DATSUN B110 1973 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 371 of 513

ENGINE

MECHANICAL

20

Install

the

push

rods

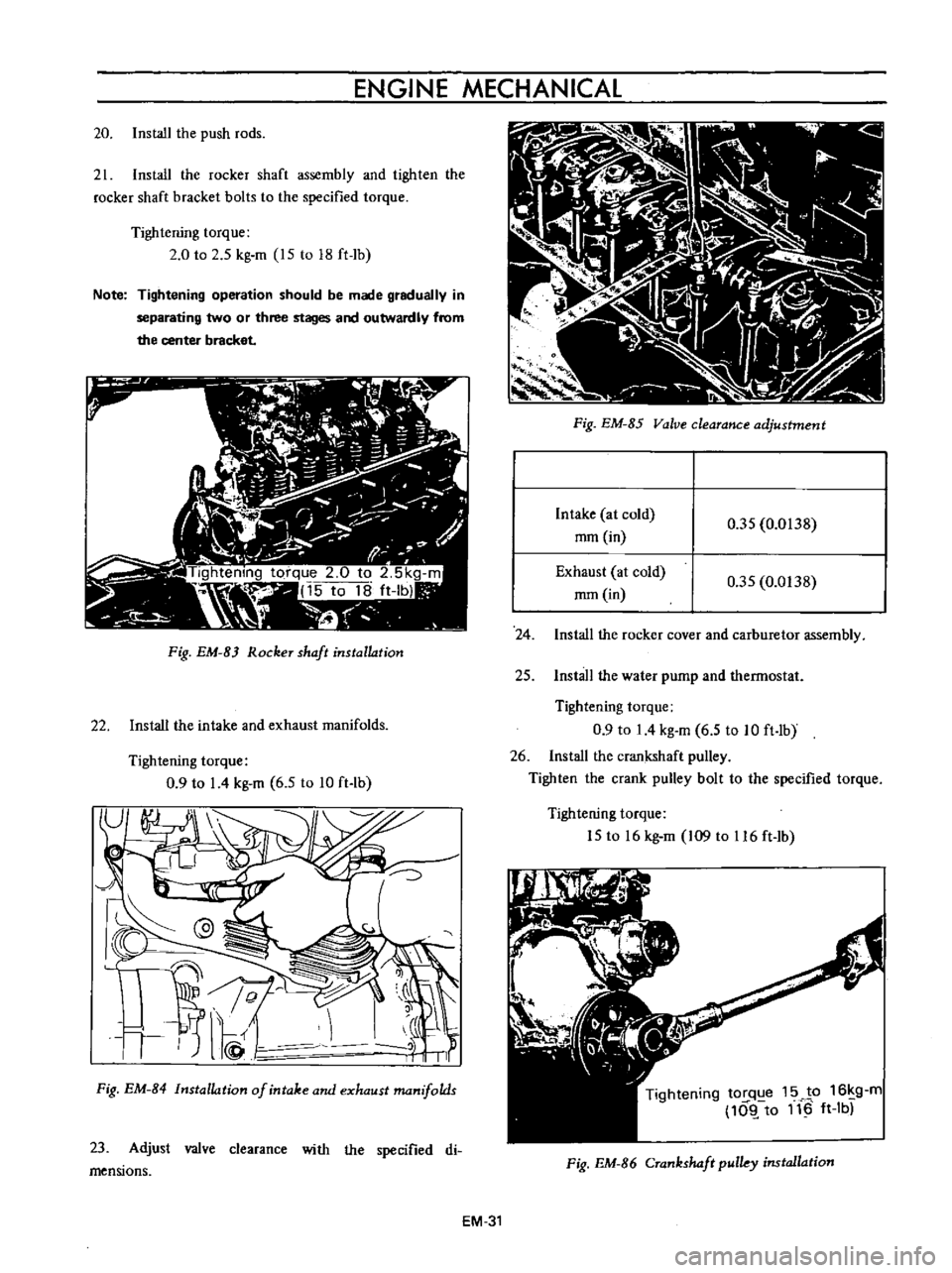

21

Install

the

rocker

shaft

assembly

and

tighten

the

rocker

shaft

bracket

bolts

to

the

specified

torque

Tightening

torque

2

0

to

2

5

kg

m

15

to

18

ft

Ib

Note

Tightening

operation

should

be

made

gradually

in

separating

two

or

three

stages

and

outwardly

from

the

center

bracket

Fig

EM

B

RockeT

shaft

installation

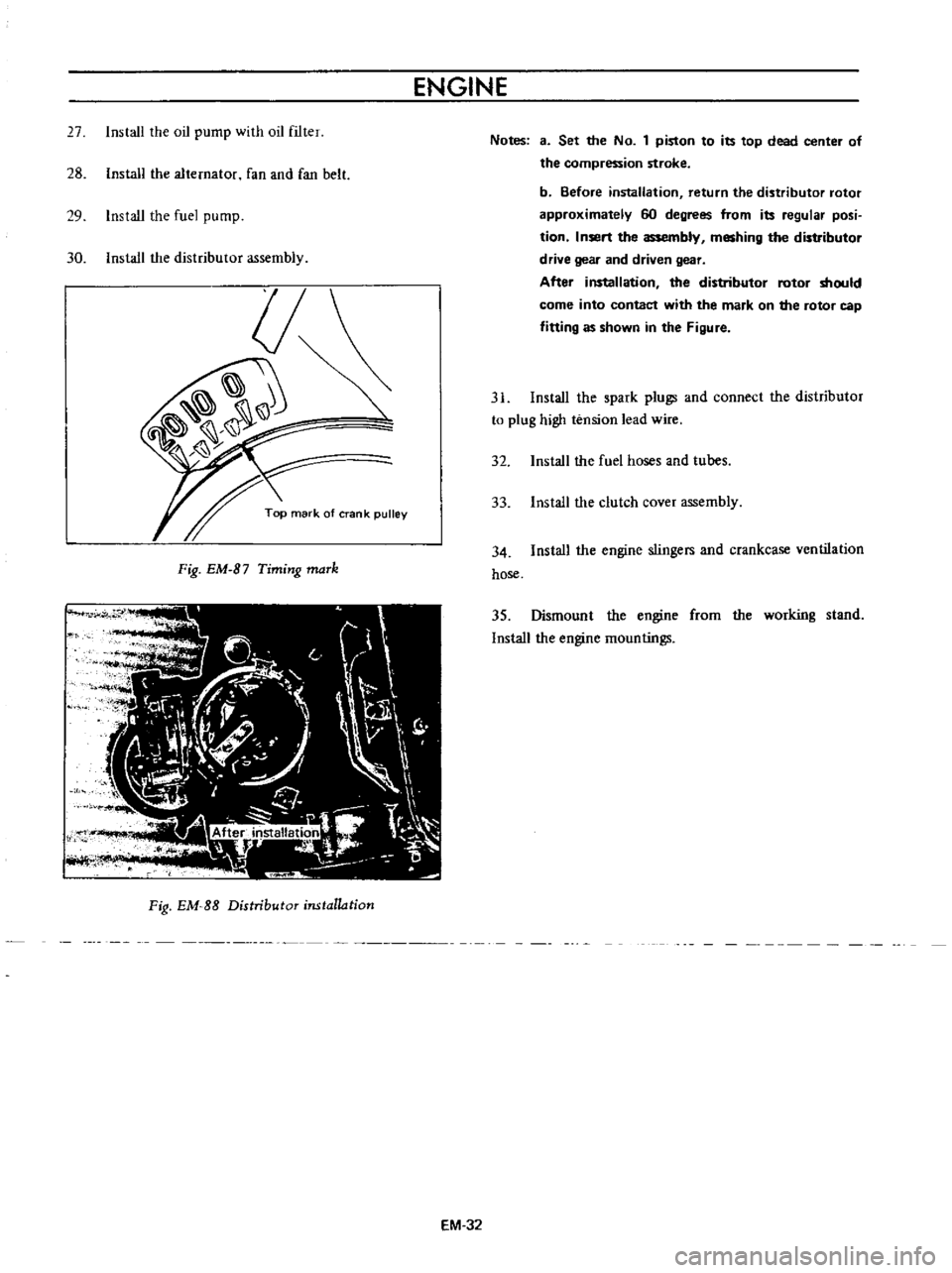

22

Install

the

intake

and

exhaust

manifolds

Tightening

torque

0

9

to

I

4

kg

m

6

5

to

10

ft

lb

Fig

EM

B4

Installation

of

intake

and

exhaust

manifolds

23

Adjust

valve

clearance

with

the

specified

di

mensions

Fig

EM

85

Valve

clearance

adjustment

Intake

at

cold

rom

in

0

35

0

0138

Exhaust

at

cold

rom

in

0

35

0

0138

24

Install

the

rocker

cover

and

carburetor

assembly

25

Install

the

water

pump

and

thermostat

Tightening

torque

0

9

to

I

4

kg

m

6

5

to

10

ft

lb

26

Install

the

crankshaft

pulley

Tighten

the

crank

pulley

bolt

to

the

specified

torque

Tightening

torque

15

to

16

kg

m

109

to

116

ft

lb

Tightening

tOI

q

e

15

JP

16

g

m

10l

to

11

ft

Ib

Fig

EM

B6

CTankshaft

pulky

installation

EM

31

Page 372 of 513

ENGINE

27

Install

the

oil

pump

with

oil

filter

28

Install

the

alternator

fan

and

fan

belt

29

Install

the

fuel

pump

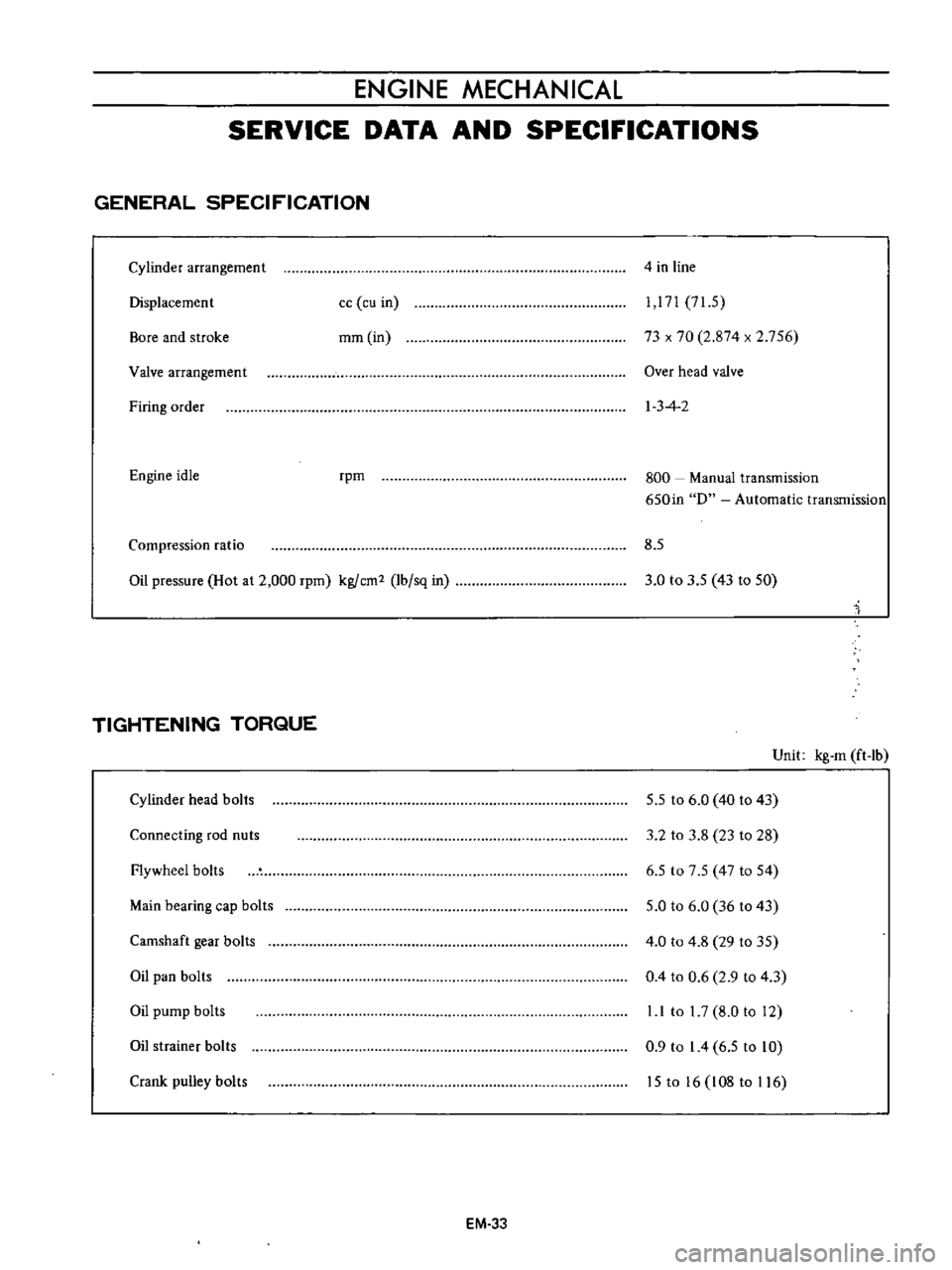

30

Install

the

distributor

assembly

Fig

EM

B7

Timing

maTk

Fig

EM

SS

Distributor

installation

EM

32

Notes

3

Set

the

No

1

piston

to

its

top

dead

center

of

the

compression

stroke

b

Before

installation

return

the

distributor

rotor

approximately

60

degrees

from

its

regular

posi

tion

Insert

the

assembly

meshing

the

distributor

drive

gear

and

driven

gear

After

installation

the

distributor

rotor

should

come

into

contact

with

the

mark

on

the

rotor

cap

fitting

as

shown

in

the

Figure

31

Install

the

spark

plugs

and

connect

the

distributor

to

plug

high

tension

lead

wire

32

Install

the

fuel

hoses

and

tubes

33

Install

the

clutch

cover

assembly

34

Install

the

engine

stingers

and

crankcase

ventilation

hose

35

Dismount

the

engine

from

the

working

stand

Install

the

engine

mountings

Page 373 of 513

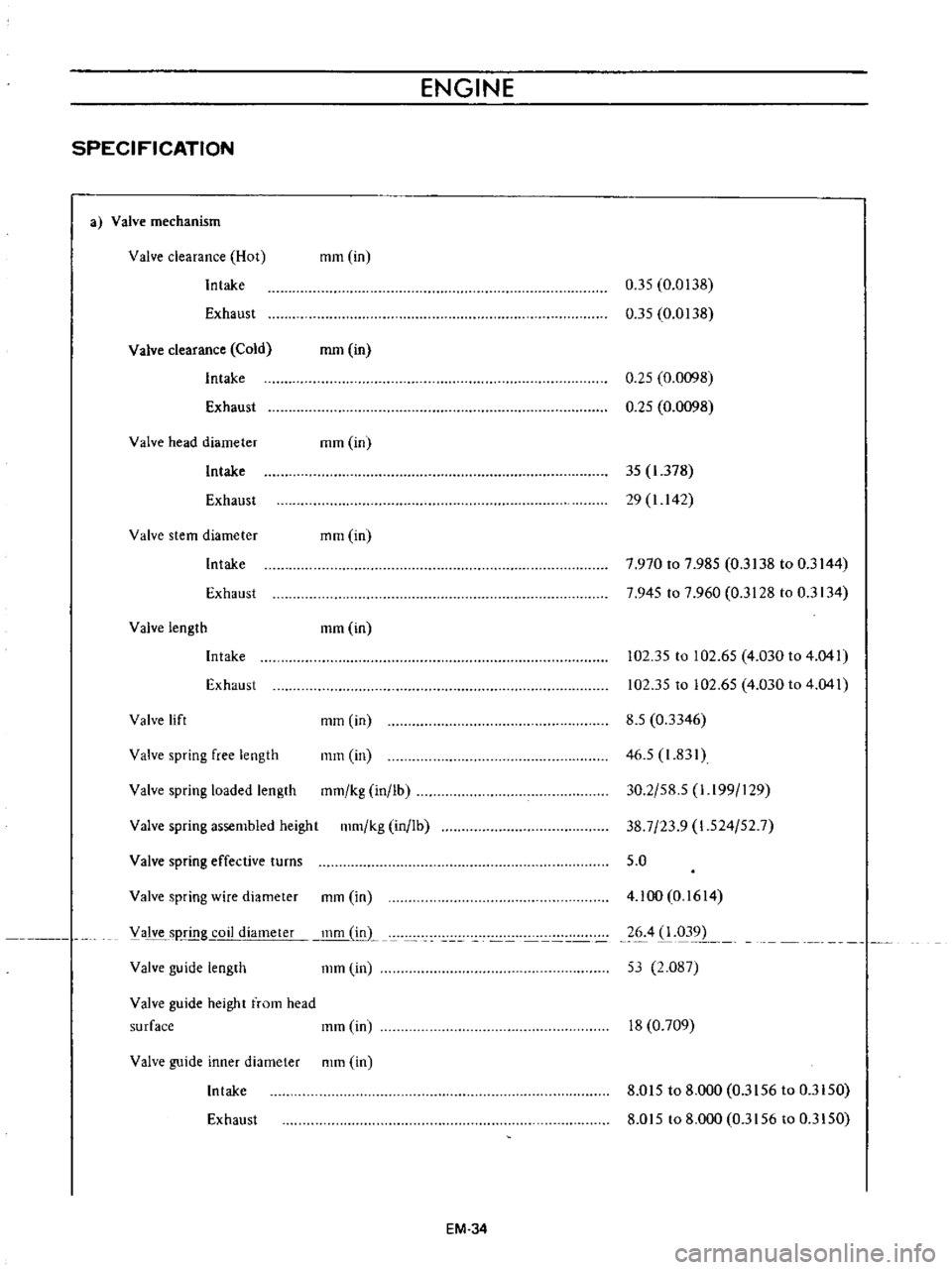

ENGINE

MECHANICAL

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATION

Cylinder

arrangement

4

in

line

Displacement

cc

cu

in

mm

in

1

171

71

5

73

x

70

2

874

x

2

756

Bore

and

stroke

Valve

arrangemen

t

Over

head

valve

Firing

order

I

3

4

2

Engine

idle

rpm

800

Manual

transmission

650in

D

Automatic

transmission

Compression

ratio

8

5

Oil

pressure

Hot

at

2

000

rpm

kgfcm2

Ibfsq

in

3

0

to

3

5

43

to

50

TIGHTENING

TORQUE

Unit

kg

m

ft

lb

Cylinder

head

bolts

Flywheel

bolts

5

5

to

6

0

40

to

43

3

2

to

3

8

23

to

28

6

5

to

7

5

47

to

54

5

0

to

6

0

36

to

43

4

0

to

4

8

29

to

35

0

4

to

0

6

2

9

to

4

3

l

l

to

I

7

8

0

to

12

0

9

to

I

4

6

5

to

10

15

to

16

108

to

116

Connecting

rod

nuts

Main

bearing

cap

bolts

Camshaft

gear

bolts

Oil

pan

bolts

Oil

pump

bolts

Oil

strainer

bolts

Crank

pulley

bolts

EM

33

Page 374 of 513

ENGINE

SPECIFICATION

a

Valve

mechanism

Valve

clearance

Hot

Intake

mm

in

Exhaust

0

35

0

0138

0

35

0

0138

Valve

clearance

Cold

Intake

Exhaust

mm

in

0

25

0

0098

0

25

0

0098

Valve

head

diameter

mm

in

Intake

35

1

378

29

1

142

Exhaust

Valve

stem

diameter

mm

in

Intake

7

970

to

7

985

0

3138

to

0

3144

7

945

to

7

960

0

3128

to

0

3134

Exhaust

Valve

length

mm

in

Intake

Exhaust

102

35

to

102

65

4

030

to

4

041

102

35

to

102

65

4

030

to

4

041

Valve

spring

assembled

height

111m

kg

in

lb

8

5

0

3346

46

5

1

831

30

2

58

5

1

I99

129

38

7

23

9

1

524

52

7

5

0

Valve

lift

mm

in

Valve

spring

free

length

mm

in

Valve

spring

loaded

length

mm

kg

in

lb

Valve

spring

effective

turns

Valve

guide

length

111m

in

4

100

0

1614

26

4

1

031

1

53

2

087

Valve

spring

wire

diameter

mm

in

V

alve

sp

g

coil

diameter

inm

L

Valve

guide

height

from

head

surface

111m

in

18

0

709

Valve

guide

inner

diameter

mm

in

Intake

8

015

to

8

000

0

3156

to

0

3150

Exhaust

8

015

to

8

000

0

3156

to

0

3150

EM

34

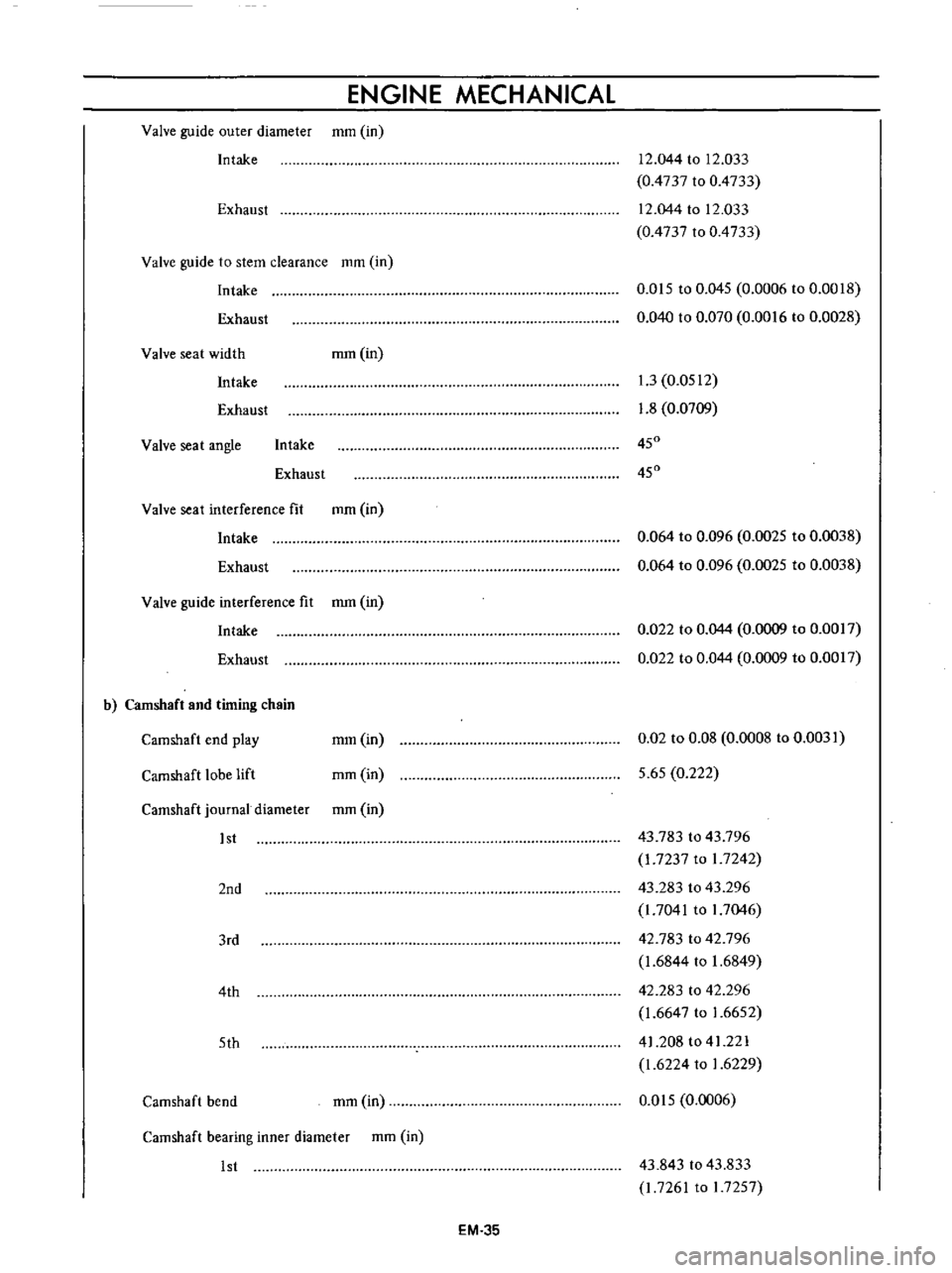

Page 375 of 513

ENGINE

MECHANICAL

Valve

guide

outer

diameter

mm

in

Intake

12

044

to

12

033

0

4737

to

0

4733

Exhaust

12

044

to

12

033

0

4737

to

0

4733

Valve

guide

to

stem

clearance

mm

in

Exhaust

O

oJ5

to

0

045

0

0006

to

0

0018

0

040

to

0

070

0

0016

to

0

0028

Intake

Valve

seat

width

Intake

Exhaust

mm

in

1

3

0

0512

1

8

0

0709

Valve

sea

tangle

Intake

450

Exhaust

450

Valve

seat

interference

fit

mm

in

Intake

0

064

to

0

096

0

0025

to

0

0038

Exhaust

0

064

to

0

096

0

0025

to

0

0038

Valve

guide

interference

fit

rom

in

Intake

Exhaust

0

022

to

0

044

0

0009

to

0

0017

0

022

to

0

044

0

0009

to

0

0017

b

Camshaft

and

timing

chain

Camshaft

lobe

lift

mm

in

mm

in

0

02

to

0

08

0

0008

to

0

0031

Camshaft

end

play

5

65

0

222

Camshaft

journal

diameter

mm

in

1st

43

783

to

43

796

I

7237

to

I

7242

2nd

43

283

to

43

296

1

7041

to

1

7046

3rd

42

783

to

42

796

1

6844

to

1

6849

4th

42

283

to

42

296

1

6647

to

1

6652

5th

41

208

to

41

221

1

6224

to

1

6229

Camshaft

bend

mm

in

0

015

0

0006

Camshaft

bearing

inner

diameter

mm

in

1st

43

843

to

43

833

I

7261

to

1

7257

EM

35

Page 376 of 513

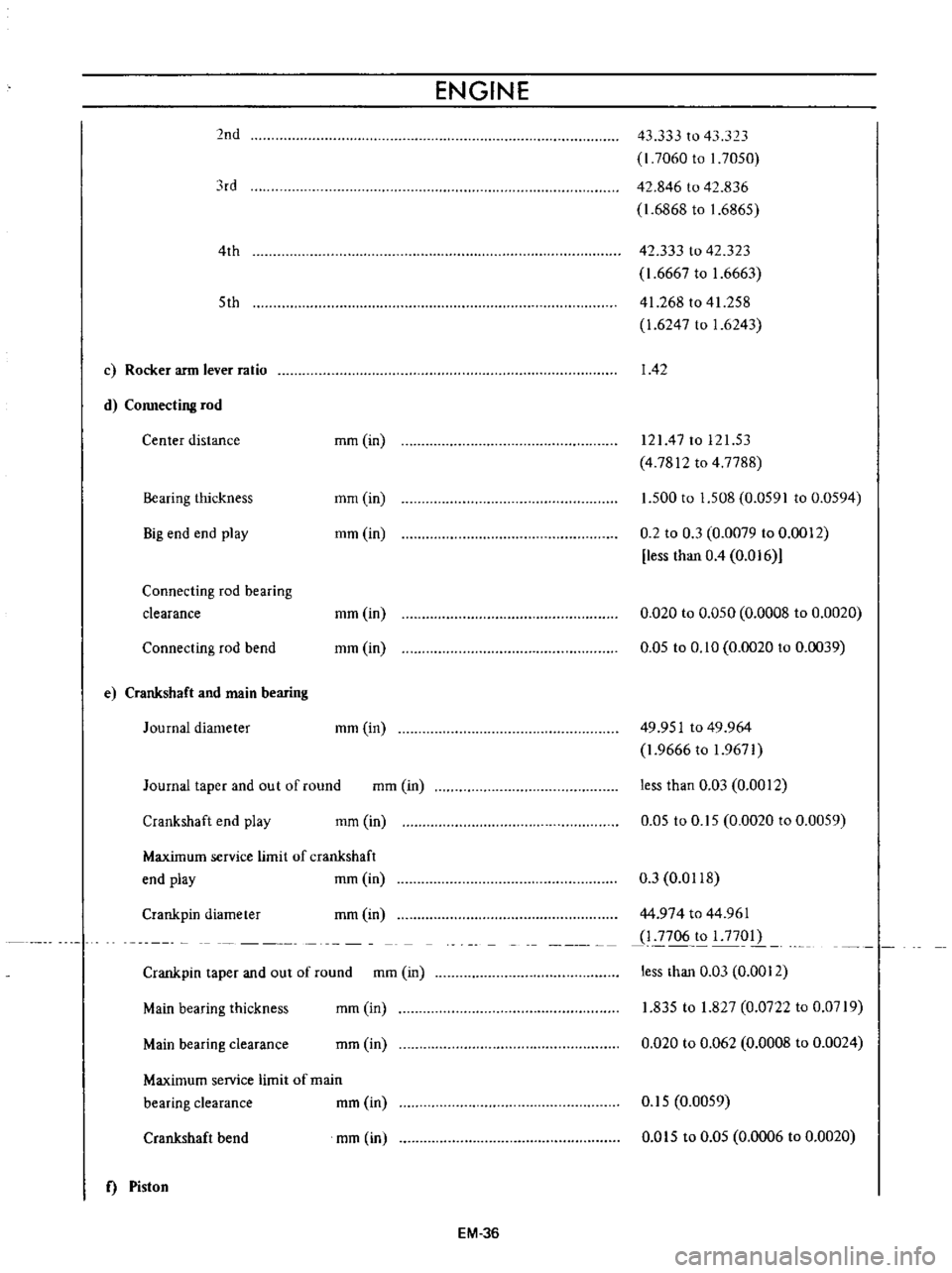

2nd

lrd

4th

5th

c

Rocker

arm

lever

ratio

d

Connecting

rod

Center

distance

Bearing

thickness

Big

end

end

play

Connecting

rod

bearing

clearance

Connecting

rod

bend

e

Crankshaft

and

main

bearing

Journal

diameter

Journal

taper

and

out

of

round

Crankshaft

end

play

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

Maximum

service

limit

of

crankshaft

mm

in

end

play

Crank

pin

diameter

mm

in

Main

bearing

thickness

Crank

pin

taper

and

out

of

round

mm

in

mm

in

Main

bearing

clearance

mm

in

Maximum

seIVice

limit

of

main

bearing

clearance

mm

in

Crankshaft

bend

f

Piston

mm

in

ENGINE

43

333

to

43

323

l

7060

to

I

7050

42

846

to

42

836

1

6868

to

1

6865

42

333

to

42

323

1

6667

to

1

6663

41

268

to

41

258

1

6247

to

1

6243

142

12147

to

121

53

4

7812

to

4

7788

1

500

to

1

508

0

0591

to

0

0594

0

2

to

0

3

0

0079

to

0

0012

less

than

0

4

0

016

0

020

to

0

050

0

0008

to

0

0020

0

05

to

0

10

0

0020

to

0

0039

49

951

to

49

964

1

9666

to

1

9671

less

than

0

03

0

0012

0

05

to

0

15

0

0020

to

0

0059

0

3

0

0118

44

974

to

44

961

1

2706

1

177012

less

than

0

03

0

0012

1

835

to

1

827

0

0722

to

0

0719

0

020

to

0

062

0

0008

to

0

0024

0

15

0

0059

0

Gl5

to

0

05

0

0006

to

0

0020

EM

36

Page 377 of 513

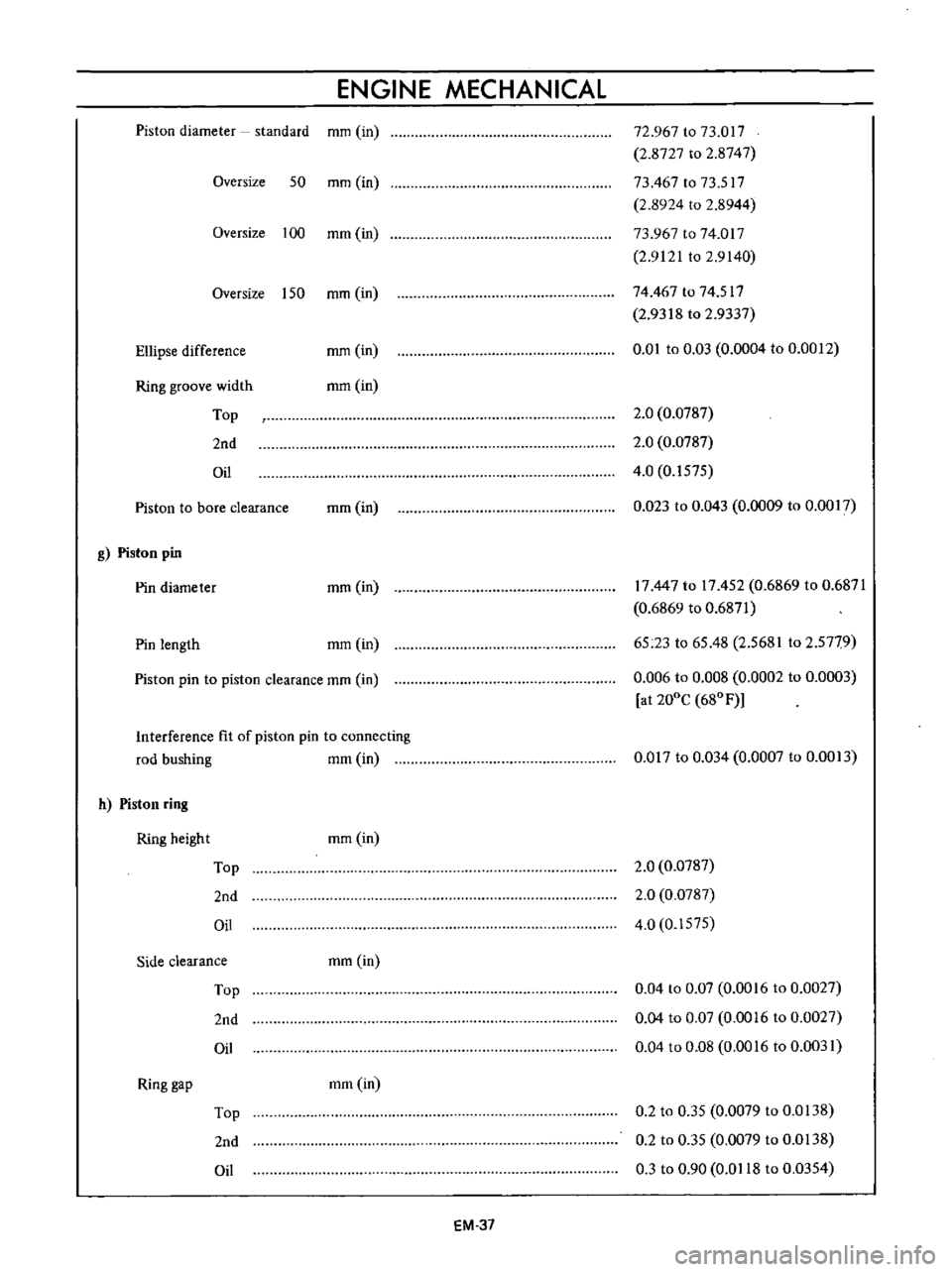

ENGINE

MECHANICAL

Piston

diameter

standard

mm

in

Oversize

50

mm

in

Oversize

100

mm

in

Oversize

150

mm

in

Ellipse

difference

mm

in

Ring

groove

width

Top

2nd

Oil

mm

in

Piston

to

bore

clearance

mm

in

g

Piston

pin

Pin

diameter

mm

in

Pin

length

mm

in

Piston

pin

to

piston

clearance

mm

in

Interference

fit

of

piston

pin

to

connecting

rod

bushing

mm

in

h

Piston

ring

Ring

height

Top

2nd

Oil

mm

in

Side

clearance

mm

in

Top

2nd

Oil

Ring

gap

mm

in

Top

2nd

Oil

EM

37

72

967

to

73

017

2

8727

to

2

8747

73

467

to

73

517

2

8924

to

2

8944

73

967

to

74

017

2

9121

to

2

9140

74

467

to

74

517

2

9318

to

2

9337

0

01

to

0

03

0

0004

to

0

0012

2

0

0

0787

2

0

0

0787

4

0

0

1575

0

023

to

0

043

0

0009

to

0

0017

17

447

to

17

452

0

6869

to

0

6871

0

6869

to

0

6871

65

23

to

65

48

2

5681

to

2

5779

0

006

to

0

008

0

0002

to

0

0003

at

200e

680

F

0

017

to

0

034

0

0007

to

0

0013

2

0

0

0787

2

0

0

0787

4

0

0

1575

0

04

to

0

07

0

0016

to

0

0027

0

04

to

0

07

0

0016

to

0

0027

0

04

to

0

08

0

0016

to

0

0031

0

2

to

0

35

0

0079

to

0

0138

0

2

to

0

35

0

0079

to

0

0138

0

3

to

0

90

0

0118

to

0

0354

Page 378 of 513

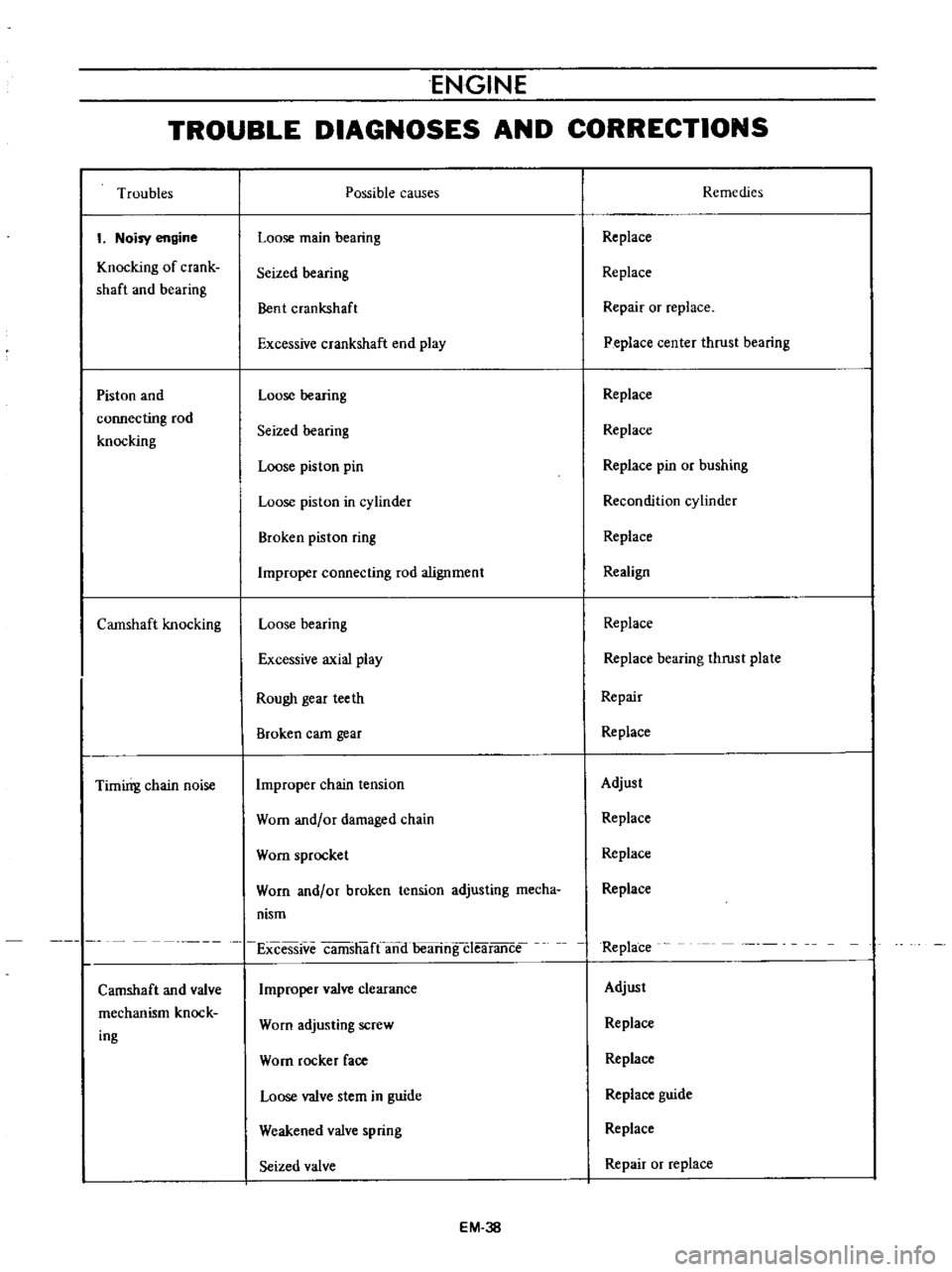

ENGINE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Troubles

I

Noisy

engine

Knocking

of

crank

shaft

and

bearing

Piston

and

connecting

rod

knocking

Camshaft

knocking

Timirrg

chain

noise

Camshaft

and

valve

mechanism

knock

ing

Possible

causes

Loose

main

bearing

Seized

bearing

Bent

crankshaft

Excessive

crankshaft

end

play

Loose

bearing

Seized

bearing

Loose

piston

pin

Loose

piston

in

cylinder

Broken

piston

ring

Improper

connecting

rod

alignment

Loose

bearing

Excessive

axial

play

Rough

gear

teeth

Broken

eam

gear

Improper

chain

tension

Worn

and

or

damaged

chain

Worn

sprocket

Worn

and

or

broken

tension

adjusting

mecha

nism

Excessive

camsh

ifCano

bearing

cIearance

Improper

valve

clearance

Worn

adjusting

screw

Worn

rocker

face

Loose

valve

stem

in

guide

Weakened

valve

spring

Seized

valve

EM

38

Remedies

Replace

Replace

Repair

or

replace

Peplace

center

thrust

bearing

Replace

Replace

Replace

pin

or

bushing

Recondition

cylinder

Replace

Realign

Replace

Replace

bearing

thrust

plate

Repair

Replace

Adjust

Replace

Replace

Replace

Replace

Adjust

Replace

Replace

Replace

guide

Replace

Repair

or

replace

Page 379 of 513

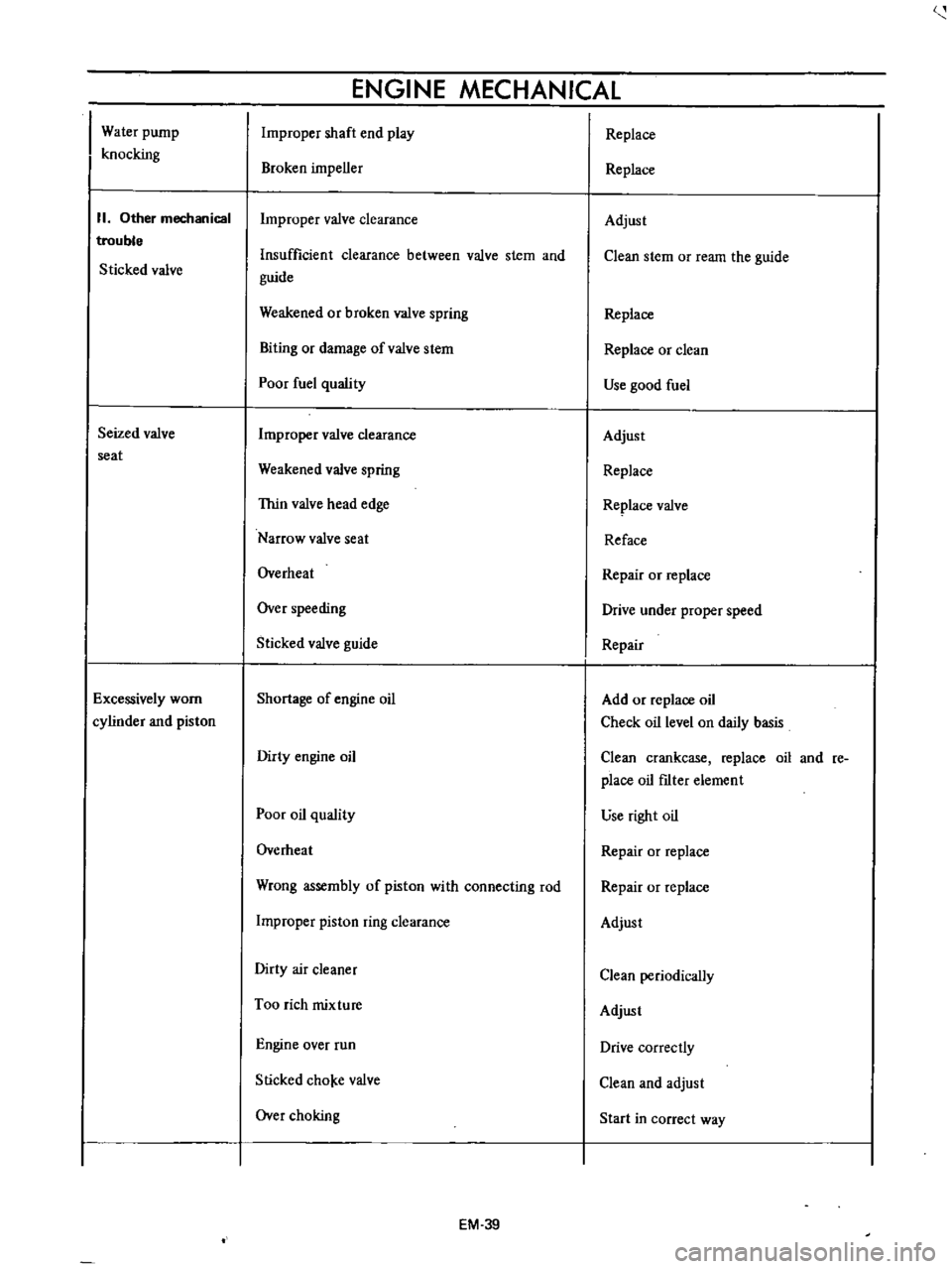

Water

pump

knocking

II

Other

mechanical

trouble

Sticked

valve

Seized

valve

seat

Excessively

worn

cylinder

and

piston

ENGINE

MECHANICAL

Improper

shaft

end

play

Broken

impeller

Improper

valve

clearance

Insufficient

clearance

between

valve

stem

and

guide

Weakened

or

broken

valve

spring

Biting

or

damage

ofvalve

stem

Poor

fuel

quality

Improper

valve

clearance

Weakened

valve

spring

Thin

valve

head

edge

Narrow

valve

seat

Overheat

Over

speeding

Sticked

valve

guide

Shortage

of

engine

oil

Dirty

engine

oil

Poor

oil

quality

Overheat

Wrong

assembly

of

piston

with

connecting

rod

Improper

piston

ring

clearance

Dirty

air

cleaner

Too

rich

mixture

Engine

over

run

Slicked

cho

e

valve

Over

choking

EM

39

Replace

Replace

Adjust

Clean

stem

or

ream

the

guide

Replace

Replace

or

clean

Use

good

fuel

Adjust

Replace

Replace

valve

Reface

Repair

or

replace

Drive

under

proper

speed

Repair

Add

or

replace

oil

Check

oil

level

on

daily

basis

Clean

crankcase

replace

oil

and

re

place

oil

fIlter

element

use

right

oil

Repair

or

replace

Repair

or

replace

Adjust

Clean

periodically

Adjust

Drive

correctly

Clean

and

adjust

Start

in

correct

way

Page 380 of 513

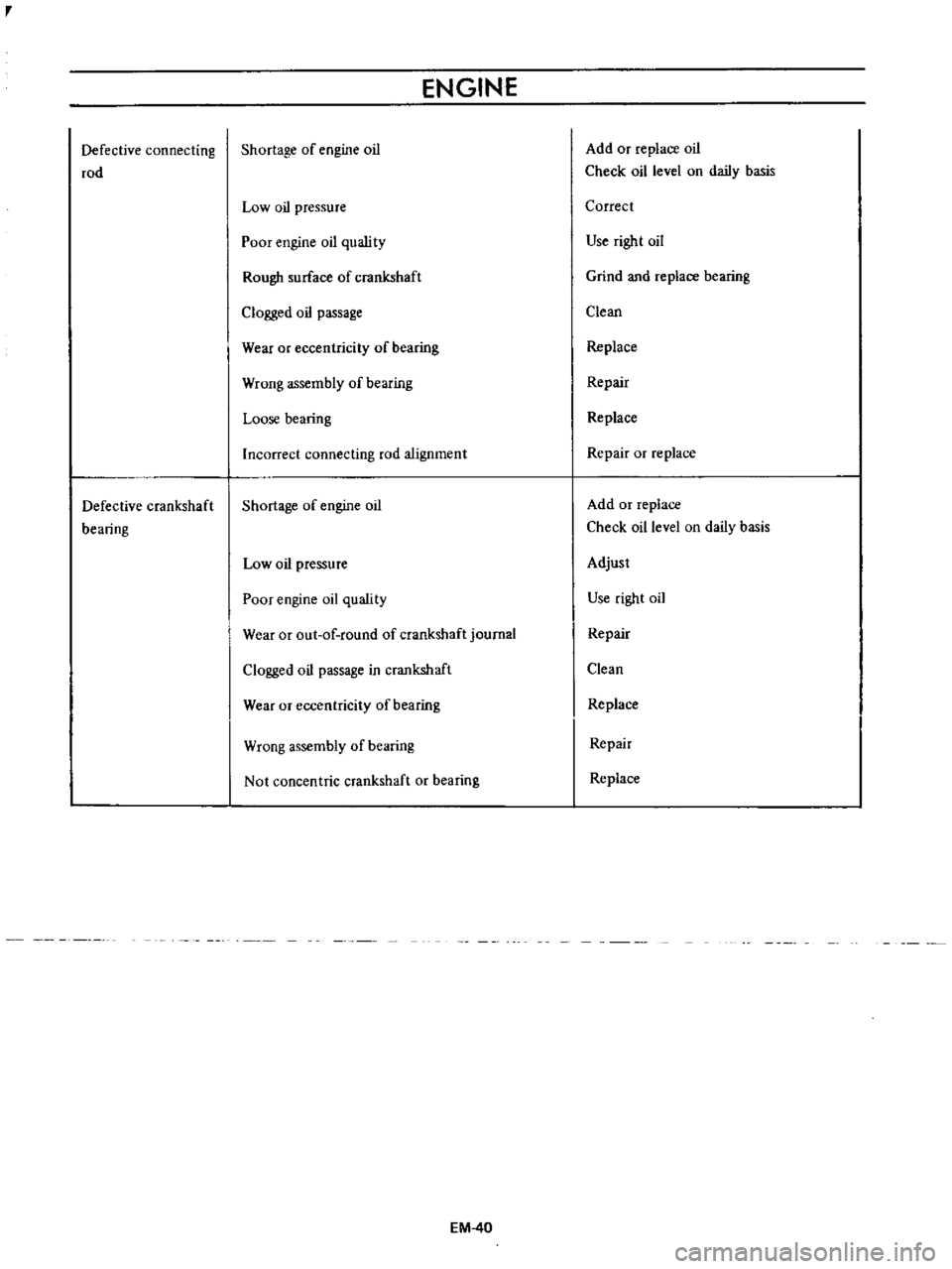

r

Defective

connecting

rod

Defective

crankshaft

bearing

ENGINE

Shortage

of

engine

oil

Low

oil

pressure

Poor

engine

oil

quslity

Rough

surface

of

crankshaft

Clogged

oil

passage

Wear

or

eccentricity

of

bearing

Wrong

assembly

of

bearing

Loose

bearing

Incorrect

connecting

rod

alignment

Shortage

of

engine

oil

Low

oil

pressure

Poor

engine

oil

quality

Wear

or

out

of

round

of

crankshaft

journal

Clogged

oil

passage

in

crankshaft

Wear

or

eccentricity

of

bearing

Wrong

assembly

of

bearing

Not

concentric

crankshaft

or

bearing

EM

40

Add

or

replace

oil

Check

oil

level

on

daily

basis

Correct

Use

right

oil

Grind

and

replace

bearing

Clean

Replace

Repair

Replace

Repair

or

replace

Add

or

replace

Check

oil

level

on

daily

basis

Adjust

Use

right

oil

Repair

Clean

Replace

Repair

Replace