wheel DATSUN B110 1973 Service Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 166 of 513

I

CHASSIS

4

Adjust

the

preload

of

the

worm

bearing

by

selecting

the

thickness

of

he

worm

bearing

shim

five

kinds

0

05

to

0

20

mm

0

0020

to

0

0079

in

so

that

the

initial

torque

of

the

steering

wheel

is

2

0

to

5

0

kg

cm

27

8

to

694

in

oz

without

sector

shaft

J

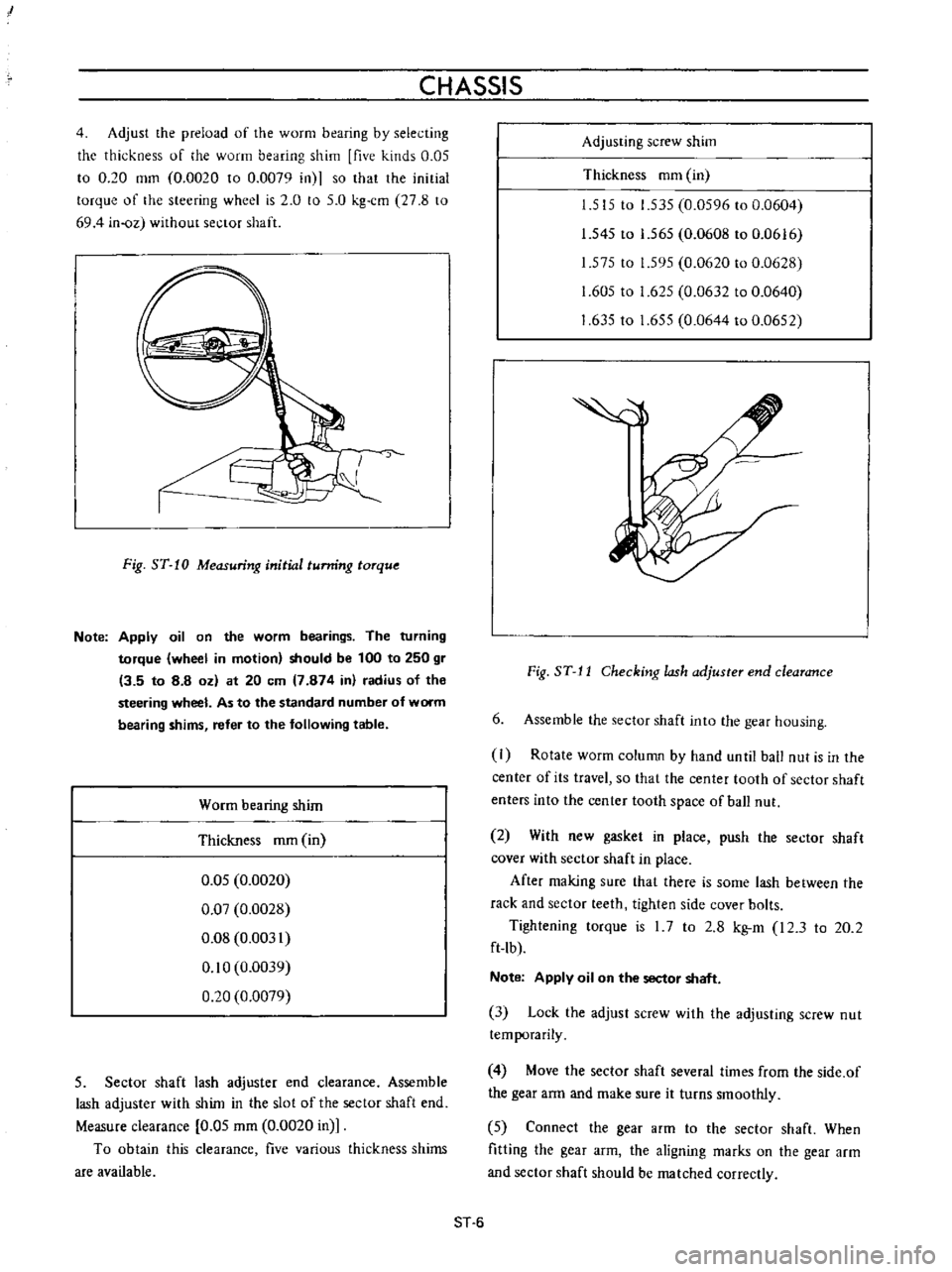

Fig

ST

10

Measuring

initial

tunring

torque

Note

Apply

oil

on

the

worm

bearings

The

turning

torque

wheel

in

motion

should

be

100

to

250

gr

13

5

to

8

8

oz

at

20

em

7

874

in

radius

of

the

steering

wheel

As

to

the

standard

number

of

worm

bearing

shims

refer

to

the

following

table

Worm

bearing

shim

Thickness

mm

in

0

05

0

0020

0

07

0

0028

0

08

0

0031

0

10

0

0039

0

20

0

0079

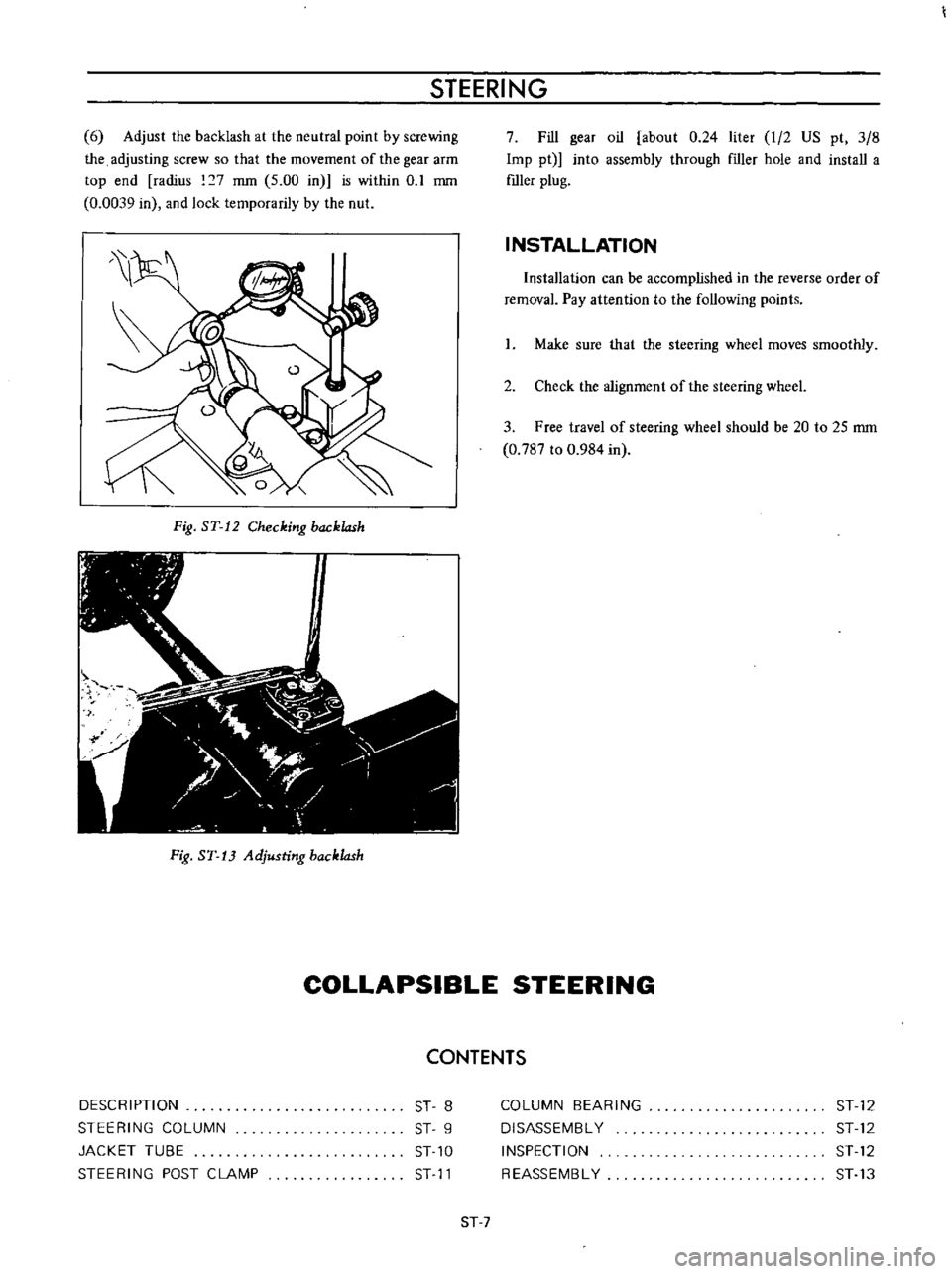

5

Sector

shaft

lash

adjuster

end

clearance

Assemble

lash

adjuster

with

shim

in

the

slot

of

the

sector

shaft

end

Measure

clearance

0

05

mm

0

0020

in

To

obtain

this

clearance

five

various

thickness

shims

are

available

Adjusting

screw

shim

Thickness

mm

in

1

515

to

1

535

0

0596

to

0

0604

1

545

to

1

565

0

0608

to

0

0616

1

575

to

1

595

0

0620

to

0

0628

1

605

to

1

625

0

0632

to

0

0640

1

63510

1

655

0

0644

to

0

0652

Fig

ST

J

J

Checking

lash

adjuster

end

clearance

6

Assemble

the

sector

shaft

into

the

gear

housing

I

Rotate

worm

column

by

hand

unlil

ball

nut

is

in

the

center

of

its

travel

so

that

the

center

tooth

of

sector

shaft

enters

into

the

center

tooth

space

of

ball

nut

2

With

new

gasket

in

place

push

the

sector

shaft

cover

with

sector

shaft

in

place

After

making

sure

that

there

is

some

lash

between

the

rack

and

sector

teeth

tighten

side

cover

bolts

Tightening

torque

is

I

7

to

2

8

kg

m

I2

3

to

20

2

ft

lb

Note

Apply

oil

on

the

sector

shaft

3

Lock

the

adjust

screw

with

the

adjusting

screw

nut

temporarily

4

Move

the

sector

shaft

several

times

from

the

side

of

the

gear

arm

and

make

sure

it

turns

smoothly

5

Connect

the

gear

arm

to

the

sector

shaft

When

fitting

the

gear

arm

the

aligning

marks

on

the

gear

arm

and

sector

shaft

should

be

matched

correctly

ST

6

Page 167 of 513

STEERING

6

Adjust

the

backlash

at

the

neutral

point

by

screwing

the

adjusting

screw

so

that

the

movement

of

the

gear

arm

top

end

radius

7

mm

5

00

in

is

within

0

1

mm

0

0039

in

and

lock

temporarily

by

the

nut

Fig

ST

12

Checking

backlash

Fig

ST

13

Adjusting

backlash

7

Fill

gear

oil

about

0

24

liter

I

2

US

pt

3

8

Imp

pt

into

assembly

through

f1ller

hole

and

install

a

mIer

plug

INSTALLATION

Installation

can

be

accomplished

in

the

reverse

order

of

removal

Pay

attention

to

the

following

points

I

Make

sure

that

the

steering

wheel

moves

smoothly

2

Check

the

alignment

of

the

steering

wheeL

3

Free

travel

of

steering

wheel

should

be

20

to

25

mm

0

787

to

0

984

in

COLLAPSIBLE

STEERING

CONTENTS

DESCRIPTION

STEERING

COLUMN

JACKET

TUBE

STEERING

POST

CLAMP

ST

8

ST

9

ST

10

ST

11

COLUMN

BEARING

DISASSEMBL

Y

INSPECTION

REASSEMBL

Y

ST

12

ST

12

ST

12

ST

13

ST

7

Page 168 of 513

CHASSIS

I

l

I

I

2

fa

r

o

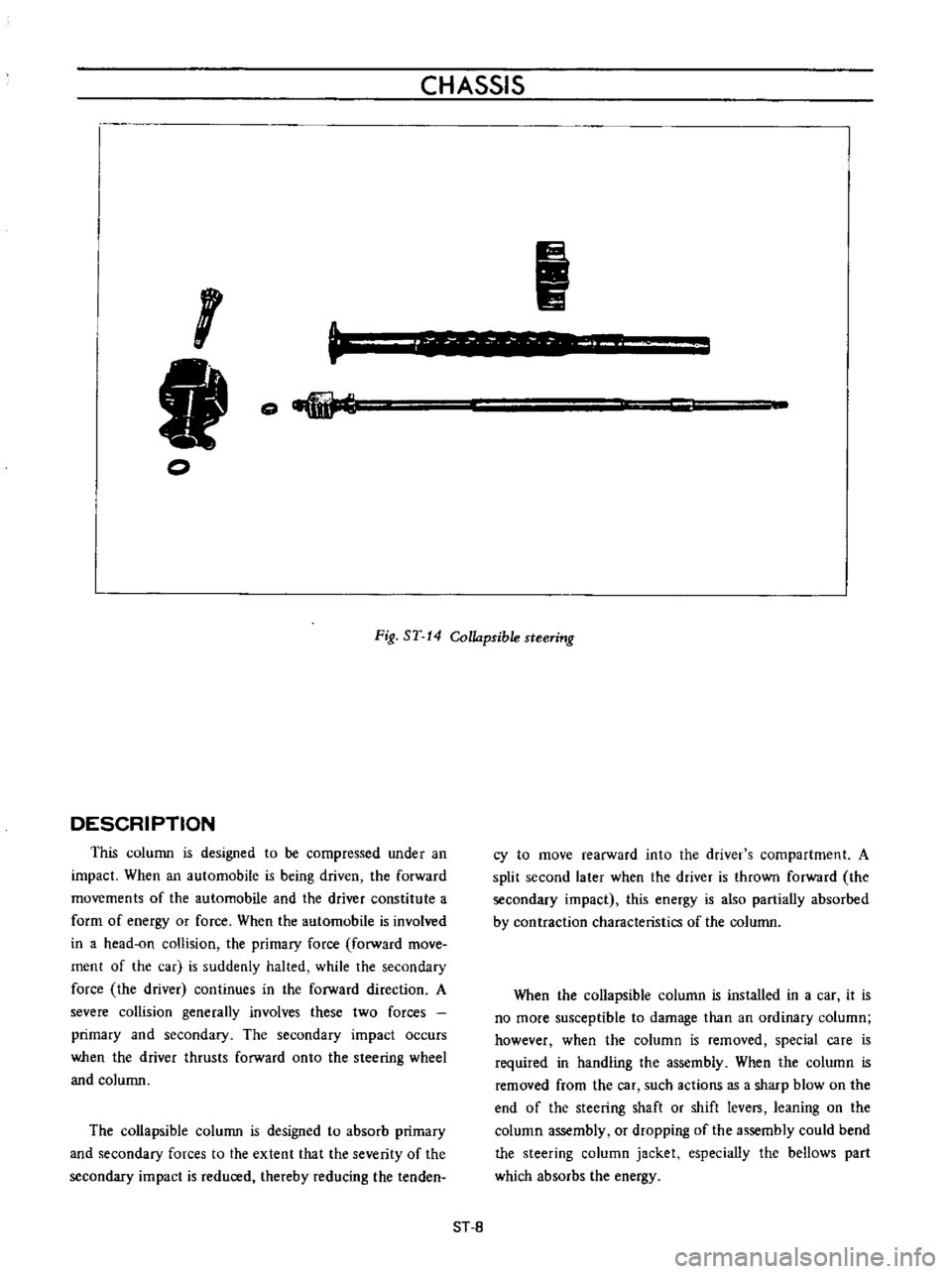

Fig

ST

14

Collapsible

steering

DESCRIPTION

This

column

is

designed

to

be

compressed

under

an

impact

When

an

automobile

is

being

driven

the

forward

movements

of

the

automobile

and

the

driver

constitute

a

form

of

energy

or

force

When

the

automobile

is

involved

in

a

head

on

collision

the

primary

force

forward

move

ment

of

the

car

is

suddenly

halted

while

the

secondary

force

the

driver

continues

in

the

forward

direction

A

severe

collision

generally

involves

these

two

forces

primary

and

secondary

The

secondary

impact

occurs

when

the

driver

thrusts

forward

onto

the

steering

wheel

and

column

The

collapsible

column

is

designed

to

absorb

primary

and

secondary

forces

to

the

extent

that

the

severity

of

the

secondary

impact

is

reduced

thereby

reducing

the

tenden

cy

to

move

rearward

into

the

driver

s

compartment

A

split

second

later

when

the

driver

is

thrown

forward

the

secondary

impact

this

energy

is

also

partially

absorbed

by

contraction

characteristics

of

the

column

When

the

collapsible

column

is

installed

in

a

car

it

is

no

more

susceptible

to

damage

than

an

ordinary

column

however

when

the

column

is

removed

special

care

is

required

in

handling

the

assembly

When

the

column

is

removed

from

the

car

such

actions

as

a

sharp

blow

on

the

end

of

the

steering

shaft

or

shift

levers

leaning

on

the

column

assembly

or

dropping

of

the

assembly

could

bend

the

steering

column

jacket

especially

the

bellows

part

which

absorbs

the

energy

ST

8

Page 172 of 513

CHASSIS

The

sliding

block

is

secured

on

the

steering

post

bracket

with

bolts

upper

half

of

the

steering

column

is

supported

on

the

bracket

and

thus

the

steering

post

clamp

is

installed

on

the

body

When

a

large

impact

is

applied

from

the

driver

side

the

plastic

pins

are

cut

off

and

leaving

the

sliding

block

in

the

steering

post

bracket

side

the

clamp

proper

is

disengaged

downward

together

with

the

jacket

tube

For

any

force

applied

from

front

direction

of

the

vehicle

the

steering

post

clamp

sliding

block

does

not

move

rearward

This

construction

is

called

One

way

slide

system

and

with

this

construction

projection

of

the

column

shaft

toward

the

driver

is

prevented

completely

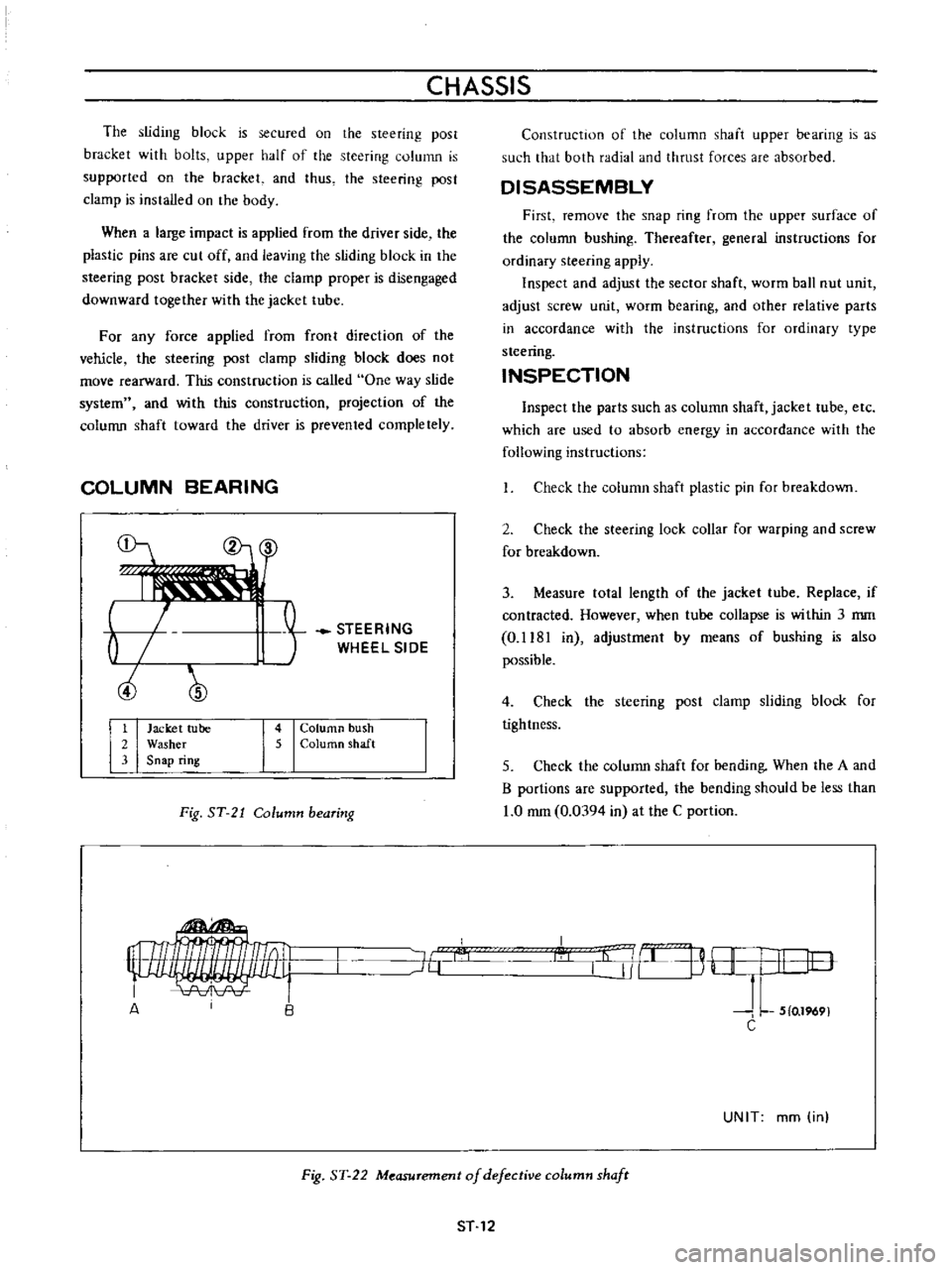

COLUMN

BEARING

b

ciJ

STEERING

WHEEL

SIDE

1

Jacket

tube

2

Washer

3

Snap

ring

4

Column

bush

5

ColurtlO

shaft

Fig

ST

21

Column

bearing

Construction

of

the

column

shaft

upper

bearing

is

as

such

that

both

radial

and

thrust

forces

are

absorbed

DISASSEMBLY

First

remove

the

snap

ring

from

the

upper

surface

of

the

column

bushing

Thereafter

general

instructions

for

ordinary

steering

apply

Inspect

and

adjust

the

sector

shaft

worm

ball

nut

unit

adjust

screw

unit

worm

bearing

and

other

relative

parts

in

accordance

with

the

instructions

for

ordinary

type

steering

INSPECTION

Inspect

the

parts

such

as

column

shaft

jacket

tube

etc

which

are

used

to

absorb

energy

in

accordance

with

the

following

instructions

Check

the

column

shaft

plastic

pin

for

breakdown

2

Check

the

steering

lock

collar

for

warping

and

screw

for

breakdown

3

Measure

tolal

length

of

the

jacket

tube

Replace

if

contracted

However

when

tube

collapse

is

within

3

mm

0

1181

in

adjustmenl

by

means

of

bushing

is

also

possible

4

Check

the

steering

post

clamp

sliding

block

for

tightness

5

Check

the

column

shaft

for

bending

When

the

A

and

B

portions

are

supported

the

bending

should

be

less

than

1

0

mm

0

0394

in

at

the

C

portion

I

l

j

B

H

I

I

lO

J

L

5

0

1969

C

J6

A

UNIT

mm

in

Fig

ST

22

Measurement

of

defective

column

shafr

ST

12

Page 176 of 513

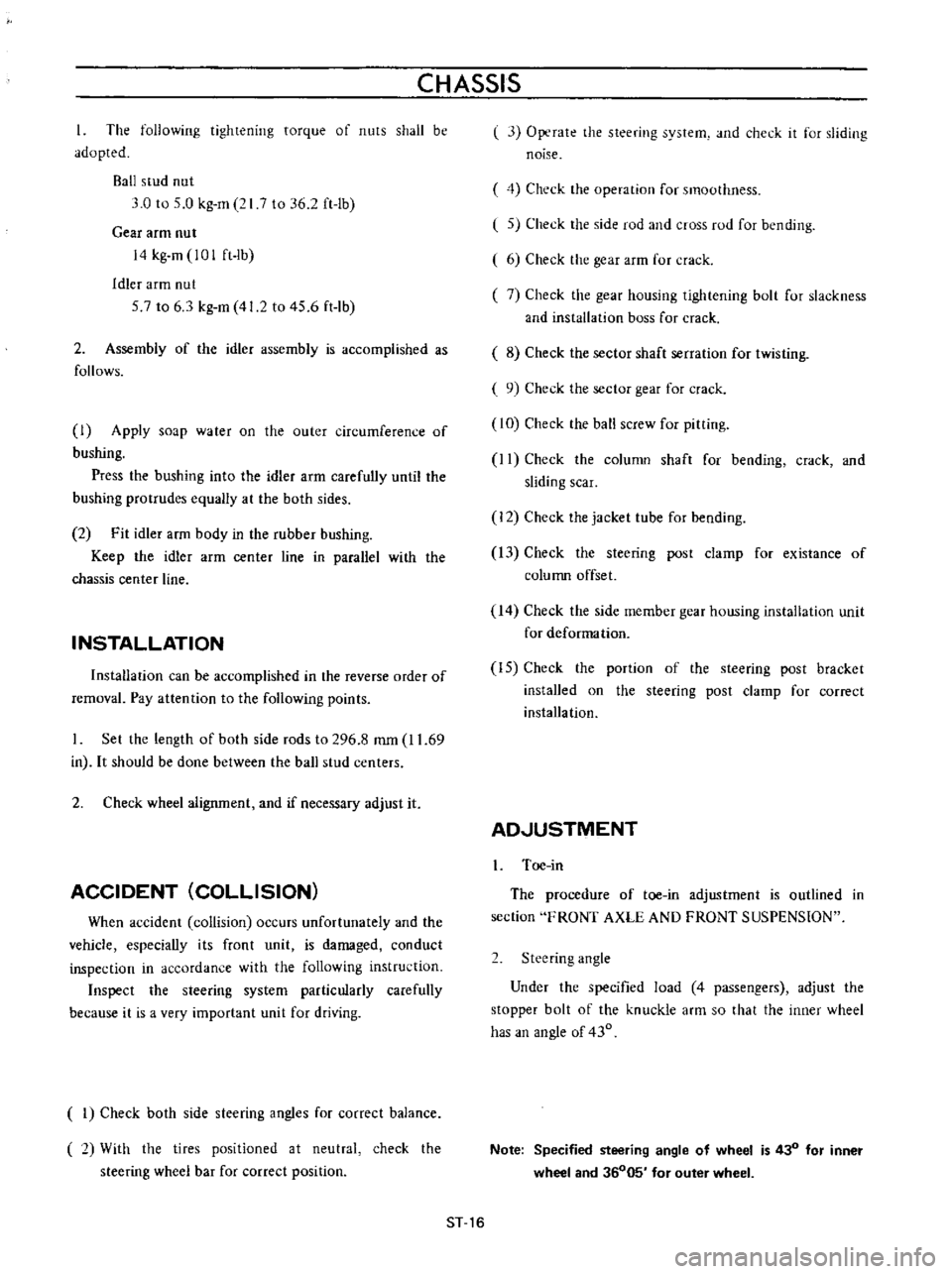

CHASSIS

The

following

tightening

torque

of

nuts

shall

be

adopted

Ball

stud

nut

3

0

to

5

0

kg

m

21

7

to

36

2

ft

lb

Gear

arm

nut

14

kg

m

101

ft

lb

Idler

arm

nut

57

to

6

3

kg

m

41

2

to

45

6

ft

lb

2

Assembly

of

the

idler

assembly

is

accomplished

as

follows

I

Apply

soap

water

on

the

outer

circumference

of

bushing

Press

the

bushing

into

the

idler

arm

carefully

until

the

bushing

protrudes

equally

at

the

both

sides

2

Fit

idler

arm

body

in

the

rubber

bushing

Keep

the

idler

arm

center

line

in

parallel

with

the

chassis

center

line

INSTALLATION

Installation

can

be

accomplished

in

the

reverse

order

of

removal

Pay

attention

to

the

following

points

Set

the

length

of

both

side

rods

to

296

8

mm

11

69

in

It

should

be

done

between

the

ball

stud

centers

2

Check

wheel

alignment

and

if

necessary

adjust

it

ACCIDENT

COLLISION

When

accident

collision

occurs

unfortunately

and

the

vehicle

especially

its

front

unit

is

damaged

conduct

inspection

in

accordance

with

the

following

instruction

Inspect

the

steering

system

particularly

carefully

because

it

is

a

very

important

unit

for

driving

I

Check

both

side

steering

angles

for

correct

balance

2

With

the

tires

positioned

at

neutral

steering

wheel

bar

for

correct

position

check

the

l

3

Operate

the

steering

system

and

check

it

for

sliding

noise

4

Check

the

operation

for

smoothness

l

5

Check

the

side

rod

and

cross

rod

for

bending

6

Check

the

gear

arm

for

crack

7

Check

the

gear

housing

tiglltening

bolt

for

slackness

and

installation

boss

for

crack

8

Check

the

sector

shaft

serration

for

twisting

9

Check

the

sector

gear

for

crack

10

Check

the

ball

screw

for

pitting

II

Check

the

column

shaft

for

bending

crack

and

sliding

scar

12

Check

the

jacket

tube

for

bending

13

Check

the

steering

post

clamp

for

existance

of

column

offset

14

Check

the

side

member

gear

housing

installation

unit

for

deformation

IS

Check

the

portion

of

the

steering

post

bracket

installed

on

the

steering

post

clamp

for

correct

installation

AD

JUSTMENT

I

Toe

in

The

procedure

of

toe

in

adjustment

is

outlined

in

section

FRONT

AXLE

AND

FRONT

SUSPENSION

2

Steering

angle

Under

the

specified

load

4

passengers

adjust

the

stopper

bolt

of

the

knuckle

arm

so

that

the

inner

wheel

has

an

angle

of

430

Note

Specified

steering

angle

of

wheel

is

430

for

inner

wheel

and

36005

for

outer

wheel

ST

16

Page 177 of 513

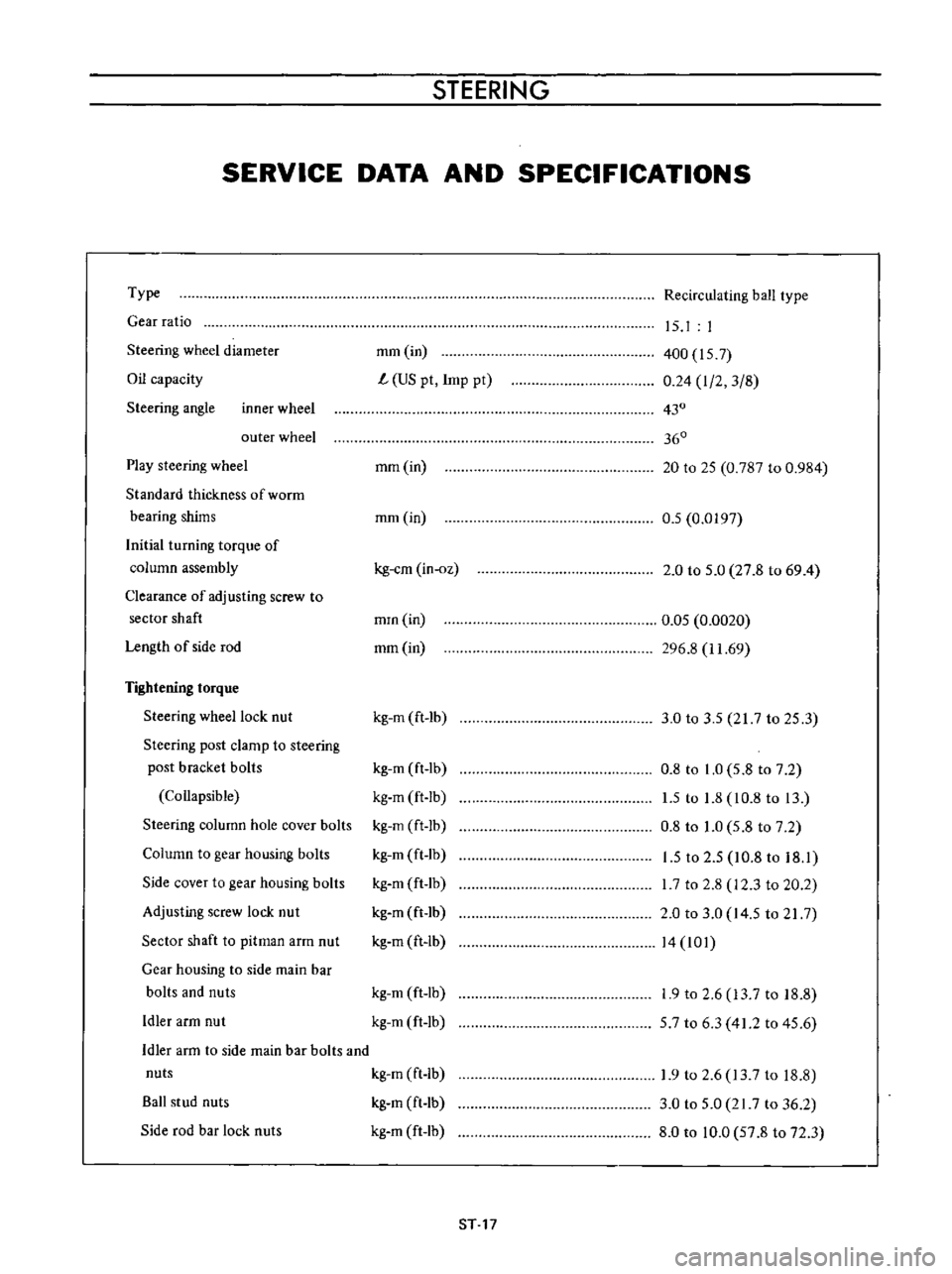

STEERING

SERVICE

DATA

AND

SPECIFICATIONS

Type

Gear

ratio

Steering

wheel

diameter

Oil

capacity

Steering

angle

inner

wheel

outer

wheel

Play

steering

wheel

Standard

thickness

of

worrn

bearing

shims

Initial

turning

torque

of

column

assembly

Clearance

of

adjusting

screw

to

sector

shaft

Length

of

side

rod

Tightening

torque

Steering

wheel

lock

nut

Steering

post

clamp

to

steering

post

bracket

bolls

Collapsible

Steering

column

hole

cover

bolts

Column

to

gear

housing

bolts

Side

cover

to

gear

housing

bolts

Adjusting

screw

lock

nut

Sector

shaft

to

pitman

arm

nut

Gear

housing

to

side

main

bar

bolts

and

nuts

Idler

arm

nut

Recirculating

ball

type

mm

in

L

US

pt

Imp

pt

15

I

I

400

157

0

24

I

2

3

8

430

360

mm

in

20

to

25

0

787

to

0

984

mm

in

0

5

0

0197

kg

em

in

oz

2

0

to

5

0

27

8

to

69

4

mrn

in

mm

in

0

05

0

0020

296

8

11

69

kg

m

ft

lb

3

0

to

3

5

217

to

25

3

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

0

8

to

1

0

5

8

to

7

2

1

5

to

1

8

10

8

to

13

0

8

to

1

0

5

8

to

7

2

1

5

to

2

5

10

8

to

18

1

I

7

to

2

8

12

3

to

20

2

2

0

to

3

0

14

5

to

21

7

14

101

kg

m

ft

lb

kg

m

ft

lb

1

9

to

2

6

13

7

to

18

8

57

to

6

3

41

2

to

45

6

Idler

arm

to

side

main

bar

bolts

and

nuts

kg

m

ft

Ib

Ball

stud

nuts

kg

m

ft

lb

Side

rod

bar

lock

nuts

kg

m

ft

lb

1

9

to

2

6

13

7

to

18

8

3

0

to

5

0

21

7

to

36

2

8

0

to

10

0

57

8

to

72

3

ST

17

Page 178 of 513

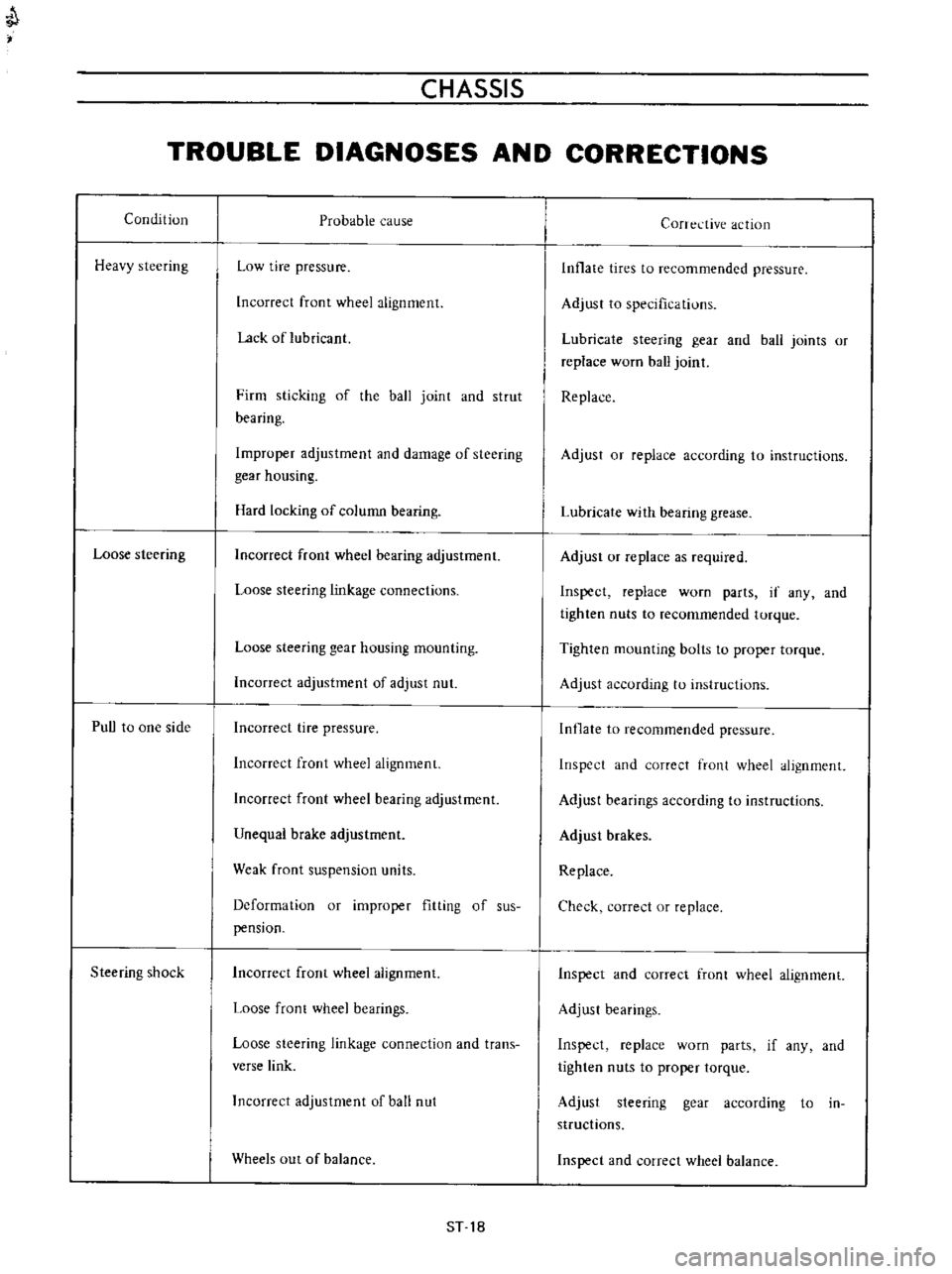

CHASSIS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Heavy

steering

Loose

steering

PuU

to

one

side

Steering

shock

Probable

cause

Low

tire

pressure

Incorrect

front

wheel

alignment

Lack

of

lubricant

Firm

sticking

of

the

ball

joint

and

strut

bearing

Improper

adjustment

and

damage

of

steering

gear

housing

Hard

locking

of

column

bearing

Incorrect

front

wheel

bearing

adjustment

Loose

steering

linkage

connections

Loose

steering

gear

housing

mounting

Incorrect

adjustment

of

adjust

nut

Incorrect

tire

pressure

Incorrect

front

wheel

alignment

Incorrect

front

wheel

bearing

adjustment

Unequal

brake

adjustment

Weak

front

suspension

units

Deformation

or

improper

fitting

of

sus

pension

Incorrect

front

wheel

alignment

Loose

front

wheel

bearings

Loose

steering

linkage

connection

and

trans

verse

link

Incorrect

adjustment

of

ball

nut

Wheels

out

of

balance

ST

18

Corrective

action

Inflate

tires

to

recommended

pressure

Adjust

to

specifications

Lubricate

steering

gear

and

ball

joints

or

replace

worn

ball

joint

Replace

Adjust

or

replace

according

to

instructions

Lubricate

with

bearing

grease

Adjust

or

replace

as

required

Inspect

replace

worn

parts

if

any

and

tighten

nuts

to

recommended

torque

Tighten

mounting

bolts

to

proper

torque

Adjust

according

to

instructions

Inflate

to

recommended

pressure

Inspect

and

correct

front

wheel

alignment

Adjust

bearings

according

to

instructions

Adjust

brakes

Replace

Check

correct

or

replace

Inspect

and

correct

front

wheel

alignment

Adjust

bearings

Inspect

replace

worn

parts

if

any

and

tighten

nuts

to

proper

torque

Adjust

steering

gear

according

to

in

structions

Inspect

and

correct

wheel

balance

Page 193 of 513

@

7

11

@

C

C

B

B

@

I

L

IJ

A

A

F

F

n

18

@

1

@

H

H

@

@

Y

J

@

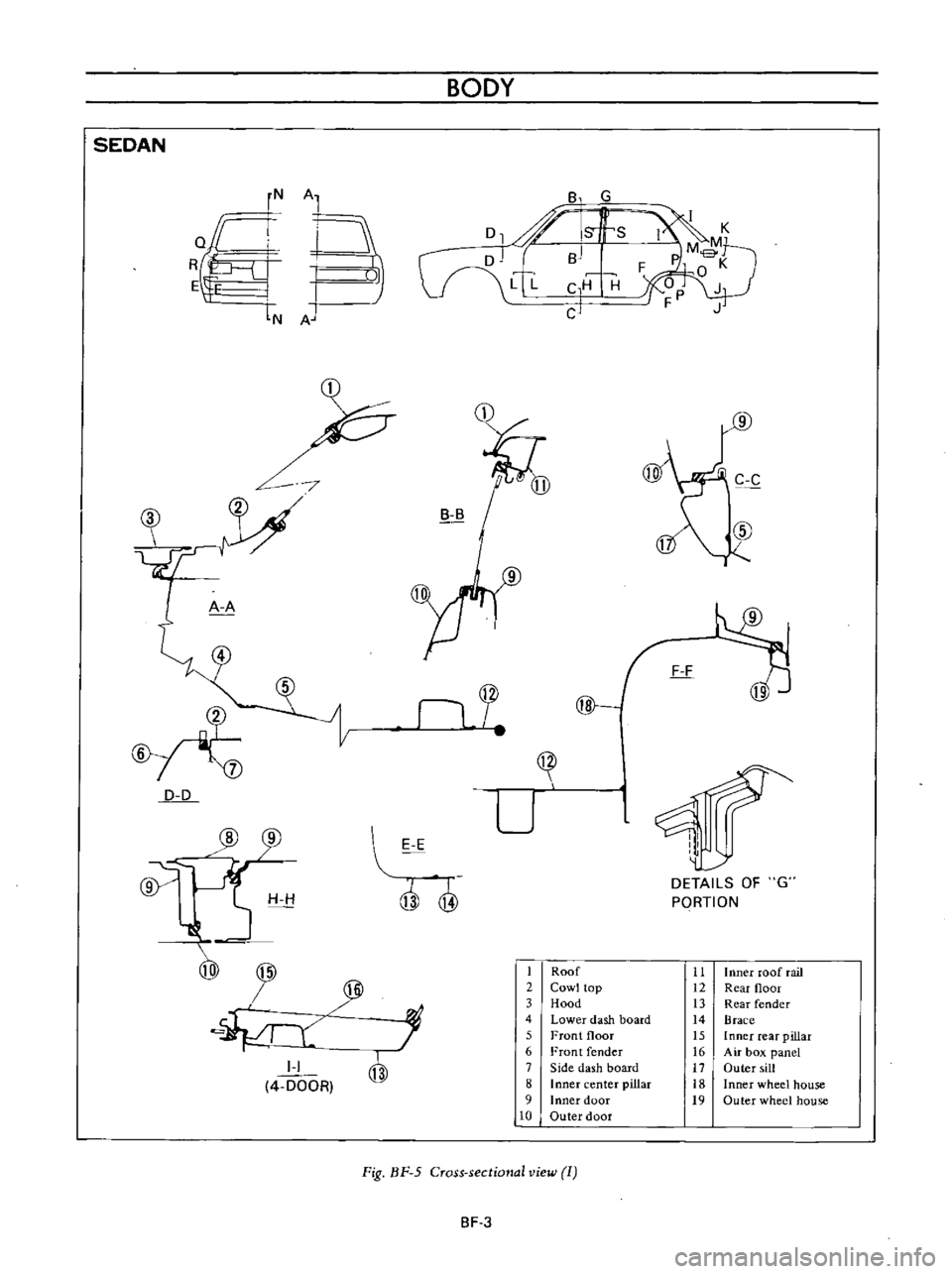

SEDAN

rN

Al

RQ

I

l

E

IN

A

D

D

I

I

4

DOOR

BODY

8

G

D1

J

Is

s

r

Jn

BJ

V

V

L

C

H

H

CJ

U

I

II

I

E

E

Q

@

DETAILS

OF

G

PORTION

1

Roof

11

Inner

roof

rail

2

Cowl

top

12

Rear

floor

3

Hood

13

Rear

fender

4

Lower

dash

board

14

Brace

5

Front

floor

15

Inner

reaT

pillar

6

Front

fender

16

Air

box

panel

7

Side

dash

board

17

Outer

sill

B

Inner

center

pillar

18

Inner

wheel

house

9

Inner

dOOf

19

Outer

wheel

house

10

Outer

door

Fig

nF

5

Cross

sectional

view

1

BF

3

Page 194 of 513

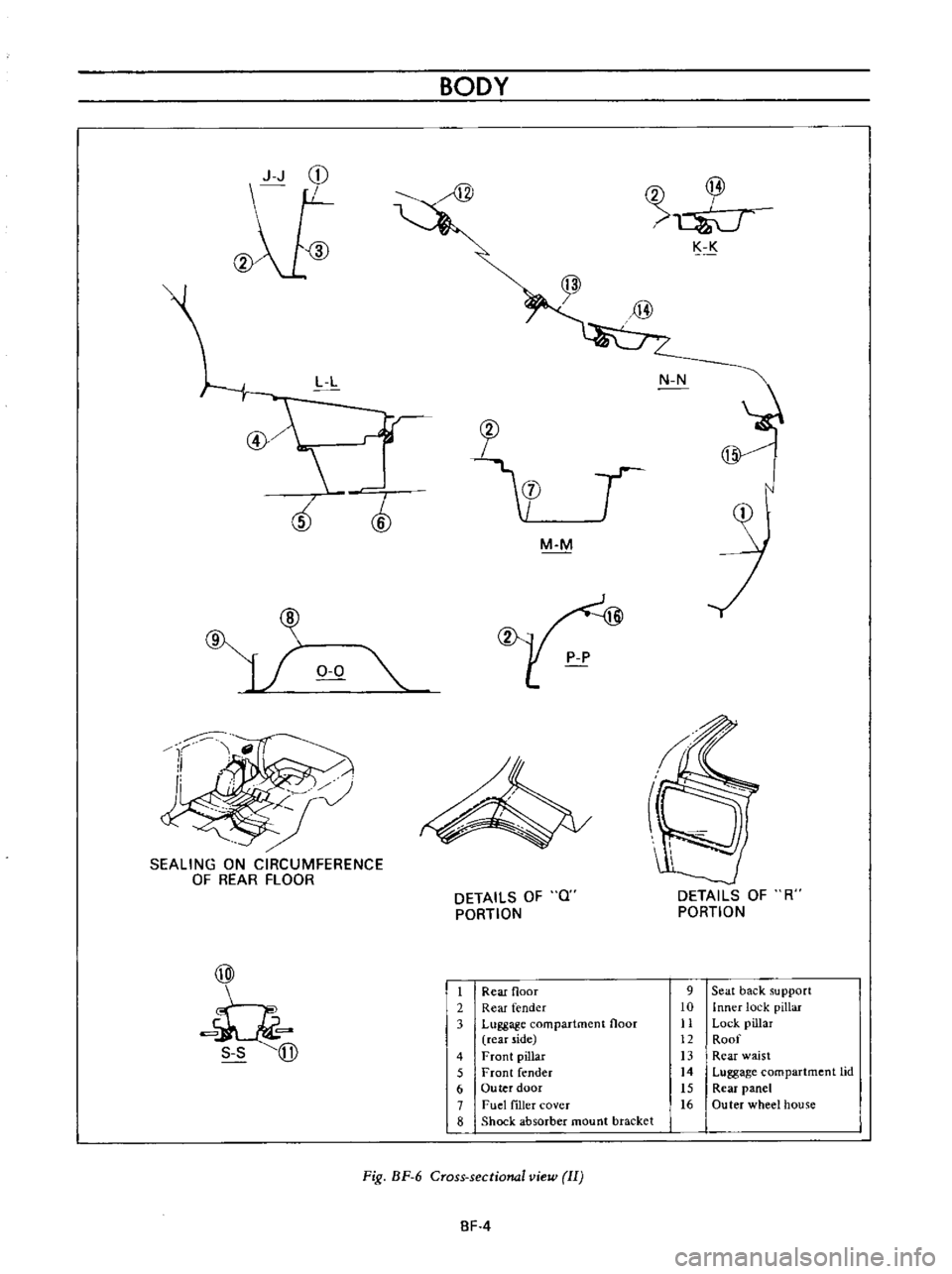

J

J

CD

11

BODY

I

K

L

L

N

N

@

r

T

I

c

cb

I

cp

M

M

J

Ii

0

0

SEALING

ON

CIRCUMFERENCE

OF

REAR

FLOOR

@

Ii

DETAILS

OF

Q

PORTION

DETAILS

OF

R

PORTION

1

Rear

floor

2

Rear

fender

3

Luggage

compartment

floor

rear

side

4

Front

pillar

5

Front

fender

6

Ou

tee

door

7

Fue

filler

cover

8

Shock

absorber

mount

bracket

9

Seat

back

support

10

Inner

lock

pillar

11

Lock

pillar

12

Roof

13

Rear

waist

14

Luggage

compartment

lid

15

Rear

panel

16

Outer

wheel

house

Fig

BF

6

Cross

sectional

view

II

BF

4

Page 195 of 513

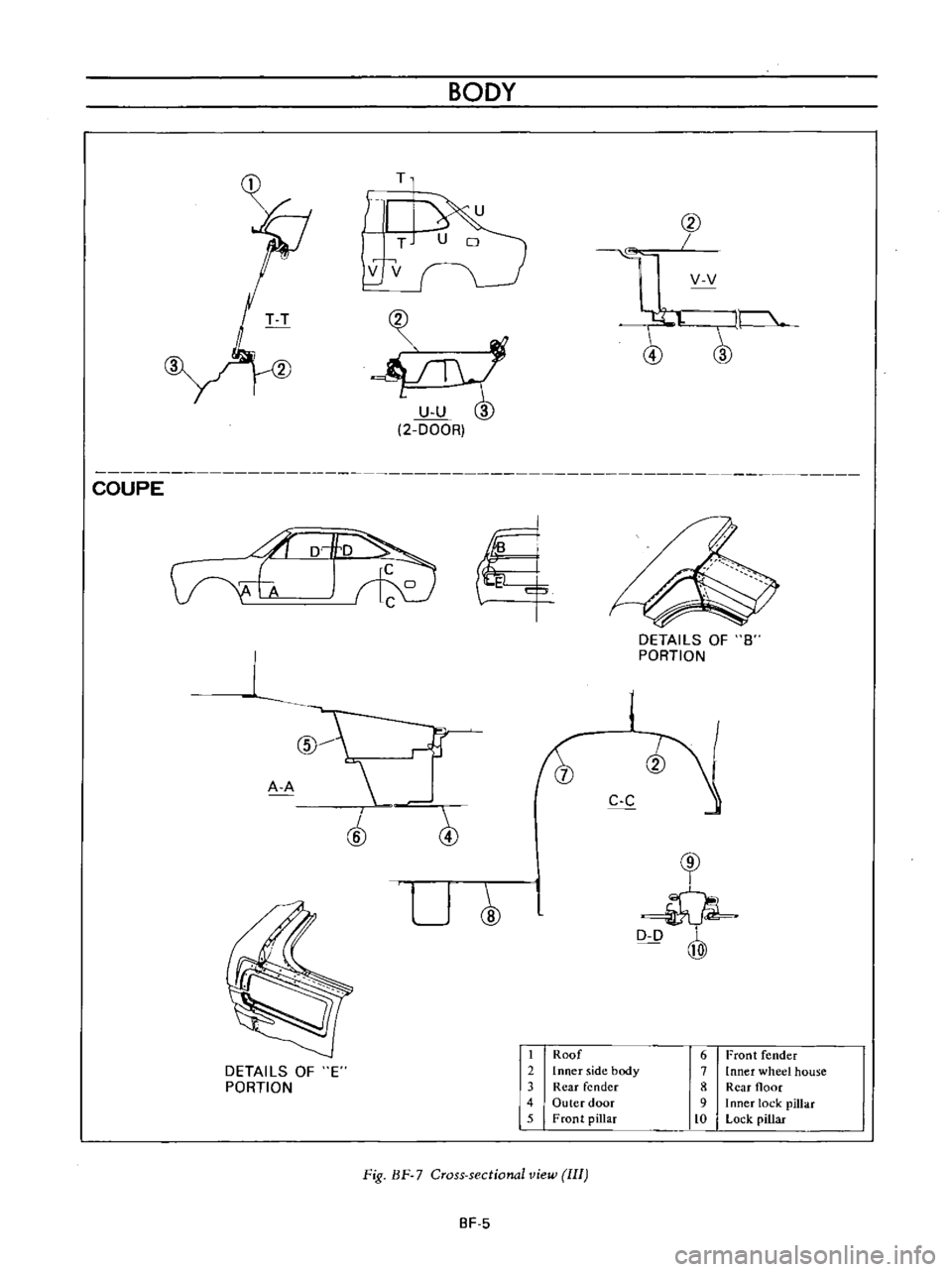

COUPE

BODY

T

@

T

v

v

vv

l

2

DOOR

1

5

Vv

t

t

tJ

DETAILS

OF

8

PORTION

1

r

I

A

A

J

C

C

j

@

cr

U

D

D

@

DETAILS

OF

E

PORTION

1

Roof

2

Inner

side

body

3

Rear

fender

4

Outer

door

5

Front

pillar

6

Front

fender

7

loner

wheel

house

8

Rear

floor

9

I

Rner

lock

pilla

c

to

Lock

pillar

Fig

BF

7

Cross

sectional

view

III

SF

5