DATSUN B110 1973 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 451 of 513

ENGINE

ElECTRICAL

SYSTEM

CHECKING

AND

ADJUSTMENT

Cap

and

rotor

head

Cap

and

rotor

head

must

always

be

kept

clean

to

maintain

good

insulation

durability

since

high

tension

voltage

from

ignition

coil

is

imposed

on

them

Sometimes

inside

of

the

cap

and

rotor

head

is

covered

with

fine

carbon

particles

and

dust

Whenever

crack

or

trace

of

leakage

is

found

on

the

cap

replace

with

a

new

one

Recommend

the

rotor

head

also

be

replaced

with

a

new

one

if

excessively

damaged

Point

When

point

surface

is

roughened

due

to

burning

polish

with

a

fine

emery

paper

No

500

or

600

or

oil

stone

When

the

point

is

worn

excessively

replace

When

the

point

is

replaced

with

a

new

one

apply

grease

to

the

arm

pivot

receiver

and

earn

surface

For

causes

of

damaged

burnt

point

improper

point

contact

insufficient

point

gap

and

defective

condenser

are

considered

The

standard

point

gap

is

0

45

to

0

55

mm

0

0177

to

0

0217

in

When

gap

is

deviated

from

the

standard

gap

adjust

Turn

the

shaft

to

a

position

where

the

breaker

arm

heel

rides

the

com

lug

a

position

where

point

gap

is

maximum

loosen

the

gap

adjusting

screw

apply

a

thickness

gauge

between

contacts

and

adjust

to

the

standard

point

gap

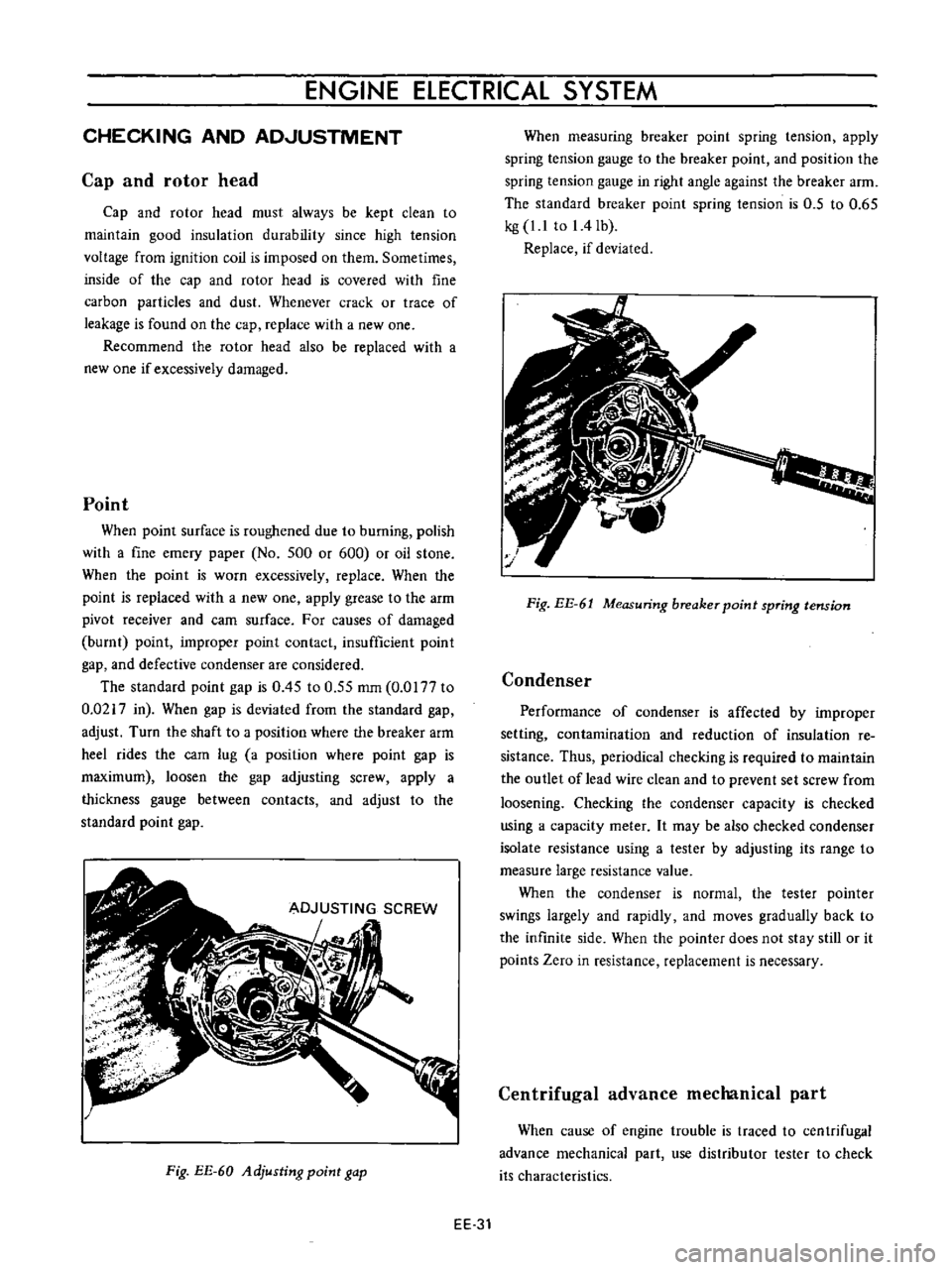

Fig

EE

60

Adjusting

point

gap

When

measuring

breaker

point

spring

tension

apply

spring

tension

gauge

to

the

breaker

point

and

position

the

spring

tension

gauge

in

right

angle

against

the

breaker

arm

The

standard

breaker

point

spring

tension

is

0

5

to

0

65

kg

1

1

to

I

4Ib

Replace

if

deviated

Fig

EE

61

Measuring

breaker

point

spring

tension

Condenser

Performance

of

condenser

is

affected

by

improper

setting

contamination

and

reduction

of

insulation

re

sistance

Thus

periodical

checking

is

required

to

maintain

the

outlet

of

lead

wire

clean

and

to

prevent

set

screw

from

loosening

Checking

the

condenser

capacity

is

checked

using

a

capacity

meter

It

may

be

also

checked

condenser

isolate

resistance

using

a

tester

by

adjusting

its

range

to

measure

large

resistance

value

When

the

condenser

is

normal

the

tester

pointer

swings

largely

and

rapidly

and

moves

gradually

back

to

the

infinite

side

When

the

pointer

does

not

stay

still

or

it

points

Zero

in

resistance

replacement

is

necessary

Centrifugal

advance

mechanical

part

When

cause

of

engine

trouble

is

traced

to

centrifugal

advance

mechanical

part

use

distributor

tester

to

check

its

characteristics

EE

31

Page 452 of 513

ENGINE

When

nothing

is

wrong

with

its

characteristics

con

ceivable

causes

are

defectiveness

or

abnormal

wearing

of

driving

part

or

others

Do

not

disassemble

it

When

characteristics

are

improper

check

earn

as

sembly

governor

weight

shaft

and

governor

spring

and

other

relative

parts

carefully

When

reassembling

the

centrifugal

advance

mechanical

part

be

sure

to

check

advance

characteristics

by

the

use

of

a

distributor

tester

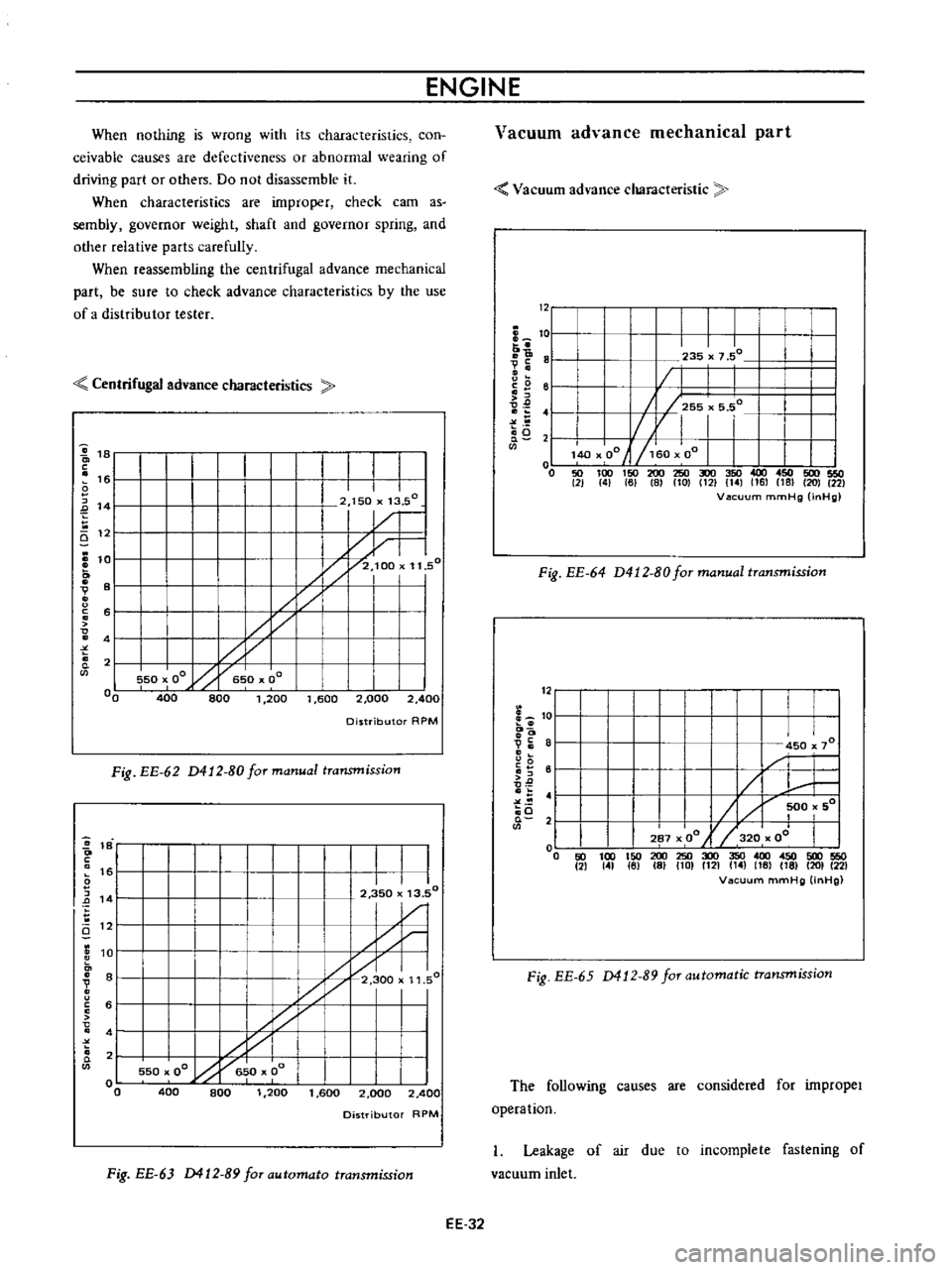

Centrifugal

advance

characteristics

1

c

1

Ei

12

L

o

V

o

u

c

o

o

t

D

c

s

151

14

e

101

0

81

V

0

u

c

51

0

41

t

0

Q

2

01

0

I

I

I

1

rj

11

50

I

J

2

100

50

oQ

5

00

400

800

1

200

1

600

2

00

Distributor

RPM

Fig

EE

62

D412

80formanual

transmission

I

I

I

2

350

13

50

1

1

1

300

1

1

550

00

h

6

0

0

I

400

800

1

200

1

600

2

000

Distributor

RPM

Fig

EE

63

D412

B9

faT

automata

transmission

2

400

I

11

50

2

400

EE

32

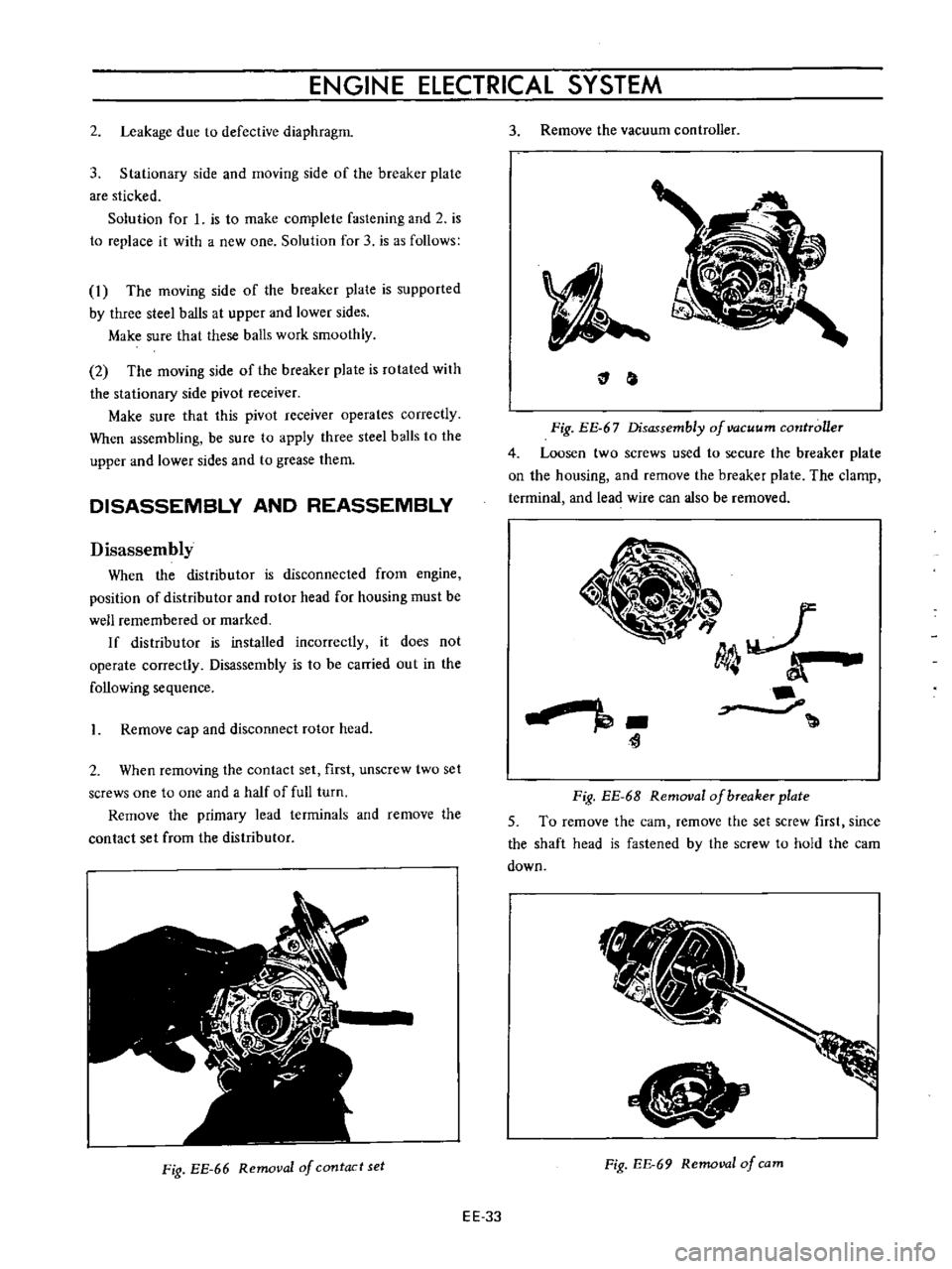

Vacuum

advance

mechanical

part

Vacuum

ad

ance

characteristic

12

I

I

I

I

I

II1

5515

5Q

i

01

40

00

i1j

50

00

1

I

o

50

100

150

200

250

300

350

400

450

500

550

21

41

6

8

101

C121

141

161

181

201

22

V2Icuum

mmHg

inHg

I

I

I

I

7

50

1

1Q

Ii

V

I

o

0

u

i

e

6

tI

2

o

i5

0

235

Fig

EE

64

D412

80

for

manual

transmission

c

1

0

I

o

9i

8

o

u

0

i

61

0

0

0

4

o

Q

2

I

I

I

450

x

70

L

H

1

500

501

287

00

l

320

oJ

I

I

200250300350400450500550

IS

101

1121

t4

16

16

1201

22

Vacuum

mmHg

OnHg

o

50

100

150

2

141

161

Fig

EE

65

0412

89

for

automatic

transmission

The

following

causes

are

considered

for

impropeI

opera

tion

I

Leakage

of

air

due

to

incomplete

fastening

of

vacuum

inlet

Page 453 of 513

ENGINE

ElECTRICAL

SYSTEM

2

Leakage

due

to

defective

diaphragm

3

Stationary

side

and

moving

side

of

the

breaker

plate

are

sticked

Solution

for

1

is

to

make

complete

fastening

and

2

is

to

replace

it

with

a

new

one

Solution

for

3

is

as

follows

I

The

moving

side

of

the

breaker

plate

is

supported

by

three

steel

balls

at

upper

and

lower

sides

Make

sure

that

these

balls

work

smoothly

2

The

moving

side

of

the

breaker

plate

is

rotated

with

the

stationary

side

pivot

receiver

Make

sure

that

this

pivot

receiver

operates

correctly

When

assembling

be

sure

to

apply

three

steel

balls

to

the

upper

and

lower

sides

and

to

grease

them

DISASSEMBLY

AND

REASSEMBLY

Disassembly

When

the

distributor

is

disconnected

from

engine

position

of

distributor

and

rotor

head

for

housing

must

be

weB

remembered

or

marked

If

distributor

is

installed

incorrectly

it

does

not

operate

correctly

Disassembly

is

to

be

carried

out

in

the

following

sequence

I

Remove

cap

and

disconnect

rotor

head

2

When

removing

the

contact

set

first

unscrew

two

set

screws

one

to

one

and

a

half

of

full

turn

Remove

the

primary

lead

terminals

and

remove

the

contact

set

from

the

distributor

Fig

EE

66

Removal

of

contact

set

EE

33

3

Remove

the

vacuum

controller

Fig

EE

67

Disassembly

of

vacuum

controller

4

Loosen

two

screws

used

to

secure

the

breaker

plate

on

the

housing

and

remove

the

breaker

plate

The

clamp

terminal

and

lead

wire

can

also

be

removed

r

Fig

EE

6B

Removal

ofbTeaker

plate

5

To

remove

the

earn

remove

the

set

screw

first

since

the

shaft

head

is

fastened

by

the

screw

to

hold

the

cam

down

Fig

EE

69

Removal

of

cam

Page 454 of 513

ENGINE

6

Drive

out

the

knock

pin

and

disconnect

the

pinion

to

remove

the

whole

rotary

unit

Fig

EE

70

Removal

of

knock

pin

7

Remove

the

whole

rotary

unit

When

disconnecting

the

governor

spring

from

the

governor

weight

be

careful

not

to

stretch

or

deform

the

governor

spring

tJ

0

Fig

EE

71

Removal

of

Totation

pari

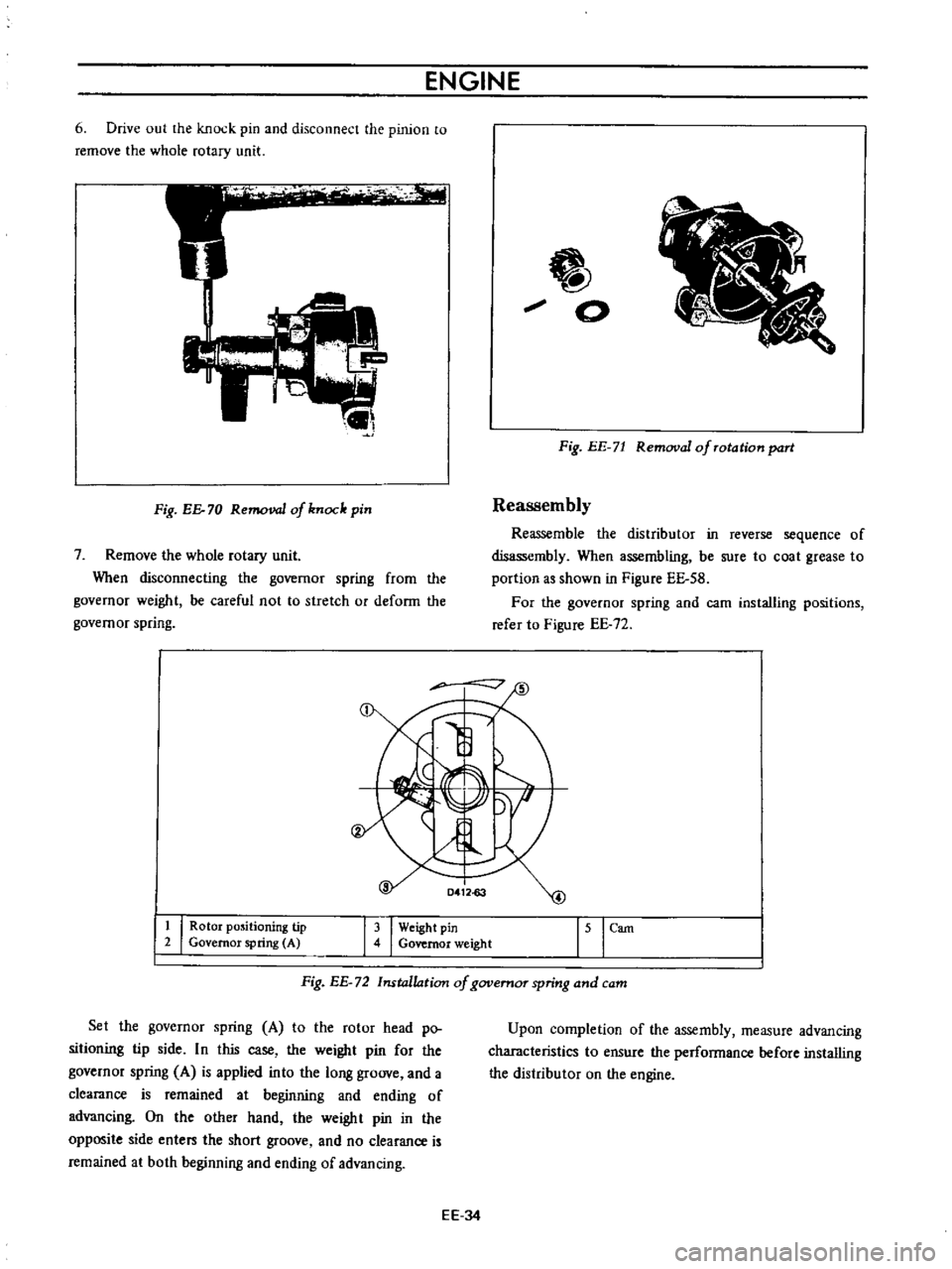

Reassembly

Reassemble

the

distributor

in

reverse

sequence

of

disassembly

When

assembling

be

sure

to

coat

grease

to

portion

as

shown

in

Figure

EE

58

For

the

governor

spring

and

earn

installing

positions

refer

to

Figure

EE

72

1

I

Rotor

positioning

tip

2

Governor

spring

A

13

I

Weight

pin

4

Governor

weight

15

I

earn

Fig

EE

72

Installation

of

governor

spring

and

cam

Set

the

governor

spring

A

to

the

rotor

head

po

sitioning

tip

side

In

this

case

the

weight

pin

for

the

governor

spring

A

is

applied

into

the

long

groove

and

a

clearance

is

remained

at

beginning

and

ending

of

advancing

On

the

other

hand

the

weight

pin

in

the

opposite

side

enters

the

short

groove

and

no

clearance

is

remained

at

both

beginning

and

ending

of

advancing

Upon

completion

of

the

assembly

measure

advancing

characteristics

to

ensure

the

performance

before

installing

the

distributor

on

the

engine

EE

34

Page 455 of 513

ENGINE

ElECTRICAL

SYSTEM

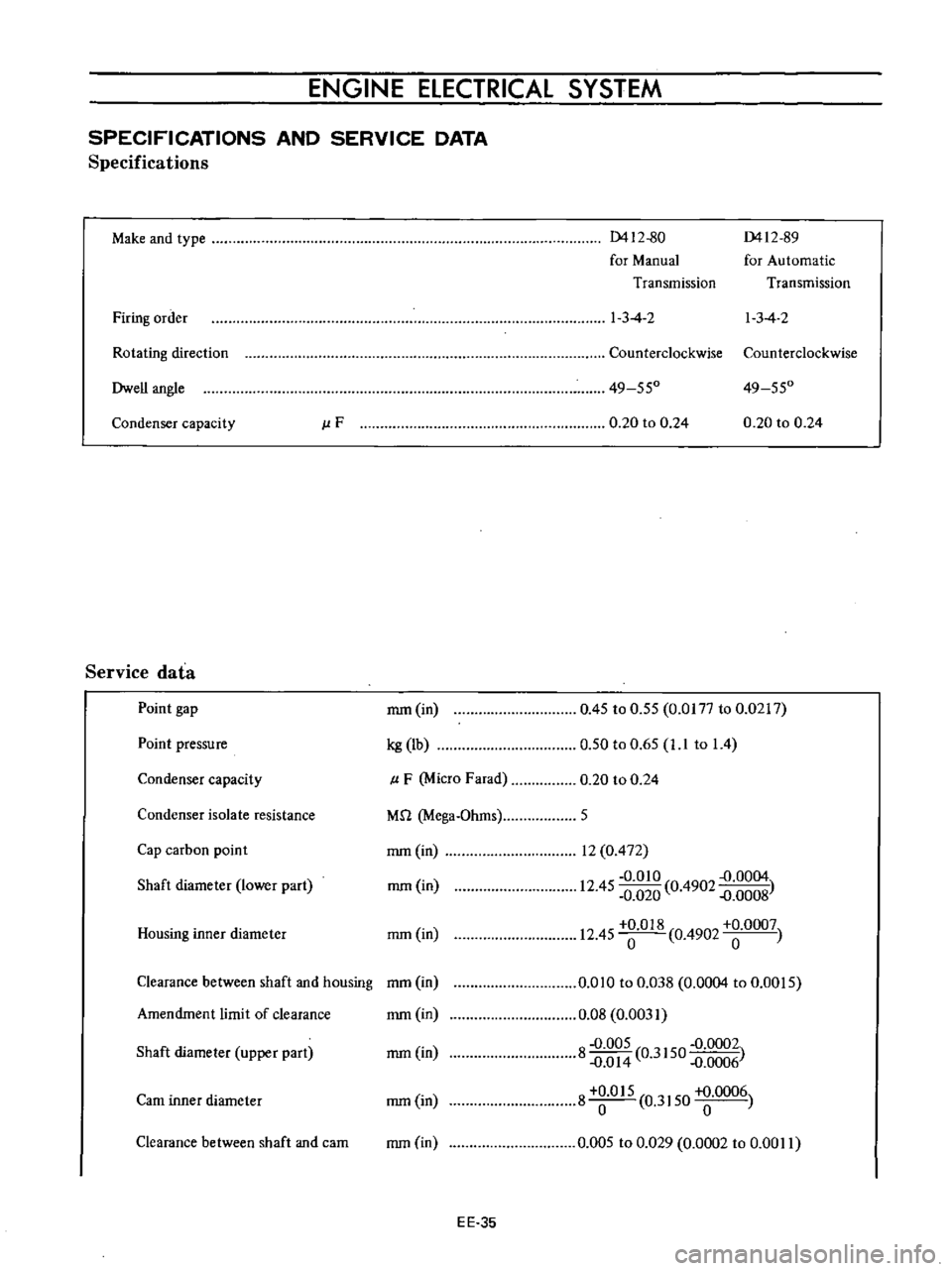

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Make

and

type

0412

80

0412

89

for

Manual

for

Automatic

Transmission

Transmission

Firing

order

1

3

4

2

I

3

4

2

Rotating

direction

Counterclockwise

Counterclockwise

Dwell

angle

49

550

49

550

Condenser

capacity

J

lF

0

20

to

0

24

0

20

to

0

24

Service

data

Point

gap

mm

in

0

45

to

0

55

0

0177

to

0

0217

0

50

to

0

65

1

1

to

1

4

Point

pressure

kg

lb

Condenser

capacity

p

F

Micro

Farad

0

20

to

0

24

Condenser

isolate

resistance

M

1

Mega

Ohms

5

Cap

carbon

point

mm

in

rom

in

Housing

inner

diameter

mm

in

12

0

472

0

010

D

0004

12

45

0

020

0

4902

D

0008

12

45

018

0

4902

0007

Shaft

diameter

lower

part

Clearance

between

shaft

and

housing

mm

in

Amendment

limit

of

clearance

mm

in

0

010

to

0

Q38

0

0004

to

0

0015

0

08

0

0031

8

0

005

0

3150

0

0002

D

O

14

D

0006

8

O

15

0

3150

0006

0

005

to

0

029

0

0002

to

0

00

II

Shaft

diameter

upper

part

mm

in

earn

inner

diameter

rom

in

Clearance

between

shaft

and

cam

mm

in

EE

35

Page 456 of 513

ENGINE

Weight

pivot

diameter

mm

in

Weight

hole

diameter

mm

in

Clearance

between

pivot

and

hole

mmOn

5

0

028

0

9

9

1

0011

1

005

1

6

1

0002

5

1

018

0

1969

0

0007

o

0

0

005

to

0

046

0

0002

to

0

0018

IGNITION

COIL

CONTENTS

DESCRIPTION

EE

36

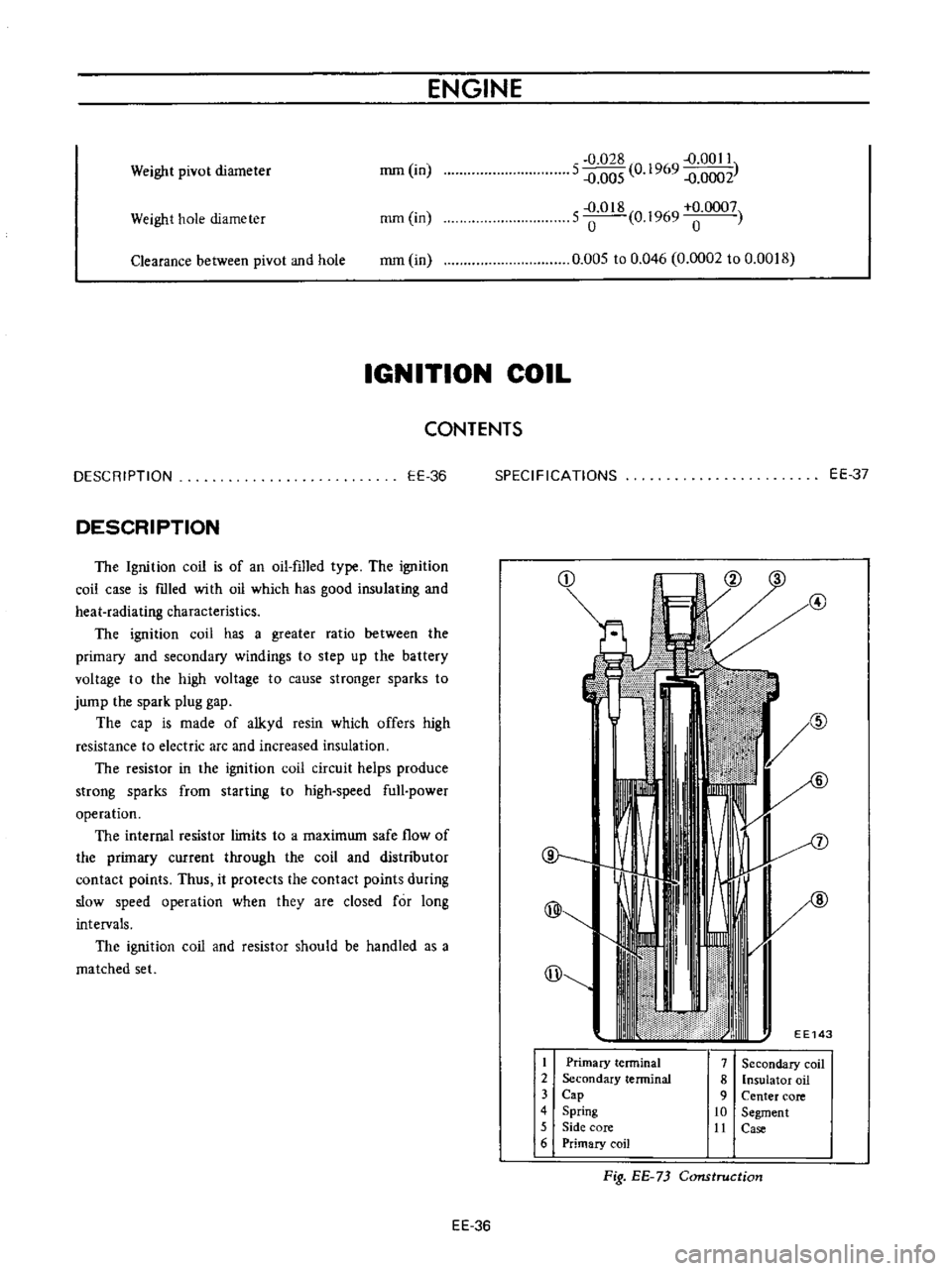

DESCRIPTION

The

Ignition

coil

is

of

an

oil

filled

type

The

ignition

coil

case

is

mted

with

oil

which

has

good

insulating

and

heat

radiating

characteristics

The

ignition

coil

has

a

greater

ratio

between

the

primary

and

secondary

windings

to

step

up

the

battery

voltage

to

the

high

voltage

to

cause

stronger

sparks

to

jump

the

spark

plug

gap

The

cap

is

made

of

alkyd

resin

which

offers

high

resistance

to

electric

arc

and

increased

insulation

The

resistor

in

the

ignition

coil

circuit

helps

produce

strong

sparks

from

starting

to

high

speed

full

power

operation

The

internal

resistor

limits

to

a

maximum

safe

flow

of

the

primary

current

through

the

coil

and

distributor

contact

points

Thus

it

protects

the

contact

points

during

slow

speed

operation

when

they

are

closed

for

long

intervals

The

ignition

coil

and

resistor

should

be

handled

as

a

matched

set

EE

36

SPECIFICATIONS

EE

37

@

@

@l

@

EE143

I

Primary

terminal

2

Secondary

terminal

3

Cap

4

Spring

5

Side

core

6

Primary

coil

7

Secondary

coil

8

insulator

oil

9

Center

core

10

Segment

tt

Case

Fig

EE

73

Construction

Page 457 of 513

ENGINE

ElECTRICAL

SYSTEM

SPECIFICATIONS

Make

and

type

Primary

voltage

v

Spark

gap

mm

in

Primary

resistance

at

200C

680

F

n

Secondary

resistance

at

200C

680F

Kn

External

resistor

at

200C

680

F

n

Applied

resistor

HANSHIN

HITACHI

H5

15

2

C6R

601

12

12

more

than

7

more

than

7

0

28

0

28

1

17

to

I

43

l

l

7

to

I

43

11

2

to

16

8

11

2

to

16

8

l

3tol7

l

3tol7

RC

15

5560R

151O

SPARK

PLUG

CONTENTS

DESCRIPTION

INSPECTION

CLEANING

AND

REGAP

EE

37

EE

37

EE

38

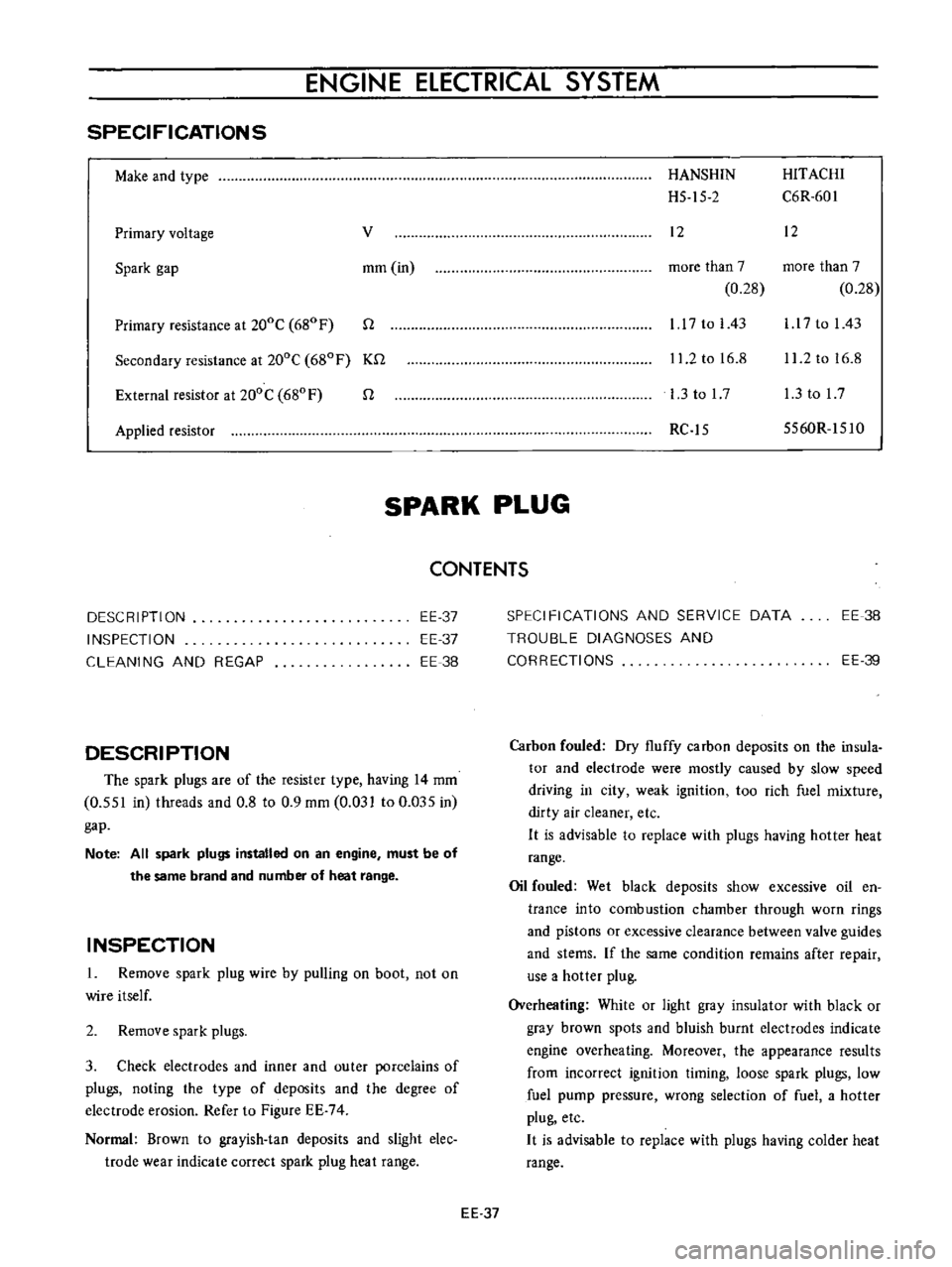

DESCRIPTION

The

spark

plugs

are

of

the

resister

type

having

14

mm

0

551

in

threads

and

0

8

to

0

9

mm

0

031

to

0

Q35

in

gap

Note

All

spark

plugs

installed

on

an

engine

must

be

of

the

same

brand

and

number

of

heat

range

INSPECTION

1

Remove

spark

plug

wire

by

pulling

on

boot

not

on

wire

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Figure

EE

74

Normal

Brown

to

grayish

tan

deposits

and

slight

elec

trode

wear

indicate

correct

spark

plug

heat

range

SPECIFICATIONS

AND

SERVICE

DATA

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EE

38

EE

39

Carbon

fouled

Dry

fluffy

carbon

deposits

on

the

insula

tor

and

electrode

were

mostly

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

H

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

show

excessive

oil

en

trance

into

combustion

chamber

through

worn

rings

and

pistons

or

excessive

clearance

between

valve

guides

and

stems

If

the

same

condition

remains

after

repair

use

a

hotter

plug

Overheating

White

or

light

gray

insulator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

Moreover

the

appearance

results

from

incorrect

ignition

timing

loose

spark

plugs

low

fuel

pump

pressure

wrong

selection

of

fuel

a

hotter

plug

etc

H

is

advisable

to

replace

with

plugs

having

colder

heat

range

EE

37

Page 458 of 513

ENGINE

Overheating

Normal

Carbon

fould

Fig

EE

74

SpaTk

plug

Life

4

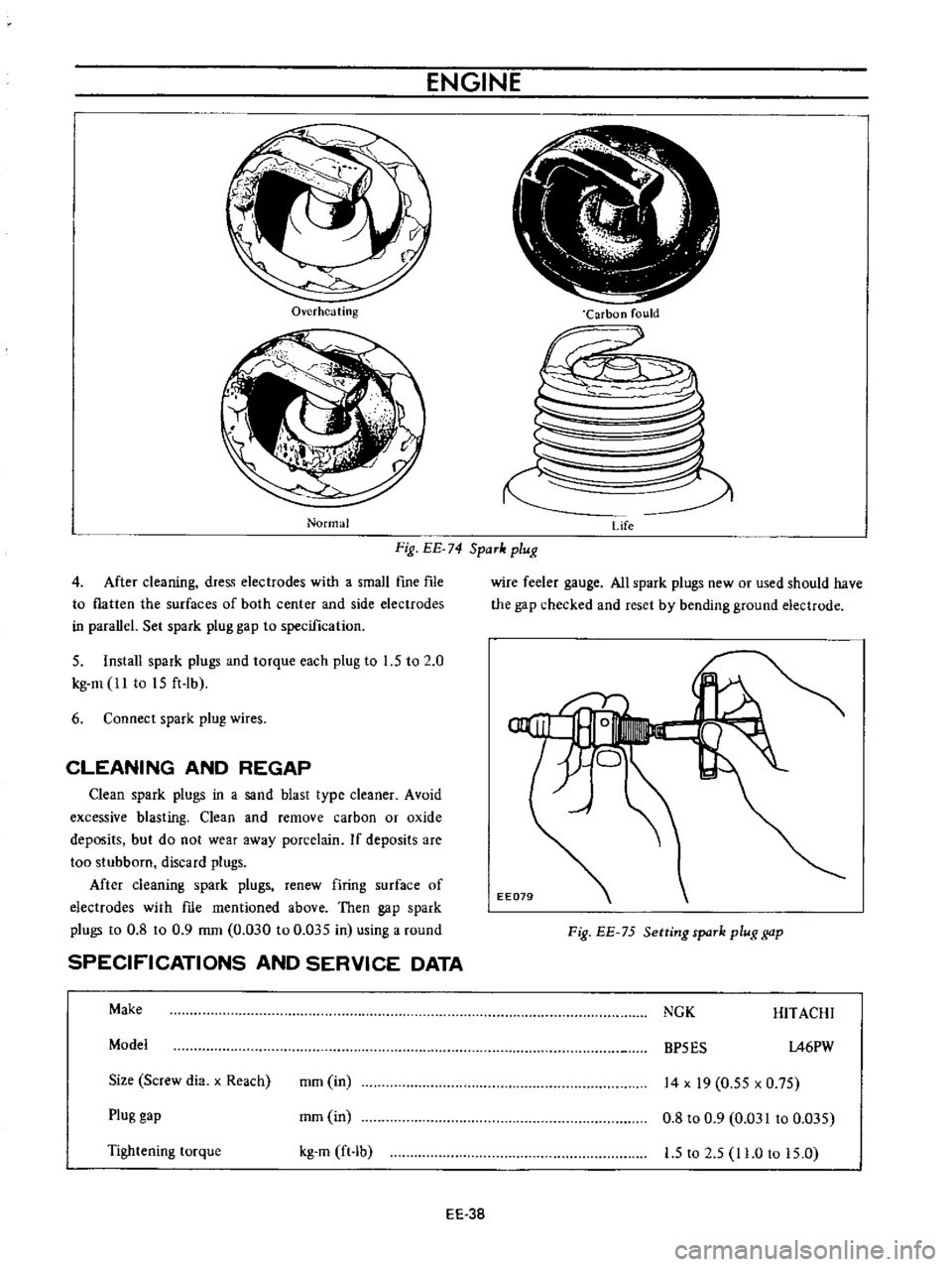

After

cleaning

dress

electrodes

with

a

small

fine

fIle

to

flatten

the

surfaces

of

both

center

and

side

electrodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

to

1

5

to

2

0

kg

m

ll

to

15

ft

lb

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porcelain

If

deposits

are

too

stubborn

discard

plugs

Mter

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

me

mentioned

above

Then

gap

spark

plugs

to

0

8

to

0

9

mm

0

030

to

0

035

in

using

a

round

SPECIFICATIONS

AND

SERVICE

DATA

Make

Model

Size

Screw

dia

x

Reach

mm

in

Plug

gap

mm

in

Tightening

torque

kg

m

ft

b

EE

38

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

Fig

EE

75

Setting

spaTk

plug

gap

NGK

HITACHI

BP5ES

1A6PW

14

x

19

0

55

x

0

75

0

8

to

0

9

0

031

to

0

035

1

5

to

2

5

11

0

to

15

0

Page 459 of 513

ENGINE

ELECTRICAL

SYSTEM

TROUBLE

DIAGNOSES

AND

CORRECTIONS

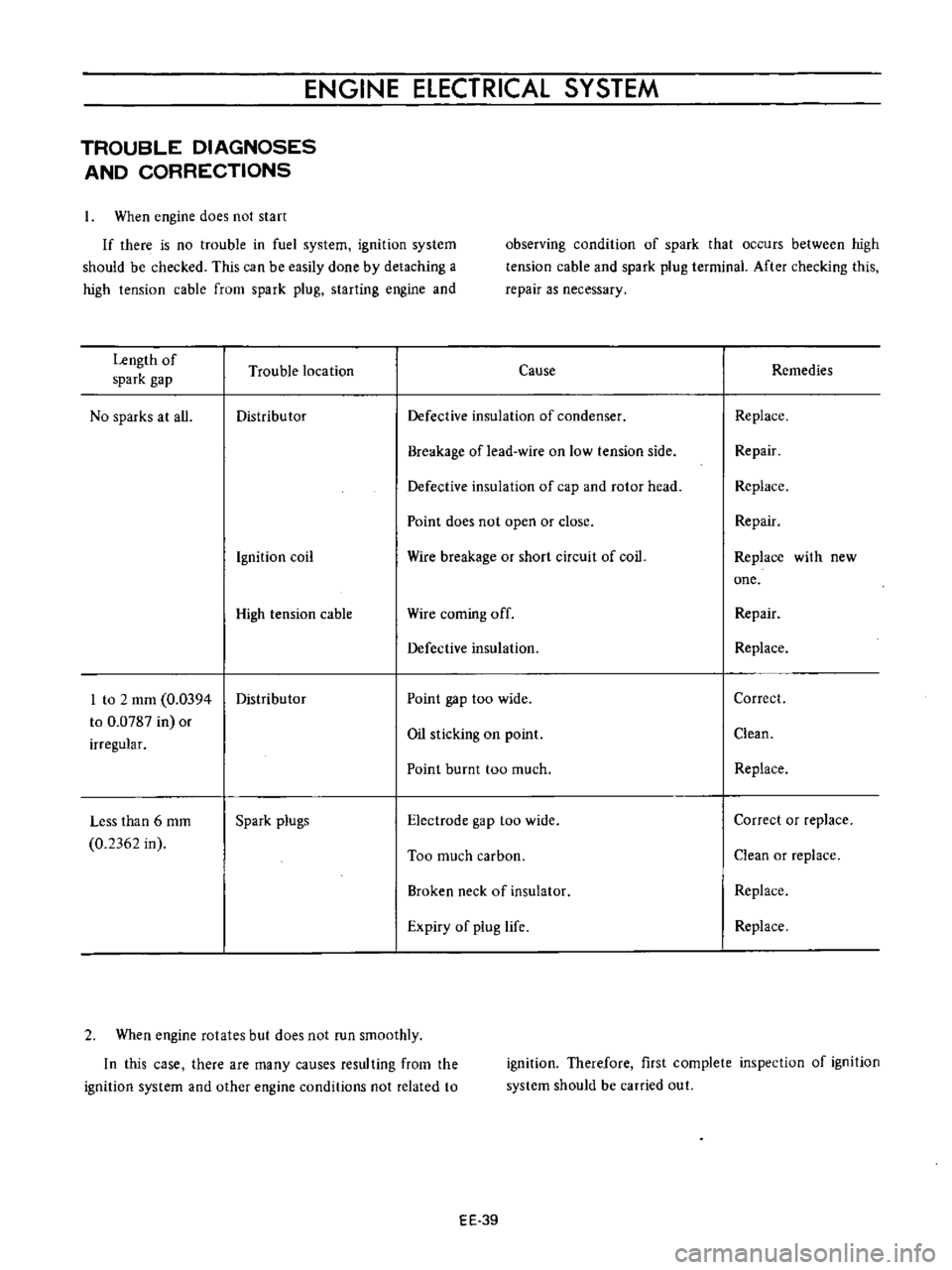

When

engine

does

not

start

If

there

is

no

trouble

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

cable

from

spark

plug

starting

engine

and

observing

condition

of

spark

that

occurs

between

high

tension

cable

and

spark

plug

terminal

After

checking

this

repair

as

necessary

Length

of

Trouble

location

Cause

Remedies

spark

gap

No

sparks

at

all

Distributor

Defective

insulation

of

condenser

Replace

Breakage

of

lead

wire

on

low

tension

side

Repair

Defective

insulation

of

cap

and

rotor

head

Replace

Point

does

not

open

or

close

Repair

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

cable

Wire

coming

off

Repair

Defective

insulation

Replace

I

to

2

mm

0

0394

Distributor

Point

gap

too

wide

Correct

to

0

0787

in

or

Oil

sticking

on

point

Clean

irregular

Point

burnt

too

much

Replace

Less

than

6

mm

Spark

plugs

Electrode

gap

too

wide

Correct

or

replace

0

2362

in

Too

much

carbon

Clean

or

replace

Broken

neck

of

insulator

Replace

Expiry

of

plug

life

Replace

2

When

engine

rotates

but

does

not

run

smoothly

In

this

case

there

are

many

causes

resulting

from

the

ignition

system

and

other

engine

conditions

not

related

to

ignition

Therefore

first

complete

inspection

of

ignition

system

should

be

carried

out

EE

39

Page 460 of 513

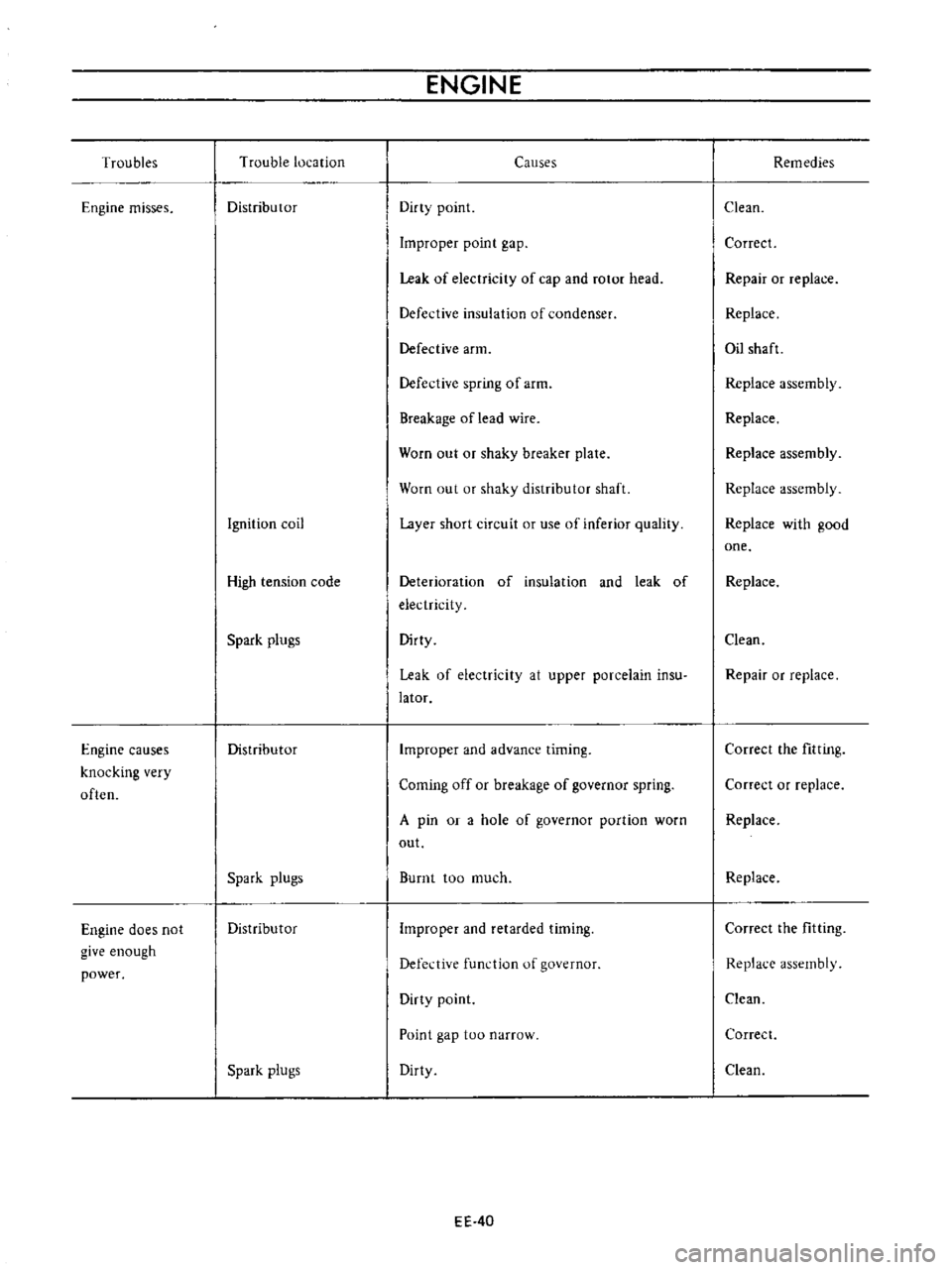

Troubles

Engine

misses

Engine

causes

knocking

very

often

Engine

does

not

give

enough

power

Trouble

location

Distributor

Ignition

coil

High

tension

code

Spark

plugs

Distributor

Spark

plugs

Distributor

Spark

plugs

ENGINE

Causes

Dirty

point

Improper

point

gap

Leak

of

electricity

of

cap

and

rotor

head

Defective

insulation

of

condenser

Defective

arm

Defective

spring

of

arm

Breakage

oflead

wire

Worn

out

or

shaky

breaker

plate

Worn

out

or

shaky

distributor

shaft

Layer

short

circuit

or

use

of

inferior

quality

Deterioration

of

insulation

and

leak

of

electricity

Dirty

Leak

of

electricity

at

upper

porcelain

insu

lator

Improper

and

advance

timing

Coming

off

or

breakage

of

governor

spring

A

pin

or

a

hole

of

governor

portion

worn

out

Burnt

too

much

Improper

and

retarded

timing

Defedive

function

of

governor

Dirty

point

Point

gap

too

narrow

Dirty

EE

40

Remedies

Clean

Correct

Repair

or

replace

Replace

Oil

shaft

Replace

assembly

Replace

Replace

assembly

Replace

assembly

Replace

with

good

one

Replace

Clean

Repair

or

replace

Correct

the

fitting

Correct

or

replace

Replace

Replace

Correct

the

fitting

Replace

assembly

Clean

Correct

Clean