace

pump

assembly

o

C0026

Fig

CO

2

Water

pump

and

front

cover

Removal

Fig

CO

3

Water

pump

removal

Drain

cooling

water

completely

2

Take

the

fan

belt

off

the

pulley

3

Remove

fan

and

pulley

4

Remove

the

water

pump

THERMOSTAT

A

pellet

type

thermostat

is

used

in

the

wa

ter

outlet

passage

to

control

the

flow

of

coolant

providing

fast

engine

warm

up

and

regulating

coolant

temperature

A

wax

pellet

in

the

thermostat

expands

when

heated

and

contracts

when

cooled

The

pellet

is

connected

through

a

piston

to

a

valve

and

when

the

peUet

is

heated

pressure

is

exerted

against

a

rubber

diaphragm

and

the

valve

opens

As

the

pellet

is

cooled

the

contraction

allows

the

spring

to

close

the

valve

Removal

Drain

cooling

water

2

Remove

radiator

hose

3

Remove

water

outlet

elbow

Then

take

out

the

thermostat

11

I

Thermostat

12

Water

outlet

Fig

CO

4

Thermostat

removal

Inspection

To

test

the

thermostat

for

proper

operating

tern

perature

submerge

the

unit

in

a

container

of

water

Heat

the

water

and

observe

the

temperature

CO

2

Page 389 of 513

COOLING

SYSTEM

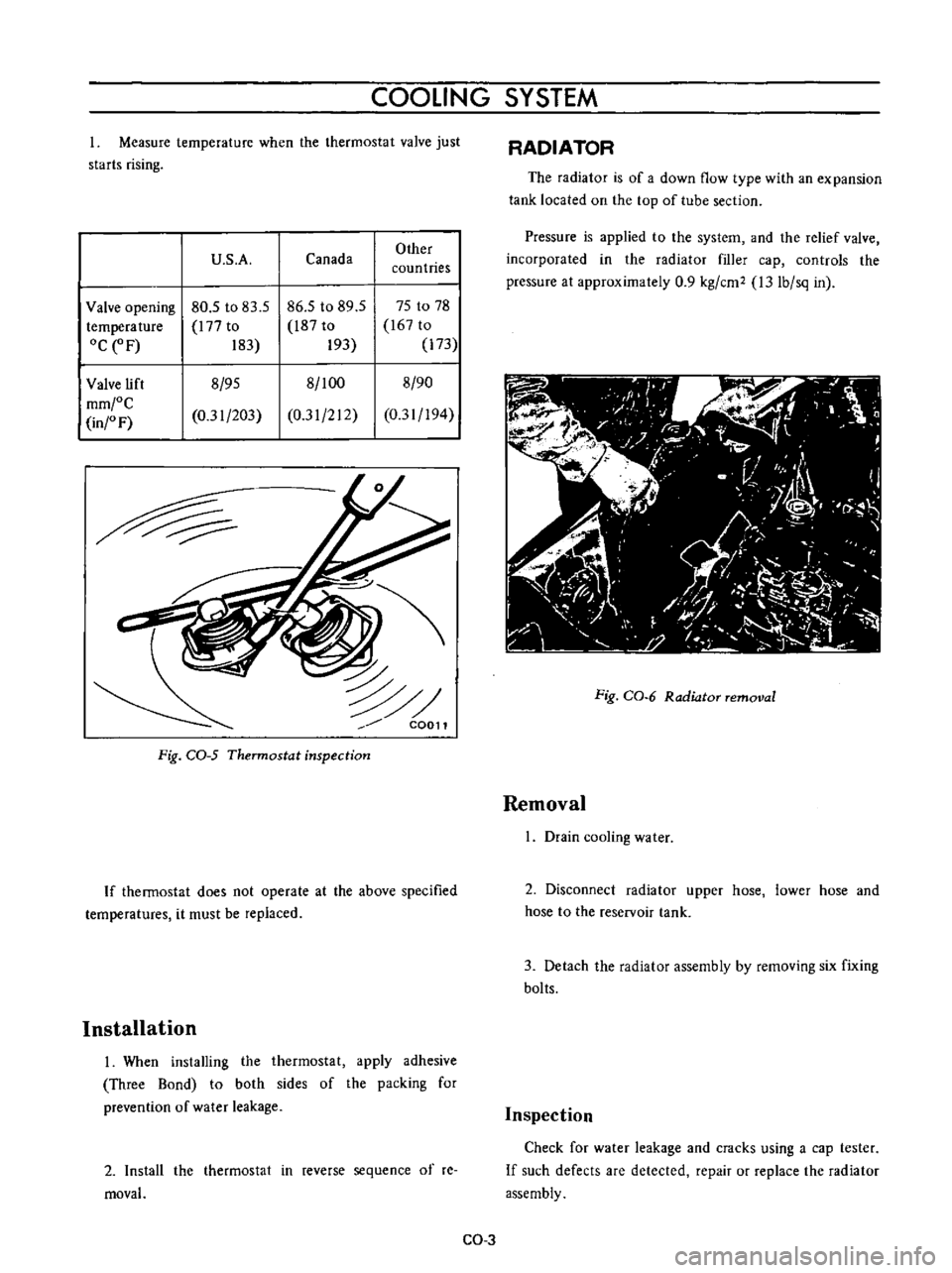

Measure

temperature

when

the

thermostat

valve

just

starts

rising

U

S

A

Canada

Other

countries

Valve

opening

80

5

to

83

5

86

5

to

89

5

75

to

78

temperature

l77

to

l87

to

167

to

OCeF

183

193

173

Valve

lift

8

95

8

100

8

90

mm

C

0

31

203

0

31

212

0

31

194

in

F

C0011

Fig

CQ

5

Thermostat

inspection

If

thermostat

does

not

operate

at

the

above

specified

temperatures

it

must

be

replaced

Installation

I

When

installing

the

thermostat

apply

adhesive

Three

Bond

to

both

sides

of

the

packing

for

prevention

of

water

leakage

2

Install

the

thermostat

in

reverse

sequence

of

re

moval

RADIATOR

The

radiator

is

of

a

down

flow

type

with

an

expansion

tank

located

on

the

top

of

tube

section

Pressure

is

applied

to

the

system

and

the

relief

valve

incorporated

in

the

radiator

filler

cap

controls

the

pressure

at

approximately

0

9

kg

cm2

l3

Ib

sq

in

Fig

CO

6

Radiator

removal

Removal

I

Drain

cooling

water

2

Disconnect

radiator

upper

hose

lower

hose

and

hose

to

the

reservoir

tank

3

Detach

the

radiator

assembly

by

removing

six

fixing

bolts

Inspection

Check

for

water

leakage

and

cracks

using

a

cap

tester

If

such

defects

are

detected

repair

or

replace

the

radiator

assembly

CO

3

Page 390 of 513

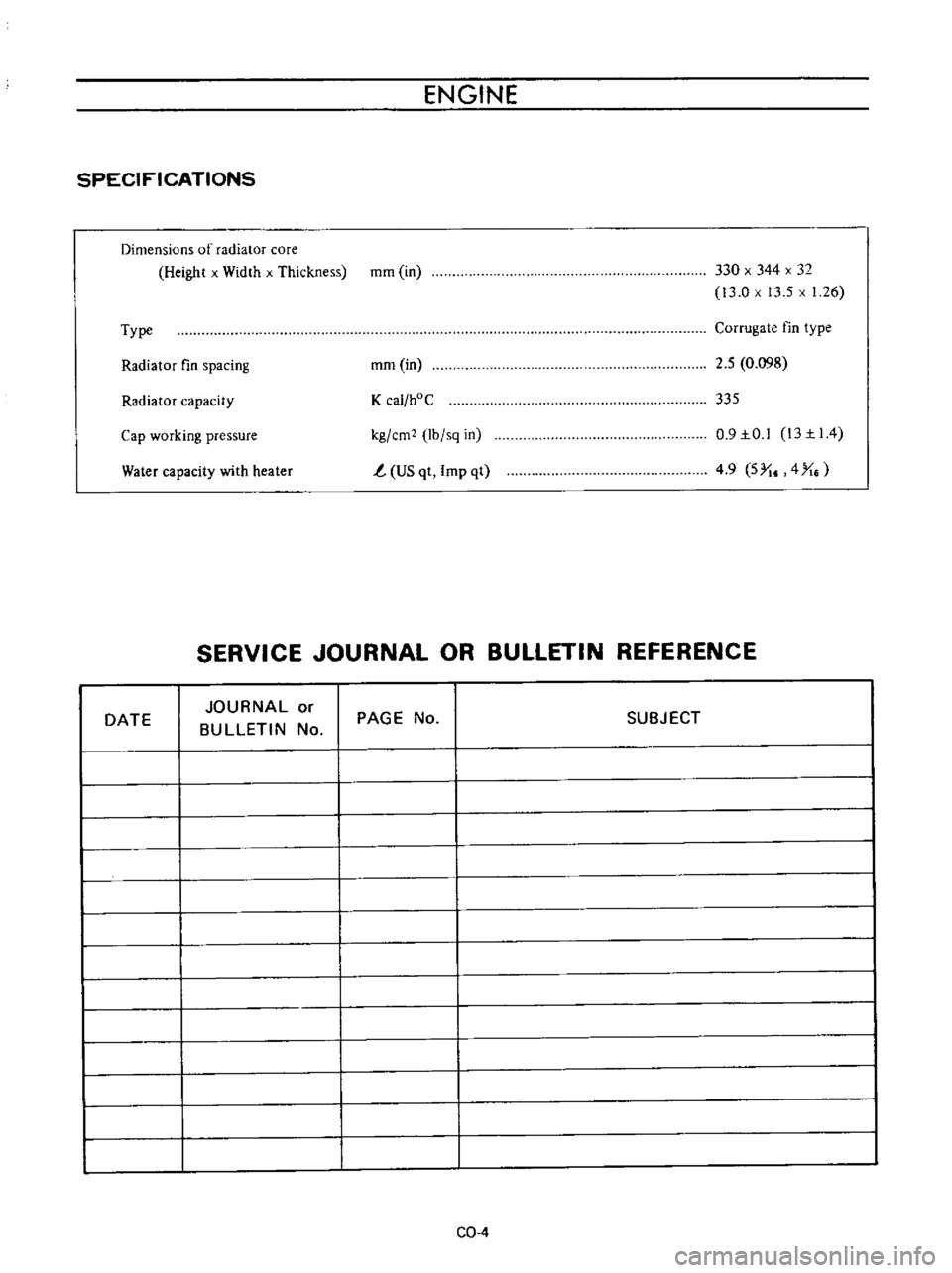

ENGINE

SPECIFICATIONS

Dimensions

of

radiator

core

Height

x

Width

x

Thickness

mm

in

330

x

344

x

32

13

0

x

13

5

x

1

26

Type

Corrugate

fin

type

Radiator

fin

spacing

mm

in

2

5

0

098

Radiator

capacity

K

cal

hoC

335

Water

capacity

with

heater

kg

em

lb

sq

in

t

US

qt

Imp

qt

0

9IO

l

13II4

4

9

5

I

4

X

Cap

working

pressure

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

CQ

4