wheel DATSUN B110 1973 Service Manual Online

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 405 of 513

ENGINE

AD

JUSTMENT

Idling

adjustment

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

and

calibrated

Warm

up

the

engine

sufficiently

2

Continue

engine

operation

for

one

minute

under

idling

speed

3

Adjust

throttle

adjusting

screw

so

that

engine

speed

is

800

rpm

in

N

position

for

automatic

transmission

4

Check

ignition

timing

if

necessary

adjust

it

to

the

specifications

Ignition

timing

50

800

rpm

5

Adjust

idle

adjusting

screw

so

that

ca

percentage

is

1

5

t

0

5

6

Repeat

the

adjustments

as

described

in

steps

3

and

5

above

so

that

ca

percentage

is

1

5

to

5

at

800

rpm

Cautions

a

On

automatic

transmission

equipped

model

check

must

be

done

in

the

0

position

Be

sure

to

apply

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Hold

brake

pedal

while

stepping

down

on

accelerator

pedal

Otherwise

car

will

rush

out

dangerously

7

On

automatic

transmission

equipped

model

make

sure

that

the

adjustment

has

been

made

with

the

selector

lever

in

N

position

And

then

check

the

specifications

with

the

lever

in

D

position

Insure

that

CO

percent

and

idle

speed

are

as

follows

Idle

rpm

650

ca

percentage

with

lever

in

D

position

15

to

5

If

necessary

adjust

by

progressively

turning

throttle

adjusting

screw

and

idle

adjusting

screw

until

correct

adjustments

are

made

Notes

a

Do

not

attempt

to

screw

down

the

id

Ie

adjusting

screw

completely

to

avoid

damage

to

the

EF

14

tip

which

will

tend

to

cause

malfunctions

b

After

idle

adjustment

has

been

made

shift

the

lever

to

N

or

p

position

for

automatic

transmission

c

Remove

wheel

chocks

before

starting

the

car

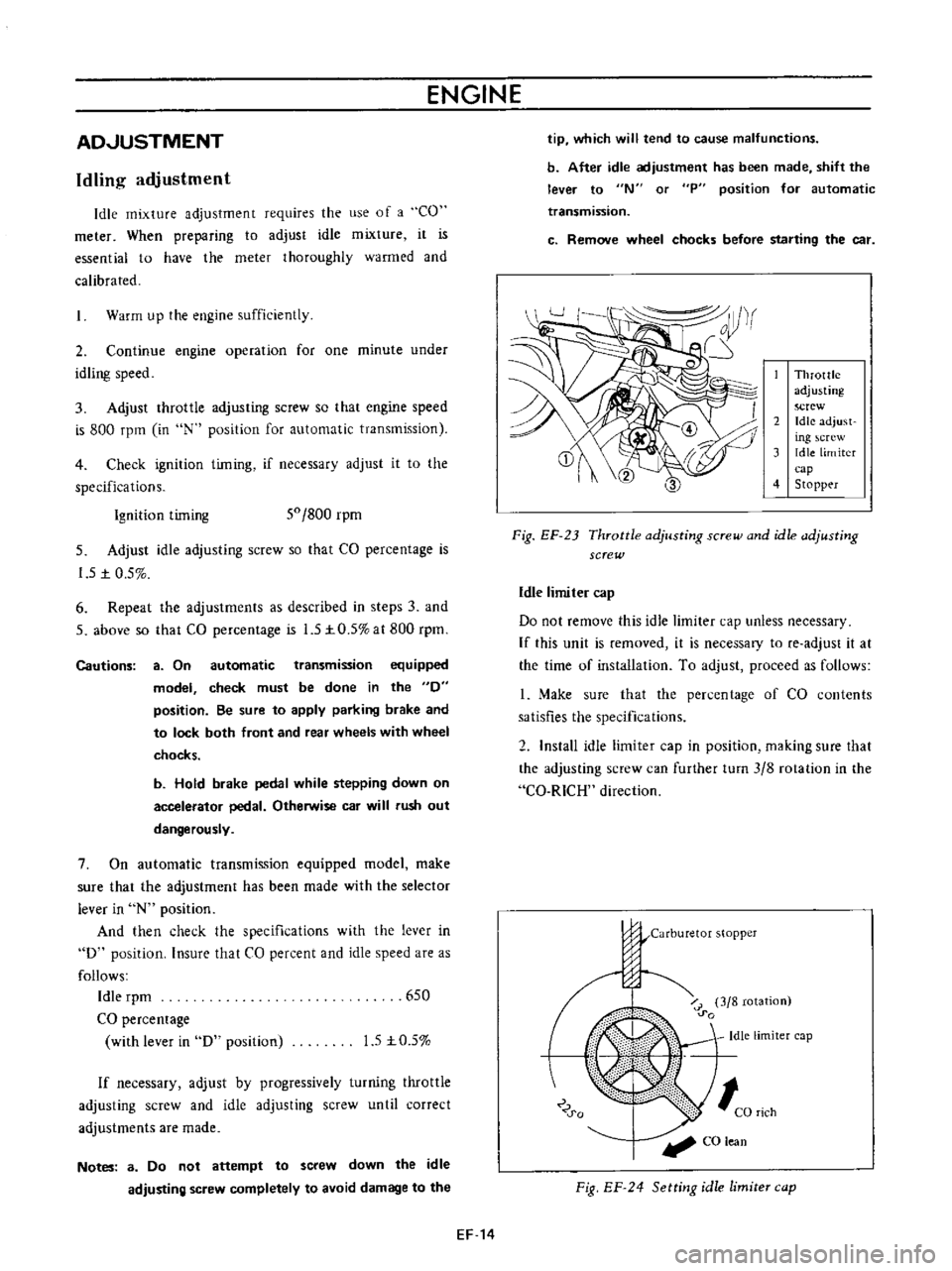

Throttle

adjusting

screw

2

Idle

adjust

ing

crew

3

Idle

limiter

cap

4

Stopp

r

Fig

EF

23

Throttle

adjusting

screw

and

idle

adjusting

screw

Idle

limiter

cap

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

removed

it

is

necessary

to

fe

adjust

it

at

the

time

of

installation

To

adjust

proceed

as

follows

1

Make

sure

that

the

percentage

of

CO

contents

satisfies

the

specifications

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

can

further

turn

3

8

rotation

in

the

Ca

RICH

direction

j

j

Carburetor

stopper

o

u

o

i

r

3

8

rotation

0

0

Idle

limiter

cap

0

0

CO

lean

Fig

EF

24

Setting

idle

limite

cap

Page 423 of 513

ENGINE

ElECTRICAL

SYSTEM

5

If

the

specific

gravity

is

above

1

260

200C

or

680F

after

charging

adjust

it

by

adding

distilled

water

6

Keep

any

open

flame

away

from

the

place

where

the

battery

is

being

charged

7

Replace

vent

plugs

and

clean

the

upper

face

of

the

battery

after

charging

BATTERY

FREEZING

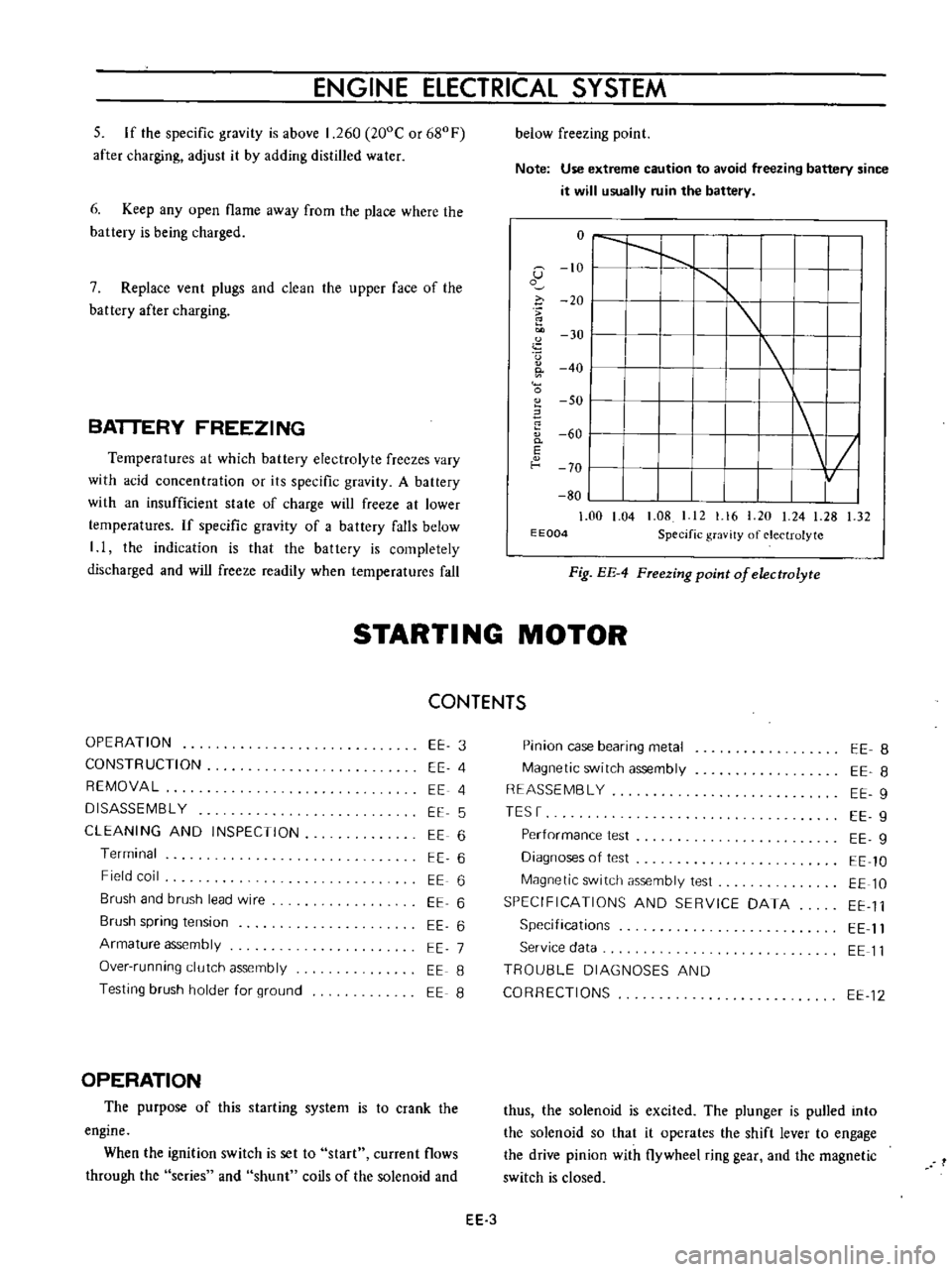

Temperatures

at

which

battery

electrolyte

freezes

vary

with

acid

concentration

or

its

specific

gravity

A

battery

with

an

insufficient

state

of

charge

will

freeze

at

lower

temperatures

If

specific

gravity

of

a

battery

falls

below

I

I

the

indication

is

that

the

battery

is

completely

discharged

and

will

freeze

readily

when

temperatures

fall

below

freezing

point

Note

Use

extreme

caution

to

avoid

freezing

battery

since

it

will

usually

ruin

the

battery

o

I

I

1

G

10

I

1

o

i

20

I

u

30

I

I

0

40

I

0

SO

I

60

0

I

E

f

o

70

I

80

1

00

1

04

1

08

I

12

1

16

20

24

1

28

1

32

E

E004

Specific

gravity

of

electrolyte

Fig

EE

4

FTeezing

point

of

electrolyte

STARTI

NG

MOTOR

CONTENTS

OPERATION

CONSTRUCTION

REMOVAL

DISASSEMBL

Y

CLEANING

AND

INSPECTION

Terminal

Field

coil

Brush

and

brush

lead

wire

Brush

spring

tension

Armature

assembly

Over

running

clutch

assembly

Testing

brush

holder

for

ground

EE

3

EE

4

EE

4

EE

5

EE

6

EE

6

EE

6

EE

6

EE

6

EE

7

EE

8

EE

8

OPERATION

The

purpose

of

this

starting

system

is

to

crank

the

engine

When

the

ignition

switch

is

set

to

start

current

flows

through

the

series

and

shunt

coils

of

the

solenoid

and

Pinion

case

bearing

metal

Magnetic

switch

assembly

REASSEMBL

Y

TESr

Performance

test

Diagnoses

of

test

Magnetic

switch

assembly

test

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Service

data

TROU8LE

DIAGNOSES

AND

CORRECTIONS

EE

8

EE

8

EE

9

EE

9

EE

g

EE

10

EE

10

EE

11

EE

11

EE

11

EE

12

thus

the

solenoid

is

excited

The

plunger

is

pulled

into

the

solenoid

so

that

it

operates

the

shift

lever

to

engage

the

drive

pinion

with

flywheel

ring

gear

and

the

magnetic

switch

is

closed

EE

3

Page 428 of 513

ENGINE

EE022

Fig

EE

18

Ground

test

of

armature

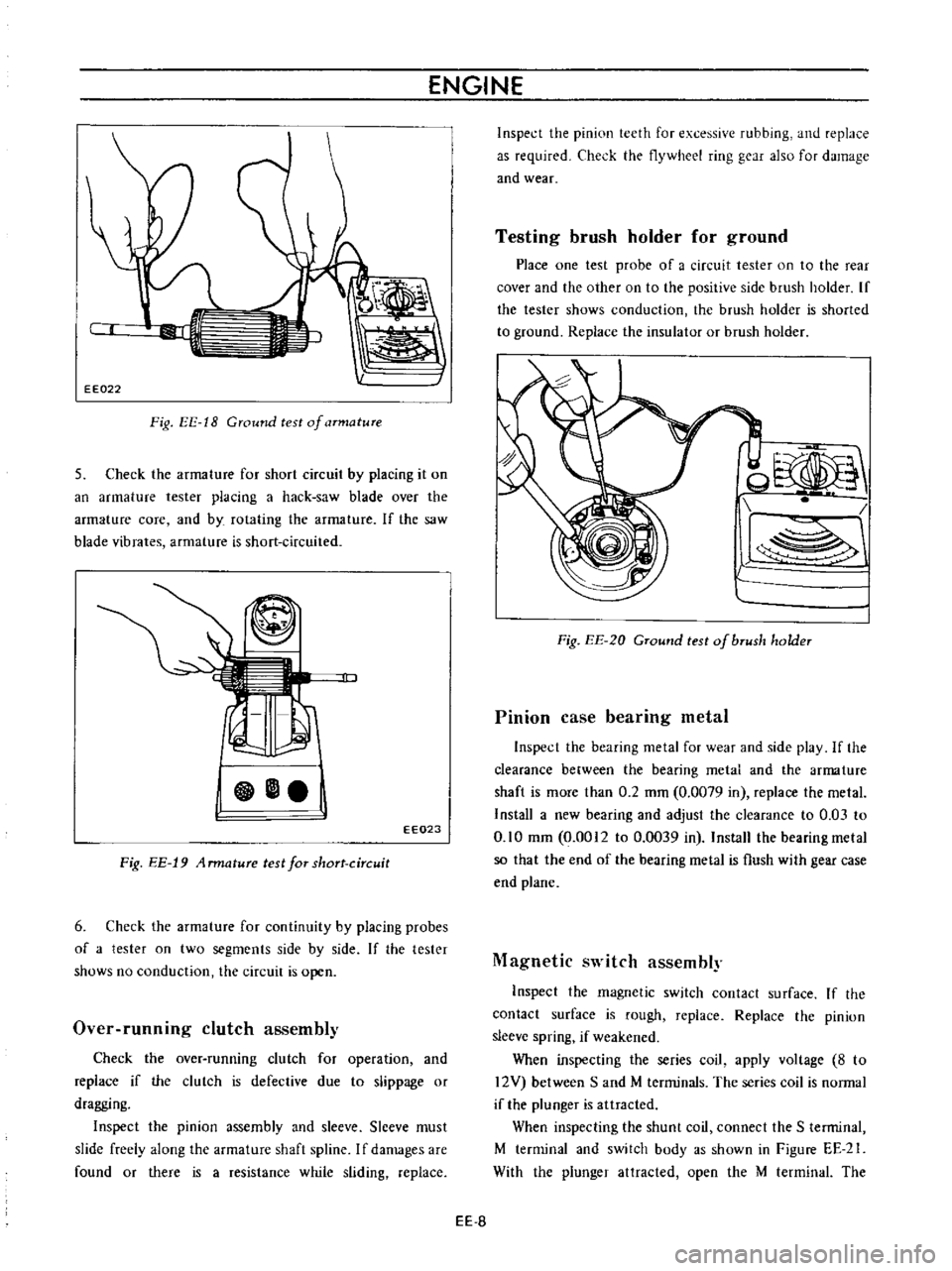

5

Check

the

armature

for

short

circuit

by

placing

it

on

an

armature

tester

placing

a

hack

saw

blade

over

the

armature

core

and

by

rotating

the

armature

If

the

saw

blade

vibrates

armature

is

short

circuited

EE023

Fig

EE

19

4

rmature

test

for

short

circuit

6

Check

the

armature

for

continuity

by

placing

probes

of

a

tester

on

two

segments

side

by

side

If

the

tester

shows

no

conduction

the

circuit

is

open

Over

runnmg

clutch

assembly

Check

the

over

running

clutch

for

operation

and

replace

if

the

clutch

is

defective

due

to

slippage

or

dragging

Inspect

the

pinion

assembly

and

sleeve

Slceve

must

slide

freely

along

the

armature

shaft

spline

I

f

damages

are

found

or

there

is

a

resistance

while

sliding

replace

Inspect

the

pinion

teeth

for

excessive

rubbing

and

replace

as

required

Check

the

flywheel

ring

gear

also

for

damage

and

wear

Testing

brush

holder

for

ground

Place

one

test

probe

of

a

circuit

tester

on

to

the

rear

cover

and

the

other

on

to

the

positive

side

brush

holder

If

the

tester

shows

conduction

the

brush

holdcr

is

shorted

to

ground

Replace

the

insulator

or

brush

holder

od

l

Fig

EE

20

GTound

test

of

bTush

holder

Pinion

case

bearing

metal

Inspect

the

bearing

metal

for

wear

and

sidc

play

If

the

clearance

between

the

bearing

metal

and

the

arma

ture

shaft

is

mOTe

than

0

2

mm

0

0079

in

replace

the

metal

Install

a

new

bearing

and

adjust

the

clearance

to

0

03

to

0

10

mm

0

0012

to

0

0039

in

Install

the

bearing

metal

so

that

the

end

of

the

bearing

metal

is

flush

with

gear

case

end

plane

Magnetic

switch

assembly

Inspect

the

magnetic

switch

contact

surface

If

the

contact

surface

is

rough

replace

Replace

the

pinion

sleeve

spring

if

weakened

When

inspecting

the

series

coil

apply

voltagc

8

to

12V

between

Sand

M

terminals

The

series

coil

is

normal

if

the

plunger

is

attracted

When

inspecting

the

shunt

coil

connect

the

S

terminal

M

terminal

and

switch

body

as

shown

in

Figure

EE

21

With

the

plunger

attracted

open

the

M

terminal

The

EE

S

Page 472 of 513

CHASSIS

REMOVAL

The

clutch

assembly

is

dismounted

primarily

in

the

same

manner

as

the

engine

assembly

Thus

when

dis

mounting

the

clutch

assembly

refer

to

the

Section

TM

Transmission

Removal

and

other

relative

sections

W

II

11

I

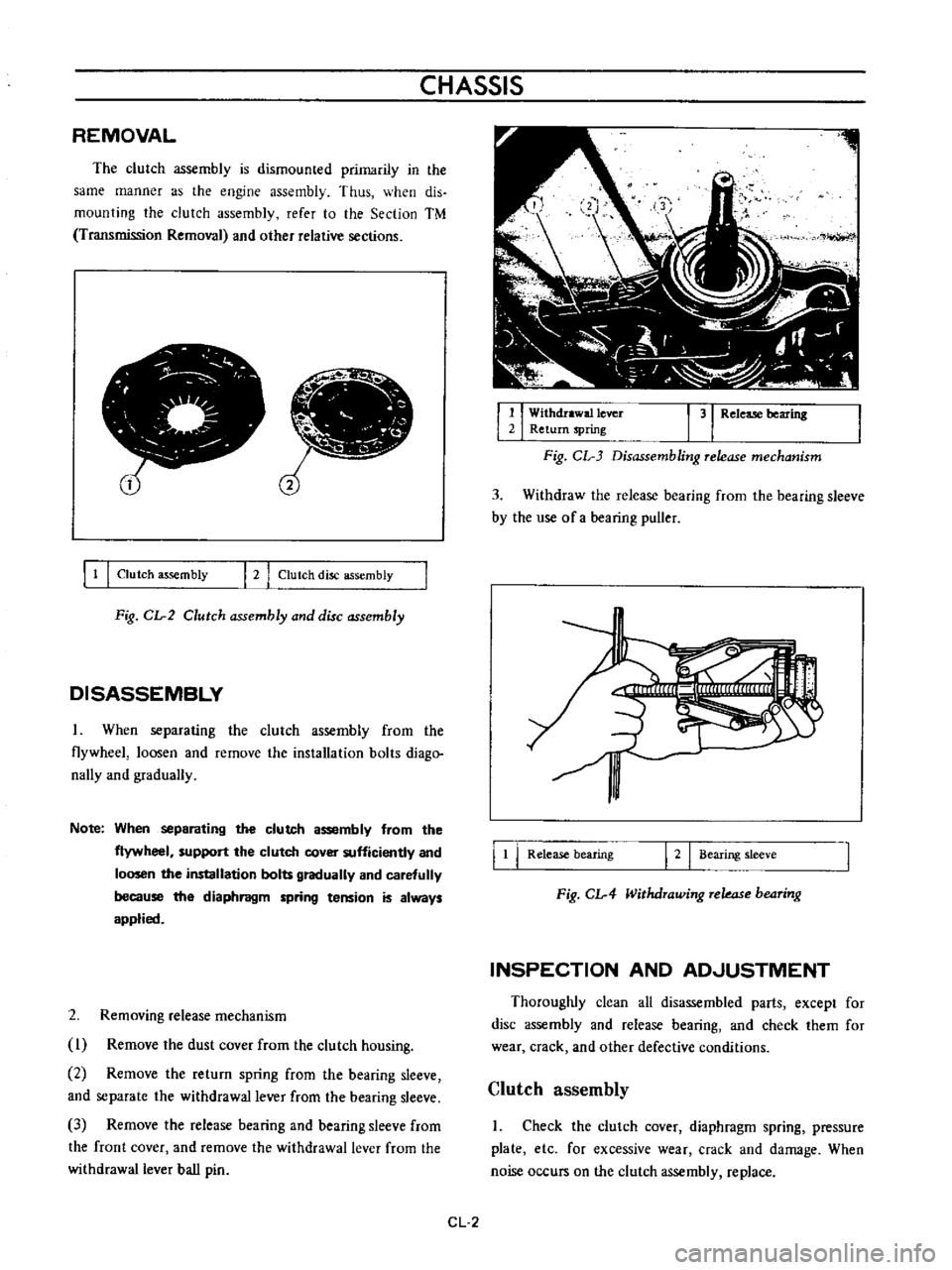

Clutch

assembly

I

2

I

Clutch

disc

assembly

Fig

CIr2

Clutch

assembly

and

disc

assembly

DISASSEMBLY

When

separating

the

clutch

assembly

from

the

flywheel

loosen

and

remove

the

installation

bolts

diago

nally

and

gradually

Note

When

separating

the

clutch

assembly

from

the

flywheel

support

the

clutch

cover

sufficiently

and

loosen

the

installation

bolts

gradually

and

carefully

because

the

diaphragm

spring

tension

is

always

applied

2

Removing

release

mechanism

I

Remove

the

dust

cover

from

the

clutch

housing

2

Remove

the

return

spring

from

the

bearing

sleeve

and

separate

the

withdrawal

lever

from

the

bearing

sleeve

3

Remove

the

release

bearing

and

bearing

sleeve

from

the

front

cover

and

remove

the

withdrawal

lever

from

the

withdrawal

lever

ball

pin

1

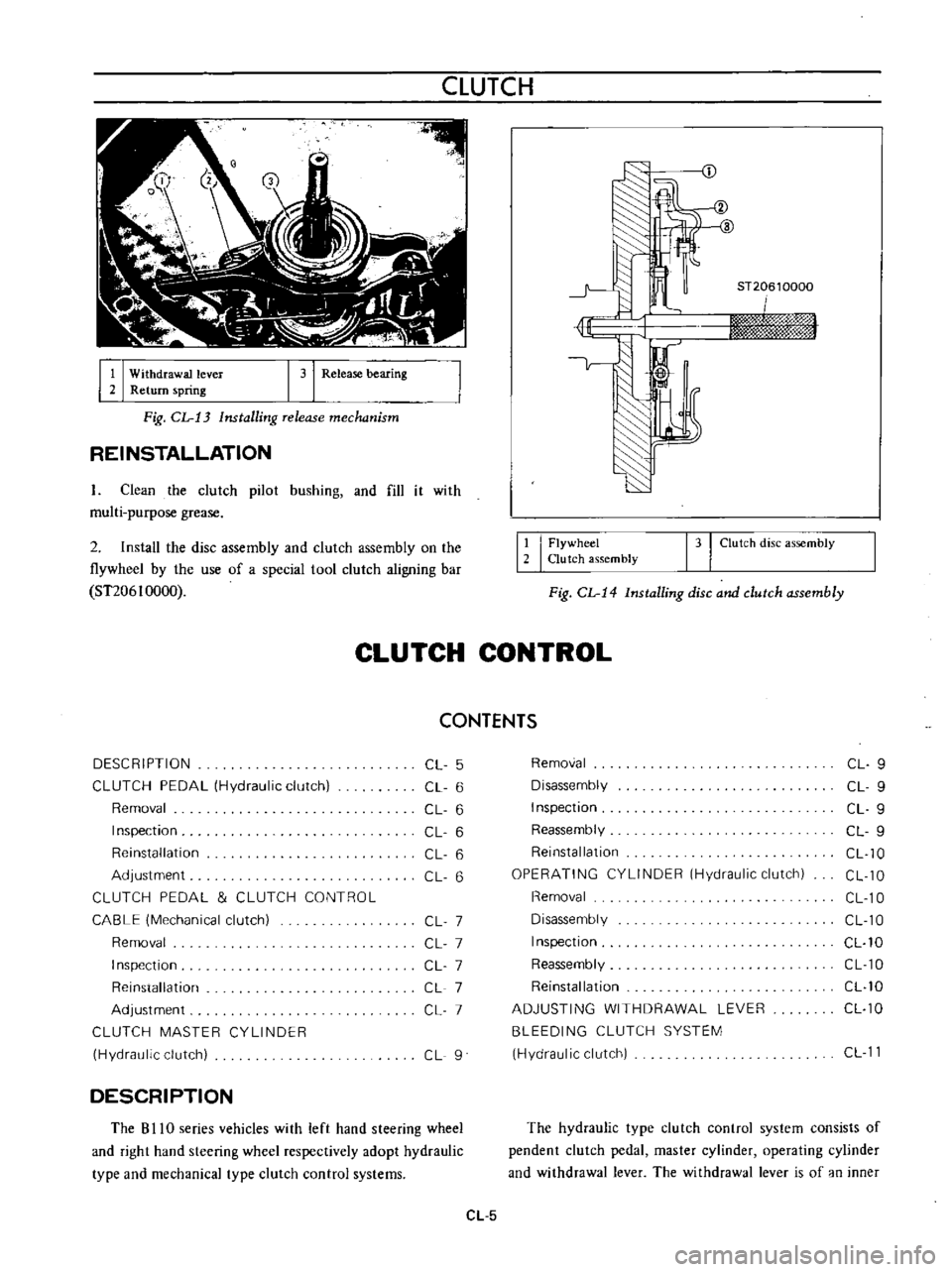

I

Withdrawal

lever

3

Release

bearing

2

Return

spring

Fig

CL

3

Disassembling

release

mechanism

3

Withdraw

the

release

bearing

from

the

bearing

sleeve

by

the

use

of

a

bearing

puller

I

t

I

Release

bearing

I

2

I

Bearing

sleeve

Fig

CIr4

Withdrawing

rekas

b04ring

INSPECTION

AND

ADJUSTMENT

Thoroughly

clean

all

disassembled

parts

except

for

disc

assembly

and

release

bearing

and

check

them

for

wear

crack

and

other

defective

conditions

Clutch

assembly

I

Check

the

clutch

cover

diaphragm

spring

pressure

plate

etc

for

excessive

wear

crack

and

damage

When

noise

occurs

on

the

clutch

assembly

replace

CL

2

Page 475 of 513

CLUTCH

J

I

I

Withdrawal

lever

2

Return

spring

I

31

Release

bearing

ST20610000

iwn

rm

hj

sf

W

Fig

CL

13

Installing

release

mechanism

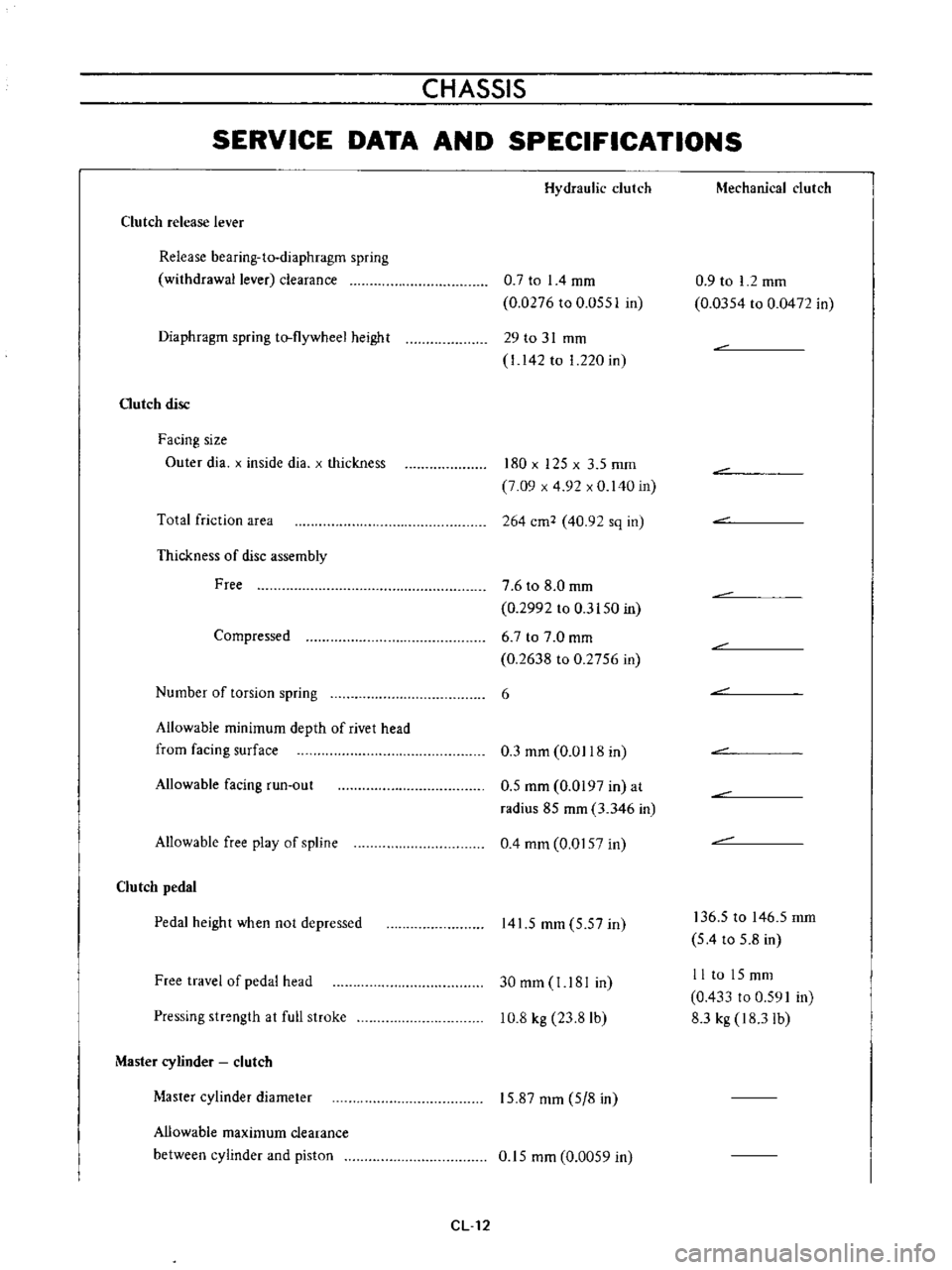

REINSTALLATION

L

Clean

the

clutch

pilot

bushing

and

fill

it

with

multi

purpose

grease

2

Install

the

disc

assembly

and

clutch

assembly

on

the

flywheel

by

the

use

of

a

special

tool

clutch

aligning

bar

ST206

I

0000

12

I

Flywheel

Clutch

assembly

131

Clutch

disc

assembly

Fig

CL

14

Installing

disc

and

clutch

assembly

CLUTCH

CONTROL

CONTENTS

DESCRIPTION

CL

5

Removal

CL

9

CLUTCH

PEDAL

Hydraulic

clutch

CL

6

Disassembly

CL

9

Removal

CL

6

Inspection

CL

9

Inspection

CL

6

Reassembly

CL

9

Reinstallation

CL

6

Reinstallation

CL

10

Adjustment

CL

6

OPERATING

CYLINDER

Hydraulic

clutch

CL

10

CLUTCH

PEDAL

CLUTCH

CONTROL

Removal

CL

10

CABLE

Mechanical

clutch

CL

7

Disassembly

CL

10

Removal

CL

7

Inspection

CL

10

Inspection

CL

7

Reassembly

CL

10

Reinstallation

CL

7

Reinstallation

CL

10

Adjustment

CL

7

ADJUSTING

WITHDRAWAL

LEVER

CL

10

CLUTCH

MASTER

CYLINDER

BLEEDING

CLUTCH

SYSTEM

Hydraulic

clutch

CL

9

Hydraulic

clutch

CL

11

DESCRIPTION

The

B

I

IO

series

vehicles

with

left

hand

steering

wheel

and

right

hand

steering

wheel

respectively

adopt

hydraulic

type

and

mechanical

type

clutch

control

systems

The

hydraulic

type

clutch

control

system

consists

of

pendent

clutch

pedal

master

cylinder

operating

cylinder

and

withdrawal

lever

The

withdrawal

lever

is

of

an

inner

CL

5

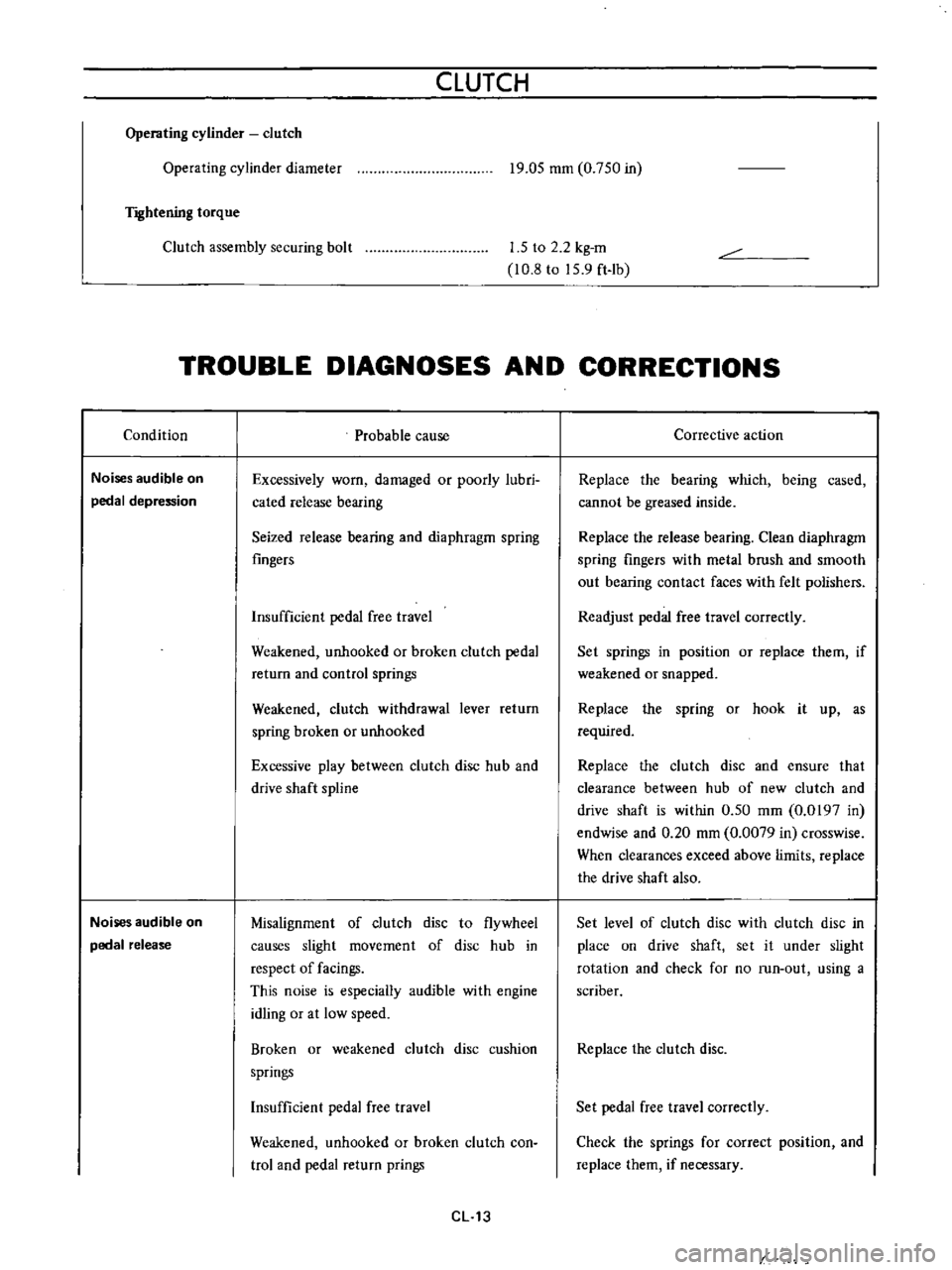

Page 482 of 513

CHASSIS

SERVICE

DATA

AND

SPECIFICATIONS

Clutch

release

lever

Release

bearing

ta

diaphragm

spring

withdrawal

lever

clearance

Diaphragm

spring

to

flywheel

height

Gutch

disc

Facing

size

Outer

dia

x

inside

dia

x

thickness

Total

friction

area

Thickness

of

disc

assembly

Free

Compressed

Number

of

torsion

spring

Allowable

minimum

depth

of

rivet

head

from

facing

surface

Allowable

facing

run

out

Allowable

free

play

of

spline

Clutch

pedal

Pedal

height

when

not

depressed

Free

travel

of

pedal

head

Pressing

strength

at

full

stroke

Master

cylinder

clutch

Master

cylinder

diameter

Allowable

maximum

clearance

between

cylinder

and

piston

Hydraulic

clutch

0

7

to

I

4

mm

0

0276

to

0

055

in

29

to

31

mm

I

142

to

1

220

in

180

x

125

x

3

5

mm

7

09

x

4

92

x

0

140

in

264

cm2

40

92

sq

in

7

6

to

8

0

mm

0

2992

to

0

3150

in

6

7

to

7

0

mm

0

2638

to

0

2756

in

6

0

3

mm

0

0118

in

0

5

mm

0

0197

in

at

radius

85

mm

3

346

in

0

4

mm

0

0157

in

141

5

mm

5

57

in

30

mm

J

181

in

10

8

kg

23

8

Ib

15

87

mm

5

8

in

0

15

mm

0

0059

in

CL12

Mechanical

clutch

0

9

to

I

2

mm

0

0354

to

0

0472

in

136

5

to

146

5

mm

5

4

to

5

8

in

II

to

15mm

0

433

to

0

591

in

8

3

kg

18

31b

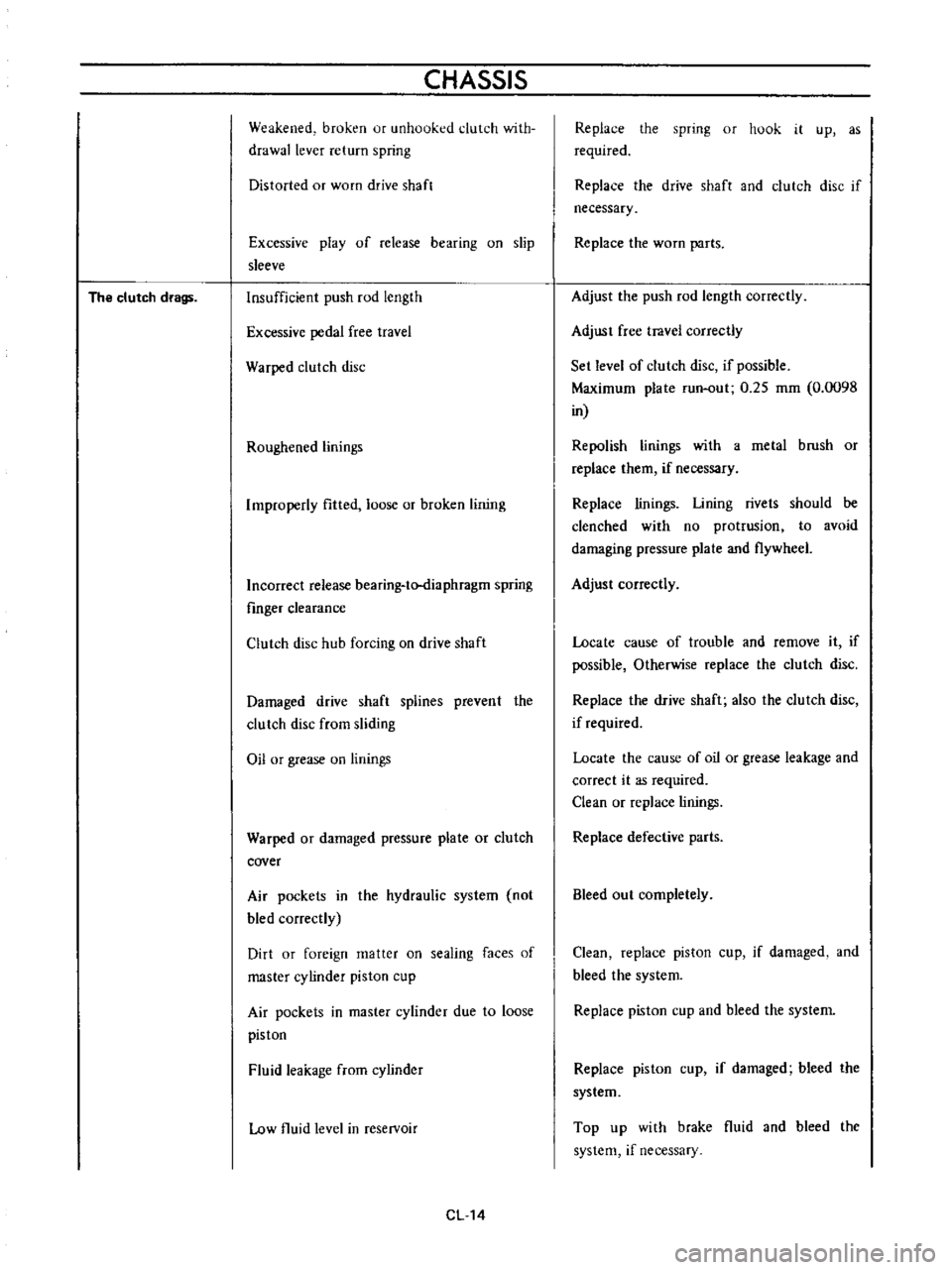

Page 483 of 513

CLUTCH

Operating

cylinder

clutch

Operating

cylinder

diameter

T

Ilhtening

torque

19

05

mm

0

750

in

Clutch

assembly

securing

bolt

1

5

to

2

2

kg

m

10

8

to

15

9

ft

Ib

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Noises

audible

on

pedal

depression

Noises

audible

on

pedal

release

Probable

cause

Excessively

worn

damaged

or

poorly

lubri

cated

release

bearing

Seized

release

bearing

and

diaphragm

spring

fingers

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

pedal

return

and

control

springs

Weakened

clutch

withdrawal

lever

return

spring

broken

or

unhooked

Excessive

play

between

clutch

disc

hub

and

drive

shaft

spline

Misalignment

of

clutch

disc

to

flywheel

causes

slight

movement

of

disc

hub

in

respect

of

facings

This

noise

is

especially

audible

with

engine

idling

or

at

low

speed

Broken

or

weakened

clutch

disc

cushion

springs

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

con

trol

and

pedal

return

prings

CL

13

Corrective

action

Replace

the

bearing

which

being

cased

cannot

be

greased

inside

Replace

the

release

bearing

Clean

diaphragm

spring

fingers

with

metal

brush

and

smooth

out

bearing

contact

faces

with

felt

polishers

Readjust

pedal

free

travel

correctly

Set

springs

in

position

or

replace

them

if

weakened

or

snapped

Replace

the

spring

or

hook

it

up

as

required

Replace

the

clutch

disc

and

ensure

that

clearance

between

hub

of

new

clutch

and

drive

shaft

is

within

0

50

mm

0

0197

in

endwise

and

0

20

mm

0

0079

in

crosswise

When

clearances

exceed

above

limits

replace

the

drive

shaft

also

Set

level

of

clutch

disc

with

clutch

disc

in

place

on

drive

shaft

set

it

under

slight

rotation

and

check

for

no

run

out

using

a

scriber

Replace

the

clutch

disc

Set

pedal

free

travel

correctly

Check

the

springs

for

correct

position

and

replace

them

if

necessary

Page 484 of 513

The

clutch

drags

CHASSIS

Weakened

broken

ur

unhooked

clutch

with

drawallever

return

spring

Distorted

or

worn

drive

shaft

Excessive

play

of

release

bearing

on

slip

sleeve

Insufficient

push

rod

length

Excessive

pedal

free

travel

Warped

clutch

disc

Roughened

linings

Improperly

fitted

loose

or

broken

lining

Incorrect

release

bearing

to

diaphragm

spring

fmger

clearance

Clutch

disc

hub

forcing

on

drive

shaft

Damaged

drive

shaft

splines

prevent

the

clutch

disc

from

sliding

Oil

or

grease

on

linings

Warped

or

damaged

pressure

plate

or

clutch

cover

Air

pockets

in

the

hydraulic

system

not

bled

correctly

Dirt

or

foreign

matter

on

sealing

faces

of

master

cylinder

piston

cup

Air

pockets

in

master

cylinder

due

to

loose

piston

Fluid

leakage

from

cylinder

Low

fluid

level

in

reservoir

CL14

Replace

the

spring

or

hook

it

up

as

required

Replace

the

drive

shaft

and

clutch

disc

if

necessary

Replace

the

worn

parts

Adjust

the

push

rod

length

correctly

Adjust

free

travel

correctly

Set

level

of

clutch

disc

if

possible

Maximum

plate

run

out

0

25

mm

0

0098

in

Repolish

linings

with

a

metal

brush

or

replace

them

if

necessary

Replace

linings

Lining

rivets

should

be

clenched

with

no

protrusion

to

avoid

damaging

pressure

plate

and

flywheel

Adjust

correctly

Locate

cause

of

trouble

and

remove

it

if

possible

Otherwise

replace

the

clutch

disc

Replace

the

drive

shaft

also

the

clutch

disc

if

required

Locate

the

cause

of

oil

or

grease

leakage

and

correct

it

as

required

Clean

or

replace

linings

Replace

defective

parts

Bleed

out

completely

Clean

replace

piston

cup

if

damaged

and

bleed

the

system

Replace

piston

cup

and

bleed

the

system

Replace

piston

cup

if

damaged

bleed

the

system

Top

up

with

brake

fluid

and

bleed

the

system

if

necessary

Page 485 of 513

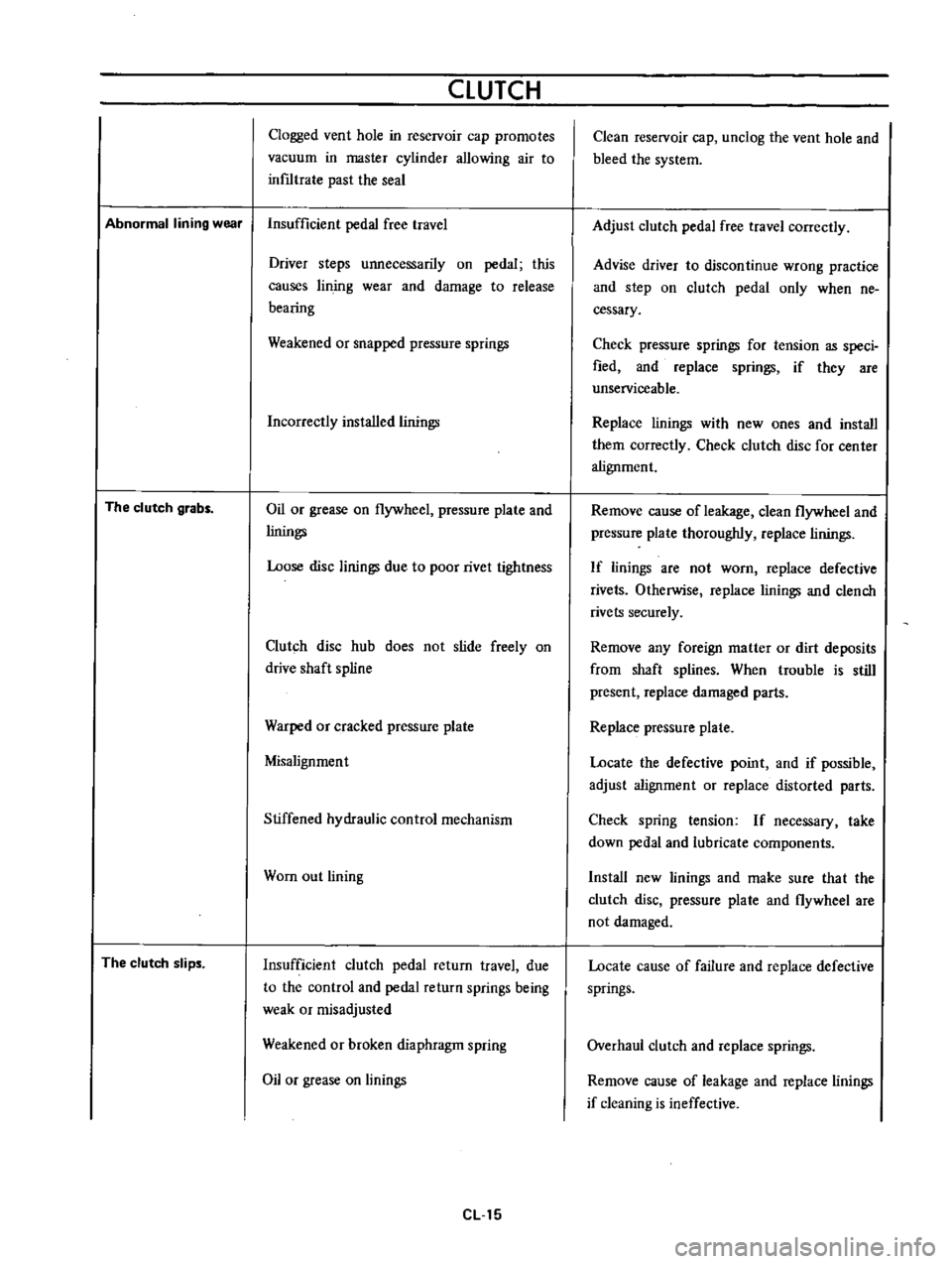

CLUTCH

Clogged

vent

hole

in

reservoir

cap

promotes

vacuum

in

master

cylinder

allowing

air

to

inf1ltrate

past

the

seal

Abnormal

lining

wear

Insufficient

pedal

free

travel

The

clutch

grabs

The

clutch

slips

Driver

steps

unnecessarily

on

pedal

this

causes

lin

jog

wear

and

damage

to

release

bearing

Weakened

or

snapped

pressure

springs

Incorrectly

installed

linings

Oil

or

grease

on

flywheel

pressure

plate

and

linings

Loose

disc

linings

due

to

poor

rivet

tightness

Clutch

disc

hub

does

not

slide

freely

on

drive

shaft

spline

Warped

or

cracked

pressure

plate

Misalignment

Stiffened

hydraulic

control

mechanism

Wom

out

lining

Insufficient

clutch

pedal

return

travel

due

to

the

control

and

pedal

return

springs

being

weak

or

misadjusted

Weakened

or

broken

diaphragm

spring

Oil

or

grease

on

linings

eLl5

Clean

reservoir

cap

unclog

the

vent

hole

and

bleed

the

system

Adjust

clutch

pedal

free

travel

correctly

Advise

driver

to

discontinue

wrong

practice

and

step

on

clutch

pedal

only

when

ne

cessary

Check

pressure

springs

for

tension

as

speci

fied

and

replace

springs

if

they

are

unserviceable

Replace

linings

with

new

ones

and

install

them

correctly

Check

clutch

disc

for

center

alignment

Remove

cause

of

leakage

clean

flywheel

and

pressure

plate

thoroughly

replace

linings

If

linings

are

not

worn

replace

defective

rivets

Otherwise

replace

linings

and

clench

rivets

securely

Remove

any

foreign

matter

or

dirt

deposits

from

shaft

splines

When

trouble

is

still

present

replace

damaged

parts

Replace

pressure

plate

Locate

the

defective

point

and

if

possible

adjust

alignment

or

replace

distorted

parts

Check

spring

tension

If

necessary

take

down

pedal

and

lubricate

components

Install

new

linings

and

make

sure

tha

t

the

clutch

disc

pressure

plate

and

flywheel

are

not

damaged

Locate

cause

of

failure

and

replace

defective

springs

Overhaul

clutch

and

replace

springs

Remove

cause

of

leakage

and

replace

linings

if

cleaning

is

ineffective

Page 504 of 513

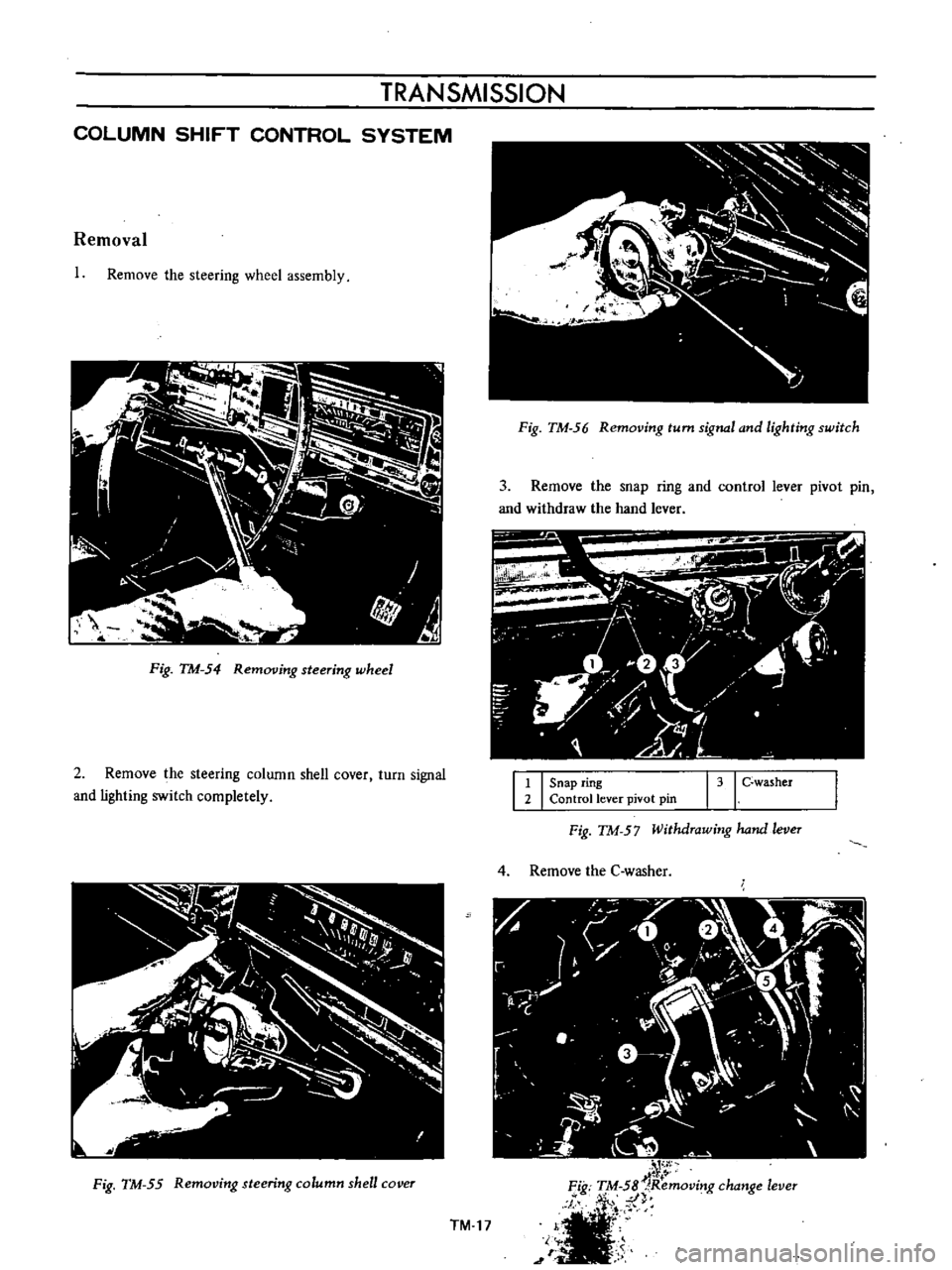

TRANSMISSION

COLUMN

SHIFT

CONTROL

SYSTEM

Removal

Remove

the

steering

wheel

assembly

Fig

TM

54

Rem01

ing

steering

wheel

2

Remove

the

steering

column

shell

cover

turn

signal

and

lighting

switch

completely

Fig

TM

55

Removing

steering

column

shell

cover

Fig

TM

56

Removing

turn

signal

and

lighting

switch

3

Remove

the

snap

ring

and

control

lever

pivot

pin

and

withdraw

the

hand

lever

A

A

V

l

Y

e

f

I

1

I

V

e

tl

f

r

4

2i

L

1

I

Snap

ring

2

Control

lever

pivot

pin

I

3

I

C

washer

Fig

TM

57

Withdrawing

hand

ever

4

Remove

the

C

washer

TM

17

i

MI

ig

r

M

5J

emOVing

change

lever

J

y

Ji

1

r

oJ