torque DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 430 of 513

ENGINE

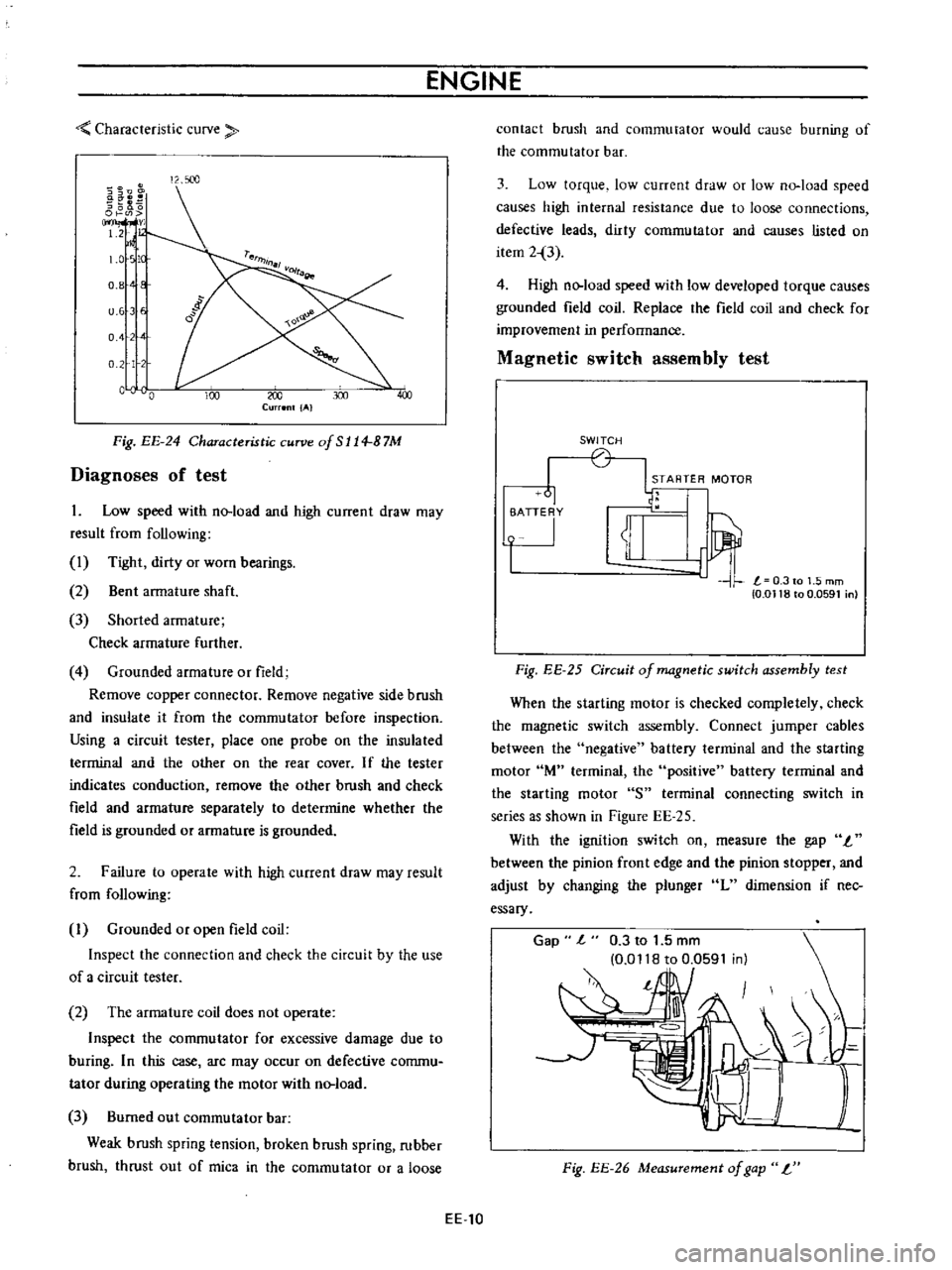

Characteristic

curve

i

8

s

l00

0

OJ

m

v

1

2

1

0

tc

0

8

E

u

6

E

o

4

0

2

L

c

0

00

J

300

Current

IAI

Fig

EE

24

Characteristic

curve

of

S

114

B

7M

Diagnoses

of

test

1

Low

speed

with

no

load

and

high

current

draw

may

result

from

following

1

Tight

dirty

or

worn

bearings

2

Bent

armature

shaft

3

Shorted

armature

Check

armature

further

4

Grounded

armature

or

field

Remove

copper

connector

Remove

negative

side

brush

and

insulate

it

from

the

commutator

before

inspection

Using

a

circuit

tester

place

one

probe

on

the

insulated

terminal

and

the

other

on

the

rear

cover

If

the

tester

indicates

conduction

remove

the

other

brush

and

check

field

and

armature

separately

to

determine

whether

the

field

is

grounded

or

armature

is

grounded

2

Failure

to

operate

with

high

current

draw

may

result

from

following

I

Grounded

or

open

field

coil

Inspect

the

connection

and

check

the

circuit

by

the

use

of

a

circuit

tester

2

The

armature

coil

does

not

operate

Inspect

the

commutator

for

excessive

damage

due

to

buring

In

this

case

arc

may

occur

on

defective

commu

tator

during

operating

the

motor

with

no

load

3

Burned

out

commutator

bar

Weak

brush

spring

tension

broken

brush

spring

rubber

brush

thrust

out

of

mica

in

the

commutator

or

a

loose

EE

10

contact

brush

and

commutator

would

cause

burning

of

the

commutator

bar

3

Low

torque

low

current

draw

or

low

no

load

speed

causes

high

internal

resistance

due

to

loose

connections

defective

leads

dirty

commutator

and

causes

listed

on

item

2

3

4

High

no

load

speed

with

low

developed

torque

causes

grounded

field

coil

Replace

the

field

coil

and

check

for

improvement

in

performance

Magnetic

switch

assembly

test

SWITCH

STARTER

MOTOR

61

1u

i

T

0

0118

to

0

0591

n

Fig

EE

25

Circuit

of

magnetic

switch

assembly

test

When

the

starting

motor

is

checked

completely

check

the

magnetic

switch

assembly

Connect

jumper

cables

between

the

negative

battery

terminal

and

the

starting

motor

lM

terminal

the

positive

battery

terminal

and

the

starting

motor

S

terminal

connecting

switch

in

series

as

shown

in

Figure

EE

25

With

the

ignition

switch

on

measure

the

gap

I

between

the

pinion

front

edge

and

the

pinion

stopper

and

adjust

by

changing

the

plunger

L

dimension

if

nec

essary

Gap

l

0

3

to

1

5

mm

0

0118

to

0

0591

in

l

Fig

EE

26

Measurement

of

gap

L

Page 431 of 513

ENGINE

ElECTRICAL

SYSTEM

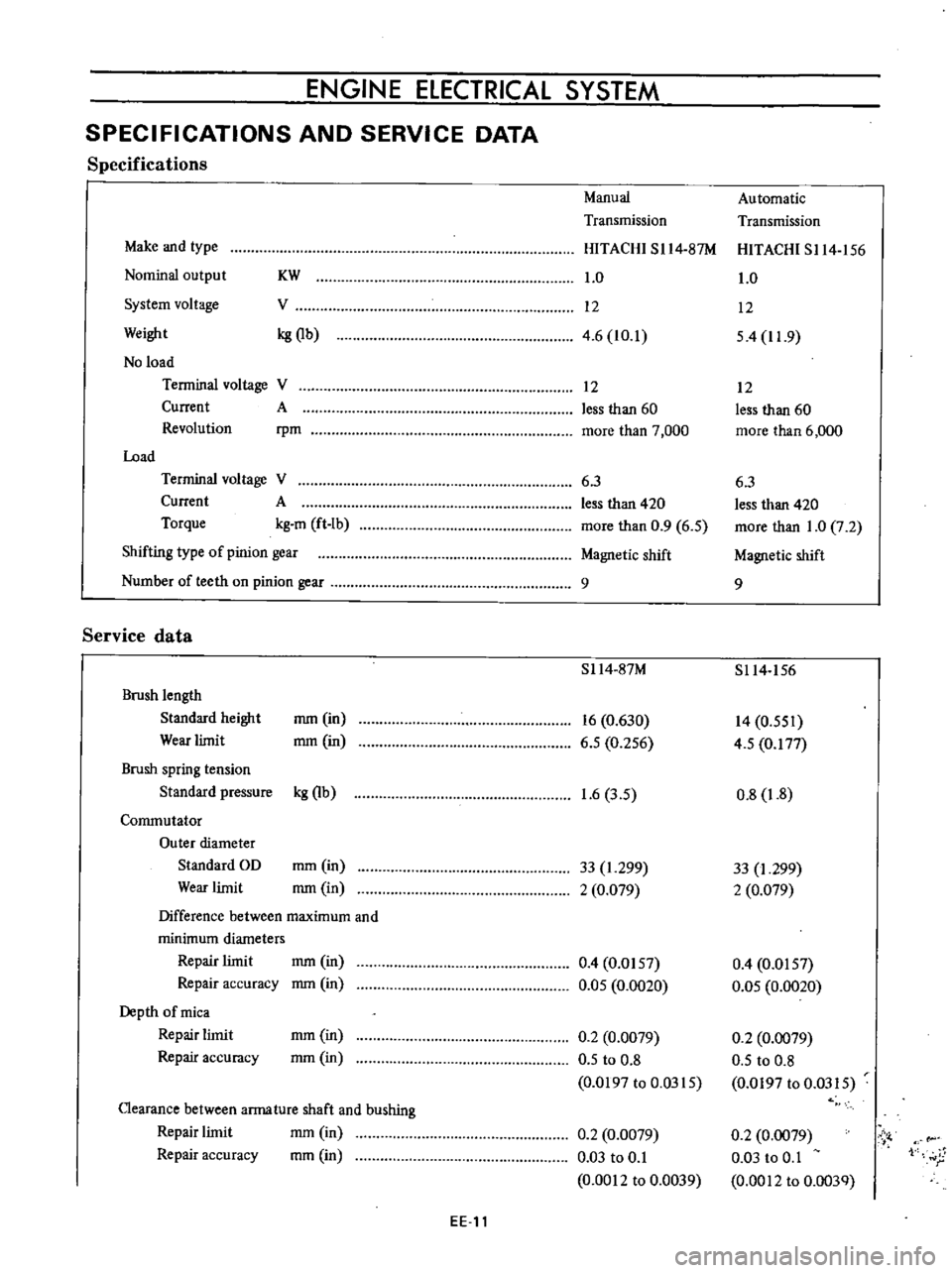

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Manual

Automatic

Transmission

Transmission

Make

and

type

HITACHI

SI14

87M

HITACHI

S114

156

Nominal

output

KW

1

0

1

0

System

voltage

V

12

12

Weight

kg

Qb

4

6

10

1

54

11

9

No

load

Terminal

voltage

V

12

12

Current

A

less

than

60

less

than

60

Revolution

rpm

more

than

7

000

more

than

6

000

Load

Terminal

voltage

V

6

3

6

3

Current

A

less

than

420

less

than

420

Torque

kg

m

ft

Ib

more

than

0

9

6

5

more

than

1

0

7

2

Shifting

type

of

pinion

gear

Magnetic

shift

Magnetic

shift

Number

of

teeth

on

pinion

gear

9

9

Service

data

S114

87M

S114

156

Brush

length

Standard

height

mm

in

16

0

630

14

0

551

Wear

limit

mm

in

6

5

0

256

4

5

0

177

Brush

spring

tension

Standard

pressure

kg

Qb

1

6

3

5

0

8

1

8

Commutator

Outer

diameter

Standard

OD

mm

in

33

1

299

33

I

299

Wear

limit

mm

in

2

0

079

2

0

079

Difference

between

maximum

and

minimum

diameters

Repair

limit

mm

in

0

4

0

0157

0

4

0

0157

Repair

accuracy

mm

in

0

05

0

0020

0

05

0

0020

Depth

of

mica

Repair

limit

mm

in

0

2

0

0079

0

2

0

0079

Repair

accuracy

mm

in

0

5

to

0

8

0

5

to

0

8

0

0197

to

0

0315

0

0197

to

0

0315

Clearance

between

arma

ture

shaft

and

bushing

mm

in

Repair

limit

0

2

0

0079

0

2

0

0079

Vi

Repair

accuracy

mm

in

0

03

to

0

1

0

03

to

0

1

1

r

0

0012

to

0

0039

0

0012

to

0

003Q

EE

11

Page 441 of 513

ENGINE

ElECTRICAL

SYSTEM

EE127

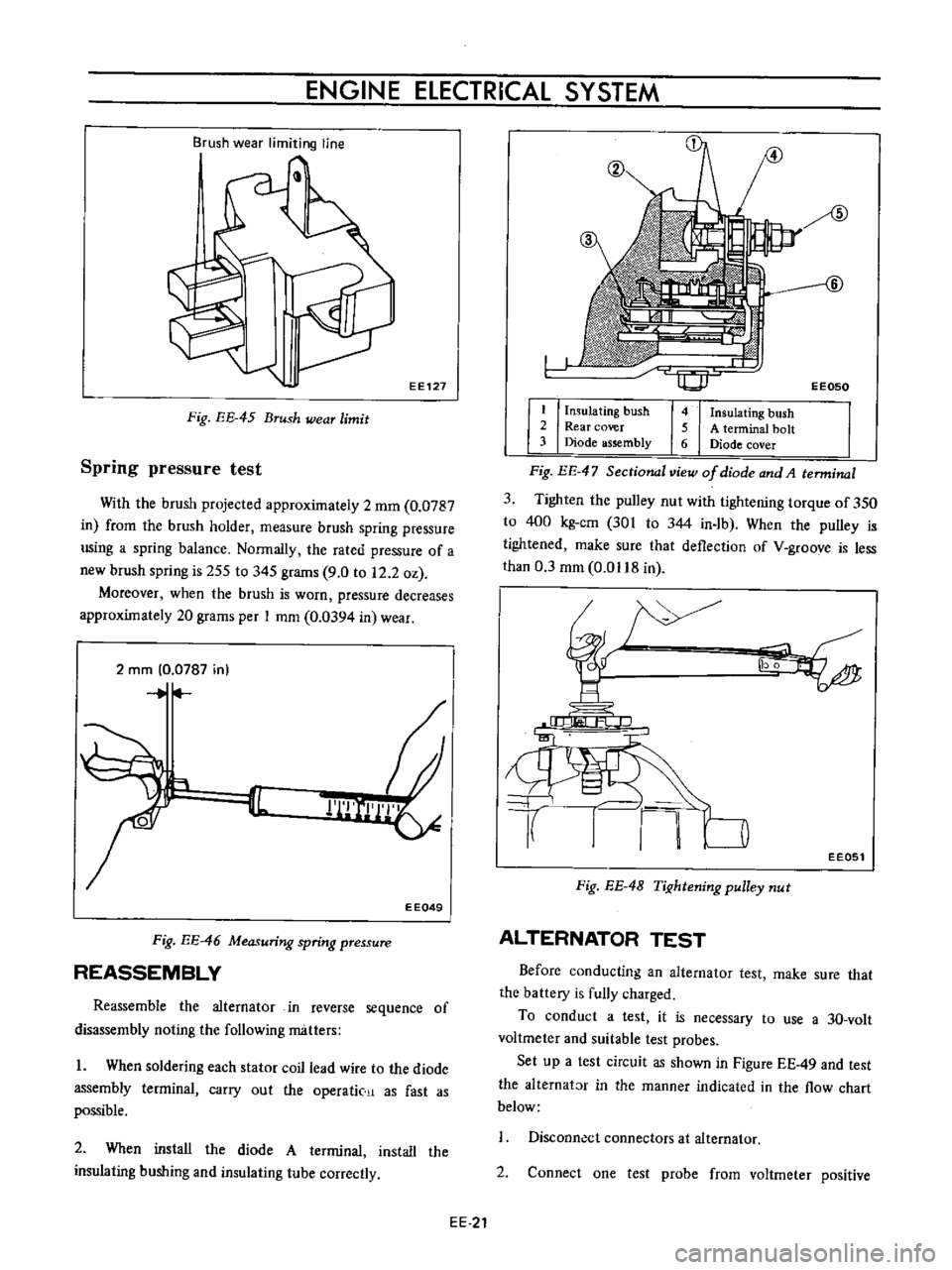

Fig

EE

45

Brush

wear

limit

Spring

pressure

test

With

the

brush

projected

approximately

2

mm

0

0787

in

from

the

brush

holder

measure

brush

spring

pressure

using

a

spring

balance

Normally

the

rated

pressure

of

a

new

brush

spring

is

255

to

345

grams

9

0

to

12

2

oz

Moreover

when

the

brush

is

worn

pressure

decreases

approximately

20

grams

per

I

mm

0

0394

in

wear

2

rnm

0

0787

in

r

II

EEQ49

Fig

EE

46

Measuring

spring

pressure

REASSEMBLY

Reassemble

the

alternator

in

reverse

sequence

of

disassembly

noting

the

following

matters

I

When

soldering

each

stator

coil

lead

wire

to

the

diode

assembly

terminal

carry

out

the

operatic

as

fast

as

possible

2

When

install

the

diode

A

terminal

install

the

insulating

bushing

and

insulating

tube

correctly

EE

21

EE050

I

Insulating

bush

2

Rear

cover

3

Diode

assembly

4

Insulating

bush

5

A

terminal

bolt

6

Diode

cover

Fig

EE

47

Sectional

view

of

diode

and

A

terminal

3

Tighten

the

pulley

nut

with

tightening

torque

of

350

to

400

kg

cm

301

to

344

in

Ib

When

the

pulley

is

tightened

make

sure

that

deflection

of

V

groove

is

less

than

0

3

mm

0

0118

in

EE051

Fig

EE

4B

TiJ

htening

pulley

nut

ALTERNATOR

TEST

Before

conducting

an

alternator

test

make

sure

that

the

battery

is

fully

charged

To

conduct

a

test

it

is

necessary

to

use

a

3D

volt

voltmeter

and

suitable

test

probes

Set

up

a

test

circuit

as

shown

in

Figure

EE

49

and

test

the

alternator

in

the

manner

indicated

in

the

flow

chart

below

Disconn

ct

connectors

at

alternator

2

Connect

one

test

probe

from

voltmeter

positive

Page 458 of 513

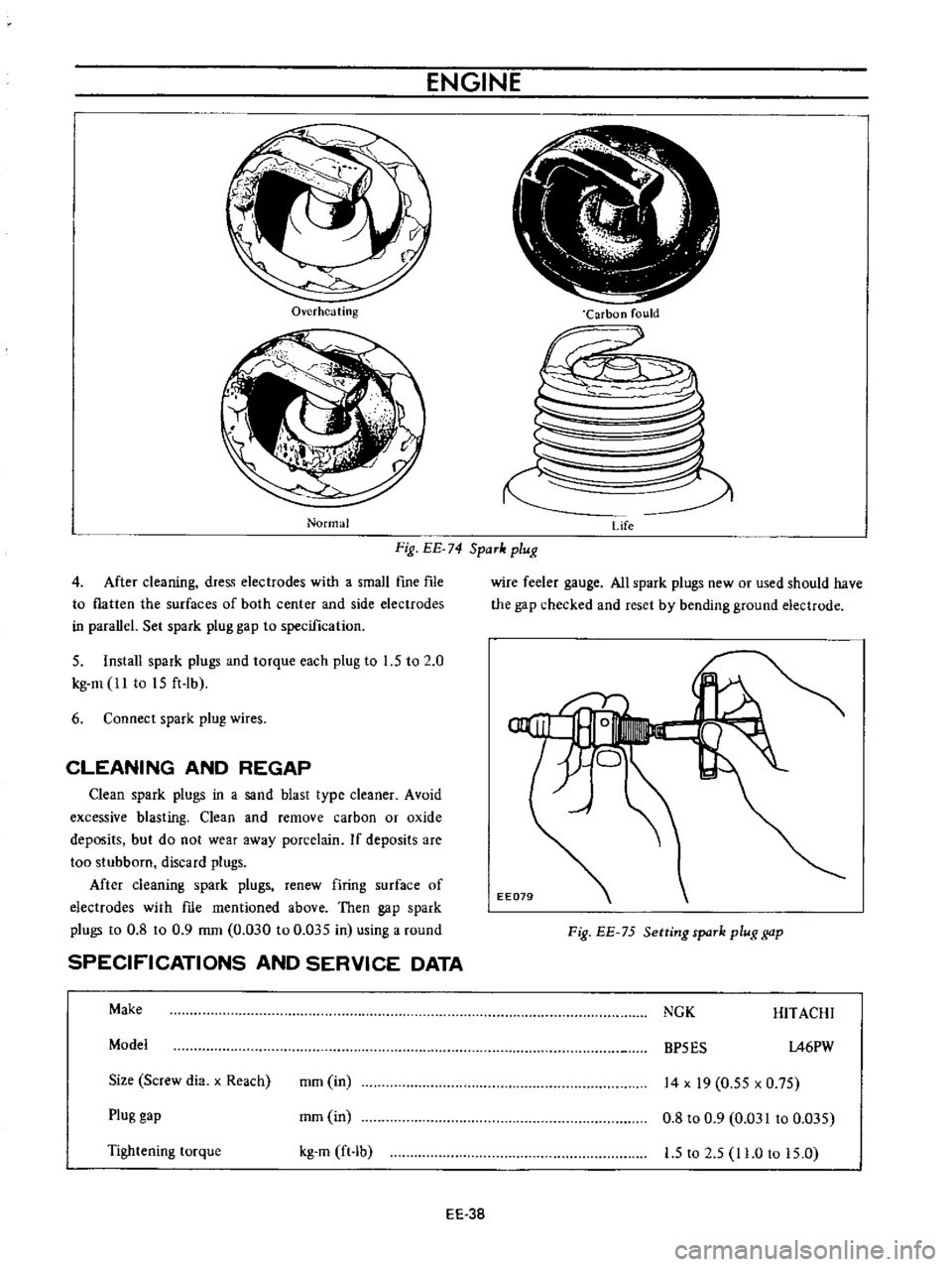

ENGINE

Overheating

Normal

Carbon

fould

Fig

EE

74

SpaTk

plug

Life

4

After

cleaning

dress

electrodes

with

a

small

fine

fIle

to

flatten

the

surfaces

of

both

center

and

side

electrodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

to

1

5

to

2

0

kg

m

ll

to

15

ft

lb

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porcelain

If

deposits

are

too

stubborn

discard

plugs

Mter

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

me

mentioned

above

Then

gap

spark

plugs

to

0

8

to

0

9

mm

0

030

to

0

035

in

using

a

round

SPECIFICATIONS

AND

SERVICE

DATA

Make

Model

Size

Screw

dia

x

Reach

mm

in

Plug

gap

mm

in

Tightening

torque

kg

m

ft

b

EE

38

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

Fig

EE

75

Setting

spaTk

plug

gap

NGK

HITACHI

BP5ES

1A6PW

14

x

19

0

55

x

0

75

0

8

to

0

9

0

031

to

0

035

1

5

to

2

5

11

0

to

15

0

Page 465 of 513

CHASSIS

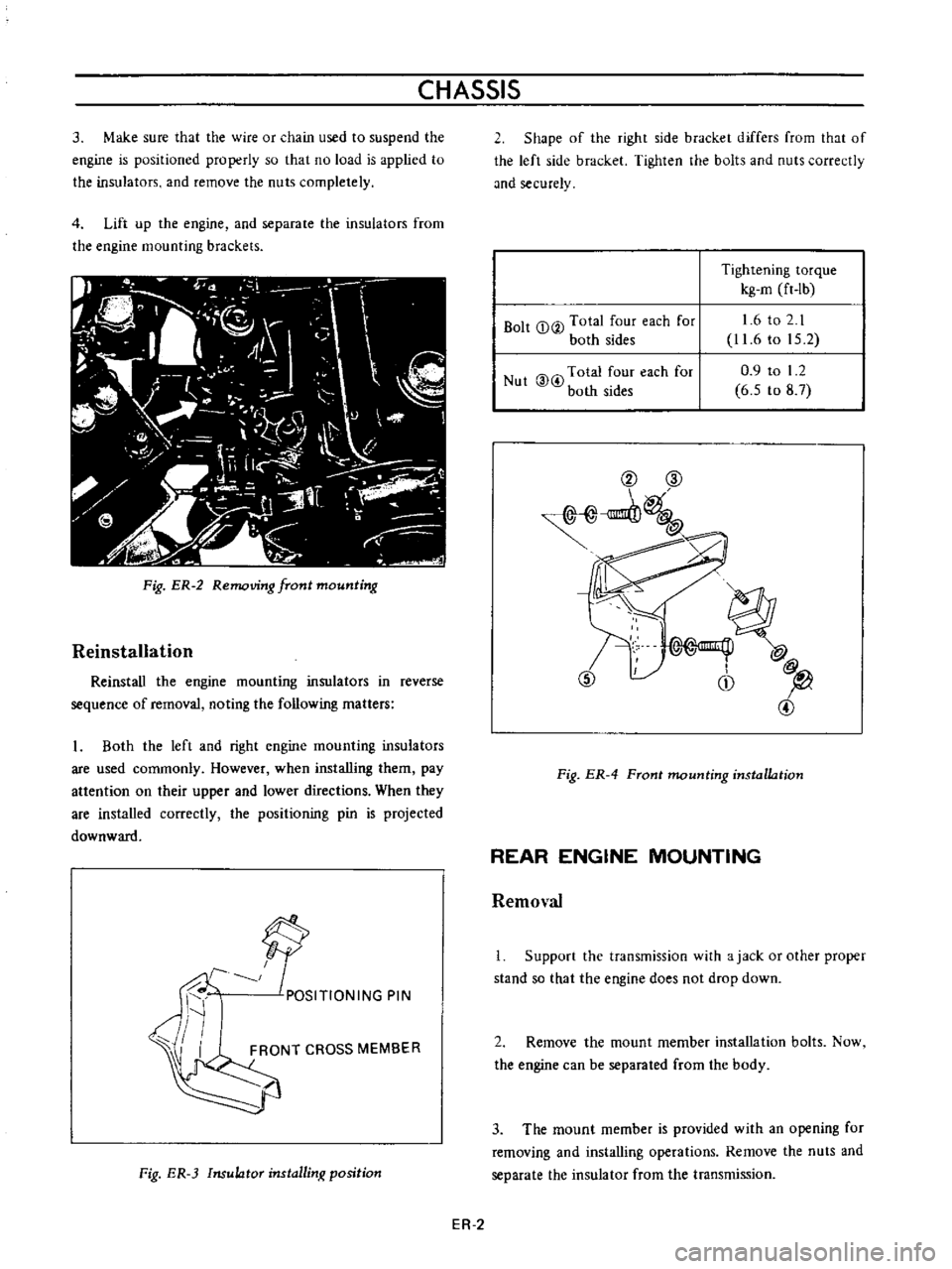

3

Make

sure

that

the

wire

or

chain

used

to

suspend

the

engine

is

positioned

properly

so

that

no

load

is

applied

to

the

insulators

and

remove

the

nuts

completely

4

Lift

up

the

engine

and

separate

the

insulators

from

the

engine

mounting

brackets

l

J

o

II

f

T

io

I

t

i

1

A

t

t

I

21

u

I

1

Qj

1

It

I

j

fi

I

I

lt

y

Ii

Fig

ER

2

Removing

front

mounting

Reinstallation

Reinstall

the

engine

mounting

insulators

in

reverse

sequence

of

removal

noting

the

following

matters

Both

the

left

and

right

engine

mounting

insulators

are

used

commonly

However

when

installing

them

pay

attention

on

their

upper

and

lower

directions

When

they

are

installed

correctly

the

positioning

pin

is

projected

downward

f

9

POSITIONING

PIN

I

FRONT

CROSS

MEMBER

Fig

ER

3

Insulator

installinx

position

2

Shape

of

the

right

side

bracket

differs

from

that

of

the

left

side

bracket

Tighten

the

bolts

and

nuts

correctly

md

securely

Bolt

CD

V

Total

four

each

for

both

sides

Tightening

torque

kg

m

ft

Ib

1

6

to

2

1

11

6

to

15

2

0

9

to

I

2

6

5

to

8

7

Nut

@

i

Total

four

each

for

both

sides

@

CID

1

@

CD

l

Fig

ER

4

Front

mounting

installation

REAR

ENGINE

MOUNTING

Removal

Support

the

transmission

with

ajack

or

other

proper

stand

so

that

the

engine

does

not

drop

down

2

Remove

the

mount

member

installation

bolts

Now

the

engine

can

be

separated

from

the

body

3

The

mount

member

is

provided

with

an

opening

for

removing

and

installing

operations

Remove

the

nuts

and

separate

the

insulator

from

the

transmission

ER

2

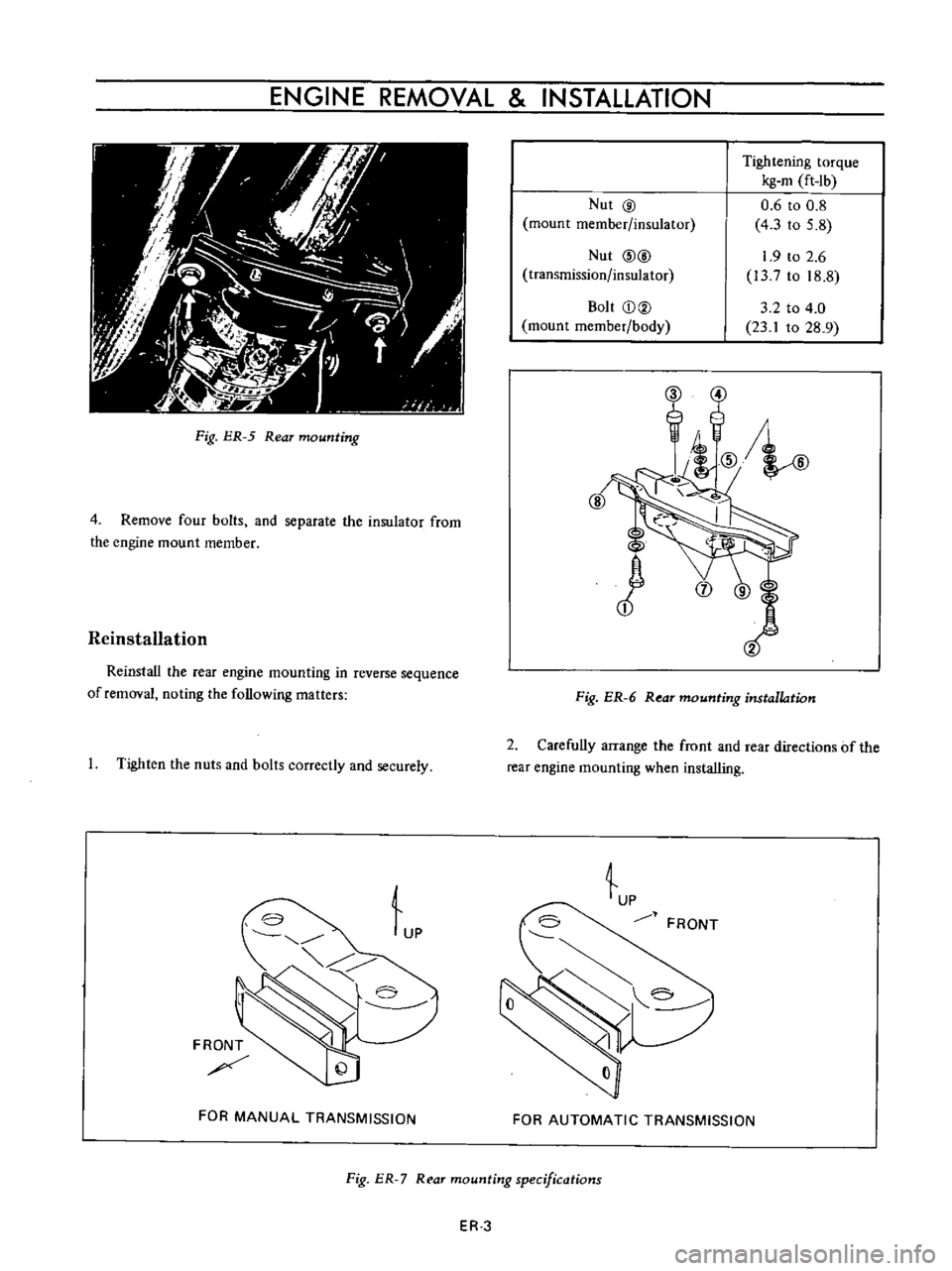

Page 466 of 513

ENGINE

REMOVAL

INSTAllATION

Fig

ER

5

Rear

mounting

4

Remove

four

bolts

and

separate

the

insulator

from

the

engine

mount

member

Reinstallation

Reinstall

the

rear

engine

mounting

in

reverse

sequence

of

removal

noting

the

following

matters

I

Tighten

the

nuts

and

bolts

correctly

and

securely

Lp

FRONT

FOR

MANUAL

TRANSMISSION

Nut

@

mount

member

insulator

Nut

@@

transmission

insulator

Bolt

CD@

mount

member

body

Tightening

torque

kg

m

ft

Ib

0

6

to

0

8

4

3

to

5

8

1

9

to

2

6

l3

to

18

8

3

2

to

4

0

23

1

to

28

9

Fig

ER

6

Rear

mounting

installation

2

Carefully

arrange

the

front

and

rear

directions

of

the

rear

engine

mounting

when

installing

tp

FRONT

FOR

AUTOMATIC

TRANSMISSION

Fig

ER

7

R

ar

mounting

specifications

ER

3

Page 483 of 513

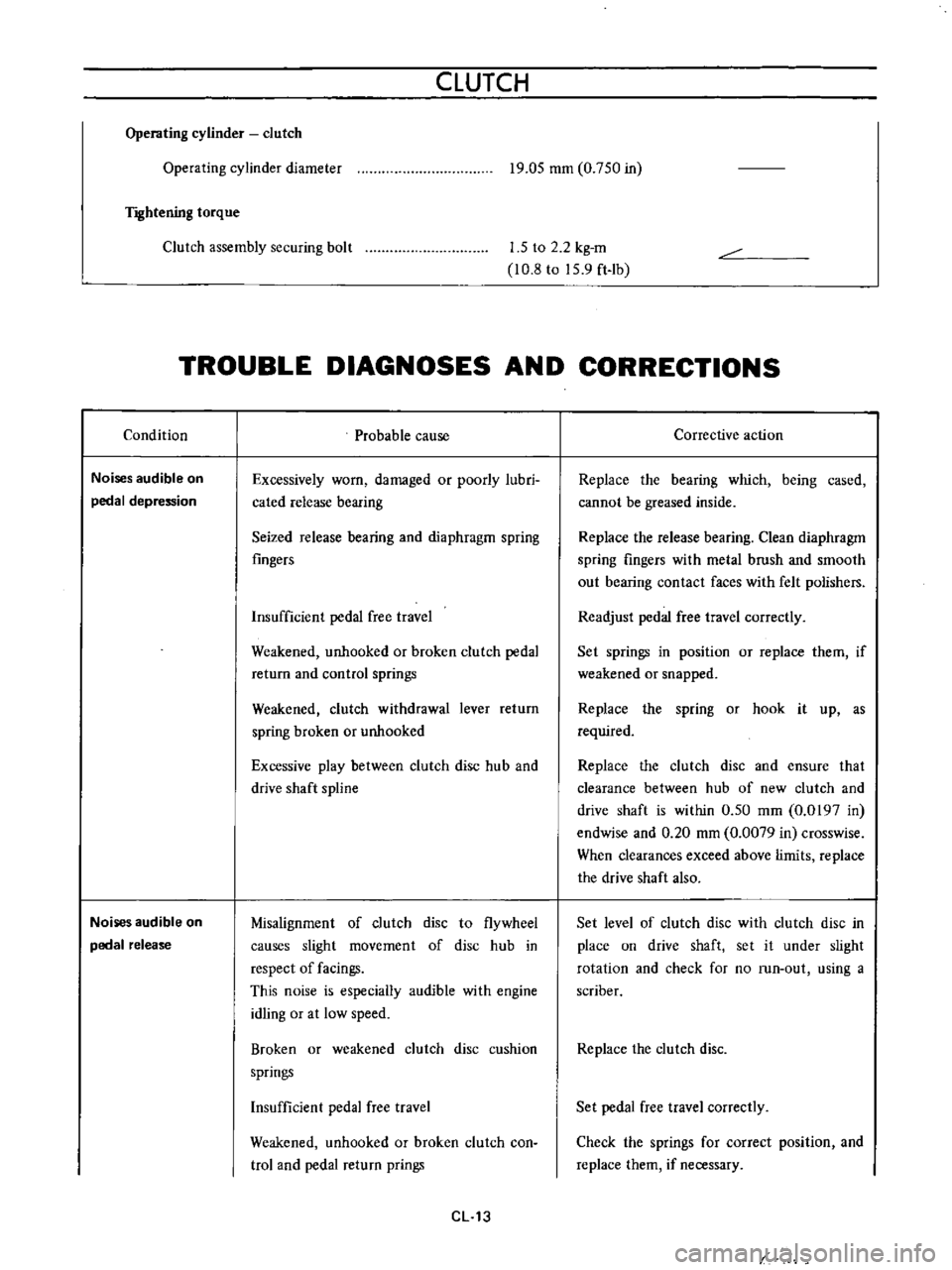

CLUTCH

Operating

cylinder

clutch

Operating

cylinder

diameter

T

Ilhtening

torque

19

05

mm

0

750

in

Clutch

assembly

securing

bolt

1

5

to

2

2

kg

m

10

8

to

15

9

ft

Ib

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Noises

audible

on

pedal

depression

Noises

audible

on

pedal

release

Probable

cause

Excessively

worn

damaged

or

poorly

lubri

cated

release

bearing

Seized

release

bearing

and

diaphragm

spring

fingers

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

pedal

return

and

control

springs

Weakened

clutch

withdrawal

lever

return

spring

broken

or

unhooked

Excessive

play

between

clutch

disc

hub

and

drive

shaft

spline

Misalignment

of

clutch

disc

to

flywheel

causes

slight

movement

of

disc

hub

in

respect

of

facings

This

noise

is

especially

audible

with

engine

idling

or

at

low

speed

Broken

or

weakened

clutch

disc

cushion

springs

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

con

trol

and

pedal

return

prings

CL

13

Corrective

action

Replace

the

bearing

which

being

cased

cannot

be

greased

inside

Replace

the

release

bearing

Clean

diaphragm

spring

fingers

with

metal

brush

and

smooth

out

bearing

contact

faces

with

felt

polishers

Readjust

pedal

free

travel

correctly

Set

springs

in

position

or

replace

them

if

weakened

or

snapped

Replace

the

spring

or

hook

it

up

as

required

Replace

the

clutch

disc

and

ensure

that

clearance

between

hub

of

new

clutch

and

drive

shaft

is

within

0

50

mm

0

0197

in

endwise

and

0

20

mm

0

0079

in

crosswise

When

clearances

exceed

above

limits

replace

the

drive

shaft

also

Set

level

of

clutch

disc

with

clutch

disc

in

place

on

drive

shaft

set

it

under

slight

rotation

and

check

for

no

run

out

using

a

scriber

Replace

the

clutch

disc

Set

pedal

free

travel

correctly

Check

the

springs

for

correct

position

and

replace

them

if

necessary

Page 507 of 513

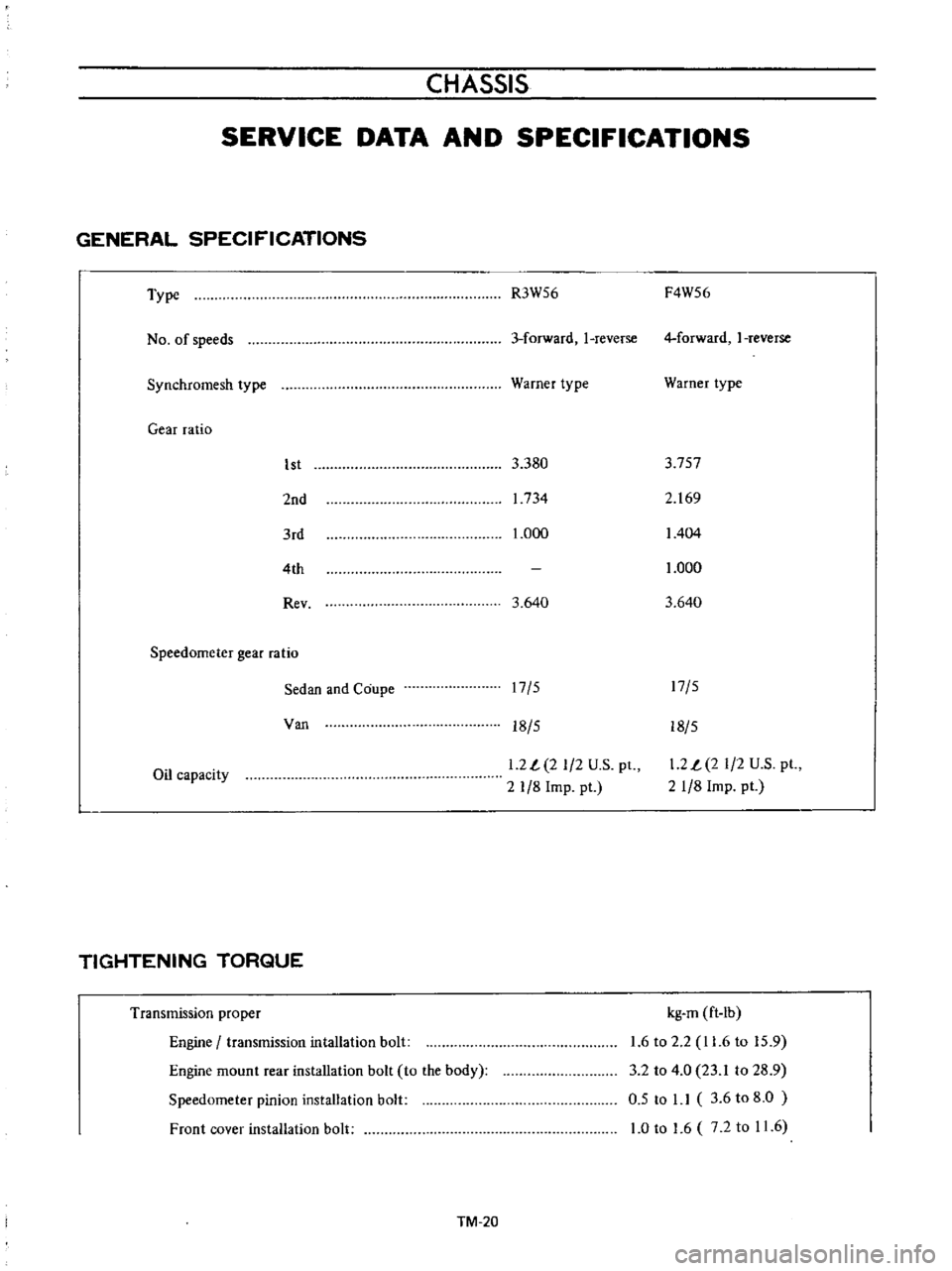

CHASSIS

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

Type

No

of

speeds

Synchromesh

type

Gear

ratio

1st

2nd

3rd

4th

Rev

Speedometer

gear

ratio

Sedan

and

Coupe

Van

Oil

capacity

TIGHTENING

TORQUE

Transmission

proper

Engine

transmission

intallation

bolt

Engine

mount

rear

installation

bolt

to

the

body

Speedometer

pinion

installation

bolt

Front

cover

installation

bolt

TM

20

R3W56

F4W56

3

forward

I

reverse

4

forward

I

reverse

Warner

type

Warner

type

3

380

3

757

1734

2

169

1

000

1404

1

000

3

640

3

640

17

5

17

5

18

5

18

5

1

2

L

2

1

2

U

S

pt

2

1

8

Imp

pt

1

2

L

2

1

2

U

S

pt

21

8

Imp

pt

kg

m

ft

Ib

1

6

to

2

2

11

6

to

15

9

3

2

to

4

0

23

1

to

28

9

0

5

to

1

1

3

6

to

8

0

1

0

to

1

6

7

2

to

11

6