DATSUN B110 1973 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 411 of 513

ENGINE

Y

Q

0

Fig

EF

34

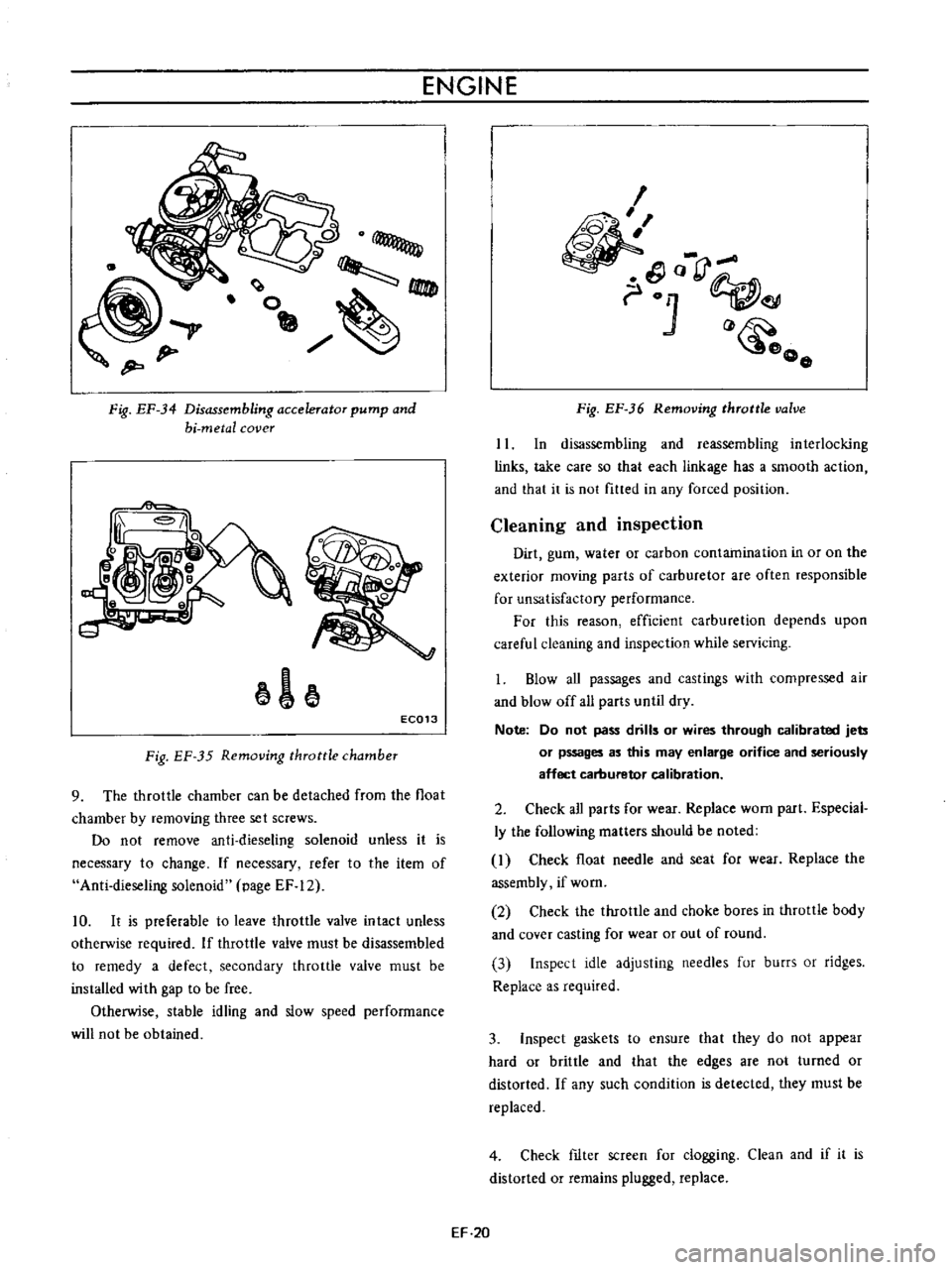

Disassembling

accelerator

pump

and

hi

metal

cover

1

EC013

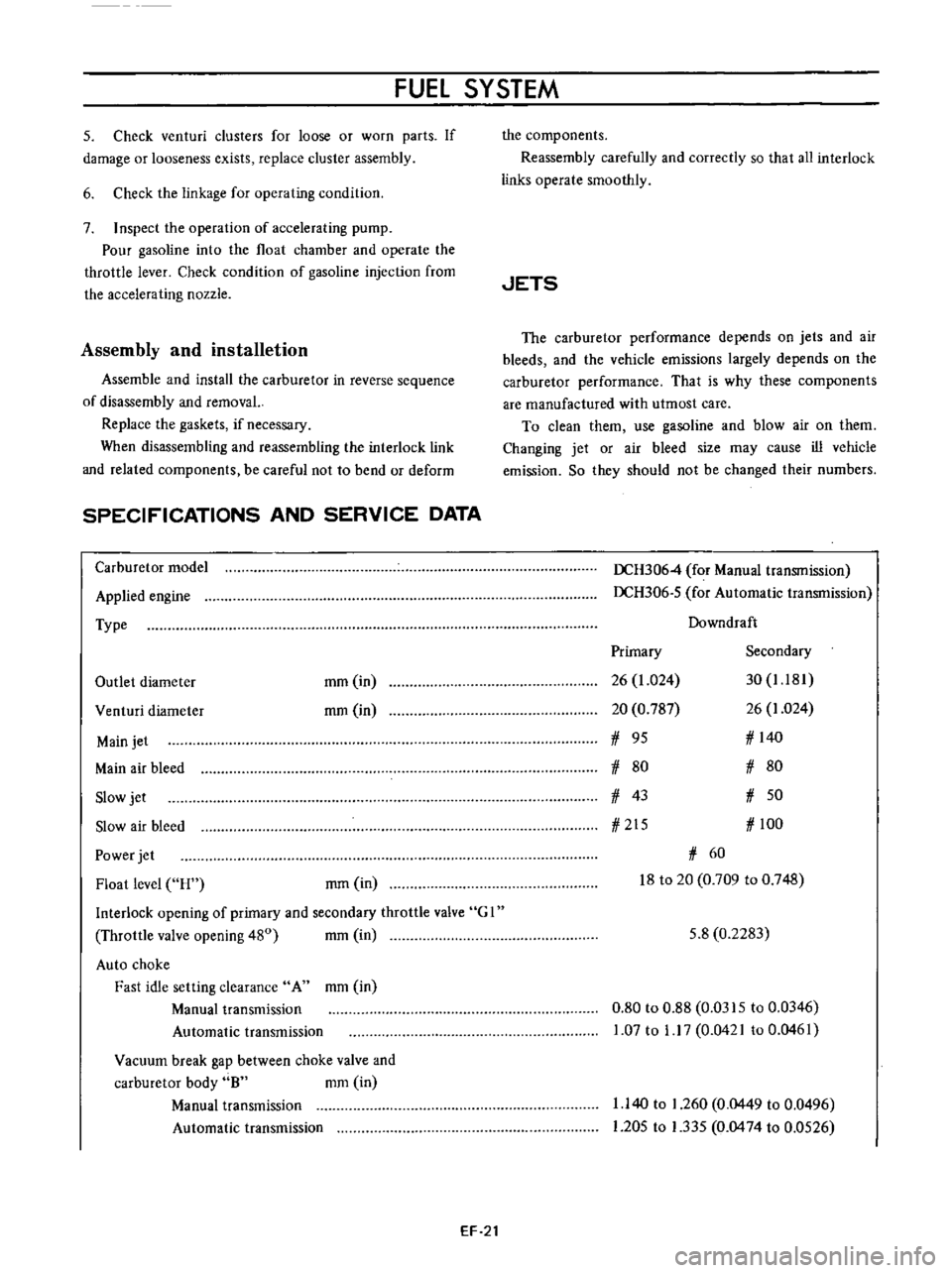

Fig

EF

35

Removing

throttle

chamber

9

The

throttle

chamber

can

be

detached

from

the

float

chamber

by

removing

three

set

screws

Do

not

remove

anti

dieseling

solenoid

unless

it

is

necessary

to

change

If

necessary

refer

to

the

item

of

Anti

dieseling

solenoid

page

EF

12

10

It

is

preferable

to

leave

throttle

valve

intact

unless

otherwise

required

If

throttle

valve

must

be

disassembled

to

remedy

a

defect

secondary

throttle

valve

must

be

installed

with

gap

to

be

free

Otherwise

stable

idling

and

slow

speed

performance

will

not

be

obtained

I

o

rJ

01

o

o

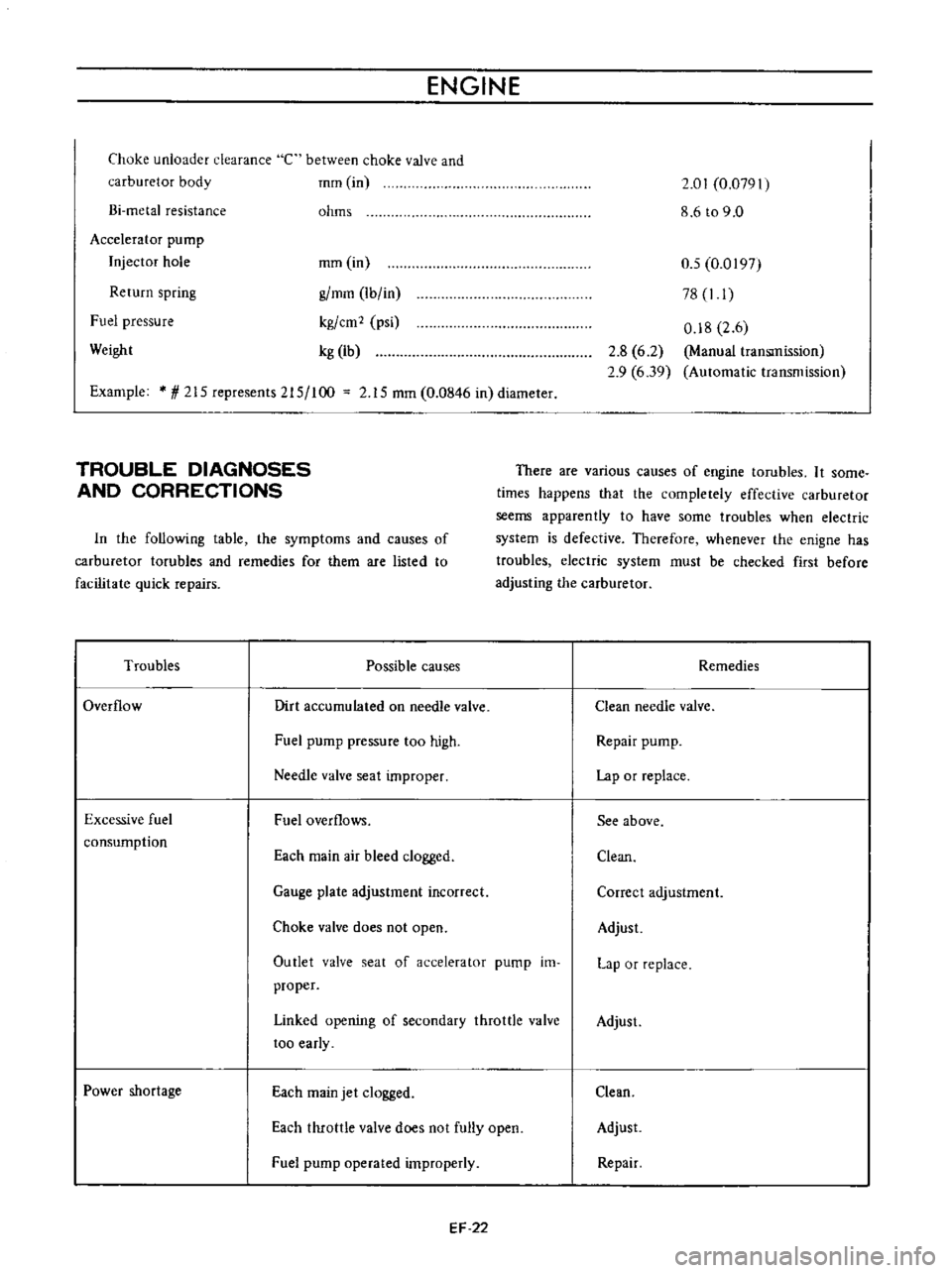

Fig

EF

36

Removing

throttle

valve

II

In

disassembling

and

reassembling

interlocking

links

take

care

so

that

each

linkage

has

a

smooth

action

and

that

it

is

not

fitted

in

any

forced

position

Cleaning

and

inspection

Dirt

gum

water

or

carbon

contamination

in

or

on

the

exterior

moving

parts

of

carburetor

are

often

responsible

for

unsatisfactory

performance

For

this

reason

efficient

carburetion

depends

upon

careful

cleaning

and

inspection

while

servicing

1

Blow

aU

passages

and

castings

with

compressed

air

and

blow

off

all

parts

until

dry

Note

Do

not

pass

drills

or

wires

through

calibrated

jets

or

pssages

as

this

may

enlarge

orifice

and

seriously

affect

carburetor

calibration

2

Check

all

parts

for

wear

Replace

worn

part

Especial

ly

the

following

matters

should

be

noted

I

Check

float

needle

and

seat

for

wear

Replace

the

assembly

if

worn

2

Check

the

throttle

and

choke

bores

in

throttle

body

and

cover

casting

for

wear

or

out

of

round

3

Inspect

idle

adjusting

needles

fur

burrs

or

ridges

Replace

as

required

3

Inspect

gaskets

to

ensure

that

they

do

not

appear

hard

or

brittle

and

that

the

edges

are

not

turned

or

distorted

If

any

such

condition

is

detected

they

must

be

replaced

4

Check

fIlter

screen

for

clogging

Clean

and

if

it

is

distorted

or

remains

plugged

replace

EF

20

Page 412 of 513

FUEL

SYSTEM

5

Check

venturi

clusters

for

loose

or

worn

parts

If

damage

or

looseness

exists

replace

cluster

assembly

6

Check

the

linkage

for

operating

condition

7

Inspect

the

operation

of

accelerating

pump

Pour

gasoline

into

the

float

chamber

and

operate

the

throttle

lever

Check

condition

of

gasoline

injection

from

the

accelerating

nozzle

Assembly

and

instalIetion

Assemble

and

install

the

carburetor

in

reverse

sequence

of

disassembly

and

removal

Replace

the

gaskets

if

necessary

When

disassembling

and

reassembling

the

interlock

link

and

related

components

be

careful

not

to

bend

or

deform

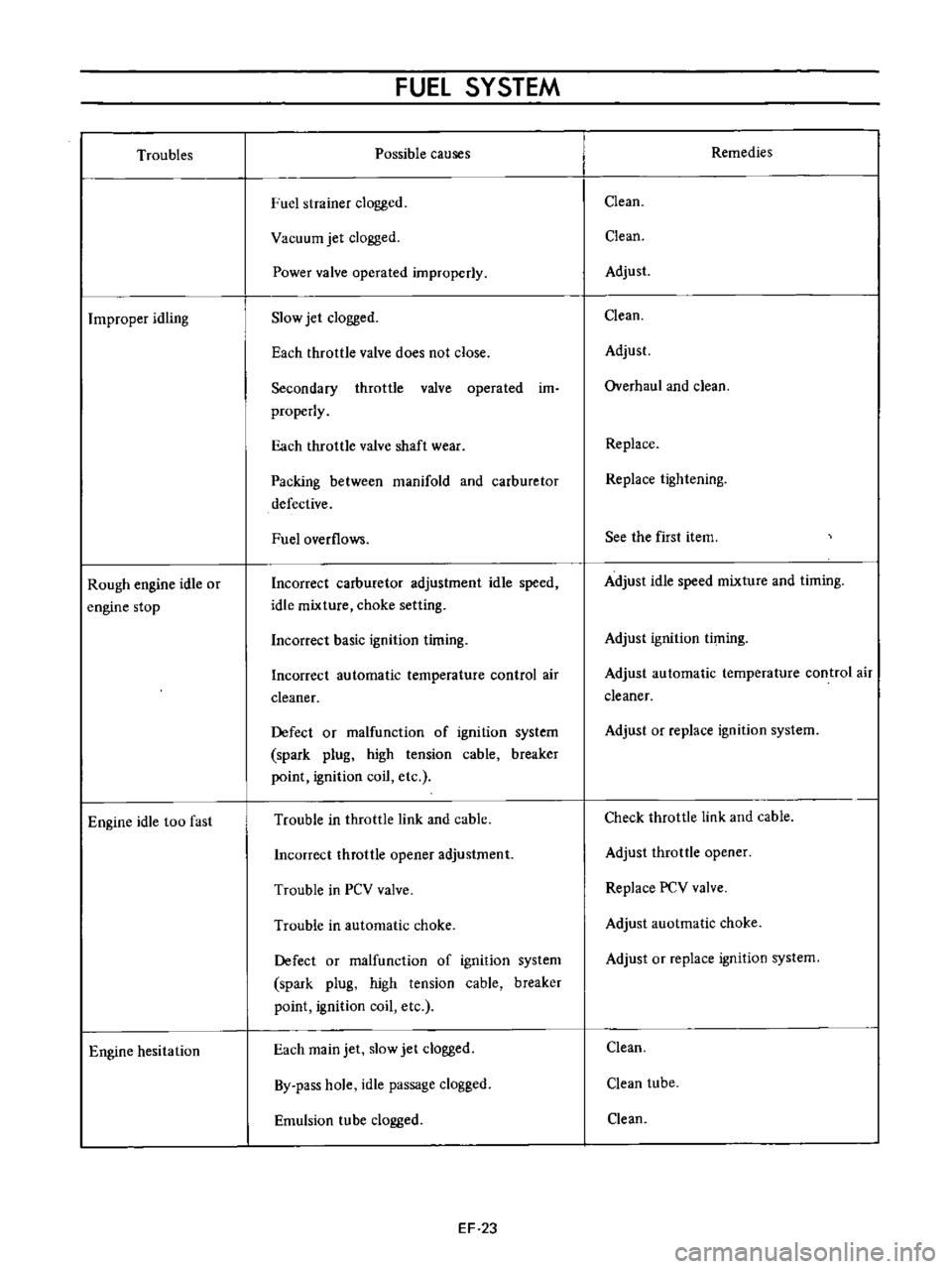

SPECIFICATIONS

AND

SERVICE

DATA

Carburetor

model

Applied

engine

Type

Outlet

diameter

mm

in

rom

in

Venturi

diameter

Main

jet

Main

air

bleed

Slow

jet

Slow

air

bleed

Power

jet

Float

level

H

rom

in

Interlock

opening

of

primary

and

secondary

throttle

valve

G

I

Throttle

valve

opening

480

mm

in

Auto

choke

Fast

idle

setting

clearance

A

mm

in

Manual

transmission

Automatic

transmission

Vacuum

break

gap

between

choke

valve

and

carburetor

body

8

mm

in

Manual

transmission

Automatic

transmission

EF

21

the

components

Reassembly

carefully

and

correctly

so

that

all

interlock

links

operate

smoothly

JETS

The

carburetor

performance

depends

on

jets

and

air

bleeds

and

the

vehicle

emissions

largely

depends

on

the

carburetor

performance

That

is

why

these

components

are

manufactured

with

utmost

care

To

clean

them

use

gasoline

and

blow

air

on

them

Changing

jet

or

air

bleed

size

may

cause

ill

vehicle

emission

So

they

should

not

be

changed

their

numbers

DCH3064

for

Manual

transmission

DCH306

5

for

Automatic

transmission

Downdraft

Primary

Secondary

26

1

024

30

1

181

20

0

787

26

1

024

1

95

1

140

1

80

1

80

1

43

1

50

1

215

1

100

1

60

18

to

20

0

709

to

0

748

5

8

0

2283

0

80

to

0

88

0

0315

to

0

0346

1

07

to

1

17

0

0421

to

0

0461

1

140

to

1

260

0

0449

to

0

0496

1

205

to

1

335

0

0474

to

0

0526

Page 413 of 513

ENGINE

Choke

unloader

clearance

carburetor

body

C

between

choke

valve

and

mm

in

Bi

metal

resistance

ohms

2

01

0

07911

8

6t09

0

Accelerator

pump

Injector

hole

Return

spring

Fuel

pressure

mm

in

g

mm

Ib

in

kg

cm

2

psi

kg

lb

0

5

0

0197

78

I

I

0

18

2

6

Manual

transmission

Automatic

transmission

Weight

2

8

6

2

2

9

6

39

Example

1

215

represents

215

100

2

15

mm

0

0846

in

diameter

TROUBLE

DIAGNOSES

AND

CORRECTIONS

There

are

various

causes

of

engine

tarubles

It

some

times

happens

that

the

completely

effective

carburetor

seems

apparently

to

have

some

troubles

when

electric

system

is

defective

Therefore

whenever

the

enigne

has

troubles

electric

system

must

be

checked

first

before

adjusting

the

carburetor

In

the

following

table

the

symptoms

and

causes

of

carburetor

tarubles

and

remedies

for

them

are

listed

to

facilitate

quick

repairs

Troubles

Possible

causes

Remedies

Overflow

Dirt

accumulated

on

needle

valve

Clean

needle

valve

Fuel

pump

pressure

too

high

Repair

pump

Needle

valve

seat

improper

Lap

or

replace

Excessive

fuel

consumption

Fuel

overflows

See

above

Each

main

air

bleed

clogged

Clean

Gauge

plate

adjustment

incorrect

Correct

adjustment

Choke

valve

does

not

open

Adjust

Outlet

valve

seat

of

accelerator

pump

im

proper

Lap

or

replace

Linked

opening

of

secondary

throttle

valve

too

early

Adjust

Power

shortage

Each

main

jet

clogged

Clean

Each

throttle

valve

does

not

fully

open

Adjust

Fuel

pump

operated

improperly

Repair

EF

22

Page 414 of 513

Troubles

Improper

idling

Rough

engine

idle

or

engine

stop

Engine

idle

too

fast

Engine

hesitation

FUEl

SYSTEM

Possible

causes

ruel

strainer

clogged

Vacuum

jet

clogged

Power

valve

operated

improperly

Slow

jet

clogged

Each

throttle

valve

does

not

close

Secondary

throttle

valve

operated

im

properly

Each

throttle

valve

shaft

wear

Packing

between

manifold

and

carburetor

defective

Fuel

overflows

Incorrect

carburetor

adjustment

idle

speed

idle

mixture

choke

setting

Incorrect

basic

ignition

timing

Incorrect

automatic

temperature

control

air

cleaner

Defect

or

malfunction

of

ignition

system

spark

plug

high

tension

cable

breaker

point

ignition

coil

etc

Trouble

in

throttle

link

and

cable

Incorrect

throttle

opener

adjustment

Trouble

in

PCV

valve

Trouble

in

automatic

choke

Defect

or

malfunction

of

ignition

system

spark

plug

high

tension

cable

breaker

point

ignition

coil

etc

Each

main

jet

slow

jet

clogged

By

pass

hole

idle

passage

clogged

Emulsion

tube

clogged

EF

23

Remedies

Clean

Clean

Adjust

Clean

Adjust

Overhaul

and

clean

Replace

Replace

tightening

See

the

first

item

Adjust

idle

speed

mixture

and

timing

Adjust

ignition

timing

Adjust

automatic

temperature

control

air

cleaner

Adjust

or

replace

ignition

system

Check

throttle

link

and

cable

Adjust

throttle

opener

Replace

PCV

valve

Adjust

auotmatic

choke

Adjust

or

replace

ignition

system

Clean

Clean

tube

Clean

Page 415 of 513

Troubles

Car

knock

when

coasting

Engine

does

not

start

ENGINE

Possible

causes

Idling

adjustment

incorrect

Secondary

throttle

valve

operated

im

properly

Incorrect

throttle

opener

adjustment

Trouble

in

PCV

valve

Defect

or

malfunction

of

ignition

system

spark

plug

high

tension

cable

breaker

point

ignition

coil

etc

Fuel

overflows

No

fu

el

Idling

adjustment

incorrect

Fast

idle

adjustment

incorrect

Damaged

anti

dieseling

solenoid

Bi

metal

rod

in

contact

with

hi

metal

case

EF

24

Remedies

Correct

adjustment

Overhaul

and

clean

Adjust

throttle

opener

Replace

PCV

valve

Adjust

or

replace

ignition

system

See

the

first

item

Check

pump

fuel

pipe

and

needle

valve

Correct

adjustment

Correct

adjustment

Replace

Adjust

Page 416 of 513

FUEl

SYSTEM

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

CONTENTS

OESCRI

PTION

Flow

guide

valve

MAINTENANCE

AND

TESTING

Checking

fuel

tank

vapor

liquid

separator

and

vapor

vent

I

ins

EF

25

EF

26

EF

26

EF

26

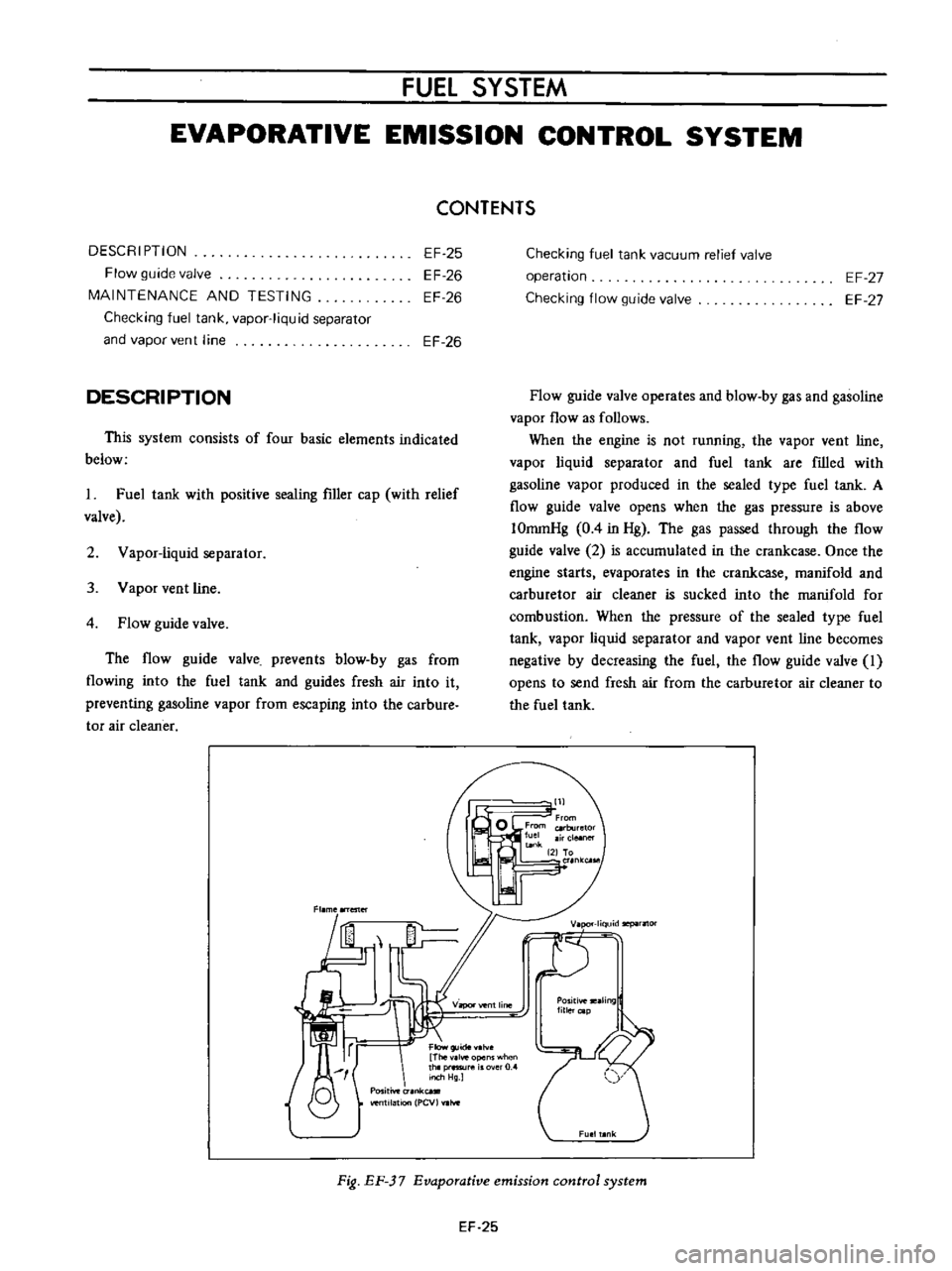

DESCRIPTION

This

system

consists

of

four

basic

elements

indicated

below

I

Fuel

tank

with

positive

sealing

filler

cap

with

relief

valve

2

Vapor

liquid

separator

3

Vapor

vent

line

4

Flow

guide

valve

The

flow

guide

valve

prevents

blow

by

gas

from

flowing

into

the

fuel

tank

and

guides

fresh

air

into

it

preventing

gasoline

vapor

from

escaping

into

the

carbure

tor

air

cleaner

Fl

me

ester

I

f

Flow

Thev

lve

opens

when

thlp

1l

rO

Inch

Hg

O

Positive

unk

venlI1atlon

PCV

hoe

Checking

fuel

tank

vacuum

relief

valve

operation

Checking

flow

guide

valve

EF

27

EF

27

Flow

guide

valve

operates

and

blow

by

gas

and

gasoline

vapor

flow

as

follows

When

the

engine

is

not

running

the

vapor

vent

line

vapor

liquid

separator

and

fuel

tank

are

filled

with

gasoline

vapor

produced

in

the

sealed

type

fuel

tank

A

flow

guide

valve

opens

when

the

gas

pressure

is

above

IOromHg

0

4

in

Hg

The

gas

passed

through

the

flow

guide

valve

2

is

accumulated

in

the

crankcase

Once

the

engine

starts

evaporates

in

the

crankcase

manifold

and

carburetor

air

cleaner

is

sucked

into

the

manifold

for

combustion

When

the

pressure

of

the

sealed

type

fuel

tank

vapor

liquid

separator

and

vapor

vent

line

becomes

negative

by

decreasing

the

fuel

the

flow

guide

valve

I

opens

to

send

fresh

air

from

the

carburetor

air

cleaner

to

the

fuel

tank

lill

K

riquidllepilrflOr

T

VilPOl

vent

line

Positiveteilling

lillercap

Fig

EF

37

Evaporative

emission

control

system

EF

25

Page 417 of 513

ENGINE

ffi68

mmAq

14

5

mAq

3

way

connector

Cock

II

M

nam

e

Flow

guide

valve

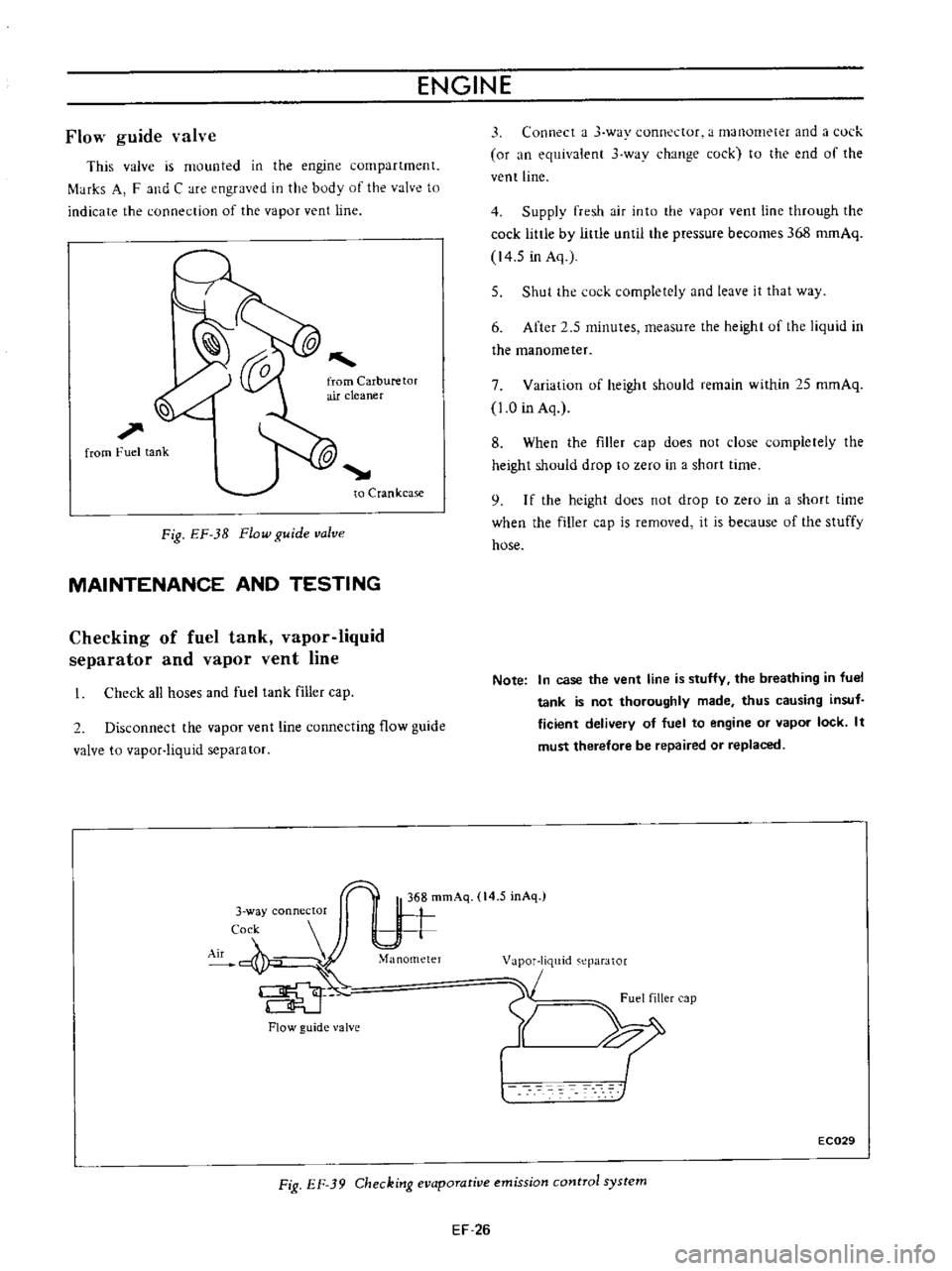

This

valve

is

mounted

in

the

engine

compartment

f

tHks

A

F

and

C

are

engraved

in

the

body

of

the

valve

to

indicate

the

connection

of

the

vapor

vent

line

l

l

1

from

Fuel

tank

to

Crankcase

Fig

EF

3B

Flow

guide

valve

MAINTENANCE

AND

TESTING

Checking

of

fuel

tank

vapor

liquid

separator

and

vapor

vent

line

Check

all

hoses

and

fuel

tank

filler

cap

2

Disconnect

the

vapor

vent

line

connecting

flow

guide

valve

to

vapor

liquid

separator

Flow

guide

valve

3

Connect

a

J

way

connector

a

manometer

and

a

l

ul

k

or

an

equivalent

3

wav

change

cock

to

the

end

of

the

vent

line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

the

pressure

becomes

368

romAq

14

5

in

Aq

5

Shut

the

cock

completely

and

leave

it

that

way

6

After

2

5

minutes

measure

the

height

uf

the

liquid

in

the

manometer

7

Variation

of

height

should

remain

within

25

mmAq

1

0

in

Aq

8

When

the

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

I

f

the

height

docs

not

drop

to

zero

in

a

short

time

when

the

filler

cap

is

removed

it

is

because

of

the

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

made

thus

causing

insuf

ficient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

therefore

be

repaired

or

replaced

1

m

eparator

1

Fuel

filler

cap

Y

XI

EC029

Fig

EF

39

Checking

evaporative

emission

control

system

EF

26

Page 418 of 513

FUEL

SYSTEM

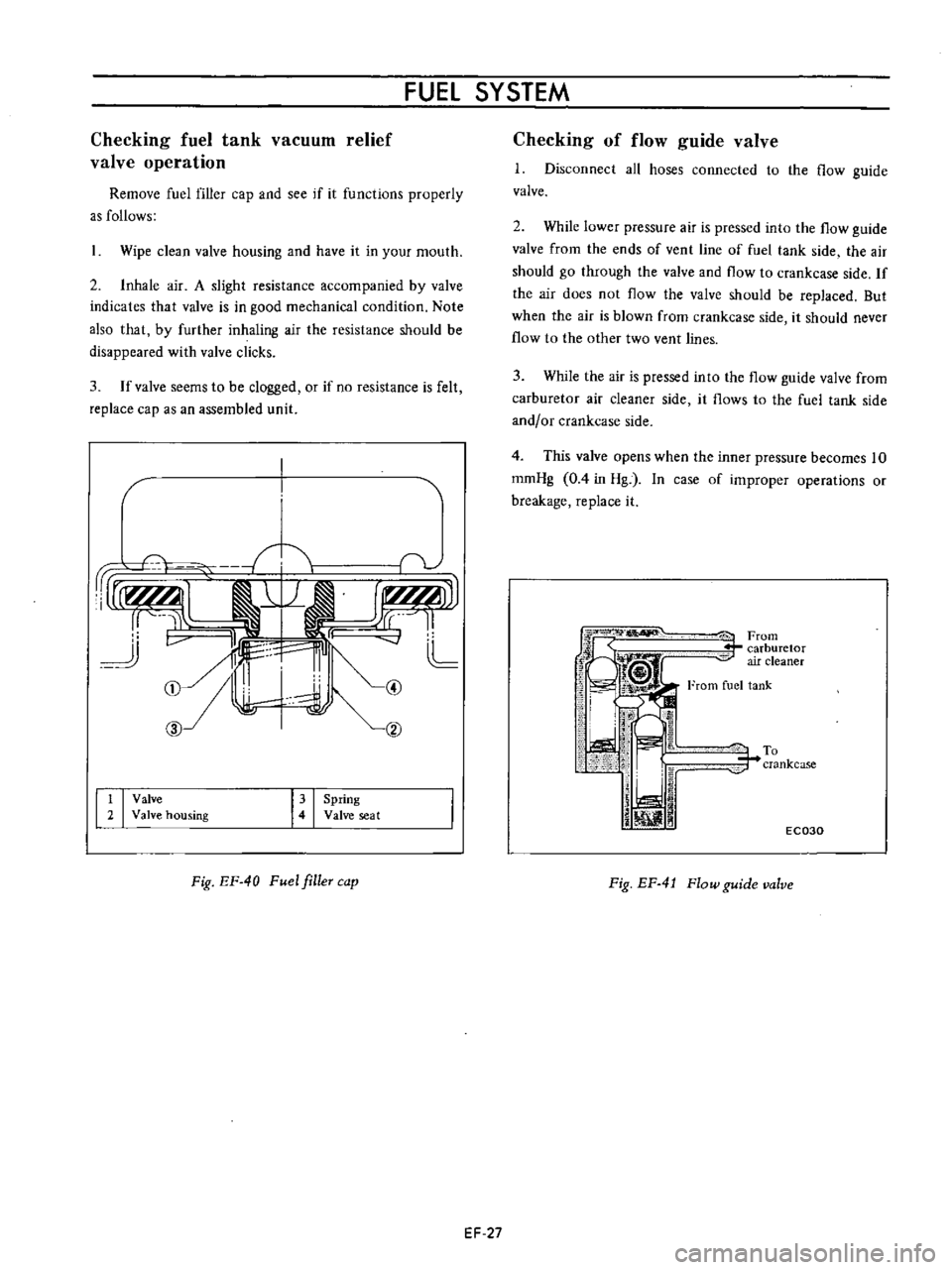

Checking

fuel

tank

vacuum

relief

valve

operation

Remove

fuel

filler

cap

and

see

if

it

functions

properly

as

follows

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

accompanied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

clicks

3

If

valve

seems

to

be

clogged

or

if

no

resistance

is

felt

replace

cap

as

an

assembled

unit

1

1

1I

L

CD

hl

cv

CID

t

I

Valve

2

Valve

housing

I

I

Spring

Valve

seat

Fig

EF

40

Fuel

filleT

cap

EF

27

Checking

of

flow

guide

valve

1

Disconnect

all

hoses

connected

to

the

flow

guide

valve

2

While

lower

pressure

air

is

pressed

into

the

flow

guide

valve

from

the

ends

of

vent

line

of

fuel

tank

side

the

air

should

go

through

the

valve

and

flow

to

crankcase

side

If

the

air

does

not

flow

the

valve

should

be

replaced

But

when

the

air

is

blown

from

crankcase

side

it

should

never

flow

to

the

other

two

vent

lines

3

While

the

air

is

pressed

into

the

flow

guide

valve

from

carburetor

air

cleaner

side

it

flows

to

the

fuel

tank

side

and

or

crankcase

side

4

This

valve

opens

when

the

inner

pressure

becomes

10

romHg

0

4

in

Hg

In

case

of

improper

operations

or

breakage

replace

it

iFrom

r

carburetor

air

cleaner

From

fuel

tank

To

r

crankcase

j

iJ

i

ill

1

1

EC030

Fig

EF

4

J

Flow

guide

valve

Page 419 of 513

DATE

ENGINE

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

EF

28

Page 420 of 513

DATSUN

1200

MODEL

B

11

0

SERIES

L

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

EE

ENGINE

ELECTRICAL

SYSTEM

BATTERY

STARTING

MOTOR

CHARGING

CIRCUIT

ALTERNATOR

REGULATOR

IGNITIO

N

CIRCUIT

DISTRIBUTOR

IGNITION

COIL

SPARK

PLUG

EEl

EE

3

EE

15

EE

16

EE

23

EE

29

EE

29

EE

36

EE

37