check engine DATSUN B110 1973 Service Manual Online

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 428 of 513

ENGINE

EE022

Fig

EE

18

Ground

test

of

armature

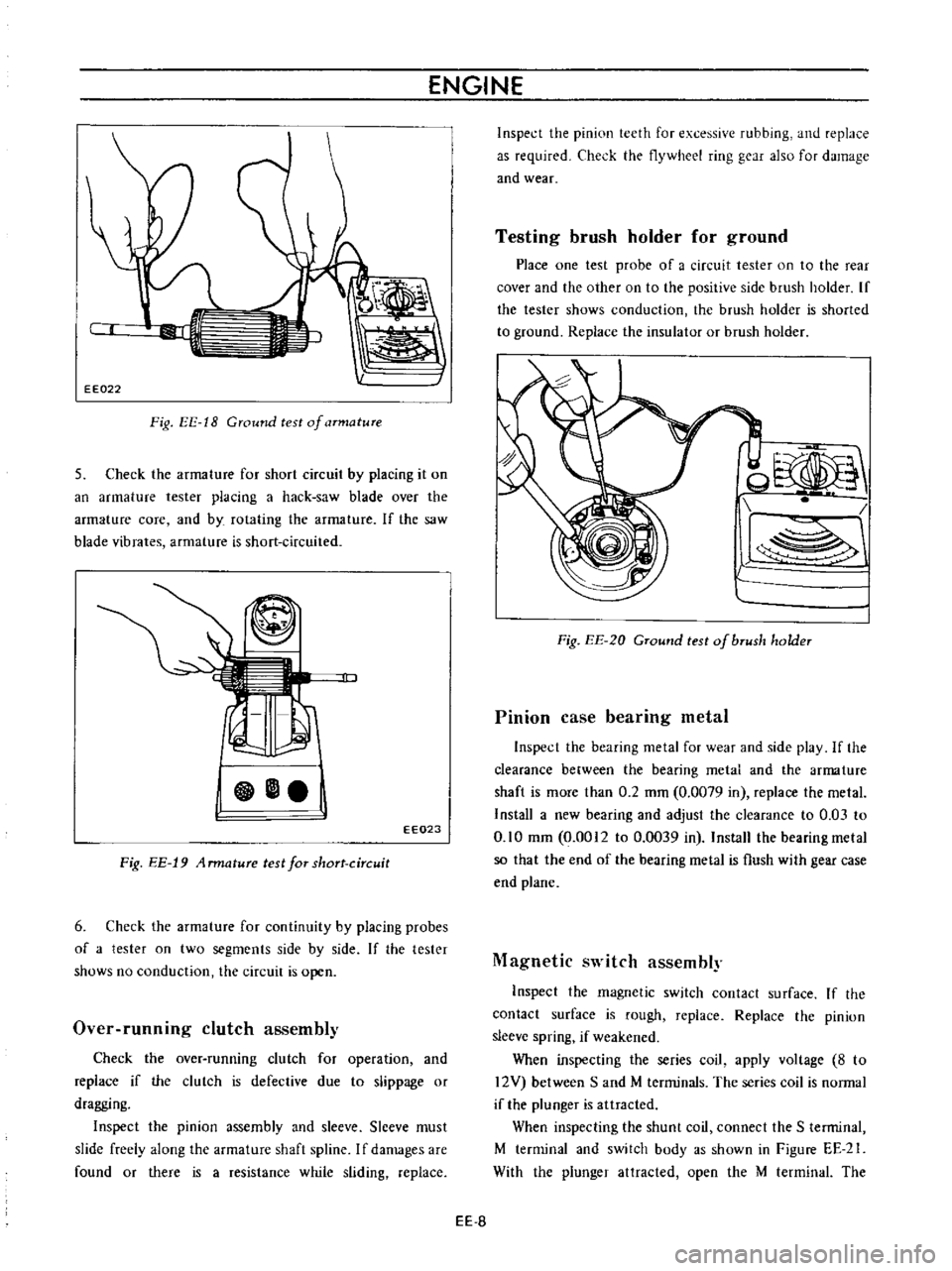

5

Check

the

armature

for

short

circuit

by

placing

it

on

an

armature

tester

placing

a

hack

saw

blade

over

the

armature

core

and

by

rotating

the

armature

If

the

saw

blade

vibrates

armature

is

short

circuited

EE023

Fig

EE

19

4

rmature

test

for

short

circuit

6

Check

the

armature

for

continuity

by

placing

probes

of

a

tester

on

two

segments

side

by

side

If

the

tester

shows

no

conduction

the

circuit

is

open

Over

runnmg

clutch

assembly

Check

the

over

running

clutch

for

operation

and

replace

if

the

clutch

is

defective

due

to

slippage

or

dragging

Inspect

the

pinion

assembly

and

sleeve

Slceve

must

slide

freely

along

the

armature

shaft

spline

I

f

damages

are

found

or

there

is

a

resistance

while

sliding

replace

Inspect

the

pinion

teeth

for

excessive

rubbing

and

replace

as

required

Check

the

flywheel

ring

gear

also

for

damage

and

wear

Testing

brush

holder

for

ground

Place

one

test

probe

of

a

circuit

tester

on

to

the

rear

cover

and

the

other

on

to

the

positive

side

brush

holder

If

the

tester

shows

conduction

the

brush

holdcr

is

shorted

to

ground

Replace

the

insulator

or

brush

holder

od

l

Fig

EE

20

GTound

test

of

bTush

holder

Pinion

case

bearing

metal

Inspect

the

bearing

metal

for

wear

and

sidc

play

If

the

clearance

between

the

bearing

metal

and

the

arma

ture

shaft

is

mOTe

than

0

2

mm

0

0079

in

replace

the

metal

Install

a

new

bearing

and

adjust

the

clearance

to

0

03

to

0

10

mm

0

0012

to

0

0039

in

Install

the

bearing

metal

so

that

the

end

of

the

bearing

metal

is

flush

with

gear

case

end

plane

Magnetic

switch

assembly

Inspect

the

magnetic

switch

contact

surface

If

the

contact

surface

is

rough

replace

Replace

the

pinion

sleeve

spring

if

weakened

When

inspecting

the

series

coil

apply

voltagc

8

to

12V

between

Sand

M

terminals

The

series

coil

is

normal

if

the

plunger

is

attracted

When

inspecting

the

shunt

coil

connect

the

S

terminal

M

terminal

and

switch

body

as

shown

in

Figure

EE

21

With

the

plunger

attracted

open

the

M

terminal

The

EE

S

Page 430 of 513

ENGINE

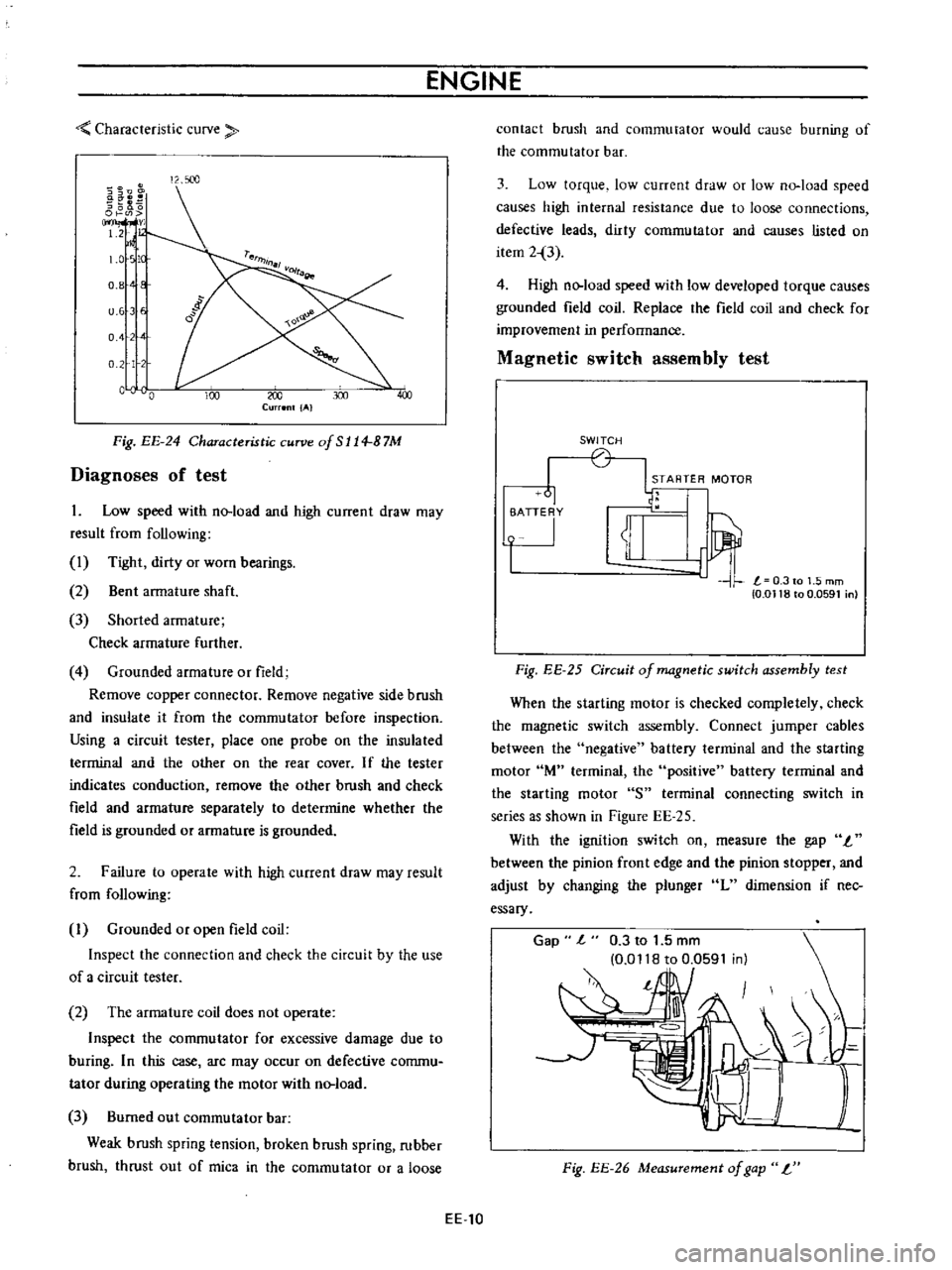

Characteristic

curve

i

8

s

l00

0

OJ

m

v

1

2

1

0

tc

0

8

E

u

6

E

o

4

0

2

L

c

0

00

J

300

Current

IAI

Fig

EE

24

Characteristic

curve

of

S

114

B

7M

Diagnoses

of

test

1

Low

speed

with

no

load

and

high

current

draw

may

result

from

following

1

Tight

dirty

or

worn

bearings

2

Bent

armature

shaft

3

Shorted

armature

Check

armature

further

4

Grounded

armature

or

field

Remove

copper

connector

Remove

negative

side

brush

and

insulate

it

from

the

commutator

before

inspection

Using

a

circuit

tester

place

one

probe

on

the

insulated

terminal

and

the

other

on

the

rear

cover

If

the

tester

indicates

conduction

remove

the

other

brush

and

check

field

and

armature

separately

to

determine

whether

the

field

is

grounded

or

armature

is

grounded

2

Failure

to

operate

with

high

current

draw

may

result

from

following

I

Grounded

or

open

field

coil

Inspect

the

connection

and

check

the

circuit

by

the

use

of

a

circuit

tester

2

The

armature

coil

does

not

operate

Inspect

the

commutator

for

excessive

damage

due

to

buring

In

this

case

arc

may

occur

on

defective

commu

tator

during

operating

the

motor

with

no

load

3

Burned

out

commutator

bar

Weak

brush

spring

tension

broken

brush

spring

rubber

brush

thrust

out

of

mica

in

the

commutator

or

a

loose

EE

10

contact

brush

and

commutator

would

cause

burning

of

the

commutator

bar

3

Low

torque

low

current

draw

or

low

no

load

speed

causes

high

internal

resistance

due

to

loose

connections

defective

leads

dirty

commutator

and

causes

listed

on

item

2

3

4

High

no

load

speed

with

low

developed

torque

causes

grounded

field

coil

Replace

the

field

coil

and

check

for

improvement

in

performance

Magnetic

switch

assembly

test

SWITCH

STARTER

MOTOR

61

1u

i

T

0

0118

to

0

0591

n

Fig

EE

25

Circuit

of

magnetic

switch

assembly

test

When

the

starting

motor

is

checked

completely

check

the

magnetic

switch

assembly

Connect

jumper

cables

between

the

negative

battery

terminal

and

the

starting

motor

lM

terminal

the

positive

battery

terminal

and

the

starting

motor

S

terminal

connecting

switch

in

series

as

shown

in

Figure

EE

25

With

the

ignition

switch

on

measure

the

gap

I

between

the

pinion

front

edge

and

the

pinion

stopper

and

adjust

by

changing

the

plunger

L

dimension

if

nec

essary

Gap

l

0

3

to

1

5

mm

0

0118

to

0

0591

in

l

Fig

EE

26

Measurement

of

gap

L

Page 439 of 513

ENGINE

ELECTRICAL

SYSTEM

Note

Use

care

in

handling

diode

assembly

to

prevent

an

undue

stress

on

it

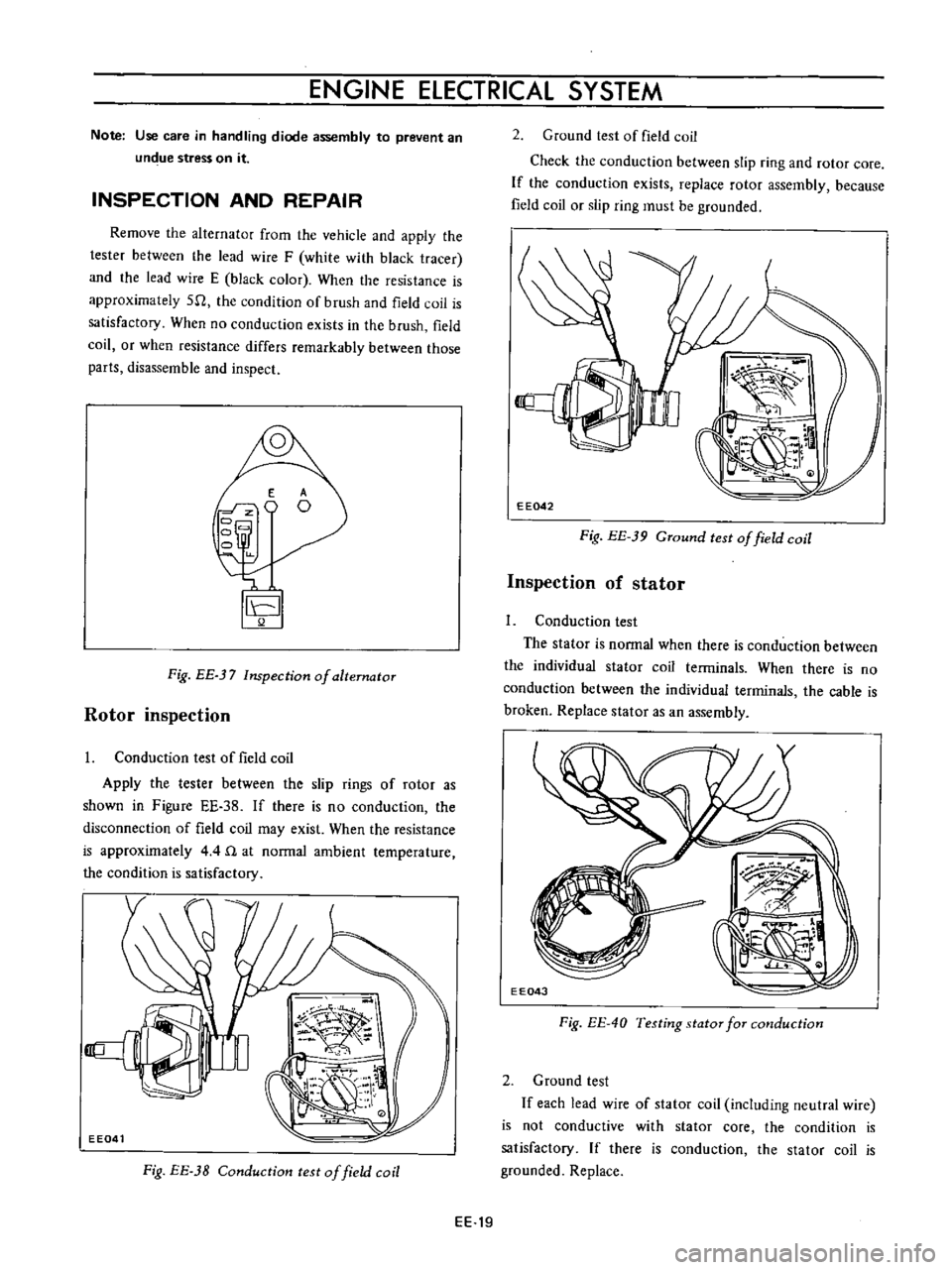

INSPECTION

AND

REPAIR

Remove

the

alternator

from

the

vehicle

and

apply

the

tester

between

the

lead

wire

F

white

with

black

tracer

and

the

lead

wire

E

black

color

When

the

resistance

is

approximately

511

the

condition

of

brush

and

field

coil

is

satisfactory

When

no

conduction

exists

in

the

brush

field

coil

or

when

resistance

differs

remarkably

between

those

parts

disassemble

and

inspect

E

o

Fig

BE

37

Inspection

of

alternator

Rotor

inspection

I

Conduction

test

of

field

coil

Apply

the

tester

between

the

slip

rings

of

rotor

as

shown

in

Figure

EE

38

If

there

is

no

conduction

the

disconnection

of

field

coil

may

exist

When

the

resistance

is

approximately

4

4

n

at

normal

ambient

temperature

the

condition

is

satisfactory

Fig

EE

3B

Conduction

test

of

field

coil

2

Ground

test

of

field

coil

Check

the

conduction

between

slip

ring

and

rotor

core

If

the

conduction

exists

replace

rotor

assembly

because

field

coil

or

slip

ring

must

be

grounded

EE042

Fig

EE

39

GTound

test

of

field

coil

Inspection

of

stator

1

Conduction

test

The

stator

is

normal

when

there

is

conduction

between

the

individual

stator

coil

terminals

When

there

is

no

conduction

between

the

individual

terminals

the

cable

is

broken

Replace

stator

as

an

assembly

EE043

Fig

EE

40

Testing

stator

for

cmlduction

2

Ground

test

If

each

lead

wire

of

stator

coil

including

neutral

wire

is

not

conductive

with

stator

core

the

condition

is

satisfactory

If

there

is

conduction

the

stator

coil

is

grounded

Replace

EE

19

Page 440 of 513

ENGINE

Stator

core

EE044

Fig

EE

41

Testing

stator

for

ground

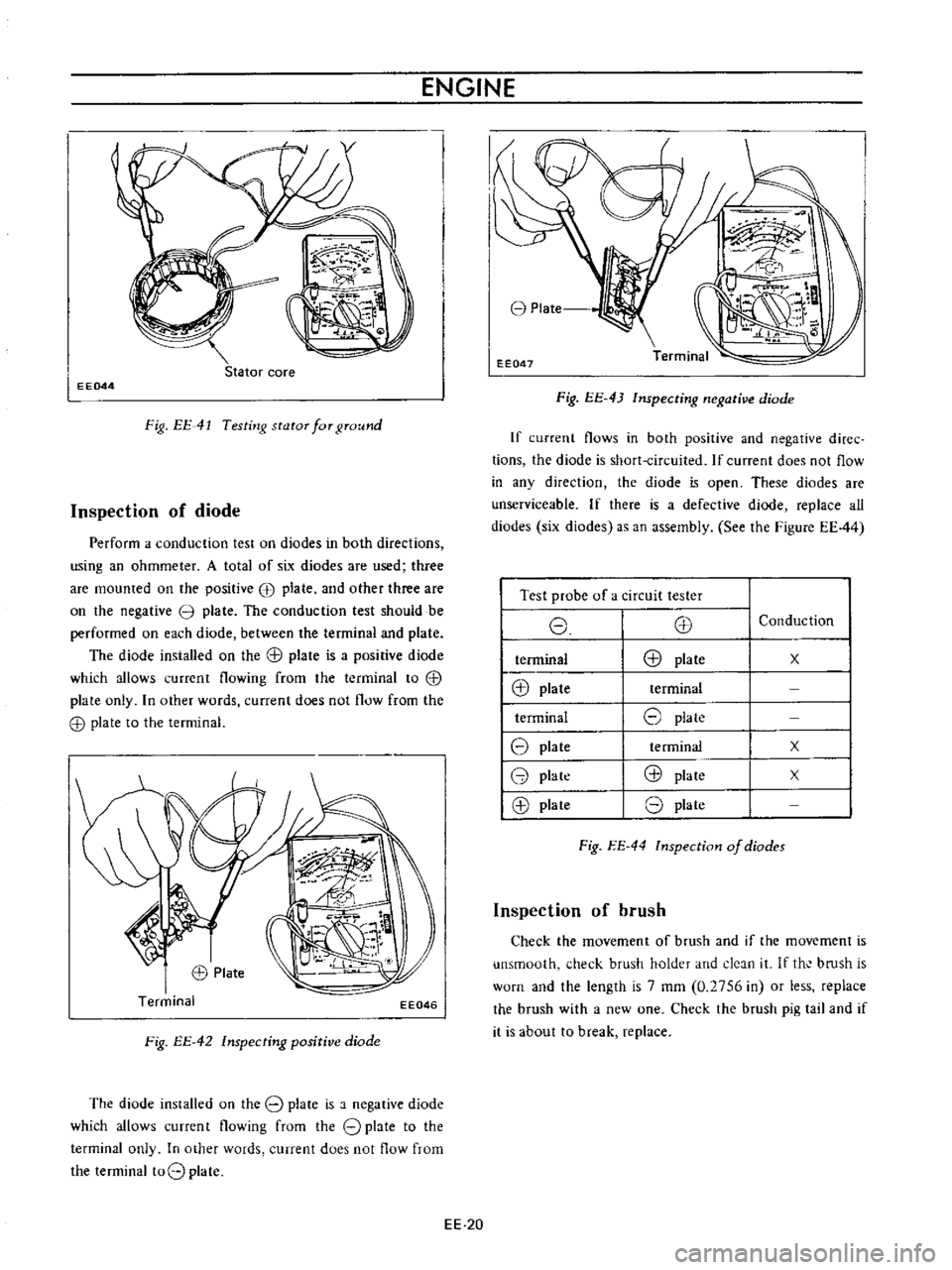

Inspection

of

diode

Perform

a

conduction

test

on

diodes

in

both

directions

using

an

ohmmeter

A

total

of

six

diodes

are

used

three

are

mounted

on

the

positive

EB

plate

and

other

three

are

on

the

negative

3

plate

The

conduction

test

should

be

performed

on

each

diode

between

the

terminal

and

plate

The

diode

installed

on

the

G

l

plate

is

a

positive

diode

which

allows

current

flowing

from

the

terminal

to

G

l

plate

only

In

other

words

current

does

not

flow

from

the

G

l

plate

to

the

terminal

EE046

Fig

EE

42

Inspecting

positive

diode

The

diode

installed

on

the

8

plate

is

a

negative

diode

which

allows

current

flowing

from

the

8

plate

to

the

terminal

only

In

other

words

current

does

not

flow

from

the

terminal

t08

plate

EE

20

8

Plate

EE047

Fig

EE

43

Inspecting

negative

diode

If

current

flows

in

both

positive

and

negative

diree

tions

the

diode

is

short

circuited

If

current

does

not

flow

in

any

direction

the

diode

is

open

These

diodes

are

unserviceable

If

there

is

a

defective

diode

replace

all

diodes

six

diodes

as

an

assembly

See

the

Figure

EE44

I

Test

probe

of

a

circuit

tester

I

8

E8

I

terminal

E8

plate

I

@

plate

terminal

I

terminal

8

plate

18

plate

te

rminal

18

plate

@

plate

18

plate

8

plate

Conduction

x

x

x

Fig

EE

44

lnspection

of

diodes

Inspection

of

brush

Check

the

movement

of

brush

and

if

the

movement

is

unsmooth

check

brush

holder

and

deJn

it

If

th

bmsh

is

worn

and

the

length

is

7

mm

0

2756

in

or

less

replace

the

brush

with

a

new

one

Check

the

brush

pig

tail

and

if

it

is

about

to

break

replace

Page 442 of 513

ENGINE

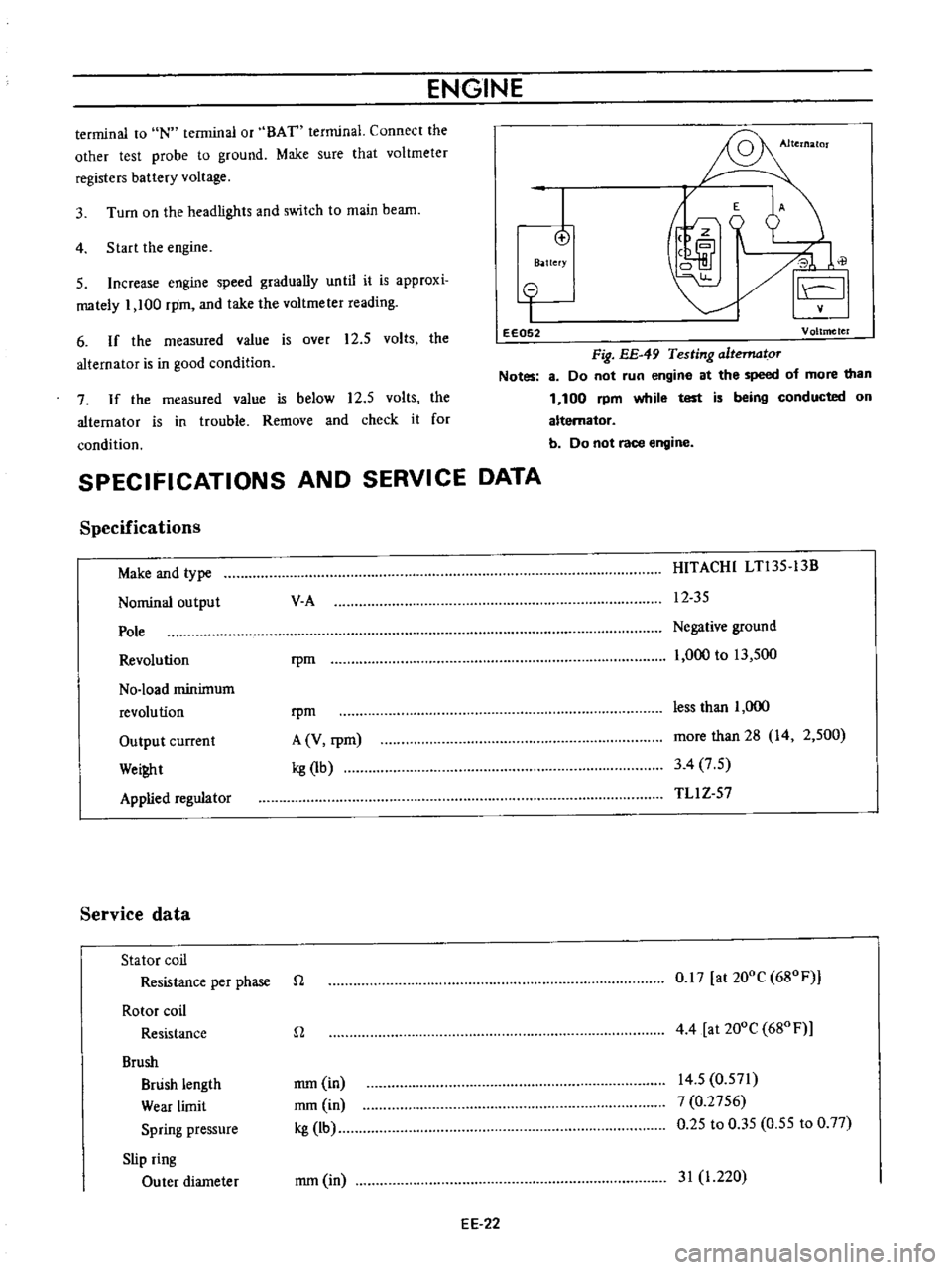

terminal

to

IN

terminal

or

BAT

terminal

Connect

the

other

test

probe

to

ground

Make

sure

that

voltmeter

registers

battery

voltage

4

Start

the

engine

3

Turn

on

the

headlights

and

switch

to

main

beam

I

o

B

ttefY

E

A

J

0

il

I

5

Increase

engine

speed

gradually

until

it

is

approxi

mately

1

100

rpm

and

take

the

voltmeter

reading

6

If

the

measured

value

is

over

12

5

volts

the

alternator

is

in

good

condition

o

I

eE052

Voltmeter

Fig

EE

49

Testing

altematoT

Notes

8

Do

not

run

engine

at

the

speed

of

more

than

1

100

rpm

while

test

is

being

conducted

on

alternator

b

Do

not

race

engine

7

If

the

measured

value

is

below

12

5

volts

the

alternator

is

in

trouble

Remove

and

check

it

for

condition

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Make

and

type

Nominal

output

Pole

Revolution

No

load

minimum

revolution

Output

current

Wei

t

Applied

regulator

Service

data

Stator

coil

Resistance

per

phase

Rotor

coil

Resistance

Brush

Brush

length

Wear

limit

Spring

pressure

Slip

ring

Outer

diameter

V

A

HITACHI

LTl35

13B

12

35

rpm

Negative

ground

1

000

to

13

500

rpm

A

V

rpm

kg

1b

less

than

1

000

more

than

28

14

2

500

3

4

7

5

TLl

Z

57

n

0

17

at

200C

680F

n

4

4

at

200e

680

F

mm

in

mm

in

kg

lb

14

5

0

571

7

0

2756

0

25

to

0

35

0

55

to

0

77

mm

in

31

1

220

EE

22

Page 444 of 513

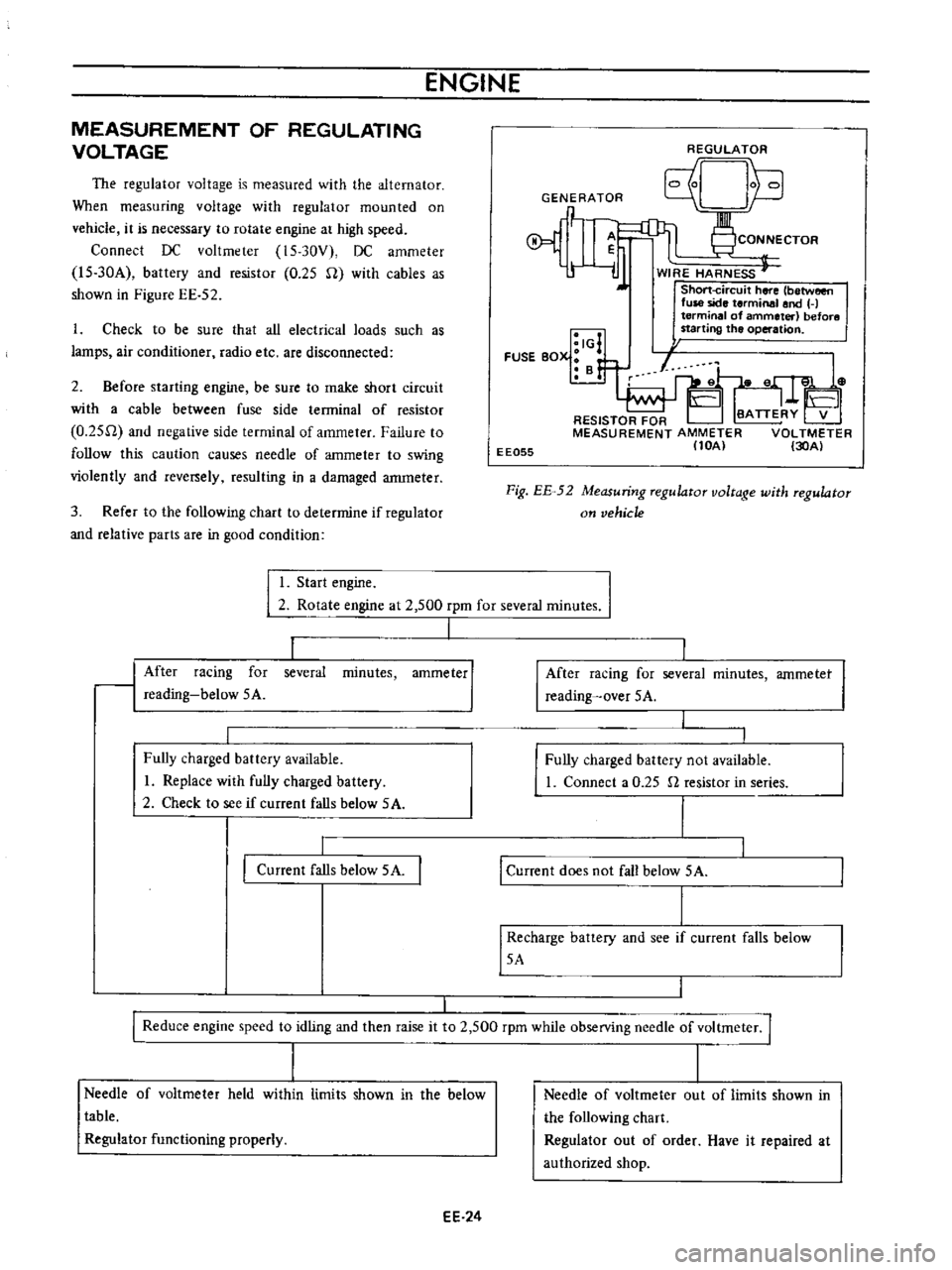

ENGINE

MEASUREMENT

OF

REGULATING

VOLTAGE

The

regulator

voltage

is

measured

with

the

alternator

When

measuring

voltage

with

regulator

mounted

on

vehicle

it

is

necessary

to

rotate

engine

at

high

speed

Connect

DC

voltmeter

15

30V

DC

ammeter

l5

30A

battery

and

resistor

0

25

U

with

cables

as

shown

in

Figure

EE

52

1

Check

to

be

sure

that

all

electrical

loads

such

as

lamps

air

conditioner

radio

etc

are

disconnected

2

Before

starting

engine

be

sure

to

make

short

circuit

with

a

cable

between

fuse

side

terminal

of

resistor

O

25U

and

negative

sIde

terminal

of

ammeter

Failure

to

follow

this

caution

causes

needle

of

ammeter

to

swing

violently

and

rever

ely

resulting

in

a

damaged

anuneter

3

Refer

to

the

following

chart

to

determine

if

regulator

and

relative

parts

are

in

good

condition

REGULATOR

Unh

GENERATOR

q

P

1

CONNECTOR

r

l

ij

WIRE

HARNESS

J

Short

circuit

here

between

fuse

side

terminal

and

H

terminal

of

ammeter

before

starting

the

operation

I

I

I

IG

FUSE

BOX

B

f

EE055

Fig

EE

52

Measuring

regulator

voltage

with

regulator

on

vehicle

I

Start

engine

I

2

Rotate

engine

at

2

500

rpm

for

several

minutes

I

1

minutes

ammeter

I

After

racing

for

reading

below

5A

several

Fully

charged

battery

available

I

Replace

with

fully

charged

battery

2

Check

to

see

if

current

falls

below

5A

Current

falls

below

5A

I

After

racing

for

several

reading

over

5A

minutes

ammetet

I

Fully

charged

battery

not

available

1

Connect

a

0

25

n

resistor

in

series

I

Current

does

not

fall

below

5A

I

Recharge

battery

and

see

if

current

falls

below

5A

I

I

Reduce

engine

speed

to

idling

and

then

raise

it

to

2

500

rpm

while

observing

needle

of

voltmeter

I

I

I

Needle

of

voltmeter

held

within

limits

shown

in

the

below

table

Regulator

functioning

properly

EE

24

Needle

of

voltmeter

out

of

limits

shown

in

the

following

chart

Regulator

out

of

order

Have

it

repaired

at

authorized

shop

Page 446 of 513

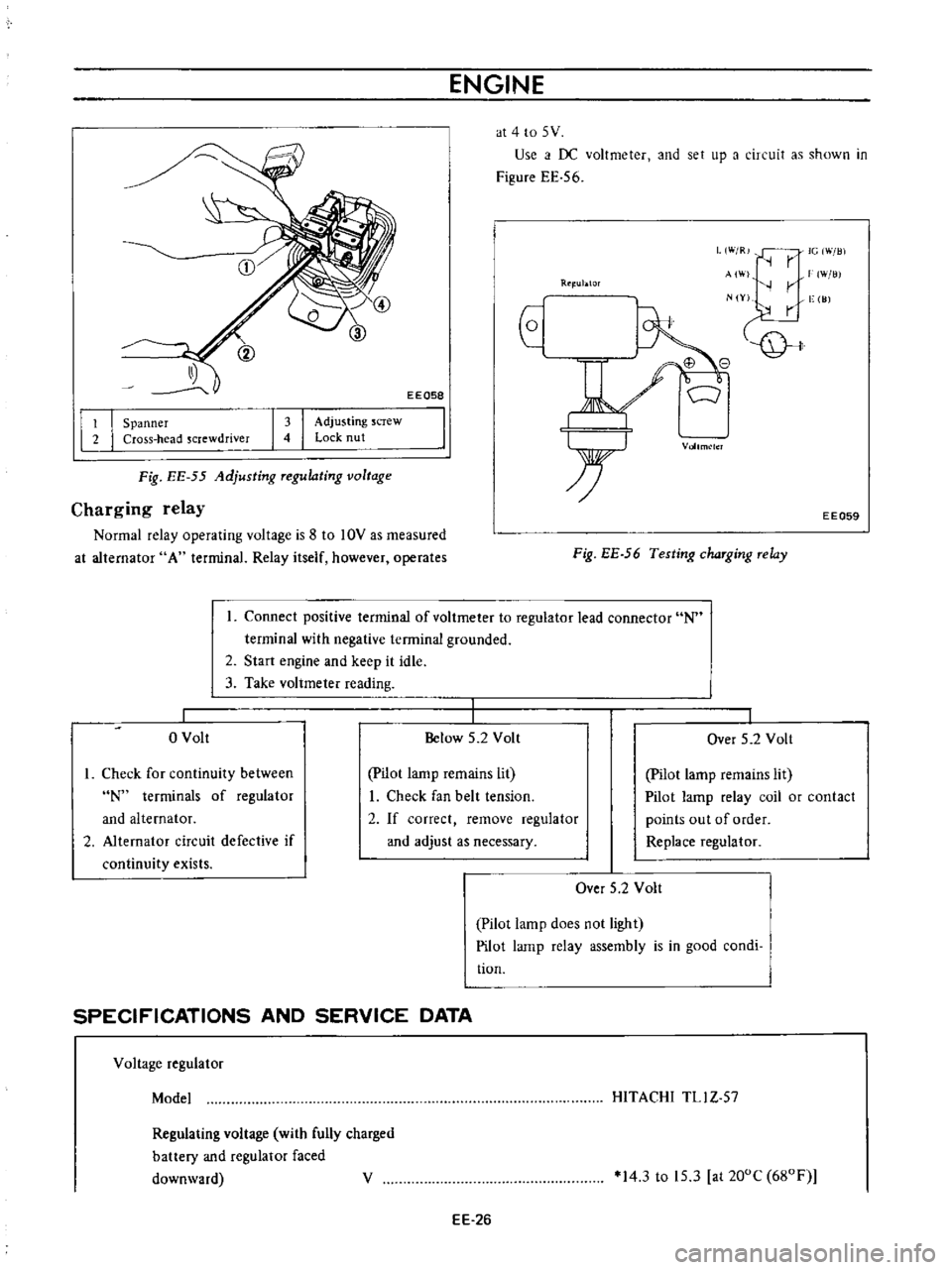

ENGINE

at

4

to

5

V

Use

i

f

DC

voltmeter

and

set

up

a

circuit

as

shown

in

Figure

EE

56

EEQ58

L

W

R

IG

Will

r

AI

W

lli

r

N

Y

vge

I

JJ

Rtl

ublOr

I

I

Spanner

Cross

head

screwdriver

I

I

Adjusting

screw

Lock

nut

Vollm

lcl

Fig

EE

55

Adjusting

Tegulating

voltage

Charging

relay

Normal

relay

operating

voltage

is

8

to

10V

as

measured

at

alternator

A

terminal

Relay

itself

however

operates

EE059

Fig

EE

56

Testing

chaTging

Telay

Connect

positive

terminal

of

voltmeter

to

regulator

lead

connector

N

terminal

with

negative

terminal

grounded

2

Start

engine

and

keep

it

idle

3

Take

voltmeter

reading

o

Volt

Below

5

2

Volt

I

Over

5

2

Volt

I

Check

for

continuity

between

N

terminals

of

regulator

and

alternator

2

Alternator

circuit

defective

if

continuity

exists

pilot

lamp

remains

lit

I

Check

fan

belt

tension

2

If

correct

remove

regulator

and

adjust

as

necessary

Pilot

lamp

remains

lit

Pilot

lamp

relay

coil

or

contact

points

out

of

order

Replace

regulator

Over

5

2

Volt

Pilot

lamp

does

not

light

Pilot

lamp

relay

assembly

is

in

good

condi

tion

SPECIFICATIONS

AND

SERVICE

DATA

Voltage

regulator

Model

HITACHI

TLl

Z

57

Regulating

voltage

with

fully

charged

battery

and

regulator

faced

downward

V

14

3

to

15

3

at

200C

680F

EE

26

Page 448 of 513

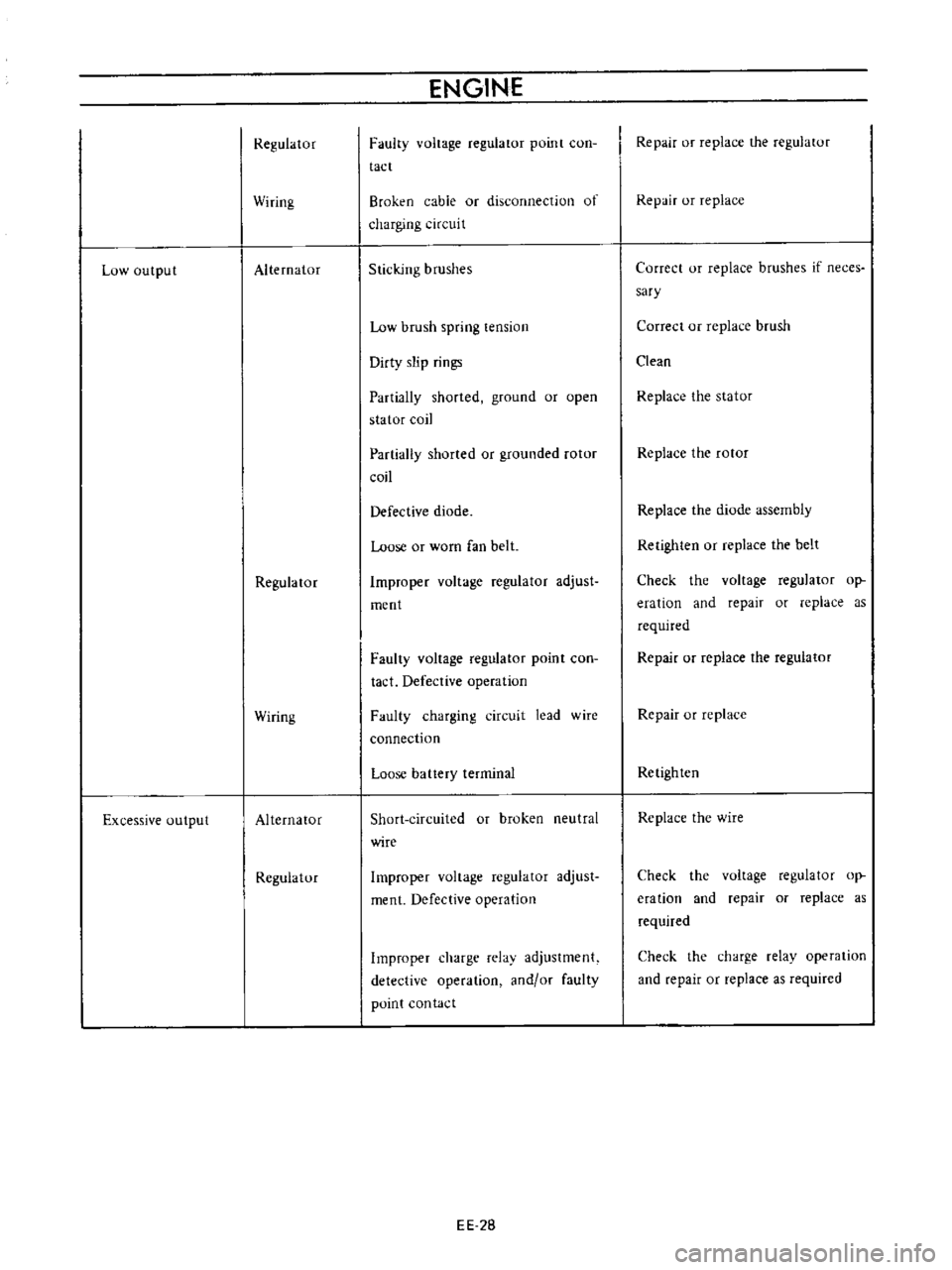

Low

output

Excessive

output

Regulator

Wiring

Alternator

Regula

tor

Wiring

Alternator

Regulatur

ENGINE

Faulty

voltage

regulator

point

con

tact

Broken

cable

or

disconnection

of

charging

cireui

t

Sticking

brushes

Low

brush

spring

tension

Dirty

slip

rings

Partially

shorted

ground

or

open

stator

coil

Partially

shorted

or

grounded

rotor

coil

Defective

diode

Loose

or

worn

fan

belt

Improper

voltage

regulator

adjust

ment

Faulty

voltage

regulator

point

con

tact

Defective

operation

Faulty

charging

circuit

lead

wire

connection

Loose

battery

terminal

Short

circuited

or

broken

neutral

wire

Improper

voltage

regulator

adjust

ment

Defective

operation

Improper

charge

relav

adjustment

detective

operation

and

or

faulty

point

contact

EE

28

Repair

or

replace

the

regulatur

Repair

or

replace

Correct

or

replace

brushes

if

neces

sary

Correct

or

replace

brush

Clean

Replace

the

stator

Replace

the

rotor

Replace

the

diode

assembly

Retighten

or

replace

the

belt

Check

the

voltage

regulator

op

eration

and

repair

or

replace

as

required

Repair

or

replace

the

regulator

Repair

or

replace

Retighten

Replace

the

wire

Check

the

voltage

regulator

op

eration

and

repair

or

replace

as

required

Check

the

charge

relay

operation

and

repair

or

replace

as

required

Page 449 of 513

ENGINE

ElECTRICAL

SYSTEM

IGNITION

CIRCUIT

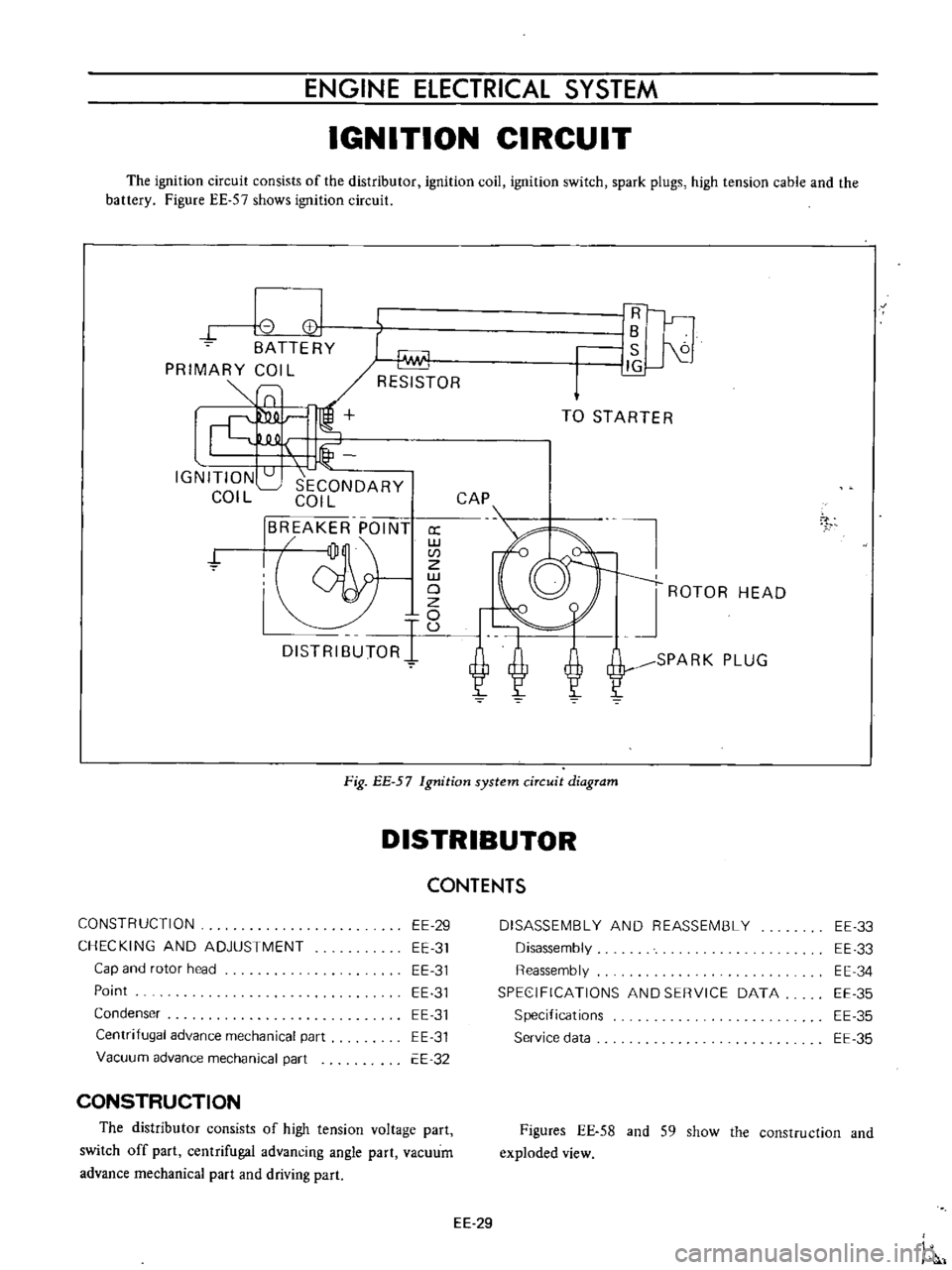

The

ignition

circuit

consists

of

the

distributor

ignition

coil

ignition

switch

spark

plugs

high

tension

cable

and

the

battery

Figure

EE

57

shows

ignition

circuit

8

I

CC

BATTERY

PRIMARY

COIL

SlO

Lf

IGNITION

SECONDARY

COIL

COIL

BREAKER

POINT

jJ

a

w

CI

Z

w

19

DISTRIBUTORI

U

1Fl

r

lB

S

J1G

TO

STARTER

CAP

ROTOR

HEAD

SPARK

PLUG

7

Fig

EE

57

Ignition

system

circuit

diagram

DISTRIBUTOR

CONSTRUCTION

CHECKING

AND

ADJUSTMENT

Cap

and

rotor

head

Point

Condenser

Centrifugal

advance

mechanical

part

Vacuum

advance

mechanical

part

EE

29

EE

31

EE

31

EE

31

EE

31

EE

31

EE

32

CONSTRUCTION

The

distributor

consists

of

high

tension

voltage

part

switch

off

part

centrifugal

advancing

angle

part

vacuum

advance

mechanical

part

and

driving

part

CONTENTS

DISASSEMBLY

AND

REASSEMBLY

Disassembly

Reassembly

SPEC

IFICATIONS

AND

SERVICE

DATA

Specifications

Service

data

EE

33

EE

33

EE

34

EE

35

EE

35

EE

35

Figures

EE

58

and

S9

show

the

construction

and

exploded

view

EE

29

Page 451 of 513

ENGINE

ElECTRICAL

SYSTEM

CHECKING

AND

ADJUSTMENT

Cap

and

rotor

head

Cap

and

rotor

head

must

always

be

kept

clean

to

maintain

good

insulation

durability

since

high

tension

voltage

from

ignition

coil

is

imposed

on

them

Sometimes

inside

of

the

cap

and

rotor

head

is

covered

with

fine

carbon

particles

and

dust

Whenever

crack

or

trace

of

leakage

is

found

on

the

cap

replace

with

a

new

one

Recommend

the

rotor

head

also

be

replaced

with

a

new

one

if

excessively

damaged

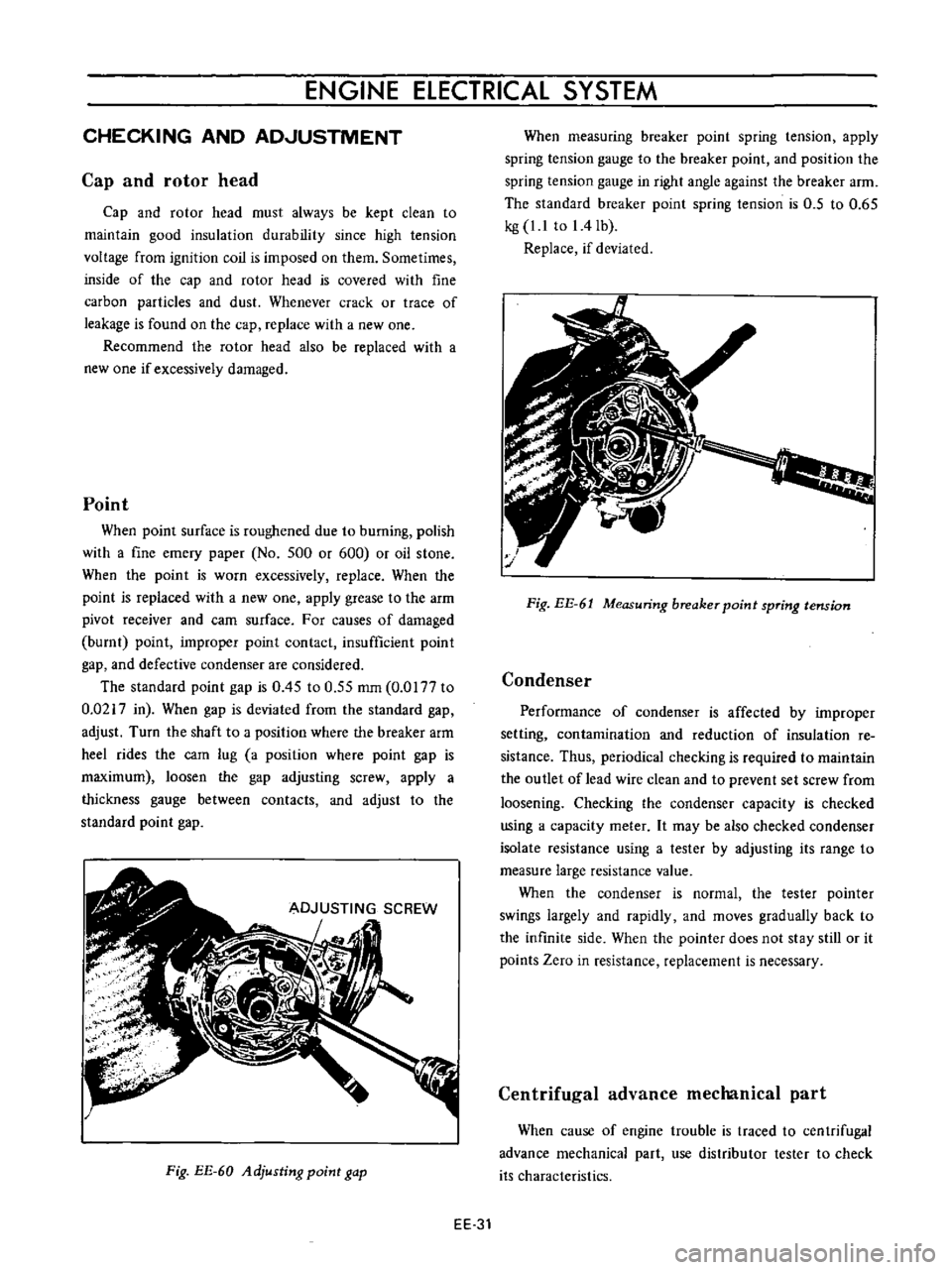

Point

When

point

surface

is

roughened

due

to

burning

polish

with

a

fine

emery

paper

No

500

or

600

or

oil

stone

When

the

point

is

worn

excessively

replace

When

the

point

is

replaced

with

a

new

one

apply

grease

to

the

arm

pivot

receiver

and

earn

surface

For

causes

of

damaged

burnt

point

improper

point

contact

insufficient

point

gap

and

defective

condenser

are

considered

The

standard

point

gap

is

0

45

to

0

55

mm

0

0177

to

0

0217

in

When

gap

is

deviated

from

the

standard

gap

adjust

Turn

the

shaft

to

a

position

where

the

breaker

arm

heel

rides

the

com

lug

a

position

where

point

gap

is

maximum

loosen

the

gap

adjusting

screw

apply

a

thickness

gauge

between

contacts

and

adjust

to

the

standard

point

gap

Fig

EE

60

Adjusting

point

gap

When

measuring

breaker

point

spring

tension

apply

spring

tension

gauge

to

the

breaker

point

and

position

the

spring

tension

gauge

in

right

angle

against

the

breaker

arm

The

standard

breaker

point

spring

tension

is

0

5

to

0

65

kg

1

1

to

I

4Ib

Replace

if

deviated

Fig

EE

61

Measuring

breaker

point

spring

tension

Condenser

Performance

of

condenser

is

affected

by

improper

setting

contamination

and

reduction

of

insulation

re

sistance

Thus

periodical

checking

is

required

to

maintain

the

outlet

of

lead

wire

clean

and

to

prevent

set

screw

from

loosening

Checking

the

condenser

capacity

is

checked

using

a

capacity

meter

It

may

be

also

checked

condenser

isolate

resistance

using

a

tester

by

adjusting

its

range

to

measure

large

resistance

value

When

the

condenser

is

normal

the

tester

pointer

swings

largely

and

rapidly

and

moves

gradually

back

to

the

infinite

side

When

the

pointer

does

not

stay

still

or

it

points

Zero

in

resistance

replacement

is

necessary

Centrifugal

advance

mechanical

part

When

cause

of

engine

trouble

is

traced

to

centrifugal

advance

mechanical

part

use

distributor

tester

to

check

its

characteristics

EE

31