wheel DATSUN B110 1973 Service Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 297 of 513

GENERAL

INFORMATION

MODEL

VARIATION

Model

Engine

model

Transmission

type

Brake

type

model

Front

Rear

LBllOTRU

Manual

transmission

Disc

Drum

F4W56L

2

door

Sedan

LBllOARU

Automatic

transmission

Disc

Drum

3N71B

AI2

KLBllOU

Manual

transmission

Disc

Drum

F4W56L

Coupe

Automatic

transmission

KLBllOAU

3N71B

Disc

Drum

Model

Identification

KLBIIOATRU

I

U

for

U

S

A

and

Canada

R

2

door

T

Floor

shift

vehicle

A

Automatic

transmission

L

Left

hand

drive

K

Coupe

SuffIx

PrefIx

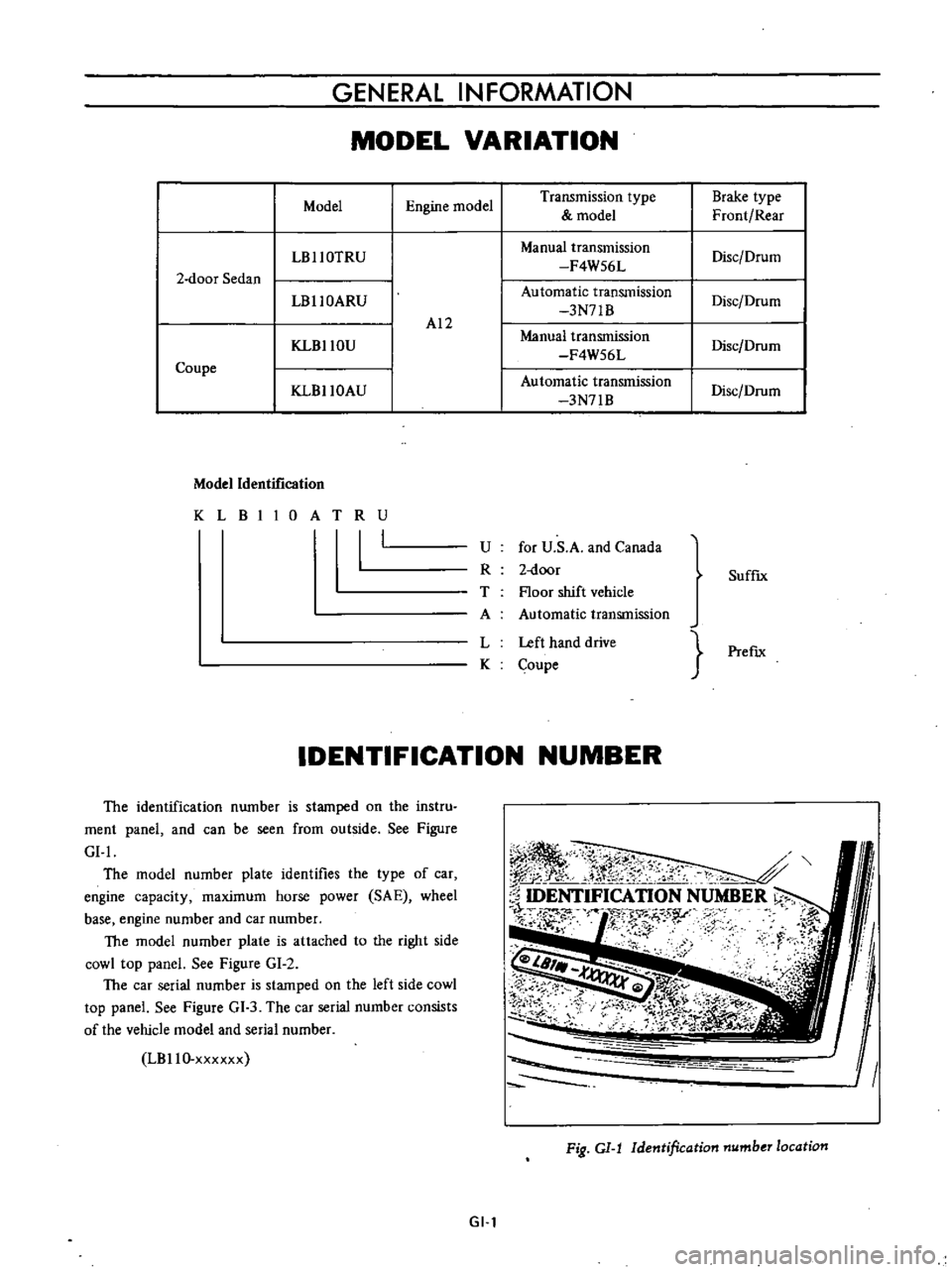

IDENTIFICATION

NUMBER

The

identification

number

is

stamped

on

the

instru

ment

panel

and

can

be

seen

from

outside

See

Figure

GI

I

The

model

number

plate

identifles

the

type

of

car

engine

capacity

maximum

horse

power

SA

E

wheel

base

engine

number

and

car

number

The

model

number

plate

is

attached

to

the

right

side

cowl

top

panel

See

Figure

GI

2

The

car

serial

number

is

stamped

on

the

left

side

cowl

top

panel

See

Figure

GI

3

The

car

serial

number

consists

of

the

vehicle

model

and

serial

number

LBllO

xxxxxx

I

ll

r

N

t

0

S

k

j

c

ftr

o

l

l

r

2

0

IDENTIFICATION

NUMBER

l

r

f

N

s

r

F

i

u

I

Fig

GI

J

Identification

number

location

GI

l

Page 300 of 513

GENERAL

INFORMATION

spring

etc

support

the

rear

cruss

member

with

stands

In

other

cases

support

both

ends

of

the

rear

axle

housing

with

stands

Fig

CI

9

Rear

jacking

point

Fig

C

J

0

Rear

supportable

point

TOWING

Manual

transmission

model

When

the

car

is

towed

forward

connect

the

rope

securely

to

the

notched

portion

of

the

tension

rod

bracket

In

no

event

should

a

rope

be

applied

to

the

transverse

link

To

two

another

car

connect

a

rope

to

the

rear

shackle

of

rear

spring

Note

Avoid

applying

load

suddenly

to

a

rope

as

it

may

cause

damage

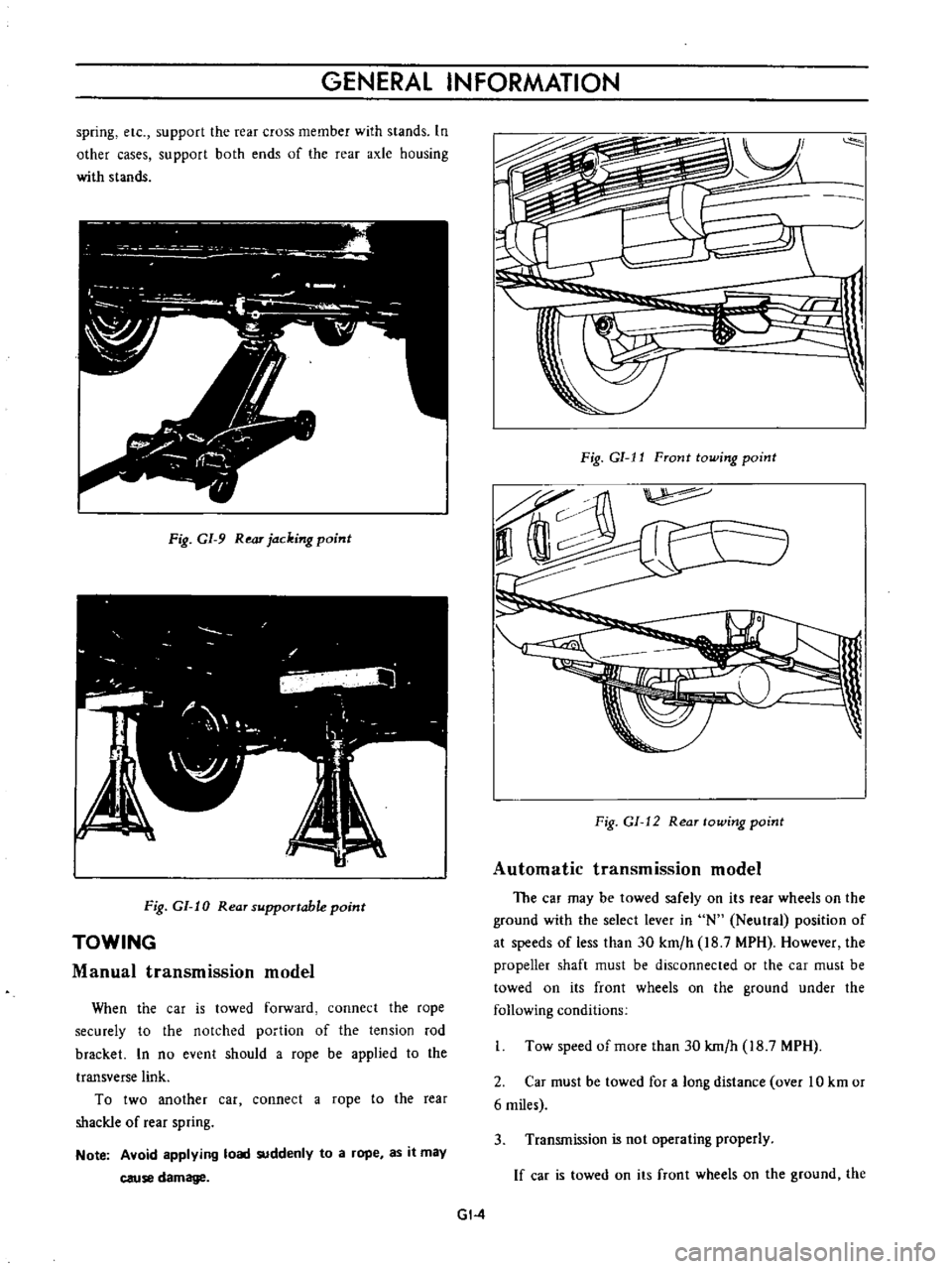

Fig

GI

l1

Front

towing

point

Fig

GI

12

Rear

towing

point

Automatic

transmission

model

The

car

may

be

towed

safely

on

its

rear

wheels

on

the

ground

with

the

select

lever

in

N

Neutral

position

of

at

speeds

of

less

than

30

km

h

18

7

MPH

However

the

propeller

shaft

must

be

disconnected

or

the

car

must

be

towed

on

its

front

wheels

on

the

ground

under

the

following

conditions

Tow

speed

of

more

than

30

kro

h

18

7

MPH

2

Car

must

be

towed

for

a

long

distance

over

10

km

or

6

miles

3

Transmission

is

not

operating

properly

If

car

is

towed

on

its

front

wheels

on

the

ground

the

GI

4

Page 301 of 513

GENERAL

INFORMATION

steering

wheel

should

be

secured

to

maintain

a

straight

ahead

position

TIE

DOWN

The

front

tie

down

hook

is

used

the

both

front

end

of

tension

rod

Do

not

apply

the

hook

at

the

center

of

tension

rod

or

suspension

member

The

rear

tie

down

hook

is

used

the

both

front

shackle

of

rear

spring

APPROXIMATE

REFILL

CAPACITY

Liter

U

S

A

measure

I

Imp

measure

Sedan

Fuel

tank

Coupe

with

heater

Cooling

system

without

heater

40

L

38

L

4

9

L

4

2

L

2

7

L

0

54

L

1

2

L

5

5

L

0

75

L

0

24

L

Oil

pan

Oilf1lter

Transmission

case

Manual

Automatic

Differential

case

Steering

gear

box

RECOMMENDED

GASOLINE

FUEL

Use

a

no

lead

or

low

lead

gasoline

with

a

minimum

octane

rating

of

87

the

average

of

the

Research

and

1O

gal

8Y

gal

10

gal

8

gal

5

v

qt

4

M

qt

4

Y

6

qt

3

Y

qt

2Ji

qt

2

qt

1

pt

I

pt

2

pt

2

pt

5Ji

qt

4

qt

1

pt

1

pt

pt

pi

Motor

Octane

Numbers

in

the

U

S

When

the

figure

is

based

on

the

Research

Octane

Number

use

a

gasoline

with

a

minimum

octane

rating

of

91

RON

in

Canada

RECOMMENDED

LUBRICANTS

GI

5

r

Page 313 of 513

ENGINE

Adjusting

carburetor

idle

rpm

mixture

ratio

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

and

calibrated

Warm

up

the

engine

sufficiently

2

Continue

engine

operation

for

one

minute

under

idling

speed

3

Adjust

throttle

adjusting

screw

so

that

engine

speed

is

800

rpm

in

NO

position

for

automatic

transmission

4

Check

ignition

timing

if

necessary

adjust

it

to

the

specifications

Ignition

timing

SO

800

rpm

S

Adjust

idle

adjusting

screw

so

that

CO

percentage

is

1

5

t

O

S

6

Repeat

the

adjustments

as

described

in

steps

3

and

S

above

so

that

CO

percentage

is

I

i

t

O

S

at

800

rpm

Cautions

a

On

automatic

transmission

equipped

model

check

must

be

done

in

the

0

position

Be

sure

to

apply

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Hold

brake

pedal

while

stepping

down

on

accelerator

pedal

Otherwise

car

will

rush

out

dangerously

7

On

automatic

transmission

equipped

model

make

sure

that

the

adjustment

has

been

made

with

the

selector

lever

in

N

position

And

then

check

the

specifications

with

the

lever

in

D

position

Insure

that

CO

percent

and

idle

speed

are

as

follows

Idle

rpm

CO

percentage

with

lever

in

D

position

6S0

I

S

t

O

S

If

necessary

adjust

by

progressively

turning

throttle

adjusting

screw

and

idle

adjusting

screw

until

correct

adjustments

are

made

Notes

a

Do

not

attempt

to

screw

down

the

idle

adjusting

screw

completely

to

avoid

damage

to

the

tip

which

will

tend

to

cause

malfunctions

b

After

idle

adjustment

has

been

made

shift

the

lever

to

N

or

p

position

for

automatic

transmission

c

Remove

wheel

chocks

before

starting

the

car

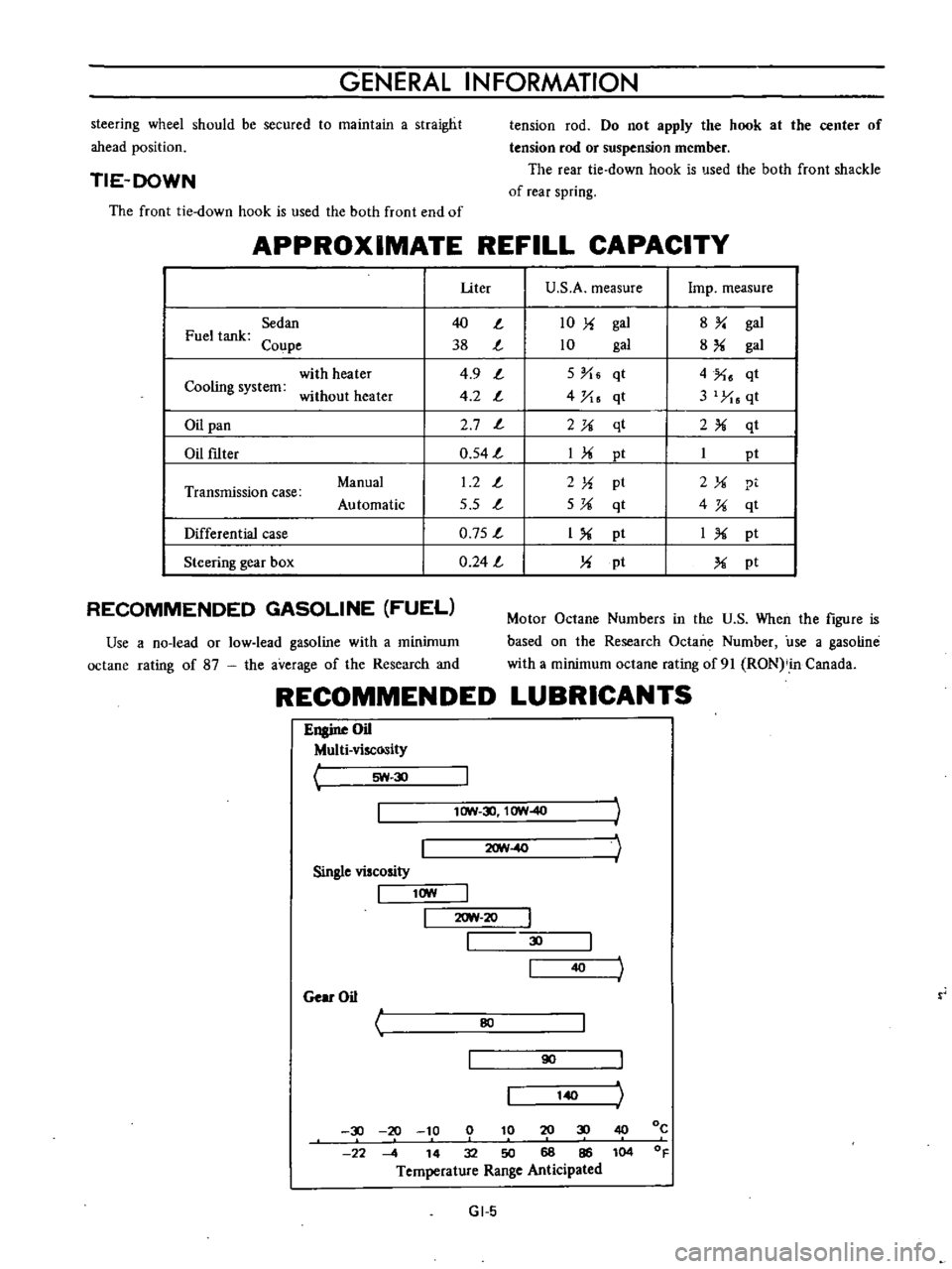

Throttle

adjusting

screw

Idle

adjust

ing

screw

3

Idle

limitter

cap

4

Stopper

Fig

ET

13

Throttle

adjusting

screw

and

idle

adjusting

screw

Idle

limiter

cap

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

removed

it

is

necessary

to

re

adjust

it

at

the

time

of

installation

To

adjust

proceed

as

follows

L

Make

sure

that

the

percentage

of

CO

contents

satisfies

the

specifications

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

can

further

turn

3

8

rotation

in

the

CO

RICH

direction

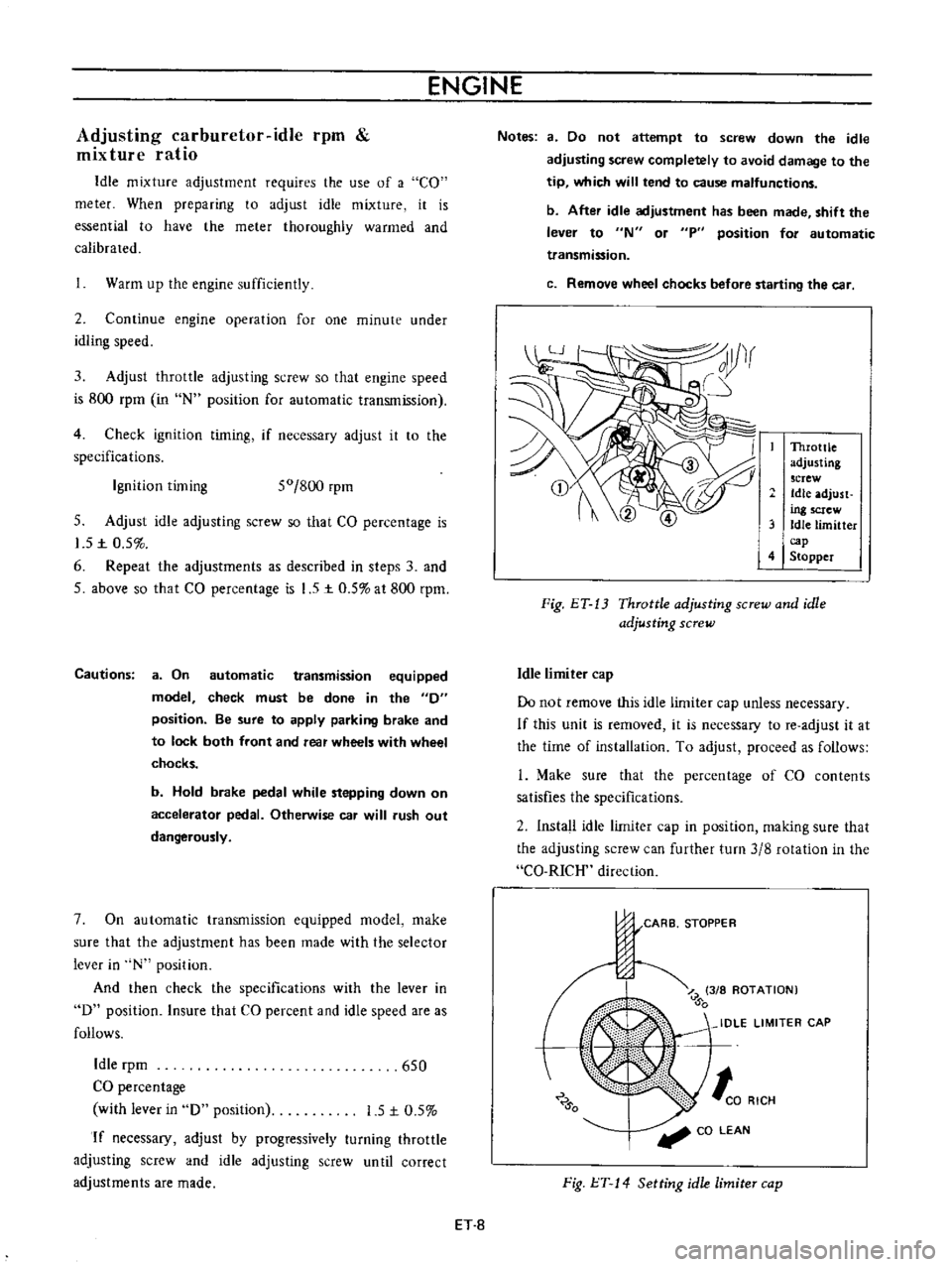

CARB

STOPPER

J

Z

3

8

ROTATION

0

IDLE

LIMITER

CAP

0

to

RICH

CO

LEAN

Fig

l

T

14

Setting

idle

limiter

cap

ET

8

Page 325 of 513

ENGINE

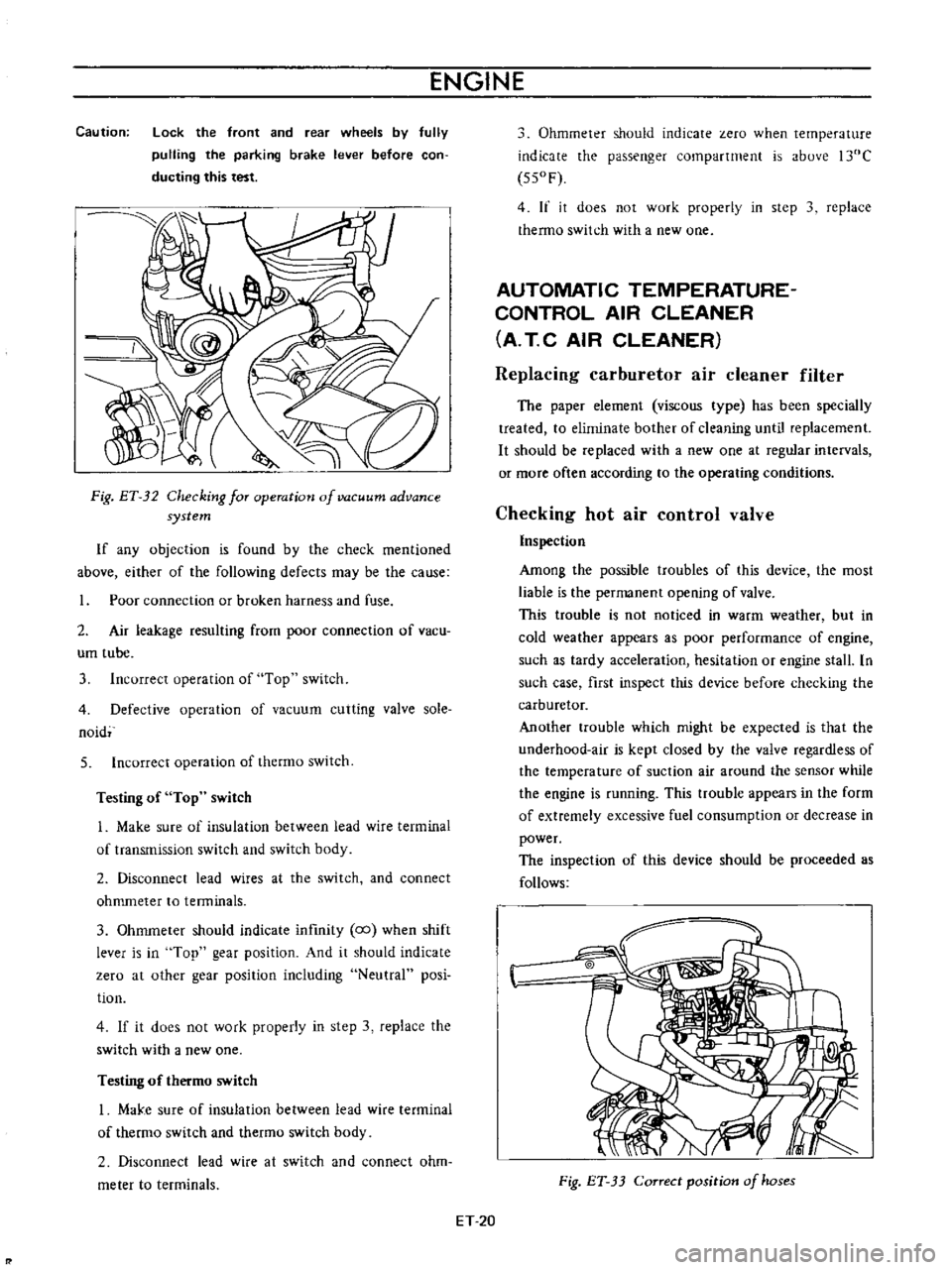

Caution

lock

the

front

and

rear

wheels

by

fully

pulling

the

parking

brake

lever

before

con

ducting

this

test

Fig

ET

32

Checking

for

operation

of

vacuum

advance

system

If

any

objection

is

found

by

the

check

mentioned

above

either

of

the

following

defects

may

be

the

cause

Poor

connection

or

broken

harness

and

fuse

2

Air

leakage

resulting

from

poor

connection

of

vacu

um

tube

3

Incorrect

operation

of

Top

switch

4

Defective

operation

of

vacuum

cutting

valve

sole

naid

5

Incorrect

operation

of

thermo

switch

Testing

of

Top

switch

1

Make

sure

of

insulation

between

lead

wire

terminal

of

transmission

switch

and

switch

body

2

Disconnect

lead

wires

at

the

switch

and

connect

ohmmeter

to

tenninals

3

Ohmmeter

should

indicate

infmity

co

when

shift

lever

is

in

Top

gear

position

And

it

should

indicate

zero

at

other

gear

position

including

Neutral

posi

tion

4

If

it

does

not

work

properly

in

step

3

replace

the

switch

with

a

new

one

Testing

of

thermo

switch

I

MaJ

e

sure

of

insulation

between

lead

wire

terminal

of

thermo

switch

and

thetmo

switch

body

2

Disconnect

lead

wire

at

switch

and

connect

ohm

meter

to

terminals

Ohmmeter

should

indicate

zero

when

temperature

indicate

the

passenger

compartment

is

above

l30C

550F

4

If

it

does

not

work

properly

in

step

3

replace

thermo

switch

with

a

new

one

AUTOMATIC

TEMPERATURE

CONTROL

AIR

CLEANER

A

T

C

AIR

CLEANER

Replacing

carburetor

air

cleaner

filter

The

paper

element

viscous

type

has

been

specially

treated

to

eliminate

bother

of

cleaning

until

replacement

It

should

be

replaced

with

a

new

one

at

regular

intervals

or

more

often

according

to

the

operating

conditions

Checking

hot

air

control

valve

Inspection

Among

the

possible

troubles

of

this

device

the

most

liable

is

the

permanent

opening

of

valve

This

trouble

is

not

noticed

in

warm

weather

but

in

cold

weather

appears

as

poor

performance

of

engine

such

as

tardy

acceleration

hesitation

or

engine

stall

In

such

case

first

inspect

this

device

before

checking

the

carburetor

Another

trouble

which

might

be

expected

is

that

the

underhood

air

is

kept

closed

by

the

valve

regardless

of

the

temperature

of

suction

air

around

the

sensor

while

the

engine

is

running

This

ttOuble

appears

in

the

form

of

extremely

excessive

fuel

consumption

or

decrease

in

power

The

inspection

of

this

device

should

be

proceeded

as

follows

Fig

ET

33

Correct

position

of

hoses

ET

20

Page 347 of 513

ENGINE

MECHANICAL

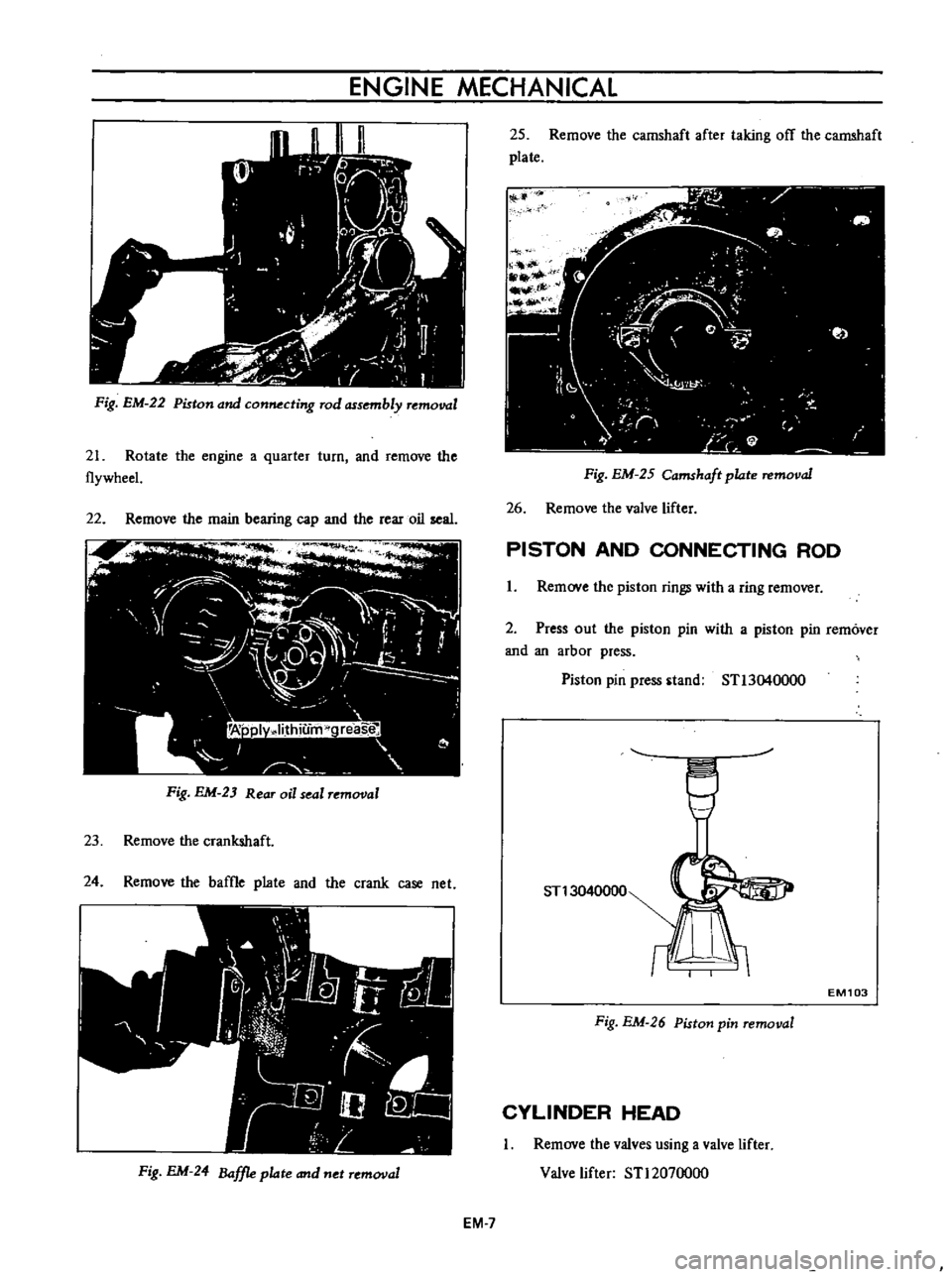

Fig

EM

22

Piston

and

conMcting

rod

assembly

removal

21

Rotate

the

engine

a

quarter

turn

and

remove

the

flywheeL

22

Remove

the

main

bearing

cap

and

the

rear

oil

seal

Fig

EM

2J

Rear

oil

seal

removal

23

Remove

the

crankshaft

24

Remove

the

baffie

plate

and

the

crank

case

net

Fig

EM

24

Baffle

plate

and

net

removal

25

Remove

the

camshaft

after

taking

ofT

the

camshaft

plate

Fig

EM

25

Camshaft

plate

removal

26

Remove

the

valve

lifter

PISTON

AND

CONNECTING

ROD

1

Remove

the

piston

rings

with

a

ring

remover

2

Press

out

the

piston

pin

with

a

piston

pin

remover

and

an

arbor

press

Piston

pin

press

oland

STl3040000

ST13040000

EM103

Fig

EM

26

Piston

pin

removal

CYLINDER

HEAD

Remove

the

valves

using

a

valve

lifter

Valve

lifter

STl2070000

EM

Page 348 of 513

ENGINE

J

I

r

I

I

J

fj

7

L

j

8

if

d1

I

ilfi

3

c

7

I

t

j

v

1

Ji

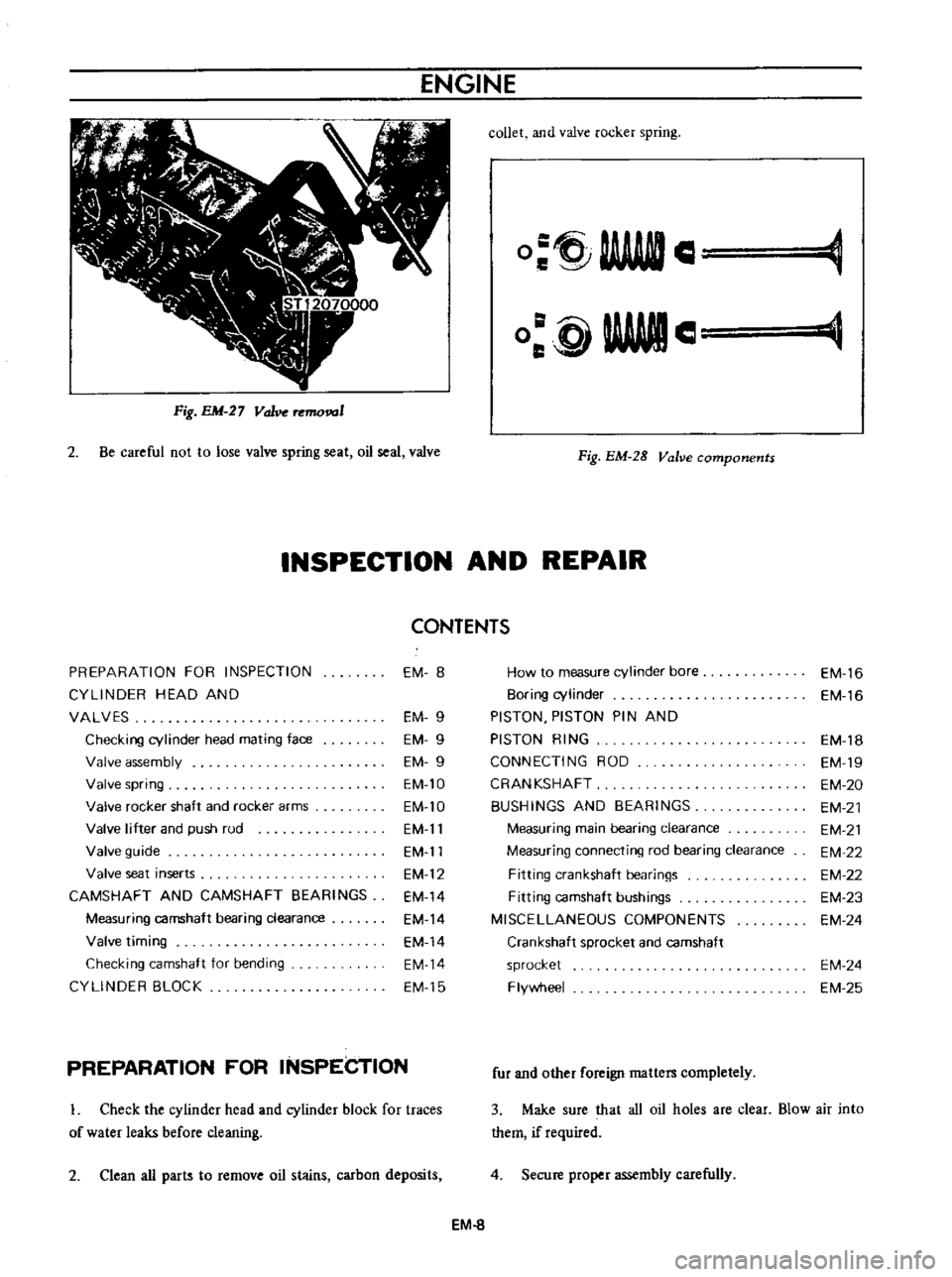

Fig

EM

27

Valve

mo

1

2

Be

careful

not

to

lose

valve

spring

seat

oil

seal

valve

collet

and

valve

rocker

spring

O

tj

AAAftIl

C

e

WWII

o

glAWle

Fig

EM

28

Valve

components

INSPECTION

AND

REPAIR

CONTENTS

PREPARATION

FOR

INSPECTION

EM

8

How

to

measure

cylinder

bore

EM

16

CYLlNOER

HEAD

AND

80ring

cylinder

EM

16

VALVES

EM

9

PISTON

PISTON

PIN

AND

Checking

cylinder

head

mating

face

EM

9

PISTON

RING

EM

18

Valve

assembly

EM

9

CONNECTING

ROD

EM

19

Valve

spring

EM

10

CRANKSHAFT

EM

20

Valve

rocker

shaft

and

rockei

arms

EM

lO

BUSHINGS

AND

BEARINGS

EM

21

Valve

lifter

and

push

rud

EM

11

Measuring

main

bearing

clearance

EM

21

Valve

guide

EM

11

Measuring

connecting

rod

bearing

clearance

EM

22

Valve

seat

inserts

EM

12

Fitting

crankshaft

bearings

EM

22

CAMSHAFT

AND

CAMSHAFT

BEARINGS

EM

14

Fitting

camshaft

bushings

EM

23

Measuring

camshaft

bearing

clearance

EM

14

MISCELLANEOUS

COMPONENTS

EM

24

Valve

timing

EM

14

Crankshaft

sprocket

and

camshaft

Checking

camshaft

for

bending

EM

14

sprocket

EM

24

CYLlNOER

BLOCK

EM

15

Flywheel

EM

25

PREPARATION

FOR

INSPECTION

L

Check

the

cylinder

head

and

cylinder

block

for

traces

of

water

leaks

before

cleaning

2

Clean

all

parts

to

remove

oil

stains

carbon

deposits

fur

and

other

foreign

matters

completely

3

Make

sure

that

all

oil

holes

are

clear

Blow

air

into

them

if

required

4

Secure

proper

assembly

carefully

EM

8

Page 365 of 513

ENGINE

MECHANICAL

Standard

mm

in

Camshaft

sprocket

run

out

Thrust

deviation

O

OIS

0

0006

Locating

plate

thrust

clearance

0

02

to

0

08

0

0008

to

0

003

Wear

limit

mm

in

less

than

0

0

0039

O

OS

0

0020

0

1

0

0039

3

Check

the

chain

for

damage

excessive

wear

and

stretch

at

its

roller

links

Replace

chain

if

defective

Flyw

heel

I

Check

the

clutch

disc

contact

surface

of

the

flywheel

for

damage

and

wear

Repair

or

replace

if

necessary

2

Measure

deviation

of

the

clutch

disc

contact

surface

with

a

dial

gauge

If

it

exceeds

0

2

mm

0

0079

in

replace

it

3

Check

tooth

surfaces

of

the

ring

gear

for

flaw

and

wear

Replace

if

necessary

Note

Replace

the

ring

gear

at

about

180

to

2000C

356

to

3920

Fl

ENGINE

ASSEMBLY

PRECAUTION

CYLINDER

HEAD

PRECAUTION

CONTENTS

EM

25

EM

25

Use

thoroughly

cleaned

parts

Particularly

make

sure

that

oil

holes

are

clear

of

foreign

matter

2

When

installing

sliding

parts

such

as

bearings

be

sure

to

apply

engine

oil

to

them

3

Use

new

packings

and

oil

seals

4

Keep

tools

and

work

benches

clean

S

Keep

the

necessary

parts

and

tools

near

at

hand

6

Be

sure

to

follow

specified

tightening

torque

and

orders

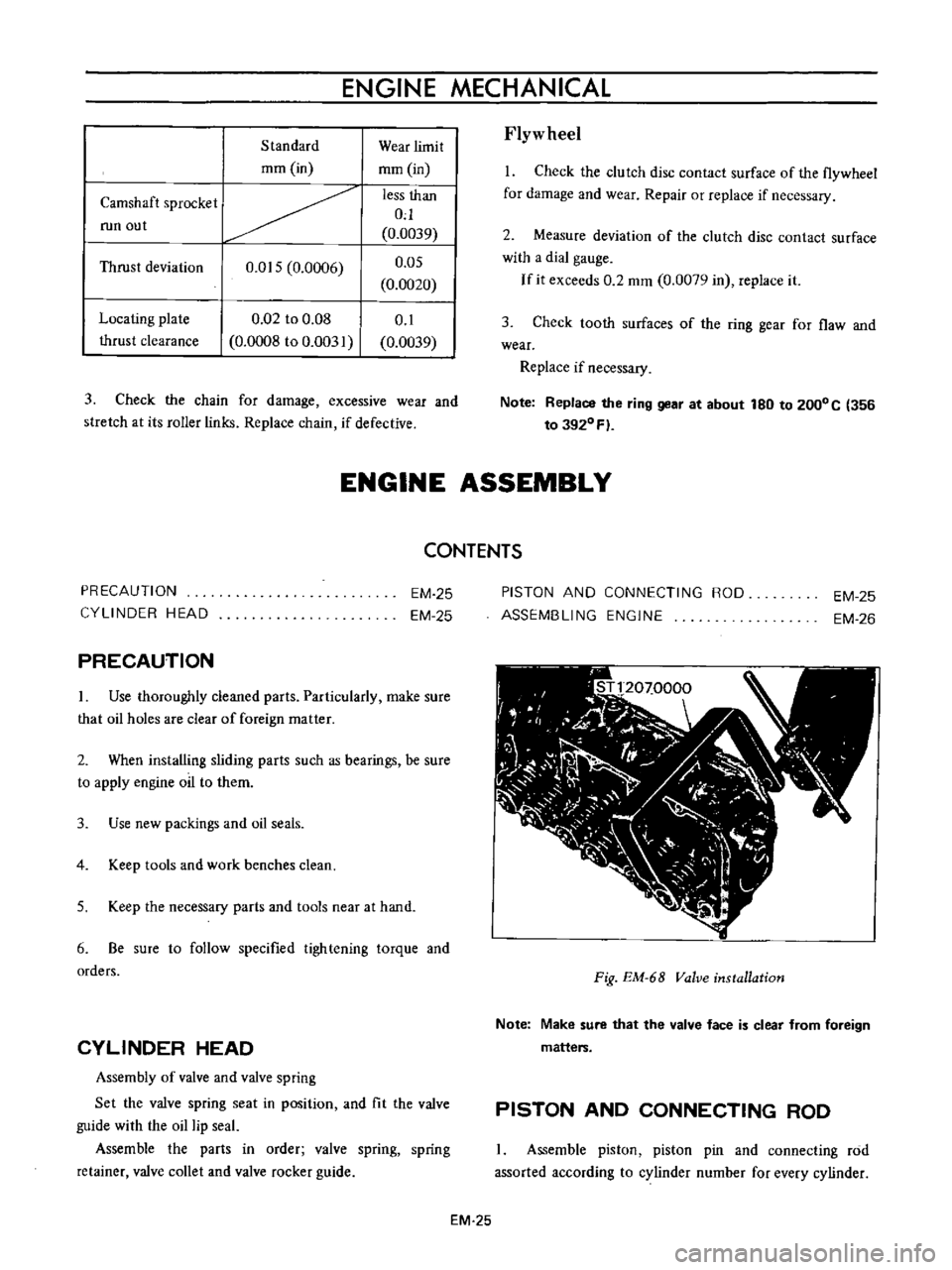

CYLINDER

HEAD

Assembly

of

valve

and

valve

spring

Set

the

valve

spring

seat

in

position

and

fit

the

valve

guide

with

the

oil

lip

seal

Assemble

the

parts

in

order

valve

spring

spring

retainer

valve

collet

and

valve

rocker

guide

PISTON

AND

CONNECTING

ROO

ASSEMBLING

ENGINE

EM

25

EM

26

I

I

11

00

I

I

I

t

I

J

ftr

J

J

1

l

J

r

N

1

n

r

VI

I

I

C

I

L

I

Fig

EM

68

Valve

installation

Note

Make

sure

that

the

valve

face

is

clear

from

foreign

matters

PISTON

AND

CONNECTING

ROD

Assemble

piston

piston

pin

and

connecting

rod

assorted

according

to

cylinder

number

for

every

cylinder

EM

25

Page 367 of 513

ENGINE

MECHANICAL

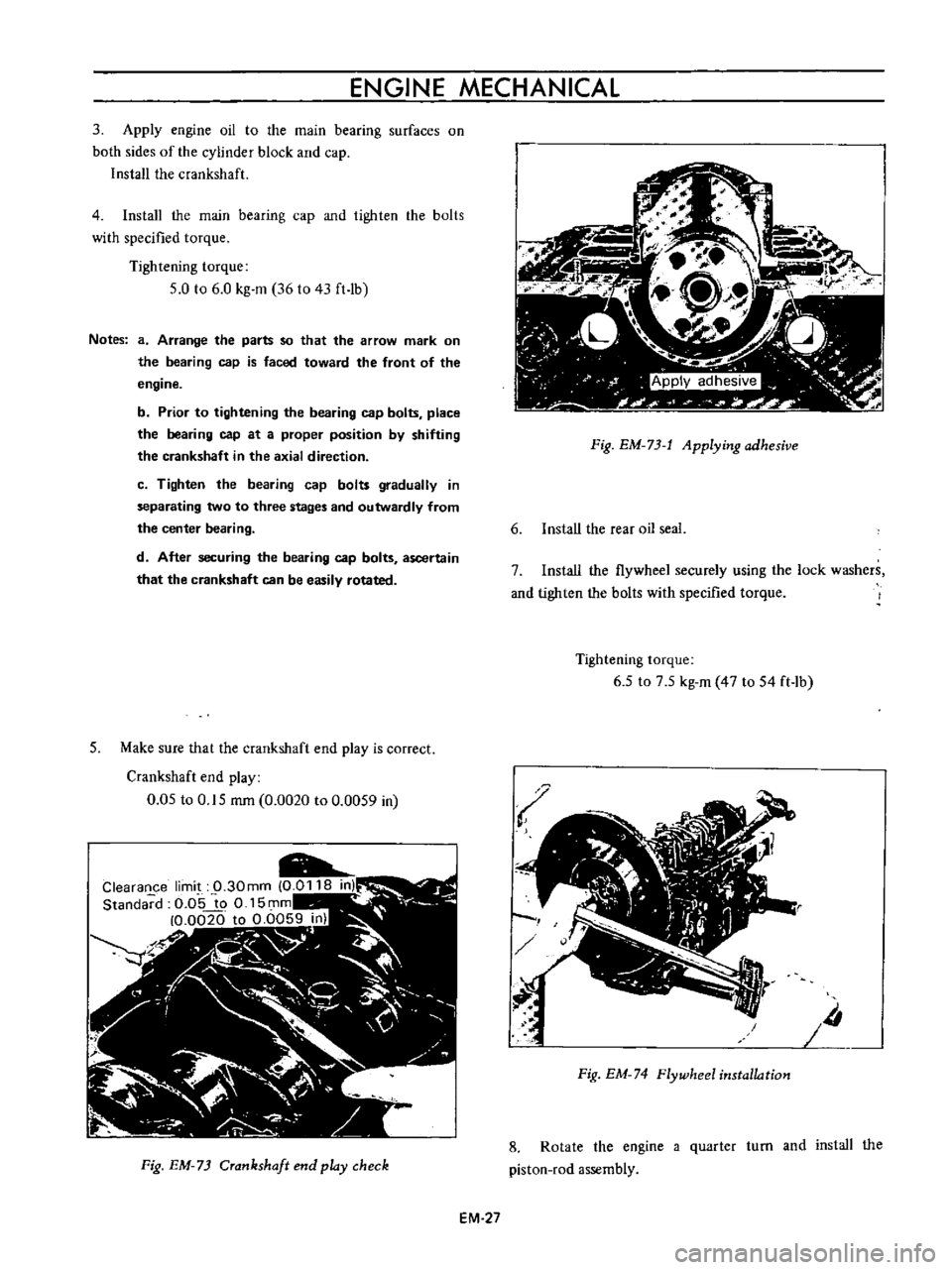

3

Apply

engine

oil

to

the

main

bearing

surfaces

on

both

sides

of

the

cylinder

block

and

cap

Install

the

crankshaft

4

Install

the

main

bearing

cap

and

tighten

the

bolts

with

specified

torque

Tightening

torque

5

0

to

6

0

kg

m

36

to

43

ft

lb

Notes

a

Arrange

the

parts

so

that

the

arrow

mark

on

the

bearing

cap

is

faced

toward

the

front

of

the

engine

b

Prior

to

tightening

the

bearing

cap

bolts

place

the

bearing

cap

at

a

proper

position

by

shifting

the

crankshaft

in

the

axial

direction

c

Tighten

the

bearing

cap

bolts

gradually

in

separating

two

to

three

stages

and

outwardly

from

the

center

beari

ng

d

After

securing

the

bearing

cap

bolts

ascertain

that

the

crankshaft

can

be

easily

rotated

5

Make

sure

that

the

crankshaft

end

play

is

correct

Crankshaft

end

play

0

05

to

0

15

rom

0

0020

to

0

0059

in

Fig

EM

73

Crankshaft

end

play

check

EM

27

Fig

EM

73

t

Applying

adhesive

6

Install

the

rear

oil

seal

7

Install

the

flywheel

securely

using

the

lock

washers

and

tighten

the

bolts

with

specified

torque

Tightening

torque

6

5

to

7

5

kg

m

47

to

54

ft

lb

Iii

Fig

EM

74

Flywheel

installation

8

Rotate

the

engine

a

quarter

turn

and

install

the

piston

rod

assembly

Page 373 of 513

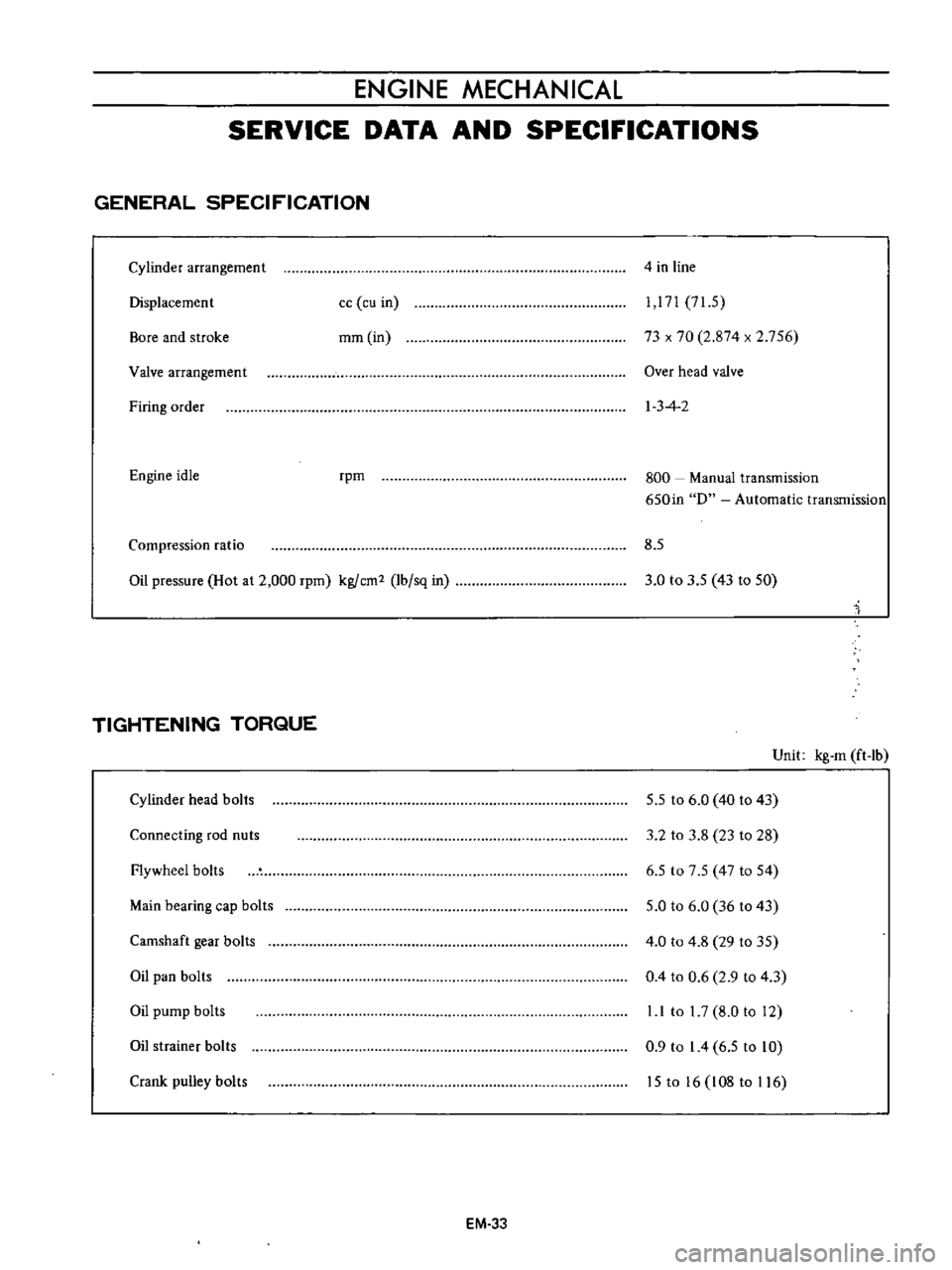

ENGINE

MECHANICAL

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATION

Cylinder

arrangement

4

in

line

Displacement

cc

cu

in

mm

in

1

171

71

5

73

x

70

2

874

x

2

756

Bore

and

stroke

Valve

arrangemen

t

Over

head

valve

Firing

order

I

3

4

2

Engine

idle

rpm

800

Manual

transmission

650in

D

Automatic

transmission

Compression

ratio

8

5

Oil

pressure

Hot

at

2

000

rpm

kgfcm2

Ibfsq

in

3

0

to

3

5

43

to

50

TIGHTENING

TORQUE

Unit

kg

m

ft

lb

Cylinder

head

bolts

Flywheel

bolts

5

5

to

6

0

40

to

43

3

2

to

3

8

23

to

28

6

5

to

7

5

47

to

54

5

0

to

6

0

36

to

43

4

0

to

4

8

29

to

35

0

4

to

0

6

2

9

to

4

3

l

l

to

I

7

8

0

to

12

0

9

to

I

4

6

5

to

10

15

to

16

108

to

116

Connecting

rod

nuts

Main

bearing

cap

bolts

Camshaft

gear

bolts

Oil

pan

bolts

Oil

pump

bolts

Oil

strainer

bolts

Crank

pulley

bolts

EM

33