check engine DATSUN B110 1973 Service Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 344 of 513

ENGINE

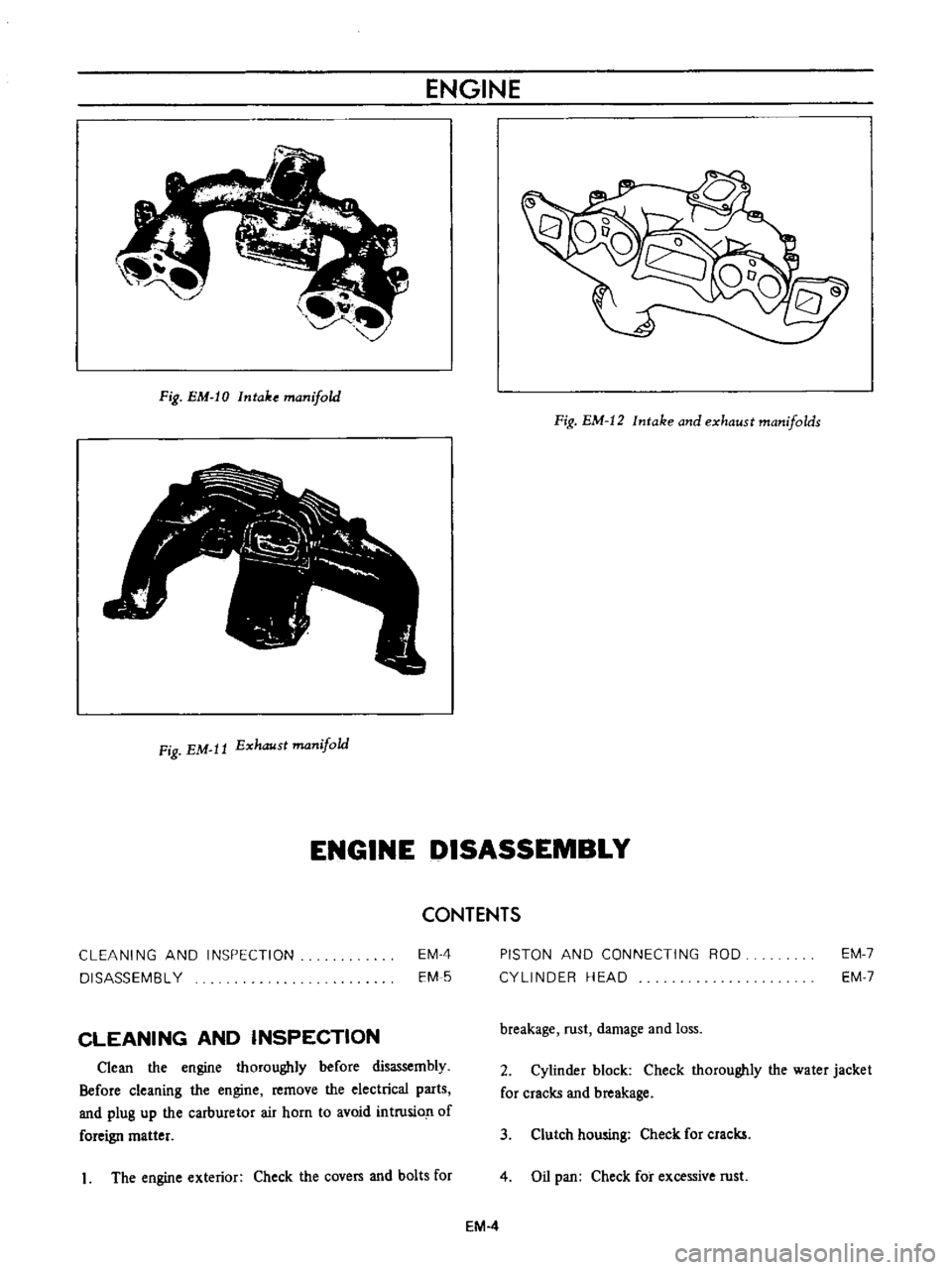

Fig

EM

IO

Intake

manifold

Fig

EM

12

Intake

and

exhaust

manifolds

Fig

EM

It

Exhaust

manifold

ENGINE

DISASSEMBLY

CONTENTS

CLEANING

AND

INSPECTION

DISASSEMBL

Y

EM

4

EM

5

PISTON

AND

CONNECTING

ROD

CYLINDER

HEAD

EM

7

EM

7

CLEANING

AND

INSPECTION

breakage

rust

damage

and

loss

Clean

the

engine

thoroughly

before

disassembly

Before

cleaning

the

engine

remove

the

electrical

parts

and

plug

up

the

carburetor

air

horn

to

avoid

intrusio

n

of

foreign

matter

2

Cylinder

block

Check

thoroughly

the

water

jacket

for

cracks

and

breakage

3

Clutch

howing

Check

for

cracks

1

The

engine

exterior

Check

the

covers

and

bolts

for

4

Oil

pan

Check

for

excessive

rust

EM

4

Page 348 of 513

ENGINE

J

I

r

I

I

J

fj

7

L

j

8

if

d1

I

ilfi

3

c

7

I

t

j

v

1

Ji

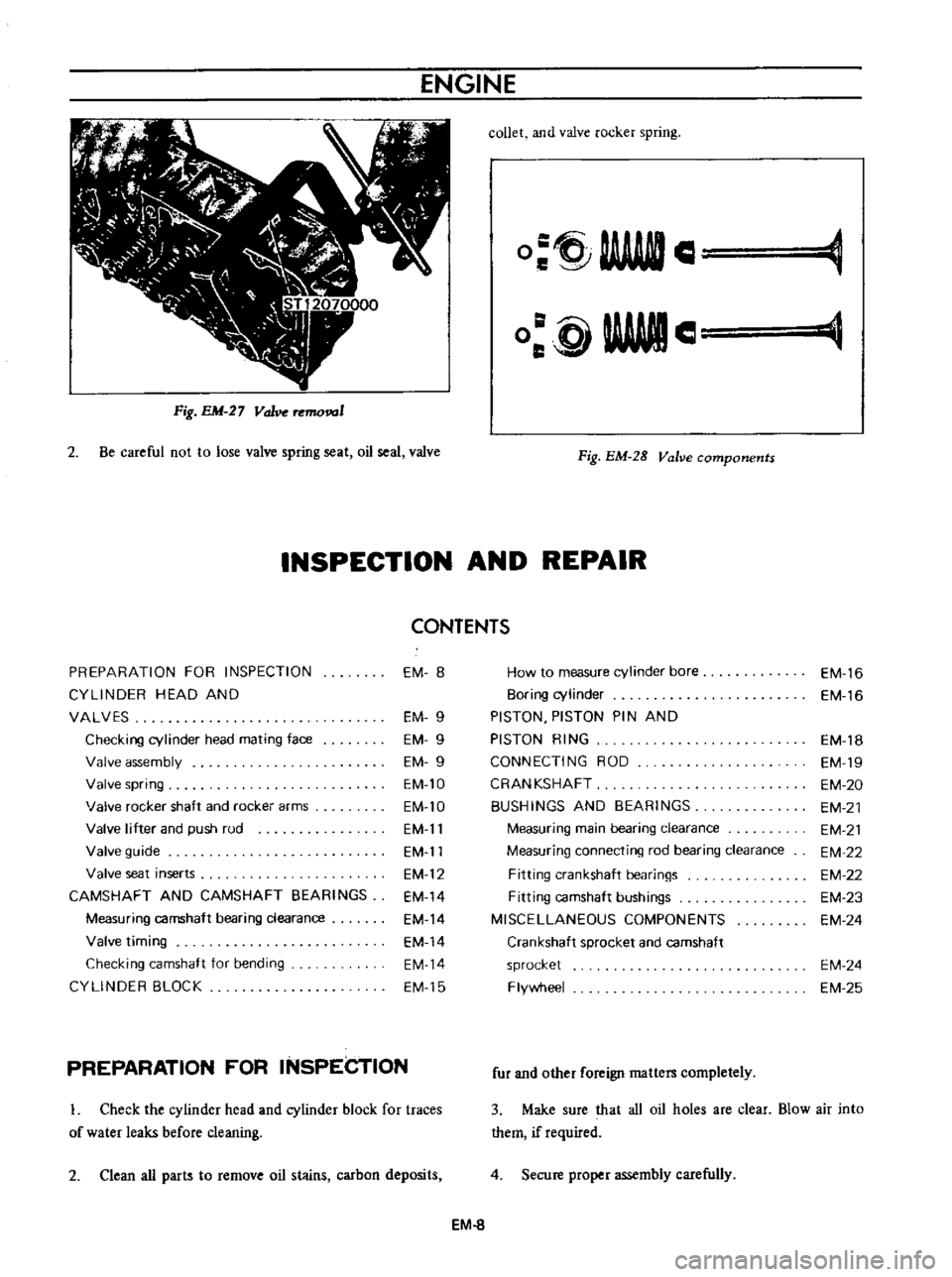

Fig

EM

27

Valve

mo

1

2

Be

careful

not

to

lose

valve

spring

seat

oil

seal

valve

collet

and

valve

rocker

spring

O

tj

AAAftIl

C

e

WWII

o

glAWle

Fig

EM

28

Valve

components

INSPECTION

AND

REPAIR

CONTENTS

PREPARATION

FOR

INSPECTION

EM

8

How

to

measure

cylinder

bore

EM

16

CYLlNOER

HEAD

AND

80ring

cylinder

EM

16

VALVES

EM

9

PISTON

PISTON

PIN

AND

Checking

cylinder

head

mating

face

EM

9

PISTON

RING

EM

18

Valve

assembly

EM

9

CONNECTING

ROD

EM

19

Valve

spring

EM

10

CRANKSHAFT

EM

20

Valve

rocker

shaft

and

rockei

arms

EM

lO

BUSHINGS

AND

BEARINGS

EM

21

Valve

lifter

and

push

rud

EM

11

Measuring

main

bearing

clearance

EM

21

Valve

guide

EM

11

Measuring

connecting

rod

bearing

clearance

EM

22

Valve

seat

inserts

EM

12

Fitting

crankshaft

bearings

EM

22

CAMSHAFT

AND

CAMSHAFT

BEARINGS

EM

14

Fitting

camshaft

bushings

EM

23

Measuring

camshaft

bearing

clearance

EM

14

MISCELLANEOUS

COMPONENTS

EM

24

Valve

timing

EM

14

Crankshaft

sprocket

and

camshaft

Checking

camshaft

for

bending

EM

14

sprocket

EM

24

CYLlNOER

BLOCK

EM

15

Flywheel

EM

25

PREPARATION

FOR

INSPECTION

L

Check

the

cylinder

head

and

cylinder

block

for

traces

of

water

leaks

before

cleaning

2

Clean

all

parts

to

remove

oil

stains

carbon

deposits

fur

and

other

foreign

matters

completely

3

Make

sure

that

all

oil

holes

are

clear

Blow

air

into

them

if

required

4

Secure

proper

assembly

carefully

EM

8

Page 349 of 513

ENGINE

MECHANICAL

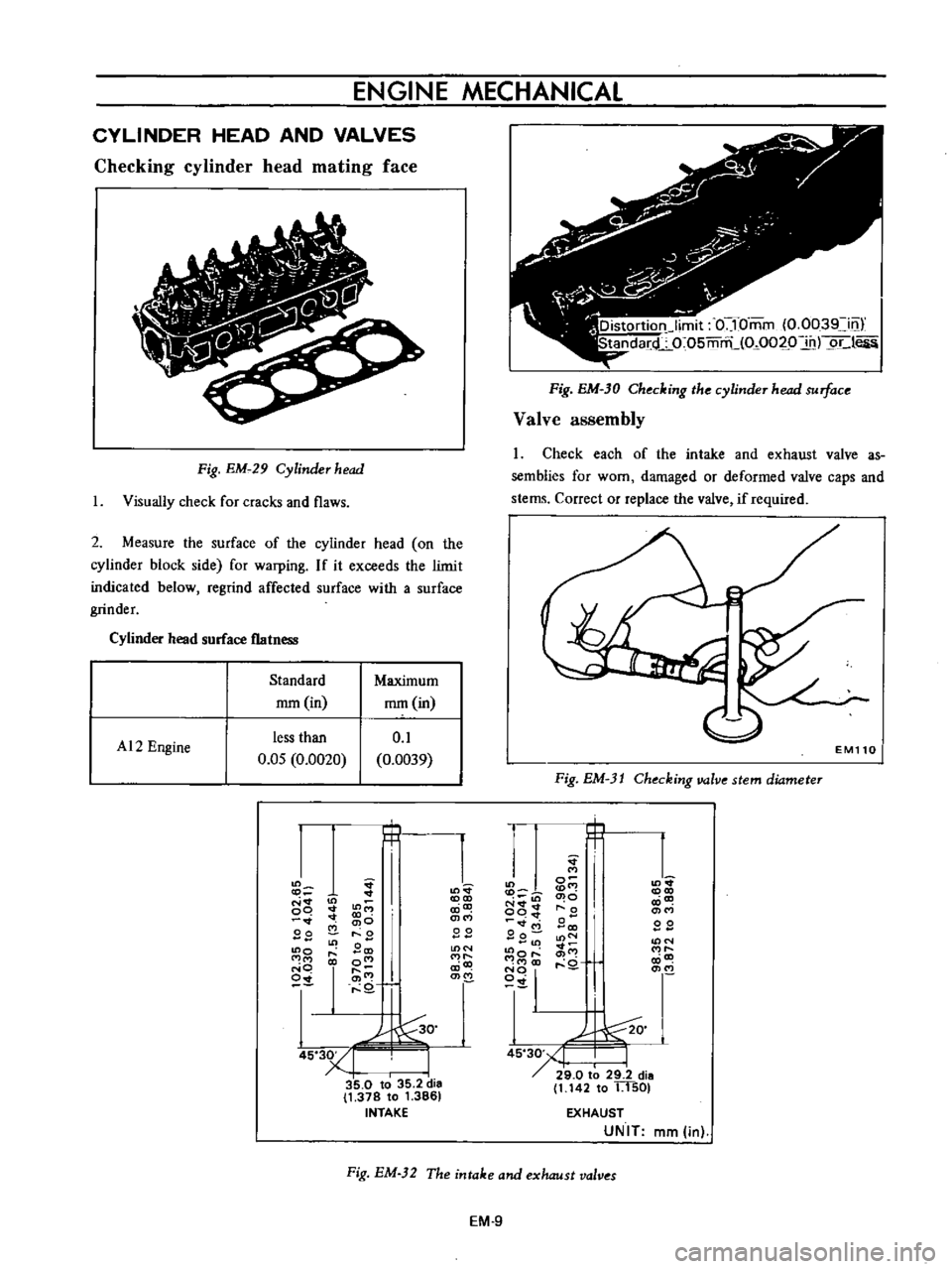

CYLINDER

HEAD

AND

VALVES

Checking

cylinder

head

mating

face

Fig

EMc29

Cylinder

head

I

Visually

check

for

cracks

and

flaws

2

Measure

the

surface

of

the

cylinder

head

on

the

cylinder

block

side

for

warping

If

it

exceeds

the

limit

indicated

below

regrind

affected

surface

with

a

surface

grinder

Cylinder

head

surface

flatness

Standard

Maximum

rom

in

mm

in

AI2

Engine

less

than

0

1

O

OS

0

0020

0

0039

t

C

in

00

co

0

00

2

0

Sco

co

0

0

i

Q

coco

a

ilt

BE

mIX

2

00

5

3YI

I

35

0

to

35

2

dia

1

378

to

1

3861

INTAKE

Fig

EM

30

Checking

the

cylinder

head

surface

Valve

a88embly

I

Check

each

of

the

intake

and

exhaust

valve

asc

semblies

for

wom

damaged

or

deformed

valve

caps

and

stems

Correct

or

replace

the

valve

if

required

l

EM110

Fig

EM

31

Chuking

valve

stem

diameter

t

L

coco

CO

co

BE

Ln

oq

q

od

M

2

g

tOo

18co1

O

c

0

DO

o

0

0

co

o

CO

co

J00

45

30

1

I

I

2

9

0

t

29

2

dia

1

142

to

1

l501

EXHAUST

UNIT

mm

in

Fig

EM

32

The

intake

and

exhaust

valves

EM

9

Page 350 of 513

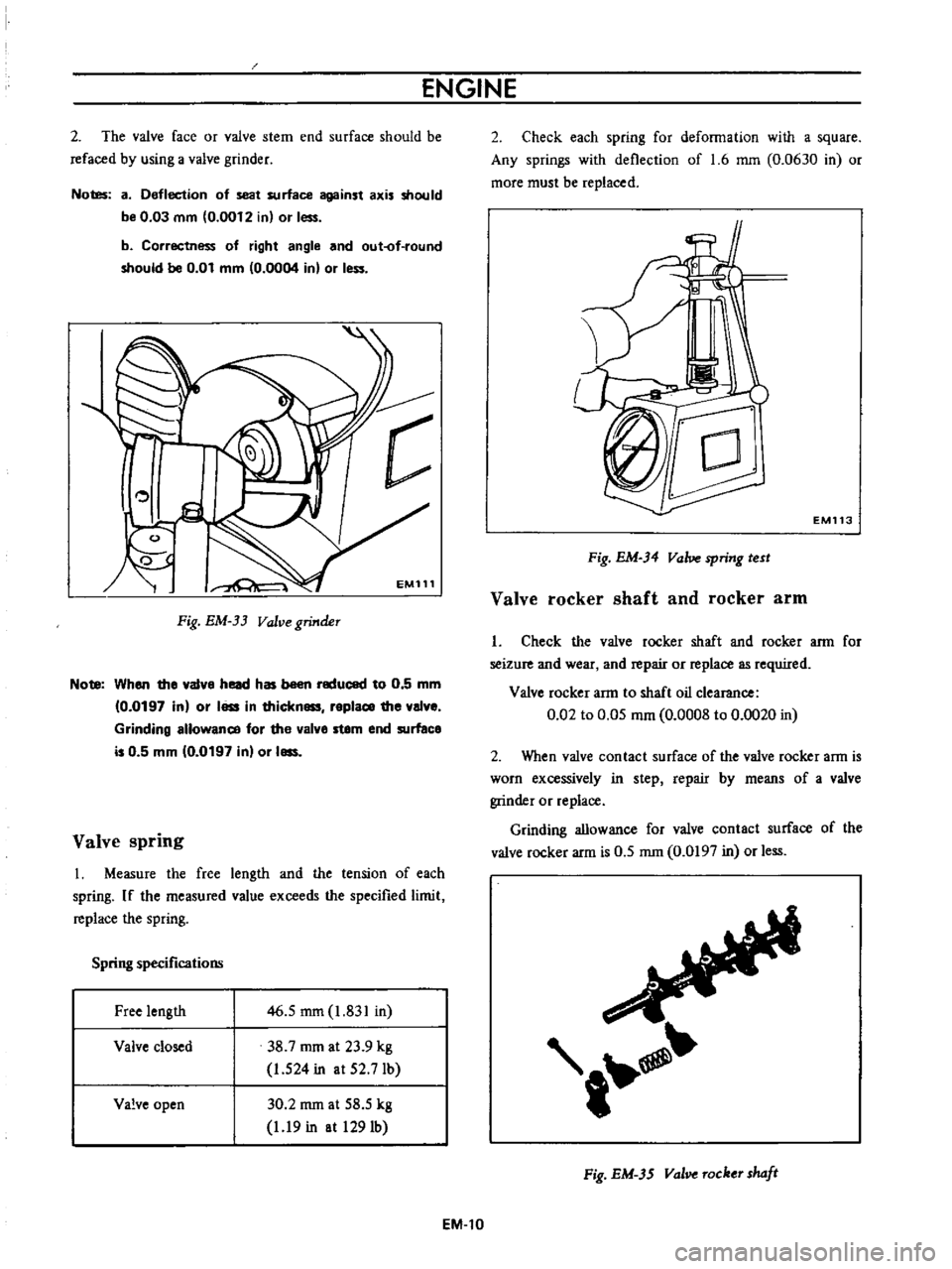

ENGINE

2

The

valve

face

or

valve

stem

end

surface

should

be

refaced

by

using

a

valve

grinder

Notes

a

Deflection

of

seat

surface

against

axis

should

be

0

03

mm

0

0012

in

or

less

b

Correctness

of

right

angle

and

out

of

round

should

be

0

01

mm

0

0004

in

or

I

c

EM111

Fig

EM

33

Valve

grinder

Note

When

the

a1ve

head

has

been

reduced

to

0

5

mm

0

0197

in

or

I

in

thickn

replace

the

al

e

Grinding

allowance

for

the

alve

stem

end

surface

is

0

5

mm

10

0197

in

or

I

Valve

spring

I

Measure

the

free

length

and

the

tension

of

each

spring

If

the

measured

value

exceeds

the

specified

limit

replace

the

spring

Spring

specifications

Free

length

46

5

mm

1

831

in

38

7

rom

at

23

9

kg

1

524

in

at

52

7Ib

Valve

closed

Valve

open

30

2

rom

at

58

5

kg

1

19

in

at

1291b

EM

l0

2

Check

each

spring

for

deformation

with

a

square

Any

springs

with

deflection

of

1

6

mm

0

0630

in

or

more

must

be

replaced

EM113

Fig

EM

34

Valve

spring

test

Valve

rocker

shaft

and

rocker

arm

I

Check

the

valve

rocker

shaft

and

rocker

arm

for

seizure

and

wear

and

repair

or

replace

as

required

Valve

rocker

arm

to

shaft

oil

clearance

0

02

to

0

05

mm

0

0008

to

0

0020

in

2

When

valve

contact

surface

of

the

valve

rocker

arm

is

worn

excessively

in

step

repair

by

means

of

a

valve

grinder

or

replace

Grinding

allowance

for

valve

contact

surface

of

the

valve

rocker

arm

is

0

5

rom

0

0197

in

or

less

t

Fig

EM

3S

val

Tocker

shaft

Page 351 of 513

ENGINE

MECHANICAL

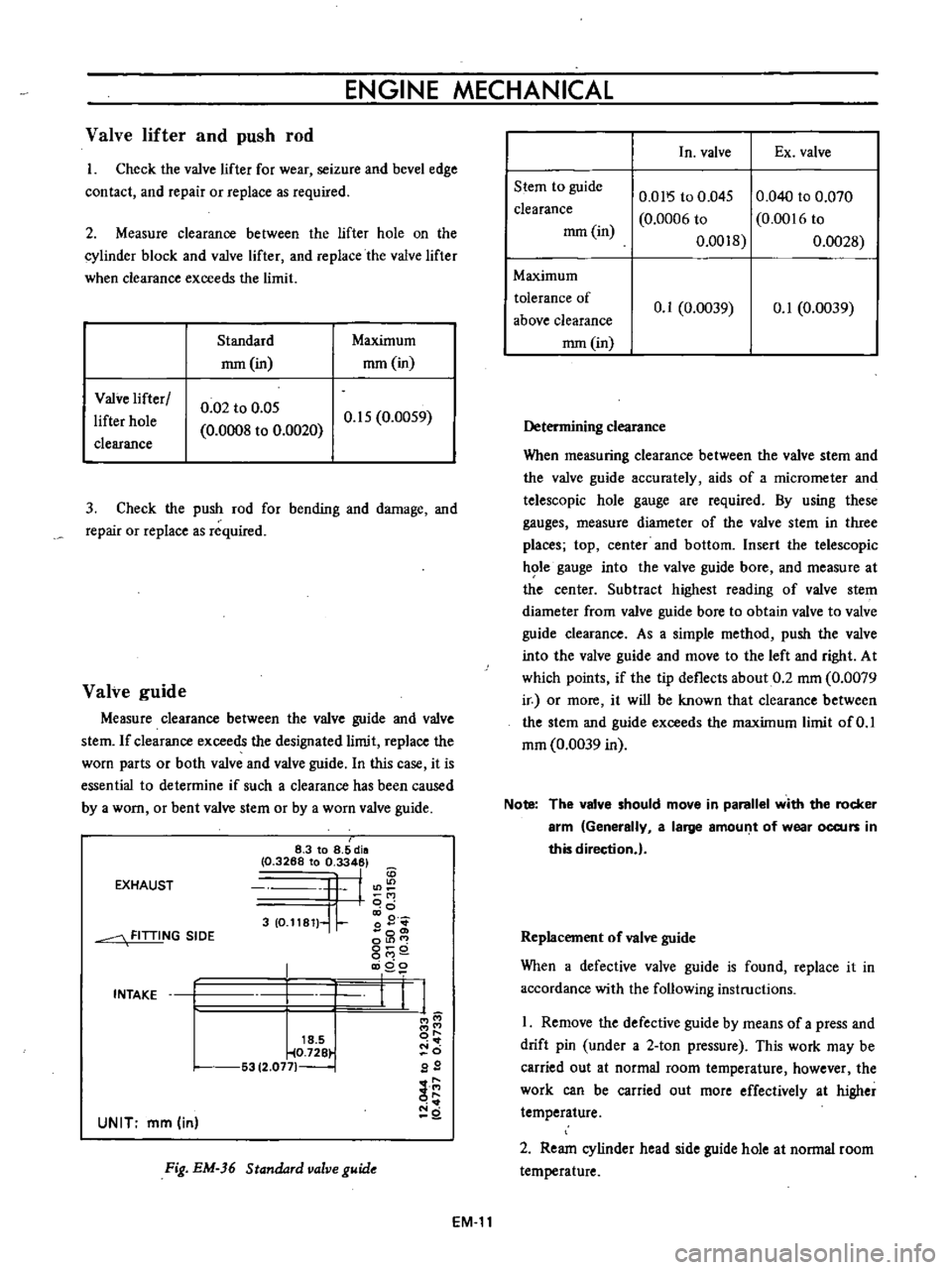

Valve

lifter

and

push

rod

L

Check

the

valve

lifter

for

wear

seizure

and

bevel

edge

contact

and

repair

or

replace

as

required

2

Measure

clearance

between

the

lifter

hole

on

the

cylinder

block

and

valve

lifter

and

replace

the

valve

lifter

when

clearance

exceeds

the

limit

Standard

rom

in

Maximum

rom

in

Valve

lifter

lifter

hole

clearance

0

02

to

0

05

0

0008

to

0

0020

0

15

0

0059

3

Check

the

push

rod

for

bending

and

damage

and

repair

or

replace

as

required

Valve

guide

Measure

clearance

between

the

valve

guide

and

valve

stem

If

clearance

exceeds

the

designated

limit

replace

the

worn

parts

or

both

valve

and

valve

guide

In

this

case

it

is

essential

to

determine

if

such

a

clearance

has

been

caused

by

a

worn

or

bent

valve

stem

or

by

a

worn

valve

guide

EXHAUST

8

3

to

8

5

dill

03266

to

T

3

10

11S11

I

FITTING

SIDE

iD

o

0

co

0

o

c

o

LOt

0

0

0

a

9

ll

l

INTAKE

1S

5

o

O

726

5312

0771

iO

0

N

0

00

E

2

UNIT

mm

in

Fig

EM

J6

Standard

valve

guide

In

valve

Ex

valve

Stem

to

guide

clearance

rom

in

0

Dl

5

to

0

045

0

0006

to

0

0018

0

040

to

0

070

0

0016

to

0

0028

Maximum

tolerance

of

above

clearance

rom

in

o

I

0

0039

0

1

0

0039

Determining

clearance

When

measuring

clearance

between

the

valve

stem

and

the

valve

guide

accurately

aids

of

a

micrometer

and

telescopic

hole

gauge

are

required

By

using

these

gauges

measure

diameter

of

the

valve

stem

in

three

places

top

center

and

bottom

Insert

the

telescopic

h

le

gauge

into

the

valve

guide

bore

and

measure

at

the

center

Subtract

highest

reading

of

valve

stem

diameter

from

valve

guide

bore

to

obtain

valve

to

valve

guide

clearance

As

a

simple

method

push

the

valve

into

the

valve

guide

and

move

to

the

left

and

right

At

which

points

if

the

tip

deflects

about

0

2

mm

0

0079

ir

or

more

it

will

be

known

that

clearance

between

the

stem

and

guide

exceeds

the

maximum

limit

of

0

1

mm

0

0039

in

Note

The

valve

should

move

in

parallel

with

the

rocker

arm

Generally

a

large

amoul

t

of

wear

occurs

in

this

direction

l

Replacement

of

valve

guide

When

a

defective

valve

guide

is

found

replace

it

in

accordance

with

the

following

instructions

I

Remove

the

defective

guide

by

means

of

a

press

and

drift

pin

under

a

2

ton

pressure

This

work

may

be

carried

out

at

normal

room

temperature

however

the

work

can

be

carried

out

more

effectively

at

higher

temperature

2

Ream

cylinder

head

side

guide

hole

at

nonnal

room

temperature

EM

l1

Page 352 of 513

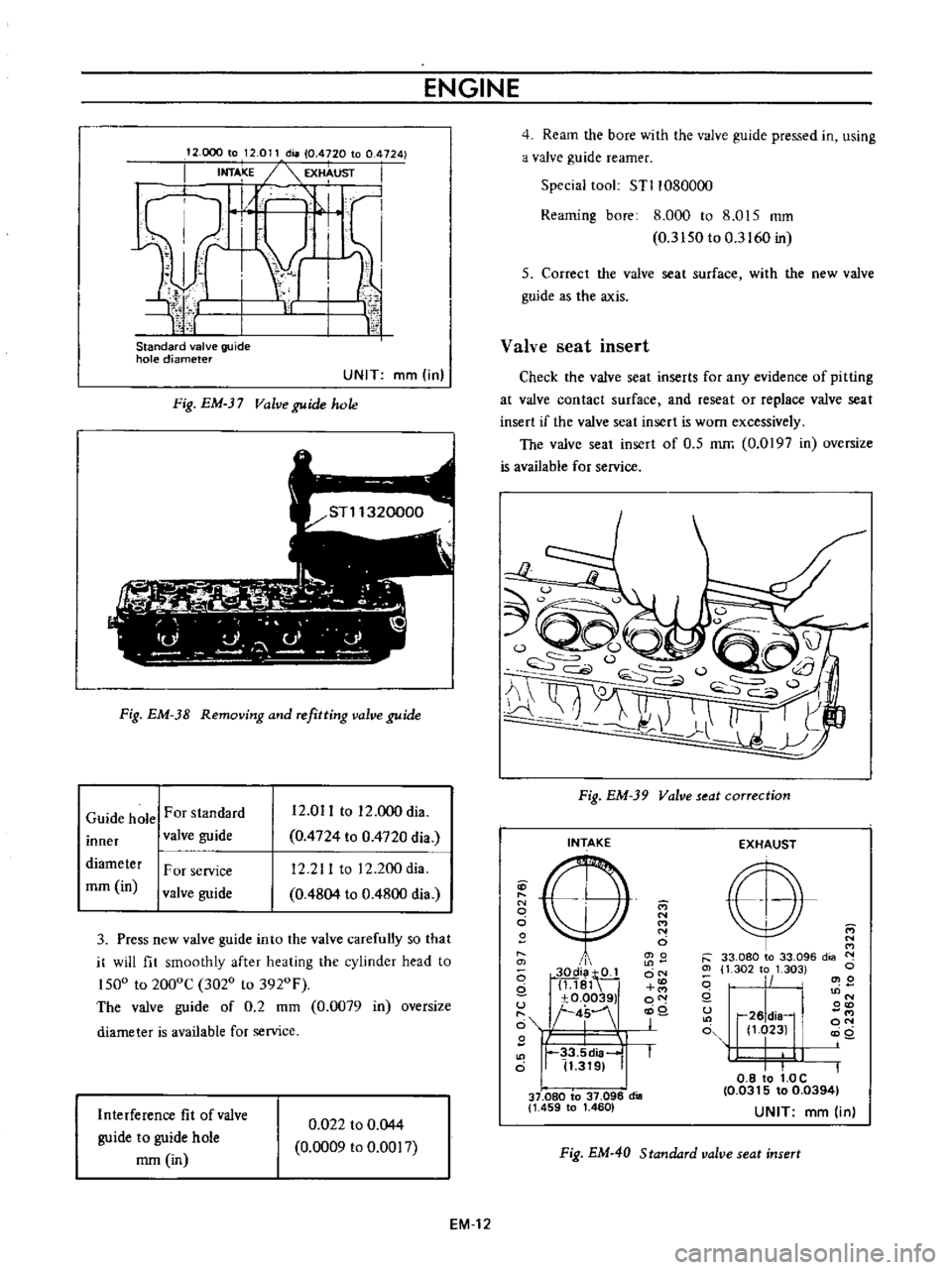

ENGINE

12

000

to

12

011

dia

0

4720

to

0

4724

I

t

r

1

1

1

ftlM

e

f

i1i

e

e

I

Standard

alve

guide

hole

diameter

UNIT

mm

in

Fig

EM

Valve

guide

hole

Fig

EM

38

Removing

and

refitting

valve

guide

Guide

hole

For

standard

inner

valve

guide

12

011

to

12

000

dia

0

4724

to

0

4720

dia

12

211

to

12

200dia

0

4804

to

0

4800

dia

diameter

rom

in

F

or

service

valve

guide

3

Press

new

valve

guide

into

the

valve

carefully

so

that

it

will

fit

smoothly

after

heating

the

cylinder

head

to

ISOo

to

2000C

3020

to

3920F

The

valve

guide

of

0

2

mm

0

0079

in

oversize

diameter

is

available

for

service

Interference

fit

of

valve

guide

to

guide

hole

mm

in

0

022

to

0

044

0

0009

to

0

0017

4

Ream

the

bore

with

the

valve

guide

pressed

in

using

a

valve

guide

reamer

Special

tool

STl1080000

Reaming

bore

8

000

to

8

015

mm

0

3

ISO

to

0

3160

in

5

Correct

the

valve

seat

surface

with

the

new

valve

guide

as

the

axis

Valve

seat

insert

Check

the

valve

seat

inserts

for

any

evidence

of

pitting

at

valve

contact

surface

and

reseat

or

replace

valve

seat

insert

if

the

valve

seat

insert

is

worn

excessively

The

valve

seat

insert

of

O

S

mrr

0

0197

in

oversize

is

available

for

service

Fig

EM

39

Valve

seat

correction

INTAKE

D

N

o

o

i

i

o

2Q

Qi

tQJ

g

1

181

u

xO

00391

t

4

I

J

1

11

33

5d

a

o

I

11

3191

37

080

to

37

096

dill

1

459

to

1

460

M

N

M

N

o

0

0

ON

o

0

j

EXHAUST

E

r

33

080

to

33

096

dia

N

Ol

1

302

to

1

303

c

i

1

2

I

N

0

r26

dia

11

023

0

0

8

to

1

0C

10

0315

to

0

03941

UNIT

mm

in

Cl

Q

u

o

Fig

EM

40

Standard

valve

seat

insert

EM

12

Page 354 of 513

ENGINE

CAMSHAFT

AND

CAMSHAFT

BEARING

Measuring

camshaft

bearing

clearance

Measure

inner

diameter

of

the

camshaft

bearing

and

outer

diameter

of

the

camshaft

journaL

If

camshaft

bearing

clearance

is

excessive

replace

the

cylinder

block

assembly

Limit

0

15mm

0

0059

in

Standard

o

oi

to

0

07mm

M012

to

0

0627

in

Fig

EM

42

Camshaft

bearing

check

1st

2nd

Oil

clearance

mm

in

3rd

4th

5th

1st

Inner

I

2nd

I

diameter

of

I

I

camshaft

3rd

bearing

mm

in

14th

I

15th

I

Standard

0

037

to

0

060

0

0015

to

0

0024

0

027

to

0

050

0

00

to

0

0020

0

040

to

0

063

0

0016

to

0

0025

0

027

to

0

050

0

0011

to

0

0020

0

037

to

0

060

0

0015

to

0

0024

43

833

to

43

843

i

7257

to

I

7261

43

323

to

43

333

l

7050

to

1

7060

42

836

to

42

846

1

6865

to

1

6868

42

323

to

42

333

1

6663

to

1

6667

41

258

to

41

268

1

6243

to

1

6247

Wear

limit

0

15

0

0059

1

1

1

1

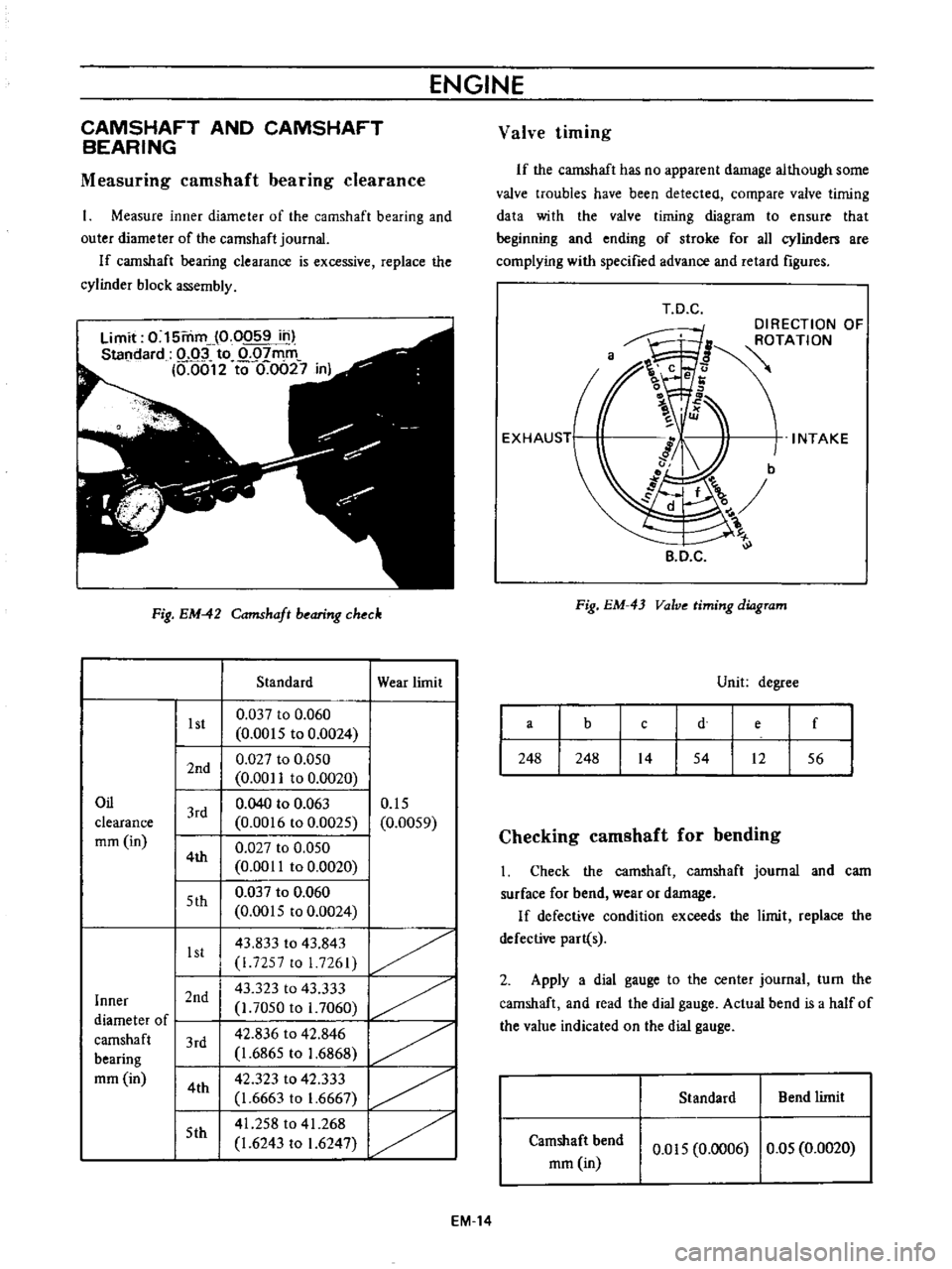

Valve

timing

If

the

camshaft

has

no

apparent

damage

although

some

valve

troubles

have

been

detected

compare

valve

timing

data

with

the

valve

timing

diagram

to

ensure

that

beginning

and

ending

of

stroke

for

all

cylinden

are

complying

with

specified

advance

and

retard

figures

T

D

C

DIRECTION

OF

ROTATION

INTAKE

B

D

C

Fig

EM

43

Valve

timing

diagram

Unit

degree

a

b

e

f

d

c

248

248

14

54

12

56

Checking

camshaft

for

bending

Check

the

camshaft

camshaft

journal

and

cam

surface

for

bend

wear

or

damage

If

defective

condition

exceeds

the

limit

replace

the

defective

part

s

2

Apply

a

dial

gauge

to

the

center

journal

turn

the

camshaft

and

read

the

dial

gauge

Actual

bend

is

a

half

of

the

value

indicated

on

the

dial

gauge

Standard

Bend

limit

Camshaft

bend

mm

in

0

015

0

0006

0

05

0

0020

EM

14

Page 355 of 513

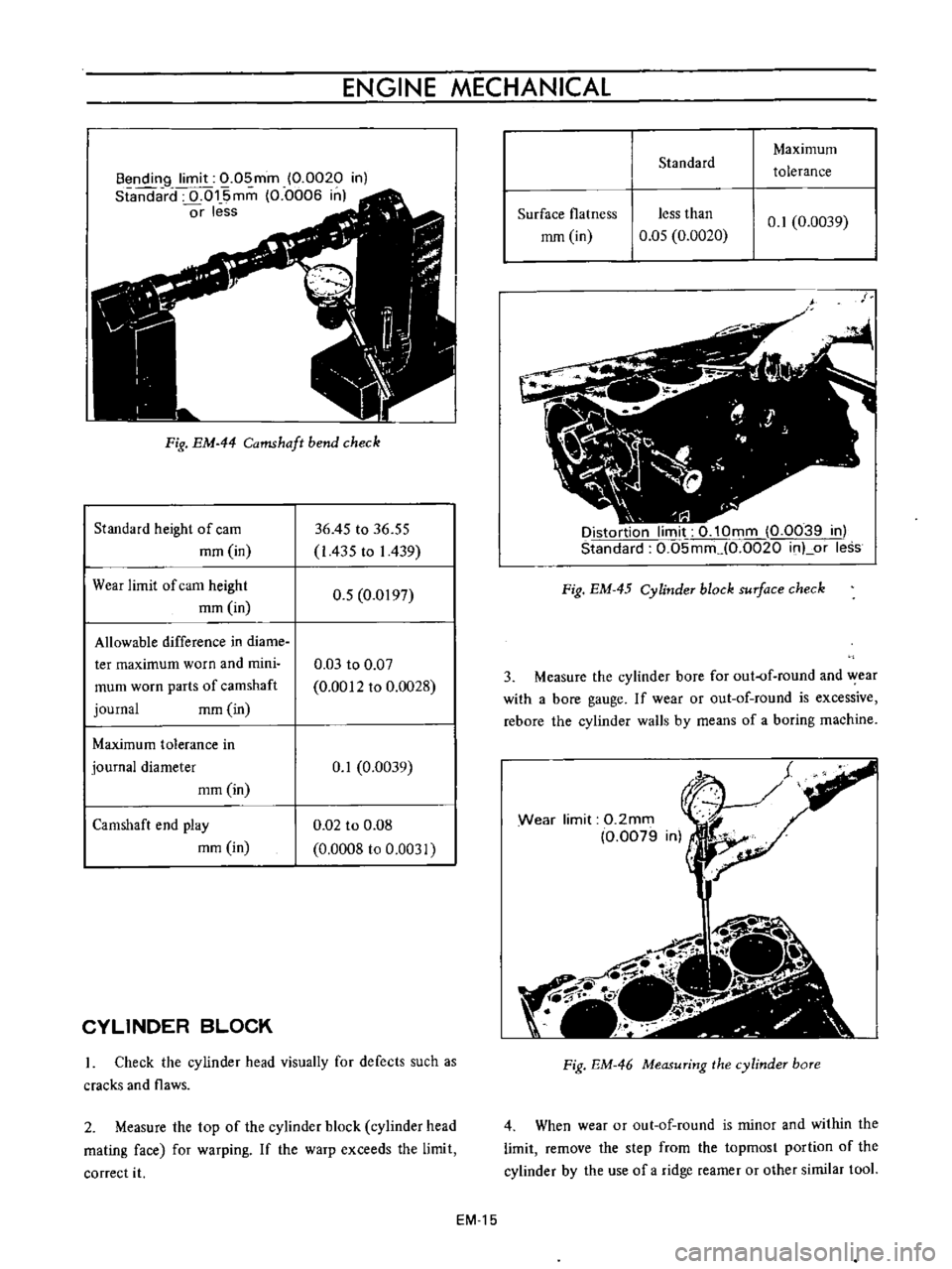

ENGINE

MECHANICAL

Bendin9

limit

0

05mm

0

0020

in

Standard

0

of5mm

0

0006

in

or

less

Fig

EM

44

Camshaft

bend

check

Standard

height

of

cam

mm

in

36

45

to

36

55

I

435

to

I

439

Wear

limit

of

cam

height

mm

in

0

5

0

0197

Allowable

difference

in

diame

ter

maximum

worn

and

mini

mum

worn

parts

of

camshaft

journal

mm

in

0

03

to

0

07

0

0012

to

0

0028

Maximum

tolerance

in

journal

diameter

mm

in

0

1

0

0039

Camshaft

end

play

mm

in

0

02

to

0

08

0

0008

to

0

0031

CYLINDER

BLOCK

Check

the

cylinder

head

visually

for

defects

such

as

cracks

and

flaws

2

Measure

the

top

of

the

cylinder

block

cylinder

head

mating

face

for

warping

If

the

warp

exceeds

the

limit

correct

it

EM

15

Standard

Maximum

tolerance

Surface

flatness

less

than

mm

in

0

05

0

0020

0

1

0

0039

Distortion

limit

0

10mm

0

0039

in

Standard

0

05mm

0

0020

inLor

less

Fig

EM

45

Cylinder

block

surface

check

3

Measure

the

cylinder

bore

for

out

of

round

and

wear

with

a

bore

gauge

If

wear

or

out

of

round

is

excessive

rebore

the

cylinder

walls

by

means

of

a

boring

machine

Wear

limit

0

2mm

0

0079

Fig

EM

46

Measuring

the

cylinder

bore

4

When

wear

or

out

of

round

is

minor

and

within

the

limit

remove

the

step

from

the

topmost

portion

of

the

cylinder

by

the

use

of

a

ridge

reamer

or

other

similar

tooL

Page 357 of 513

ENGINE

MECHANICAL

5

M

co

El

co

I

ED

I

UNIT

mm

in

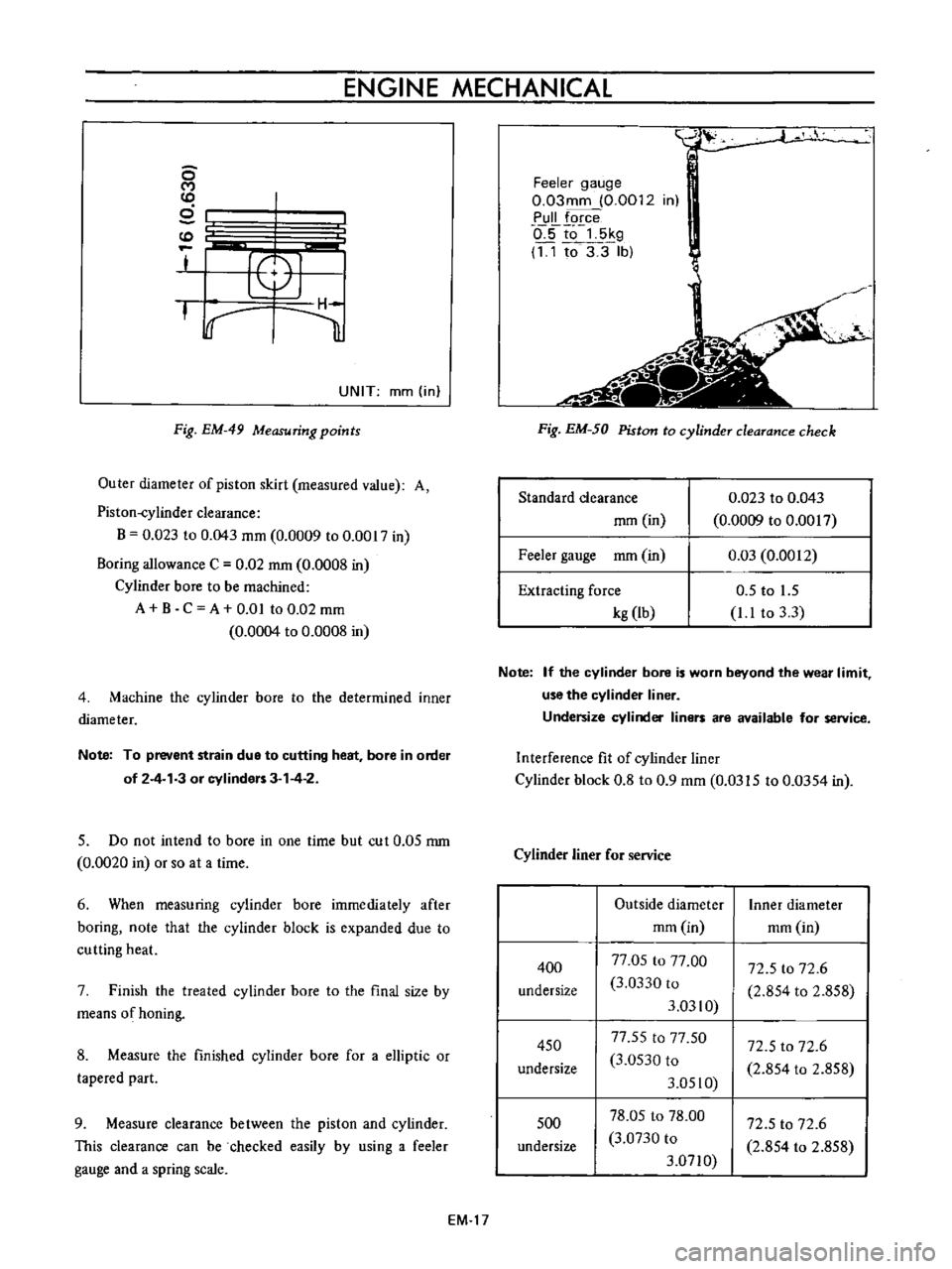

Fig

EM

49

Measuring

points

Outer

diameter

of

piston

skirt

measured

value

A

Piston

eylinder

clearance

B

0

023

to

0

043

mm

0

0009

to

0

0017

in

Boring

allowance

C

0

02

rom

0

0008

in

Cylinder

bore

to

be

machined

A

B

C

A

om

to

0

02

mm

0

0004

to

0

0008

in

4

Machine

the

cylinder

bore

to

the

determined

inner

diameter

Note

To

prevent

strain

due

to

cutting

heat

bore

in

order

of

2

4

3

or

cylinders

3

4

2

5

Do

not

intend

to

bore

in

one

time

but

cut

0

05

rom

0

0020

in

or

so

at

a

time

6

When

measuring

cylinder

bore

immediately

after

boring

note

that

the

cylinder

block

is

expanded

due

to

cutting

heat

7

Finish

the

treated

cylinder

bore

to

the

final

size

by

means

of

honing

8

Measure

the

finished

cylinder

bore

for

a

elliptic

or

tapered

part

9

Measure

clearance

between

the

piston

and

cylinder

This

clearance

can

be

checked

easily

by

using

a

feeler

gauge

and

a

spring

scale

EM

17

Feeler

gauge

0

03mm

0

0012

in

Pull

force

o

5to

5kg

11

to3

3

lb

i

Fig

EM

50

Piston

to

cylinder

clearance

check

Standard

clearance

rom

in

0

023

to

0

043

0

0009

to

0

0017

0

03

0

0012

Feeler

gauge

mm

in

Extracting

force

kg

Ib

0

5

to

1

5

1

1

to

3

3

Note

If

the

cylinder

bore

is

worn

beyond

the

wear

limit

use

the

cylinder

liner

Undersize

cylinder

liners

are

available

for

service

Interference

fit

of

cylinder

liner

Cylinder

block

0

8

to

0

9

mm

0

0315

to

0

0354

in

Cylinder

liner

for

service

400

undersize

Outside

diameter

mm

in

77

05

to

77

00

3

0330

to

3

0310

77

55

to

77

50

3

0530

to

3

0510

78

05

to

78

00

3

0730

to

3

0710

72

5

to

72

6

2

854

to

2

858

Inner

diameter

mm

in

72

5

to

72

6

2

854

to

2

858

450

undersize

72

5

to

72

6

2

854

to

2

858

500

undersize

Page 358 of 513

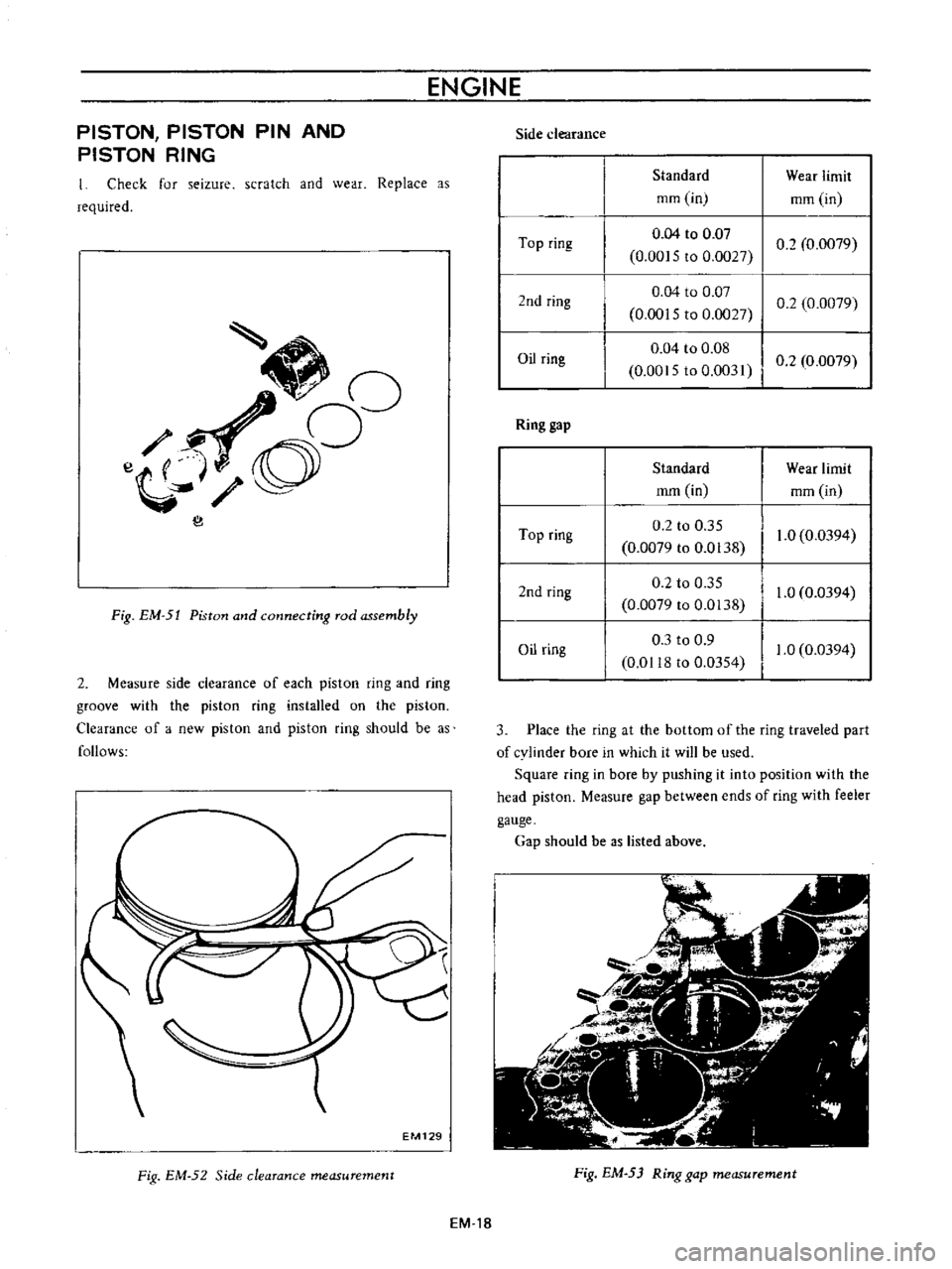

ENGINE

PISTON

PISTON

PIN

AND

PISTON

RING

Check

for

seizure

scratch

and

wear

Replace

as

required

o

10

e

O

I

l

Fig

EM

51

Piston

and

connecting

rod

assembly

2

Measure

side

clearance

of

each

piston

ring

and

ring

groove

with

the

piston

ring

installed

on

the

piston

Clearance

of

a

new

piston

and

piston

ring

should

be

as

follows

EM129

Fig

EM

52

Side

clearance

measurement

EM

18

Side

clearance

Standard

Wear

limit

mm

in

mm

in

Top

ring

0

04

to

0

Q7

02

0

0079

0

00

5

to

0

0027

2nd

ring

0

04

to

0

07

0

0015

to

0

027

0

2

0

0079

Oil

ring

0

04

to

0

08

0

0015

to

0

0031

I

0

2

0

0079

Ring

gap

Standard

Wear

limit

mm

in

mm

in

Top

ring

0

2

to

0

35

1

0

0

0394

0

0079

to

0

0138

2nd

ring

0

2

to

0

35

1

0

0

0394

0

0079

to

0

0138

Oil

ring

0

3

to

0

9

1

0

0

0394

0

01

8

to

0

0354

3

Place

the

ring

at

the

bottom

of

the

ring

traveled

part

of

cylinder

bore

in

which

it

will

be

used

Square

ring

in

bore

by

pushing

it

into

position

with

the

head

piston

Measure

gap

between

ends

of

ring

with

feeler

gauge

Gap

should

be

as

listed

above

Fig

EM

53

Ring

gap

measurement