wheel DATSUN B110 1973 Service Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 200 of 513

pointer

used

at

the

rearward

lut

atiol1

With

the

proper

scttings

the

tram

bar

will

be

on

a

piane

parallel

to

that

of

the

body

The

exception

to

this

would

be

wht

n

one

of

the

reterence

locations

is

induded

in

the

misaligned

area

then

the

parallel

plane

between

the

body

and

the

tram

bar

may

not

prevail

After

completiun

of

the

repairs

the

tram

gauge

should

be

set

at

the

specitled

dimension

to

check

the

accuracy

of

the

repair

operation

CAR

PREPARATION

Preparing

the

car

for

the

underbody

alignment

check

involves

the

following

Place

the

car

on

a

level

surface

2

The

weight

of

the

car

should

be

supported

at

the

wheel

locations

3

A

visual

damage

inspection

should

be

made

to

eliminate

unnecessary

measuring

Obviously

damaged

or

misaligned

areas

may

often

be

located

visually

BODY

TRAMMING

SEQUENCE

The

tramming

sequence

will

varv

depending

upon

the

nature

and

IOl

atiun

uf

the

misaligned

area

Priur

to

performing

any

tramming

uperation

the

h

uracy

of

refereJlce

points

to

be

used

must

be

determined

A

measurement

that

originates

from

a

reference

point

included

in

a

damaged

area

will

produce

untrue

results

and

confuse

the

evaluation

of

the

underbody

condition

Unlike

the

conventional

type

of

frame

design

the

unitized

type

of

body

construction

seldom

develops

the

condition

of

diamond

in

the

floor

pan

area

as

a

result

of

front

or

rear

end

collision

Therefore

underbody

alignment

checking

can

usually

originate

from

the

body

floor

pan

area

If

inspection

indicates

that

these

locations

have

been

disturbed

and

are

not

suitable

for

measuring

one

of

the

undamaged

suspension

locations

should

be

used

as

an

initial

reference

point

If

a

rare

situation

should

exist

where

all

of

these

lucalions

are

not

suitable

as

reference

points

repair

operations

should

begin

with

the

body

floor

pan

area

All

other

underbody

components

should

be

aligned

progressively

from

this

area

MEMO

BF

10

Page 230 of 513

Fig

BF

82

Removing

rear

seat

cushion

2

With

the

seat

back

turned

down

remove

two

screws

from

the

wheel

house

and

remove

the

seat

back

111

I

V

RH

0

1

lr

Fig

BF

83

Removing

rear

seat

back

Reinstallation

Reinstall

the

seat

cushions

and

seat

backs

in

reverse

sequence

of

removal

SEAT

SWITCH

Inspection

Seat

switch

should

operate

accurately

Prior

to

inspecting

seat

switch

disconnect

harness

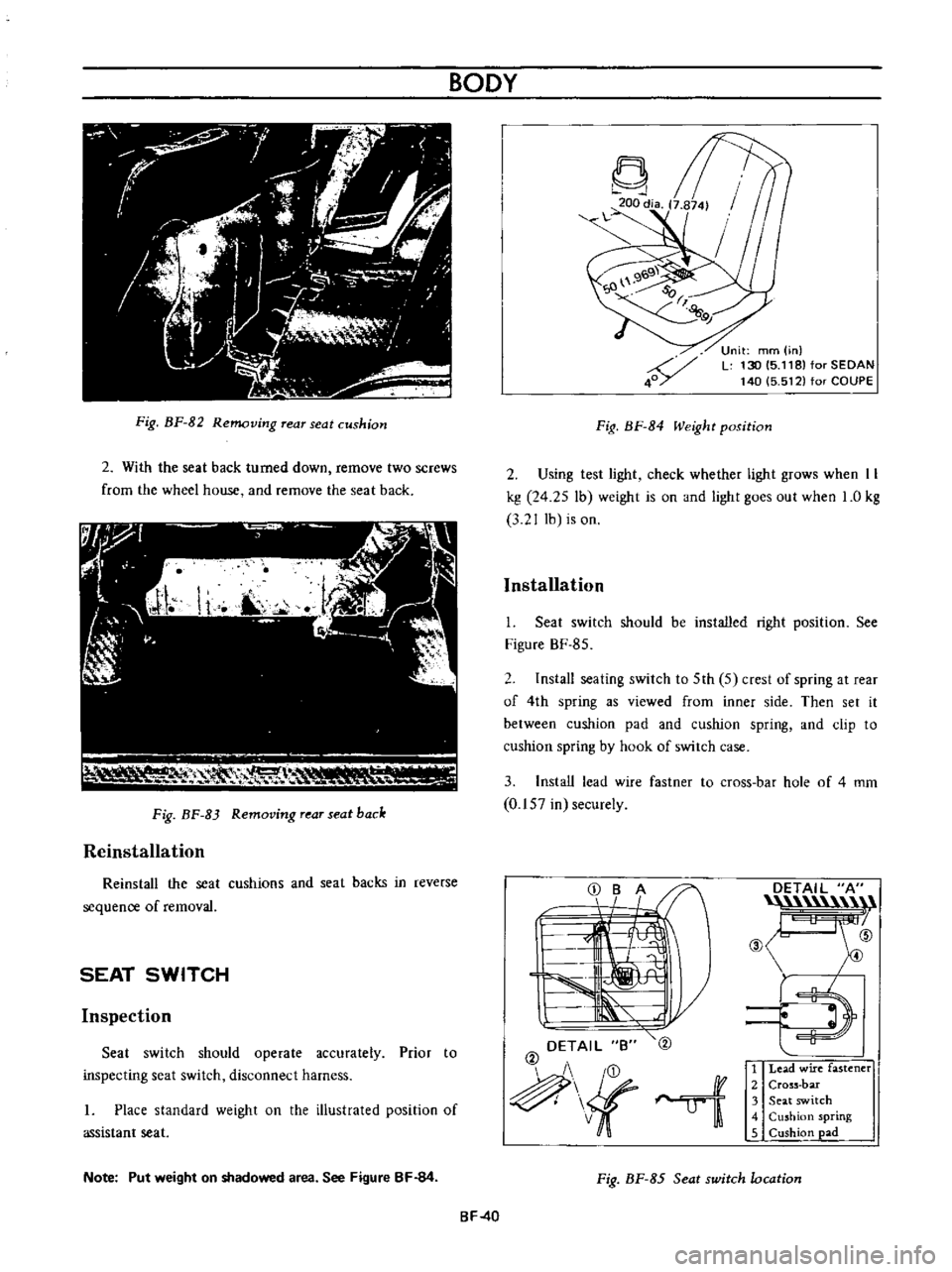

I

Place

standard

weight

on

the

illustrated

position

of

assistant

seat

Note

Put

weight

on

shadowed

area

See

Figure

BF

84

BODY

Fig

BF

84

Weight

position

Unit

mm

in

L

130

15

118

for

SEDAN

140

5

512

for

COUPE

2

Using

test

light

check

whether

light

grows

when

II

kg

24

25

lb

weight

is

on

and

light

goes

out

when

1

0

kg

3

2

J

lb

is

on

Installation

I

Seat

switch

should

be

installed

right

position

See

Figure

BF

85

2

Install

seating

switch

to

5th

5

crest

of

spring

at

rear

of

4th

spring

as

viewed

from

inner

side

Then

set

it

between

cushion

pad

and

cushion

spring

and

clip

to

cushion

spring

by

hook

of

switch

case

3

Install

lead

wire

fastner

to

cross

bar

hole

of

4

mm

0

157

in

securely

DETAIL

B

@

ui

DETAIL

A

n

@

ID

E

l

1

Lead

wire

fastener

2

Cross

bar

3

Seat

switch

4

Cushion

spring

5

Cushion

pad

Fig

BF

85

Seat

switch

location

BF

40

Page 232 of 513

BODY

INSTRUMENT

PANEL

CONTENTS

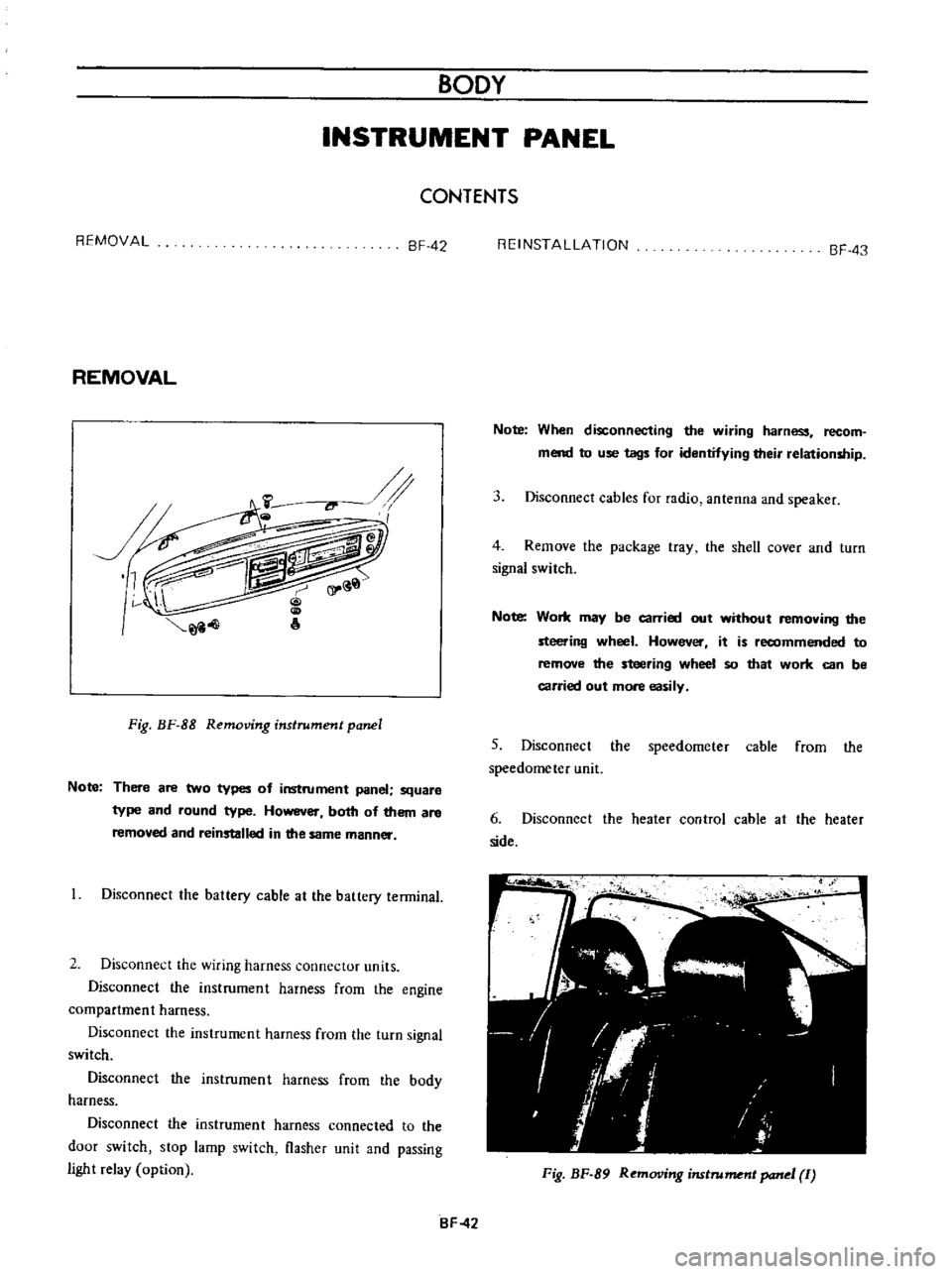

REMOVAL

BF

42

REMOVAL

Fig

BF

88

Removing

instrument

panel

Note

There

are

two

types

of

instrument

panel

square

type

and

round

type

However

both

of

them

are

removed

and

reinstalled

in

the

same

manner

Disconnect

the

battery

cable

at

the

battery

terminal

2

Disconnect

the

wiring

harness

connector

units

Disconnect

the

instrument

harness

from

the

engine

compartment

harness

Disconnect

the

instrument

harness

from

the

turn

signal

switch

Disconnect

the

instrument

harness

frorn

the

body

harness

Disconnect

the

instrumen

t

harness

connected

to

the

door

switch

stop

lamp

switch

flasher

unit

and

passing

light

relay

option

REINSTALLATION

BF

43

Note

When

disconnecting

the

wiring

harness

recom

mend

to

use

tags

for

identifying

their

relationship

3

Disconnect

cables

for

radio

antenna

and

speaker

4

Remove

the

package

tray

the

shell

cover

and

turn

signal

switch

Note

Work

may

be

carried

out

without

removing

die

steering

wheel

However

it

is

recommended

to

remove

the

steering

wheel

50

that

work

can

be

carried

out

more

easily

5

Disconnect

the

speedometer

cable

from

the

speedometer

unit

6

Disconnect

the

heater

control

cable

at

the

heater

side

Fig

BF

89

Removing

imtrument

panel

Ii

BF

42

Page 238 of 513

BODY

ELECTRICAL

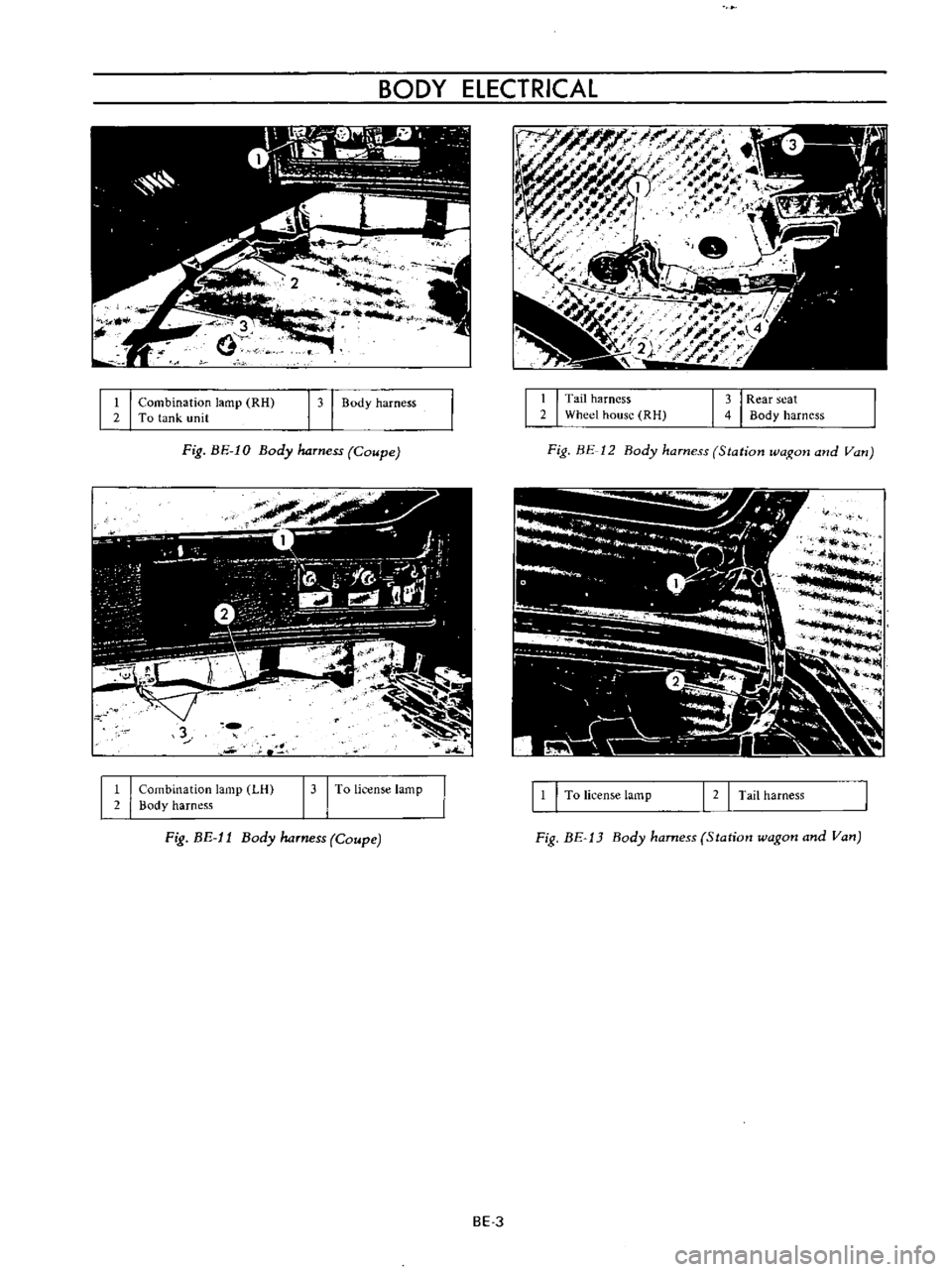

I

I

Combination

lamp

RH

To

tank

unit

131

Body

harness

Fig

BE

10

Body

harness

Coupe

1

I

Combination

lamp

LH

2

Body

harness

I

J

I

To

license

lamp

Fig

BE

11

Body

harness

Coupe

I

I

Tail

harness

2

Wheel

house

RH

3

I

Rear

cat

4

Body

harness

Fig

BE

12

Body

hamess

Station

waKonand

Van

11

I

To

license

lamp

I

2

I

Tail

harness

Fig

BE

13

Body

hamess

Station

wagon

and

Van

BE

3

Page 245 of 513

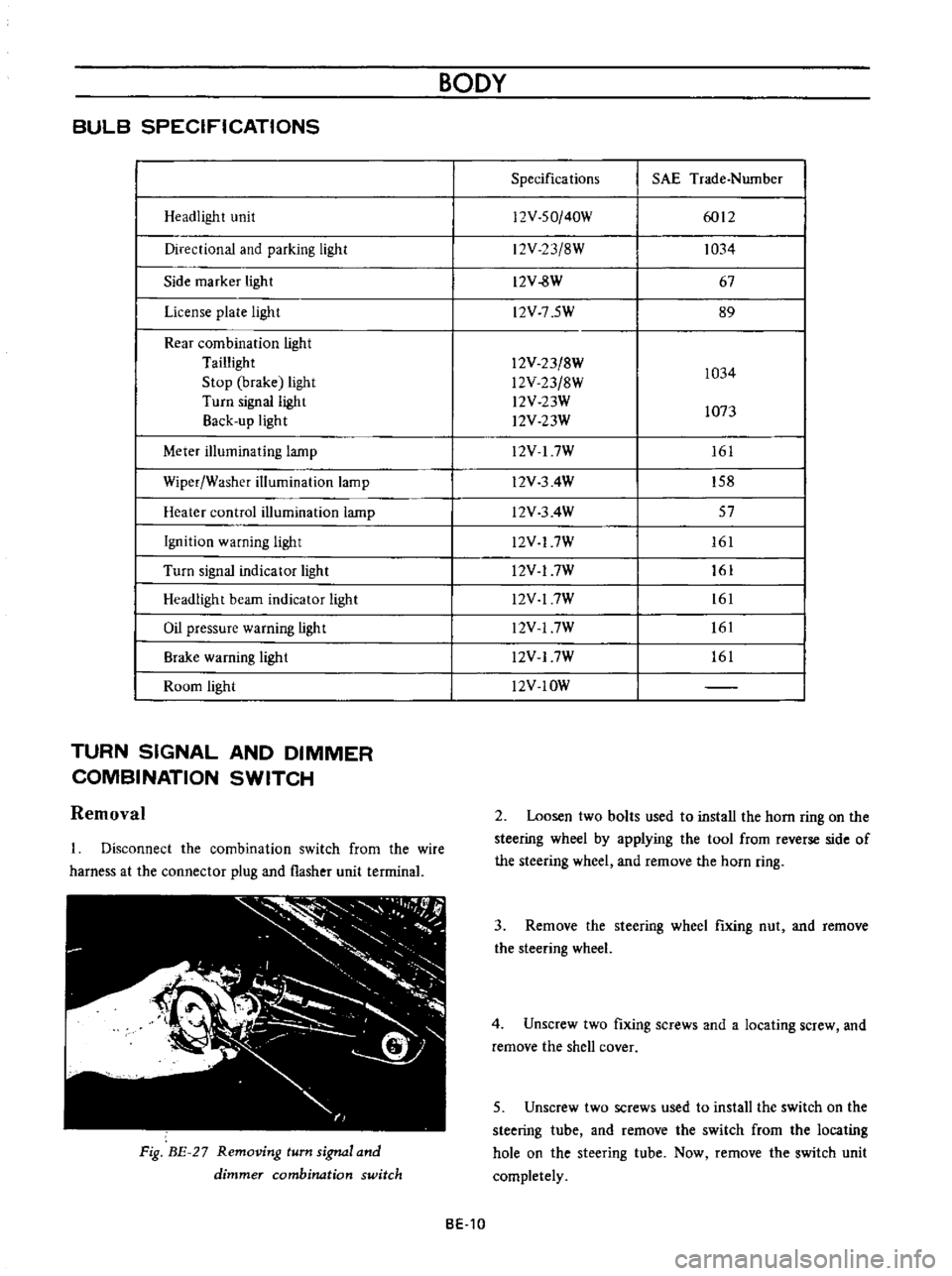

BULB

SPECIFICATIONS

Headlight

unit

Directional

and

parking

light

Side

marker

light

License

plate

light

Rear

combination

light

Taillight

Stop

brake

light

Turn

signal

light

Back

up

light

Meter

illuminating

lamp

Wiper

Washer

illumination

lamp

Heater

control

illumination

lamp

Ignition

warning

light

Turn

signal

indicator

light

Headlight

beam

indicator

light

Oil

pressure

warning

light

Brake

warning

ligh

t

Room

light

TURN

SIGNAL

AND

DIMMER

COMBINATION

SWITCH

Removal

Disconnect

the

combination

switch

from

the

wire

harness

at

the

connector

plug

and

flasher

unit

terrninal

Fig

BE

27

Removing

turn

signal

and

dimmer

combination

switch

BODY

Specifications

SAE

Trade

Number

12V

SO

40W

6012

12V

23

8W

1034

12V

8W

67

l2V

7

5W

89

12V

23

8W

1034

l2V

23

8W

l2V

23W

1073

l2V

23W

12V

I

7W

161

l2V

3

4W

158

l2V

3

4W

57

l2V

17W

161

l2V

17W

161

l2V

17W

161

l2V

17W

161

l2V

17W

161

l2V

IOW

2

Loosen

two

bolts

used

to

install

the

horn

ring

on

the

steering

wheel

by

applying

the

tool

from

reverse

side

of

the

steering

wheel

and

remove

the

horn

ring

3

Remove

the

steering

wheel

fixing

nut

and

remove

the

steering

wheel

4

Unscrew

two

fixing

screws

and

a

locating

screw

and

remove

the

shell

cover

5

Unscrew

two

screws

used

to

install

the

switch

on

the

steering

tube

and

remove

the

switch

from

the

locating

hole

on

the

steering

tube

Now

remove

the

switch

unit

completely

BE

10

Page 262 of 513

BODY

ELECTRICAL

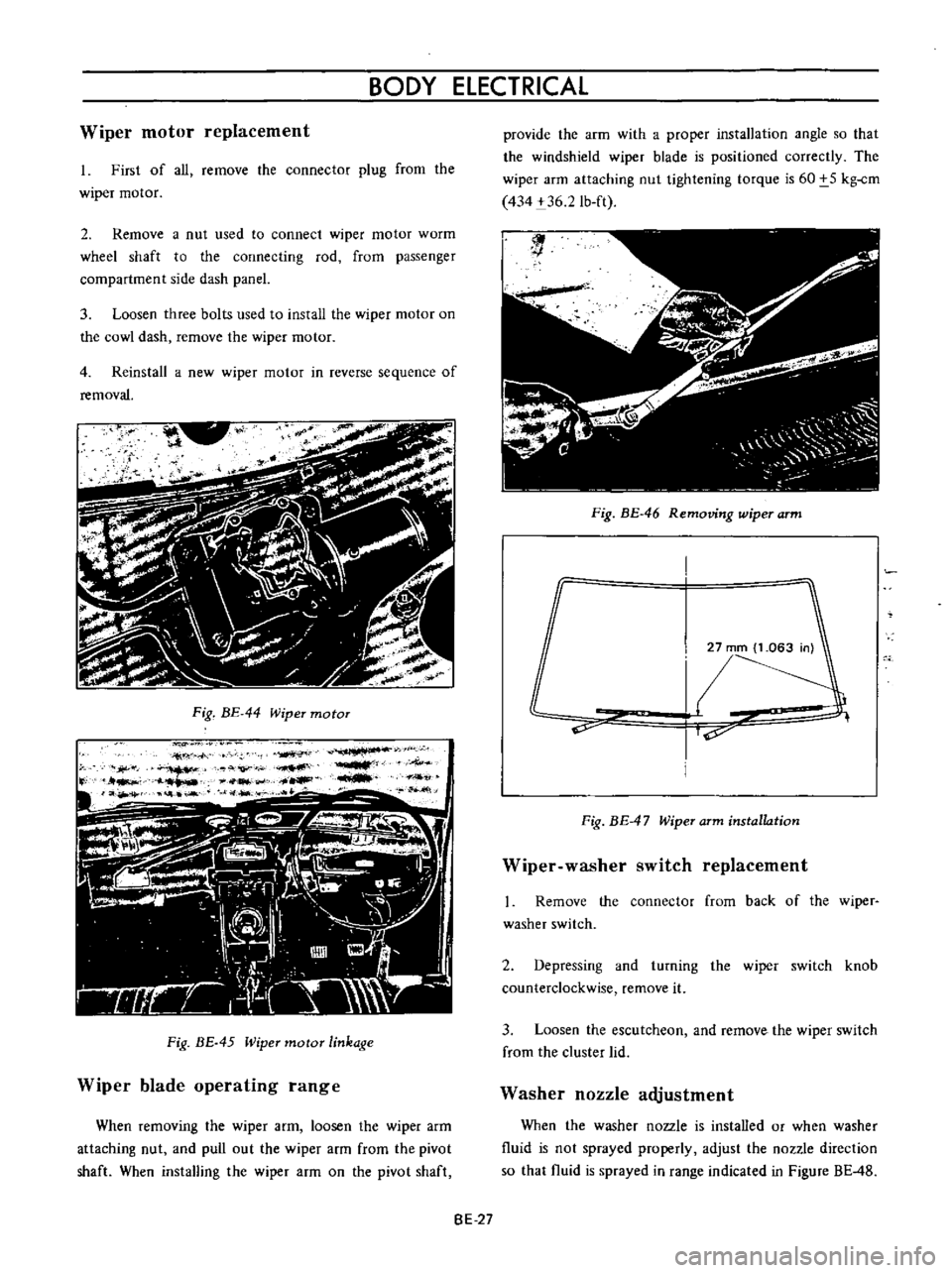

Wiper

motor

replacement

First

of

all

remove

the

connector

plug

from

the

wiper

motoI

2

Remove

a

nut

used

to

connect

wiper

motor

worm

wheel

shaft

to

the

connecting

rod

from

passenger

compartment

side

dash

panel

3

Loosen

three

bolts

used

to

install

the

wiper

motor

on

the

cowl

dash

remove

the

wiper

motor

4

Reinstall

a

new

wiper

motor

in

reverse

sequence

of

removal

Fig

BE

44

Wiper

motor

Q

V

rt

ir

o

y

At

Jllif

Fig

BE

45

Wiper

motor

linkage

Wiper

blade

operating

range

When

removing

the

wiper

arm

loosen

the

wiper

arm

attaching

nut

and

pull

out

the

wiper

arm

from

the

pivot

shaft

When

installing

the

wiper

arm

on

the

pivot

shaft

provide

the

arm

with

a

proper

installation

angle

so

that

the

windshield

wiper

blade

is

positioned

correctly

The

wiper

arm

attaching

nut

tightening

torque

is

60

5

kg

m

434

36

2lb

ft

Fig

BE

46

Removing

wiper

arm

00

I

i

Fig

BE

47

Wiper

arm

installation

Wiper

washer

switch

replacement

Remove

the

connector

from

back

of

the

wiper

washer

switch

2

Depressing

and

turning

the

wiper

switch

knob

counterclockwise

remove

it

3

Loosen

the

escutcheon

and

remove

the

wiper

switch

from

the

cluster

lid

Washer

nozzle

adjustment

When

the

washer

nozzle

is

installed

or

when

washer

fluid

is

not

sprayed

properly

adjust

the

nozzle

direction

so

that

fluid

is

sprayed

in

range

indicated

in

Figure

BE

48

BE

27

Page 265 of 513

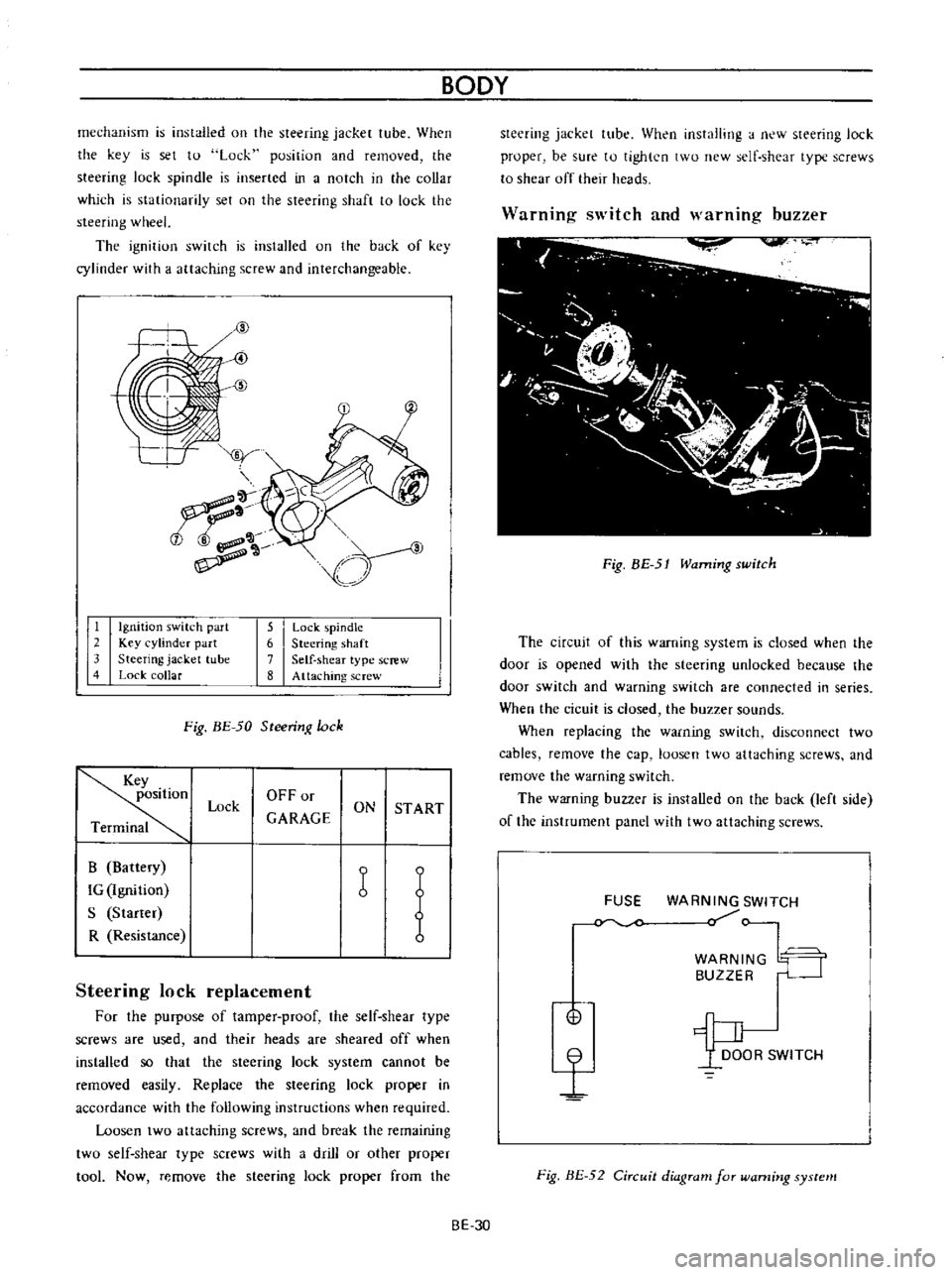

mechanism

is

installed

on

the

steering

jacket

tube

When

the

key

is

set

to

Lock

position

and

removed

the

steering

lock

spindle

is

inserted

in

a

notch

in

the

collar

which

is

stationarity

set

on

the

steering

shaft

to

lock

the

steering

wheel

The

ignitiun

switch

is

installed

on

the

back

of

key

cylinder

with

a

attaching

screw

and

interchangeable

tf

iY

t

7

a

1

Ignition

switch

part

2

Key

cylinder

part

3

Steering

jacket

tube

4

Lock

collar

5

Lock

pindle

6

Steering

shaft

7

Self

shear

type

screw

8

Attaching

screw

Fig

BE

50

Steering

lock

Key

position

Terminal

OFFor

GARAGE

Lock

ON

ST

ART

B

Battery

IG

Ignition

S

Starter

R

Resistance

b

1

Steering

lock

replacement

For

the

purpuse

of

tamper

proof

the

self

shear

type

screws

are

used

and

their

heads

are

sheared

off

when

installed

so

that

the

steering

lock

system

cannot

be

removed

easily

Replace

the

steering

lock

proper

in

accordance

with

the

following

instructions

when

required

Loosen

two

attaching

screws

and

break

the

remaining

twu

self

shear

type

screws

with

a

drill

or

other

proper

tool

Now

remove

the

steering

lock

proper

from

the

BODY

BE

30

steering

jacket

tube

When

installing

a

new

steering

lock

proper

be

sure

tu

tighten

two

new

self

shear

type

screws

to

shear

off

their

heads

Warning

switch

and

warnmg

buzzer

Fig

BE

51

Warning

switch

The

circuit

of

this

warning

system

is

closed

when

the

door

is

opened

with

the

steering

unlocked

because

the

door

switch

and

warning

switch

are

connected

in

series

When

the

cicuit

is

closed

the

buzzer

sounds

When

replacing

the

warning

switch

disconnect

two

cables

remove

the

cap

loosen

two

attaching

screws

and

remove

the

warning

switch

The

warning

buzzer

is

installed

on

the

back

left

side

of

the

instrument

panel

with

two

attaching

screws

FUSE

WARNING

SWITCH

WARN

BUZZ

G

n

WITCH

t

Fig

BE

52

Circuit

diagram

for

warning

system

Page 284 of 513

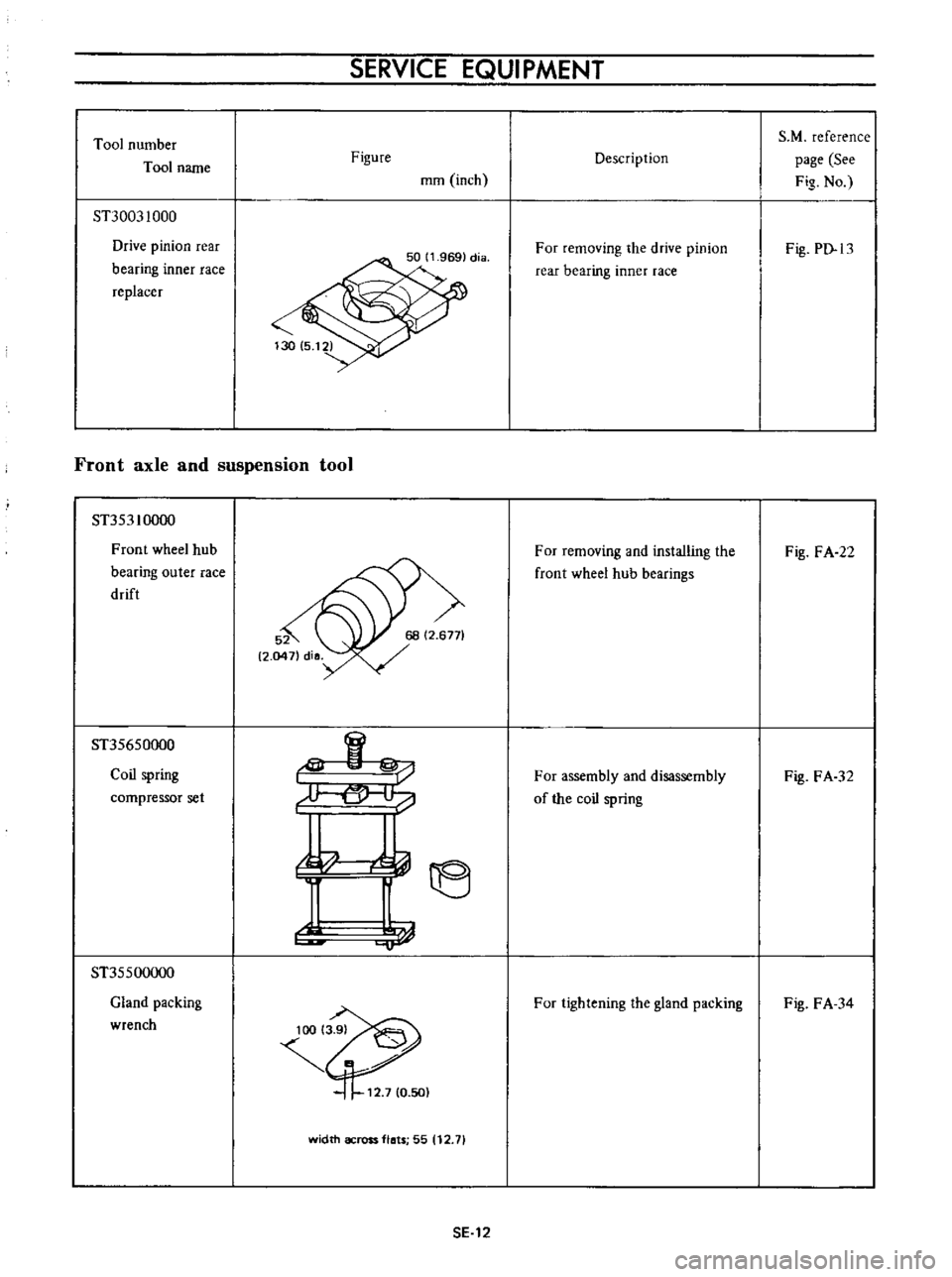

Tool

number

Tool

name

ST30031000

Drive

pinion

rear

bearing

inner

race

replacer

SERVICE

EQUIPMENT

Figure

mm

inch

Front

axle

and

suspension

tool

ST353

10000

Front

wheel

hub

bearing

outer

race

drift

ST35650000

Coil

spring

compressor

set

ST35500000

Gland

packing

wrench

rU

jb

1118

1

1

width

across

flats

55

12

71

SE

12

Descrip

tion

For

removing

the

drive

pinion

rear

bearing

inner

race

For

removing

and

installing

the

front

wheel

hub

bearings

For

assembly

and

disassembly

of

the

coil

spring

For

tightening

the

gland

packing

S

M

reference

page

See

Fig

No

Fig

PD

13

Fig

FA

22

Fig

FA

32

Fig

FA

34

Page 286 of 513

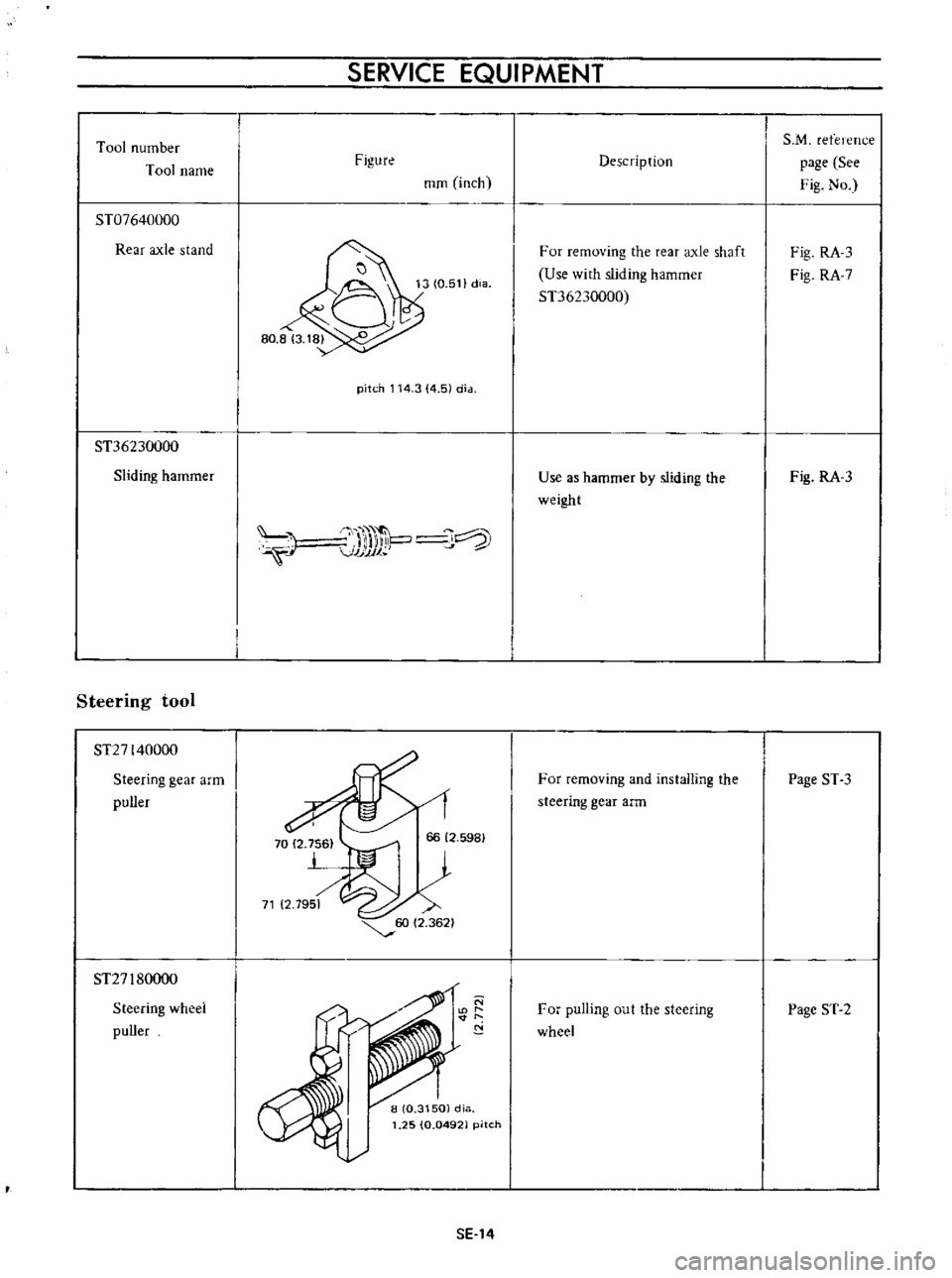

Tool

number

Tool

name

ST07640000

Rear

axle

stand

ST36230000

Sliding

hammer

Steering

tool

ST27140000

Steering

gear

arm

puller

ST27

I

80000

Steering

wheel

puller

SERVICE

EQUIPMENT

Figure

mm

inch

pitch

114

3

4

51

dia

J

l

VJJJJ1

P

J

SE

14

Description

For

removing

the

rear

axle

shaft

Use

with

sliding

hammer

ST36230000

Use

as

hammer

by

sliding

the

weight

For

removing

and

installIng

the

steering

gear

arm

For

pulling

out

the

steering

wheel

S

M

refelcTu

e

page

See

Fig

No

Fig

RA

3

Fig

RA

7

Fig

RA

3

Page

ST

3

Page

ST

2

Page 291 of 513

ti

r

f

o

1

b

4

AI

I

W

n

t

i

i

1

i

f

f

7i

ii

y

0

r

1

J

1

t

I

r

I

DATSUN

1200

SERVICE

MANUAL

MODEL

8110

SERIES

N

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

j

QUICK

REFERENCE

INDEX

GENERAL

INfORMATION

GI

EMISSION

CONTROL

AND

TUNE

UP

ET

ENGINE

MECHANICAL

EM

REAR

AXlE

8

REAR

SUSPENSiON

BRAKE

WHEEL

AND

TIRE

STEERING

ENGINE

CONTROL

fUEL

8

EXHAUST

BODY

BODY

ElECTRICAL

SERVICE

EQUIPMENT