torque DATSUN B110 1973 Service Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 64 of 513

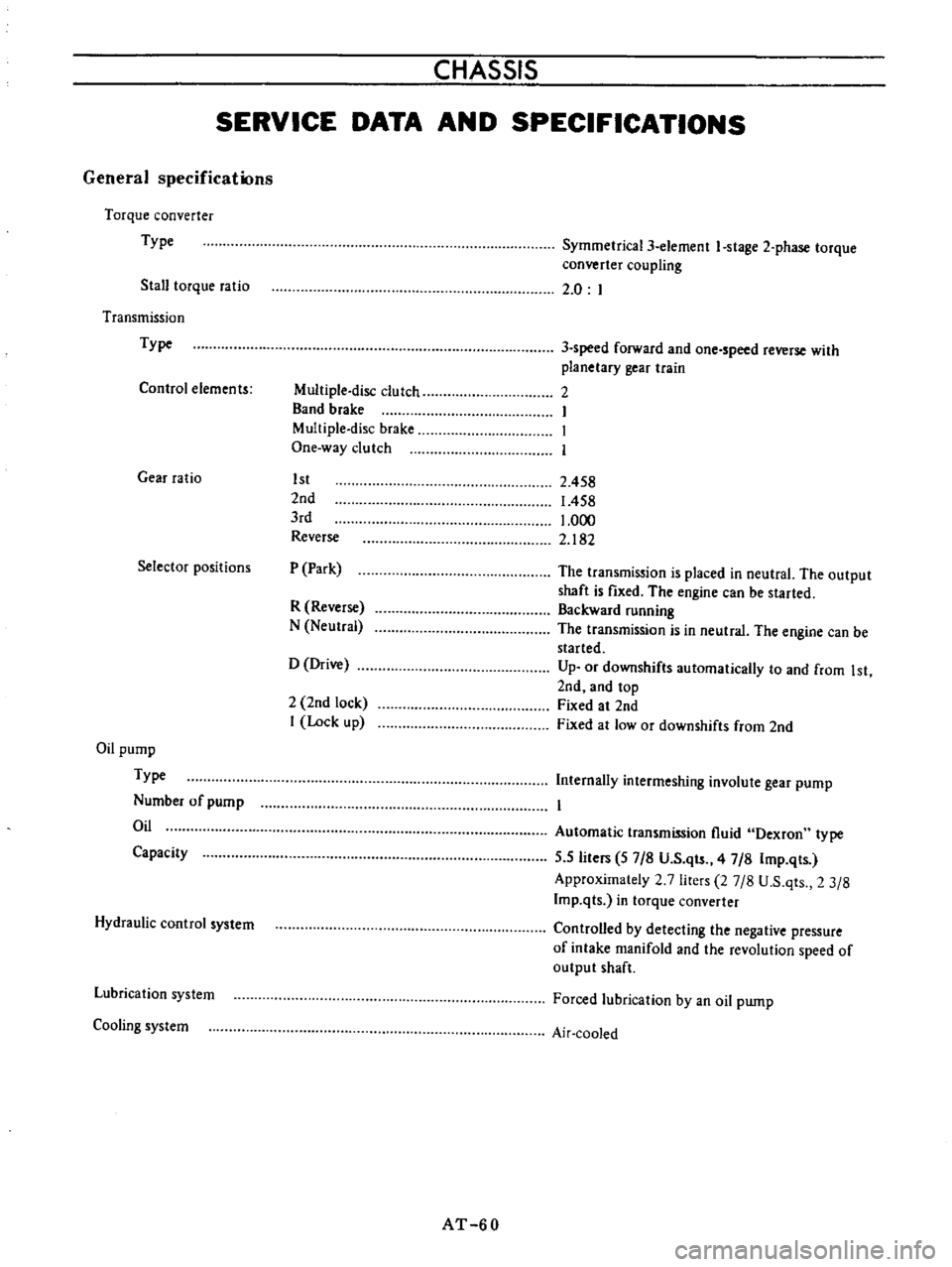

CHASSIS

SERVICE

DATA

AND

SPECIFICATIONS

General

specifications

Torque

converter

Type

Stall

torque

ratio

Transmission

Type

Control

elements

Gear

ratio

Selector

positions

Oil

pump

Type

Number

of

pump

Oil

Capacity

Hydraulic

control

system

Lubrication

system

Cooling

system

Multiple

disc

clutch

Band

brake

Multiple

disc

brake

One

way

clutch

1st

lnd

3rd

Reverse

P

Park

R

Reverse

N

Neutral

D

Drive

1

lnd

lock

I

Lock

up

AT

60

Symmetrical3

element

I

stage

l

phase

torque

converter

coupling

2

0

I

3

speed

forward

and

one

speed

reverse

with

planetary

gear

train

1

I

I

I

2

458

1

458

1

000

2

182

The

transmission

is

placed

in

neutral

The

output

shaft

is

fixed

The

engine

can

be

started

Backward

running

The

transmission

is

in

neutral

The

engine

can

be

started

Up

or

downshifts

automatically

to

and

from

1st

lnd

and

top

Fixed

at

2nd

Fixed

at

low

or

downshifts

from

2nd

Internally

intermeslting

involute

gear

pump

Automatic

transmission

fluid

Dexron

type

5

5

liters

57

8

U

S

qts

47

8

Imp

qts

Approximately

1

7

liters

27

8

U

S

qts

2

3

8

Imp

qts

in

torque

converter

Controlled

by

detecting

the

negative

pressure

of

intake

manifold

and

the

revolution

speed

of

output

shaft

Forced

lubrication

by

an

oil

pwnp

Air

cooled

Page 65 of 513

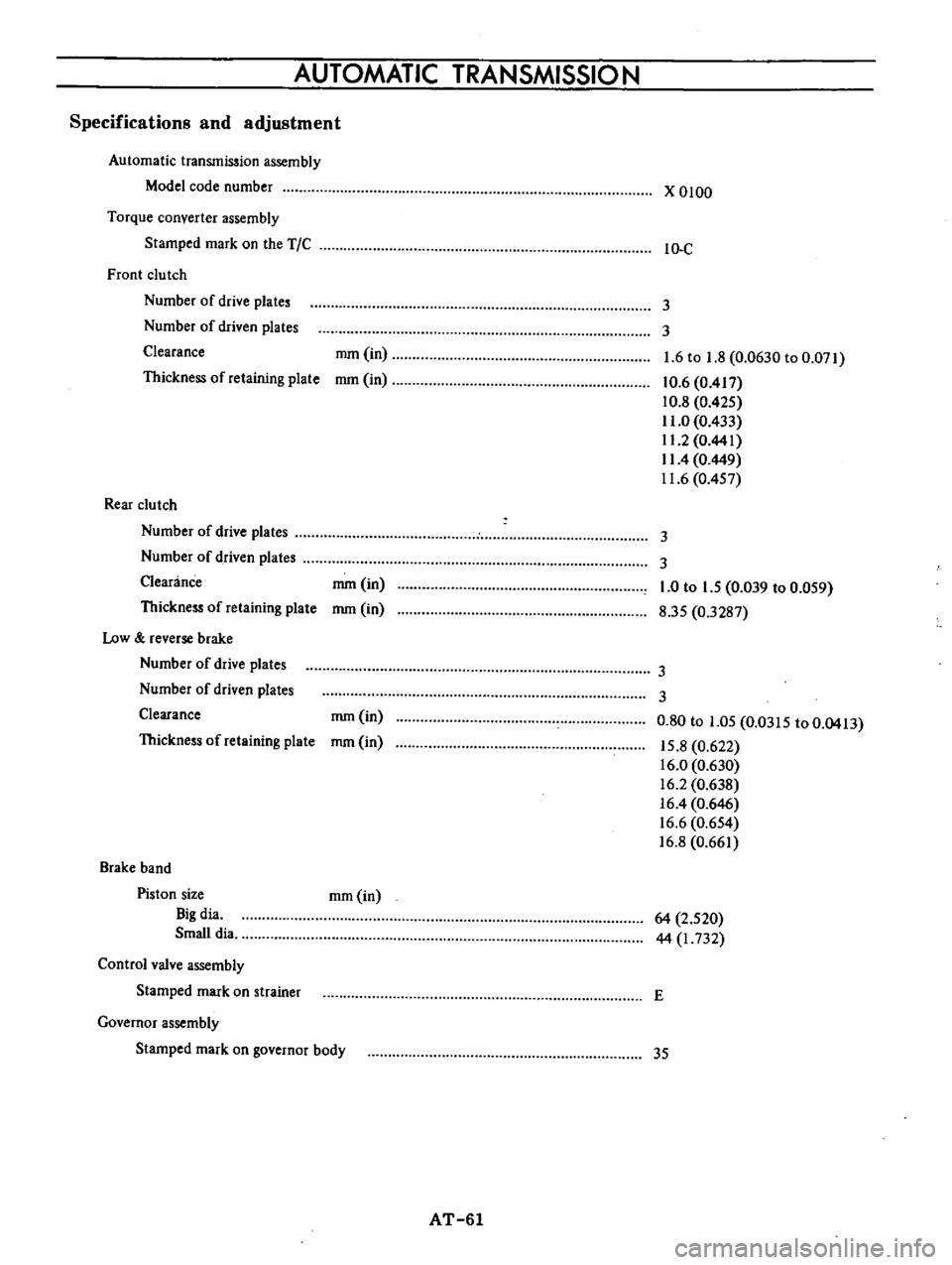

AUTOMATIC

TRANSMISSION

Specifications

and

adjustment

Automatic

transmission

assembly

Model

code

number

Torque

converter

assembly

Stamped

mark

on

the

TIC

Front

clu

tch

Number

of

drive

plate

Number

of

driven

plates

Clearance

Thickness

of

retaining

plate

Rear

clutch

Number

of

drive

plates

Number

of

driven

plate

Clearance

Thickness

of

retaining

plate

Low

reverse

brake

Number

of

drive

plates

Number

of

driven

plates

Clearance

Thickness

of

retaining

plate

Brake

band

Piston

size

Big

dia

Small

dia

Control

valve

assembly

Stamped

mark

on

trainer

Governor

assembly

Stamped

mark

on

governor

body

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

AT

61

x

0100

IO

C

3

3

1

6

to

1

8

0

0630

to

0

071

10

6

0

417

10

8

0

425

11

0

0

433

11

2

0

441

II

4

0

449

11

6

0

457

3

3

1

0

to

1

5

0

039

to

0

059

8

35

0

3287

3

3

0

80

to

1

05

0

0315

to

0

0413

15

8

0

622

16

0

0

630

16

2

0

638

16

4

0

646

16

6

0

654

16

8

0

661

64

2

520

44

I

732

E

35

Page 66 of 513

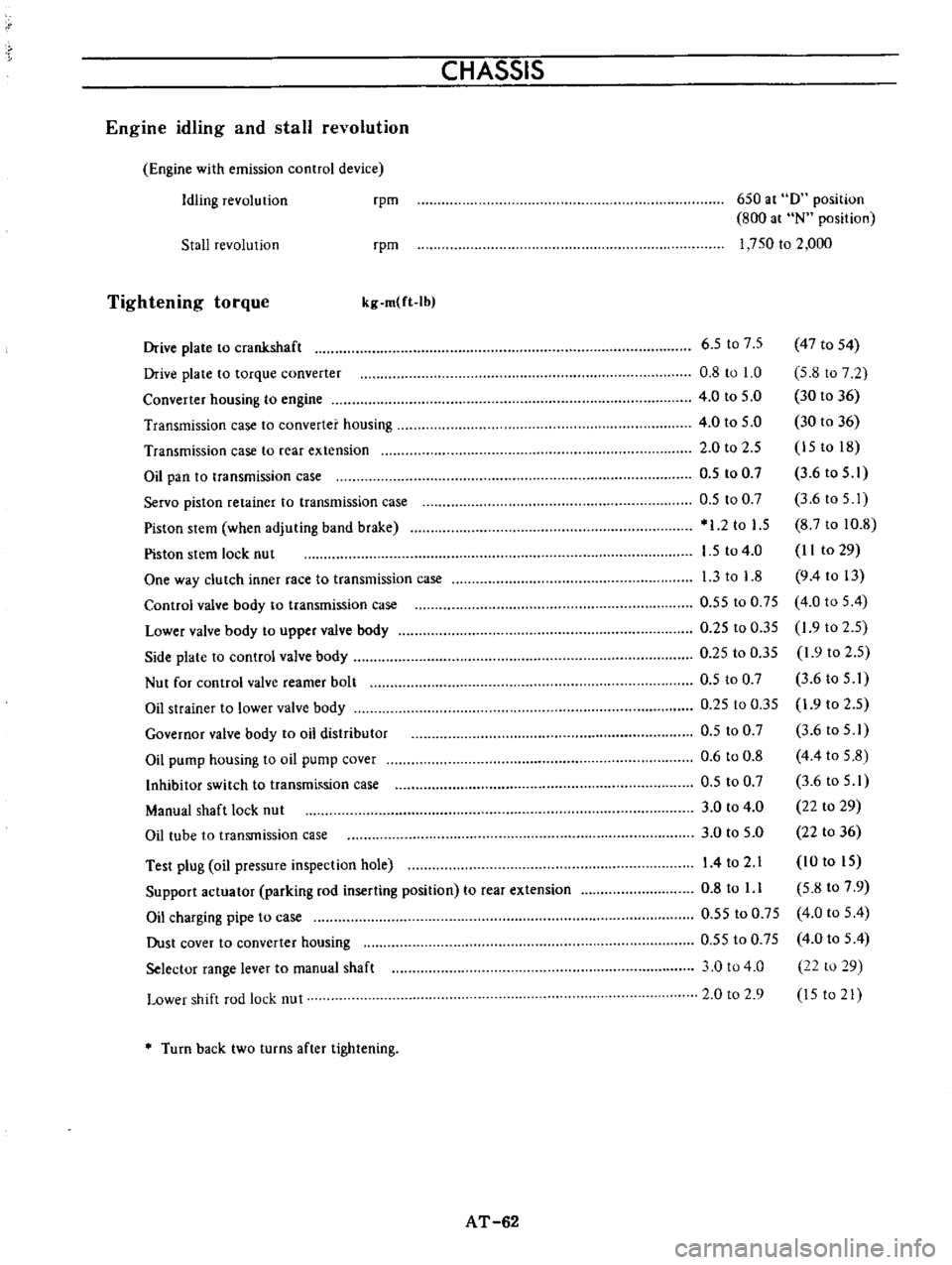

CHASSIS

Engine

idling

and

stall

revolution

Engine

with

emission

control

device

Idling

revolution

rpm

650

at

0

position

800

at

N

position

1

750

to

2

000

Stall

revolution

rpm

Tightening

torque

kg

m

ft

Ib

Test

plug

oil

pressure

inspection

hole

Support

actuator

parking

rod

inserting

position

to

rear

extension

Oil

charging

pipe

to

case

Dust

cover

to

converter

housing

Selector

range

lever

to

manual

shaft

Lower

shift

rod

lock

nut

6

5

t07

5

47

to

54

0

8

to

1

0

5

8

to

7

2

4

0

to

5

0

30

to

36

4

0

to

5

0

30

to

36

2

0

to

2

5

15

to

18

0

5

to

0

7

3

6

to

5

1

0

5

to

0

7

3

6toS

I

1

2

to

1

5

8

7

to

10

8

1

5

to

4

0

II

to

29

1

3

to

1

8

9

4

to

13

0

55

to

0

75

4

0

to

5

4

0

25

to

0

35

1

9

to

2

5

0

25

to

0

35

1

9

to

2

5

0

5

to

0

7

3

6

to

5

I

0

25

to

0

35

1

9

to

2

5

0

5

to

0

7

3

6

to

5

1

0

6

to

0

8

4

4

to

5

8

0

5

to

0

7

3

6

to

5

1

3

0

to

4

0

22

to

29

3

0

to

5

0

22

to

36

14

to

2

1

10

to

15

0

8

to

l

l

5

8

to

7

9

0

55

to

0

75

4

0

to

5

4

0

55

to

0

75

4

0

to

5

4

3

0

to

4

0

22

to

29

2

0

to

2

9

15

to

21

Drive

plate

to

crankshaft

Drive

plate

to

torque

converter

Converter

housing

to

engine

Transmission

case

to

converter

housing

Transmission

case

to

rear

extension

Oil

pan

to

transmission

case

Servo

piston

retainer

to

transmission

case

Piston

stem

when

adjuting

band

brake

Piston

stem

lock

nut

One

way

clutch

inner

race

to

transmission

case

Control

valve

body

to

transmission

case

Lower

valve

body

to

upper

valve

body

Side

plate

to

control

valve

body

Nut

for

control

valve

reamer

bolt

Oil

strainer

to

lower

valve

body

Governor

valve

body

to

oil

distributor

Oil

pump

housing

to

oil

pump

cover

Inhibitor

switch

to

transmh

sion

case

Manual

shaft

lock

nut

Oil

tube

to

transmission

case

Turn

back

two

turns

after

tightening

AT

62

Page 70 of 513

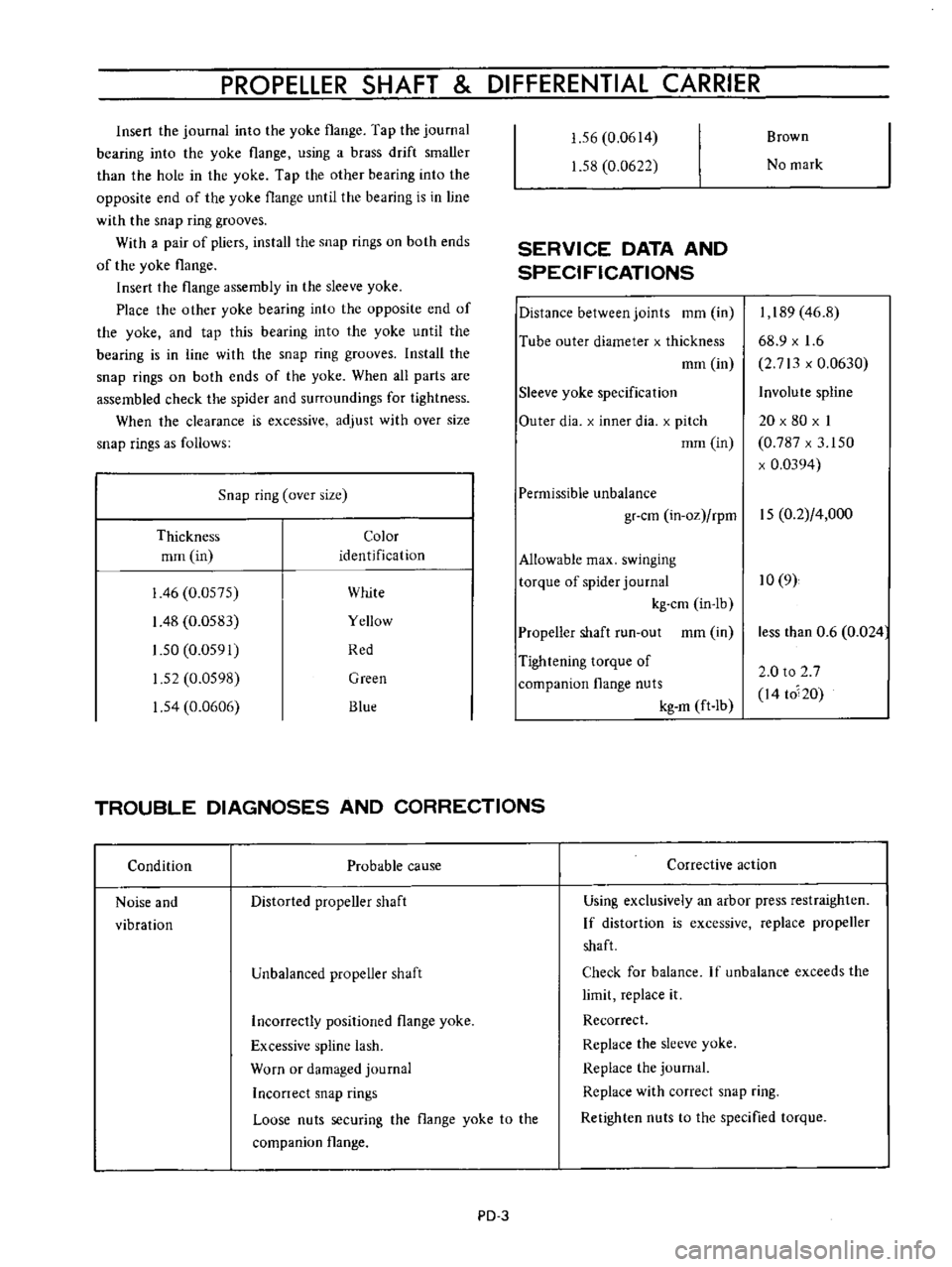

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Insert

the

journal

into

the

yoke

flange

Tap

the

journal

bearing

into

the

yoke

flange

using

a

brass

drift

smaller

than

the

hole

in

the

yoke

Tap

the

other

bearing

into

the

opposite

end

of

the

yoke

flange

until

the

bearing

is

in

line

with

the

snap

ring

grooves

With

a

pair

of

pliers

install

the

snap

rings

on

both

ends

of

the

yoke

flange

Insert

the

flange

assembly

in

the

sleeve

yoke

Place

the

other

yoke

bearing

into

the

opposite

end

of

the

yoke

and

tap

this

bearing

into

the

yoke

until

the

bearing

is

in

line

with

the

snap

ring

grooves

Install

the

snap

rings

on

both

ends

of

the

yoke

When

all

parts

are

assembled

check

the

spider

and

surroundings

for

tightness

When

the

clearance

is

excessive

adjust

with

over

size

snap

rings

as

follows

Snap

ring

over

size

Thickness

Color

mrn

in

identification

I

46

0

0575

White

I

48

0

0583

Yellow

1

50

0

0591

Red

1

52

0

0598

Green

1

54

0

0606

Blue

1

56

0

0614

1

58

0

0622

SERVICE

DATA

AND

SPECIFICATIONS

Distance

between

joints

mm

in

Tube

outer

diameter

x

thickness

mm

in

Sleeve

yoke

specification

Outer

dia

x

inner

dia

x

pitch

mm

in

Brown

No

mark

I

189

46

8

68

9

x

1

6

2

713

x

0

0630

Involute

spline

20

x

80

x

I

0

787

x

3

150

x

0

0394

Permissible

unbalance

gr

cm

in

oz

rpm

15

0

2

4

000

Allowable

max

swinging

torque

of

spider

journal

10

9

kg

cm

in

lb

Propeller

shaft

run

out

mm

in

Tightening

torque

of

companion

flange

nuts

kg

m

ft

Ib

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Noise

and

vibration

Distorted

propeller

shaft

Unbalanced

propeller

shaft

Corrective

action

less

than

0

6

0

024

2

0

to

2

7

I4

to

20

Using

exclusively

an

arbor

press

restraighten

If

distortion

is

excessive

replace

propeller

shaft

Check

for

balance

If

unbalance

exceeds

the

limit

replace

it

Recorrect

Replace

the

sleeve

yoke

Replace

the

journal

Replace

with

correct

snap

ring

Retighten

nuts

to

the

specified

torque

Incorrectly

positioned

flange

yoke

Excessive

spline

lash

Worn

or

damaged

journal

Inconect

snap

rings

Loose

nuts

securing

the

flange

yoke

to

the

companion

flange

PD

3

Page 71 of 513

CHASSIS

DIFFERENTIAL

CARRIER

CONTENTS

DESCRIPTION

REMOVAL

DISASSEMBL

Y

INSPECTION

AND

REPAIR

ASSEMBLY

AND

ADJUSTMENT

Assembling

differential

gear

case

Setting

and

adjusting

drive

pinion

PD

4

PD

5

PD

5

PD

7

PD

8

PD

9

PD

10

Adjusting

drive

pinion

preload

Setting

and

adjusting

side

bearing

shims

INSTALLATION

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SERVICE

DATA

AND

SPECIFICATIONS

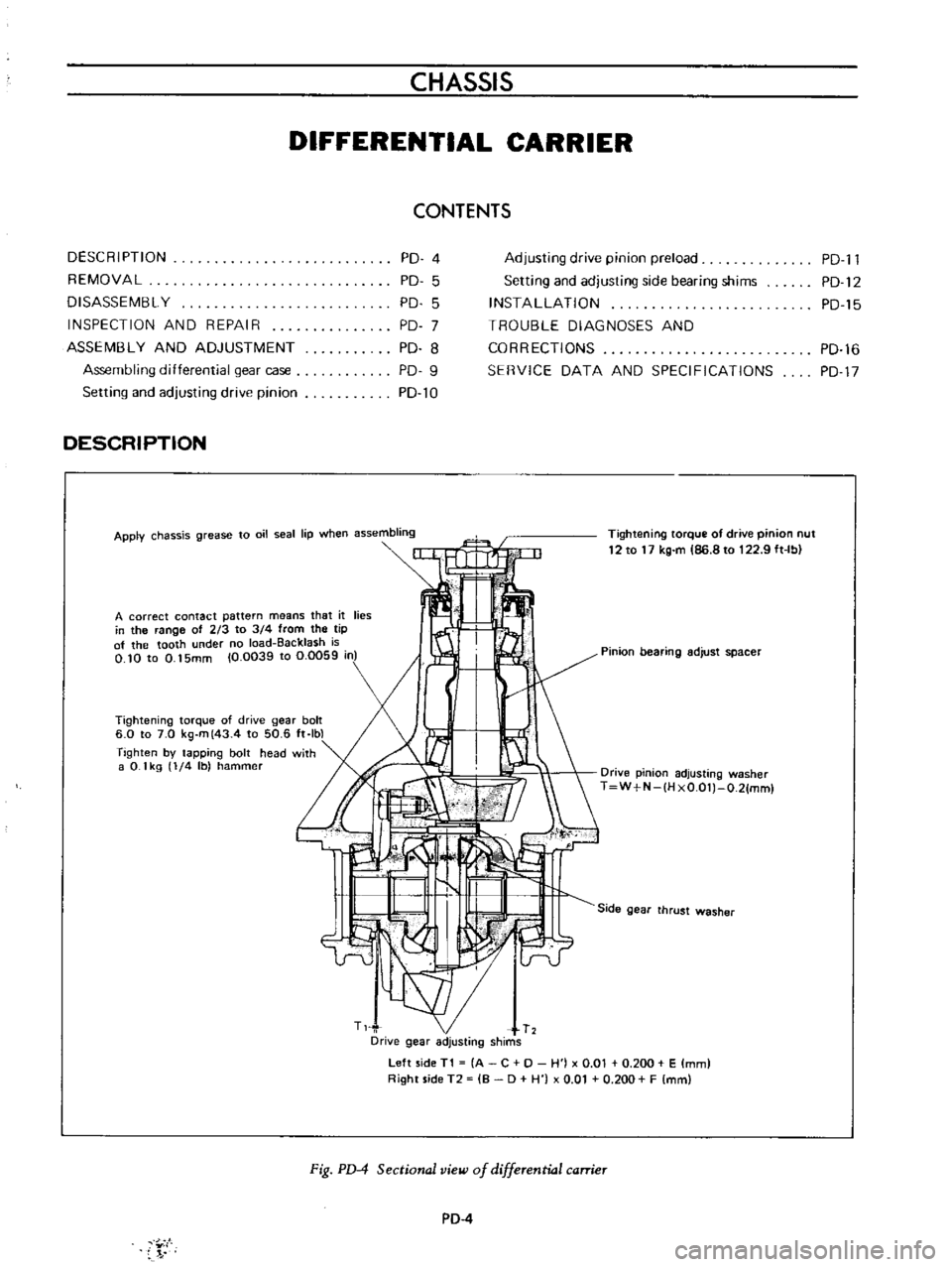

DESCRIPTION

Apply

chassis

grease

to

oil

seal

lip

when

assembling

Tightening

torque

of

drive

pinion

nut

12

to

17

kg

m

86

8

to

122

9

ft

Ib

A

correct

contact

pattern

means

that

it

lies

in

the

range

of

213

to

3

4

from

the

tip

of

the

tooth

under

no

load

Backlash

is

O

10

to

0

15mm

10

0039

to

0

0059

in

Pinion

bearing

adjust

spacer

Tightening

torque

of

drive

gear

bolt

6

0

to

7

0

kg

m

43

4

to

50

6

ft

Ibl

Tighten

by

tapping

bolt

head

with

a

0

1

kg

1

4

Ib

hammer

Drive

pinion

adjusting

washer

T

W

N

IH

xO

OlJ

O

21mml

Side

gear

thrust

washer

Left

side

T1

A

C

0

H

j

x

0

01

0

200

E

mm

Right

side

T2

B

0

H

0

01

0

200

F

mm

Fig

PD

4

Sectional

view

of

differential

carrier

PD

4

Y

I

PD

l1

PD

12

PD

15

PD

16

PD

17

Page 74 of 513

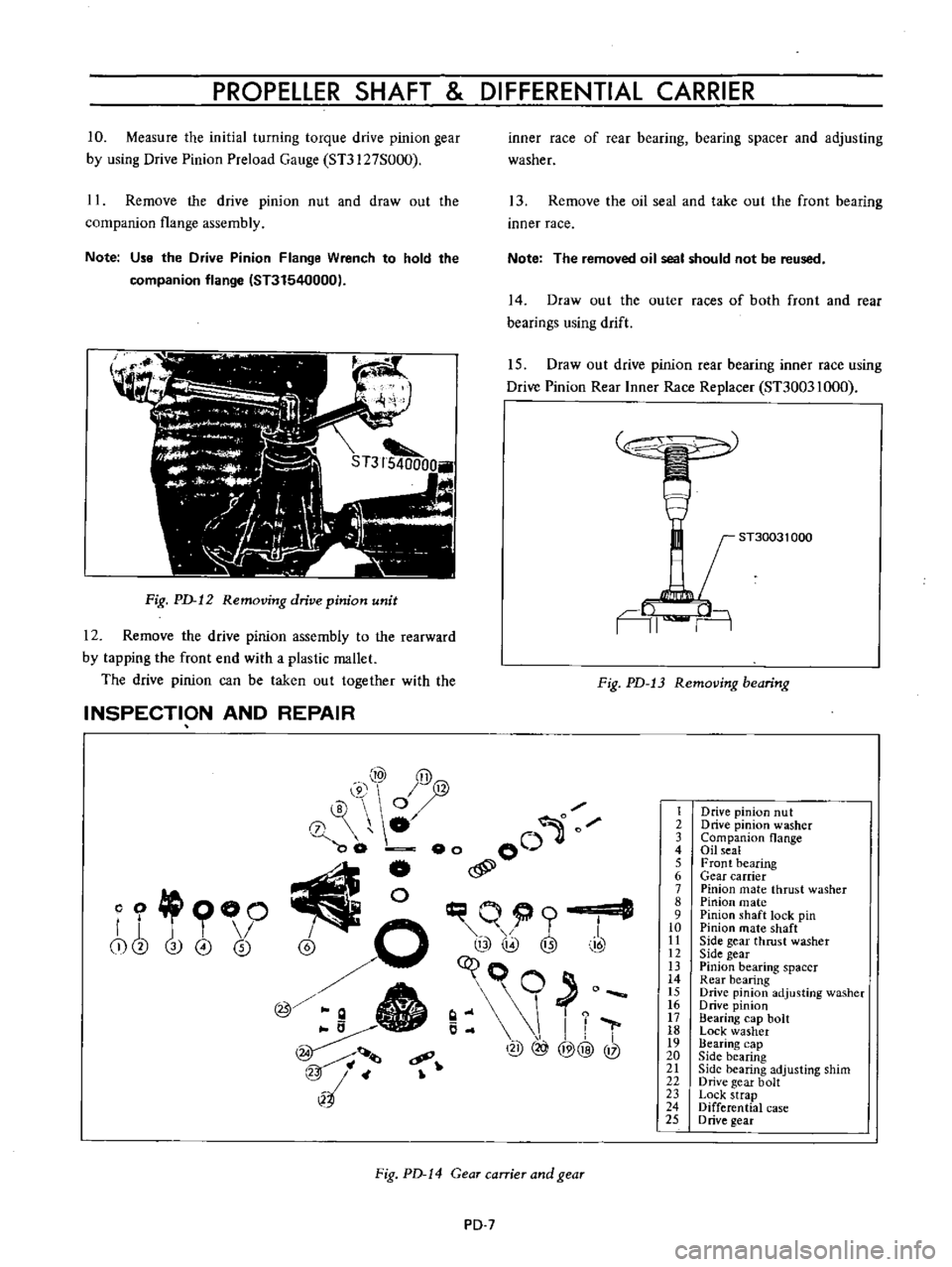

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

10

Measure

the

initial

turning

torque

drive

pinion

gear

by

using

Drive

Pinion

Preload

Gauge

Sn127S000

11

Remove

the

drive

pinion

nut

and

draw

out

the

companion

flange

assembly

Note

Use

the

Drive

Pinion

Flange

Wrench

to

hold

the

companion

flange

IST31540000

Fig

PD

12

Removing

drive

pinion

unit

12

Remove

the

drive

pinion

assembly

to

the

rearward

by

tapping

the

front

end

with

a

plastic

mallet

The

drive

pinion

can

be

taken

out

together

with

the

INSPECTION

AND

REPAIR

inner

race

of

rear

bearing

bearing

spacer

and

adjusting

washer

13

Remove

the

oil

seal

and

take

out

the

front

bearing

inner

race

Note

The

removed

oil

seal

should

not

be

reused

14

Draw

out

the

outer

races

of

both

front

and

rear

bearings

using

drift

15

Draw

out

drive

pinion

rear

bearing

inner

race

using

Drive

Pinion

Rear

Inner

Race

Replacer

ST30031000

ST30031

000

AI

n

Fig

PD

13

Removing

bearing

10

y@

@

0

0

0

00

eo

00

j

l

I

@

o

q@

@

t

I

7

c9

@

@@

@

l2

4

o

OO

r

j

T

I

i

cb

3

0

0

Fig

PD

14

Gear

carrier

and

gear

PD

7

1

2

3

4

S

6

7

8

9

10

II

12

IJ

14

IS

16

17

18

19

20

21

22

23

24

25

Drive

pinion

nut

Drive

pinion

washer

Companion

flange

Oil

seal

Front

bearing

Gear

carrier

Pinion

mate

thrust

washer

Pinion

mate

Pinion

shaft

lock

pin

Pinion

mate

shaft

Side

gear

thrust

washer

Side

gear

Pinion

bearing

spacer

Rear

bearing

Drive

pinion

adjusting

washer

o

rive

pinion

Bearing

cap

bolt

Lock

washer

Bearing

cap

Side

bearing

Side

bearing

adjusting

shim

Drive

gear

bolt

Lock

strap

Differential

case

D

rive

gear

Page 75 of 513

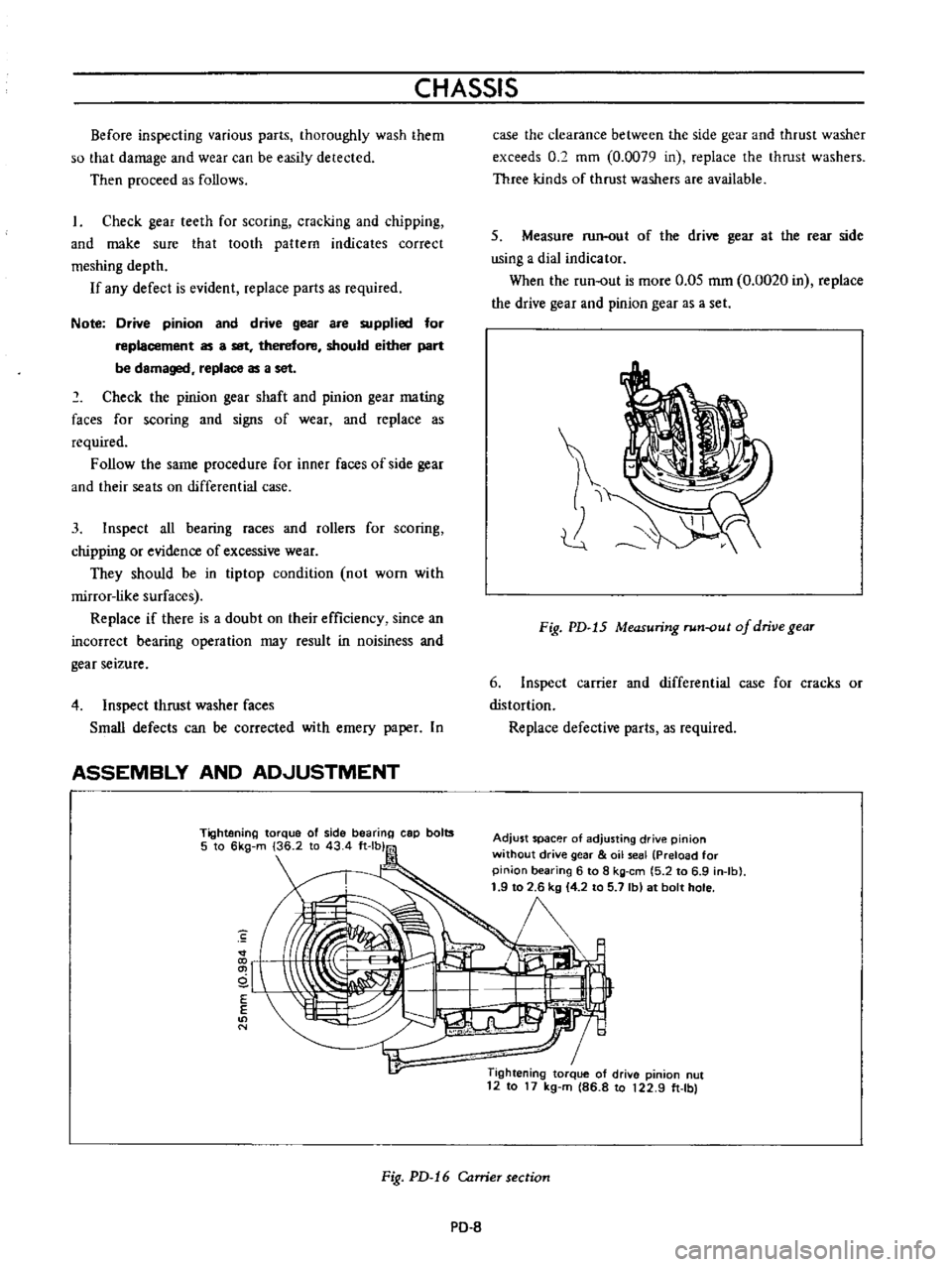

CHASSIS

Before

inspecting

various

parts

thoroughly

wash

them

so

that

damage

and

wear

can

be

easily

detected

Then

proceed

as

follows

Check

gear

teeth

for

scoring

cracking

and

chipping

and

make

sure

that

tooth

pattern

indicates

correct

meshing

depth

If

any

defect

is

evident

replace

parts

as

required

Note

Drive

pinion

and

drive

gear

are

supplied

for

replacement

as

a

set

therefore

should

either

part

be

damaged

replace

as

a

set

Check

the

pinion

gear

shaft

and

pinion

gear

mating

faces

for

scoring

and

signs

of

wear

and

replace

as

required

Follow

the

same

procedure

for

inner

faces

of

side

gear

and

their

seats

on

differential

case

3

Inspect

all

bearing

races

and

rollers

for

scoring

chipping

or

evidence

of

excessive

wear

They

should

be

in

tiptop

condition

not

worn

with

mirror

like

surfaces

Replace

if

there

is

a

doubt

on

their

efficiency

since

an

incorrect

bearing

operation

may

result

in

noisiness

and

gear

seizure

4

Inspect

thrust

washer

faces

Small

defects

can

be

corrected

with

emery

paper

In

ASSEMBLY

AND

AD

JUSTMENT

Tightening

torque

of

side

bearing

cap

bolts

5

to

6kg

m

36

2

to

43

4

ft

lb

co

g

E

E

on

N

case

the

clearance

between

the

side

gear

and

thrust

washer

exceeds

0

2

mm

0

0079

in

replace

the

thrust

washers

Three

kinds

of

thrust

washers

are

available

5

Measure

run

out

of

the

drive

gear

at

the

rear

side

using

a

dial

indicator

When

the

run

out

is

more

0

05

mm

0

0020

in

replace

the

drive

gear

and

pinion

gear

as

a

set

Fig

PD

15

Measuring

run

out

of

drive

gear

6

Inspect

carrier

and

differential

case

for

cracks

or

distortion

Replace

defective

parts

as

required

Adjust

spacer

of

adjusting

drive

pinion

without

drive

gear

oil

seal

Preload

for

pinion

bearing

6

to

8

kg

em

5

2

to

6

9

in

Ib

1

9

to

2

6

kg

4

2

to

5

7

Ib

at

bolt

hole

1

Tightening

torque

of

drive

pinion

nut

12

to

17

kg

m

86

8

to

122

9

ft

Ibl

Fig

PD

16

Carrier

section

PO

8

Page 76 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

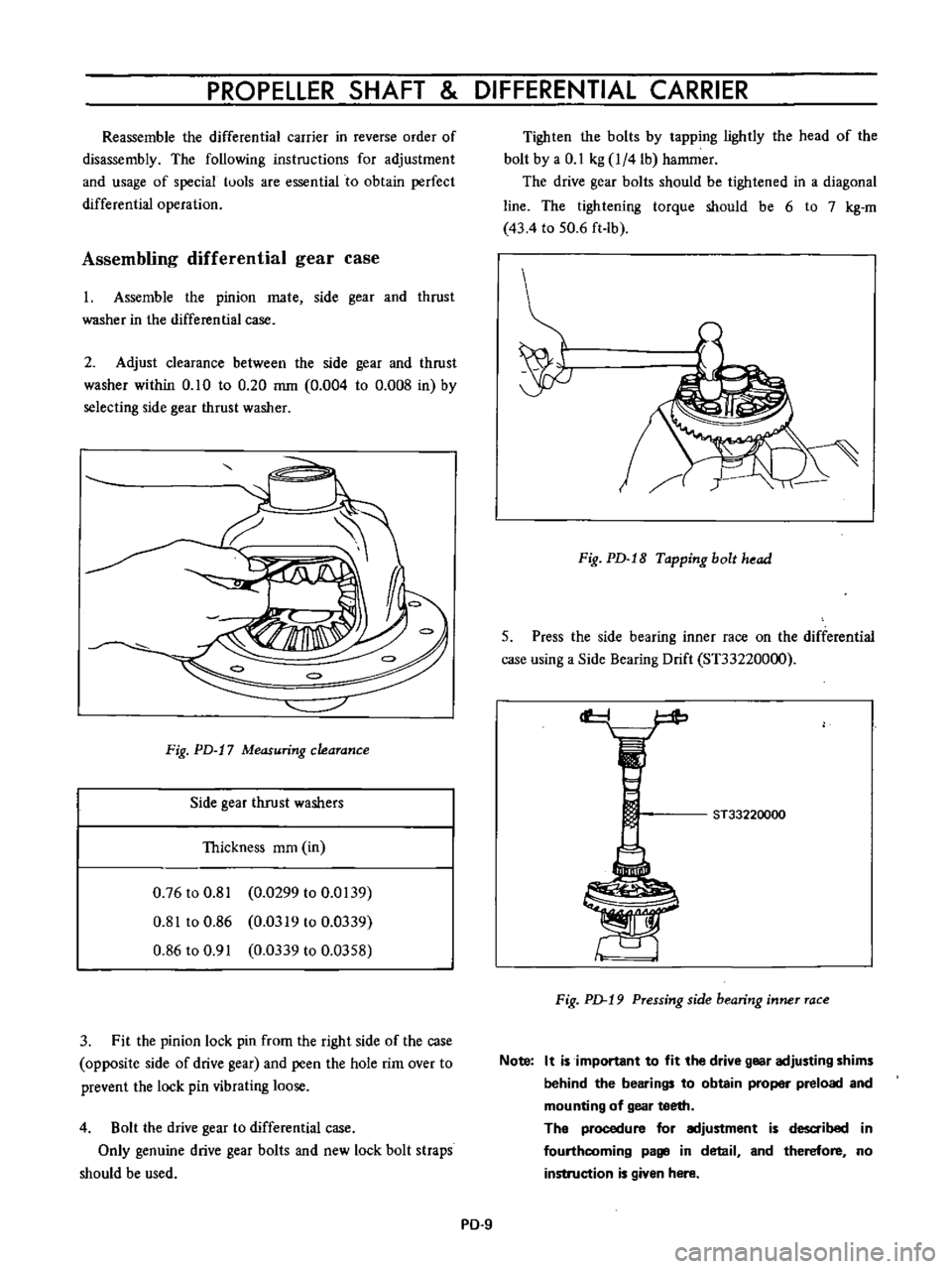

Reassemble

the

differential

carrier

in

reverse

order

of

disassembly

The

following

instructions

for

adjustment

and

usage

of

special

tuols

are

essential

to

obtain

perfect

differential

operation

Assembling

differential

gear

case

1

Assemble

the

pinion

mate

side

gear

and

thrust

washer

in

the

differential

case

2

Adjust

clearance

between

the

side

gear

and

thrust

washer

within

0

10

to

0

20

mm

0

004

to

0

008

in

by

selecting

side

gear

thrust

washer

Fig

PD

17

Measuring

clearance

Side

gear

thrust

washers

Thickness

mm

in

0

76

to

0

81

0

0299

to

0

0139

0

81

to

0

86

0

0319

to

0

0339

0

86

to

0

91

0

0339

to

0

0358

3

Fit

the

pinion

lock

pin

from

the

right

side

of

the

case

opposite

side

of

drive

gear

and

peen

the

hole

rim

over

to

prevent

the

lock

pin

vibrating

loose

4

Bolt

the

drive

gear

to

differential

case

Only

genuine

drive

gear

bolts

and

new

lock

bolt

straps

should

be

used

Tighten

the

bolts

by

tapping

lightly

the

head

of

the

bolt

by

a

0

1

kg

l

4lb

hammer

The

drive

gear

bolts

should

be

tightened

in

a

diagonal

line

The

tightening

torque

should

be

6

to

7

kg

m

43

4

to

50

6

ft

lb

Fig

PD

18

Tapping

bolt

head

5

Press

the

side

bearing

inner

race

on

the

differential

case

using

a

Side

Bearing

Drift

ST33220000

cf

ST33220000

F

ig

p

19

Pressing

side

bearing

inner

race

Note

It

is

important

to

fit

the

drive

gear

adjusting

shims

behind

the

bearings

to

obtain

proper

preload

and

mounting

of

gear

teeth

The

procedure

for

adjustment

is

d

ibed

in

fourthcoming

page

in

detail

and

therefore

no

instruction

is

given

here

PD

9

Page 78 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

6

Formula

to

calculate

thickness

of

drive

pinion

adjusting

shims

T

W

N

H

x

0

01

0

2

mm

Where

W

Thickness

of

shim

inserted

mm

T

Required

thickness

of

rear

bearing

ad

justing

shim

mm

N

Measured

clearance

between

Height

Gauge

and

Dummy

Shaft

face

mm

H

Figure

marked

on

the

drive

pinion

head

Example

W

2

92

mm

N

0

3

mm

H

1

T

2

92

0

3

1

x

0

01

0

2

3

03

mm

Use

a

3

04

mm

washer

7

Remove

the

Dummy

Shaft

from

the

gear

carrier

housing

8

Withdraw

the

pinion

rear

bearing

from

the

Dummy

Shaft

apply

a

shims

selected

based

on

the

above

formula

and

refit

the

pinion

rear

bearing

and

drive

pinion

together

using

Drive

Pinion

Bearing

Drift

STJ0600000

Note

Be

sure

to

face

inside

faced

surface

of

the

shimes

toward

back

of

the

pinion

gear

Drive

pinion

height

adjusting

shims

Thickness

mm

in

Thickness

mm

in

2

74

0

1079

2

77

0

i091

2

80

0

1102

2

83

0

1114

2

86

0

1126

2

89

0

1138

2

92

0

1150

2

95

0

1161

2

98

0

1173

3

01

0

1185

3

04

0

1197

3

07

0

1209

3

10

0

i

220

3

13

0

1232

3

16

0

1244

319

0

1256

3

22

0

1268

3

25

0

1280

PD

Adjusting

drive

pinion

preload

Adjust

the

preload

of

drive

pinion

with

collapsible

spacer

This

procedure

has

nothing

to

do

with

thickness

of

pinion

height

adjusting

washer

Note

Reuse

of

a

collapsible

spacer

must

not

be

allowed

After

adjusting

pinion

height

lubricate

front

bearing

with

gear

oil

and

place

it

in

carrier

2

Install

a

new

oil

seal

in

carrier

Lubricate

cavity

between

seal

lips

with

grease

when

installing

3

Place

a

new

collapsible

spacer

on

drive

pinion

and

lubricate

pinion

rear

bearing

with

gear

oil

4

Insert

companion

flange

into

oil

seal

and

hold

it

firmly

against

pinion

fron

bearing

cone

From

the

rear

of

the

carrier

insert

drive

pinion

into

companion

flange

5

Ascertain

that

threaded

portion

of

drive

pinion

a

new

pinion

nut

and

washer

are

free

from

oil

or

grease

6

Holding

companion

flange

with

Drive

Pinion

Flange

Wrench

ST31540000

tighten

nut

and

then

drive

pinion

is

pulled

into

front

bearing

cone

and

into

flange

As

drive

pinion

is

pulled

into

front

bearing

cone

drive

pinion

end

play

is

reduced

While

there

is

still

end

play

in

drive

pinion

companion

flange

and

cone

will

be

felt

to

bottom

This

indicates

that

bearing

cone

and

companion

flange

have

bottomed

on

collapsible

spacer

From

this

point

a

much

greater

torque

must

be

applied

to

turn

pinion

nut

since

spacer

must

be

collapsed

From

this

point

nut

should

also

be

tightened

very

slowly

and

drive

pinion

end

play

checked

often

so

that

pinion

bearing

preload

does

not

exceed

the

limits

When

the

drive

pinion

end

play

is

eliminated

the

specified

preload

is

being

approached

Replace

collapsible

spacer

if

this

specification

is

exceeded

Note

Do

not

decrease

preload

by

loosening

pinion

nut

This

will

remove

compression

between

pinion

front

and

rear

bearing

cones

and

collapsible

spacer

and

may

permit

front

bearing

cone

to

turn

on

drive

pinion

moreover

nut

becomes

loose

Page 79 of 513

CHASSIS

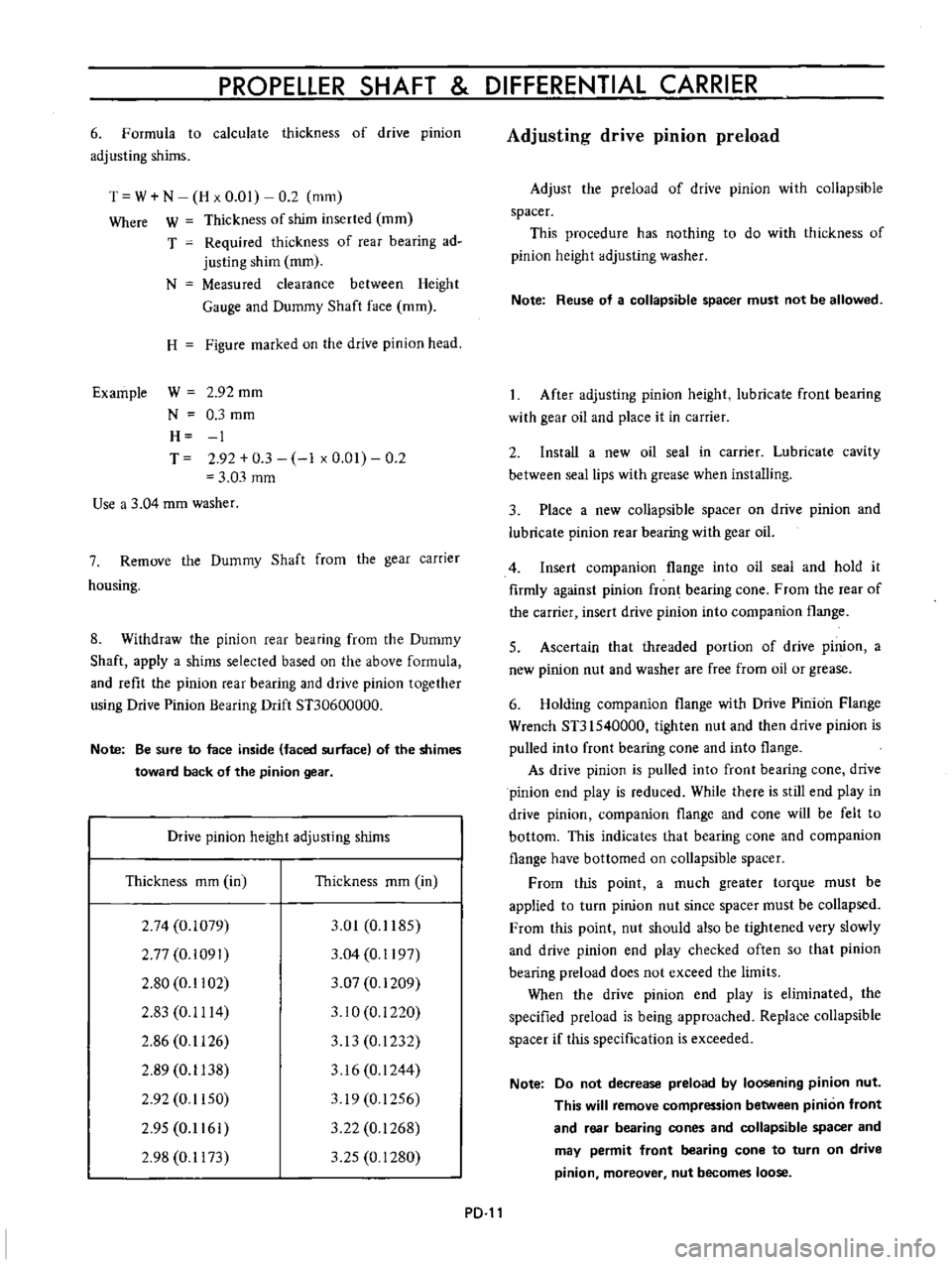

7

Turn

drive

pinion

in

both

directions

several

times

to

set

bearing

rollers

And

adjust

bearing

preload

to

specifi

cations

Drive

pinion

bearing

preload

with

oil

seal

7

to

9

kg

cm

6

1

to

7

8

in

1b

At

companion

flange

bolt

hole

2

25

to

2

95

kg

4

96

to

6

50

1b

Pinion

nut

tightening

torque

12

to

17

kg

m

86

8

to

122

9

ft

1b

Fig

PD

24

Measuring

pinion

preload

Setting

and

adjusting

side

bearing

shims

When

reassembling

the

side

bearing

without

replacing

be

sure

to

install

a

shim

having

same

thickness

as

that

before

disassembly

The

following

instructions

apply

when

the

hearing

is

replaced

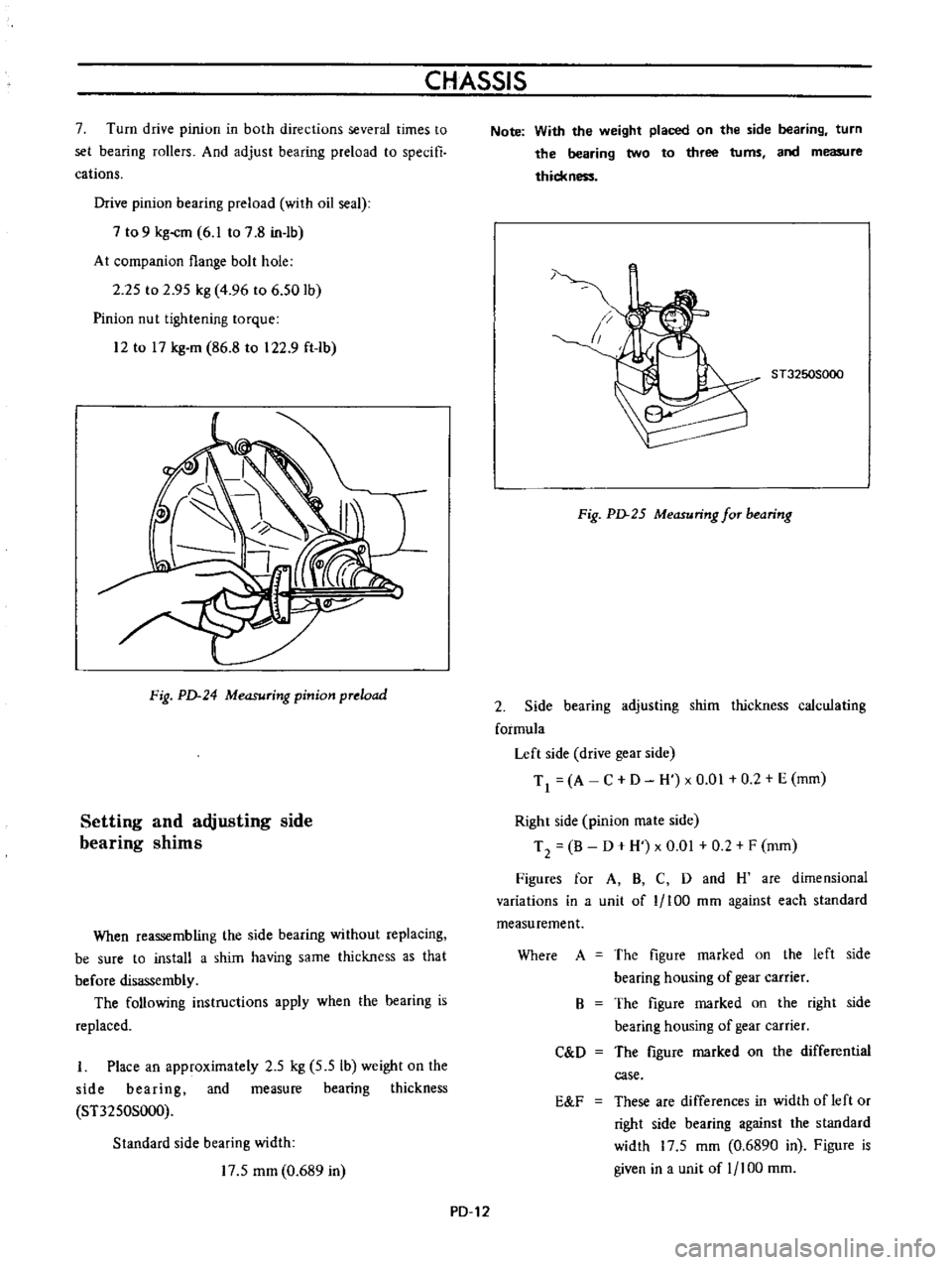

I

Place

an

approximately

2

5

kg

5

5

Ib

weight

on

the

side

bearing

and

measure

bearing

thickness

ST3250S000

Standard

side

bearing

width

17

5

mm

0

689

in

Note

With

the

weight

placed

on

the

side

bearing

turn

the

bearing

two

to

three

turns

and

measure

thickn

1

ST3250S000

Fig

PD

25

Measuring

for

bearing

2

Side

bearing

adjusting

shim

thickness

calculating

formula

Left

side

drive

gear

side

Tl

A

C

D

H

xO

01

0

2

E

mm

Right

side

pinion

mate

side

T

2

B

D

H

x

0

01

0

2

F

mm

Figures

for

A

B

C

D

and

H

are

dimensional

variations

in

a

unit

of

1

100

mm

against

each

standard

measurement

Where

A

The

figure

marked

on

the

left

side

bearing

housing

of

gear

carrier

The

figure

marked

on

the

right

side

bearing

housing

of

gear

carrier

The

figure

marked

on

the

differential

case

B

C

D

E

F

These

are

differences

in

width

of

left

or

right

side

bearing

against

the

standard

width

17

5

mm

0

6890

in

Figure

is

given

in

a

unit

of

1

100

mm

PD

12